Page 1

KOBOLD MAS Series

Thermal Mass

Flowmeters

March 1997

r2_12-13

Part Number:

IM-82

(412) 788-2830 · (800) 998-1020 · Fax (412) 788-4890

KOBOLD Instruments Inc

1801 Parkway View Drive · Pittsburgh, PA 15205

Page 2

MAS Instruction Manual

The purpose of this instruction manual is to cover the following

Kobold Instruments Inc products:

Model MAS-1000 Flowmeter with Po

Model MAS-2000 Flowmeter with Polyamide body and no display.

Model MAS-3000 Flowmeter with stainless steel flow body and

display.

Model MAS-4000 Flowmeter with stainless steel flow body and no

display.

Model MAS-1100 Flowmeter with aluminum body and display.

Model MAS-2100 Flowmeter with aluminum body and no display.

Kobold Instruments’ MAS Series Flowmeters measure the mass

flow rate of gases in ranges from 0-10 standard cubic centimeters

per minute (SCCM) to 0-500 standard liters per minute (SLM). For

most models, accuracy is 1.5% of full scale over a wide temperature

and pressure range, and time response is 2 seconds to within 2%

of final flow. Certain models are rated at 1% or 5% of full scale.

lyamide body and display.

1

INTRODUCTION

1.1

Purpose

The MAS is ideal for a complete range of gas flow applications

including general process control, laboratories, instrument OEM’s,

gas panels, and flow calibration.

Figure 1-1

Tiltable Display is Viewed

from any Angle

Page 1

Page 3

MAS Instruction Manual

CAUTION! Any application whatsoever related to humanCAUTION! Any application whatsoever related to human

CAUTION! Any application whatsoever related to human

CAUTION! Any application whatsoever related to humanCAUTION! Any application whatsoever related to human

respiration must have the written consent of Koboldrespiration must have the written consent of Kobold

respiration must have the written consent of Kobold

respiration must have the written consent of Koboldrespiration must have the written consent of Kobold

Instruments Inc.Instruments Inc.

Instruments Inc.

Instruments Inc.Instruments Inc.

The versatile MAS Flowmeter digitally displays the mass flow

rate directly in engineering units or percent of full scale. The

display is tiltable over 180° for easy viewing and can be removed

for remote mounting on a front panel.

The Kobold MAS directly monitors the mass flow rate of the gas.

This means it measures molecular flow – the measurement quality

of direct concern in most applications, such as human respiration,

chemical processes, combustion, and heating or cooling. No

temperature or pressure corrections are required, as in the case of

most other flow monitoring devices like rotameters, turbine meters,

and orifice plates.

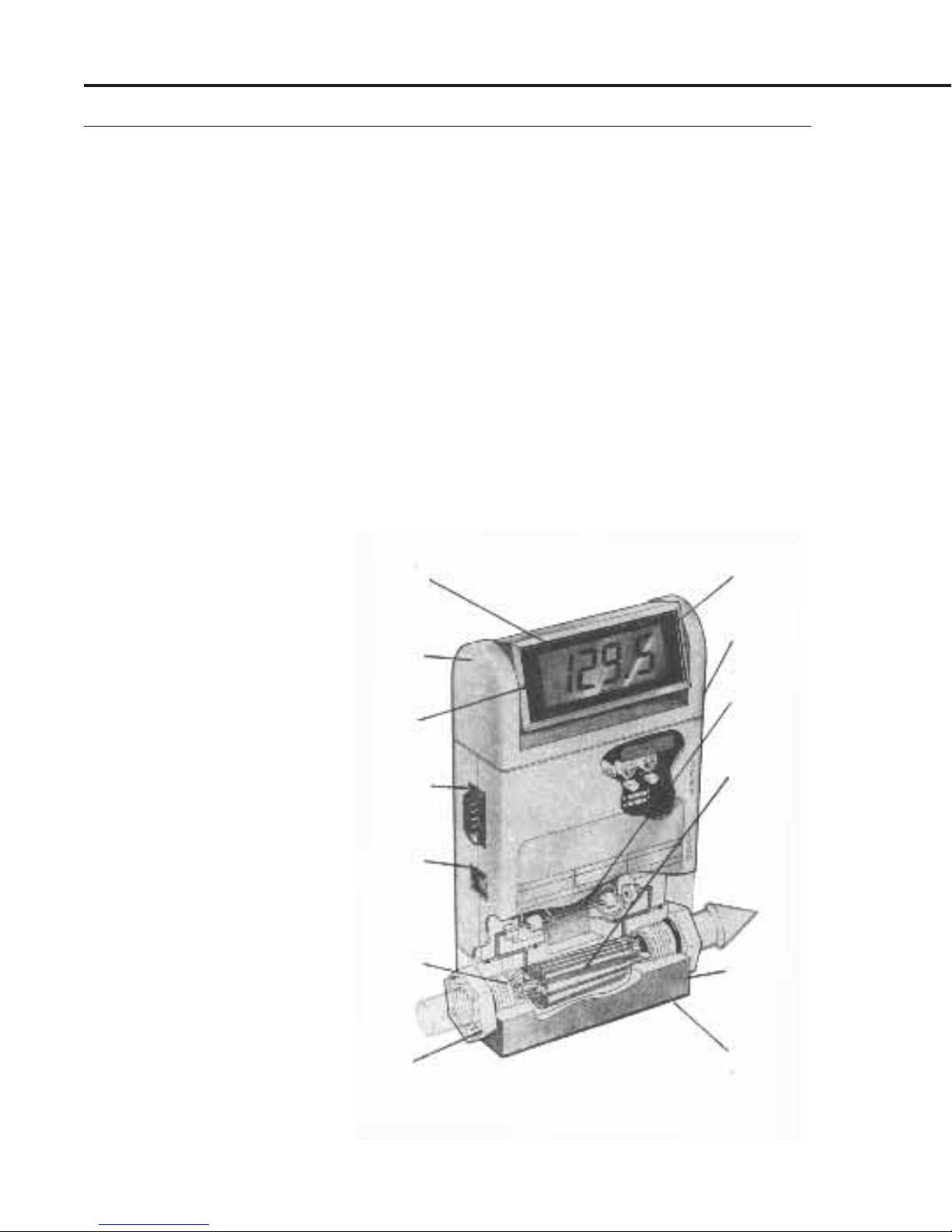

Figure 1-2

MAS Operation

and Features

Direct Monitoring of

Mass Flow.

No temperature or

pressure corrections

required.

Unexcelled Performance.

● ±

1.5% accuracy.

●

0.5% repeatability.

●

2 second response time

Tiltable Display.

9 positions provide easy

viewing from any angle.

Connector.

9-Pin "D" Sub-type. Has

0-5 VDC or 4-20 mA

(optional) output signal

linearly proportional to

mass flow rate.

Input Power Jack.

Accepts 12 to15 VDC or

24 VDC input power from

Kobold power supply or

customer supplied power.

Inlet Screen.

Filters out particulates.

Easily removable.

Digital Display.

Gives mass flow

rate in engineering

units.

Zero and Span

Potentiometers.

Adjustable from

outside of enclosure.

Patented Sensor

Tube.

Straight, large-I.D.

sensor tube is easy

to clean.

Patented Laminar

Flow Bypass.

Provides a variety of

flow ranges. Unique

cutouts make range

changes easy.

Flow Body.

Corrosion resistant

plastic or stainless

steel.

FKM

rings standard.

"O"-

Inlet/Outlet Fittings.

Available with Female

NPT or Swagelok®

style compression

fittings.

Page 2

Mounting Holes.

The MAS mounts in any

position for convenience

of installation.

Page 4

The MAS Flowmeter is a transducer requiring a 12-15 VDC (24

VDC optional) external power source. A 0-5 VDC or optional 4-20

mA output singal linearly proportional to gas mass flow rate is

provided for recording, data-logging, or control. A 9-Pin “D” subconnector is provided for power input and signal output. The MAS

is available in several basic configurations with either

(female) or

1

/4 to 1/2 inch O.D. tube compression inlet/outlet fittings,

1

/4 inch NPT

with or without the digital display, or the optional power supply.

