Page 1

03/08- 2016

MIK

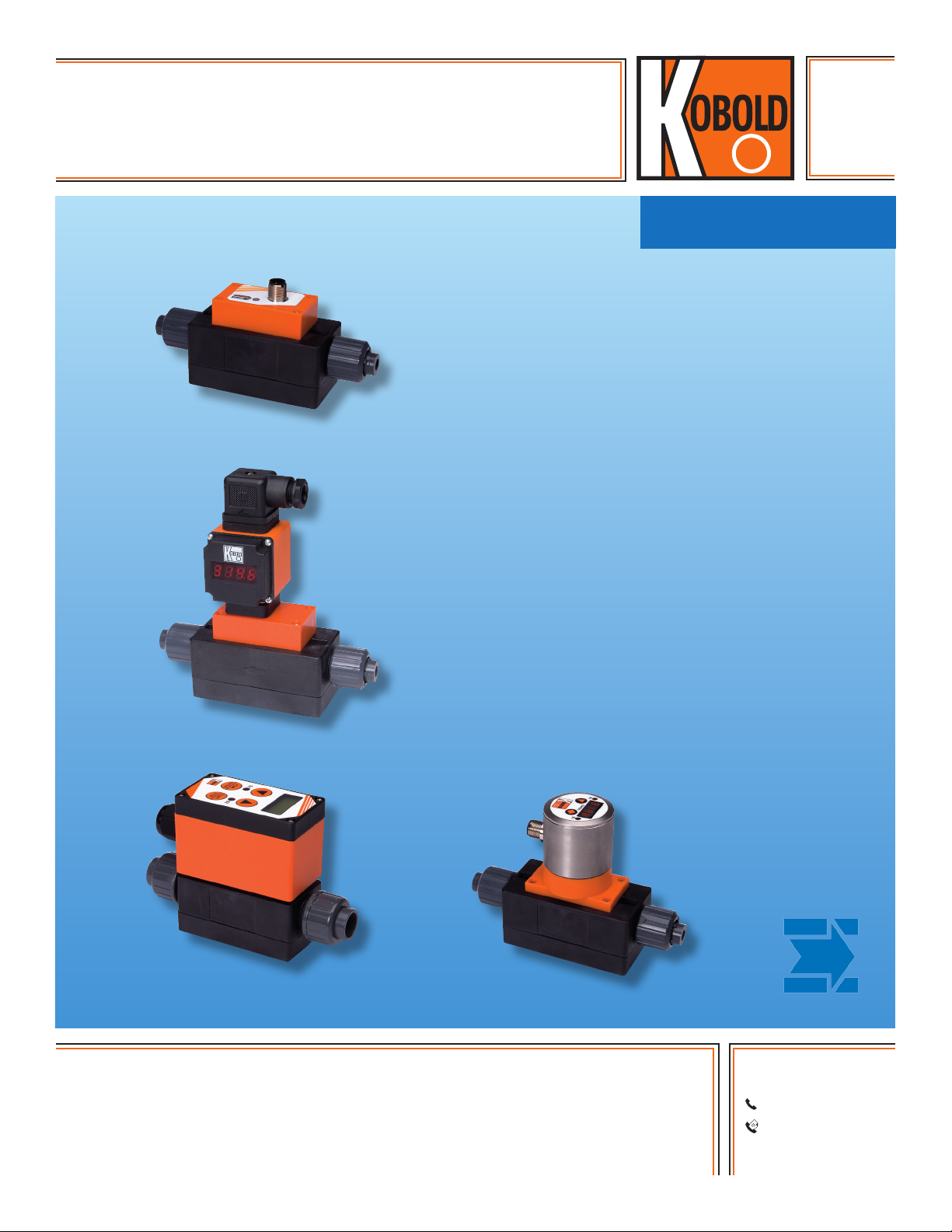

Compact Magneto-Inductive

Flowmeter

●● Flow Ranges: 0.18...7.8 GPH to 9...180 GPM

●● Accuracy: ±2 % of Full Scale

●● p

: 145 psi; t

max

●● Connection: G½...G 2¾ Male with

Optional NPT, Socket, and Hose Connections

●● Materials: PPS Body with Stainless Steel

Electrodes; PVDF Body with Hastelloy® or

Tantalum Electrodes

: 176 °F

max

measuring

•

monitoring

•

analyzing

●● Electronic Packages: Frequency or Current

Outputs, Adjustable Switches, and Integral

Totalizers or Batch Controllers

●● Highlights:

