Page 1

Operating Instructions

for

Liquid Level Transducer

Model : MM Series

Page 2

MM series

page 2 DT0593

1 Contents

1 Contents ........................................................................................................ 2

2 Note .............................................................................................................. 3

3 Instrument Inspection .................................................................................... 3

4 Regulation Use .............................................................................................. 4

5 Float designs ................................................................................................. 4

6 Operating Principle ........................................................................................ 5

7 Mechanical Connection ................................................................................. 5

8 Area of application ........................................................................................ 5

9 Maintenance .................................................................................................. 6

10 Technical details ........................................................................................... 6

11 Head transmitter ............................................................................................ 7

12 Display .......................................................................................................... 8

13 Electrical Connection .................................................................................... 8

13.1 General ................................................................................................ 8

13.2 Wiring diagram resistance output sensor ............................................. 8

13.3 Wiring diagram with transmitter ........................................................... 9

13.4 Wiring diagram with touch screen LCD display type D ........................ 9

13.5 Wiring diagram with touch screen LCD display type R ........................ 9

13.6 Wiring diagram with LCD display type C .............................................. 9

13.7 Wiring diagram with LED display type E .............................................. 9

13.8 Electrical connection in intrinsically safe mode Ex ia ......................... 10

13.9 Electrical connection in explosion proof mode Ex d ........................... 10

14 Safety Instructions ( ATEX ) ........................................................................ 11

14.1 Area of validity ................................................................................... 11

14.2 Guidelines. ......................................................................................... 11

14.3 Protection against ESD ( electro static discharges ) .......................... 12

14.4 Chemical resistance ........................................................................... 12

14.5 Maintenance and repairs ................................................................... 12

14.6 Storage .............................................................................................. 12

15 Installation in hazardous zone ..................................................................... 13

16 ATEX Label Description .............................................................................. 13

17 Declaration of conformity ATEX Ex ia ......................................................... 14

18 Declaration of conformity ATEX Ex d .......................................................... 15

19 Declaration of conformity ............................................................................ 16

20 EC-TYPE CERTIFICATE ............................................................................ 17

21 Notes ........................................................................................................... 27

Manufactured by:

Kobold Mesura S.L.U.

Avda. Conflent 68 nave 15

08915 Badalona

Tel.: +34 93 460 38 83

Fax: +34 93 460 38 76

E-Mail: info.es@kobold.com

Internet: www.kobold.com

Edition: June 2017

Page 3

MM series

page 3 DT0593

2 Note

Please read these operating instructions before unpacking and setting the unit into

operation. Follow the instructions precisely as described herein.

The devices are only to be used, maintained and serviced by persons familiar with

these operating instructions and in accordance with local regulations applying to

Health & Safety and prevention of accidents.

When used in machines, the measuring unit should be used only when the

machines fulfil the EC-machine guidelines.

3 Instrument Inspection

Instruments are inspected before shipping and sent out in perfect condition.

Should damage to a device be visible, we recommend a thorough inspection of the

delivery packaging. In case of damage, please inform your parcel service /

forwarding agent immediately, since they are responsible for damages during

transit.

Scope of delivery:

The standard delivery includes:

Liquid Level Transducer model: MM-...

Operating Instruction

Caution: Heavy mechanical stress, such as bending, impact or shock

loads to the level transducer could damage the transducer and/or the

magnet.

Page 4

MM series

page 4 DT0593

4 Regulation Use

Kobold level transducers are used for the continuous level indication and level

control of all kinds of liquids. The simple design with only one moving part (the

float) is suitable for applications that demand reliability. Kobold level transducers

allow the continuous level indication and level control of liquids unaffected by

electrical conductivity, temperature, pressure. The level transducer may only be

used in liquids that will assure free movement of the float. The following points

must be noted:

no large particles

density of the fluid must not be less than that specified for the float type

pressure and temperature to be held within the limits given in the technical

specifications

A variety of transducers in various designs, connecting configurations and

materials are available for the acquisition of the measuring values.

Attention! These units should not be installed in the vicinity of strong

magnetic fields, since this can impair their intended functionality.

5 Float designs

Model Form Materials

Float

Outside

[mm]

Height

[mm]

Bore

Hole

[mm]

Min. Liquid

Density

[kg/dm³]

Max.