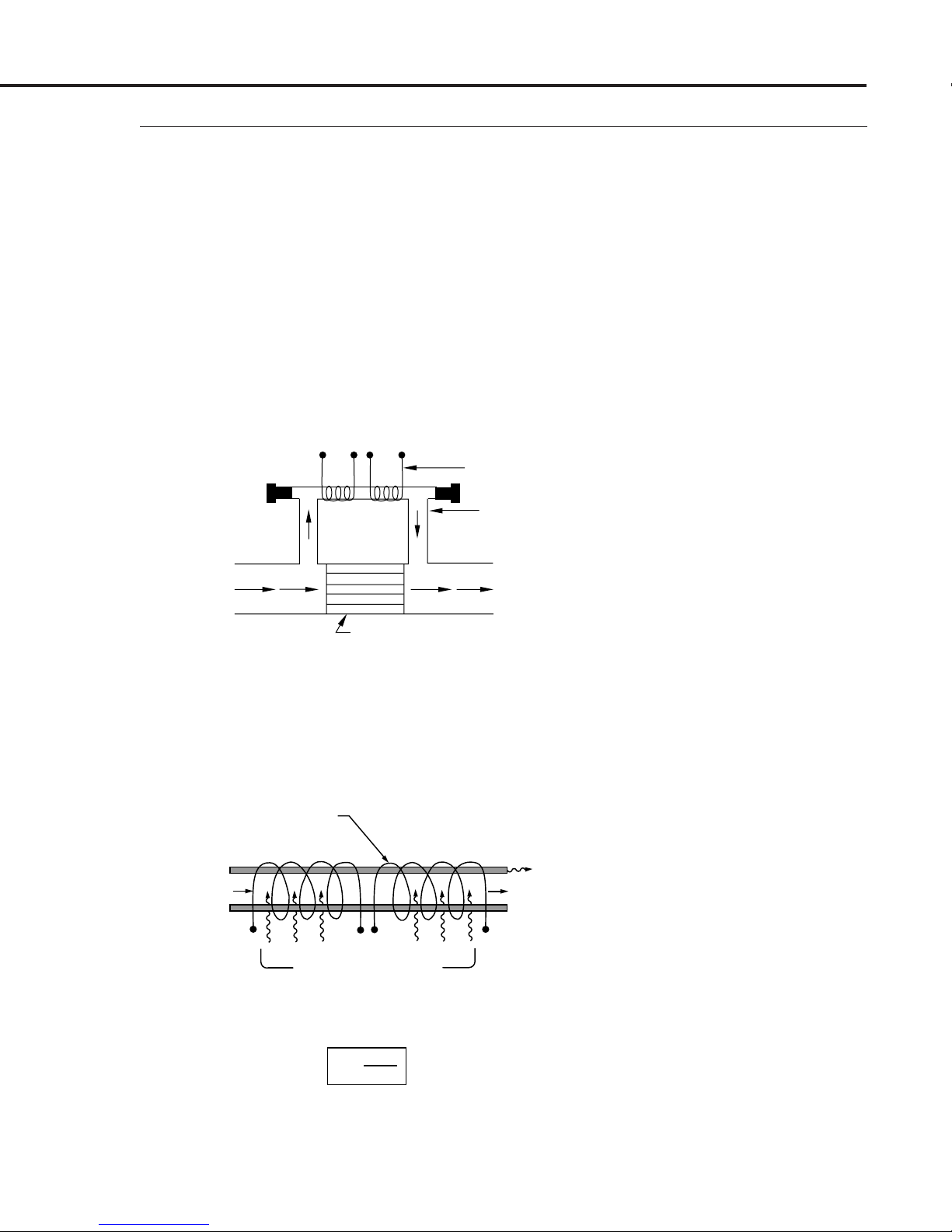

Gas enters the MAS flow body and divides into two flow paths.

Most of the flow goes through the laminar flow bypass. This creates

a pressure drop that forces a small fraction of the flow through the

sensor tube.

TWO COILS

MAS Instruction Manual

1.2

Principle of

Operation

SENSOR

TUBE

m

•

m

1

P

1

•

•

m

2

P

2

LAMINAR FLOW BYPASS

The patented* straight sensor tube is mounted parallel to the

bypass flow path. Since both paths are perfectly laminar, the ratio

of the total flow (

˙

m

) to the sensed flow (

˙

m

) is constant. Two

1

resistance temperature detector (RTD) coils around the sensor

tube direct a constant amount of heat into the gas stream.

RTD COILS

, T

R

1

1

·

m

1

R2, T

2

H

0

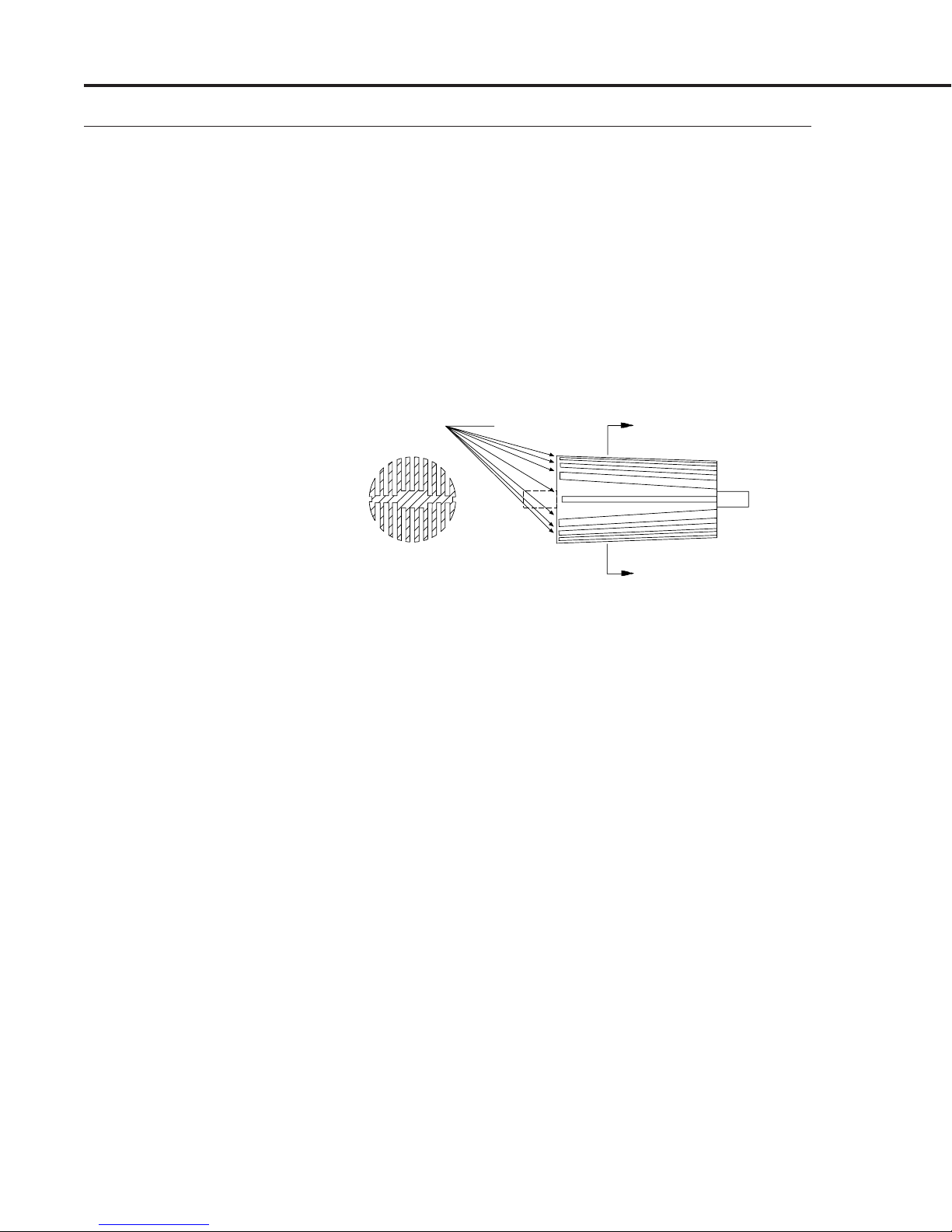

Figure 1-3

Two Flow Paths

CONSTANT HEAT, H

FIRST LAW OF THERMODYNAMICS

(HEAT IN = HEAT OUT)

H = m·

*U.S. Patent No. 4,487,062.

(T2 – T1) + H

1 Cp

H–H

m· =

Cp∆T

Figure 1-4

Measuring Sensor Flow

0

0

Page 3

Page 5

MAS Instruction Manual

A

A

“GATES”

SECT. A-A

Figure 1-5

Changing Flow Ranges

is Easy with MAS’s

Patented Bypass

In actual operation, the gas mass flow carries heat from the

upstream coil to the downstream coil. The resulting temperature

difference T

is detected by the RTD coils and gives the output

2–T1

signal. Since the molecules of the gas carry away the heat, the

output signal is directly and linearly proportional to gas mass

flow.

MAS's patented laminar flow bypass makes changing of flow

ranges easy with the proper calibration facilities. Each of the two

bypasses in the optional Laminar Flow Bypass Set has a

combination of rectangular slots along its circumference as shown

in Figure 1-5 below.