· No Moving Parts in the Flow Body

· Low Pressure Loss

· Universal Mounting

· High Quality at a Low Price

KOBOLD companies worldwide:

ARGENTINA, AUSTRALIA, AUSTRIA, BELGIUM, BULGARIA, CANADA, CHILE, CHINA, COLOMBIA, CZECH

REPUBLIC, EGYPT, FRANCE, GERMANY, HUNGARY, INDIA, INDONESIA, ITALY, MALAYSIA, MEXICO,

NETHERLANDS, PERU, POLAND, REPUBLIC OF KOREA, ROMANIA, SINGAPORE, SPAIN, SWITZERLAND,

TAIWAN, THAILAND, TUNISIA, TURKEY, UNITED KINGDOM, USA, VIETNAM

KOBOLD Instruments, Inc.

1801 Parkway View Drive

Pittsburgh, PA 15205

Main Ofce:

1.800.998.1020

1.412.788.4890

info@koboldusa.com

www.koboldusa.com

Page 2

Compact Magneto-Inductive Flowmeter Model MIK

Description

The KOBOLD MIK fl ow meter is used for measuring and

monitoring small to medium-sized fl ows of conductive liquids in

pipes. The sensor operates according to the electromagnetic

measurement principle. According to Faraday’s Law of magnetic

induction, a voltage is induced in a conductor moving through

a magnetic fi eld. The electrically conductive media acts as the

conductor. The voltage induced in the media is proportional

to the fl ow velocity and is therefore a value for the volumetric

fl ow. The media must have a minimum conductivity of 30 μS

/cm (200 μS /cm for U0 & U1 ranges) for proper operation.

The induced voltage is picked up by two sensing electrodes

which are in contact with the media and sent to the measuring

amplifi er. The fl ow rate will be calculated based on the cross

sectional area of the pipe.

The measurement is not dependent on the process liquid and its

material properties such as density, viscosity, and temperature.

The device may be equipped with a switch, frequency, or analog

output. Moreover, there is a compact electronic option, which

contains a switch and an analog output. The sensor series is

completed by an optional batching or totalizer electronic option.

The totalizer electronic option displays the current fl ow rate on

the fi rst line of the display and shows the partial or grand total

volume on the second. A batching electronic controls simple

fi lling duties and also measures the fl ow rate, grand total

volume, and fi lling volume. The analog output and two relay

outputs can be utilized for the further processing.

Media

Conductive Liquids

Acids and Caustic Solutions

Drinking, Cooling, and Waste Water

Ground Water, Raw Water

Aggressive or Salty Solutions

Unsuitable for Oils & Other Low or Non-Conductive Medias

Areas of Application

Flow Monitoring, Flow Measuring, Batching and

Totalizing for:

Machine Building

Chemical Industry

Paper Industry

Automobile Industry

Cement Industry

Laboratories

Technical Data

Range: See Table

Accuracy: ±2.0 % of f. s.

Repeat Accuracy: ±1.0 % of f. s.

(f. s. = full scale)

Measurement Process: Electromagnetic

Electrical Conductivity: Min. 30 μS /cm (MIK-..U0.. & MIK-..

U1.., Min. 200 μS /cm)

Mounting Position: Universal,

Flow in Direction of the Arrow

Inlet/Outlet Straight Run: 3 x PD / 2 x PD (Pipe Diameters)

Media Temperature: -4 ... 176 °F (max. 140 °F

with PVC-connection Set)

Ambient Temperature: 14 ... 140 °F

Max. Pressure: 145 psi

Max. Pressure Loss: Max. 3.7 psi at f.s.

