Page 1

Operating Instructions

for

Compact Magnetic-Inductive

Flow Meter

Model: MIK

Page 2

MIK

1. Contents

1. Contents ........................................................................................................ 2

2. Note .............................................................................................................. 3

3. Instrument Inspection .................................................................................... 3

4. Regulation Use .............................................................................................. 3

5. Operating Principle ........................................................................................ 4

5.1 General ................................................................................................ 4

5.2 Minimum electrical conductivity / contained gases .............................. 4

5.3 Deposits ............................................................................................... 5

5.4 Measuring electrodes........................................................................... 5

6. Mechanical Connection ................................................................................. 6

6.1 Check operating conditions .................................................................. 6

6.2 Installation ............................................................................................ 6

7. Electrical Connection .................................................................................... 8

7.1 General ................................................................................................ 8

7.2 MIK-...S300 .......................................................................................... 8

7.3 MIK-...S30D ......................................................................................... 8

7.4 MIK-...F300; MIK-...L3x3 ...................................................................... 9

7.5 MIK-...L443 .......................................................................................... 9

7.6 MIK-...C30.. .......................................................................................... 9

7.7 MIK-...C34.. .......................................................................................... 9

7.8 MIK-...Ex4R, MIK-...Gx4R .................................................................. 10

8. Operation .................................................................................................... 11

8.1 Switch point setting MIK-...S300, MIK-…S30D .................................. 11

8.2 Counter electronics MIK-…Ex4R ....................................................... 11

8.3 Dosing electronics MIK-…Gx4R ........................................................ 11

9. Adjustments – Compact Electronics MIK-...C3.. ......................................... 12

9.1 Button function ................................................................................... 12

9.2 Settings .............................................................................................. 12

9.3 Value setting ...................................................................................... 13

9.4 Set-up mode ...................................................................................... 14

9.5 Main menu items ............................................................................... 16

10.Maintenance ............................................................................................... 19

11.Technical Information .................................................................................. 20

12.Order Codes ............................................................................................... 23

13.Dimensions ................................................................................................. 24

14.Declaration of Conformance ....................................................................... 27

Manufactured and sold by:

Kobold Messring GmbH

Nordring 22-24

D-65719 Hofheim

Tel.: +49(0)6192-2990

Fax: +49(0)6192-23398

E-Mail: info.de@kobold.com

Internet: www.kobold.com

page 2 MIK K07/0614

Page 3

MIK

2. Note

Please read these operating instructions before unpacking and putting the unit

into operation. Follow the instructions precisely as described herein.

The devices are only to be used, maintained and serviced by persons familiar

with these operating instructions and in accordance with local regulations

applying to Health & Safety and prevention of accidents.

When used in machines, the measuring unit should be used only when the

machines fulfil the EWG-machine guidelines.

as per PED 97/23/EG

In acc. with Article 3 Paragraph (3), "Sound Engineering Practice", of the

PED 97/23/EC no CE mark.

Diagram 8, Pipelines, Group 1, dangerous fluids

3. Instrument Inspection

Instruments are inspected before shipping and sent out in perfect condition.

Should damage to a device be visible, we recommend a thorough inspection of

the delivery packaging. In case of damage, please inform your parcel service /

forwarding agent immediately, since they are responsible for damages during

transit.

Scope of delivery:

The standard delivery includes:

Compact Magnetic-Inductive Flow Meter model: MIK

Operating Instructions

4. Regulation Use

Any use of the Compact Magnetic-Inductive Flow Meter, model: MIK, which

exceeds the manufacturer’s specifications, may invalidate its warranty. Therefore,

any resulting damage is not the responsibility of the manufacturer. The user

assumes all risk for such usage.

MIK K07/0614 page 3

Page 4

MIK

5. Operating Principle

5.1 General

The new KOBOLD flow meter Type MIK is used for measuring and monitoring

smaller and medium-sized flow of conductivity liquids in pipes. The device

operates according to the electromagnetic measuring method. According to

Faraday’s Law of electromagnetic induction a voltage is induced in a conductor

moving through a magnetic field. The electroconductive measuring medium acts

as the moved conductor. The voltage induced in the measuring medium is

proportional to the flow velocity and is therefore a value for the volumetric flow.

The flowing media must have a minimum conductivity. The induced voltage is

picked up by two sensing electrodes which are in contact with the measuring

medium and sent to the measuring amplifier. The flow rate will be calculated

based on the cross sectional area of the pipe.

The measurement is not depending on the process liquid and its material

properties such as density, viscosity and temperature.

The device may be equipped with a switch, frequency or analogue output.

Moreover, there is a compact electronic system to be selected from, which

contains a digital display, a switch and an analogue output.

The device series is completed by an optionally obtainable dosing and counter

electronic system. The counter electronic system shows the current flow rate on

the first line of the display and shows the partial or overall volume on the second

line. A dosing electronic system controls simple filling duties and also measures

the flow rate, overall volume and filling volume. The analogue output and two

relay outputs can be utilised for the further processing of signals.

5.2 Minimum electrical conductivity / contained gases

It is necessary for the correct function of the device that the current canal is

always filled completely with medium.

As of a minimum electrical conductivity of 30 µS/cm the MIK works within the

guaranteed margins of error. The conductivity of the medium is continuously

monitored by the device’s electronic system. If the electronic system registers

that the conductivity has under-run minimum, the output signal is suppressed for

2 seconds, after which the value for zero flow is output.

Air bubbles in the flowing medium or media with changing conductivity in the

range of the minimum conductivity can interfere with the measuring function and

reduce the MIK’s measuring accuracy.

The gases contained in the fluid are included in the volume flow measurements

and consequently cause erroneous measurements. If necessary, suitable vents

should be fitted upstream in the device.

page 4 MIK K07/0614

Page 5

MIK

5.3 Deposits

Minor deposits on the measuring tube do not compromise the accuracy of

measurement in general, as long as their conductivity does not seriously deviate

from that of the fluid. In the case of fluids that have a tendency to deposit

sediment, the measuring tube should be checked at regular intervals and cleaned

if necessary.

5.4 Measuring electrodes

The electrodes used with the MIK have a galvanic pick-off. They are in direct

contact with the fluid and are fitted opposite one another, and insulated from the

measuring tube. The standard electrodes are made of 1.4404 stainless steel or

Hastelloy C4.

MIK K07/0614 page 5

Page 6

MIK

6. Mechanical Connection

6.1 Check operating conditions

flow rate

max. operating pressure

max. operating temperature

In general the MIK is subjected to the same loads as the piping into which it is

installed. The MIK should therefore be kept away from extreme loads, such as

pressure surges with strong, dynamic pipe movements, vibrations in the proximity

of centrifugal pumps, high temperature media, flooding etc.