1.3

Specifications

To change the flow range of your MAS, follow the instructions

provided with the Kobold Model EL Laminar Flow Bypass Set and

cut away the “gate(s)” leading to the right combination of laminar

flow paths in one of the two bypasses. This procedure requires

proper calibration facilities and minimal skill in electronics.

FLOW RANGES

_________________________________________________________________

_________________________________________________________________

_________________________________________________________________

Flow ranges specified are for an equivalent flow of nitrogen at 760 mm

Hg and 21°C (70°F). Other ranges are available.

GASES

Most gases; check compatibility with wetted materials; specify

when ordering.

Code SCCM Code S LM

01 0-10 07 0-1

02 0-20 08 0-2

03 0-50 09 0-5

04 0-100 10 0-10

05 0-200 11 0-20

06 0-500 12 0-30

13 0-40

DISPLAY

Page 4

31/2 digit LCD (0.5 inches tall); removable for remote mounting.

Page 6

OUTPUT SIGNAL

Linear 0-5 VDC standard, 1000 ohms min. load impedance; 4-20

mA optional, 50 to 500 ohms loop resistance.

POWER REQUIREMENTS

12-15 VDC nominal; 100 mA max (24 VDC optional, specify when

ordering).

ACCURACY

±1.5% of full scale including linearity over 15 to 25 °C and 5 to 60

psia (0.35 to 4.2 kg/cm

2

); with special calibration ±1% of full scale

accuracy at a specific temperature and pressure is available.

REPEATABILITY

±0.5% of full scale.

TEMPERATURE COEFFICIENT

0.15% of full scale per °C, or better.

MAS Instruction Manual

PRESSURE COEFFICIENT

0.01% of full scale per psi (0.07 kg/cm2), or better.

RESPONSE TIME

800 ms time constant; 2 seconds (typical) to within ±2% of final

value over 25 to 100% of full scale.

PRESSURE DROP

____________________________________________________________

Typical Maximum Pressure Drop

_____________________________________________________________

Flow Rates (cm of Water)

100 SCCM .025

1 SLM .454

1 0 SL M 6.00

2 0 S L M 23.83

3 0 S L M 45.60

___________________________________________________________

4 0 S L M 83.36

GAS PRESSURE

150 psi (10 kg/cm2) gauge max; 20 psi (1.4 kg/cm2) gauge optimum.

LEAK INTEGRITY

–4

1×10

SCCS of helium max to outside environment.

GAS AND AMBIENT TEMPERATURE

0 to 50 °C.

Page 5

Page 7

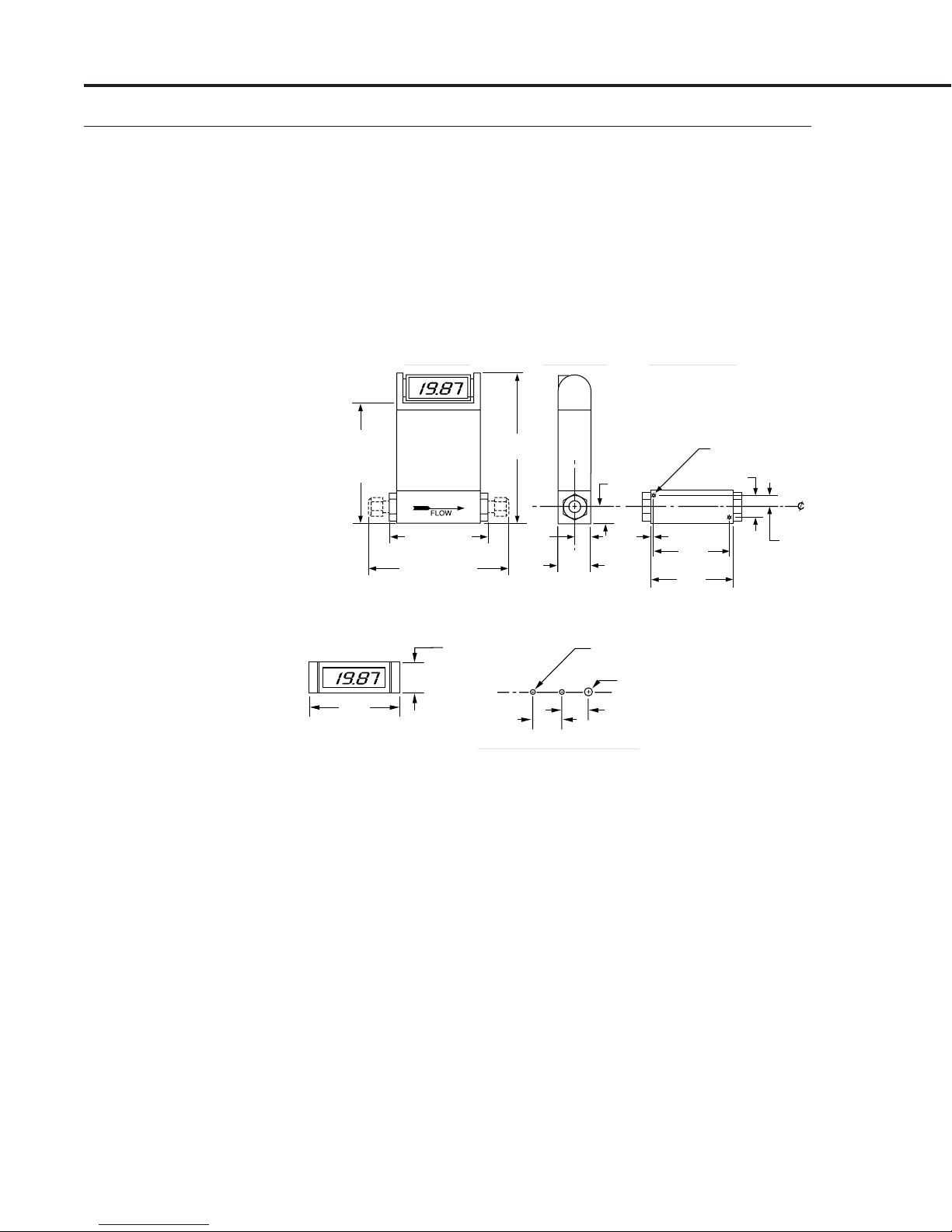

MAS Instruction Manual

1.15

(29.21)

3.05

(77.47)

4.16

(105.66)

(WITHOUT

DISPLAY)

5.38

(136.65)

3.50 (88.90)

1

/4" NPT

6.68 (169.67)

1

/4" SWAGELOCK

®

ALL DIMENSIONS IN INCHES

0.58

(14.73)

1.16

(29.46)

0.56

(14.22)

6-32 X 0.15 DP.

(SELF TAPPING)

0.75 (19.05)

0.38

(9.65)

0.13 (3.30)

2.75

(69.85)

3.00

(76.20)

0.125 DIA. THRU PANEL-2 PLACES;

FOR TWO 4-40 FLAT HEAD SCREWS

0.25 DIA. THRU; FOR 4 WIRES

0.88 (22.35)

1.00 (25.4)

PANEL MOUNTING HOLES

DIMENSIONS IN INCHES

(DIMENSIONS IN MILLIMETERS IN PARENTHESES)

SIDE VIEW

END VIEW

BOTTOM VIEW

Dimensions

WETTED MATERIALS

5% glass-filled Polyamide 6/6; 316 stainless steel; FKM “O”-

rings standard, FFKM and silicone O-rings optional.

WEIGHT

2 lb. (0.9 kg) net; 3 lb. (1.4 kg) shipping.

Page 6

Page 8

MAS Instruction Manual

Many options are available for your Kobold MAS. Please consult

Kobold’s current Price List for the respective prices.

V4 (Optional) 4-20 mA output signal

C( ) Cable assembly, specify cable type (round or ribbon) and

length

T2 1-5 Channel Power Supply, in NEMA Box, 115 VAC

T4 1-5 Channel Power Supply, in NEMA Box, 230 VAC

T5 Power Supply, for one channel, 110 VAC

T6 Power Supply, for one channel, 230 VAC

UV Upstream valve

DV Downstream valve

M S Replacement mass flow sensor, includes “O”-rings and

mounting flanges

OV

Complete set of FKM “O”-rings

T P Tip plate for electrical enclosure

RD–( ) Remote display

1.4

Options

* U.S. and foreign patents pending.

® Registered trademarks:

Swagelok, VCO, VCR–Crawford Fitting Co.

Page 7

Page 9

MAS Instruction Manual

2

INSTALLATION

2.1

Receipt of Your

MAS

2.2

Return Shipment

When

packing carton for damage incurred in shipment. If the packing

carton is damaged, the local carrier should be notified at once

regarding their liability. Kobold’s Customer Service Department

should also be notified immediately.