Max. Media Viscosity: Max. 20 cSt for ranges: U0...U8

Max. 70 cSt for ranges: UA...UH

Wetted Parts

Sensor Housing: PPS or PVDF, Fiberglass-reinforced

Native Connection: G 1/2 to G 2-3/4

Optional Connection Set: NPT, PVC-glue Connections, Hose

Barb, or Butt Weld Connections

316L Stainless Steel

Electrodes: 316L Stainless Steel, Hastelloy C4,

or Tantalum

Seal: NBR, FKM, or FFKM

Response Time t

: ca. 1 s

90

Protection: IP 65

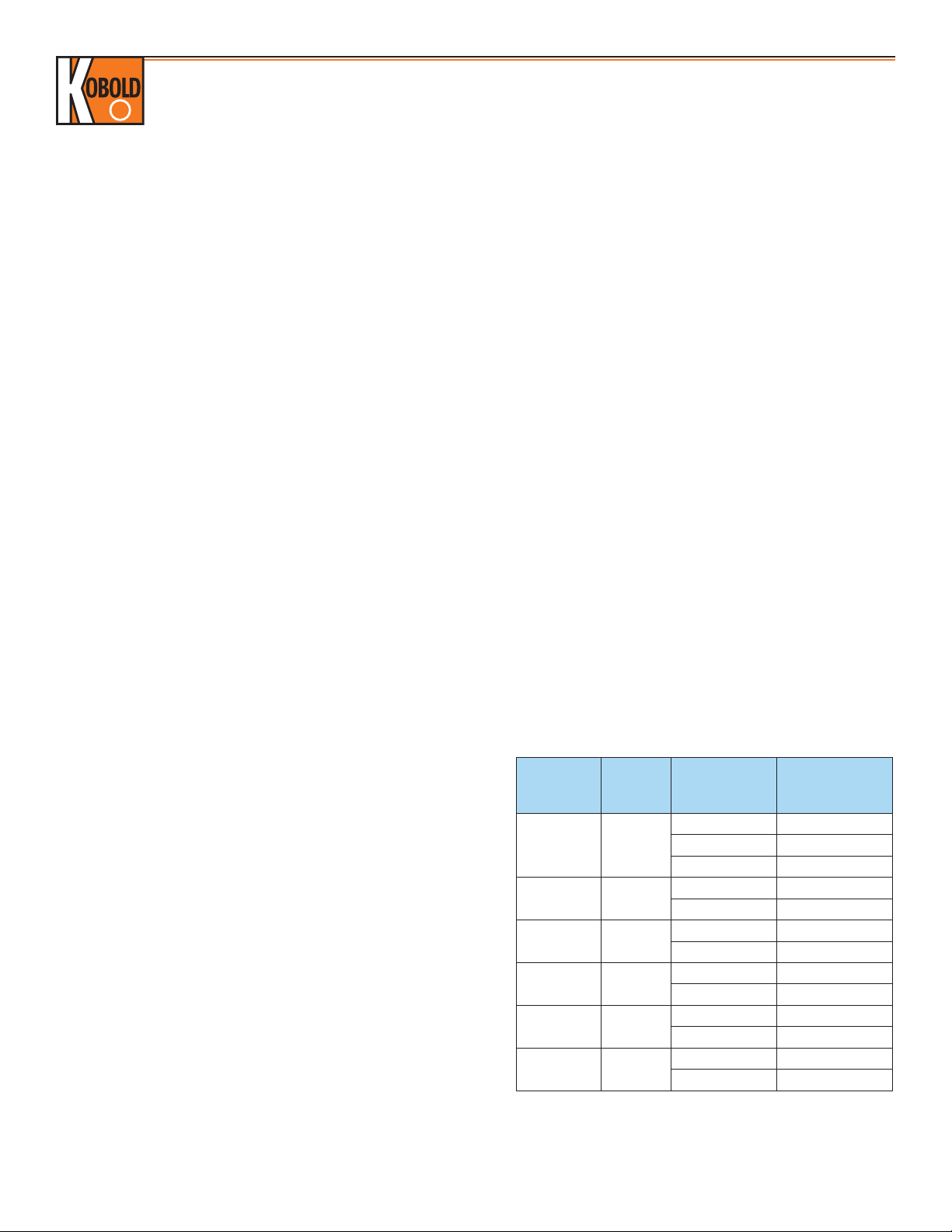

Connection/Ranges

Native

Connection

G ½ male 5 mm

G ¾ male 10 mm

G 1 male 15 mm

G 1 ½ male 20 mm

G 2 male 32 mm

G 2 ¾ male 54 mm

Inside

Diameter

Flow Velocity

at f.s.

