Page 1

Operating Instructions

for

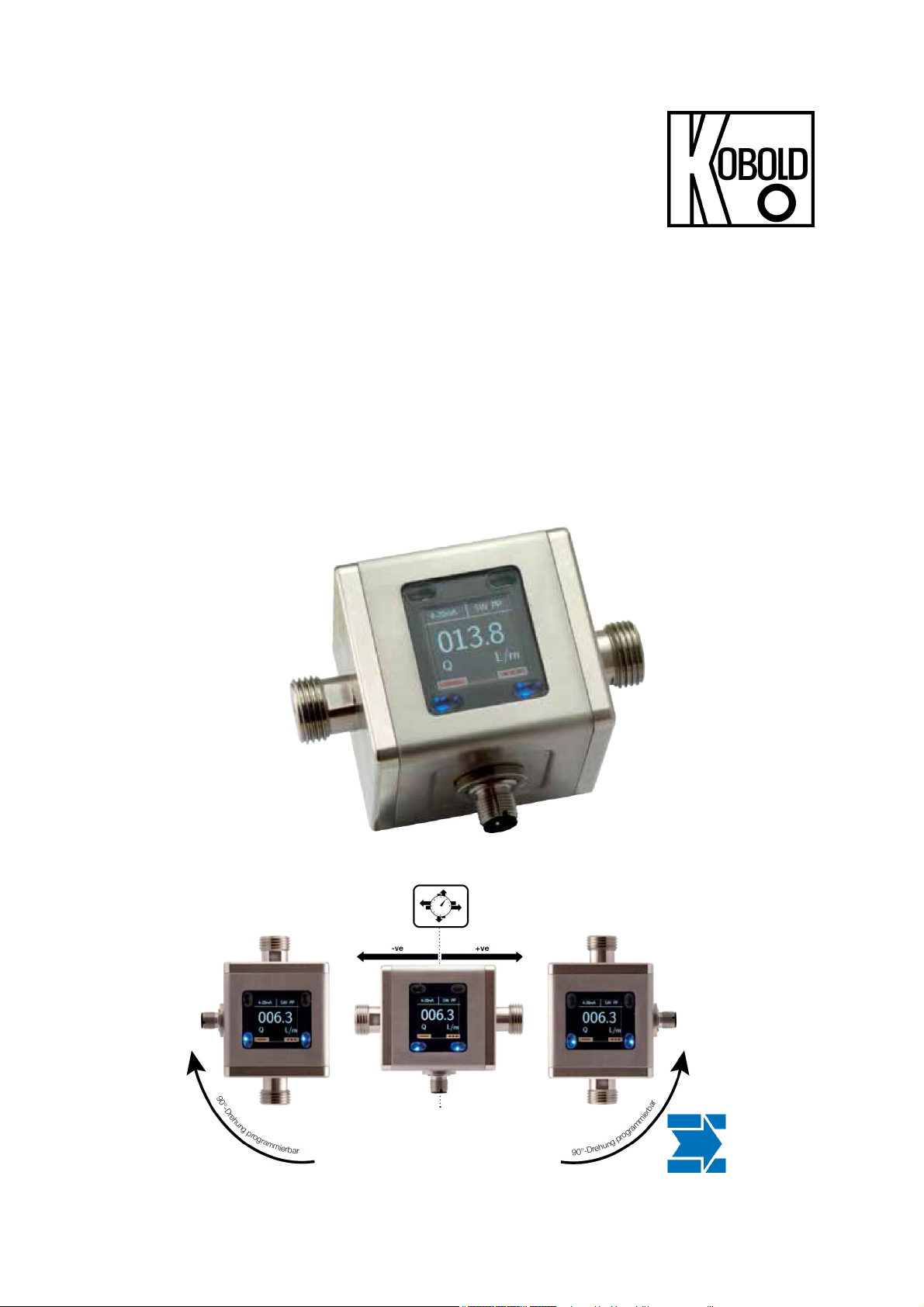

Electromagnetic Flowmeter

Model: MIM

Page 2

MIM-

We don’t accept warranty and liability claims neither upon this publication nor in

case of improper treatment of the described products.

The document may contain technical inaccuracies and typographical errors. The

content will be revised on a regular basis. These changes will be implemented in

later versions. The described products can be improved and changed at any time

without prior notice.

© Copyright

All rights reserved.

1. Contents

1. Contents ........................................................................................................ 2

2. Note .............................................................................................................. 4

3. Instrument Inspection .................................................................................... 4

4. Regulation Use .............................................................................................. 4

5. Environment .................................................................................................. 5

6. Operating principle ........................................................................................ 5

6.1 General ................................................................................................ 5

6.2 Minimum electrical conductivity / gas bubbles ..................................... 5

6.3 Deposits ............................................................................................... 6

6.4 Measuring electrodes........................................................................... 6

7. Mechanical connection .................................................................................. 7

7.1 Check operating conditions .................................................................. 7

7.2 Installation ............................................................................................ 7

8. Electrical Connection .................................................................................... 9

8.1 General ................................................................................................ 9

8.2 Pin assignment .................................................................................. 10

9. Operation and menu structure .................................................................... 11

9.1 General .............................................................................................. 11

9.2 Measuring mode ................................................................................ 12

9.3 Menu Mode ........................................................................................ 15

10.Device configuration .................................................................................... 16

10.1 Sequence of device parameterization ................................................ 16

10.2 Overview of the menu functions / device parameters ........................ 17

10.3 Display ............................................................................................... 20

10.4 Measurement ..................................................................................... 20

10.5 Outputs .............................................................................................. 23

10.6 User service ....................................................................................... 27

10.7 Service / Factory service .................................................................... 28

10.8 Information ......................................................................................... 28

10.9 Device default settings ....................................................................... 29

11.Technical Information .................................................................................. 30

12.Order Codes ............................................................................................... 31

13.Dimensions ................................................................................................. 32

14.EU Declaration of Conformance .................................................................. 33

page 2 MIM K02/1217

Page 3

MIM-

Manufactured and sold by:

Kobold Messring GmbH

Nordring 22-24

D-65719 Hofheim

Tel.: +49(0)6192-2990

Fax: +49(0)6192-23398

E-Mail: info.de@kobold.com

Internet: www.kobold.com

MIM K02/1217 page 3

Page 4

MIM-

2. Note

Please read these operating instructions before unpacking and putting the unit

into operation. Follow the instructions precisely as described herein.

The devices are only to be used, maintained and serviced by persons familiar

with these operating instructions and in accordance with local regulations

applying to Health & Safety and prevention of accidents.

When used in machines, the measuring unit should be used only when the

machines fulfil the EC-machine guidelines.

as per PED 2014/68/EU

In acc. with Article 4 Paragraph (3), "Sound Engineering Practice", of the PED

2014/68/EU no CE mark.

Diagram 8, Pipe, Group 1 dangerous fluids

3. Instrument Inspection

Instruments are inspected before shipping and sent out in perfect condition.

Should damage to a device be visible, we recommend a thorough inspection of

the delivery packaging. In case of damage, please inform your parcel service /

forwarding agent immediately, since they are responsible for damages during

transit.