Customer Service Phone Number:

For our customers other than the USA, Canada and Mexico please

call the distributor from whom you purchased your MAS or call our

head office in Germany for the Kobold location nearest you:

Remove the packing slip from its envelope and verify that the

carton contains all parts listed. Inspect the carton and packing

material thoroughly to ensure that no spare parts or accessories

are mistakenly discarded. In case of shortages, please contact

Customer Service at the above phone number, or they may be

contacted in writing at the address listed in the next section.

Please do not return any equipment without a Return Material

Authorization, which is obtained from the Customer Service

Department. Information describing the problem, corrective action

or work to be performed at the factory, the purchase order number

that the equipment was purchased under, and the name of the

person to contact must be included with the returned equipment.

The use of a Return Material Authorization is for your benefit. It

makes the proper service and return of your equipment much

easier to accomplish.

Return shipping address:

the equipment is received, carefully check the outside

USA (412) 788-2830, or Fax (412) 788-4890

Germany 49(0)61-92-29-90 or Fax 49(0)61-92-23-398

Non-North American customers may contact the KOBOLD

Messring GmbH Customer Service Department Technical

Assistance at:

NOTE: Equipment returned for repair that is found to be completely

operational will be subject to the current “no problem found”

billing rate.

Page 8

USA KOBOLD INSTRUMENTS INC.

1801 Parkway View Drive

Pittsburgh, PA 15205

Europe KOBOLD MESSRING GmbH

Nordring 22-24

65719 Hofheim/Ts.

Germany

Page 10

CAUTION! The maximum pressure and temperature in theCAUTION! The maximum pressure and temperature in the

CAUTION! The maximum pressure and temperature in the

CAUTION! The maximum pressure and temperature in theCAUTION! The maximum pressure and temperature in the

flow line in which your MAS is to be installed must notflow line in which your MAS is to be installed must not

flow line in which your MAS is to be installed must not

flow line in which your MAS is to be installed must notflow line in which your MAS is to be installed must not

exceed 150 psig (10 kg/cmexceed 150 psig (10 kg/cm

exceed 150 psig (10 kg/cm

exceed 150 psig (10 kg/cmexceed 150 psig (10 kg/cm

respectively.respectively.

respectively.

respectively.respectively.

22

2

22

gauge) or 150 gauge) or 150

gauge) or 150°

gauge) or 150 gauge) or 150

F (65F (65

F (65°

F (65F (65

C),C),

C),

C),C),

MAS Instruction Manual

In order to ensure a successful installation, inlet and outlet tubing

or piping should be in a clean state prior to plumbing your MAS to

the system. MAS is applicable to

clean gas onlyclean gas only

clean gas only because

clean gas onlyclean gas only

particulates and other foreign matter may clog the sensor tube and

laminar flow element over a period of time. If the gas contains

particulate matter, install a high-efficiency, 50 to 100 micron, inline filter upstream of the MAS.

Do not locate the MAS Flowmeter in areas subject to sudden

temperature changes, moisture, drafts, or near equipment radiating

significant amounts of heat. Allow adequate space for cable

connectors and wiring. If your MAS is to be mounted in other than

a horizontal position, the zero will need adjustment. See Section

5.2, R

CAUTION! Be sure the arrow on the side of the transducerCAUTION! Be sure the arrow on the side of the transducer

CAUTION! Be sure the arrow on the side of the transducer

CAUTION! Be sure the arrow on the side of the transducerCAUTION! Be sure the arrow on the side of the transducer

points in the direction of flow.points in the direction of flow.

points in the direction of flow.

points in the direction of flow.points in the direction of flow.

ECALIBRATION OVER THE SAME FLOW RANGE.

The MAS may be mounted to a chassis with two 6-32 self-tapping

screws. See Section 1.3, S

PECIFICATIONS, for hole dimensions.

2.3

Mechanical

Installation

Your MAS is supplied with either

1

/4 , 3/8 or 1/2 inch compression inlet and outlet fittings. These

or

1

/4 inch female NPT (standard)

fittings should not be removed unless your MAS is being cleaned

®

or calibrated for a new flow range. VCO

1

available on special order.

/4-inch pipe requires a good quality

or VCR® fittings are

paste pipe thread sealant and should be installed in the inlet and

1

outlet fittings 1

CAUTION! Over-tightening will crack the fittings andCAUTION! Over-tightening will crack the fittings and

CAUTION! Over-tightening will crack the fittings and

CAUTION! Over-tightening will crack the fittings andCAUTION! Over-tightening will crack the fittings and

shift calibration.shift calibration.

shift calibration.

shift calibration.shift calibration.

/2 turns beyond hand-tight.

For the first installation of compression fittings, simply insert the

tubing into the fitting. Make sure that the tubing rests firmly on

the shoulder of the fitting and that the nut is hand-tight. Scribe the

nut at the six o’clock position. While holding the fitting body steady

1

with a back-up wrench, tighten the nut 1

/4 turns, watching the

scribe mark make one complete revolution and continue to the nine

o’clock position. After this, the fitting can be reconnected by

snugging with a wrench. Do not fail to use a back-up wrench or the

inlet fitting may be damaged.

2.4

Plumbing

Connections

Page 9

Page 11

MAS Instruction Manual

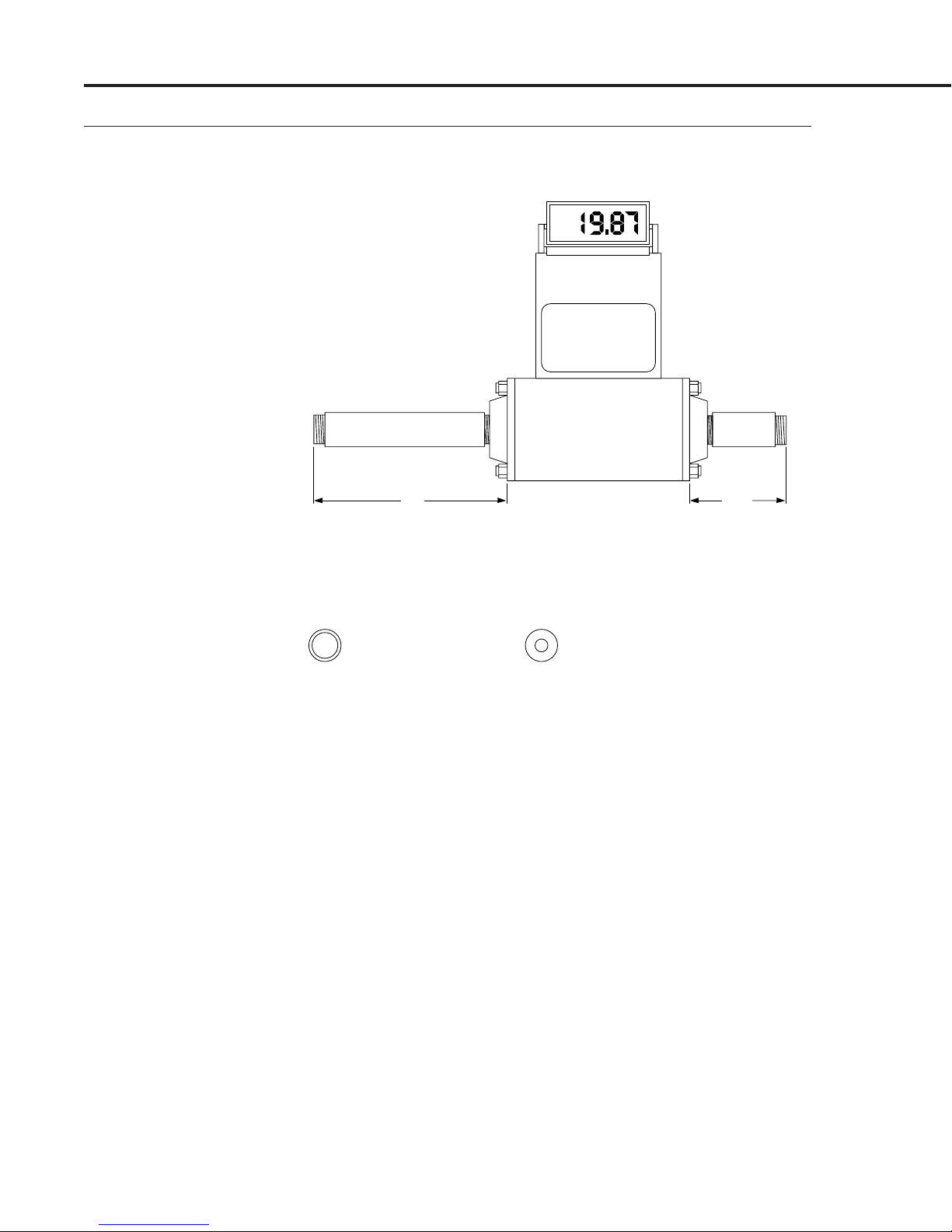

Figure 2-1

Plumbing Requirements

for Model’s 1100/2100

FLOW

➡

5.0"

(127 mm)

1

/2" NPT PIPE

(10 DIAMETERS)

EXAMPLE: Cross Section

CORRECT

1

/2" NPT pipe for

1

/2" NPT flow body

CAUTION! Do not mix or interchange parts of tube fittingsCAUTION! Do not mix or interchange parts of tube fittings

CAUTION! Do not mix or interchange parts of tube fittings

CAUTION! Do not mix or interchange parts of tube fittingsCAUTION! Do not mix or interchange parts of tube fittings

made by different manufacturers.made by different manufacturers.

made by different manufacturers.

made by different manufacturers.made by different manufacturers.