Temperature

°C

Nominal

Pressure

[bar] at

20 °C

MM05

Cylinder

hollow

PP 42 40 14 > 0.6 -10...+80°C 3 bar

MM07

Cylinder

hollow

PVC-U 42 40 14 > 0.9 0...+60 °C 3 bar

MM08

Cylinder

hollow

St. steel

1.4404

44 52 15 > 0.65 -20...+130°C 20 bar

MM10

Ball

hollow

St. steel

1.4404

52 52 15 > 0.6 -20...+130°C 30 bar

MM13

Cylinder

hollow

PVDF 38 60 18 > 0.6 -10...+125°C 2 bar

MM15

Cylinder

hollow

PP 60 60 18 > 0.4 -10...+80ºC 6 bar

MM16

Cylinder

hollow

PVC-U 60 60 18 > 0.6 0...+60°C 3 bar

MM20

Ball

hollow

St. steel

1.4404

95 95 20.8 > 0.5 -10...+130°C 15 bar

Page 5

MM series

page 5 DT0593

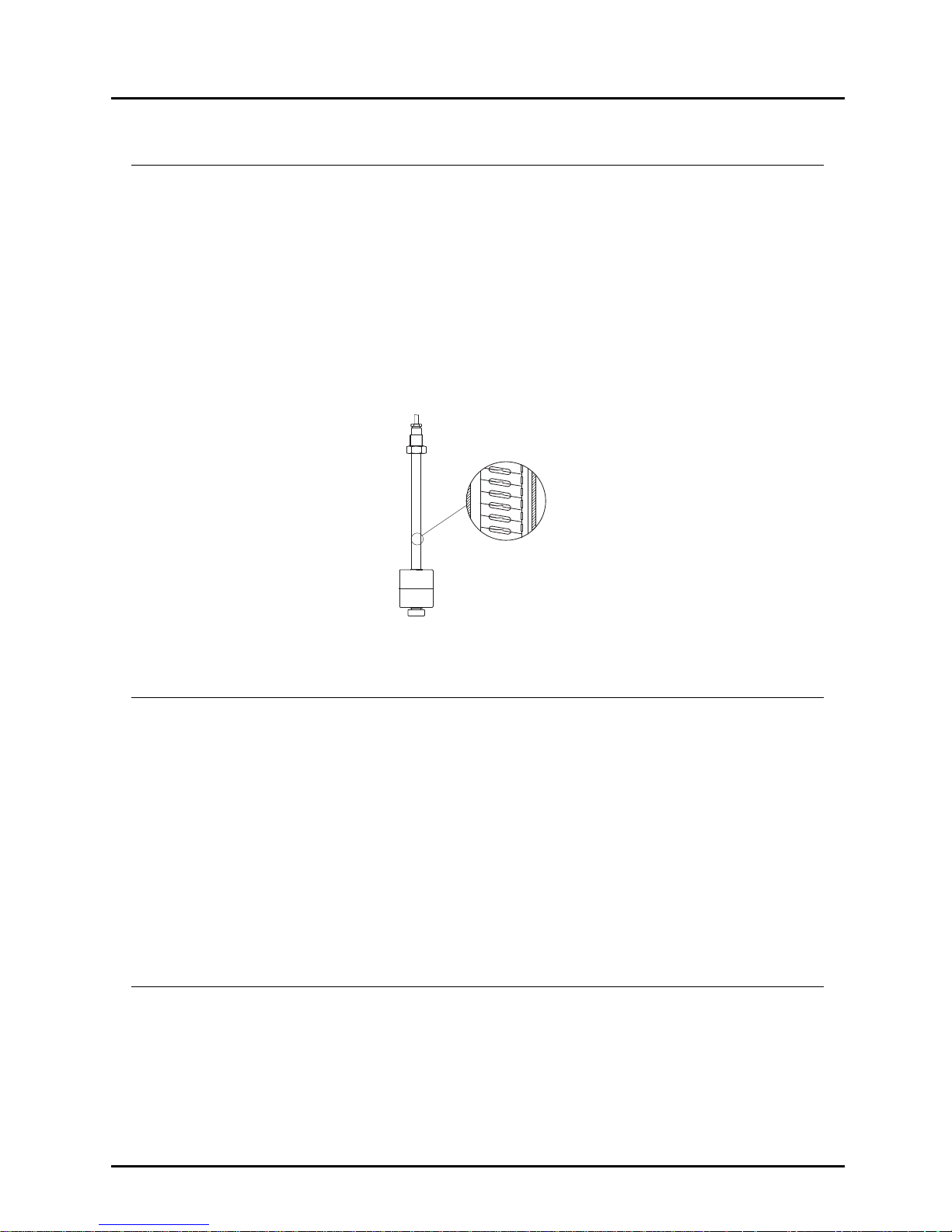

6 Operating Principle

The Kobold-liquid Level Transducers consist of a tube on which a float travels with