approx. 0.45 m/s 0.18... 7.8 gph

approx. 0.9 m/s 0.78... 15.6 gph

approx. 2.7 m/s 2.4... 48.0 gph

approx. 2.2 m/s 0.13 ... 2.6 gpm

approx. 3.5 m/s 0.2 ... 4.0 gpm

approx. 3.0 m/s 0.4 ... 8.0 gpm

approx. 4.7 m/s 0.65 ... 13 gpm

approx. 3.3 m/s 0.8... 16 gpm

approx. 5.3 m/s 1.3 ... 26 gpm

approx. 3.3 m/s 2.0 ... 40 gpm

approx. 5.9 m/s 4.0 ... 75 gpm

approx. 3.6 m/s 6.5 ... 130 gpm

approx. 5.1 m/s 9.0 ... 180 gpm

Range

2

www.koboldusa.com

No responsibility taken for errors;

subject to change without prior notice.

Page 3

Compact Magneto-Inductive Flowmeter Model MIK

MIK-...F300, MIK-...F390

Pulse Output: PNP, Open Collector, max. 200 mA

500 Hz at f. s. (...F300)

50...1000 Hz at f. s. (...F390)

Factory Set as per Customer Request

Power Supply: 24 VDC ±20 %

Power Consumption: 60 mA

Electrical Connection: Plug M 12 x 1

MIK-...S300, MIK-...S30D

Display: Duo-LED for Switch Status

Switching Output: Relay SPDT, Max. 1A/30V

or Active 24 VDC, N/C / N/O

DC

Switch Point: 10 ...100% of f. s. in 10%-Steps

User Configured via Rotary Switch

Power Supply: 24 VDC ±20 %

Power Consumption: 80 mA

Electrical Connection: Plug M 12 x 1, 5-pin

MIK-...L343

Output: 4-20 mA, 3-wire

Max. Load: 500 Ω

Power Supply: 24 VDC ±20%

Power Consumption: 80 mA

Electrical Connection: Plug M 12 x 1

MIK-...L443 (Optional Use with AUF-3000)

Output: 4-20 mA, 3-wire

Max. Load: 500 Ω

Power Supply: 24 VDC ±20%

Power Consumption: 80 mA

Electrical Connection: Plug DIN 43650

MIK-...Ex4R (Totalizing Electronic)

Display: LCD, 2 x 8 Digit, Illuminated

Rate, Total, and Grand Total

Unit Selectable

Quantity Meter: 8-digit

Analog Output: 4-20 mA Adjustable

Load: Max. 500 Ω

Switching Output: 2 Relays, Max. 30 V / 2 A

Settings: Via 4 buttons

Functions: Reset, MIN / MAX Memory,

Flow Switch, Monitoring for Total

and Grand Total, Language

Power Supply: 24 VDC ±20 %, 3-wire

Power Consumption: Approx. 150 mA

Electrical Connections: Cable Connection or M12 Plug

MIK-...Gx4R (Batching Electronic)

Display: LCD, 2 x 8 Digit, Illuminated

Batching, Total, and Grand Total

Unit Selectable

Quantity Meter: 8-digit

Batch: 5-digit

Analog Output: 4-20 mA Adjustable

Load: Max. 500 Ω

Switching Output: 2 relays, Max. 30 V / 2 A

Settings: Via 4 Buttons

Functions: Batching (Relay S2), Start, Stop,

Reset, Fine Batching,

Correction Amount, Flow Switch,

Total Quantity, Language

Power Supply: 24 VDC ±20 %, 3-wire

Power Consumption: Approx. 150 mA

Electrical Connection: Cable Connection or M12 Plug

MIK-...C3xx (Compact Electronics)