INCORRECT

Avoid use of compression

fitting on inlet of flow body. The

reduction of internal diameter of

the fitting results in a “jet”, creating

noise and affecting calibration.

DO NOT reduce down right at the

inlet with

1

/4" pipe.

2.50"

(63.5 mm)

1

/2" NPT PIPE

(5 DIAMETERS)

Finally, check the system’s entire flow path thoroughly for leaks

before proceeding to Section 3, O

CAUTION! All instruments are leak-tested prior to shipping.CAUTION! All instruments are leak-tested prior to shipping.

CAUTION! All instruments are leak-tested prior to shipping.

CAUTION! All instruments are leak-tested prior to shipping.CAUTION! All instruments are leak-tested prior to shipping.

To check your installation, test the fittings only. Do not useTo check your installation, test the fittings only. Do not use

To check your installation, test the fittings only. Do not use

To check your installation, test the fittings only. Do not useTo check your installation, test the fittings only. Do not use

liquid leak detectors such as Snoop® to search for leaksliquid leak detectors such as Snoop® to search for leaks

liquid leak detectors such as Snoop® to search for leaks

liquid leak detectors such as Snoop® to search for leaksliquid leak detectors such as Snoop® to search for leaks

inside or outside the MAS. Instead, monitor pressureinside or outside the MAS. Instead, monitor pressure

inside or outside the MAS. Instead, monitor pressure

inside or outside the MAS. Instead, monitor pressureinside or outside the MAS. Instead, monitor pressure

decay.decay.

decay.

decay.decay.

Page 10

PERATION.

Page 12

MAS Instruction Manual

MAS flowmeters require a single +12 to +15 VDC power supply

capable of providing a minimum current of 100 mA. The MAS can

also be configured for +24 VDC power at 100 mA.

Operating power input is via either the DC power jack or the 9-pin

“D” connector on the side of the enclosure. Kobold offers the Model

MAS-5000 single channel power supplies for single transducer

applications and the Model MAS-5100 for powering up to eight

transducers through the "D" connector.

CAUTION! Do not supply + DC power at the “D” connectorCAUTION! Do not supply + DC power at the “D” connector

CAUTION! Do not supply + DC power at the “D” connector

CAUTION! Do not supply + DC power at the “D” connectorCAUTION! Do not supply + DC power at the “D” connector

while using an MAS-5000 power supply at the DC powerwhile using an MAS-5000 power supply at the DC power

while using an MAS-5000 power supply at the DC power

while using an MAS-5000 power supply at the DC powerwhile using an MAS-5000 power supply at the DC power

jack. Do not plug power connector into DB9 connector.jack. Do not plug power connector into DB9 connector.

jack. Do not plug power connector into DB9 connector.

jack. Do not plug power connector into DB9 connector.jack. Do not plug power connector into DB9 connector.

Damage to electronics will result.Damage to electronics will result.

Damage to electronics will result.

Damage to electronics will result.Damage to electronics will result.

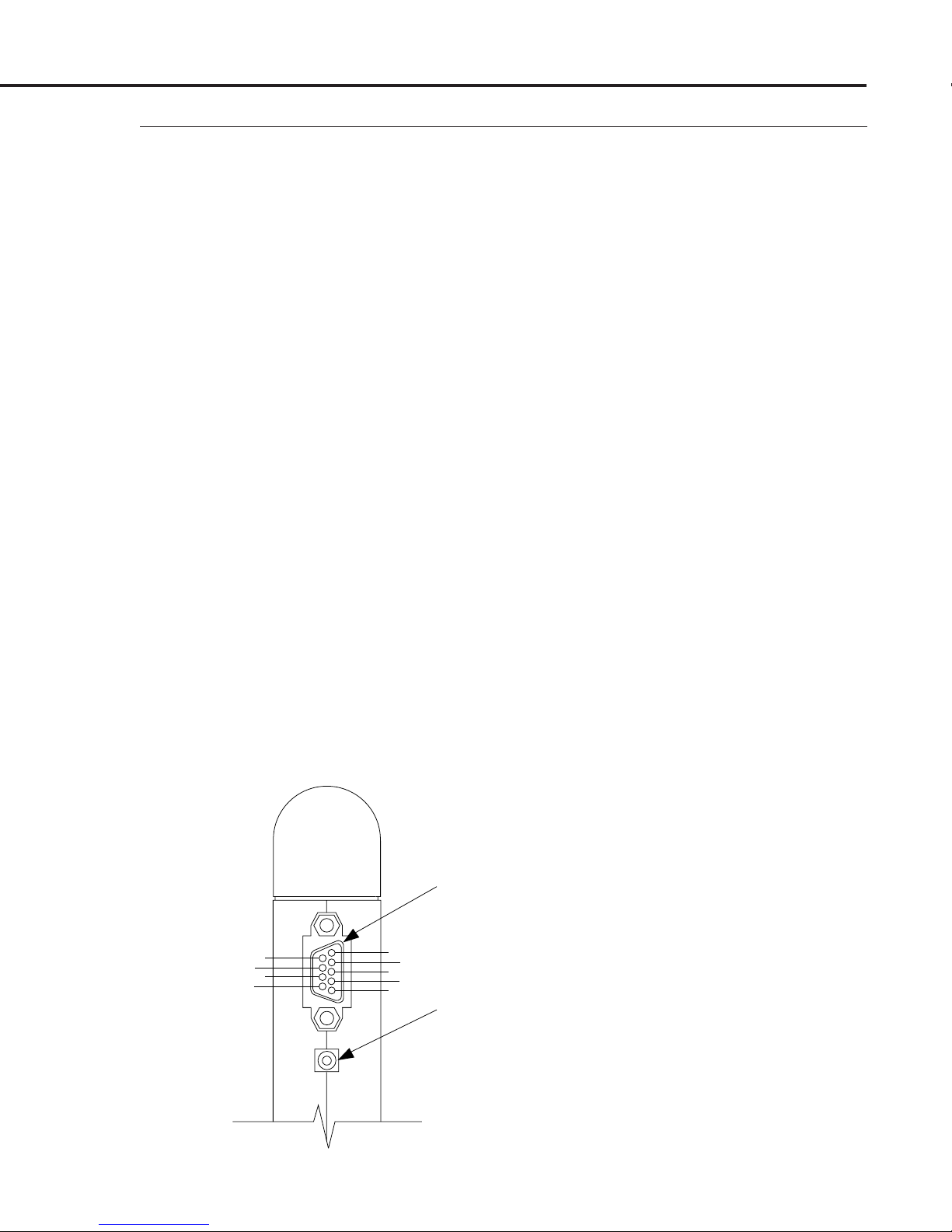

The standard MAS is provided with a 9-pin “D” sub type connector

located on the side of the MAS enclosure as shown in Figure 2-2.

The pin numbers for this “D” connector are also shown in Figure 22, and the pin assignments are given in Table 2-1 on the next page.

The output signal is obtained from the 9-pin “D” connector. A 0 to

5 VDC output signal linearly proportional to gas mass flow rate is

standard. A 4-20 mA current loop signal is optionally available.

The mating connector is included.

2.5

Electrical

Connections

2.5.1

9-Pin “D”-Connector

Pin Assignments

When the MAS is configured for a remote display, connections are

made via the 9-pin “D” connector. Power connections for the

display and transducer are shared in this mode unless the accessory

MAS-5000 power supply is used.

