Page 1

KOBOLD Model MPT

DRAFT

Universal Panel Display

Operating Instructions

KOBOLD Instruments, Inc.

1801 Parkway

Pittsburgh, PA 15205

P +1.412.788.2830

www.koboldusa.com

View Drive

Page 2

KOBOLD Model MPT Operating Instructions

DRAFT

Disclaimer

The information contained in this document is subject to change

without notice. KOBOLD Instruments Inc. makes no representations

or warranties with respect to the contents hereof, and specifically

disclaims any implied warranties of merchantability or fitness for a

particular purpose.

Registered Trademarks

Modbus® is a registered trademark of Schneider Automation Inc. All

other trademarks mentioned in this document are the property of

their respective owners.

© 2016 KOBOLD Instruments Inc. All rights reserved.

INTRODUCTION

The KOBOLD Model MPT is a multipurpose, easy-to-use digital panel

meter. It accepts current, voltage, thermocouple, and RTD signals. The

four front panel buttons make the setup and programming an easy task.

The isolated 24 VDC transmitter power (optional) can be used to power

the input transmitter, the 4-20 mA output, or other devices.

The two relays (optional) can be used for alarm indication or process control

applications, such as pump alternation control.

Two relays and a 4-20 mA output are available together in the same meter.

The 4-20 mA isolated output and Modbus

options make the MPT an excellent addition to any system.

®

RTU serial communication

2

Page 3

KOBOLD Model MPT Operating Instructions

DRAFT

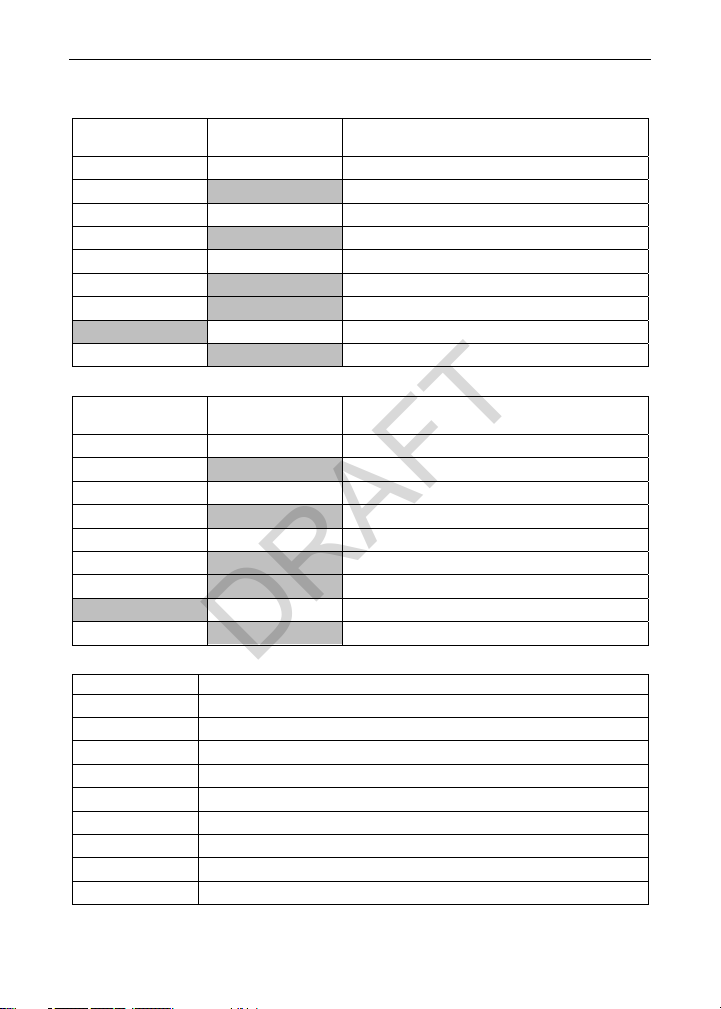

ORDERING INFORMATION

Standard Models

85-265 VAC

Model

MPT-11500 MPT-11300 No options

MPT-11510 24 V transmitter supply

MPT-11502 MPT-11302 2 relays

MPT-11512 2 relays & 24 V transmitter supply

MPT-11503 MPT-11303 4-20 mA output

MPT-11513 4-20 mA output & 24 V supply

MPT-11523 4-20 mA output & dual 24 V supplies

MPT-11514 2 relays, 4-20 mA output, & 24 V supply

Large Display Models

85-265 VAC

Model

MPT-12500 MPT-12300 No options

MPT-12510 24 V transmitter supply

MPT-12502 MPT-12302 2 relays

MPT-12512 2 relays & 24 V transmitter supply

MPT-12503 MPT-12303 4-20 mA output

MPT-12513 4-20 mA output & 24 V supply

MPT-12523 4-20 mA output & dual 24 V supplies

MPT-12514 2 relays, 4-20 mA output, & 24 V supply

Accessories

Model Description

PDA7232 RS-232 serial adapter with PDA7420 included

PDA7420 MPT meter copy cable, 7' (2.1 m)

PDA7422 RS-485 serial adapter with PDA7420 included

PDA7485-I RS-232 to RS-485 isolated converter

PDA7485-N RS-232 to RS-485 non-isolated converter

PDA8485-I USB to RS-422/485 isolated converter

PDA8485-N USB to RS-422/485 non-isolated converter

PDA8006 USB Serial Adapter

MeterView® Free MeterView® software download at www.koboldusa.com

12-36 VDC

Model

MPT-11304 2 relays & 4-20 mA output

12-36 VDC

Model

MPT-12304 2 relays & 4-20 mA output

Options Installed

Options Installed

3

Page 4

KOBOLD Model MPT Operating Instructions

DRAFT

Table of Contents

INTR

ODUCTION ------------------------------------------------------------ 2

ORDERING INFORMATION --------------------------------------------- 3

SPECIFICATIONS ---------------------------------------------------------- 7

General ------------------------------------------------------------------------------- 7

Process Input ---------------------------------------------------------------------- 8

Temperature Inputs -------------------------------------------------------------- 9

Relays Option -------------------------------------------------------------------- 10

Isolated 4-20 mA Transmitter Output ------------------------------------ 11

Serial Communications ------------------------------------------------------- 11

COMPLIANCE INFORMATION ---------------------------------------- 12

Safety ------------------------------------------------------------------------------- 12

Electromagnetic Compatibility --------------------------------------------- 12

SAFETY INFORMATION ------------------------------------------------ 13

INSTALLATION ------------------------------------------------------------ 14

Unpacking ------------------------------------------------------------------------- 14

Panel Mounting ------------------------------------------------------------------ 14

Connections ---------------------------------------------------------------------- 15

Connector Labeling ---------------------------------------------------------- 15

Power Connections ---------------------------------------------------------- 16

Signal Connections ---------------------------------------------------------- 16

Serial Communication ------------------------------------------------------- 20

Relays and 24 V Output Connections ----------------------------------- 20

Switching Inductive Loads -------------------------------------------------- 20

4-20 mA Output & Input Signal Connections -------------------------- 22

SETUP AND PROGRAMMING ---------------------------------------- 23

Front Panel Buttons and Status LED Indicators --------------------- 24

Display Functions and Messages ----------------------------------------- 25

Main Menu ------------------------------------------------------------------------ 28

Setting Numeric Values ------------------------------------------------------ 28

Setting Up the Meter (setu) ------------------------------------------------- 29

Setting the Input Signal (inpt) -------------------------------------------- 30

Setting the Decimal Point (dc.pt) ----------------------------------------- 31

Setting the Temperature Scale (F C) ---------------------------------- 31

Programming the Meter (prog) ------------------------------------------- 32

Scaling the Meter (scal) ---------------------------------------------------- 33

Calibrating the Meter (Cal) ------------------------------------------------- 35

Recalibrating Temperature Inputs (Cal) -------------------------------- 35

4

Page 5

KOBOLD Model MPT Operating Instructions

DRAFT

Recalibrating Process Inputs (ICal) ------------------------------------- 36

Setting the Relay Operation (rely) -------------------------------------- 37

Relay and Alarm Operation ------------------------------------------------ 41

Pump Alternation Control Operation ------------------------------------- 46

Scaling the 4-20 mA Analog Output (Aout) ---------------------------- 47

Program the Sensor Break Output Value (SEbr) --------------------- 48

Analog Output when Display is Out of Range ------------------------- 48

Setting Up the Password (pass) ------------------------------------------- 49

Locking the Meter ------------------------------------------------------------ 49

Unlocking the Meter ---------------------------------------------------------- 49

Advanced Features Menu ---------------------------------------------------- 50

Advanced Features Menu & Display Messages ---------------------- 51

Offset Adjustment (Adj) ----------------------------------------------------- 53

Noise Filter (fltr) ------------------------------------------------------------ 53

Noise Filter Bypass (byps) ------------------------------------------------- 54

Serial Communications (serl) -------------------------------------------- 54

Protocol Selection Menu (Prot) ------------------------------------------ 54

Select Menu (SElc) ---------------------------------------------------------- 55

Linear or Square Root Function (linr or Sqrt) ---------------------- 55

Low-Flow Cutoff (cutF) ----------------------------------------------------- 56

Display Intensity (inty) ----------------------------------------------------- 56

Meter Copy Function (Copy) ----------------------------------------------- 57

Internal Calibration (ICal) -------------------------------------------------- 59

OPERATION ---------------------------------------------------------------- 62

Front Panel Buttons Operation -------------------------------------------- 62

Maximum/Minimum Readings ---------------------------------------------- 63

MOUNTING DIMENSIONS ---------------------------------------------- 64

TROUBLESHOOTING ---------------------------------------------------- 65

Diagnostics Menu (diag) ----------------------------------------------------- 65

Determining Software Version -------------------------------------------- 65

Reset Meter to Factory Defaults ------------------------------------------- 66

Factory Defaults & User Settings ----------------------------------------- 67

Troubleshooting Tips --------------------------------------------------------- 69

QUICK INTERFACE REFERENCE GUIDE ------------------------- 70

5

Page 6

KOBOLD Model MPT Operating Instructions

DRAFT

Table of Figures

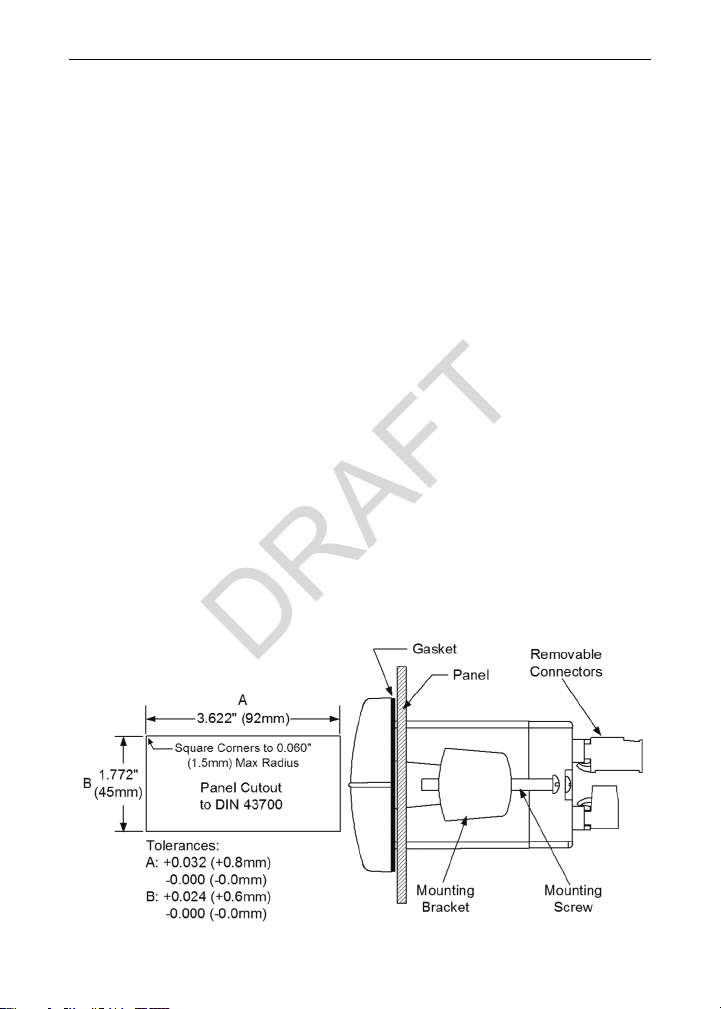

Figure 1. Panel Cutout and Mounting ............................................... 14