Scope of delivery:

The standard delivery includes:

Electromagnetic Flowmeter model: MIM

Operating Instructions

4. Regulation Use

The MIM flowmeter has been specially developed for the measurement, display

and transmission of both, flow rates and temperature of conductive liquids. The

instrument has a graphic TFT display, rotatable in 90 ° steps and can display flow

rate, temperature, daily volume counter (resettable) and total volume counter in

the units of measurement selected by the operator. A clear menu guides the user

through the parameterization of the device, which largely eliminates the need to

look into the operating instructions.

Any use of the magnetic flowmeter, model: MIM, which exceeds the

manufacturer’s specification, may invalidate its warranty. Therefore, any resulting

damage is not the responsibility of the manufacturer. The user assumes all risk

for such usage.

page 4 MIM K02/1217

Page 5

MIM-

5. Environment

The MIM device with stainless steel housing and stainless steel electrodes is

weatherproof and conforms to protection class IP67. The meter is designed for

harsh indoor or outdoor environments and complies with Directive 2014/30/EU

(Electromagnetic Compatibility).

6. Operating principle

6.1 General

The new KOBOLD MIM Flowmeter is designed to measure and monitor small

and medium flows of conductive fluids in piping.

The device works on the magnetic-inductive measuring principle. According to

Faraday's law of induction, a voltage is induced in a conductor moving in a

magnetic field. The electrically conductive measuring medium corresponds to the

moving conductor in the process. The voltage induced by the measuring medium

is proportional to the flow rate and thus a measure of the volume throughput.

Prerequisite is a minimum electrical conductivity of the flowing medium. The

induced voltage is fed to a measuring amplifier via two electrodes, which are in

conductive contact with the medium. The volume flow is calculated via the

defined pipe diameter.

The measurement is independent of the medium and its physical properties such

as density, viscosity and temperature. The device can be configured via the

display. There are two outputs available, which can each be configured as alarm,

frequency, pulse, voltage, and current outputs.

The device also provides a dosing function. The dosing function can be activated

in measuring mode via the four buttons. The dosing function controls simple filling

tasks and also measures flow rate and partial amount.

6.2 Minimum electrical conductivity / gas bubbles

For the correct function of the instrument, it is necessary that the flow channel is

always completely filled with medium. From a minimum electrical conductivity of

20 μS / cm, the MIM operates within the specified error limits. The conductivity of

the medium is constantly monitored by the device electronics. If the electronics

detects that the minimum conductivity has fallen below min. value, this is signaled

by displaying the error message 'Empty pipe' and the flow rate reading is set to

'0'. Air bubbles in the flowing medium or media with varying conductivity in the

range of the minimum conductivity can disturb the measuring function and reduce

the measuring accuracy of the MIM. Gases contained in the liquid are also

measured as a volume flow and lead to measurement errors. If necessary, install

appropriate vents in the flow of the unit.

MIM K02/1217 page 5

Page 6

MIM-

6.3 Deposits

Minor deposits on the measuring tube generally do not affect the measuring

accuracy unless their conductivity deviates significantly from the liquid. For liquids

that have a tendency to deposit, periodically inspect the meter tube and, if

necessary, clean it.

6.4 Measuring electrodes

The MIM uses electrodes with galvanic tapping. They are in direct contact with

the medium. The standard electrodes are made of stainless steel 1.4404.

page 6 MIM K02/1217

Page 7

MIM-

7. Mechanical connection

7.1 Check operating conditions

flow rate

max. operating pressure

max. operating temperature

In general, MIM is subjected to the same loads as the piping into which it is

installed. The MIM should therefore be kept away from extreme loads, such as

pressure surges with strong, dynamic pipe movements, vibrations in the proximity

of centrifugal pumps, high temperature media, flooding etc.

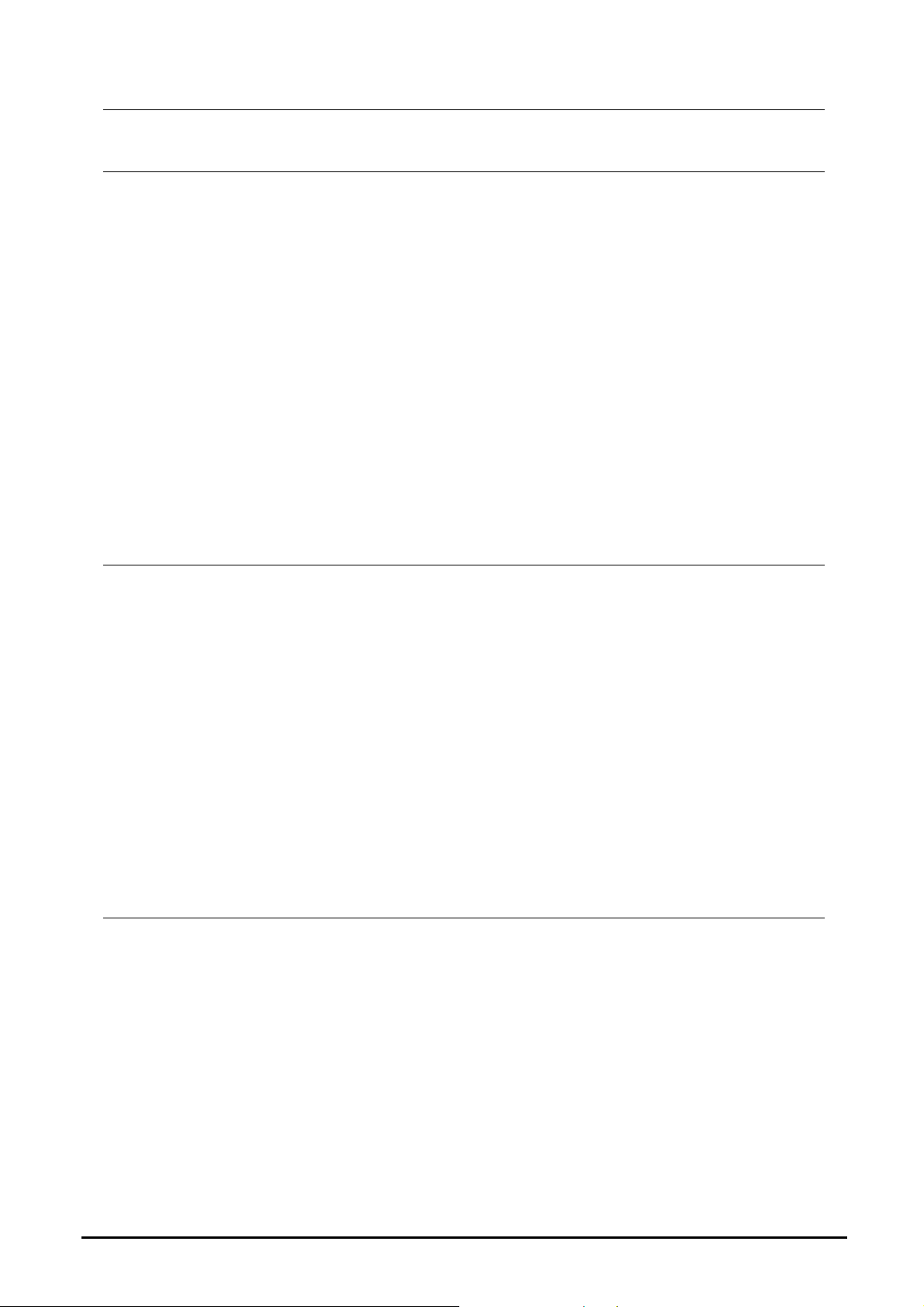

7.2 Installation

Remove all packing materials and transport retainers and ensure that no such

materials remain in the device.