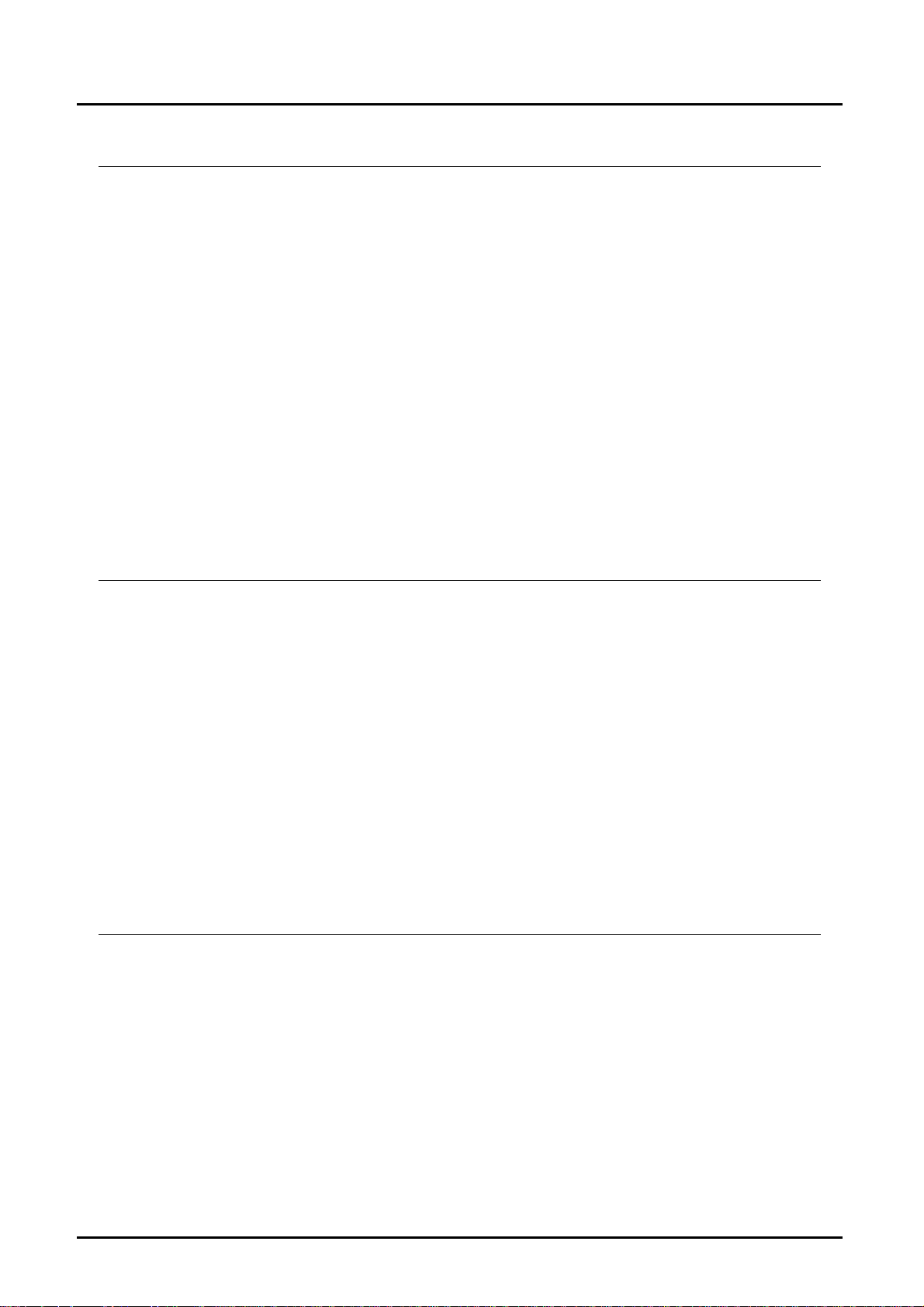

6.2 Installation

Remove all packing materials and transport retainers and ensure that no such

materials remain in the device.

It can be installed in vertical, horizontal or rising pipes. Flow in direction of the

arrow.

Avoid pressure and tensile load.

Mounting the inlet and outlet pipe in a distance of 50 mm from the connections.

Attention! The sensor housing made of PPS and PVDF is not

allowed to be subjected to a torsional stress during installation.

The connecting of the respective connection thread with the

pipeline should be adapted to the material used, over tightening

the connection will damage the sensor housing, a loose

tightening may result in loosening the connection.

Avoid valves or large reduction on the inlet section (this increases the

inaccuracy of measurements).

Check the leak tightness of the connections.