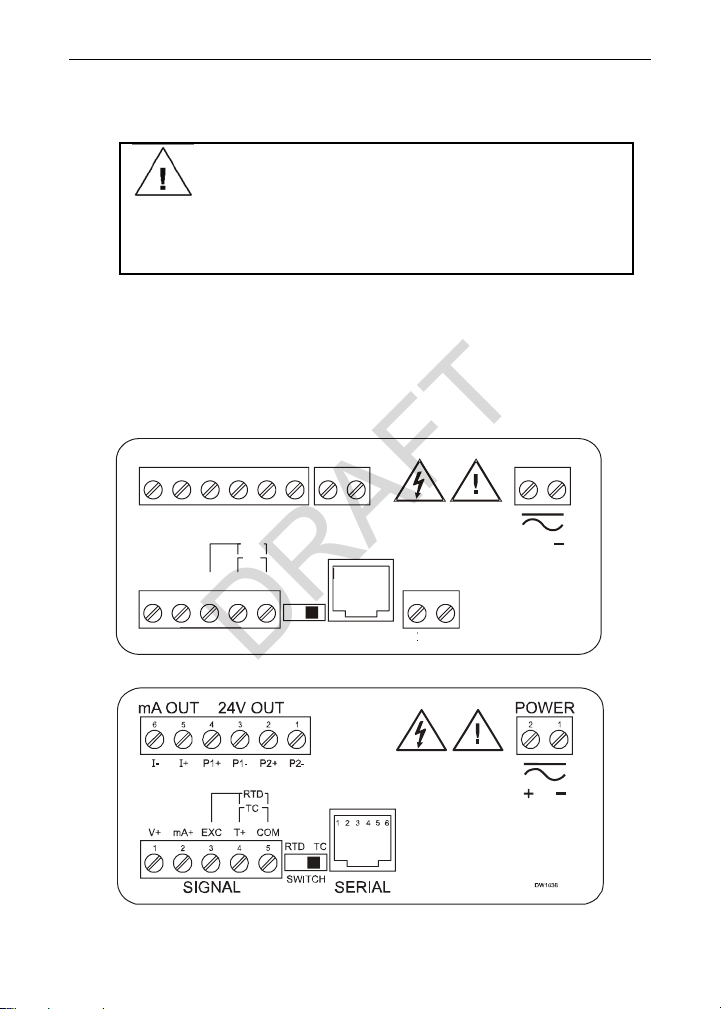

Figure 2. Labeling for 2 Relay, Analog Out, & 24 V Supply Model . 15

Figure 3. Labeling for Analog Out & Two 24 V Supply Model ........ 15

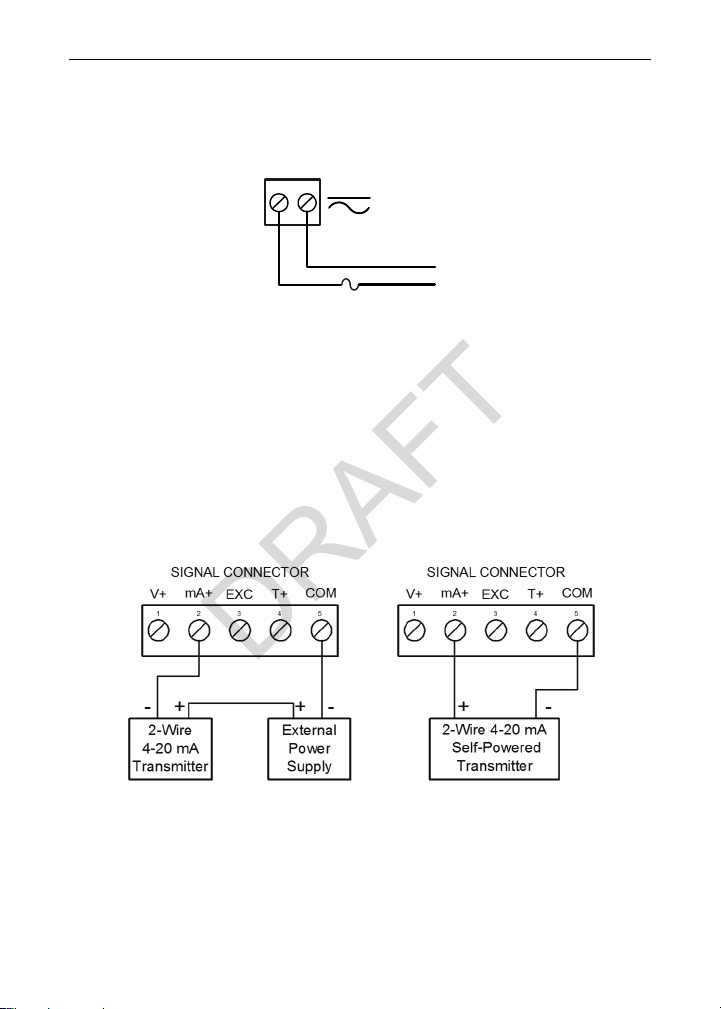

Figure 4. Power Connections ............................................................ 16

Figure 5. Transmitter Powered by Ext. Supply or Self-Powered .... 16

Figure 6. Transmitters Powered by Internal Supply (Optional) ...... 17

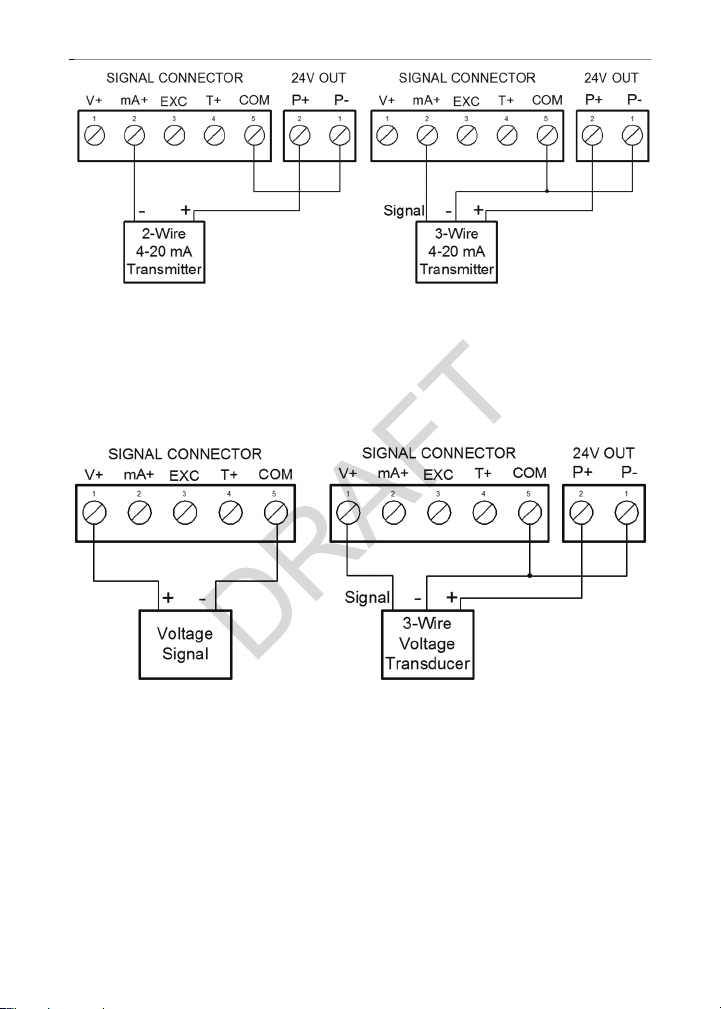

Figure 7. Voltage Input Connections ................................................ 17

Figure 8. Thermocouple Input Connections .................................... 18

Figure 9. Three-Wire RTD Input Connections .................................. 18

Figure 10. Two-Wire RTD Input Connections ................................... 19

Figure 11. Four-Wire RTD Input Connections .................................. 19

Figure 12. Relay & 24 V Output Connections ................................... 20

Figure 13. AC and DC Loads Protection ........................................... 20

Figure 14. Low Voltage DC Loads Protection .................................. 21

Figure 15. 4-20 mA Output & Input Signal Powered by Meter ........ 22

Figure 16. 4-20 mA Output Powered Externally ............................... 22

Figure 17. Meter Copy Connection ................................................... 57

Figure 18. Meter Dimensions – Side View ........................................ 64

Figure 19. Case Dimensions – Top View .......................................... 64

6

Page 7

KOBOLD Model MPT Operating Instructions

DRAFT

SPECIFICATIONS

Except where noted all specifications apply to operation at +25°C.

General

DISPLAY Standard: 0.56" (14 mm), Large Display: 1.20" (31 mm),

DISPLAY INTENSITY Eight intensity levels

DISPLAY

UPDATE RATE

OVERRANGE

UNDERRANGE

PROGRAMMING

METHODS

NOISE FILTER Programmable from 2 to 199 (0 will disable filter)

RECALIBRATION All ranges are calibrated at the factory. Recalibration is

MAX/MIN

DISPLAY

PASSWORD Programmable password restricts modification of settings.

NON-VOLATILE

MEMORY

POWER

OPTIONS

FUSE Required fuse: UL Recognized, 5 A max, slow blow

ISOLATED

TRANSMITTER

POWER SUPPLY

NORMAL MODE

REJECTION

ISOLATION 4 kV input/output-to-power line

OVERVOLTAGE

CATEGORY

Four digits (-1999 to 9999), automatic lead zero blanking.

Process/RTD: 3.7-5/second

Thermocouple: 1.8-2.5/second

Display flashes

Display flashes

Four front panel buttons, PC and MeterView® software, or

cloning using Copy function

recommended at least every 12 months.

Max/min readings reached by the process are stored until

reset by the user or until power to the meter is turned off.

All programmed settings are stored in non-volatile memory

for a minimum of ten years if power is lost.

85-265 VAC, 50/60 Hz

90-265 VD

or

12-36 VDC, 12-24 VAC, 6 W max

See table for power consumption

(*x: number depends on option)

Up to 6 meters may share one 5 A fuse

One or two transmitter power supplies (Optional)

P or P1: 24 VDC ± 10% @ 200 mA max. (-xxx1x)

P1 & P2: 24 VDC ± 10% @ 200 mA & 40 mA max. (-xxx2x)

64 dB at 50/60 Hz

500 V input-to-output or output-to-P1/P2 supplies

-6R5 & -6X5 models only: 100 V output-to-24 VDC supply

Installation Overvoltage Category II:

Local level with smaller transient overvoltages than Installation Overvoltage Category III.