“D” CONNECTOR

7

8

9

6

1

2

3

4

5

DC POWER JACK

Figure 2-2

“D” Connector and DC

Power Jack Location and

Number Assignments

Page 11

Page 13

MAS Instruction Manual

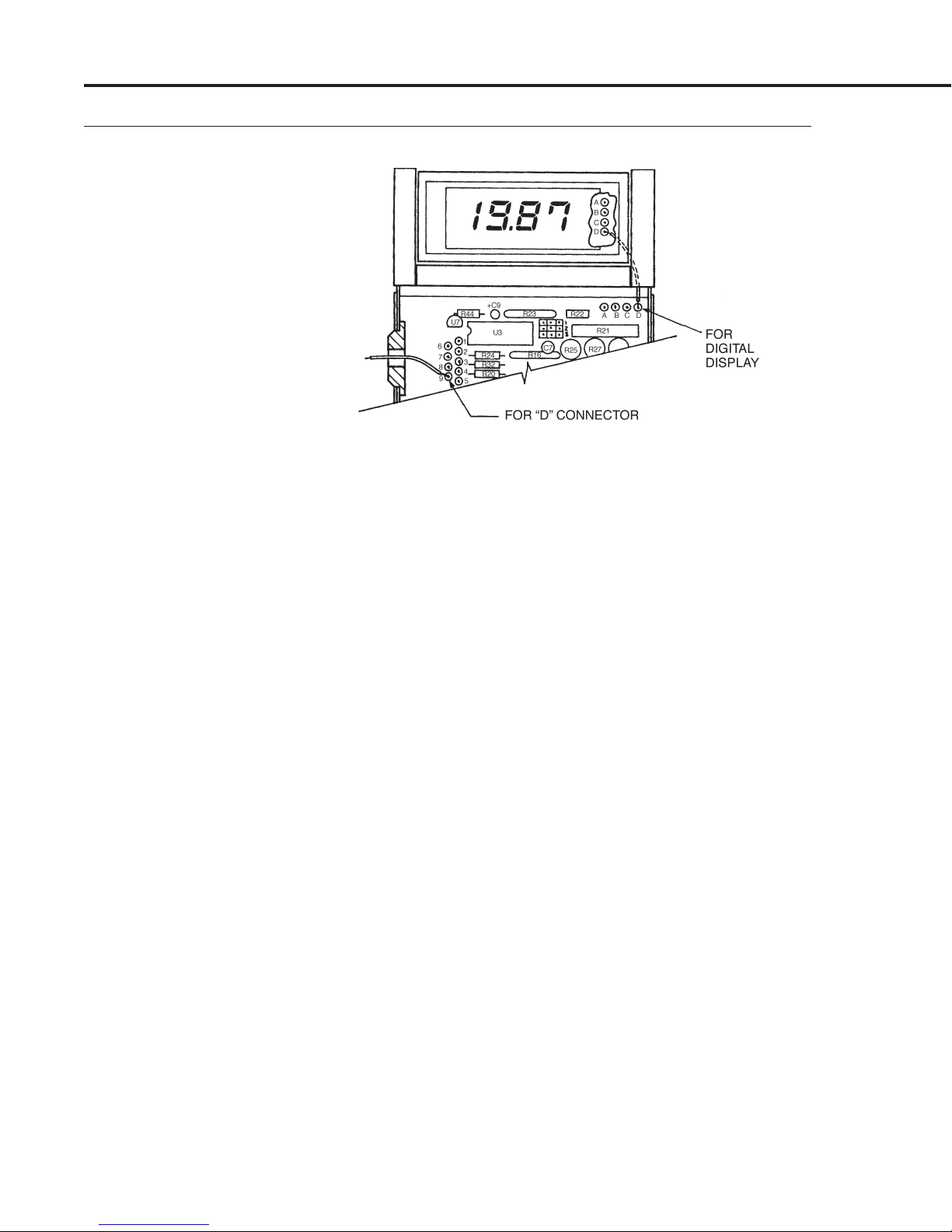

Figure 2-3

Printed Circuit Board

Input/Output Solder Pad

Assignments (wires shown

are typical)

Table 2-1

The following connection points can be made through the “D”

connector or, in OEM applications, made through the circuit board

solder pad connections.

The display pad connections are shown for applications requiring

remote mounting of the digital display. The letters appear on the

display circuit board and are shown in Figure 2-3.

___________________________________________________________

____________________________________________________________

Pin No. Function Display Pad

1 No Connection N/A

2 Signal Common N/A

3 0 to +5 VDC Flow Signal N/A

4 + Power Supply (12 or 24 VDC)

*1, *2

(A)

5 Remote Display Flow Signal (D)

6 Remote Display Reference (C)

7 Power Common (B)

8 4 to 20 mA Return (Common) N/A

____________________________________________________________

9 4 to 20 mA Output N/A

NOTE: the numbers on the connector plug may not agree with the

numbering system as it appears on our Figure 2-2 (on previous

page). It is important to make sure that the proper wires are in the

proper location rather than the proper number. Most connectors

utilize a standard numbering scheme but there are a few that do

not.

The remote display connects through the 9-pin “D” connector only.

The pads A-D in the top right of the main circuit board are for

integral display mounting only.

*1 Power supply voltage must be specified at time of order. Operating a 12 VDC meter at

*2 Do not supply + DC power at the “D” connector while using a power supply at the DC

Page 12

24 VDC will cause damage. Running a 24 VDC meter at 12 VDC will result in faulty

operation.

power jack. Both supplies may be damaged.

Page 14

MAS Instruction Manual

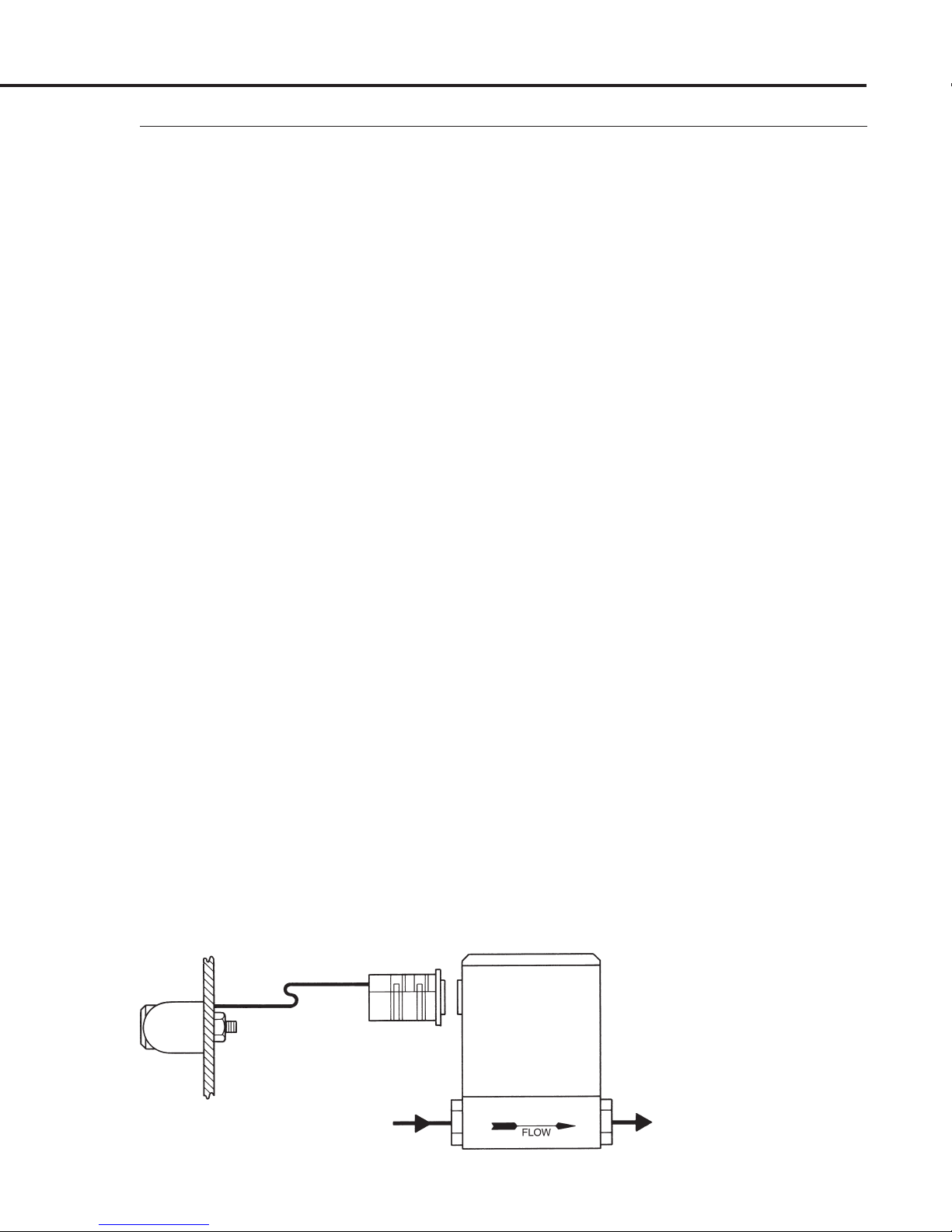

As shown in Figure 2-4, the digital display on your MAS may be

removed and mounted remotely on a front panel. The MAS

transducer is mounted at any convenient location in your system.