page 6 MIK K07/0614

Page 7

MIK

in- and outlet

mounting top down avoid this mounting position

MIK K07/0614 page 7

Page 8

MIK

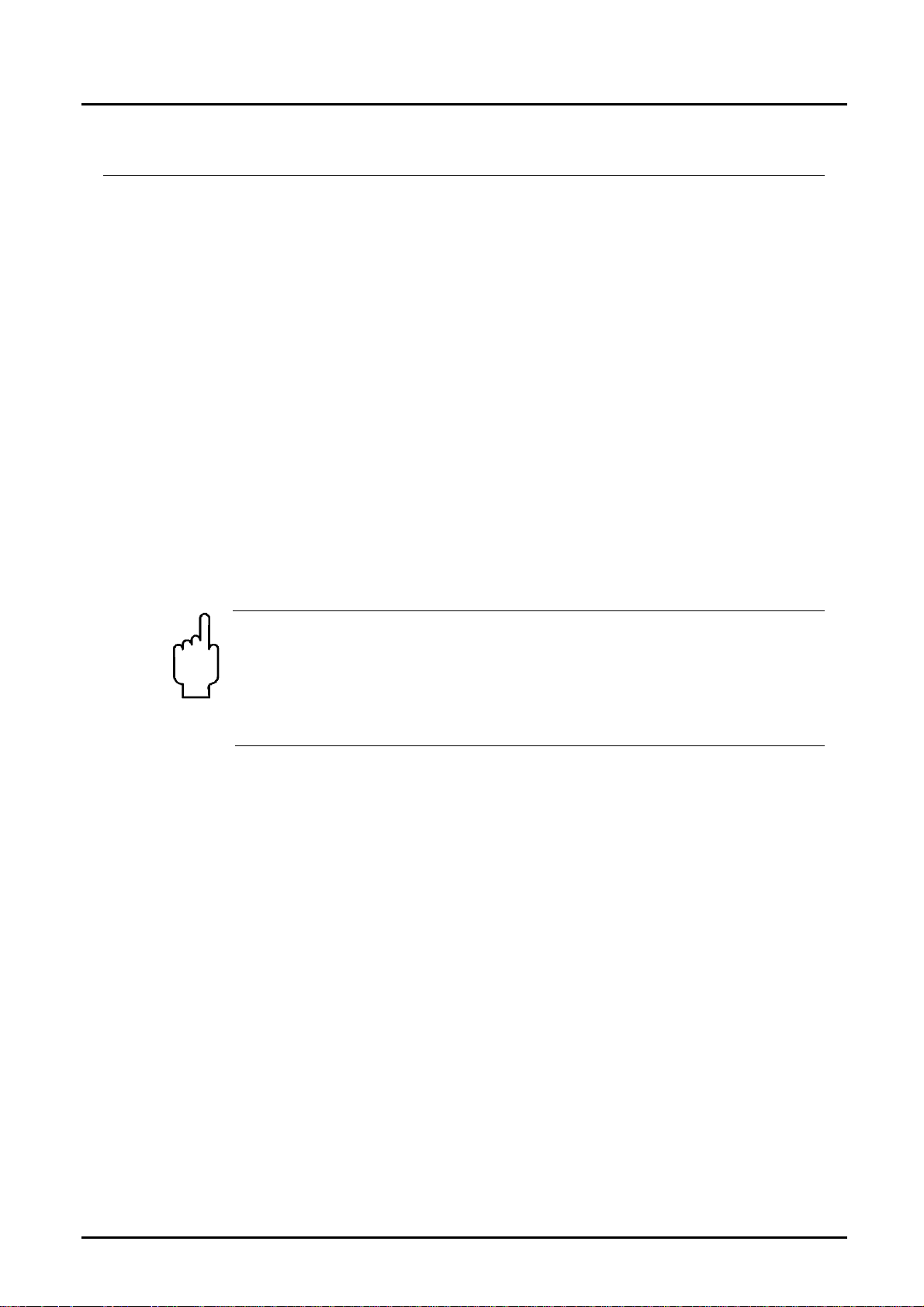

7. Electrical Connection

7.1 General

Attention! Make sure that the voltage values of your system

correspond with the voltage values of the measuring unit.

Make sure that the supply wires are de-energised.

Connect the supply voltage and the output signal to the plug PIN’s as stated

below.

We recommend the use of wires with cross sectional area of min. 0,25 mm².

Attention! The measuring electrodes are galvanically connected

with the reference potential of the supply voltage and the signal

output.

7.2 MIK-...S300

Output

N/O

2

5

GND

3

7.3 MIK-...S30D

Output

N/C

1

Common

4

12

+Vs

Output

Output

N/C

+Vs

GND

3

page 8 MIK K07/0614

4

Output

N/O

Page 9

MIK

1

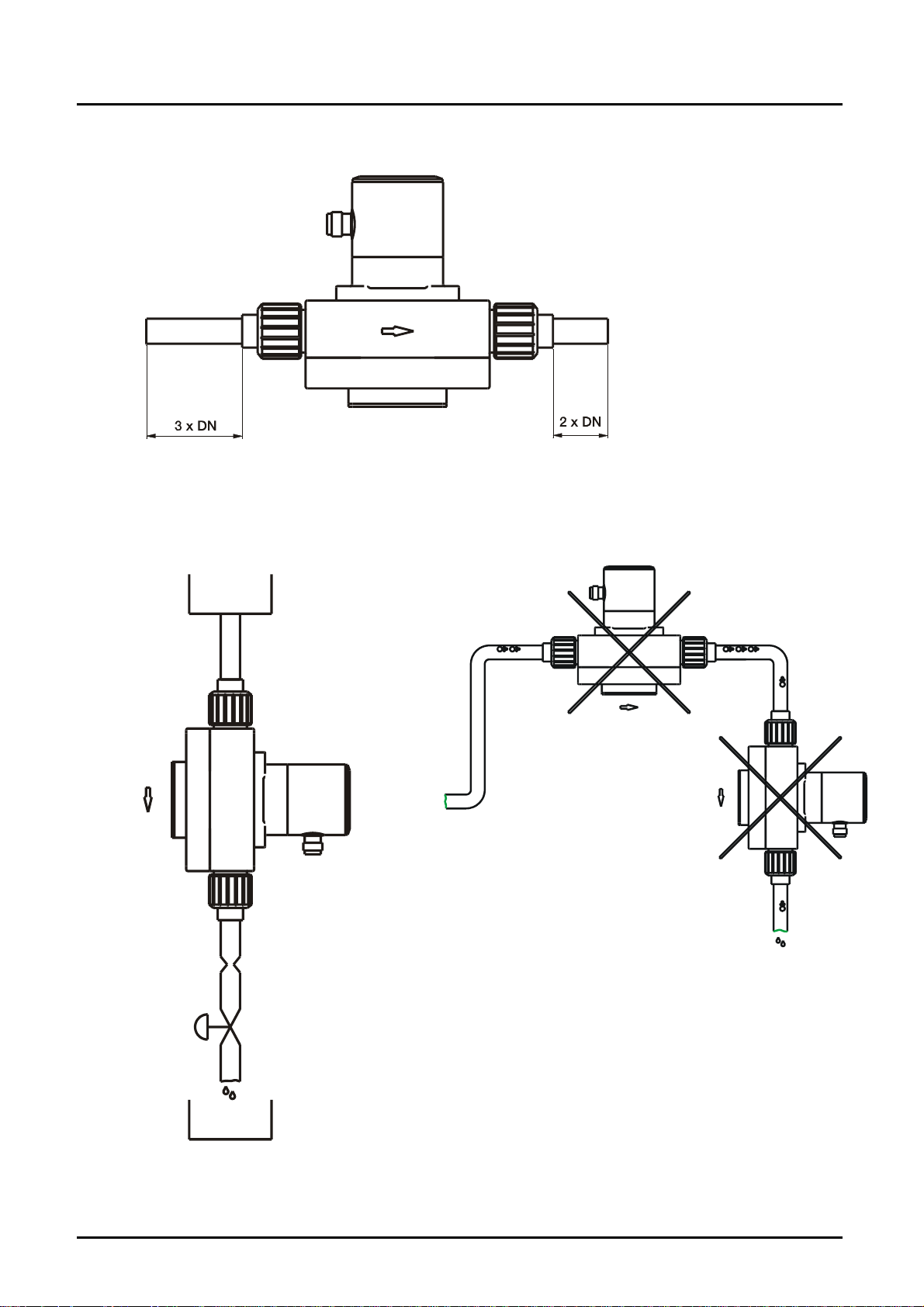

7.4 MIK-...F300; MIK-...L3x3

Connection example MIK-...L3x3

+Vs

n.c.