C, 20

9999

-1999

W max

7

Model Watts

MPT-1x50x 8

MPT-1x5{1,2}x 20

MPT-1x30x 6

Page 8

KOBOLD Model MPT Operating Instructions

DRAFT

ENVIRONMENTAL Operating temperature range: -40 to 65°C

CONNECTIONS Removable screw terminal blocks accept 12 to 22 AWG

ENCLOSURE 1/8 DIN, high impact plastic, UL 94V-0, color: gray

MOUNTING 1/8 DIN panel cutout required. Two panel mounting bracket

TIGHTENING

TORQUE

OVERALL

DIMENSIONS

WEIGHT 9.5 oz. (269 g) (including options)

WARRANTY 3 years parts & labor

Storage temperature range: -40 to 85°C

Relative humidity: 0 to 90% non-condensing

wire, RJ11 for serial communication adapters

assemblies provided

Screw terminal connectors: 5 lb-in (0.56 Nm)

2.45" x 4.68" x 4.19" (62 mm x 119 mm x 106 mm)

(H x W x D)

Process Input

INPUTS Field selectable:

ACCURACY ±0.05% of span ±1 count, square root: 10-100% FS

FUNCTION Linear or square root

LOW-FLOW

CUTOFF

TEMPERATURE

DRIFT

DECIMAL POINT Up to three decimal places for process inputs:

CALIBRATION

RANGE

INPUT

IMPEDANCE

INPUT

OVERLOAD

±20 mADC (0-20, 4-20 mA) and ±10 VDC (0-5, 1-5, 0-10 V)

0-9999 (0 disables cutoff function)

0 to 65°C ambient -40 to 0°C ambient

Current: ±0.20% FS (50 PPM/°C)

Voltage: ±0.02% FS (1.7 PPM/°C)

Current: ±0.80% FS

Voltage: ±0.06% FS

d.ddd, dd.dd, ddd.d, or dddd

An Error message will appear if input 1 and input 2 signals

are too close together.

Input Range Minimum Span

4-20 mA

±10 V

Voltage ranges: greater than 1 MΩ

Current ranges: 50 - 100 Ω

Current input protected by resettable fuse.

Fuse resets automatically after fault is removed.

Input 1 & Input 2

0.40 mA

0.20 V

(depending on resettable fuse impedance)

8

Page 9

KOBOLD Model MPT Operating Instructions

DRAFT

Temperature Inputs

INPUTS Field selectable: type J, K, T, or E thermocouples;

RESOLUTION

ACCURACY

Input Type Range Accuracy

Type J

Type K

Type T

Type T

0.1° Res

Type E

100 Ω RTD

COLD

JUNCTION

REFERENCE

OFFSET

ADJUSTMENT

INPUT

IMPEDANCE

SENSOR BREAK

DETECTION

100 Ω platinum RTD (0.00385 or 0.00392 curve)

1° or 0.1° for all RTD inputs. 1° for all thermocouples.

1° or 0.1° for Type T thermocouple

(0 - 65 C)

-58° to 1382° F

-50° to 7

-58° to 2300° F

-50° to 1

-292° to 700° F

-180° to

-199.9° to 700.0°

-180.0° t

-58° to 1578° F

-50° to 8

-328° to 1382°

-200° to 750°C

Automatic, fixed, no user calibration needed

Programmable to ±19.9°. This parameter allows the user to

apply an offset value to the temperature being displayed.

Greater than 100 kΩ

Open TC or RTD sensor indicated by display flashing oPEn.

All relays and alarm status LEDs go to alarm or non-alarm

state, programmable for each relay individually.

Analog output goes to the programmed sensor break value.

50°

C

260°

C

371°

C

o 371.0°

70°

C

F

±2°F

±1°C

±2°F

±1°C

±2°F

±1°C

±1.8°F

F

C

±1.0°C

±2°F

±1°C

±1°F

±1°C

Accuracy

(-40 - 0 C)

±5°F

±3°C

±4°F

±2°C

±13°F

±7°C

±13°F

±7.2°C

±11°F

±6°C

±5°F

±3°C

9

Page 10

KOBOLD Model MPT Operating Instructions

DRAFT

Relays Option

RATING 2 SPDT (Form C); rated 3 A @ 30 VDC or 3 A @ 250 VAC

ELECTRICAL

NOISE

SUPPRESSION

DEADBAND 0-100% of full scale, user selectable

HIGH OR LOW

ALARM

RELAY

OPERATION

RELAY RESET User selectable via front panel buttons or PC

TIME DELAY 0 to 199 seconds, on and off delays

FAIL-SAFE

OPERATION

AUTO

INITIALIZATION

resistive load; 1/14 HP @ 125/250 VAC (50 watts) for inductive loads

A suppressor (snubber) should be connected to each relay

contact switching inductive loads to prevent disruption to the

microprocessor’s operation.

Recommended suppressor value: 0.01 µF/470 Ω, 250 VAC

(PDX6901).

User may program any alarm for high or low trip point.

Automatic (non-latching)

Latching

Pump alternation control

Automatic reset only (non-latching)

Automatic + manual reset at any time (non-latching)

Manual reset only, at any time (latching)

Manual reset only after alarm condition has cleared (latching)

Automatic reset: Relays will automatically reset when the in-

put passes the reset point.

Manual reset: Front panel ACK button. Pressing ACK re-

sets all manually resettable relays.

Programmable and independent for each relay

Programmable

Independent for each relay

When power is applied to the meter, relays will reflect the

state of the input to the meter.

Fail-safe operation: relay coil is energized in non-alarm condition. In

case of power failure, relay will go to alarm state.

10

Page 11

KOBOLD Model MPT Operating Instructions

DRAFT

Isolated 4-20 mA Transmitter Output

OUTPUT RANGE 1.00 to 23.00 mA typical

CALIBRATION Factory calibrated for 4-20 mA

SCALING RANGE 0.00 to 23.99 mA for any display range,

ACCURACY ± 0.1% FS ± 0.004 mA

TEMPERATURE

DRIFT

ISOLATED

TRANSMITTER

POWER SUPPLY

EXTERNAL LOOP

POWER SUPPLY

OUTPUT LOOP

RESISTANCE

see output range above

0.4 uA/°C from -40 to 65°C ambient

Note: Analog output drift is separate from input drift.

One or two transmitter power supplies (Optional)

P1: 24 VDC ± 10% @ 200 mA max. (-1 option)

P1 & P2: 24 VDC ± 10% @ 200 mA & 40 mA max. (-2 option)

35 VDC maximum

Power supply Minimum Maximum

24 VDC

35 VDC (external)

10 Ω

100 Ω

700 Ω

1200 Ω

Serial Communications

METER

ADDRESS

BAUD RATE 300 – 19,200 bps

TRANSMIT

TIME DELAY

DATA 8 bit (1 start bit, 1 stop bit)

PARITY None (1 or 2 stop bits), even, or odd

BYTE-TO-BYTE

TIMEOUT

TURN AROUND

DELAY

Refer to PDC and Modbus Serial Communication Protocol manuals for

details. These can be downloaded from: www.koboldusa.com.

PDC protocol: 0 - 99

Modbus protocol: 1 - 247

Programmable between 0 and 199 ms

(Modbus only; PDC protocol does not use parity)

0.01 – 2.54 sec (Modbus only)

Less than 2 ms (fixed)

11

Page 12

KOBOLD Model MPT Operating Instructions

DRAFT

COMPLIANCE INFORMATION

Safety

UL LISTED USA and Canada

UL FILE NUMBER E160849

FRONT PANEL UL Type 4X, NEMA 4X, IP65; panel gasket provided

LOW VOLTAGE

DIRECTIVE

Electromagnetic Compatibility

EMISSIONS

Radiated

Emissions

AC Mains

Conducted

Emissions

IMMUNITY

RFI - Amplitude

Modulated

Electrical Fast

Transients

Electrostatic

Discharge

RFI - Conducted

AC Surge

Surge

Power-Frequency

Magnetic Field

Voltage Dips

Voltage

Interruptions

UL 508 Industrial Control Equipment

EN 61010-1:2010

Safety requirements for measurement, control, and laboratory use

EN 55011:2009 + A1:2010

Group 1 Class A ISM emissions requirements

Class A

Class A

EN 61326-1:2013

Measurement, control, and laboratory equipment

EN 61000-6-2:2005

EMC heavy industrial generic immunity standard

80 -1000 MHz 10 V/m 80% AM (1 kHz)

1.4 - 2.0 GHz 3 V/m 80% AM (1 kHz)

2.0 - 2.7 GHz 1 V/m 80% AM (1 kHz)

±2kV AC mains, ±1kV other

±4kV contact, ±8kV air

10V, 0.15-80 MHz, 1kHz 80% AM

±2kV Common, ±1kV Differential

1KV (CM)

30 A/m 70%V for 0.5 period

40%V for 5 & 50 periods

70%V for 25 periods

<5%V for 250 periods

12

Page 13

KOBOLD Model MPT Operating Instructions

DRAFT

Note:

Testing was conducted on MPT Meters installed through the covers

of grounded metal enclosures with cable shields grounded at the

point of entry representing installations designed to optimize EMC

performance.

Declaration of Conformity available at www.koboldusa.com

SAFETY INFORMATION

!

CAUTION: Read complete

instructions prior to installation and operation of the

meter.

WARNING

Hazardous voltages exist within enclosure. Installation and service

should be performed only by trained service personnel.

WARNING: Risk of

electric shock.

13

Page 14

KOBOLD Model MPT Operating Instructions

DRAFT

INSTALLATION

There is no need to remove the meter from its case to complete the installation, wiring, and setup of the meter.

Unpacking

Remove the meter from box. Inspect the packaging and contents for damage. Report damages, if any, to the carrier.

If any part is missing or the meter malfunctions, please contact

your supplier or the factory for assistance.

Panel Mounting

• Prepare a standard 1/8 DIN panel cutout – 3.622" x 1.772" (92 mm

x 45 mm). Refer to MOUNTING DIMENSIONS, page 64 for more

details.

• Clearance: allow at least 4" (102 mm) behind the panel for wiring.

• Panel thickness: 0.04" - 0.25" (1.0 mm - 6.4 mm).

Recommended minimum panel thickness to maintain Type 4X

rating: 0.06" (1.5 mm) steel panel, 0.16" (4.1 mm) plastic panel.

• Remove the two mounting brackets provided with the meter (back-off

the two screws so that there is ¼" (6.4 mm) or less through the

bracket. Slide the bracket toward the front of the case and remove).

• Insert meter into the panel cutout.

• Install mounting brackets and tighten the screws against the panel.

To achieve a proper seal, tighten the mounting bracket screws

evenly until meter is snug to the panel along its short side. DO NOT

OVER TIGHTEN, as the rear of the panel may be damaged.

Figure 1. Panel Cutout and Mounting

14

Page 15

KOBOLD Model MPT Operating Instructions

DRAFT

Connections

All connections are made to removable screw terminal connectors

located at the rear of the meter.

Use copper wire with 60°C or 60/75°C insulation

for all line voltage connections. Observe all safety

regulations. Electrical wiring should be performed

in accordance with all applicable national, state,

and local codes to prevent damage to the meter

and ensure personnel safety.

Connector Labeling

The connectors label, affixed to the meter, shows the location of all connectors available with requested configuration. It also identifies the location of the RTD/TC selector switch. The below two images are common

connector configurations for the MPT. Note that the connector in the upper left of the diagram has two different configurations based on the

model.