It can be installed in vertical, horizontal or rising pipes. Flow in direction of the

arrow.

Avoid pressure and tensile load.

Mechanically secure the inlet and outlet pipe at a distance of 50 mm from the

connections.

Avoid valves or large reduction on the inlet section (this increases the

inaccuracy of measurements).

Check the leak tightness of the connections.

While mounting MIM hold the flowmeter from spanner surface (not

from the housing) with the help of spanner.

Take into account the tightening torque.

Nominal size Tightening torque

½“ 22 to 24 Nm

¾“ 28 to 30 Nm

1“ 28 to 30 Nm

MIM K02/1217 page 7

Page 8

MIM-

Inlet and outlet run

Installation from top to bottom avoid these installation locations

Gas bubbles,

particle

Free outlet

page 8 MIM K02/1217

Page 9

MIM-

8. Electrical Connection

8.1 General

Attention! Make sure that the voltage values of your system

correspond with the voltage values of the measuring unit.

Make sure that the supply wires are de-energised.

Connect the supply voltage and the output signal to the plug PIN’s as stated

below.

We recommend the use of wires with cross sectional area of min. 0.25 mm².

Attention! The measuring electrodes are galvanically connected

with the reference potential of the supply voltage and the signal

output.

MIM K02/1217 page 9

Page 10

MIM-

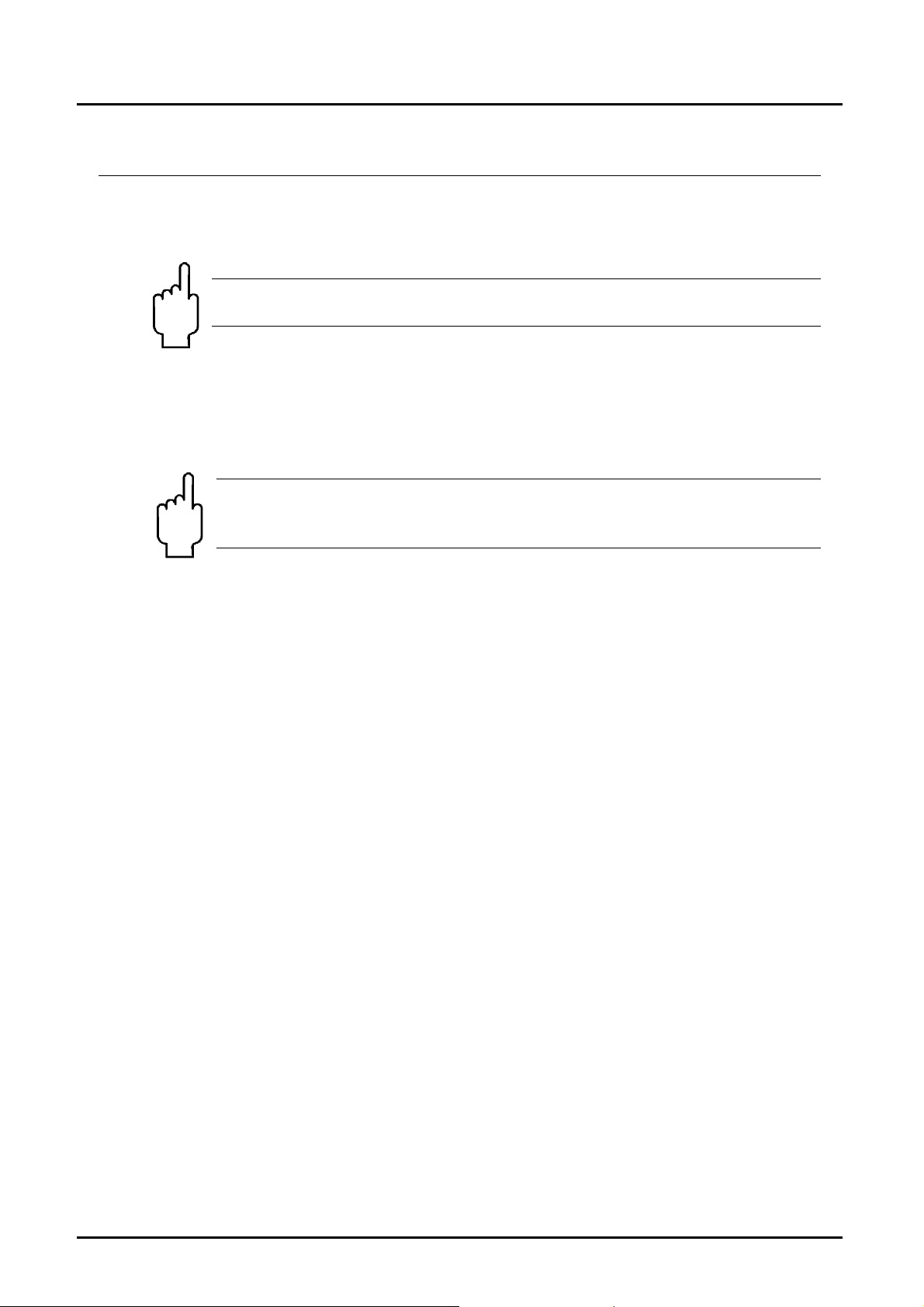

8.2 Pin assignment

Configurable output functions:

analogue output 4-20 mA analogue output 4-20 mA

analogue output 0-20 mA analogue output 0-20 mA

analogue output 0-10 V analogue output 0-10 V

alarm output alarm output

pulse output pulse output

frequency output frequency output

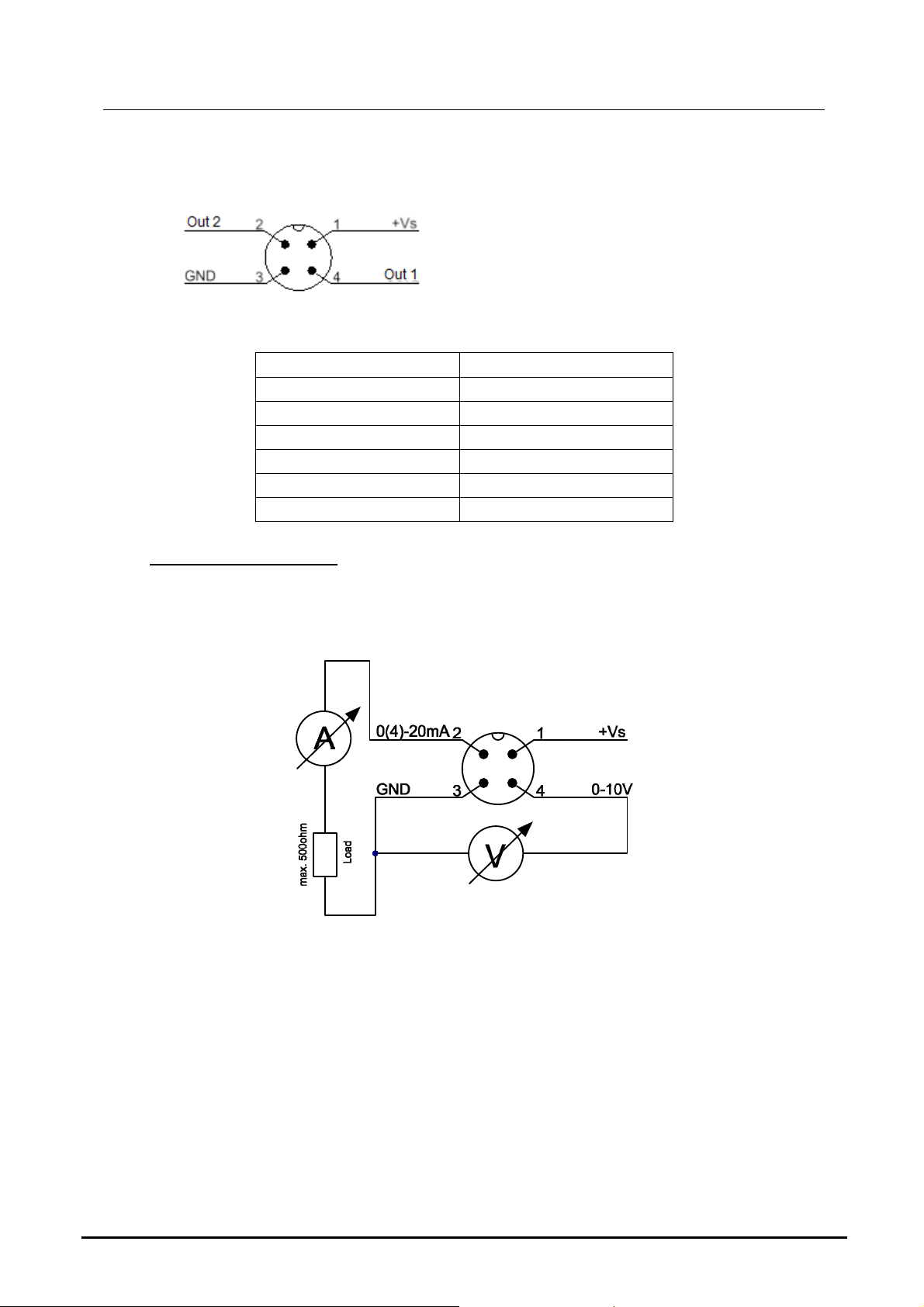

Connection example:

OUT2: analogue output 4-20 mA

OUT1: analogue output 0-10 V

Out 1 Out 2

page 10 MIM K02/1217

Page 11

MIM-

9. Operation and menu structure

9.1 General

9.1.1 Operation of the optical buttons

Deactive optical button

Optical button active

An optical button is located at each corner of the TFT display. The operability of

the respective buttons is signaled by blue backlighting; therefore non-backlit

buttons are disabled and cannot be operated. To operate the keys, the finger

must be placed on the key-dome and raised again. The orange background of the

button symbols is briefly displayed in blue as visual feedback for a detected key

press.

To avoid accidental operation in measuring mode, the operator must hold down

the menu button for 3-5 seconds to activate the function. If the menu button is

held down for more than 3 seconds, the blue backlighting will begin to flash to

alert the user to release the button.

The operation of the optical buttons can also be done with gloves or other

optically reflective objects, light dirt on the surface usually does not interfere with

the key function.

9.1.2 Function of the control buttons

The function of each control key can be recognized by the respective symbol

displayed in the corners of the TFT display.

key symbol designation

menu mode

info display

down -

Measuring mode menu mode

Activate menu

mode

hold 3-5 sec.

opens the info

menu

function

-

-

Scroll down menu /

decrease numeric

value when entering

numeric value

MIM K02/1217 page 11

Page 12

MIM-

key symbol designation

up -

forward -

backward -

Measuring mode menu mode

function

Menu scroll up /

Increase the number

value for numeric

value input

Menu level lower /

forward (last menu

level: Save value)

Menu function: menu

level higher / back

(last step: exit menu)

9.2 Measuring mode

After applying the supply voltage, the device starts in measuring mode. In this

mode, the measured values of the respective measuring variables are

continuously recorded; the current instantaneous flow values, temperature values

and the volume counter readings are cyclically calculated and displayed

according to the type of display.

In addition to the main display, the states and configuration of the outputs are

shown in the display. If the corresponding output is configured as an alarm

output, the status is also displayed with a green or red background color. If the

background color is green, the set threshold value is exceeded; if it is red, the

current value is still under threshold.

page 12 MIM K02/1217

Page 13

MIM-

Measurement Mode Display Layout 'Single'

The measurement variables are represented by their corresponding symbols:

The outputs and their status are shown on the display as follows:

The measured variables flow, temperature and volume counter can in principle be

assigned to each output function. The assignment of the respective output is

indicated by the display of the symbol of the measuring variable. The

representation of the assignment is independent of the set display layout (single,

dual).

MIM K02/1217 page 13

Page 14

MIM-

Measurement Mode Display Layout 'Dual'

9.2.1 Display area of the flow meters

The number of digits displayed on the volume counter display (partial and total

volumetric counters) is limited to max. 8 digits. The partial and total volumetric

meters therefore have a smaller font size than the flow and temperature display.

If the 8-digit display range of the meter is exceeded, this is indicated by the

display of 8 minus characters (--------). In this case, the meter reading can no

longer be read. The user now has the option of bringing the counter reading back

into the display area by changing the volume counter unit.

page 14 MIM K02/1217

Page 15

MIM-

9.3 Menu Mode

In menu mode, all device parameters can be set. The individual parameters are

arranged in menu groups by function. While the menu mode is activated, the

signal processing and the outputs are still active in the background. However, all

display parameters and outputs are updated after exiting the menu mode or in the

measuring mode.

Note: The menu mode will not exit automatically after a certain time

without using the buttons. The menu mode remains active until the user

presses the button to the measuring mode.

9.3.1 Parameter setting

9.3.1.1 List Selection

Parameters with predefined selection values are defined by means of list

selection. The currently selected menu item is displayed in orange text. The

selection can be moved with the keys, the key

is used to accept the selection.

To activate the menu mode, press the button for 3-5 seconds. The

parameters are divided into main groups and subgroups.

The buttons are used to select the main groups. In the main menu

not all menu groups can be shown on the display at the same time, the list of

individual menu items then scrolls up or down when the selection has reached

the top or bottom. To choose the selection, the key is pressed and the

device jumps to the corresponding submenu or parameter setting level. For

selection of predefined parameter values and are

used. After changing the value of the parameter and confirming with the

parameter is saved and the return to the higher menu level. To return to the main

menu or to exit the menu mode, press (repeatedly) .