2

GND

3

7.5 MIK-...L443

1

4

+Vs

GND

+Vs

Signal

Out

2

n.c.

GND

Signal

Out

GND

3

+Vs

GND

1

4

+Vs

Signal

Out

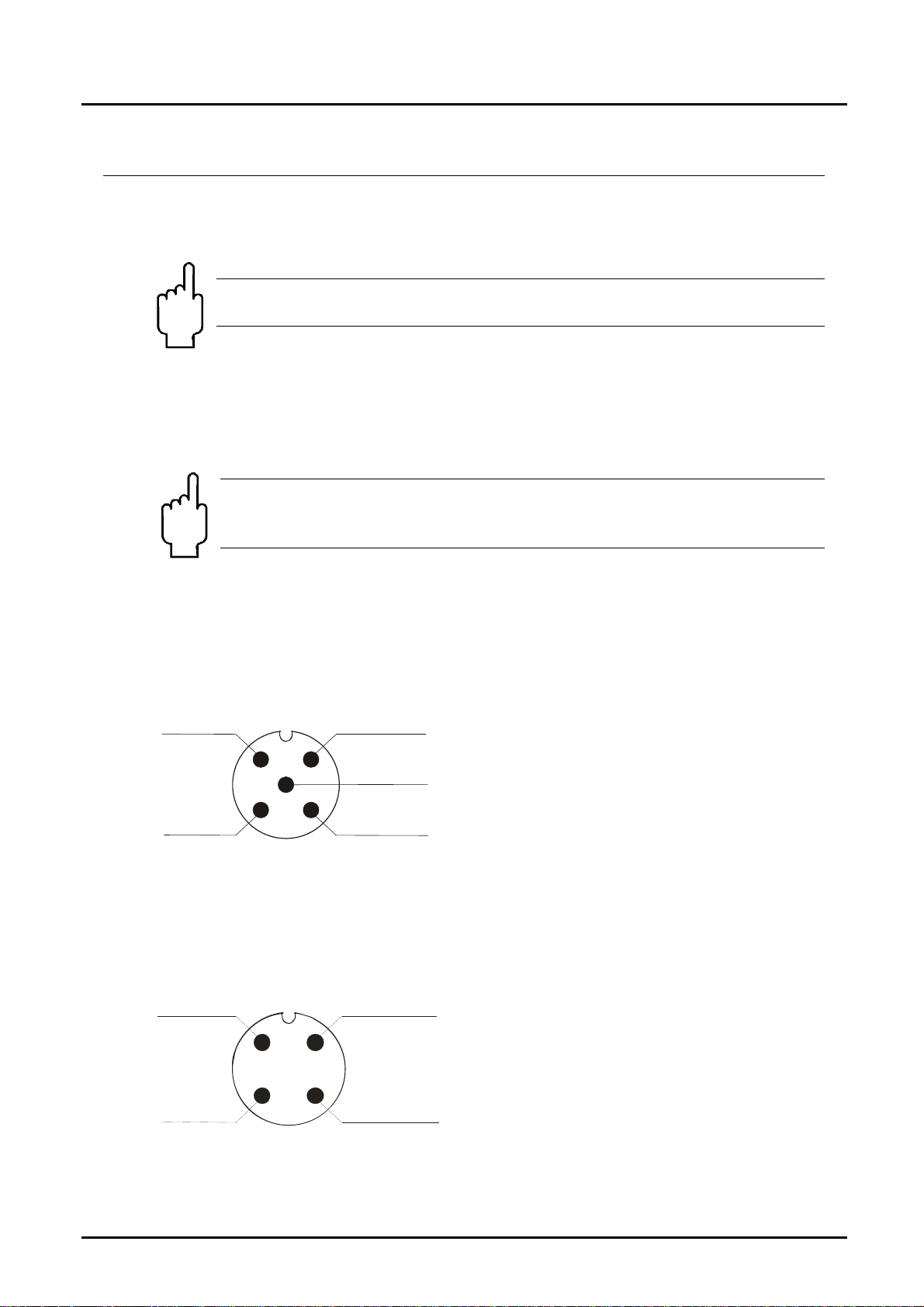

7.6 MIK-...C30..

Switch

Out 2

GND

MIK K07/0614 page 9

2

5

3

4

1

+Vs

GND

Switch

Out 1

7.7 MIK-...C34..

0(4)-20 mA

2

5

GND

3

1

+Vs

GND

Switch out

4

Page 10

MIK

7.8 MIK-...Ex4R, MIK-...Gx4R

Cable connection

Wire number

MIK-...E14R

Counter electronics

1 +24 VDC +24 VDC

2 GND GND

3 4-20 mA 4-20 mA

4 GND GND

5 n. c. Control 1*

6 Reset part quantity Control 2*

7 Relay S1 Relay S1

8 Relay S1 Relay S1

9 Relay S2 Relay S2

10 Relay S2 Relay S2

*Control 1<->GND: Start-dosing

Control 2<->GND: Stop-dosing

Control 1 <-> Control 2 <-> GND: Reset-dosing

Plug connection

-E34 R

+ Vs

0 (4) - 20 mA

MIK-...G14R

Dosing electronics

S 2

Reset TM

d.c. *)

1

5

34

30 V / 2 A

AC/DC

1

8

6

5

Output

GND

3

4

*) Do not connect !

page 10 MIK K07/0614

Page 11

MIK

8. Operation

The units are preset and after electrical connection ready for operation.

8.1 Switch point setting MIK-...S300, MIK-…S30D

Switch setting Switch point

0 Switch function deactivated

1 10 % of f.s.

2 20 % of f.s.

3 30 % of f.s.

4 40 % of f.s.

5 50 % of f.s.

6 60 % of f.s.

7 70 % of f.s.

8 80 % of f.s.

9 90 % of f.s.

Flow above switch point: DUO-LED green

Flow below switch point: DUO-LED red

8.2 Counter electronics MIK-…Ex4R

Operating please see Operating Instructions ZED-Z

8.3 Dosing electronics MIK-…Gx4R

Operating please see Operating Instructions ZED-D

MIK K07/0614 page 11

Page 12

MIK

9. Adjustments – Compact Electronics MIK-...C3..

Connect the compact electronics according to previous connection diagram and

supply with the indicated power supply.

After power on, the measuring range (end current) will be shown for 3

seconds.