RELAY2 RELAY1

4

6 5

3

COM NONO NC NC COM

RTD

TC

EXC T+ V+ mA+ COM

3 41 2 5

SIGNAL

2 1

RTD

SWITC H

24V OUT

2 1

P+ P-

1 2 3 4 5 6

TC

SERIAL

mA OUT

6 5

I

-I +

POWER

2 1

+

DW2206

Figure 2. Labeling for 2 Relay, Analog Out, & 24 V Supply Model

Figure 3. Labeling for Analog Out & Two 24 V Supply Model

15

Page 16

KOBOLD Model MPT Operating Instructions

DRAFT

Power Connections

Power connections are made to a two-terminal connector labeled

POWER on Figure 2. The meter will operate regardless of DC polarity

connection. The + and - symbols are only a suggested wiring convention.

POWER CONNECTOR

12

+-

AC or DC

Required External Fuse:

5 A max, Slow Blow

Figure 4. Power Connections

Signal Connections

Signal connections are made to a five-terminal connector labeled

SIGNAL on Figure 2. The COM (common) terminal is the return for all

types of input signals.

Current and Voltage Connections

The following figures show examples for current and voltage connections.

There are no switches or jumpers to set up for current and voltage inputs.

Setup and programming is performed through the front panel buttons.

POWER

Figure 5. Transmitter Powered by Ext. Supply or Self-Powered

16

Page 17

KOBOLD Model MPT Operating Instructions

DRAFT

Figure 6. Transmitters Powered by Internal Supply (Optional)

The current input is protected against current overload by a resettable

fuse. The display may or may not show a fault condition depending on

the nature of the overload.

The fuse limits the current to a safe level when it detects a fault condition, and automatically resets itself when the fault condition is removed.

Figure 7. Voltage Input Connections

The meter is capable of accepting any voltage from -10 VDC to +10 VDC.

17

Page 18

KOBOLD Model MPT Operating Instructions

DRAFT

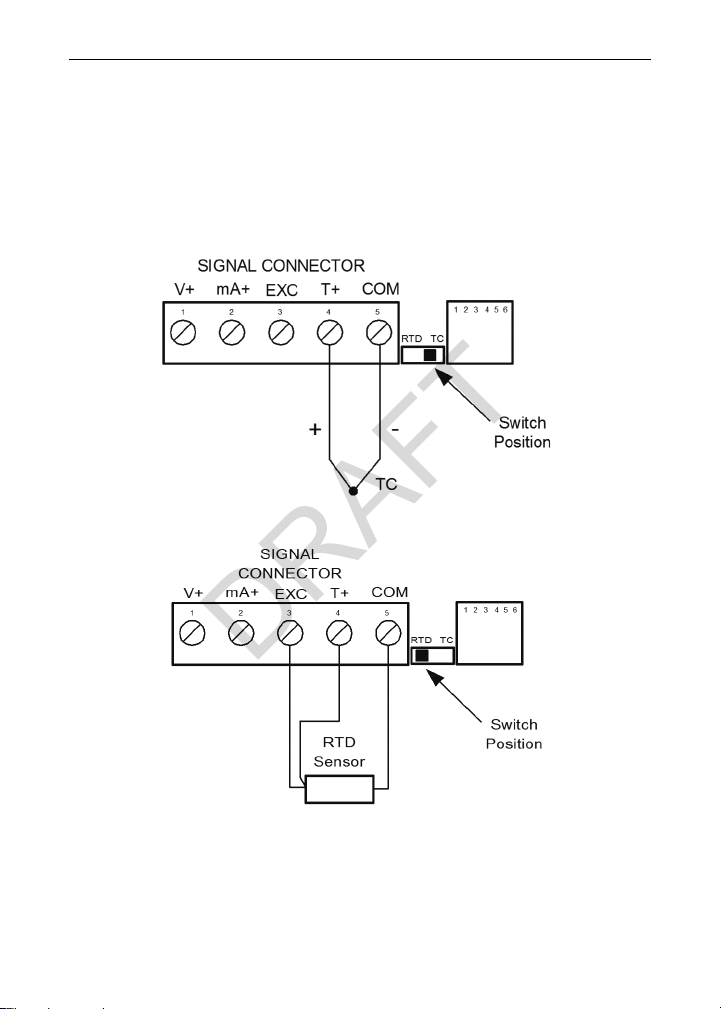

Thermocouple and RTD Connections

The following figures show examples for thermocouple and RTD connections.

The RTD/TC selector switch must be set to the proper position for the

meter to accept the selected temperature input.

The input type is selected using the Setup menu.

Selected thermocouple input must correspond to thermocouple sensor

and wire type used.

Figure 8. Thermocouple Input Connections

Figure 9. Three-Wire RTD Input Connections

T

he meter accepts two, three, or four-wire RTDs. The three-wire RTD

connection has built-in lead wire compensation.

18

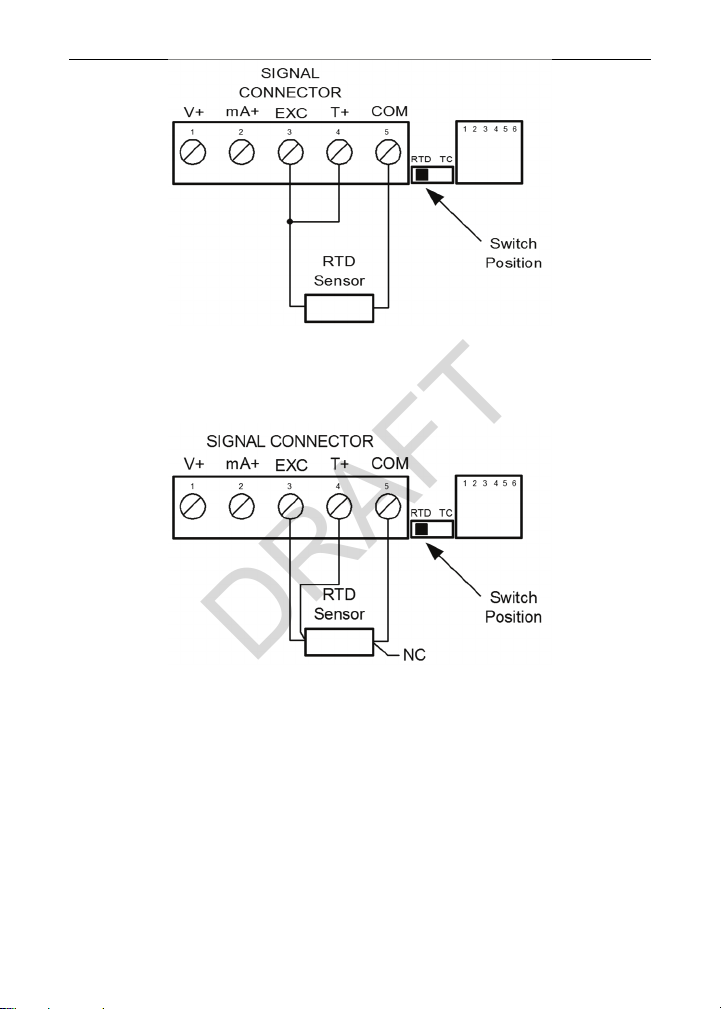

Page 19

KOBOLD Model MPT Operating Instructions

DRAFT

Figure 10. Two-Wire RTD Input Connections

Lead wire compensation for two-wire RTDs can be applied using the

Adjust menu. See Offset Adjustment (Adj), page 53.

Figure 11. Four-Wire RTD Input Connections

The four-wire RTD connection is similar to the three-wire. One of the

leads of a four-wire RTD is not connected, and may be clipped off.

The three-wire connection provides sufficient lead wire compensation to

provide accurate readings even with long leads.

19

Page 20

KOBOLD Model MPT Operating Instructions

DRAFT

Serial Communication

Serial communication connection is made to an RJ11 connector labeled

SERIAL on Figure 2. Use PDA7232 for RS-232 interfacing.

Use PDA7422 for RS-485 interfacing.

Use PDA7420 for meter-to-meter interfacing for cloning purposes (i.e.

copying programmed settings from one meter to other meters).

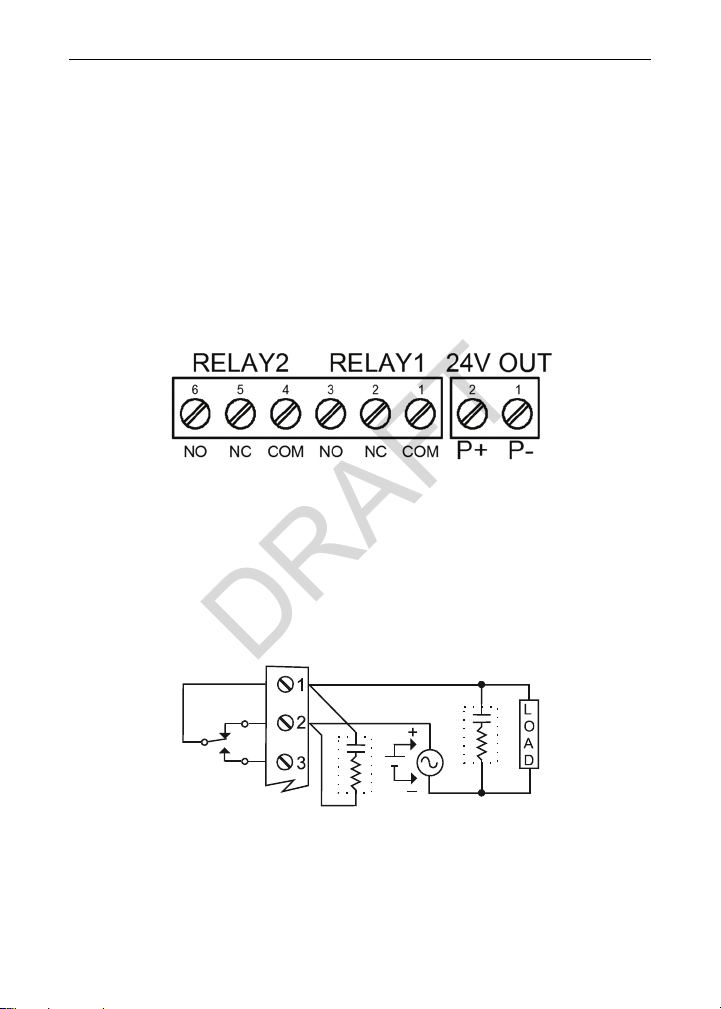

Relays and 24 V Output Connections

Relay connections are made to a six-terminal connector labeled

RELAY1, RELAY2 on Figure 2. The COM (common) terminals of the relays should not be confused with the COM (common) terminal of the

SIGNAL connector. The 24 VDC output is available at the connector labeled 24V OUT, next to the relays connector.