inserted magnet, similar to the Kobold level float switch, in models without float on

the tube, the float is placed in and adjacent bypass tube to actuate the reed chain

contacts, however, in the MM, the magnet remotely actuates the reed contacts

inside the tube.

However, the well-known principle of the level float switch has been changed, in

such a way that the tube of the level transducer contains an electric resistance

chain and a reed contact chain.

The float remotely actuates the contacts through the tube wall and a voltage

proportional to the liquid level can be taken from the chain. This voltage sensing

corresponds to the function of the slide of a resistance potentiometer.

7 Mechanical Connection

The reed chain tube should not be bent or exposed to hard impacts, since

otherwise the reed contacts inside the tube can be damaged.

Ensure the correct use of cable gland and gasket on float switches with plug to

prevent the penetration of humidity.

While installation is carried out, please ensure that the float can move freely (due

allowance should be given to distances from side-walls!).

Mounting position of the slide-tube may not deviate more than ±30° from vertical

position.

If the float has to be removed, pay attention to correct orientation when replacing

the float.

8 Area of application

Magnetic level sensor MM series are used exclusively for level control and

monitoring of liquid media.

The liquids should not contain suspended solids or tendency to crystallize.

Ensure that the construction materials of the float switch have chemical resistance

sufficient to prevent mechanical deformations that may affect it.

Page 6

MM series

page 6 DT0593

9 Maintenance

In liquids that can cause deposits, the float has to be cleaned at regular intervals.

In this case the measuring tube and float should be cleaned from such deposits

(valid for models where float is directly guided on the reed chain). Other

maintenance jobs are not required.

10 Technical details

Power supply: Output resistance: max. 24Vdc, 125 mW.

Ex ia parameters: Pi: 1,2W

Output 4…20 mA and 4…20 mA HART

®

: 8…35 Vdc

Ex ia parameters: Ui:30 Vdc, Ii: 120 mA, Pi: 0,84 W,

Li: 10uH, Ci: 1 nF

Output transmitter PROFIBUS

®

/FIELDBUS® : 9…32 Vdc

Ex ia parameters:

Ui:30 Vdc, Ii: 120 mA, Pi: 0,84 W,

Li: 1uH, Ci: 2 nF

Version with display model D: 14,5…35 Vdc

Ex ia parameters:

Ui:30 Vdc, Ii: 100 mA, Pi: 0,75 W,

Li: 10uH, Ci: 15 nF

Version with display model R: 14,5…35 Vdc

Relays 0…60 Vp, 75 mA

Ex ia parameters display:

Ui:30 Vdc, Ii: 100 mA,

Pi: 0,75 W, Li: 10uH, Ci: 15 nF.

Ex ia parameters relays:

Ui:30 Vdc, Ii: 75 mA, Pi: 0,75 W,

Li: 10uH, Ci: 10 nF

Version with display model C: 10…35 Vdc

Version with display model E: 11,7…35 Vdc

Protection type: IP65 (IP68 possible with housing type L, C,

and E)

Min. liquid density: See float design table

Min. measuring length “L”: 300 mm

Max. measuring length “L”: 6000 mm (types M08, M10, M20)

5000 mm (types M15, M17, M13)

2000 mm (types M05, M07)

Page 7

MM series

page 7 DT0593

Max. pressure (at 20ºC): 2 bar (type M13)

3 bar (type M05, M07, M16)

6 bar (type M15)

15 bar (type M20)

20 bar (type M08)

30 bar (type M10)

Max. temp. with PVC cable: 60ºC (type M07, M16)

70ºC (type M05, M15, M13, M08, M10, M20)