MIM K02/1217 page 15

Page 16

MIM-

9.3.1.2 Numerical value input

When setting parameters with a numerical value, the assigned unit is always

displayed below the input field in square brackets in the input function. The

maximum size and the number of decimal places are fixed and cannot be

changed. After calling the input function, first the left, outer digit is displayed in

orange. This position can now be adjusted either with the keys in

the value from 0 to 9. By pressing the key , the entry point moves to the

right and the next digit can be changed. By pressing the key , the editing

point can be moved to the left again. If the editing point is on the far right, the set

value is saved by pressing the key again and switched to the higherlevel menu function.

10. Device configuration

10.1 Sequence of device parameterization

The flowmeter MIM is pre-configured in factory. Changing the parameters

"Measuring range" and "Sensor constant" or "K factor" is therefore not permitted.

The adjustment of these parameters is only possible on the part of Koboldfactory.

In the event of subsequent changes to volume or throughput units, the dependent

parameters are converted and adjusted accordingly. However, the limit

parameters of the switching outputs must always be checked and adjusted

manually when adjusting volume or throughput units - these are not automatically

converted.

An accidental change of the parameterization can be revised by the function

"Reset factory setting" in the menu Service / User menu / Factory setting.

page 16 MIM K02/1217

Page 17

MIM-

10.2 Overview of the menu functions / device parameters

The Kobold flowmeter MIM gives user the opportunity to make the

parameterization easily via the settings menu. In the following table, the menu

structure is structured by level. Using this table, each parameter and function of

the device can be set and configured.

Menu

level

Display

Measurement

Sublevel

Refresh

Orientation

Layout

Display value

Flow

Volume

Temperature Unit List selection

Part Volume

Parameter

level

[sec]

rotate CW

rotate CCW

Single

Dual

Upper display List selection

Lower display List selection

Unit List selection sets flow units

Cut off numerical input

Counting type

Unit List selection sets volume units

Counting type

Unit

Memory reset Yes/No

Subparameter

level 1

n.A.

absolute/

bidirectional

absolute/

bidirectional

List selection

Sub-

parameter

level 2

n.A. n.A.

Sub-

parameter

level 3

Description Value range

Sets display refresh

rate

rotates the display

90° clockwise

rotates the display

90° counter

clockwise

shows only one

input variable on

the main display

shows two input

variables on the

main display

variable to be

displayed on main

or upper display

variable to be

displayed on lower

display

suppresses flow

below this value

sets the counting

method for

accumulated

totalizer

sets temperature

units

sets the counting

method for partial

totalizer

sets volume units

resets partial

totalizer

0.5-10 0.5 sec

n.A n.A

n.A n.A

(Variables depend on

the type of sensor

connected. For MIM 4

Variables available i.e.

Flow, Volume,

Temperature, Part

volume)

ml/m, L/m, L/h, m3/h,

galUS/m, galUS/h,

galUK/m, galUK/h, User

0 ≤ Value ≤ M. range

start

n.A. absolute

ml, L, m3, galUS,

galUK, User

°C, °F, User

n.A. absolute

ml, L, m3, galUS,

galUK, User

n.A. n.A

Default

value

n.A

L/m

0.04

L

°C

L

MIM K02/1217 page 17

Page 18

Menu

level

Output 1/

Output 2

MIM-

Sublevel

Hier wird erst

die Variable

ausgewählt,

die

ausgegeben

werden sollte

The user is

supposed to

select the

variable he

wants to give

out as output

Parameter

level

Flow

Volume Pulse output

Subparameter

level 1

Alarm Output

4-20 mA

0-20 mA

0-10 V

Frequency

output

parameter

Function

Output Type sets characteristic

Switch

Function

Threshold

Hysteresis

Suppression

factor

Value for

4 mA

Value for

20 mA

Value for

0 mA

Value for

20 mA

Value for 0 V

Value for

10 V

max.

Frequency

Overflow

Value for

0 Hz

Value for max

Hz

Pulse unit

Pulse volume

Pulse width

Sub-

level 2

Sub-

parameter

level 3

List

selection

numerical

input

List

selection

numerical

input

Description Value range

sets function of

alarm output

of output

sets switching

function

sets threshold

sets hysteresis

switching delay

factor

sets variable value

for 4mA

sets variable value

for 20mA

sets variable value

for 0mA

sets variable value

for 20mA

sets variable value

for 0V

sets variable value

for 10V

sets max.

frequency to be

given out at Full

scale

sets overflow in %

of max.freq

sets variable value

for 0Hz

sets variable value

for max Hz

sets volume units

for Pulse volume

sets volume

represented by one

pulse

sets width of each

pulse

Limit/Window Limit

NPN/PNP/PP NPN

NO/NC

M. range start ≤ Value

≤ M. range End

-9999,0 ≤ Value ≤

+9999,0

0 ≤ Value ≤ 60

M. range start ≤ Value

< Value for 20 mA

Value for 4 mA <Value

≤ M. range End

M. range start ≤ Value

< Value for 20 mA

Value for 0 mA <Value

≤ M. range End

M. range start ≤ Value

< Value for 10 V

Value for 0 V <Value ≤

M. range End

50-1000 Hz 500 Hz

1-100 1%

M. range start ≤ Value

< Value for 0 Hz

Value for 0 Hz <Value ≤

M. range End

ml, L, m3, galUS,

galUK, User

0-999 1 L

1-20000 1ms

Default

value

NO

1 L/m

1 L/m

0

0 L/m

100 L/m

0 L/m

100 L/m

0 L/m

100 L/m

0 L/m

100 L/m

L

page 18 MIM K02/1217

Page 19

MIM-

Menu

level

User

Service

Factory

Service

Device

Status

Sublevel

Change

Password

Factory reset Yes/No

Lock Menu

Parameter

Temperature

Part volume Pulse output

numerical input

Lock/Unlock

level

Subparameter

level 1

Alarm Output

4-20 mA

0-20 mA

0-10 V

Frequency

output

Sub-

parameter

level 2

Function

Output Type sets characteristic

Switch

Function

Threshold

Hysteresis

Suppressionf

actor

Value for

4 mA

Value for

20 mA

Value for

0 mA

Value for

20 mA

Value for 0 V

Value for

10 V

max.

Frequency

Overflow

Value for

0 Hz

Value for max

Hz

Pulse unit

Pulse volume

Pulse width

n.A.