Figure 12. Relay & 24 V Output Connections

Switching Inductive Loads

The use of suppressors (snubbers) is strongly recommended when switching inductive loads to prevent disrupting the microprocessor’s operation. The suppressors also prolong the life of the relay contacts. Suppression can be obtained with

resistor-capacitor (RC) networks assembled by the user or purchased as complete assemblies. Refer to the following circuits for RC network assembly and installation:

C

C

R

Figure 13. AC and DC Loads Protection

20

R

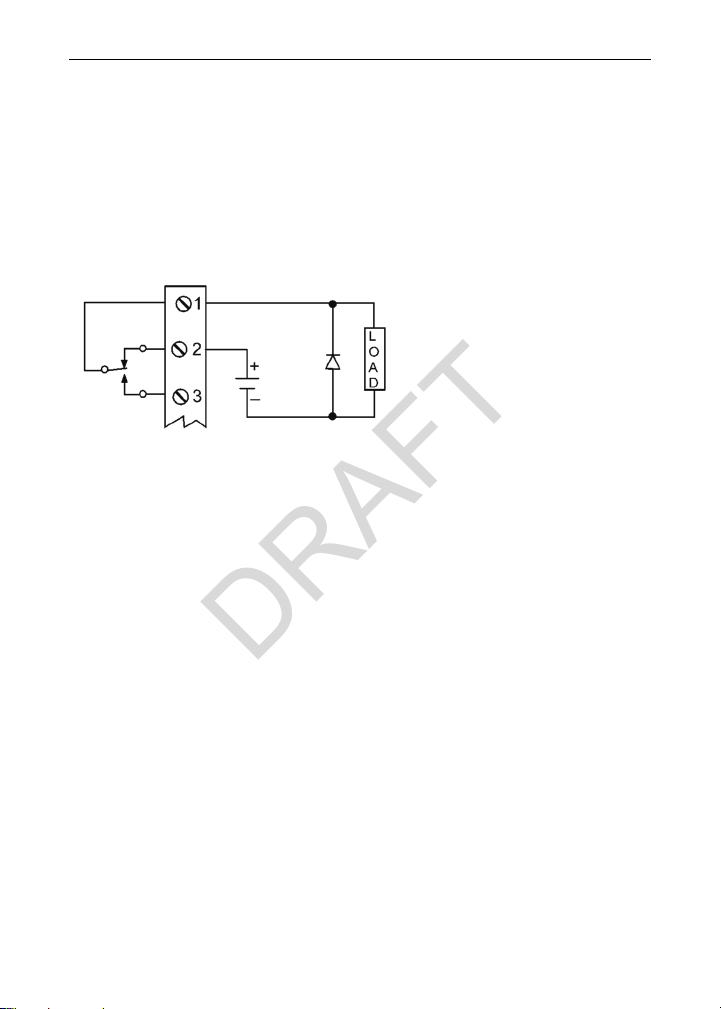

Page 21

KOBOLD Model MPT Operating Instructions

DRAFT

Choose R and C as follows:

R: 0.5 to 1 Ω for each volt across the contacts

C: 0.5 to 1 µF for each amp through closed contacts

Notes:

1. Inductive relay rating is 1/14 HP (50 W) at 115/230 VAC

2. Use capacitors rated for 250 VAC

RC networks may affect load release time of solenoid loads. Check to con-

3.

firm proper opera

4.

Install the RC network at the meter's relay screw terminals. An RC ne

may also be installed across the load. Experiment for best results.

Figure 14. Low Voltage DC Loads Protection

RC Networks Available from KOBOLD

RC networks are available from KOBOLD and should be applied to each relay

contact switching an inductive load. Part number: PDX6901.

Note:

Relays are de-rated to 1/14th HP (50 watts) with an inductive load.

tion.

.

twork

Use a diode with a reverse

breakdown voltage two to

three times the circuit voltage and forward current at

least as large as the load

current.

21

Page 22

KOBOLD Model MPT Operating Instructions

DRAFT

4-20 mA Output & Input Signal Connections

Connections for the 4-20 mA transmitter output are made to the connector terminals labeled “mA OUT, I-, I+”. The 4-20 mA output may be

powered from an internal power supply (optional) or from an external

power supply.

SIGNAL CONNECTOR

mA+

V+ T+

EXC

21 354

COM

mA OUT

I-

6

I+

24V OUT

P1-

45 312

P2+

P2-P1+

-

2-Wire

4-20 mA

Transmitter

+

Remote Display,

Chart Recorder,

etc.

-

+

Figure 15. 4-20 mA Output & Input Signal Powered by Meter

mA OUT

I-

I+

56

External

Power

Supply

-

+

+

Remote Display,

Chart Recorder,

etc.

Figure 16. 4-20 mA Output Powered Externally

-

22

Page 23

KOBOLD Model MPT Operating Instructions

DRAFT

SETUP AND PROGRAMMING

Programming from a PC with MeterView®

KOBOLD’s free MeterView® software allows all MPT setup parameters

to be programmed from a PC (requires PDC protocol selection) and to

save the configuration settings to a file for reporting or programming

other meters. And since the serial adapter is an external device, one

serial adapter can program an infinite number of meters!

The MeterView screen shot above shows how the input is selected.

Notice there are tabs for Scaling, Relays/Alarms, Advanced, and Factory Values.

•

There is

ceived from the factory.

•

The meter is

put types, in milliamps, volts, and degrees respectively. T

calibr

no need to recalibrate

factory calibrated

ation equipment is certified to NIST standards.

the meter when first re-

prior to shipment, for all in-

he

Overview

There are no jumpers involved in the setup process of the meter. The

RTD/TC selector switch, located between the SIGNAL and SERIAL connectors, must be set accordingly for the meter to accept RTD or thermocouple inputs, Figure 2.

Setup and programming is done through the front panel buttons.

After power and signal connections have been completed and verified,

apply power to the meter.

QUICK INTERFACE REFER-

For

ENCE GUIDE

go to page 70

23

Page 24

KOBOLD Model MPT Operating Instructions

DRAFT

Front Panel Buttons and Status LED Indicators

Button

Description LED Status

Symbol

Menu

Right arrow/Reset

Up arrow/Max

Enter/Ack

•

Press the

any time.

•

Press the

programming.

•

Press the Up arrow button to scroll through the menus, decimal

poi

•

Press the

•

Press the

Menu

Features Menu

Menu

button to enter or exit the Programming Mode at

Right

arrow button to move to the next digit during digit

nt, or to increment the value of a digit.

Enter/Ack

Right

button for approximately 3 seconds to access the

button to access a menu or to accept a setting.

arrow and

of the meter.

1 Alarm 1

2 Alarm 2

S

R

Menu

button simultaneously or hold the

Set point indicator

(MPT-11xxx only)

Reset point indicator

(MPT-11xxx only)

Advanced

24

Page 25

KOBOLD Model MPT Operating Instructions

DRAFT

Display Functions and Messages

The meter displays various functions and messages during setup/programming and operation. The following table shows the displayed functions and messages with their action/setting description.

Display Parameter Action/Setting

setu

inpt

4-20

0-10

rtd

a385

A392

tC

0 J

1 k

2 T

3 t.0

4 E

f C

°F

°C

dec.p

prog

scal

Cal

inp1

dis1

inp2

Setup

Input

4-20 mA

0-10 VDC

RTD

Alpha 385

Alpha 392

TC

0 J

1 K

2 T

3 T.0

4 E

°

F or °C

°

F

°

C

Decimal point

Program

Scale

Calibrate

Input 1

Display 1

Input 2

Enter Setup menu

Enter Input menu

Set meter for 4-20 mA input

Set meter for ±10 VDC input

Set meter for RTD input

Set α = 0.00385 European curve 100Ω

RTD

Set α = 0.00392 American curve 100Ω RTD

Set meter for TC input

Type J

Type K

Type T

Type T, 0.1° resolution

Type E

Set temperature scale

Set meter to Fahrenheit

Set meter to Celsius

Set decimal point

Enter the Program menu

Enter the Scale menu

Enter the Calibrate menu

Calibrate input 1 signal or program input 1

value

Program display 1 value

Calibrate input 2 signal or program input 2

value

25

Page 26

KOBOLD Model MPT Operating Instructions

DRAFT

Display Parameter Action/Setting

dis2

err

RELY

RLY1

Act1

Auto

A-m

LtCH

L-CL

Altr

oFF

Set1

rSt1

RLY2

Act2

Set2

RSt2

FLSF

FLS1

on

off

FLS2

DLAY

DLY1

On1

OFF1

DLY2

Display 2

Error

Relay

Relay 1

Action 1

Automatic

Auto-manual

Latching

Latchingcleared

Alternate

Off

Set 1

Reset 1

Relay 2

Action 2

Set 2

Reset 2

Fail-safe

Fail-safe1

On

Off

Fail-safe2

Delay

Delay 1

On 1

Off 1

Delay 2

Program display 2 value

Error, calibration not successful, check signal

Enter the Relay menu

Relay 1 setup

Set relay 1 action (automatic, latching, etc.)

Set relay for automatic reset

Set relay for automatic + manual reset any

time

Set relay for latching operation

Set relay for latching operation with manual

reset only after alarm condition has cleared

Set relays for pump alternation control

Disable relay and front panel status LEDs

Disable relay’s fail-safe operation

Program set point 1

Program reset point 1

Setup relay 2

Set relay 2 action (automatic, latching, etc.)

Program set point 2

Program reset point 2

Enter Fail-safe menu

Set relay 1 fail-safe operation

Enable fail-safe operation

Disable fail-safe operation

Set relay 2 fail-safe operation

Enter Time Delay menu

Enter relay 1 time delay setup

Set relay 1 On time delay

Set relay 1 Off time delay

Enter relay 2 time delay setup

26

Page 27

KOBOLD Model MPT Operating Instructions

DRAFT

Display Parameter Action/Setting

On2

OFF2

brek

Brk1

Off

On

Brk2

Aout

Scal

Dis1

out1

Dis2

out2

SEbr

pass

unlC

loCd

9999

-1999

open

On 2

Off 2

Break

Relay 1 Break

Off

On

Relay 2 Break

Analog output

Scale

Display 1

Output 1

Display 2

Output 2

Sensor break

Password

Unlocked

Locked

Flashing display

Set relay 2 On time delay

Set relay 2 Off time delay

Set RTD/TC input break relay behavior

Set relay 1 input break relay behavior

Set relay to non-alarm condition at break

Set relay to alarm condition at break

Set relay 2 input break relay behavior

Enter the Analog output menu

Enter the Scale menu

Program display 1 value

Program output 1 value (e.g. 4 mA)

Program display 2 value

Program output 2 value (e.g. 20 mA)

Program TC or RTD sensor break value for

analog out

Enter the Password menu

Program password to lock meter

Enter password to unlock meter

Overrange condition

Underrange condition

Open TC or RTD sensor

27

Page 28

KOBOLD Model MPT Operating Instructions

A

DRAFT

Main Menu

The main menu consists of the most commonly used functions:

Password

and

•

Press

row button to scroll main menu

.

Menu

button to enter Programming Mode then press Up ar-

.

Setup

Run

Mode

9765 setu pass

•

Press

Menu

, at any time, to exit and return to Run Mode. Changes

o settings prior to pressing

made t

•

Changes to the settings are saved to memory only after pressing

Enter/Ack

•

The display moves to the next menu every time a setting is accepted by pressing

.

Enter/Ack

Enter/Ack

.

Setting Numeric Values

The numeric values are set using the

Press

Right

arrow to select next digit and

value.

The digit being changed is displayed brighter than the rest.

Press the

button to exit without saving changes.

Enter/Ack

button, at any time, to accept a setting or

Right

Up

are not saved.

and Up arrow buttons.

arrow to increment digit

Menu

Increment Digit

Value

0 4.00 04.00 0 5. 00

Select Next Digit

The decimal point is set using the

point

menu.

Up

arrow button in the

28

ccept Setting

Next

Setting

Setup-decimal

Page 29

KOBOLD Model MPT Operating Instructions

r

DRAFT

Setting Up the Meter (setu)

The

Setup

menu is used to select:

1. Input signal the meter will accept

2. Decimal point position for process inputs

°

F or °C) for temperature inputs

Unit

3.