Max. temp. with. silicone cable: See max. temperature in float design table

Resolution: 10 mm

Accuracy: Formula in accordance to the measuring length

10 x 100 : measuring length = accuracy %

e.g.: 10 x100 : 2000 = 0,5 %

Resistance value: 36 Ω for each 10 mm, when total

length <1900 mm

10 Ω for each 10 mm, when total

length ≥1900 mm

e.g.: 2000 : 10 x 10 = 2000 ohms

1800 : 10 x 36 = 6480 ohms

Material: PVC-U, PP, PVDF, 1.4404

(others on request)

Process connection: G 3/8, G 1/2, G 1, G 1 ½, G 2, 3/8” NPT,

½” NPT, 1” NPT, 1 ½” NPT, 2” NPT and

flanged version. (others on request)

11

Head transmitter

Model 5333D: analogue output 4…20 mA, 2 wires,

Sensor error action : Namur upscale (23 mA)

Model 5337D: analogue output 4…20 mA HART

®

-protocol, 2 wires

Sensor error action : Namur upscale (23 mA)

Model 5350B : PROFIBUS

®

/FIELDBUS®

Page 8

MM series

page 8 DT0593

12 Display

- Only for 4…20 mA or HART

®

transmitters.

- Supply Voltage: loop powered

- Voltage dropout: max. 4 or 6,5 Vdc model D

max. 3,7 Vdc model E

max. 2,5 Vdc model C

Note

For programming of transmitter and/or display please refer to their separates

programming manual.

13 Electrical Connection

13.1 General

- Make sure that the supply wires are de-energized.

- To reduce the possibility of interference from other electric circuits, the

cables should be wired separately.

- Please pay attention to the potentially detrimental operating conditions

regarding the placement of the cable.

- Connect the level transducer to the electronic in accordance with the

connection diagrams below.