Password protected

Kobold Logo with Firmware version

Sub-

parameter

level 3

List

selection

numerical

input

List

selection

numerical

input

Description Value range

sets function of

alarm output

of output

sets switching

function

sets threshold

sets hysteresis

switching delay

factor

sets variable value

for 4 mA

sets variable value

for 20 mA

sets variable value

for 0 mA

sets variable value

for 20 mA

sets variable value

for 0 V

sets variable value

for 10 V

sets max.

frequency to be

given out at Full

scale

sets overflow in %

of max.freq

sets variable value

for 0Hz

sets variable value

for max Hz

sets volume units

for Pulse volume

sets volume

represented by one

pulse

sets width of each

pulse

protects user

service with

password if it is set

other than 00000

sets all the settings

to factory settings

locks the menu

entry using same

password as set

under 'Change

Password'

Limit/Window Limit

NPN/PNP/PP NPN

NO/NC

M. range start ≤ Value

≤ M. range End

-9999,0 ≤ Value ≤

+9999,0

0 ≤ Value ≤ 60

M. range start ≤ Value

< Value for 20 mA

Value for 4 mA <Value

≤ M. range End

M. range start ≤ Value

< Value for 20 mA

Value for 0 mA <Value

≤ M. range End

M. range start ≤ Value

< Value for 10 V

Value for 0 V <Value ≤

M. range End

50-1000 Hz 500 Hz

1-100 1%

M. range start ≤ Value

< Value for 0 Hz

Value for 0 Hz <Value ≤

M. range End

ml, L, m3, galUS,

galUK, User

0-999 1 L

1-20000 1ms

00000-99999 00000

Default

value

NO

1 L/m

1 L/m

0

0 L/m

100 L/m

0 L/m

100 L/m

0 L/m

100 L/m

0 L/m

100 L/m

L

n.A.

n.A.

Unlock

MIM K02/1217 page 19

Page 20

MIM-

10.3 Display

10.3.1 Refresh

Parameter "Refresh" defines the time interval within which the measuring

variables are displayed. The state of the outputs (current output, voltage output,

frequency output) is also recalculated after the measuring time has expired.

The "Refreshrate" can be increased in steps of 0.5 sec. to 10 sec. An increase in

the refresh rate time causes on one hand an increased "filtering" of the input

signals, but also an increased reaction time for the outputs.

10.3.2 Orientation

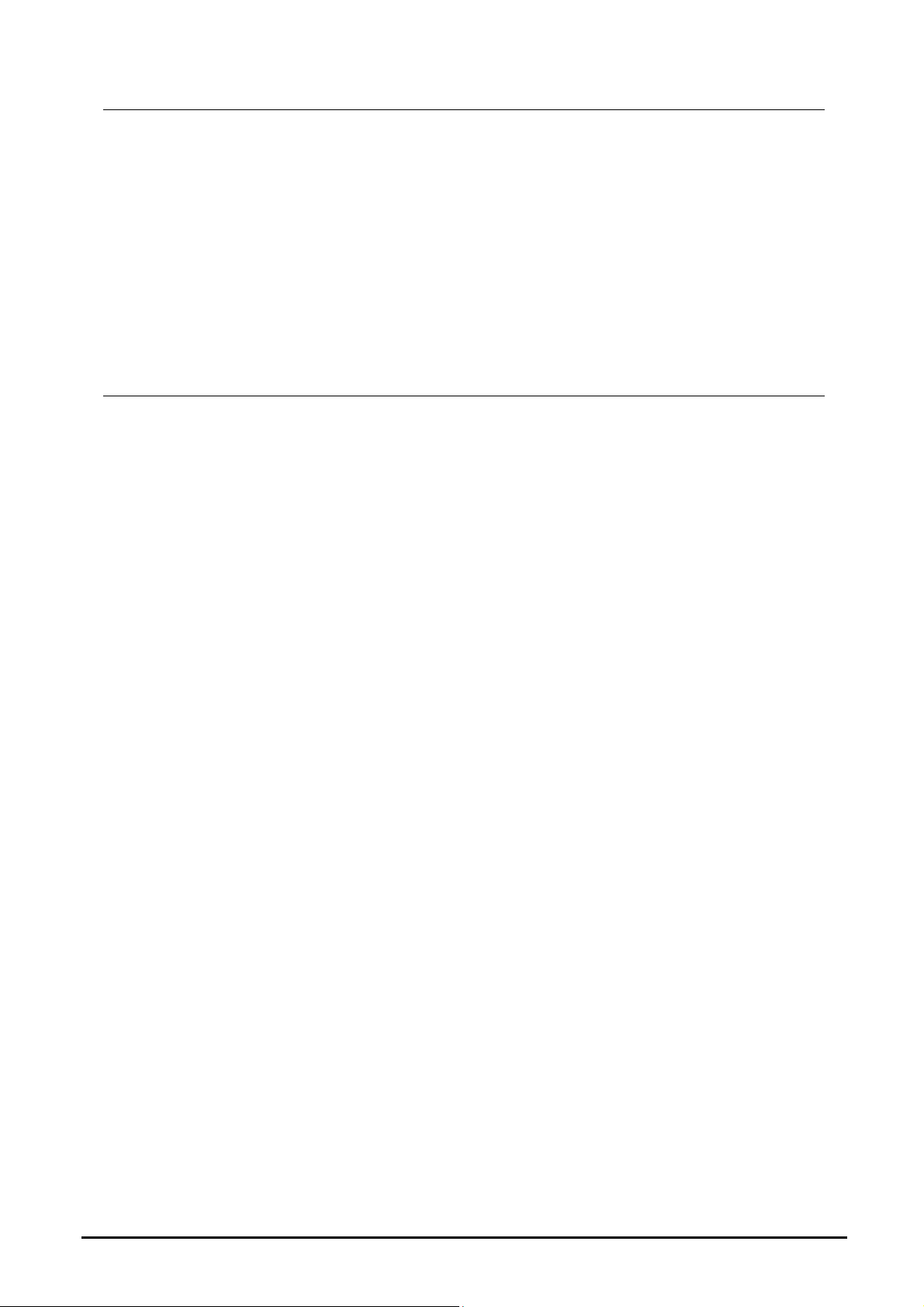

With the menu item "Orientation" the display can be rotated either clockwise or

counterclockwise in 90 ° increments. As the display rotates, both the display

contents and the function of the 4 control buttons are turned.

10.3.3 Layout

This parameter can be used to configure the display to either show one

measurement variable or two measurement variables.

10.3.4 Display value

With the aid of this parameter, the measurement variables provided by the

transmitter can be displayed. Depending on the 'Layout' display, either one or two

measuring variables can be displayed.

10.4 Measurement

The Measurement menu lists the measurement variables that the transmitter

provides. For magnetic inductive flowmeter, these are:

• Flow

• Volume (total volume counter)

• Temperature

• Part volume

Each measurement variable is still divided into its own submenu. In the submenu,

all parameters relating to the respective measuring variables can be adjusted.

page 20 MIM K02/1217

Page 21

MIM-

10.4.1 Flow

10.4.1.1 Unit

The displayed unit for the flow measurement can be selected from various

predefined standard units. It is also possible to define a user-defined unit ("user"),

here the "user unit" must be in liters / min. be programmed.

e.g. Unit User = 100 LPM, if Q = 500 LPM then the display shows 5 users.

10.4.2 Volume

10.4.2.1 Counter type

Absolute:

Regardless of the flow direction, the calculated partial volume is added to the

counters.

Bidirectional:

Depending on the flow direction, the calculated partial volume is added or

subtracted to the counters. If the measured flow value is negative, the volume

value goes down from measurement to measurement (possibly into the negative

range).