9.1 Button function

In the standard mode (measuring mode)

: Press 3 sec. Setup mode

: Switch point/Window point

In the set-up mode

: Next Step

Any time

3 sec

: Change Value

or do not press

a button for 20 sec

Standard mode

9.2 Settings

The following values can be changed in the compact electronic:

Scale range Factory setting

Switch point (SPo, SP1, SP2)

Hysteresis (HYS)

Window point (duo point) (duo)

Contact-type (Con, Co1, Co2) (no),(nc) or frequency (Fr)** no

Start current (S-C)*

End current (E-C)*

Start current selection (SCS)

Change Code (CCo)

* Start- and end value of flow relating to 0/4-20 mA

** not calibrated, frequency at f.s. approx. 500 -600Hz

0...999 0,00

-199...0 -0,00

Switch point ...999 --- (inactive)

000...999 000

000...999 FS

0-- (0 mA), 4-- (4 mA) 4 mA

000...999 000

page 12 MIK K07/0614

Page 13

MIK

9.3 Value setting

From the main menu item (for example: switch point, "SPo"), press the ""

button to set the value. The flow chart below illustrates the universal routine for

changing individual parameters.

[From the main menu item]

1. Adjust position

2. Adjust position

3. Adjust position

Adjust decimal point

Save selected value

or

save

[To the next main menu item]

enter new value.

MIK K07/0614 page 13

Page 14

MIK

g

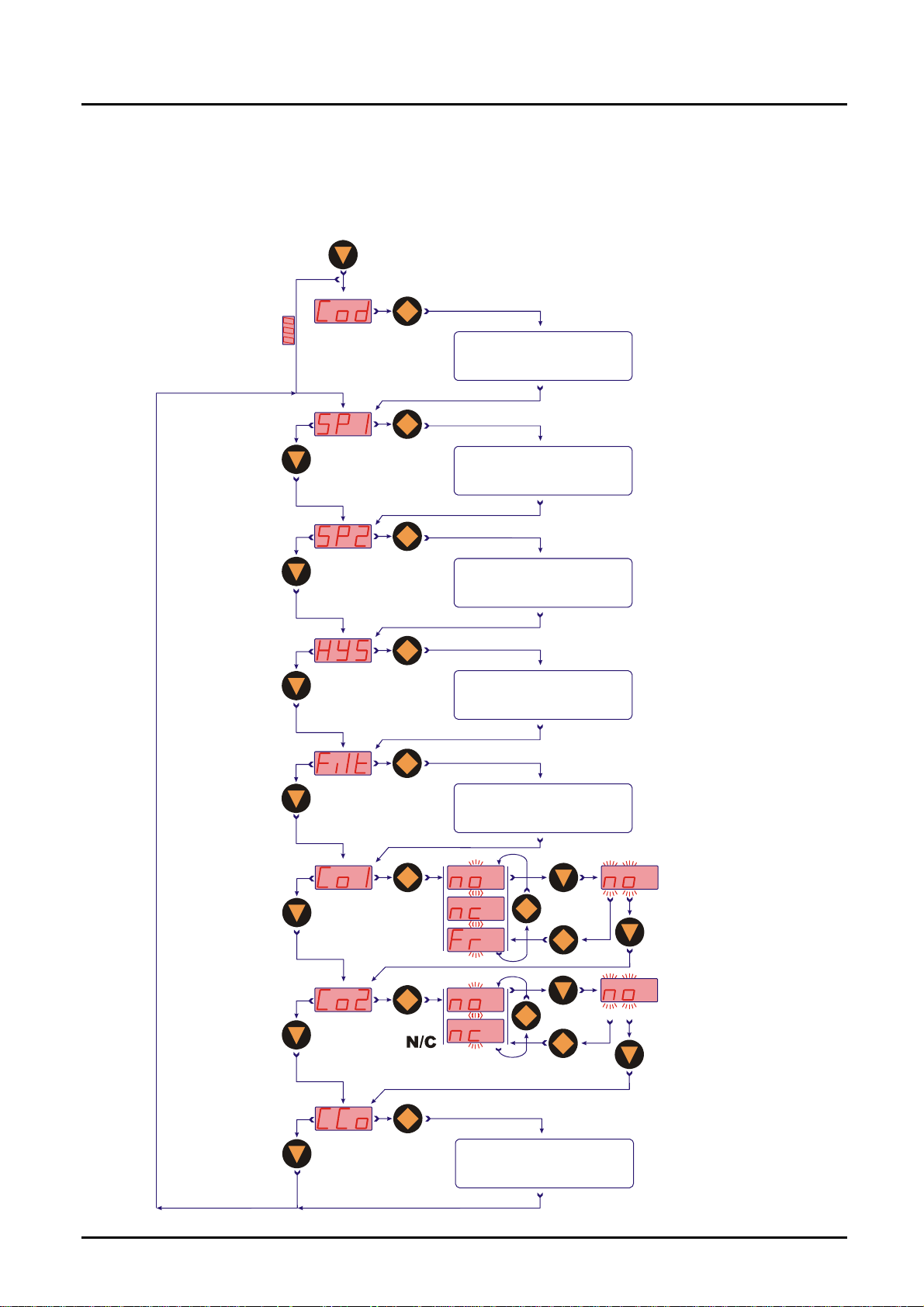

9.4 Set-up mode

Compact electronics MIK-...C30..