Remote installation is not recommended unless you possess the

proper soldering tools and skills to accomplish the job. Remote

installation of the digital display is accomplished by following

these steps:

1. Remove the digital display from your MAS by following the

procedure described in Section 2.5.3, OEM E

TIONS.

LECTRICAL C ONNEC-

2. Gain access to the printed circuit board (PCB) also by following

the procedure in Section 2.5.3, OEM E

LECTRICAL C ONNECTIONS.

3. Very carefully unsolder the four short leads from the PCB to the

display.

4. Gain access to the display circuit board by removing the two

snap rings (No. 36) and opening the “clam shell” display enclosure. Remove the four short wires by carefully unsoldering.

Solder the longer four wires (26AWG, 100 ft. max shielded cable

recommended) to the digital display and solder the other ends

to the appropriate pin numbers of the 9-pin “D” connector as

shown in Figure 2-3 and Table 2-1 (on previous page).

2.5.2

Remote Installation of

Digital Display

5. Reassemble the MAS, replacing the display base (No. 35) with

the Model TP Plain Top Cover (No. 28).

6. Make the necessary plumbing connections to the unit.

7. Mount the digital display as shown in Figure 2-4 referring to the

panel mounting hole dimensions in Section 1.3, S

PECIFICATIONS.

Figure 2-4

Remote Installation of

Digital Display

Page 13

Page 15

MAS Instruction Manual

2.5.3

OEM Electrical

Connections

The OEM version MAS flowmeter has an electrical port (hole) on

its side for electrical input/outputs. This port is just above the

input power jack (see Figure 2-2). Wires entering the MAS via this

port are soldered to the printed circuit board as shown in Figure 2-

3. The solder pad assignments are given in Table 2-1.

How to Gain Access to the MAS’s Printed Circuit Board (PCB):

To gain access to the PCB to make the solder connections, please

refer to the exploded view in Appendix A and follow these simple

steps.

1. If your MAS has the digital display:

(a) First, remove the display by carefully rotating the display

until it hits the top plate. Slowly continue to rotate until this

lever arm action snaps out the two yokes holding the display

(Nos. 30). Use extra caution during this operation as excessive

force will break the delicate wire connections. Carefully move

the display assembly to expose the two screws securing the

display base (No. 35). Do not exert excessive force on the display

while rotating as doing so could crack the LCD display.

(b) Next, remove the two screws (Nos. 21) in the display base

(No. 35) and the two screws (also Nos. 21) in the back of the

enclosure (No. 10).

2.5.4

Using Kobold’s Single,

Dual, and Flo-Box™

Electronics

(c) The top, front, and back sides of the enclosure can now be

removed, (the front slides out towards you and perpendicular to

the flow path) exposing the PCB.

2. If your MAS does not have the digital display:

(a) Remove the label (No. 29) from the plain top cover (No. 28)

to expose the two screws (Nos. 21).

(b) Then follow steps 1(b) and 1(c) above.

To reassemble, just reverse the process.

For applications requiring flow totalization or alarms simply

order the optional Model EC-( ) cable to connect to the rear panel

of Kobold Instruments’ Single-Channel, Dual-Channel, or FloBox (1-5 Channels) Electronics. The Kobold electronics will provide

you with a selectable digital readout for each channel, input power,

high, low, or window alarms, and optional flow totalization.

Page 14

Page 16

MAS Instruction Manual

Quick operating instructions are given on the first page of this

manual.

Following are important notes and comments regarding the Quick

Operating Instructions.

NOTE 1 R

EFERENCING THE FLOW RATE TO OTHER TEMPERATURE AND

PRESSURE CONDITIONS:

The gas flow rate output of your MAS is referenced to “standard”

conditions of 21°C (70°F) and 760 mm of mercury (1 atmosphere),

unless you have specified otherwise. Be sure you know the reference

conditions of your MAS, because it may make a difference if you are

comparing the output of the MAS with another type of flow meter.

For example, the output reading of the MAS will be approximately

7% lower if it is referenced to 0°C rather than 21°C. Appendix B

shows how to convert the flow rate output of your MAS to other

standard conditions and how to find the flow rate referenced to the

actual temperature and pressure conditions in the pipe where your

MAS is located.

NOTE 2 A

CCURACY:

The standard accuracy of the MAS is ±1.5% of full scale. The ±1.5%

of full scale accuracy means the 0-5 VDC output signal is accurate

to within ±0.1 VDC, and the 4-20 mA output is accurate to within

±0.4 mA. This means, for example, that the output signal for zero

flow can be as much as ± 0.1 VDC or ±0.4 mA. Please note if you get

an output signal at zero flow (as long as it is within either of these

two ranges) it does not mean your MAS is malfunctioning. For

MAS’s with the digital readout, the accuracy is simply 1.5% times

the full scale flow rate listed on your MAS’s front label. For

example, if your full scale is 10 SLM, the digital readout will be

accurate to ±0.2 SLM, and the reading at zero flow may be as much

as ±0.2 SLM and still be within the stated accuracy specification.

3

OPERATION

3.1

Quick Operating

Instructions

3.2

Notes to Operating

Instructions

NOTE 3 O

VERRANGING:

If the flow rate exceeds the full scale range listed on your MAS’s

front label, the output signal and digital display (if you have it) will

read a higher value.

The MAS has not been calibrated for overranged flows and probably

will be both non-linear and inaccurate. If the supply voltage is only

12 VDC, the overranged reading may only exceed the full scale

reading by 10% maximum. If the supply voltage is higher, such as

with the 24 VDC option, then the output can exceed full scale by as

much as 50%, or more. If you have the digital display, the display

can not exceed the four digits 1999. If the flow rate exceeds 1999 the

Page 15

Page 17

MAS Instruction Manual

right most digits will blank and only the left-hand “1” will appear

on the display.

Overrange conditions are indicated by the display and/or output

going to a high level, above the full scale range. After the overrange

condition has been removed, it may take several seconds for the

MAS to recover and resume normal operation. This will not harm

the instrument.

NOTE 4 O

PTIONAL 4-20 mA OUTPUT S IGNAL:

The 4-20 mA output signal current flows from the 4-20 mA output

pin on the “D” connector through the load (50 to 500 ohms) to

ground (see Section 2.5.1, 9-P

IN “D” CONNECTOR P IN A SSIGNMENTS).

Figures 3-1 and 3-2 illustrate single and multiple installations

with current loop outputs.

NOTE 5 Z

ERO AND SPAN ADJUSTMENTS:

The zero and span potentiometers are accessed through marked

ports on the right side of your MAS. If your zero output is more than

±1.5% of full scale, you may adjust the zero potentiometer when

you are absolutely certain that you have zero flow.

Since the output does not indicate negative numbers, it is necessary

to adjust down from a slightly positive reading. Slowly rotate the

zero pot clockwise until a positive reading is indicated. To complete

the zero adjustment, slowly turn the pot counterclockwise until

zero is reached.

Normally, span adjustments are not made unless you areNormally, span adjustments are not made unless you are

Normally, span adjustments are not made unless you are

Normally, span adjustments are not made unless you areNormally, span adjustments are not made unless you are

calibrating your MAS, as described in Section 5. calibrating your MAS, as described in Section 5.

calibrating your MAS, as described in Section 5. The span

calibrating your MAS, as described in Section 5. calibrating your MAS, as described in Section 5.

adjustment should not be used unless you have a known precise

non-zero flow rate that you wish to match.

NOTE 6 A

Unless specified otherwise, your MAS has been calibrated for

installation with the flow direction in the horizontal plane (±15°)

with the enclosure facing upward. If your actual installation

orientation is different, you will have to make a small zero

adjustment.

Page 16

TTITUDE:

Page 18

MAS Instruction Manual

Figure 3-1

Single Unit 4-20 Hookup

Figure 3-2

Multiple Installation

4-20 Hookup

Page 17

Page 19

MAS Instruction Manual

4

MAINTENANCE

4.1

General Statement

4.2

Flow Path Cleaning

Your MAS essentially requires no maintenance and has no regular

maintenance schedule, other than periodic flow path cleaning if

the gas is dirty. Calibrations may be scheduled once or twice

yearly, depending on the accuracy to be maintained, or as needed.

It is recommended that your MAS be returned to KoboldIt is recommended that your MAS be returned to Kobold

It is recommended that your MAS be returned to Kobold

It is recommended that your MAS be returned to KoboldIt is recommended that your MAS be returned to Kobold

Instruments if cleaning, repair, or recalibration are needed.Instruments if cleaning, repair, or recalibration are needed.

Instruments if cleaning, repair, or recalibration are needed.