4.

5.

s (

y operatio

Rela

n

4-20 mA analog output set up

Press the

Enter/Ack

button to access any menu or press Up arrow but-

ton to scroll through choices. Press the

R TD

Note:

Selecting R TD o

the Input menu will include the

Fahrenheit/Celsius menu in the

setup menu structure. RTD will

allow the selection of a decimal

point location after this menu and

TC has a fixed decimal point loca

tion and will not allow the selec tion of a decimal point location.

TC

TC mode from

-

Menu

button to exit at any time.

29

Page 30

KOBOLD Model MPT Operating Instructions

DRAFT

Setting the Input Signal (inpt)

Enter the Input menu to set up the meter to display current (4-20), voltage (0-10), thermocouple (tC), or RTD (rtd) inputs.

The voltage input is capable of accepting any signal from -10 to +10

VDC. Select voltage input to accept 0-5, 1-5, 0-10, or ±10 VDC signals.

The current input is capable of accepting any signal from -20 to 20 mA.

Select current input to accept 0-20 or 4-20 mA signals.

inpt

4-20 0-10 rtd tC

a385

Press Enter/Ack to

Make Selections

Press Up Arrow

to Scroll Through

Choices

Press Menu to

Exit at any Time

If RTD is selected, the display shows A385 or A392. Select the coefficient to match the RTD sensor, either 0.00385 (A385, European curve)

or 0.00392 (A392, American curve). The display then shows the decimal

point menu, DEc.P. Select the decimal point resolution as shown on page

31.

If TC is selected, scroll through the thermocouple types and select the

type matching the TC sensor.

The input signal must be connected to the appropriate input terminals

and the RTD/TC selector switch must be set, see Figure 8 on page 18.

For thermocouple inputs, allow at least 30 minutes warm-up

time for meter to reach specified accuracy.

a392

30

0 j

1 k

2 t

3 t.0

4 e

J

K

T

T.0

E

Page 31

KOBOLD Model MPT Operating Instructions

DRAFT

Setting the Decimal Point (dc.pt)

Decimal point for process inputs may be set with up to three decimal

places or with no decimal point at all.

Decimal point for RTD inputs may be set with 1 decimal place or none.

Decimal point for thermocouple inputs is fixed.

Pressing the Up arrow moves the decimal point one place to the right

until no decimal point is displayed, it then moves to the leftmost position.

Select Decimal

Point

Previous

Setting the Temperature Scale (F C)

The meter can be set to display temperature in degrees Fahrenheit or

Celsius.

Press Up arrow to change selection.

Press Enter/Ack to accept.

dec.p

dddd

31

Next

Page 32

KOBOLD Model MPT Operating Instructions

DRAFT

Programming the Meter (prog)

It is very important to read the following information, before proceeding

to program the meter:

• There is no need to recalibrate the meter when first received from

the factory.

• The meter is factory calibrated prior to shipment, for all input

types, in milliamps, volts, and degrees respectively. The calibration

equipment is certified to NIST standards.

• Use the Scale menu to scale process inputs (e.g. 4-20 mA). A cali-

brated signal source is not needed to scale the meter.

• For thermocouple and RTDs, just connect the sensor to the proper

terminals and turn the power on. No calibration needed! (when

the meter is first received from the factory).

The Program menu contains the Calibrate and the Scale menus.

Process inputs may be calibrated or scaled to any display within the

range of the meter.

prog ScAl

Additional parameters, not needed for most applications, are programmed with the Advanced Features menu, see Advanced Features

Menu, page 50.

32

CAL

Page 33

KOBOLD Model MPT Operating Instructions

DRAFT

Scaling the Meter (scal)

The process inputs (4-20 mA and ±10 VDC) can be scaled to display

the process in engineering units.

A signal source is not needed to scale the meter; simply program the inputs and corresponding display values.

Press Enter to Accept Setting

scal

Press Up to Set Digit Value

Press Right to Select Next Digit

inp1

Press Menu to Exit at any Time

04.00

Set Input 1

Value

Note:

The Scale menu is not available for temperature inputs.

dis1 00.0

Set Display 1

Value

For instructions on how to program

numeric values see Setting Numeric

Values, page 28.

33

inp2

Scale

Input 2

Page 34

KOBOLD Model MPT Operating Instructions

DRAFT

Error Message (Err)

An error message indicates that the calibration or scaling process was

not successful.

After the error message is displayed, the meter reverts to input 1, allowing the appropriate input signals to be applied.

The error message might be caused by any of the following conditions:

1. Input signal is not connected to the proper terminals or it is connected backwards.

2. Wrong signal selection in Setup menu.

3. Minimum input span requirements not maintained.

4. Input 1 signal inadvertently applied to calibrate input 2.

Minimum Input Span

The minimum input span is the minimum difference between input 1 and input 2 signals required to complete the calibration or scaling of the meter.

Input range Input 1 & input 2 span

4-20 mA 0.40 mA

±10 VDC

TC

RTD

0.20 VDC

100°F (56°C)

50°F (28°C)

34

Page 35

KOBOLD Model MPT Operating Instructions

DRAFT

Calibrating the Meter (Cal)

To scale the meter without a signal

source, refer to Scaling the Meter

(scal), page 33.

The meter can be calibrated to display the process in engineering units

by applying the appropriate input signal and following the calibration

procedure.

The use of a calibrated signal source is strongly recommended to calibrate the meter.

See Scaling the Meter for Button

Functions Description

Cal

inp1 dis1 04.00

Remember, the meter is calibrated at the factory prior to shipment. Recalibration is recommended at least every twelve months.

The Calibration (CAL) menu is used to recalibrate the thermocouple and

RTD inputs.

Display

Flashes

Accepting

Input

Recalibrating Temperature Inputs (Cal)

Allow at least 30 minutes warm-up time

before performing recalibration proce-

dure to ensure specified accuracy.

Set Display 1

Value

35

inp2

Calibrate

Input 2

Page 36

KOBOLD Model MPT Operating Instructions

DRAFT

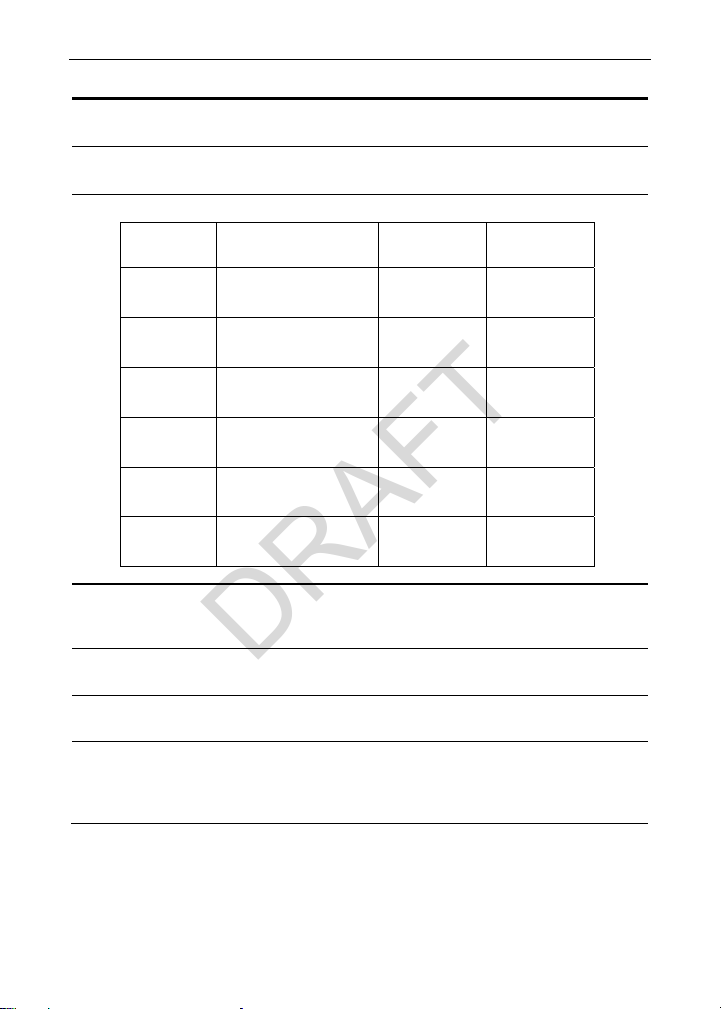

Recommended Calibration Points

To recalibrate the meter, it is recommended to use the Fahrenheit scale;

this will give a greater degree of accuracy to the calibration. The scale

can be changed to the Celsius scale after calibration is completed. The

meter will display temperature accurately in any scale. The following table shows the recommended low and high calibration points for all

types.

Type of input

Type J T/C

Type K T/C

Type T T/C

Type T T/C

Type E T/C

100 Ω RTD

(0.00385)

100 Ω RTD

(0.00392)

Input 1

(Low)

32

32

32

32.0

32

32°F

100

32°F

100

Input 2

(High)

°F 1182°F 600°F

°F 1893°F 960°F

°F 693°F 360°F

°F 693.0°F 360.0°F

°F 1652°F 840°F

1148°F

Ω

320.12

1127°F

Ω

320.89

Ω

Ω

Check

(Middle)

590

°F

215.61

580

°F

215.87

Ω

Ω

Recalibration Procedure for Temperature Inputs

1. Connect signal to the meter using the appropriate wire (e.g. type J

thermocouple

Set up the meter to accept the selected input (e.g. type J T/

2.

page 30.

3. Set up the meter to display temperature in degrees Fahrenheit, see

page 31.

Apply signal corresponding to input 1 (32°F) and program display 1

4.

32, see page 35.

5.

Apply signal corresponding to input 2 (1182°F for type J) and progra

display

After the meter accepts input 2, the display flashes the message

6.

that indicates the meter is sensing the cold junction reference. This

completes the re

wire to recalibrate type J input), see page 18.

2 accordingly, see page 35

calibration procedure for the sele

.

C), see

to

m

CJr

cted input.

Recalibrating Process Inputs (ICal)

The Internal Calibration (ICAL) menu, located in the Advanced features

menu, is used to recalibrate the current and voltage inputs. Recalibration is recommended at least every twelve months.

Refer to Internal Calibration (ICal), page 59 for instructions.

36

Page 37

KOBOLD Model MPT Operating Instructions

DRAFT

Setting the Relay Operation (rely)

This menu allows you to set up the operation of the relays:

1. Relay action

a. Automatic reset only (non-latching)

b. Automatic + manual reset at any time (non-latching)

c. Latching (manual reset only)

d. Latching with Clear (manual reset only after alarm condi-

tion has cleared)

e. Pump alternation control (automatic reset only)

f. Off (relay and status LED disabled)

2. Set point

3. Reset point

4. Fail-safe operation

a. On (enabled)

b. Off (disabled)

5. Time delay

a. On delay (0-199 seconds)

b. Off delay (0-199 seconds)

6. Break Condition Behavior

a. Off (non-alarm condition)

b. On (alarm condition)

From Setup

Menu

Refer to page 25 for a

description of Display

Functions and Messages

rELY

rLY1 rLY2

Same

Act1

Functions as

Relay 1

SEt1

rSt1

Press Enter/Ack button to access any menu

Press Menu button to exit at any time

FLSF

FLS1

FLS2

37

dLAY

dLy1

dLY2

brek

brk1

brk2

Page 38

KOBOLD Model MPT Operating Instructions

DRAFT

Setting the Relay Action

The relays’ Action menu allows the user to set up the operation of the

relays. The relays may be set up for any of the following modes of operation:

1. Automatic reset (non-latching)

2. Automatic + manual reset at any time (non-latching)

3. Latching (manual reset only, at any time)

4. Latching with Clear (manual reset only after alarm condition

has cleared)

5. Pump alternation control (automatic reset only)

6. Off (relay and status LED disabled)

The following graphic shows relay 1 action setup; relay 2 is set up in a

similar fashion.