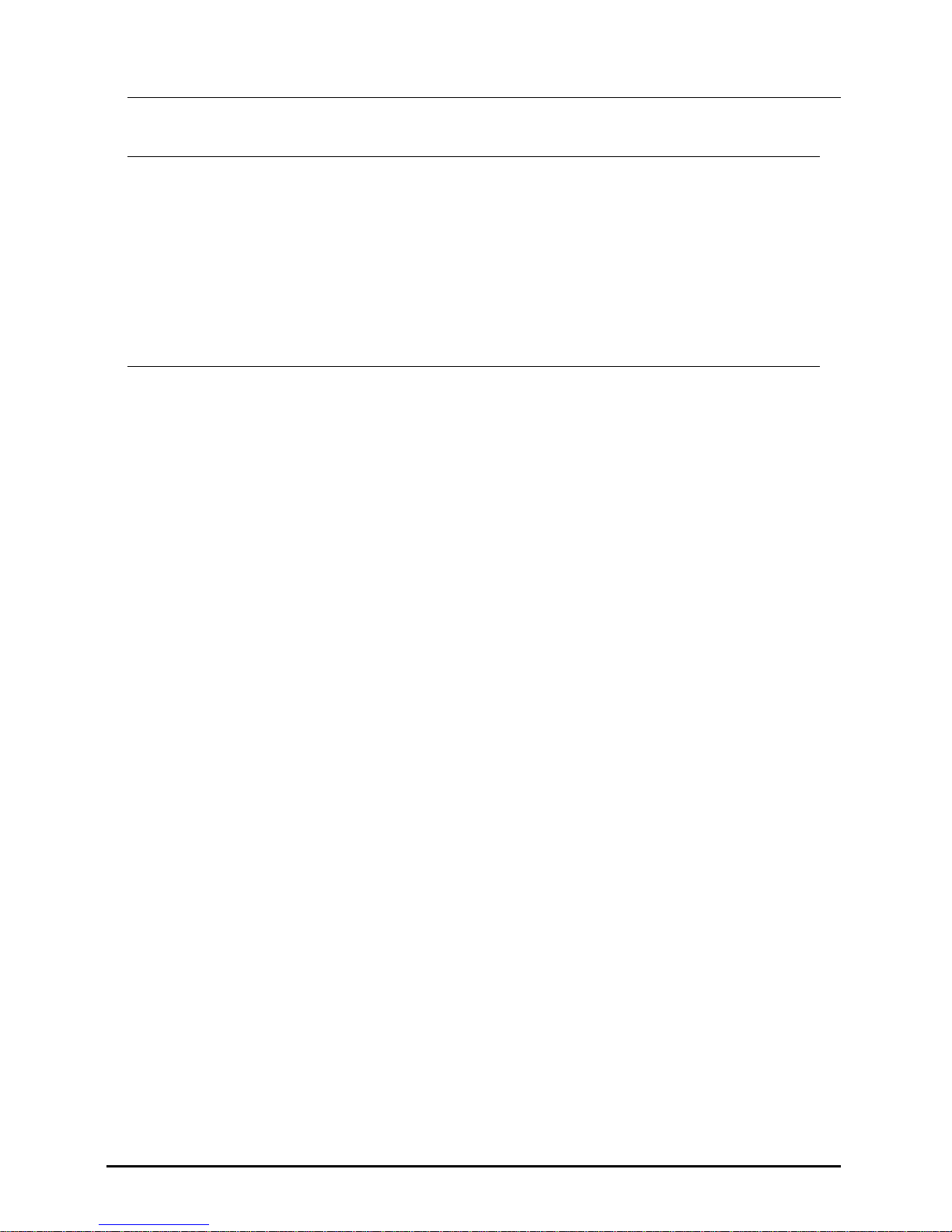

13.2 Wiring diagram resistance output sensor

Resistance value

increases

proportionally

with level

increase.

Resistance value

decreases

proportionally

with level

increase.