3 sec

Code entering

Value se tting

Code=

Swichting

point 1

Value setting

Switching

point 2

Hysteresis

Filter

Contact 1

function

Contact 2

function

7 Levels

N/O

N/C

Frequency

N/O

Value setting

Value setting

Value setting

Storin

Storing

Changing code

Value setting

page 14 MIK K07/0614

Page 15

MIK

g

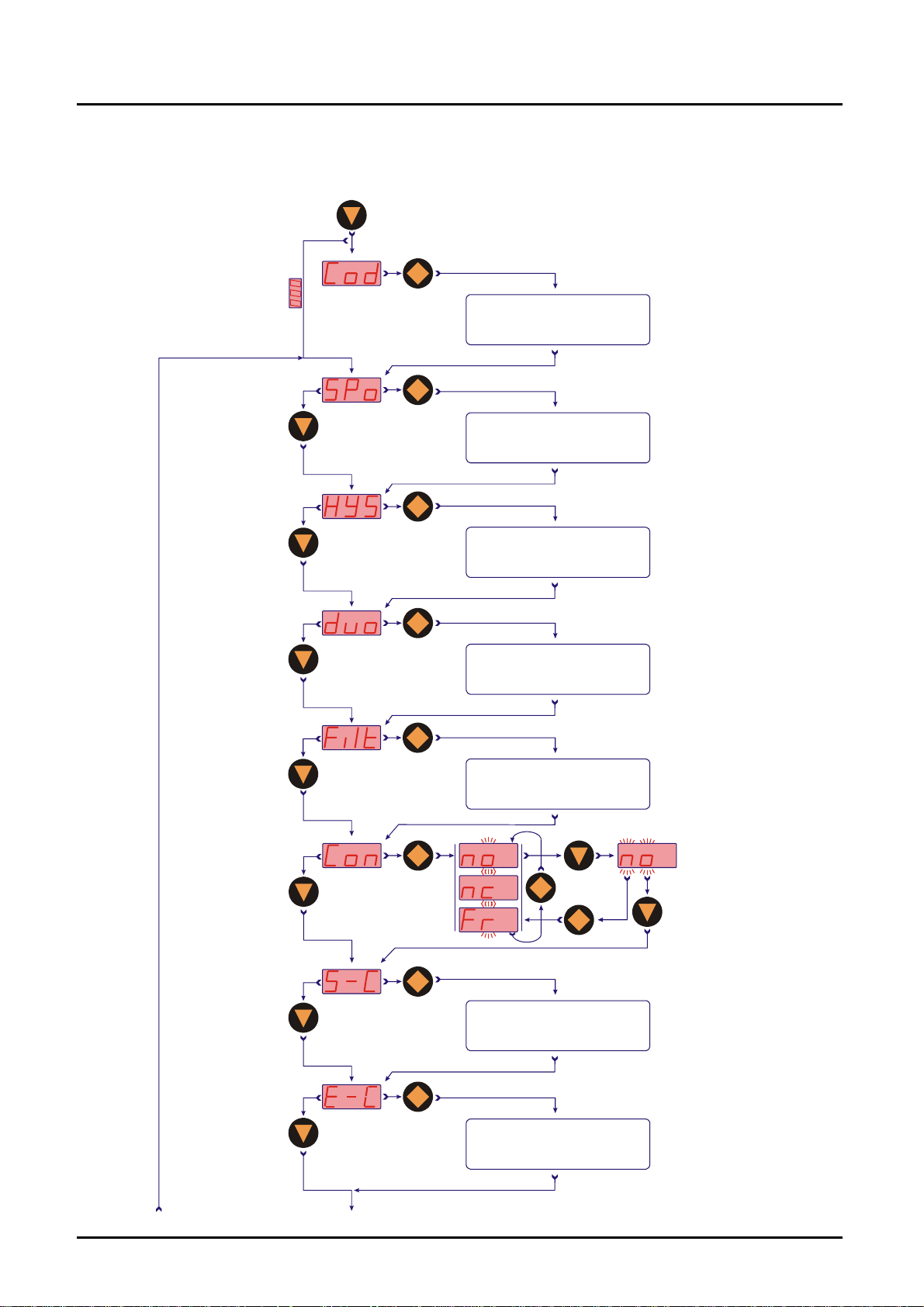

Compact electronics MIK-...C34..

3 sec

Code entering

Value setting

Code=

Switching point

Value setting

Hysteresis

Windowpoint

Filter

Contact function

Start current

7 levels

N/O

N/C

Frequency

7sec

Value setting

Value setting

Value setting

Storin

Value setting

End current

7sec

Value setting

MIK K07/0614 page 15

Page 16

MIK

Start

selection

7sec

Changing code

0-20

mA

Save

4-20

mA

Value setting

9.5 Main menu items

9.5.1 Switching point

The switching point is entered in the menu item "Spo, SP1, SP2". A setting value

between 000 and 999 can be selected. This value can also include a decimal

point. The decimal point can be set at two points (e.g. 10.0 or 1.00). If the display

value exceeds the set switch point, the electronic is activated and is signalised by

a lightning LED.

If the hysteresis is equal to zero and the window point is de-activated, the

electronic switches back whenever the indicated value falls below the switching

point.

9.5.2 Hysteresis

After the setting of the switching point, the hysteresis can be entered as a

negative value in the "HYS" menu. The standard hysteresis value is zero. In

operation condition this can lead to ambiguous switching behaviour, if the reading

fluctuates around the switching point or window point. In this case, increasing the

hysteresis can put things right. The hysteresis relates to the switching point and

the window point (switching point minus hysteresis; window point plus

hysteresis).

Example: Switch point 100 L/min; Hysteresis: -2.5 L/min

The electronics switches when 100 L/min is exceeded and switches back when

the reading under-runs below 97.5 L/min.

page 16 MIK K07/0614

Page 17

MIK

9.5.3 Window point (duo-point)

As well as the switching point, it is also to define a "duo" (duo-point), the window

point. This must be higher than the switching point. By using the window point

and the switching point it is possible to monitor the measurement value in a

certain range. The switching point limits the measurement range to smaller

values and the window point to larger values.

If the window point (duo-point) is less than or equal to the switching

point, an error report (Er4) will be indicated on the display and its

value is deleted and its function is invalid (in the case that the

window point and switching point out of adjustment).

The value is set in the same way as the switch point.

The window point is needed for process, in which monitoring of a certain

measurement range is necessary.

Example: Switching point: 100 L/min; window point: 150 L/min;

hysteresis: -1 L/min

The electronic switches when 100 L/min is exceeded. If the measured value

remains between 99 L/min (100-1) and 151 L/min (150+1), the contact will also

remain in active switching condition (LED on). If it exceeds 151 L/min or is below

99 L/min the electronic switches back.

Switching behaviour

The following diagram clarifies the switching behaviour of the electronics. The

contact closes (contact type: no) when exceeding below the switching point or

when it under-runs the window point. It only opens again if the window point plus

hysteresis is exceeded or if it drops below the switching point minus hysteresis.

LED indicates the switching condition of the switching point.

An

9.5.4 Filter

The filter function "Filt" forms a running average from the measured values. The

following values can be set (see section 9.2 Settings):

1 / 2 / 4 / 8 / 16 / 32 / 64

They correspond to the number of samples used in the running average. The

filter value determines the dynamic behaviour of the display value. The larger the

adjusted value, the slower the display response. With a filter value of "1" the filter

is switched off, i.e. the display value is equal to the unfiltered measured value.

The integrated step function detector reacts to a change of value corresponding

to approx. 6.25% of the full scale value. As soon as a step function signal is

detected, the instantaneous measured value is directly indicated in the display.

MIK K07/0614 page 17

Page 18

MIK

Display

L/min

Switchpoint

Hysteresis

Display

L/min

Hysteresis

Window point

LED on

Time / t

LED on

LED on

Switchpoint

Hysteresis

Time / t

9.5.5 Contact type

The function of the transistor switching output is set in menu item "Con, Co1 or

". The switching function switches from

Co2

no - N/O contact to

nc - N/C to

Fr – frequency (only Con and Co1)

and back.