Display: 3-digit LED

Analog Output: 4...20 mA Adjustable

(only MIK-...C34P)

Max. Load: 500 Ω

Switching Output: 1(2) Semiconductor PNP or NPN,

Set at Factory

Contact Function: N/C / N/O-Frequency

Programmable

Settings: Via 2 Buttons

Power Supply: 24 VDC ±20 %, 3-wire

Power Consumption: 120 mA

Electrical Connection: Plug M 12 x 1

No responsibility taken for errors;

subject to change without prior notice.

www.koboldusa.com

3

Page 4

Compact Magneto-Inductive Flowmeter Model MIK

1

2

Switch out 2

+Vs

Electrical Connections

MIK-...S300 MIK-...S30D

Output

2

1

+Vs

N/O

Output

4

Common

Output

N/C

5

GND

3

MIK-...L343, MIK-...F3x0 MIK-...L443

n.c.

GND

MIK-...C30x MIK-...C34x

34

GND

12

+Vs

Signal out

5

3

4

GND

Switch out 1

Output

N/C

GND

2

1

0(4)-20 mA

GND

2

3

3

GND

Signal

out

+V

1

4

S

12

5

34

+Vs

Output

N/O

+Vs

GND

Switch out 1

MIK-...E14R, MIK-...G14R Cable Connection Plug Connection

Wire Number

1 +24 V

2 GND GND

3 4-20 mA 4-20 mA

4 GND GND

5 n.c. Control 1*

6 Reset part quantity Control 2*

7 Relay S1 Relay S1

8 Relay S1 Relay S1

9 Relay S2 Relay S2

10 Relay S2 Relay S2

Control 1 <-> GND: Start-Batching

Control 2 <-> GND: Stop-Batching

Control 1 <-> Control 2: Reset-Batching

4

MIK-...E14R

Totalizing Electronics

MIK-...G14R

Batching Electronics

DC

+24 V

DC

www.koboldusa.com

+24 V

DC

Reset/Ctr 2*

d.c./Ctr 1*

S 2

1

4

30 V

7

6

AC/DC

1

U

8

U

0 (4) - 20 mA Out

2

5

3

/ 2 A

2

3

4

5

max. 500 Ω

GND

S 1

No responsibility taken for errors;

subject to change without prior notice.

Page 5

Compact Magneto-Inductive Flowmeter Model MIK

Order Details (Example: MIK-5NA U5 A F300)

Model

MIK-5NA.. = PPS-housing,

NBR-seal,

stainless steel electrode

MIK-5VA.. = PPS-housing,

FKM-seal,

stainless steel electrode

MIK-6FC.. = PVDF-housing,

FFKM-seal,

Hastelloy electrode

MIK-6FT.. = PVDF-housing,

FFKM-seal,

Tantalum electrode

Measuring Range, Native

Process Connection

..U0.. = 0.18…7.8 GPH, G ½

..U1.. = 0.78…15.6 GPH, G ½

..U2.. = 2.4…48.0 GPH, G ½

..U4.. = 0.13…2.6 GPM, G ¾

..U5.. = 0.2…4.0 GPM, G ¾

..U7.. = 0.4…8.0 GPM, G 1

..U8.. = 0.65…13 GPM, G 1

..UA.. = 0.8...16 GPM, G 1½

..UB.. = 1.3...26 GPM, G 1½

..UD.. = 2.0...40 GPM, G 2

..UE.. = 4.0...75 GPM, G 2

..UG.. = 6.5...130 GPM, G 2 ¾

..UH.. = 9.0...180 GPM, G 2 ¾

Optional Fitting Set Output/Electronics

..A.. = without

1)

..N.. = PVC, 1/4" NPT female

..P.. = PVC, 1/2" hose barb

..A.. = without

1)

..M.. = PVC, 3/8" PVC glue socket

..N.. = PVC, 3/8" NPT female

..P.. = PVC, 3/4" hose barb

..R.. = Polypropylene, 3/8" NPT female

..A.. = without

1)