From Relay 1

Menu

Press

Press

Enter/Ack

button to accept setting

Menu

button to exit at any time

Act1

Auto A-m

LtCH

L-CL

ALtroFF

Programming Set and Reset Points

High alarm indication: program set point above reset point.

Low alarm indication: program set point below reset point.

The deadband is determined by the difference between set and reset

points. Minimum deadband is one display count. If set and reset points

are programmed the same, relay will reset one count below set point.

SEt1

rSt1

Program Set

Point

Program Reset

Point

38

Quick Set Points

Press Up arrow and Menu

at the same time to access

set/reset points quickly.

Page 39

KOBOLD Model MPT Operating Instructions

DRAFT

Setting Fail-Safe Operation

The fail-safe operation is set independently for each relay. Select on to

enable or select off to disable fail-safe operation.

Press

FLSF

Press

Enter/Ack

Menu

button to accept setting

button to exit at any time

FLS1

FLS2

Programming Time Delay

The On and Off time delays may be programmed for each relay between 0 and 199 seconds. The relays will transfer only after the condition has been maintained for the corresponding time delay.

The On time delay is associated with the set point.

The Off time delay is associated with the reset point.

on oFF

on oFF

Program On

Time Delay

Program Off

Time Delay

39

Page 40

KOBOLD Model MPT Operating Instructions

DRAFT

Setting Sensor Break Condition

The sensor break relay condition may be programmed for each relay as

On (alarm) or Off (non-alarm). The relays will enter these states when a

sensor break is detected for RTD or thermocouple inputs. These settings have no effect when current or voltage inputs are selected.

40

Page 41

KOBOLD Model MPT Operating Instructions

DRAFT

Relay and Alarm Operation

The following graphs illustrate the operation of the relays, status LEDs,

and ACK button.

High Alarm Operation (Set > Reset)

or Manual reset mode, ACK can be pressed anytime to turn "off" relay.

F

For relay to turn back "on", signal must go below set point, and then go

above it.

41

Page 42

KOBOLD Model MPT Operating Instructions

DRAFT

Low Alarm Operation (Set < Reset)

or Manual reset mode, ACK can be pressed anytime to turn "off" relay.

F

For relay to turn back "on", signal must go above set point, and then go

below it.

42

Page 43

KOBOLD Model MPT Operating Instructions

DRAFT

Time Delay Operation

The following graphs show the operation of the time delay function.

On

If the signal crosses the set point, the

relay trips when the time delay has elapsed. If the signal drops below

the set point (high alarm) before the time delay has elapsed, the

time delay timer resets and the relay does not change state. The same

principle applies to the

* Note:

The LED is not affected by Time Delay when

Manual”

and reset points.

Off

time delay.

reset mode is selected. Rather the LED follows the set

time delay timer starts and the

“Automatic or

43

On

Page 44

KOBOLD Model MPT Operating Instructions

DRAFT

High Alarm with Fail-Safe Operation (Set > Reset)

Fail-safe operation:

case of power failure, relay will go to alarm state.

relay coil is energized in non-alarm condition. In

44

Page 45

KOBOLD Model MPT Operating Instructions

DRAFT

Low Alarm with Fail-Safe Operation (Set < Reset)

Fail-safe operation:

case of power failure, relay will go to alarm state.

relay coil is energized in non-alarm condition. In

45

Page 46

KOBOLD Model MPT Operating Instructions

DRAFT

Pump Alternation Control Operation

46

Page 47

KOBOLD Model MPT Operating Instructions

DRAFT

Scaling the 4-20 mA Analog Output (Aout)

The 4-20 mA analog output can be scaled to provide a 4-20 mA signal

for any display range selected.

No equipment is needed to scale the analog output; simply program the

display values to the corresponding mA output signal.

Depending on the version of meter purchased, the

may not appear in the

the factory via the

the Advanced Features Menu see page 50.

The

Analog Output menu is used to program:

1. 4-20 mA output based on display values

2. Sensor break value in mA

Setup menu. This menu is enabled or disabled at

Advanced Features menu. For more information on

Analog Output menu

Aout

Press Enter to Accept Setting

scal

Press Up to Set Digit Value

Press Right to Select Next Digit

dis1

Press Menu to Exit at any Time

00.00

Set Display 1

Value

out1 04.00

Set Output 1

Value

For instructions on how to program

numeric values see

Values

Setting Numeric

, page 28.

47

dis2

Scale

Output 2

Page 48

KOBOLD Model MPT Operating Instructions

DRAFT

Program the Sensor Break Output Value (SEbr)

The sensor break value corresponds to the output signal generated

when the meter detects a sensor break for thermocouple and RTD inputs.

For example, if there is an open thermocouple, the meter displays the

message “

break value (e.g. 3.00 mA).

The sensor break value can be programmed from 0.00 to 23.99.

The typical output signal range is 1.00 to 23.00 mA (e.g. If sensor break

value is programmed to 0.00, the actual output will not be greater than

1.00 mA).

open” and the analog output goes to the programmed sensor

Press Enter to Accept Setting

Aout

scal

sEbr

Analog Output when Display is Out of Range

The analog output reflects the display out of range conditions as follows:

Input Condition Display Analog Output

Underrange Flashing -1999 3.00 mA

Overrange Flashing 9999 21.00 mA

Open TC or RTD Flashing open Sensor break value

Press Up to Set Digit Value

Press Right to Select Next Digit

Press Menu to Exit at any Time

03.00

Set Sensor

Break Value

48

Program

Menu

Page 49

KOBOLD Model MPT Operating Instructions

DRAFT

Setting Up the Password (pass)

The Password menu is used to program a four-digit password to prevent unauthorized changes to the programmed parameter settings.

Locking the Meter

Enter the Password menu and program a four-digit password.

For instructions on how to program numeric values see Setting Numeric

Values, page 28.

Run Mode

pass unlC 0000

Program

Password

Record the password for future reference. If appropriate, it may be recorded in the space provided.

Model:

Serial Number:

Password: __ __ __ __

Unlocking the Meter

If the meter is password protected, the correct password must be entered in order to make changes to the parameter settings.

pass loCd 0000

Enter

Password

loCd

Run Mode

unlC

49

Page 50

KOBOLD Model MPT Operating Instructions

DRAFT

Entering the correct four-digit number sets the password to 0000, disabling the protection.

Changes to the programmed parameter settings are allowed only with

the password set to 0000.

If the password entered is incorrect, the meter displays

for about two seconds, then it returns to Run Mode. To try again, press

Enter/Ack while the Locked message is displayed.

LoCd (Locked)

Forgot the Password?

The password may be disabled by the following

procedure:

1.

Note display reading prior to pr

button. Ignore decimal point and sign.

2. Access the

reading and enter that number as the passwor

(e.g. displa

Password menu, add 2 to the noted

y reading = -1.23, password = 0125).

essing the Menu

d

Advanced Features Menu

To simplify the setup process, functions not needed for most applications are located in the

Press the

Menu button for approximately 3 seconds to access the

tures Menu

Right arrow and Menu button simultaneously or hold the

of the meter.

Advanced Features menu.

Advanced Fea-

Press Simultaneously

*

adj

fltr

byps

serl

* Available for temperature inputs only

* * Available for process inputs only

Press Enter/Ack to Access

Menu or to Accept Setting

Press Up to Scroll Menu and

to Increment Digit Value

Press Right to Select Next Digit

Press Menu to Exit at any Time

Copy

SELc

50

**

I Cal

diag

Page 51

KOBOLD Model MPT Operating Instructions

s

s

DRAFT

Advanced Features Menu & Display Messages

Display Parameter Action/Setting

adj

fltr

byps

serl

prot

PDC

mbs

addr

baud

trdE

prty

tbyt

Copy

send

done

Selc

Func

Linr

Sqrt

cutF

out

Aout

rEly

Aout

Yes

no

Inty

Adjust

Filter

Bypass

Serial

Protocol

PDC

Modbus

Address

Baud rate

Transmit delay

Parity

Byte-to-byte

Copy

Send

Done

Select

Function

Linear

Square root

Cutoff

Output

Analog output

Relay

Analog output

Yes

No

Intensity

Set offset adjustment for temperature, not

available for process inputs

Set noise filter value

Set filter bypass value

Set serial communication parameters

Enter the Protocol menu

Select PDC protocol

Select Modbus protocol

Set meter address

Select baud rate

Set transmit delay for serial communication

Select none, even, or odd (Modbus only)

Program byte-to-byte timeout

(silent time – Modbus only)

Enter copy function

Send meter settings to another meter

Copy function completed

Enter the Select menu (function, cutoff, out)

Select linear or square root function

Set meter for linear function

Set meter for square root extraction

Set low-flow cutoff

Set meter for either relay or analog output

(factory set only – only included in certain model

Set meter for analog output option

Set meter for relay option

Enable or disable analog output

(factory set only – only included in certain model

Enable analog output

Disable analog output

Select display intensity

51

Page 52

KOBOLD Model MPT Operating Instructions

DRAFT

Display Parameter Action/Setting

ICal

Curr

I lo

I Hi

volt

Vlo

VHi

diag

led

CJC

Cfg

pts

RELY

Aout

GoFF

SErL

Info

Initial calibration

Current

I low

I high

Volt

V low

V high

Diagnostics

LED

CJC

CFG

Points

Relays

Analog output

Gain/offset

Serial

Information

Enter initial calibration for process inputs

Calibrating current input

Calibrate low current input

Calibrate high current input

Calibrating voltage input

Calibrate low voltage input

Calibrate high voltage input

Display parameter settings

Test display

Display cold junction compensation voltage

Display meter configuration

Display calibration points for process inputs

Display relay settings

Display analog output settings

Display gain and offset for process inputs

Display serial communication settings

Display software version and S/N information

52

Page 53

KOBOLD Model MPT Operating Instructions

DRAFT

Offset Adjustment (Adj)

This parameter allows the user to select an offset adjustment to the

temperature being displayed. Offset adjustment values can be either

positive or negative and can be any number within

adjustment value is programmed through the

The offset adjustment feature can be useful to compensate for errors

due to thermocouple junctions or excessive lead wire resistance in

RTDs.

The offset adjustment value is automatically reset to zero whenever the

type of temperature sensor is changed (

curve).

Celsius/Fahrenheit conversion of the offset adjustment value is automatic, see note 2 below for important limitations.

Notes:

1. Offset adjustment is available only when TC or RTD input is selected.

2. If adjustment value is greater than 11

scale is ch

ment will be 19.9

Noise Filter (fltr)

Most applications do not require changing this parameter. It is intended

to help attain a steady display with an unsteady (noisy) input signal.

The field selectable noise filter averages any minor or quick changes in

the input signal and displays the reading with greater stability.

Increasing the filter value will help stabilize the display, however this will

reduce the display response to changes on the input signal.

The filter level may be set anywhere from 2 to 199.

Setting filter value to zero disables filter function, and bypass setting be-

comes irrelevant.

anged to Fahrenheit, the maximum applied adjust-

°F.

i.e. Thermocouple type or RTD

±19.9°. The offset

Adjust menu.