N/O contact: contact closes when switch point is exceeded

N/C contact: contact opens when switch point is exceeded

Frequency: frequency output is proportional to flow value

9.5.6 Current output

The current output is selected in menu items

"S-C" Start current indicated value < > 0(4) mA

"E-C" End current indicated value < > 20 mA

"SCS" Start current selection (0-20 mA or 4-20 mA).

The indicated value at which 0(4) mA flow is entered in menu item start current.

The indicated value at which 20 mA flow is entered in menu item end current.

page 18 MIK K07/0614

Page 19

MIK

9.5.7 Change code

The change code option "CCo" secures the unit against unauthorised tampering.

If the code is different from 000, the user must input the code immediately after

entering the adjustment mode.

10. Maintenance

The measurement device requires no maintenance if the measurement medium

does not cause deposits. In order to avoid problems, we recommend the

installation of a filter, such as the magnetic filter, model MFR.

If it is necessary to clean the sensor, the sensor can be rinsed with a suitable

liquid. Fibre parts or large particles can be carefully removed with a cleaning cloth

or similar.

Work on the electronics can only be performed by the factory, or the warranty is

otherwise voided.

MIK K07/0614 page 19

Page 20

MIK

11. T echnical Information

Range: see table

Accuracy: ±2.0 % of f.s.

Repeat accuracy: ±1 % of f.s.

(f.s. = full scale)

Measurement process: magnetic inductive

Electrical conductivity: min. 30 µS/cm

Mounting position: in all directions,

flow in direction of the arrow

Inlet / outlet: 3 x DN / 2 x DN

Media temperature: -20…+80 °C (max. +60 °C with PVC-

Ambient temperature: -10…+60 °C

Max. pressure: 10 bar

Max. pressure loss: max. 0.25 bar at f.s.

Max. medium viscosity: 20 cSt ≤ G1”

Max. medium viscosity: 70 cSt ≥ G1½”

Wetted parts

Sensor housing: PPS or PVDF, fibreglass-reinforced

Connection set: PVC-glue connection or hose connection,

Electrodes: st. st. 1.4404 or Hastelloy C4

Seal: NBR, FPM or FFKM

Response time t90: approx. 1 s

Protection: IP 65

Connection/Ranges

Inside

Connection

G ½ male 5 mm

G ¾ male 10 mm

G 1 male 15 mm

G 1½ male 20 mm

G 2 male 32 mm

G 2¾ male 54 mm

diameter

[DN]

connection set)

weld-on ends st. st. 1.4404

Flow velocity

at f.s.

approx. 0,45 m/s 10...500 mL/min

approx. 0,9 m/s 0,05...1,0 L/min

approx. 2,7 m/s 0,16...3,2 L/min

approx. 2,2 m/s 0,5...10,0 L/min

approx. 3,5 m/s 0,8...16,0 L/min

approx. 3,0 m/s 1,6...32,0 L/min

approx. 4,7 m/s 2,5...50,0 L/min

approx. 3,3 m/s 3,2...63 L/min

approx. 5,3 m/s 5,0...100 L/min

approx. 3,3 m/s 8...160 L/min

approx. 6,6 m/s 16...320 L/min

approx. 3,6 m/s 25...500 L/min

approx. 5,1 m/s 35...700 L/min

Measuring range

page 20 MIK K07/0614

Page 21

MIK

Weight Sensor Weight Electronics

Model PPS PVDF Model Weight

MIK-...08/10/15 (½“) approx. 180 g approx. 210 g

MIK-...20/25 (¾“) approx. 190 g approx. 225 g

MIK-...30/35 (1“) approx. 270 g approx. 325 g

MIK-...50/55 (1½“) approx. 410 g approx. 500 g MIK-...C3xx approx. 300 g

MIK-...60/65 (2“) approx. 560 g approx. 610 g

MIK-...80/85 (2¾“) approx. 1200 g approx. 1370 g

Total weight = weight sensor + weight electronics

MIK-...F300, MIK-…F390

Impulse output: PNP, Open Collector, max. 200 mA

500 Hz at f.s. (…F300)

50…1000 HZ at f.s. (…F390)

factory set as per customer request

Power supply: 24 V

± 20 %

DC

Power consumption: 60 mA

Electrical connection: plug M12x1

Measuring range overflow: F

approx. 2 kHz up to 105% of f.s.

out

MIK-...S300, MIK-…S30D

Display: duo-LED for switch status

Switching output (..S300): relay SPDT, max. 1 A/30 VDC

Switching output (..S30D): active 24 VDC, , N/C and N/O

Switch point: 10...90 % f.s. in 10 %-steps

that can be configured by the

customer using a rotary encoder switch

Power supply: 24 VDC ± 20 %

Power consumption: 80 mA

Electrical connection: plug M12x1, 5-pin

Measuring range overflow: flash of the DUO-LED (red/green)

up to 105 % of f.s.

MIK-...L303; MIK-...L343

Output: 0(4)-20 mA, 3-wire

Max. load: 500 Ω

Power supply: 24 V

± 20 %

DC

Power consumption: 80 mA

Electrical connection: plug M12x1

Measuring range overflow: I

approx. 20,5 mA up to 103 % of f.s.

out

MIK-...L443 (usage with AUF-3000)

Output: 4-20 mA, 3-wire

Max. load: 500 Ω

Power supply: 24 V

± 20 %

DC

Power consumption: 80 mA

Electrical connection: plug DIN 43650

Measuring range overflow: I

approx. 20,5 mA up to 103 % of f.s.

out

MIK-...F3x0

MIK-...S30x

MIK-...Lxx3

MIK-...Exxx

MIK-...Gxxx

approx. 80 g

approx. 250 g

MIK K07/0614 page 21

Page 22

MIK

MIK-...C3xx (Compact electronics)

Display: 3-digit LED

Analogue output: (0)4...20 mA adjustable

(only MIK-…C34x),

Max. load: 500 Ω

Switching output: 1(2) semiconductor PNP or NPN,

set at factory, max. 300 mA

Contact function: N/C, N/O, frequency, programmable

(frequency output not calibrated, frequency

at f.s. approx. 750 - 850 Hz)

Setting: with 2 buttons

Power supply: 24 V

± 20 %, 3-wire

DC

Power consumption: approx. 120 mA

Electrical connection: plug M12x1

MIK-...Exxx (Counter electronics)