..H.. = PVDF, 1/2" NPT female

..M.. = PVC, 1/2" glue socket

..N.. = PVC, 1/2" NPT female

..P.. = PVC, 1" hose barb

..R.. = Polypropylene, 1/2" NPT female

..V.. = PVDF, butt weld 20mm O.D. tube

..W.. = 316L SS, 1/2" NPT female

..X.. = Brass, 1/2" NPT female

..A.. = without

1)

..H.. = PVDF, 1" NPT female

..M.. = PVC, 1" glue socket

..N.. = PVC, 1" NPT female

..R.. = Polypropylene, 1" NPT female

..V.. = PVDF, butt weld 32mm O.D. tube

..A.. = without

1)

..H.. = PVDF, 1-1/4" NPT female

..M.. = PVC, 1-1/4" glue socket

..N.. = PVC, 1-1/4" NPT female

..R.. = Polypropylene, 1-1/4" NPT female

..A.. = without

1)

..H.. = PVDF, 2" NPT female

..M.. = PVC, 2" glue socket

..N.. = PVC, 2" NPT female

..R.. = Polypropylene, 2" NPT female

Frequency Output

..F300 = M12-plug, 500 Hz

..F390 = M12-plug,

50...1000 Hz

2)

Switching Output

..S300 = relay, M12-plug

..S30D = active 24 VDC,

M12-plug

Analog Output

..L343 = M12-plug, 4 - 20 mA

..L443 = DIN-plug, 4 - 20 mA

Compact Electronic

3)

..C30R = Open Coll. PNP (2x)

..C30M = Open Coll. NPN (2x)

..C34P = 4 - 20 mA,

Open Coll. PNP

..C34N = 4 - 20 mA,

Open Coll. NPN

Totalizing Electronic

..E14R = LCD, 4-20 mA,

relay (2x), 5' cable

..E34R = LCD, 4-20 mA,

relay (2x),

M12 plug (2x)

Batching Electronic

..G14R = LCD, 4-20 mA,

relay (2x), 5' cable

..G34R = LCD, 4-20 mA,

relay (2x),

M12 plug (2x)

Accessories: P/N 807.037 = 4-pin Micro-DC connector with 6-foot cable for output types F300, F390, L343, & S30D

P/N 807.007 = 5-pin Micro-DC connector with 6-foot cable for output types C3xx, S300, E34R, & G34R

P/N 807.087 = 8-pin Micro-DC connector with 6-foot cable for output types E34R & G34R

1)

incl. frontal gaskets (2 pc. O-rings)

2)

Please specify frequency at full scale in clear text while ordering

3)

Please clearly specify flow direction when ordering

Sensor Weight Electronics Weight

Model PPS PVDF

MIK-...U0/U1/U2 (½") approx. 0.40 lb approx. 0.43 lb

MIK-...U4/U5 (¾") approx. 0.42 lb approx. 0.50 lb

MIK-...U7/U8 (1") approx. 0.60 lb approx. 0.72 lb

MIK-...UA/UB (1 ½") approx. 0.90 lb approx. 1.10 lb

MIK-...UD/UE (2") approx. 1.24 lb approx. 1.35 lb

MIK-...UG/UH (2 ¾") approx. 2.65 lb approx. 3.02 lb

No responsibility taken for errors;

subject to change without prior notice.