Signal

Models with cable white Brown Green

Models with box Clamp 1 Clamp 2 Clamp 3

Page 9

MM series

page 9 DT0593

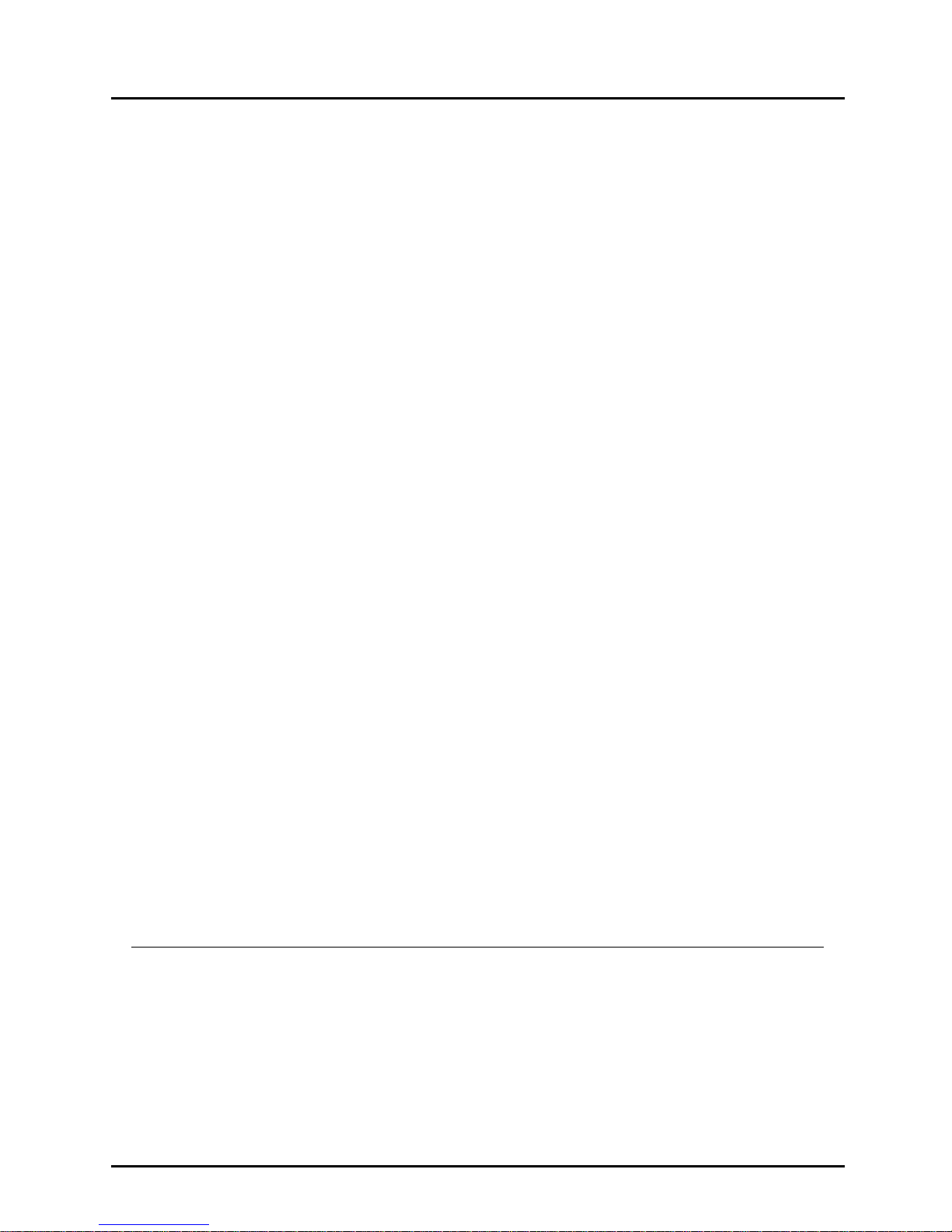

13.3 Wiring diagram with transmitter

13.4 Wiring diagram with touch screen LCD display type D

13.5 Wiring diagram with touch screen LCD display type R

13.6 Wiring diagram with LCD display type C

13.7 Wiring diagram with LED display type E

Page 10

MM series

page 10 DT0593

13.8 Electrical connection in intrinsically safe mode Ex ia

13.9 Electrical connection in explosion proof mode Ex d

Page 11

MM series

page 11 DT0593

14 Safety Instructions ( ATEX )

14.1 Area of validity

These security instructions apply to MM…E series magnetic level sensor for use in

explosion-proof atmospheres conforming to certificate LOM 06ATEX2054 X and

MM…F series conforming to CE certificate LOM 14ATEX2075 X

14.2 Guidelines.

These security instructions must be applied to the MM…E and MM…F series used in

gas explosion hazard environments.

It is necessary to follow carefully the instructions from the hazardous areas where the

MM...E or MM…F will be installed, as well as the safety instructions included in this

manual.

In models with transmitter and/or display the intrinsically safe specific parameters

are:

Ci total: Ci (sensor) + Ci (transmitter) + Ci ( display)

Li total: Li (sensor) + Li (transmitter) + Li ( display)

It must be considered the minimum value of Pi, Ii and Ui in all components used in the

assembly.

Temperature class and/or surface temperature relates solely to a device operated at

ambient temperature. On installation, the actual temperature class for process

operation has to be determined.

The maximum temperature in the enclosure head depends on the process

temperature and may not exceed the maximum service temperature indicated for the

junction box for the instruments MM…F series.

The guide tube must be mechanically protected or in locations with low risk of impact

for the instruments MM…F series.

When the tank inside is a zone 0, a degree of protection at least IP67 must be

ensured in the process connection for the instruments MM…F series.

Inlet bushing and cable glands must conform to the certification for their type in

accordance with the directive.

Models with cable must be protected with an external enclosure having at least a

degree of protection IP20 for MM…E series.

The use in zone 0 of heads made of aluminium should be restricted to locations

where the risk of ignition due to mechanical impact is not possible.

Page 12

MM series

page 12 DT0593

Verify that all data written in the label of the device matches the data required for the

installation.

Verify that there is no mechanical stress or deformation due to installation in the tank.

Remove power supply and verify that no explosion risk is present before opening

cover of the housing and check that the cover of housing is correctly mounted before

applying power to the instruments MM…F series.

The installation of instruments in hazardous areas must be exclusively done by

trained people.

14.3 Protection against ESD (electro static discharges)

Instruments with plastic parts that can produce electro statics discharges have a

label for it.

It is important to follow some rules to avoid ESD:

- Avoid rubbing the device.

- Never clean the device dry.

- Do not install the device near material airflows or near steam outlets.

14.4 Chemical resistance

Ensure that the device construction materials have chemical resistance sufficient to

prevent mechanical deformations that may affect the device.

14.5 Maintenance and repairs

The instrument does not require maintenance or servicing.

Repairs must be only carried out by Kobold Mesura (manufacturer).

14.6 Storage

Measuring instruments should be protected against humidity and dust.