°C and the temperature

53

Page 54

KOBOLD Model MPT Operating Instructions

DRAFT

Noise Filter Bypass (byps)

The meter can be programmed to filter small input changes, but allow

larger input changes to be displayed immediately, by setting the bypass

value accordingly.

If the input signal goes beyond the bypass value, it will be displayed immediately with no averaging done on it.

The noise filter bypass value may be set anywhere from 0.2 to 99.9. It

corresponds to percentage of full scale for process inputs and to degrees Fahrenheit for temperature inputs.

Increasing the bypass value may slow down the display response to

changes on the input signal.

Serial Communications (serl)

The meter is equipped with serial communications capability as a standard feature using PDC Serial Communication Protocol. The Modbus

RTU protocol is included on all models after 5/1/2010. To communicate

with a computer or other data terminal equipment, an RS-232 or RS-485

adapter option is required; see

tails.

Ordering Information on page 3 for de-

Serl Prot

When using more than one meter in a multi-drop mode, each meter

must be provided with its own unique address. The address may be programmed from 00 to 99 for PDC protocol and from 1 to 247 for Modb us

protocol. The transmit delay may be set between 0 and 199 ms (see Serial Communication Adapter manual for more details).

The MPT can also be connected directly to another MPT meter through

a cable assembly (PDA7420). This allows the user to copy all the settings from one meter to another, using the

Protocol Selection Menu (Prot)

The Protocol selection menu is used to select either the PDC or the

Modbus protocol.

Addr

54

bAud trde

Copy function.

Page 55

KOBOLD Model MPT Operating Instructions

DRAFT

Select Menu (SElc)

The Select menu is used to select linear or square root function, display

intensity, and low-flow cutoff. Selection for relay or analog output is a

factory setting depending on the option installed.

• Output options are installed

and set

up at the factory.

• Changing the output selec-

tion will cause erroneous operation.

Note:

Depending on meter model, the Select menu

will display either out or Aout. In either case,

the output selection menu is for factory use

only. Do not attempt to change output selection.

Linear or Square Root Function (linr or Sqrt)

Meters are set up at the factory for linear function. The linear function

provides a display that is linear with respect to the input signal.

The square root function is used to linearize the signal from a differential

pressure transmitter and display flow rate in engineering units.

Advanced

Features

Press Enter to Accept Setting

SELc

Func

Linr

55

Sqrt

Page 56

KOBOLD Model MPT Operating Instructions

DRAFT

Low-Flow Cutoff (cutF)

The low-flow cutoff feature allows the meter to be programmed so that

the often-unsteady output from a differential pressure transmitter, at low

flow rates, always displays zero on the meter.

The cutoff value may be programmed from 0 to 9999. Below the cutoff

value, the meter will display zero. Programming the cutoff value to zero

disables the cutoff.

Next

Menu Item

Display Intensity (inty)

The Display Intensity function allows the selection of eight levels of intensity for various lighting conditions.

Advanced

Features

SELc

Func

inty

Press Enter to Accept Setting

Press Up to Select Value

Press Menu to Exit at any Time

int3

Select Display

Intensity Level

56

Next

Page 57

KOBOLD Model MPT Operating Instructions

DRAFT

MeterView® Software

KOBOLD’s MeterView® software allows the MPT to be programmed

from a PC and to act as a data logger.

MeterView

for reporting, restoring, or programming other meters.

See

Note: PDC protocol must be selected to communicate with MeterView®.

The Copy function is used to copy (or clone) all the settings from one

meter to other meters requiring exactly the same setup and programming (

®

software allows all setup parameters to be saved to a file

Ordering Information, page 3 to order MeterView

Meter Copy Function (Copy)

i.e. type of input, scaling, decimal point, filter, bypass, etc.).

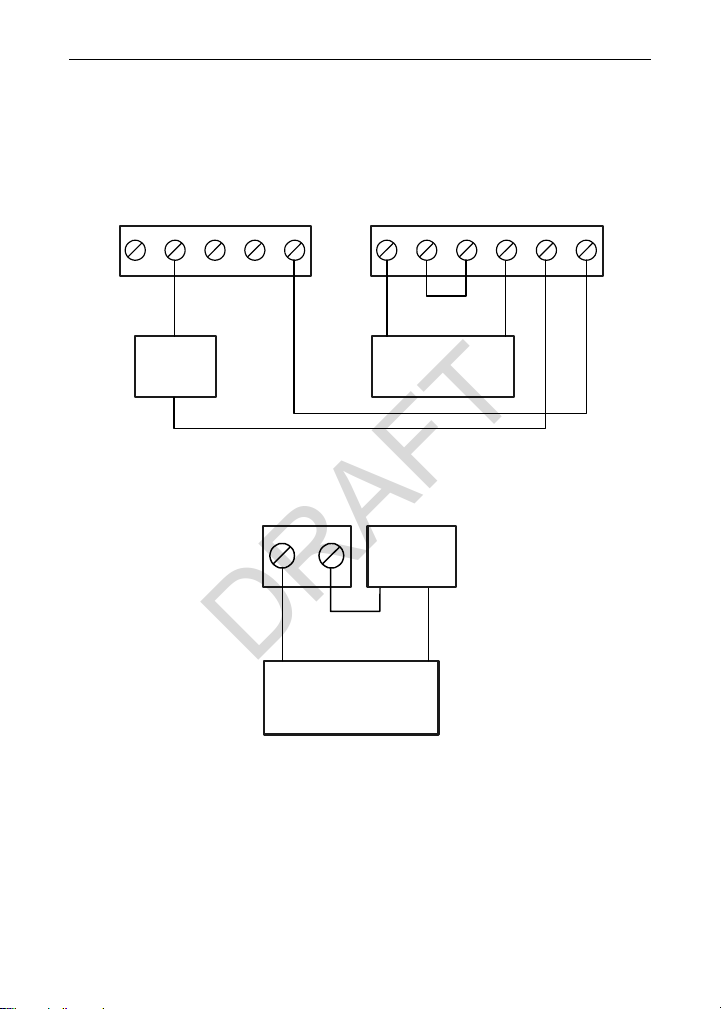

Figure 17. Meter Copy Connection

®

software.

Copy Function Requirements

To successfully copy settings from one meter to another, both meters must have:

1. Same software version

2. Same baud rate setting

3. PDC protocol selected

See Determining Software Version,

page 65 for instructions.

57

Page 58

KOBOLD Model MPT Operating Instructions

DRAFT

Meter Cloning Instructions

NOTICE!

1. Connect the two meters using cable assembly PDA7420 or equiva-

e.g. Digi-Key P/N H1663-07-ND). Cable should not exceed

lent (

7

' (2.1 m).

2. Power up both meters. Leave Clone meter in Run Mode.

3.

Ent

vanced Features Menu

4. Scroll

Enter/Ack.

5.

The meter displays the message

play flashes while sending data. The message

w

hen copying is completed.

Advanced

Features

Advanced Features Menu of the Master meter, see Ad-

er the

to

Copy function using Up arrow button then press

Copy send

Press

Menu

to Exit and

Return to Run Mode

Do not connect the two meters to

the same 4-20 mA loop while

cloning. Internal calibration may

be affected.

, page 50.

Send. Press Enter/Ack, the dis-

done is displayed

Display

Flashes While

Sending

done

6. The Clone meter displays the memory address being prog

t

hen the message

tializes and returns to Run Mode using the same settings as t

Master.

7.

If meter to be cloned does not respond to the data being sent, refe

to

Copy Function Requirements above.

done when copying is completed. The meter ini-

58

rammed

he

r

Page 59

KOBOLD Model MPT Operating Instructions

DRAFT

Internal Calibration (ICal)

• There is no need to recalibrate the meter

w

hen first received from the factory.

• The meter is factory calibrated prior to

shipment, for all input types, in milli

volts, and degrees respectively. The calibration equipment is certified to NI

st

andards.

he internal calibration allows the user to scale the meter without apply-

T

ing a signal. This menu is not available if the meter is set up for TC or

RTD inputs.

The use of calibrated signal sources is necessary to perform the internal

calibration of the meter.

Check calibration of the meter at least every 12 months. Each input type

must be recalibrated separately, if meter will be used with all input

types.

Notes:

• If meter is in operation and it is intended to

accept only one input type (e.g. 4-20 mA),

recalibration of other inputs is not necessary.

• Allow the meter to warm up for at least

utes before performing the internal cali-

15 min

bration procedure.

amps,

ST

T

he

Internal calibration menu is part of the Advanced Features Menu.

1. Press the Right arrow

Menu button for approximately 3 seconds to access the

Features Menu

Press

2.

3.

the

Up arrow button to scroll to the Internal calibration menu

and pr

ess

Enter/Ack.

The meter displays either current (

ing to the meter input setup. Press

tion process.

and Menu button simultaneously or hold the

of the meter.

Curr) or voltage (volt), accord-

Enter/Ack to start the calibra-

59

Advanced

Page 60

KOBOLD Model MPT Operating Instructions

DRAFT

Example for current input internal calibration:

4. The meter displays Low input current (I lo). Apply the low input

signal and press

while meter is accepting the low input.

5. After the display stops flashing, a number is displayed with the leftmost digit brighter than the rest. The bright digit is the active digit

that can be changed by pressing the

Right arrow button to move to the next digit.

Set the display value to correspond to the input signal being cali-

6.

brated.

7. The display moves to the high input calibration (

hig

h input signal and press

Set the display for the high input calibration in the same way as it

8.

was set for the low input calibration.

Enter/Ack. The display flashes for a moment

Up arrow button. Press the

I Hi). Apply the

Enter/Ack.

For instructions on how to pro-

gram numeric values see Setting Numeric Values

, page 28.

I Cal

Set Display Value

Curr

for Low Input

I lo 04.00

T

he graphic above shows the calibration of the current input. The volt-

age input is calibrated in a similar way.

Display

Flashes

While

Accepting

Input

60

I Hi

Calibrate

High Input

Page 61

KOBOLD Model MPT Operating Instructions

DRAFT

Tips:

Low and high input signals can be any valid values within the

•

e of the meter.

rang

• Observe minimum input span requirements between input 1

and i

nput 2.

• Low input must be less than high input signal.

Error Message (Err)

An error message indicates that the calibration or scaling process was

not successful.

After the error message is displayed, the meter reverts to input 1, allowing the appropriate input signals to be applied.

The error message might be caused by any of the following conditions:

1. Input signal is not connected to the proper terminals, or it is connected backwards.

2. Wrong signal selection in

Minimum input span requirements not maintained.

3.

Minimum Input Span

The minimum input span is the minimum difference between input 1 and input 2 signals required to complete the calibration or scaling of the meter.

Setup menu.

Input range Input 1 & input 2 span

4-20 mA 0.40 mA

±10 VDC

0.20 VDC

61

Page 62

KOBOLD Model MPT Operating Instructions

DRAFT

OPERATION

For process inputs, the meter is capable of accepting positive and negative signals and displaying these signals in engineering units from -1999

to 9999 (

to 10.00).

The temperature inputs are displayed according to the input type and

temperature units (

puts can be displayed with either 1

Front Panel Buttons Operation

e.g.

a signal from -10 to +10 VDC could be displayed as -10.00

°

F or °C) selected. RTD and Type T thermocouple in-

°

or 0.1° resolution.

Button

Symbol

Description

Press to ente

view settings, or exit Max/Min readings

Hold to enter Advanced features menu.

to reset Max/Min readings

Press

Press to displ

alternately

Press to displ

indefinitely while displaying Max/Min