Total Weight = Sensor Weight + Electronics Weight

www.koboldusa.com

Model Weight

MIK-...F3x0

MIK-...S30x

MIK-...Lxx3

MIK-...C3xx approx. 0.67 lb

MIK-...Exxx

MIK-...Gxxx

approx. 0.18 lb

approx. 0.56 lb

5

Page 6

Compact Magneto-Inductive Flowmeter Model MIK

L1

48 90

Dimensions

Model G L1 L2 L3 L4 L5 L6 H1 H2

MIK-xxxU0A

MIK-xxxU1A

G ½ 118 90 14 46 58 36 43 28

MIK-xxxU2A

MIK-xxxU4A

MIK-xxxU5A

MIK-xxxU7A

MIK-xxxU8A

MIK-xxxUAA

MIK-xxxUBA

MIK-xxxUDA

MIK-xxxUEA

MIK-xxxUGA

MIK-xxxUHA

G ¾ 122 90 16 46 58 36 43 28

G 1 126 90 18 46 58 36 49,5 29,5

G1 ½ 134 90 22 68 80 36 66 31,5

G 2 138 90 24 68 80 36 72 36

G 2 ¾ 202 150 26 96 110 75 104 52

MIK-...F3x0, MIK-...S30x, MIK-...L343 MIK-...L443

L1

L2

M12

L3 L2

26

L3

31

H1

H2

9

L4

L5

G

L6

55,5

45,5

H1

H2

9

L4

L5

MIK-...C3xx MIK-...Ex4R, MIK-...Gx4R

ø44,5

61

37,5

H1

H2

9

L4

L5

G

L3 L2

L1

M12

L6

ca. 61

H1

9

H2

L4

L5

G

L6

G

L6

L3

L2

L1

6

www.koboldusa.com

No responsibility taken for errors;

subject to change without prior notice.

Page 7

Compact Magneto-Inductive Flowmeter Model MIK

L

G

D1

D2

G

L

G

D

L1

L2

Dimensions Fitting Set ..H, M, N, R, W, X.. Connection

Reference table 7.1...table 7.5

fig. 7.1

Dimensions Fitting Set ..N.. PVC-NPT Connection

G L1 L2 D

G ½ Refer to figure 7.2 1/4" nom.

G ¾ 0.68" 0.52" 3/8" nom.

G 1 0.76" 0.68" 1/2" nom.

G 1 ½ 0.98" 0.87" 1" nom.

G 2 1.33" 0.98" 1-1/4" nom.

G 2 ¾ 1.61" 0.98" 2" nom.

table 7.1

Dimensions Fitting Set ..M.. PVC-IPS Glue Connection

G L1 L2 D

G ¾ 0.87" 0.79" 3/8" nom.

G 1 1.0" 0.89" 1/2" nom.

G 1 ½ 1.24" 1.14" 1" nom.

G 2 1.51" 1.39" 1-1/4" nom.

G 2 ¾ 1.61" 1.5" 2" nom.

table 7.2

Dimensions Fitting Set ..N.. PVC- 1/4" NPT Connection

Reference table 7.1 G ½ only

1.57“

1.10“

1.18“

G1/2

SW 1“

1/4“ NPT

fig. 7.2

Dimensions Fitting Set ..H.. PVDF-NPT Connection

G L1 L2 D

G 1 0.96" 0.79" 1/2" nom.

G 1 ½ 1.09" 0.83" 1" nom.

G 2 1.34" 0.91" 1-1/4" nom.

G 2 ¾ 1.65" 1.22" 2" nom.

table 7.3

Dimensions Fitting Set ..R.. PP-NPT Connection

G L1 L2 D

G ¾ 0.68" 0.55" 3/8" nom.

G 1 0.98" 0.79" 1/2" nom.

G 1 ½ 1.24" 0.94" 1" nom.

G 2 1.48" 1.18" 1-1/4" nom.

G 2 ¾ 1.68" 1.22" 2" nom.

table 7.4

Dimensions Fitting Set ..W, X.. SS/Brass-NPT Connection

G L1 L2 D

G 1 1.18" 0.63" 1/2" nom.

table 7.5

Dimensions Fitting Set ..V.. Butt Weld

G L D1 D2

G 1 2.09" 0.79" 0.62"

G 1 ½ 2.32" 1.26" 1.05"

No responsibility taken for errors;

subject to change without prior notice.

Dimensions Fitting Set ..P.. PVC-Hose Connection

D1

fig. 7.4

D2

fig. 7.3

G L D1 D2

table 7.6

www.koboldusa.com

G ½ 2.2" 0.55" 0.47"

G ¾ 2.36" 0.71" 0.63"

G 1 2.64" 0.87" 0.79"

table 7.7

7

Loading...

Loading...