10.4.2.2 Volume unit

The parameter "Volume unit" defines the volume unit of all volume meters. The

listed volume units are available. When changing the volume unit, the current

counter readings are converted to the new volume unit.

MIM K02/1217 page 21

Page 22

MIM-

10.4.3 Temperature

10.4.3.1 Unit

The displayed unit for the temperature measurement can be selected from

various default units. It is also possible to define a user-defined unit ("user"), in

which case the "user unit" must be programmed in ° C.

e.g. Unit user = 50 ° C, if T = 50 ° C then the display shows 1 user.

10.4.4 Part Volume

10.4.4.1 Counter type

Absolute:

Regardless of the flow direction, the calculated partial volume is added to the

counters.

Bidirectional:

Depending on the flow direction, the calculated partial volume is added or

subtracted to the counters. If the measured flow value is negative, the volume

value goes down from measurement to measurement (possibly into the

negative range).

10.4.4.2 Volume unit

The parameter "Volume unit" defines the volume unit of all volume meters. The

listed volume units are available. When changing the volume unit, the current

counter readings are converted to the new volume unit.

10.4.4.3 Memory reset

In this menu, the part quantity counter can be reset.

page 22 MIM K02/1217

Page 23

MIM-

10.5 Outputs

The MIM flowmeter provides a total of 2 outputs that are freely configurable. The

configuration of the outputs (output 1 and output 2) is done via a wizard function.

The wizard function guides the user step by step through all necessary settings.

Steps:

• Select output

• Selection of the source or the measurement variable to be output (Flow,

Volume, Temperature, Part volume)

• Selection of an output type (4-20 mA, 0-20 mA, 0-10 V, alarm, pulse,

frequency output)

• Setting the output (scaling, thresholds)

• Save the configuration

10.5.1 Alarm output

The alarm outputs can be parameterized with a limit value function or a window

function.

10.5.1.1 Function

The parameter "Function" defines the basic function. Limit value function and

window function are available.

Limit value function: The switching output is active if the current flow rate value is

above the switching threshold. It remains active until the measured value has

fallen below the switching threshold minus the hysteresis.

MIM K02/1217 page 23

Page 24

MIM-

Window function: The switching output is active if the current flow measured

value is outside a window, which is formed by the "switching threshold" and the

"lower threshold". The monitored window decreases in each case by the amount

of the "hysteresis". If the switching output is to be active within the window, the

parameter "switching function" must be changed from N/O to N/C.

10.5.1.2 Output type

The parameter "Output type" defines the function of the transistor output. NPN,

PNP or PP (push-pull) output types are available. The push-pull type combines

NPN and PNP and is therefore the best choice for most circuits. All outputs are

short circuit and overload protected.

10.5.1.3 Switching function

The "switching function" defines the mode of operation of the outputs. In the

default setting "normally open", the output becomes active (switched) when the

measured value exceeds the switching threshold. This feature is also referred to

as N.O.

In the "Normally closed" setting, the output below the switching threshold is

already active and is deactivated when the measured value exceeds the

switching threshold. This function is also referred to as N.C.

10.5.1.4 Threshold

Threshold for limit value function and upper window point for window function.

10.5.1.5 Lower threshold

The "lower threshold" defines the lower limit when using the window function.

When using the limit value function, this parameter remains ineffective.

The switching thresholds can be set both positive and negative. The setting of the

negative switching thresholds is used for "A-B" function, whereby the flow

indicator can be negative. When changing the input type, the switching thresholds

must be checked again and corrected if necessary.

page 24 MIM K02/1217

Page 25

MIM-

10.5.1.6 Hysterese

The appropriate setting of the "hysteresis" parameter ensures that the switching

outputs do not switch on and off continuously when the current measured value

fluctuates around the switching threshold. The hysteresis value should therefore

always be greater than the real measured value fluctuations. As a result, a

targeted suppression can be achieved.

10.5.1.7 Interference suppression factor

Further suppression of the switching outputs of fluctuating measuring signals can

be achieved by setting the parameter "Suppressor factor". If this parameter is

selected greater than one, then the switching threshold must be exceeded in

succession with the frequency of the set value before the corresponding

switching output is activated. With this function, sporadic limit overruns can be

safely suppressed. However, the response time increases according to the level

of the "suppression factor".

It is also possible to use the switch outputs with "limit function" for "direction

detection". To do this, the "Input type" in the "Signal input" menu must be set to

"Direction detection". In this case, both the "switching threshold" and the

"hysteresis" must be set to '0'. When changing direction, the switching output

switches depending on the "switching function".

10.5.2 Analogue outputs

10.5.2.1 Current output 0(4)-20 mA

The current output gives a measured variable (flow or temperature) in scaled

form as a 0 (4) -20 mA current signal.

Flow rate for 20 mA

The current output is scaled via the "Value for 20 mA "and" Value for 4 mA "(with

current output 0-20 mA" Value for 0mA "). By default, the "Value for 20mA"

parameter is set to the value for the end of the measuring range, but can be

parameterized as desired within the measuring range, but always >> as the

measuring range start value. The parameters "Value for 4mA" / "Value for 0mA"

define the measured values for the starting current value, which may also be set

freely in the measuring range.

Note 1: If the value is set smaller than the end of the measuring range, the

resolution and accuracy of the output voltage value are reduced.

MIM K02/1217 page 25

Page 26

MIM-

10.5.3 Pulse output

The MIM flowmeter provides a scalable pulse output. When the pulse output is

activated, the incoming volume is converted to the output pulse train. The pulse

width of the output pulse is adjustable in the range of 1 ms to 20,000 ms.

The electrical output type of the pulse output is push-pull, therefore HIGH and

LOW are actively switched through at the output.

Behavior on OVERFLOW:

If the volumetric flow measurement is in the OVERFLOW range, the pulse output

is switched off and a constant HIGH level is applied to the output.

Generation of the output pulse train:

The maximum adjustable pulse rate at the pulse output is 1000 pulses per liter.

That the minimum pulse volume that can be represented with the pulse output is

0.001 L per pulse. Furthermore, the set pulse volume must fulfill the following

condition:

Measuring range end

If the upper condition is not met, it may happen that with low pulse volume the

output pulse train lags behind after switching off the input frequency and the user

is advised to check the settings again. The following message is displayed:

"Lagging possible, please check the setting".

page 26 MIM K02/1217

Page 27

MIM-

Since the measuring range end value is set at the factory, the user should, when

configuring the pulse output, carry out a computational check to see whether the

upper condition is fulfilled.

The pulse output only takes place in measuring mode, while the menu mode is

active no pulses are given. The pulses accumulated in the menu mode are output

as soon as the measuring mode is active again. Depending on the situation, this

can also lead to a longer pulse lag.

10.5.3.1 Pulse volume

The parameter "Pulse volume" is defined as volume quantity for the output of a

pulse; the unit is corresponding to [volume quantity / pulse]. The likewise

common pulse rate [pulse / volume unit] corresponds to the reciprocal of the

pulse volume.

Example: Desired pulse rate at the output 10 pulses / liter => pulse volume = 1 /

pulse rate = 1/10 L = 0.1 L

10.5.3.2 Volume unit

The volume unit to be set is the input unit for the "Pulse volume" parameter. The

definition of a user-defined unit ("user") is also possible and can be programmed

in "liters".