Display: LCD, 2x8 digit, illuminated

total, part and flow quantities,

units selectable

Quantity meter: 8-digit

Analogue output: (0)4...20 mA adjustable

Load: max. 500 Ω

Switching output: 2 relays, max. 30 V

/2 A/60 VA

AC/DC

Settings: via 4 buttons

Functions: reset, MIN/MAX memory,

flow monitor, monitoring for part

and total quantity, language

Power supply: 24 VDC ±20 %, 3-wire

Power consumption: approx. 150 mA

Electrical connection: cable connection or M12 plug

more technical details see data sheet ZED in the brochure Z2

MIK-...Gxxx (Dosing electronics)

Display: LCD, 2x8 digit, illuminated,

dosing, total and flow quantity,

units selectable

Quantity meter: 8-digit

Dosage: 5-digit

Analogue output: (0)4...20 mA adjustable

Load: max. 500 Ω

Switching output: 2 relays, max. 30 V

/2 A/60 VA

AC/DC

Settings: via 4 buttons

Functions: dosing (relay S2), start, stop, reset, fine

dosing, correction amount, flow switch,

total quantity, language

Power supply: 24 VDC ±20 %, 3-wire

Power consumption: approx. 150 mA

Electrical connection: cable connection or M12 plug

more technical details see data sheet ZED in the brochure Z2

page 22 MIK K07/0614

Page 23

MIK

12. Order Codes

Order details (Example: MIK-5NA 10 A F300)

Model Range Connection set Electronics

..08..= 10…500 mL/min,

MIK-5NA...= PPS-housing,

NBR-seal,

st. st.- electrode

MIK-5VA...= PPS-housing,

FPM-seal,

st. st.-electrode

MIK-6FC...= PVDF-housing,

FFKM-seal,

HastelloyElectrode

MIK-6FT...= PVDF-housing,

FFKM-seal,

TantalumElectrode

G ½

..10..= 0.05…1.0 L/min,

G ½

..15..= 0.16…3.2 L/min,

G ½

..20..= 0.5…10.0 L/min,

G ¾

..25..= 0.8…16.0 L/min,

G ¾

..30..= 1.6…32.0 L/min,

G 1

..35..= 2.5…50.0 L/min,

G 1

..50.. = 3.2...63 L/min,

G 1½

..55.. = 5.0...100 L/min,

G 1½

..60.. = 8...160 L/min,

G 2

..65.. = 16...320 L/min,

G 2

..80.. = 25...500 L/min,

G 2¾

..85.. = 40...800 L/min,

G 2¾

1)

= without

..A..

..P..= PVC-hose connection

..E..= st. st. weld-on ends

1)

..A..

= without

..K..= PVC-glue connection

..P..= PVC-hose connection

..E..= st. st. weld-on ends

1)

= without

..A..

..K..= PVC-glue connection

..E..= st. st. weld-on ends

frequency output

..F300 =M12-plug, 500 Hz

..F390 =M12-plug,

50...1000 Hz

switching output

..S300 =relay, M12-plug

..S30D =active 24 VDC,

M12-plug

analogue output

..L303 =M12-plug, 0-20 mA

..L343 =M12-plug, 4-20 mA

..L443 =DIN-plug, 4-20 mA

compact electronics

..C30R =2xOpen Coll. PNP

..C30M=2xOpen Coll. NPN

..C34P =0(4)-20 mA,

1xOpen Coll. PNP

..C34N =0(4)-20 mA,

1xOpen Coll. NPN

counter electronics

..E14R =LCD, 0(4)-20 mA,

2xrelay, 1 m cable

..E34R =LCD, 0(4)-20 mA,

2xrelay, M12-plug

dosing electronics

..G14R =LCD, 0(4)-20 mA,

2xrelay, 1 m cable

..G34R =LCD, 0(4)-20 mA,

2xrelay, M12-plug

2)

1) incl. frontal gaskets (2 pc. O-rings)

2) please specify frequency at full scale in clear text while oderering

MIK K07/0614 page 23

Page 24

MIK

13. Dimensions

Model G L1 L2 L3 L4 L5 L6 H1 H2

MIK-xxx08A/10A/15A G ½ 118 90 14 46 58 36 43 28

MIK-xxx20A/25A G ¾ 112 90 16 46 58 36 43 28

MIK-xxx30A/35A G 1 126 90 18 46 58 36 49,5 29,5

MIK-xxx50A/55A G 1½ 134 90 22 68 80 36 65,6 31,5

MIK-xxx60A/65A G 2 138 90 24 68 80 36 72 36

MIK-xxx80A/85A G 2¾ 202 150 26 96 110 75 104 52

MIK-...F3x0; MIK-...S30x; MIK-...L3x3

MIK-...L443

page 24 MIK K07/0614

Page 25

MIK

MIK-...C3xx

MIK-...Ex4R, MIK-...Gx4R

MIK K07/0614 page 25

Page 26

MIK

L1

G

Dimensions Connection set PVC-glue connection

G Ø D1 Ø D2 Ø D3 L1 L2

G 1/2 not available

G 3/4 35 16 10,5 21 14

G 1 43 20 15 23 16

G 1 1/2 60 32 26 27 22

G 2 74 40 33 30 26

G 2 3/4 103 63 54 38 38

Dimensions Connection set PVC-hose connection

G Ø D1 Ø D2 L

G 1/2 14 12 56

G 3/4 18 16 60

G 1 22 20 67

G 1 1/2 not available

G 2 not available

G 2 3/4 not available

Dimensions Connection set st. st. weld-on-ends

G SW L Ø D1 Ø D2

G 1/2 24 45 10,2 5

G 3/4 32 45 13,5 10

G 1 41 45 19 15

G 1 1/2 55 60 25 20

G 2 70 60 38 32

G 2 3/4 90 60 60,3 54

G

Ø D1

L1

3

G

L2

Ø D3

Ø D2

D1

D2

ø

ø

L

øD2

øD1

38

page 26 MIK K07/0614

Page 27

MIK

14. Declaration of Conformance

We, KOBOLD Messring GmbH, Hofheim-Ts, Germany, declare under our sole

responsibility that the product:

Compact Magnetic-Inductive Flow Meter Model: MIK-…

to which this declaration relates is in conformity with the standards noted below:

EN 61320-1 2013-07

Electrical equipment for control and instrumentation technology and laboratory

use – EMC-requirements

DIN EN 61010-1 2011-07

Safety requirements for electrical measuring-, control- and laboratory instruments

Also the following EC guidelines are fulfilled:

2004/108/EC EMC Directive

Hofheim, 03.06.2014

H. Peters M. Wenzel

General Manager Proxy Holder

MIK K07/0614 page 27

Loading...

Loading...