Storage temperature: -5…+55ºC

Page 13

MM series

page 13 DT0593

15 Installation in hazardous zone

In classified zones, magnetic level switches series MM…E (intrinsically safe version),

can be installed in zone 0, 1, 2, 20, 21, 22 and series MM…F (explosion proof version)

can be installed in zone 0,1, 2, 21, 22.

Installation must be done by people trained regarding ATEX environments.

Intrinsically safe version Explosion proof version

16 ATEX Label Description

Page 14

MM series

page 14 DT0593

17 Declaration of conformity ATEX Ex ia

DECLARACIÓN DE CONFORMIDAD EU

EU DECLARATION OF CONFORMITY

EU-KONFORMITÄTSERKLÄRUNG

DÉCLARATION DE CONFORMITÉ

DICHIARAZIONE DI CONFORMITÀ EU

KOBOLD MESURA SLU

Avda. Conflent 68 nave 15 08915 Badalona (España)

Declara, bajo la propia responsabilidad, que el producto

Declares under our sole responsibility, that the product

Erklärt in alleiniger Verantwortung, dass das Produkt

Déclare sous sa seule responsabilité, que le produit

Dichiara sotto la propia responsabilità, che il prodotto

Liquid level transducer

MM-...E

A los cuales se refiere esta declaración, son conformes a las siguiente Directivas Europeas:

To which this declaration relates is in conformity with the following European Directives:

Mit folgenden Richtlinien konform ist:

À auxquels se réfère cette déclaration, ils sont conformes aux Directives Européennes suivant :

A ai quali si riferisce questa dichiarazione, sono conformi alle direttive europee seguente:

EMC2014/30/EU LVD2014/35/EU Atex2014/34/EU RoHS2011/65/EU

Normas armonizadas y documentos de la normativa aplicados:

Applied harmonised standards and normative documents:

Angewandte harmonisierte Normen und normativer Dokumente:

Normes harmonisées et documents normatifs appliqués

Norme armonizzate e documenti normativi applicati:

EN61010-1 :2011 EN60079-0:2012 (acc. EN60079-0:2013)

EN61000-6-2 :2006 EN60079-11:2012 (acc. EN60079-2013)

EN61326-1:2013

Certificado de examen CE de tipo Marcado

EC-type examination certificate Marking

EG-Baumusterprüfbescheinigung Kennzeichnung

Attestation d´examen CE de type Inscription

Certificazione per esame di tipo CE Marcatura

LOM06ATEX2054X

II 1 GD Ex ia IIC T6 Ga

-20 ºC ≤ Ta ≥ +60 ºC

Fabricado en

: KOBOLD MESURA SLU Avda. Conflent 68 nave 15 08915 BADALONA (Spain)

Made in:

Hergestellt in:

Fabriqué dans:

Fabbricato in:

Organismo notificado

: LOM 0163 Número notificación : LOM 05ATEX9070

Notified organism Notification number

Zertifizierungsstelle Zertifikatsnummer

Organization annoncée Nombre notification

Organismo informato Notifica di numero

Badalona june 2017 Gerente

DT0599

Page 15

MM series

page 15 DT0593

18 Declaration of conformity ATEX Ex d

DECLARACIÓN DE CONFORMIDAD EU

EU DECLARATION OF CONFORMITY

EU-KONFORMITÄTSERKLÄRUNG

DÉCLARATION DE CONFORMITÉ

DICHIARAZIONE DI CONFORMITÀ EU

KOBOLD MESURA SLU

Avda. Conflent 68 nave 15 08915 Badalona (España)

Declara, bajo la propia responsabilidad, que el producto

Declares under our sole responsibility, that the product

Erklärt in alleiniger Verantwortung, dass das Produkt

Déclare sous sa seule responsabilité, que le produit

Dichiara sotto la propia responsabilità, che il prodotto

Liquid level transducer

MM..F

A los cuales se refiere esta declaración, son conformes a las siguiente Directivas Europeas:

To which this declaration relates is in conformity with the following European Directives:

Mit folgenden Richtlinien Konform ist:

À auxquels se réfère cette déclaration, ils sont conformes aux Directives Européennes suivant :

A ai quali si riferisce questa dichiarazione, sono conformi alle direttive europee seguente:

EMC2014/30/EU LVD2014/35EU Atex2014/34/EU RoHS2011/65/EU

Normas armonizadas y documentos de la normativa aplicados:

Applied harmonised standards and normative documents:

Angewandte harmonisierte Normen und normativer Dokumente:

Normes harmonisées et documents normatifs appliqués

Norme armonizzate e documenti normativi applicati:

EN61010-1 :2011 EN60079-0:2012 (acc. EN60079-0:2013)

EN61000-6-2 :2006 EN60079-31:2009 (acc. EN60079-31:2016)

EN61326-1:2013 EN60079-1:2007 (acc. EN60079-1:2015)

EN60079-26:2007 (acc. EN60079-26:2015)

Certificado de examen CE de tipo

Marcado

EC-type examination certificate Marking

EG-Baumusterprüfbescheinigung Kennzeichnung

Attestation d´examen CE de type Inscription

Certificazione per esame di tipo CE Marcatura

LOM 14ATEX2075 X

II 1/2 G Ex d IIC T1..T6 Ga/Gb

II 2 D Ex t IIIC T410..T85ºC Db

Fabricado en: KOBOLD MESURA SLU Avda. Conflent 68 nave 15 08915 BADALONA (Spain)

Made in:

Hergestellt in:

Fabriqué dans:

Fabbricato in:

Organismo notificado

: LOM 0163 Número notificación : LOM 05ATEX9070

Notified organism Notification number

Zertifizierungsstelle Zertifikatsnummer

Organization annoncée Nombre notification

Organismo informato Notifica di numero

Badalona june 2017 Gerente

DT0607

Page 16

MM series

page 16 DT0593

19 Declaration of conformity

DECLARACIÓN DE CONFORMIDAD EU

EU DECLARATION OF CONFORMITY

EU-KONFORMITÄTSERKLÄRUNG

DÉCLARATION DE CONFORMITÉ

DICHIARAZIONE DI CONFORMITÀ EU

KOBOLD MESURA SLU

Avda. Conflent 68 nave 15 08915 Badalona (España)

Declara, bajo la propia responsabilidad, que el producto

Declares under our sole responsibility, that the product

Erklärt in alleiniger Verantwortung, dass das Produkt

Déclare sous sa seule responsabilité, que le produit

Dichiara sotto la propia responsabilità, che il prodotto

Liquid Level Transducer

MM

A los cuales se refiere esta declaración, son conformes a las siguiente Directivas Europeas:

To which this declaration relates is in conformity with the following European Directives:

Mit folgenden Richtlinien Konform ist:

À auxquels se réfère cette déclaration, ils sont conformes aux Directives Européennes suivant :

A ai quali si riferisce questa dichiarazione, sono conformi alle direttive europee seguente:

EMC2014/30/EU LVD2014/35/EU RoHS2011/65/EU

Normas armonizadas y documentos de la normativa aplicados:

Applied harmonised standards and normative documents:

Angewandte harmonisierte Normen und normativer Dokumente:

Normes harmonisées et documents normatifs appliqués

Norme armonizzate e documenti normativi applicati:

EN61010-1 :2011 EN61326-1:2013

EN61000-6-2 :2006

Fabricado en: KOBOLD MESURA SLU Avda. Conflent 68 nave 15 08915 BADALONA (Spain)

Made in:

Hergestellt in:

Fabriqué dans:

Fabbricato in:

Badalona june 2017 Gerente

DT0600

Page 17

MM series

page 17 DT0593

20 EC-TYPE CERTIFICATES

Page 18

MM series

page 18 DT0593

Page 19

MM series

page 19 DT0493

Page 20

MM series

page 20 DT0493

Page 21

MM series

page 21 DT0493

Page 22

MM series

page 22 DT0493

Page 23

MM series

page 23 DT0493

Page 24

MM series

page 24 DT0493

Page 25

MM series

page 25 DT0493

Page 26

MM series

page 26 DT0493

Page 27

MM series

page 27 DT0493

21 Notes

Page 28

MM series

page 28 DT0493

KOBOLD MESURA S.L.U

Avda. Conflent 68 nave 15

08915 Badalona

Tel.: +34 93 460 38 83

Fax: +34 93 460 38 76

E-Mail: info.es@kobold.com

www.kobold.com

Technical data

Subject to change without prior notice

Loading...

Loading...