Example:

Unit "user" = 10 [L], pulse volume = 2 [user]

The total pulse volume would be 2 * 10 = 20 [L]. After 20 liters, a pulse is output.

10.5.3.1 Pulse width

The pulse width of the pulse output is flexibly adjustable from 1 to 20,000 ms.

10.5.4 Frequency output

The MIM flowmeter provides a scalable frequency output. When this output is

activated, the measurement variable (flow or temperature) associated with the

frequency output is output proportionally as a frequency with a 1: 1 pulse / pause

duration. The output frequency at the end of the measuring range can be set

(parameter "maximum frequency"). With the two parameters "Value for 0 Hz" and

"Value for max Hz", the frequency output in the measuring range can be freely

scaled.

Behavior on OVERFLOW:

If the measured value is in the overflow range, a constant frequency is output at

the output with the value of the parameter "Overflow". The parameter "Overflow"

must always be greater than the parameter "max. Frequency "

The electrical output type of the frequency output is fixed push-pull, therefore

HIGH and LOW are actively switched through at the output.

10.6 User service

The user service provides the user with a reset function and password setting.

Together with the activation of a user password, therefore, the menu access for

the user on the part of a master user can be blocked.

MIM K02/1217 page 27

Page 28

MIM-

10.6.1 User service / change password

In the factory setting the user password is set to "00000", the user functions are

thus freely accessible. If the user password is changed to other than "00000", the

password prompt becomes active the next time the user menu is entered.

If the set password is no longer known, a master password can be requested

from KOBOLD.

10.6.2 User service / factory setting

By activating this function, the user can reset the device to the factory settings.

Any user settings will then be lost and the device will be back in delivery

condition.

10.7 Service / Factory service

The factory service function is password protected and not accessible to the user.

10.8 Information

10.8.1 Status

The electromagnetic flowmeter can detect and display various device or

application errors.

If there is a status or error message, the STATUS symbol in the display

alternately flashes orange / red. To call up the status / error information, the

status key must be pressed, then the status window that appears then lists all the

messages that have accumulated up to this point in time. By pressing the

key, the user confirms the knowledge of the displayed errors, the status memory

is cleared and the status window is closed. If one of the displayed errors persists,

it will be reported again by flashing the status icon.

The following status / error messages are generated:

Display text Description Debugging

Empty Pipe Measuring tube is not completely

filled with medium or medium

with too low conductivity is used.

Temp Sens Error Error in the temperature

measuring circuit

Meas saturated Flow measuring circuit

overdriven

No Subslave Internal hardware error Repair by KOBOLD Service

Check the filling of the

measuring circuit or

conductivity of the medium (>

20 μs / cm)

Repair by KOBOLD Service

necessary

Reduce flow rate

necessary

10.8.2 Firmwareversion

The firmware version is displayed at the device test below the manufacturer logo.

page 28 MIM K02/1217

Page 29

MIM-

10.9 Device default settings

The flowmeter-MIM is delivered from the factory with following settings:

Display – Dual

Upper display – Flow

Lower display – Temperature

Out 1: Q 4-20 mA

Out 2: T 4-20 mA

MIM K02/1217 page 29

Page 30

MIM-

11. Technical Information

Measurement process: electromagnetic

Range:

Media: conductive fluids

Minimum conductivity: ≥20 µS/cm

Max. medium viscosity: 70 mm2/s

Max. pressure: 16 bar

Accuracy:

Repeatability: ±0.2% of full scale

Temperature

measurement of media: PT1000, range -20 °C …+70 °C

Response time flow t

(alarm output /pulse output): <250 ms

Response time temperature t90

(signal output): <20 s

Mounting position: in all directions

In-/outlet: 3 x DN/2 x DN

Handling: 4 optical touch fields,

useable with hand gloves

Housing: stainless steel 1.4404,

display screen PMMA

Wetted parts

Connection fitting and

housing: stainless steel 1.4404

Insulation parts: PEEK

Elektrodes:

Seals: FKM

Protection: IP 67

Media temperature: -20 °C … +70 °C

Ambient temperature: -20 °C … +60 °C

90

see order details

<±(0.8% of reading+ 0.5% of full scale)*

stainless steel 1.4404

Electrical data

Supply voltage: 19 - 30 VDC, internal power consumption

max. 100 mA (without outputs)

Display:

1.4" display orientation in 90° steps

adjustable

Display repetition rate: 0.5 ... 10 s, adjustable

Pulse output Push-Pull, freely scaleable, configurable for

partial or accumulated totalizer

page 30 MIM K02/1217

TFT display, 128 x 128 pixels,

Page 31

MIM-

Frequenzy output Push-Pull, freely scaleable,

Overflow frequency adjustable

Alarm output: NPN, PNP, Push-Pull,

output) configurable max. 30 VDC, max.

200 mA short-circuit proof

Analogue output: active, 3 wire, 0(4)-20 mA,

max. load 500 Ω or 0-10 VDC, (Ri = 500 Ω)

Electrical connection: plug M12x1, 4-pin

* Under reference conditions: media temperatur: 15 °C ... 30 °C, 1 cSt, 500 µS/cm, 1 bar

ambience temperature: 15 °C ... 30 °C

12. Order Codes

Order Details (Example: MIM-12 15 G5 C3T 0)

Model Range Connection Electronics Special version

MIM-12 = housing/

electrode

VA, FKM

seal

* In preparation

05 = 0.04 ... 10 l/min G4 = G ½ male, DN5

10 = 0.1 ... 25 l/min*

15 = 0.2 ... 50 l/min

15 = 0.2 ... 50 l/min*

20 = 0.4 ... 100 l/min

G5 = G ¾ male, DN10

G6 = G 1 male, DN15

C3T = compact, TFT display,

2 outputs

(current/voltage/

pulse/frequency/alarm

output configurable),

M12x1 plug

0 = without

Y = special

(please

specify in

writing)

MIM K02/1217 page 31

Page 32

MIM-

13. Dimensions

[mm]

page 32 MIM K02/1217

Page 33

MIM-

14. EU Declaration of Conformance

We, KOBOLD Messring GmbH, Hofheim-Ts, Germany, declare under our sole

responsibility that the product:

Electromagnetic Flowmeter Model: MIM-...

to which this declaration relates is in conformity with the standards noted below:

EN 61326-1:2013 Elektrische Mess-, Steuer-, Regel- und Laborgeräte – EMV-

Anforderungen, Teil 1: Allgemeine Anforderungen

Industrielle Anwendung

EN 60529:2014 Degrees of protection provided by enclosures (IP Code)

EN 50581:2012 Technical documentation for the assessment of electrical

and electronic products with respect to the restriction of hazardous substances

Also the following EC guidelines are fulfilled:

2014/30/EU EMC Directive

2011/65/EU RoHS (category 9)

Hofheim, 14 Dec. 2017

H. Peters M. Wenzel

General Manager Proxy Holder

MIM K02/1217 page 33

Loading...

Loading...