Instruments if cleaning, repair, or recalibration are needed.Instruments if cleaning, repair, or recalibration are needed.

This is usually your most cost-effective and reliableThis is usually your most cost-effective and reliable

This is usually your most cost-effective and reliable

This is usually your most cost-effective and reliableThis is usually your most cost-effective and reliable

alternative.alternative.

alternative.

alternative.alternative.

The flow path (wetted parts) of the MAS are 5% glass-filled

Polyamide 6/6; 316 stainless steel (sensor tub e); and FKM “O”-rings

(standard).

CAUTION! IF YOU WISH TO CLEAN YOUR MAS PURGECAUTION! IF YOU WISH TO CLEAN YOUR MAS PURGE

CAUTION! IF YOU WISH TO CLEAN YOUR MAS PURGE

CAUTION! IF YOU WISH TO CLEAN YOUR MAS PURGECAUTION! IF YOU WISH TO CLEAN YOUR MAS PURGE

IT THOROUGHLY BEFORE DISCONNECTING FROM THEIT THOROUGHLY BEFORE DISCONNECTING FROM THE

IT THOROUGHLY BEFORE DISCONNECTING FROM THE

IT THOROUGHLY BEFORE DISCONNECTING FROM THEIT THOROUGHLY BEFORE DISCONNECTING FROM THE

GAS LINE WHEN TOXIC OR CORROSIVE GASES AREGAS LINE WHEN TOXIC OR CORROSIVE GASES ARE

GAS LINE WHEN TOXIC OR CORROSIVE GASES ARE

GAS LINE WHEN TOXIC OR CORROSIVE GASES AREGAS LINE WHEN TOXIC OR CORROSIVE GASES ARE

USED. NEVER RETURN AN MAS TO KOBOLDUSED. NEVER RETURN AN MAS TO KOBOLD

USED. NEVER RETURN AN MAS TO KOBOLD

USED. NEVER RETURN AN MAS TO KOBOLDUSED. NEVER RETURN AN MAS TO KOBOLD

INSTRUMENTS OR ANY OTHER REPAIR ORINSTRUMENTS OR ANY OTHER REPAIR OR

INSTRUMENTS OR ANY OTHER REPAIR OR

INSTRUMENTS OR ANY OTHER REPAIR ORINSTRUMENTS OR ANY OTHER REPAIR OR

CALIBRATION FACILITY WITHOUT FULLYCALIBRATION FACILITY WITHOUT FULLY

CALIBRATION FACILITY WITHOUT FULLY

CALIBRATION FACILITY WITHOUT FULLYCALIBRATION FACILITY WITHOUT FULLY

NEUTRALIZING ANY TOXIC GASES TRAPPED INSIDE.NEUTRALIZING ANY TOXIC GASES TRAPPED INSIDE.

NEUTRALIZING ANY TOXIC GASES TRAPPED INSIDE.

NEUTRALIZING ANY TOXIC GASES TRAPPED INSIDE.NEUTRALIZING ANY TOXIC GASES TRAPPED INSIDE.

4.2.1

Inlet and Outlet Screen

4.2.2

Laminar Flow Element

(LFE)

Please refer to the exploded drawing of the MAS transducer in

Appendix A when using the following procedures. All cleaning of

the flow path can be accomplished with Freon™, alcohol, or any

cleaner safe for the listed materials.

Remove inlet and outlet fittings (Nos. 13), pull out the LFE holddowns (Nos. 12) and either replace or clean the inlet and outlet

screens (Nos. 14).

Remove the inlet and outlet fittings as in Section 4.2.1, I

NLET AND

OUTLET S CREEN. The LFE (either No. 24 or No. 25) has a slightly

tapered shape with the larger diameter upstream (on the inlet

side). To remove the LFE for cleaning, simply push it out the inlet

side from the outlet side using a blunt object which does not mar

the flow channels. A

3

/8" (9 mm) nut driver is perfect for the job.

When cleaning, be sure to carefully clean all active flow channels

in the LFE.

IMPORTANT:IMPORTANT:

IMPORTANT: When reinstalling the LFE it is of utmost

IMPORTANT:IMPORTANT:

importance to press it in the correct distance. Refer to Figure 4-1

for the correct distance.

Page 18

Page 20

MAS Instruction Manual

.60

(15.24)

INLET

.85

(21.59)

(DIMENSIONS IN MILLIMETERS IN PARENTHESES)

CAUTION! Opening the sensor cavity will shift calibra-CAUTION! Opening the sensor cavity will shift calibra-

CAUTION! Opening the sensor cavity will shift calibra-

CAUTION! Opening the sensor cavity will shift calibra-CAUTION! Opening the sensor cavity will shift calibration.tion.

tion.

tion.tion.

DIMENSIONS IN INCHES

.61

(15.49)

OUTLET

.90

(22.86)

Do not remove the PCB Bracket (No. 7) unless it is absolutely

necessary to gain access to the sensor cavity. Doing so will shift

the calibration more than 1.5%. The remaining parts of the flow

path are disassembled as shown in the exploded view in Appendix

A. Note the position of the insulation blanket before removal and

re-install in the same fashion. After removal, the sensor tube (No.

5) can be cleaned by purging, washing with a solvent, or by rodding

out the 0.031 inch (.787 mm) internal diameter tube with a 0.029-

0.030 inch (.737-.762 mm) outside diameter rod or wire or with the

Model CK Cleaning Stylet available from Kobold Instruments. To

maximize the time response of your MAS, Kobold has designed

the sensor tube with thin walls.

extremely careful not to bend the sensor tube or to mar itsextremely careful not to bend the sensor tube or to mar its

extremely careful not to bend the sensor tube or to mar its

extremely careful not to bend the sensor tube or to mar itsextremely careful not to bend the sensor tube or to mar its

inlet or outlet edges.inlet or outlet edges.

inlet or outlet edges.

inlet or outlet edges.inlet or outlet edges.

Therefore, when cleaning, beTherefore, when cleaning, be

Therefore, when cleaning, be

Therefore, when cleaning, beTherefore, when cleaning, be

Figure 4-1

Proper LFE Location

Within The Flow Body

4.2.3

Sensor Tube

It is important when reinstalling the sensor to make sure that no

torque is imparted on the sensor tube. Torque can be eliminated

by using a good quality oxygen compatible grease on the sensor

sealing “O”-rings. The sensor assembly should slide freely into

the cavity flanges without having to twist it. Twisting will impart

undesirable torque on the sensor and could lead to long term

shifting of the zero value. Also, take

disturb or unravel the sensor windings.

EXTREMEEXTREME

EXTREME care to not

EXTREMEEXTREME

Page 19

Page 21

MAS Instruction Manual

5

FLOW

CALIBRATION

5.1

General Flow

Calibration Procedure

5.2

Recalibration Over the

Same Flow Range

Flow calibration of your MAS requires a calibration standard of at

least double accuracy and preferably an order of magnitude better.

NOTE: The factory calibration of your unit was done to MIL-STD45662 A, which has a 4:1 accuracy requirement. Most calibrations

can be done using dry nitrogen and the “K”-factors and gas tables

given in Appendix D. The standard 1.5% calibration of your MAS

is best accomplished with the Kobold Instruments’ Series 100 CalBench™.

Flow recalibration is performed by using the following procedure.

Please refer to the electrical schematics in Appendix B. Calibration

checks and minor adjustments to the zero and full scale may be

made via the access ports in the side of the enclosure. If the

linearity needs adjustment (as may be required when installing a

different laminar flow element bypass to change the range), go to

STEP 4 through 8. If linearity does not need adjustment, complete

only STEPS 1 through 3.

STEP 1 W

ARM-UP: Plug in the MAS to be calibrated and allow at

least 15 minutes warm-up time before attempting any adjustments.

STEP 2 Z

ERO A DJUST: Slide open the zero and span access ports on

the side of your MAS. Be careful to gently slide open and not bend

back access port covers, as bending back may break covers. Using

a voltmeter connected to the meter output pins, adjust the zero

potentiometer (R5) for zero flow (4 mA for 4-20 mA outputs).

STEP 3 C

HECK F ULL S CALE: Generate the full scale flow using a

metering valve in line with the MAS under test. Compare the

indicated flow rate with the flow standard reading. If they agree to

within ±10%, adjust the span potentiometer (R21) for exact

agreement.

If the readings do not agree within ± 10%, attempt to determine the

cause of disagreement. Possibilities are:

a) Partially clogged or dirty sensor tube

b) Wrong or improper use of “K” factor

c) Wrong or improper correction for temperature and pressure

d) Leaks in the system or in the MAS

e) Replacement of parts in the flow path do not exactly match the

original parts

Page 20

Page 22

This completes the calibration procedure. To adjust linearity, go to

STEP 4.

MAS Instruction Manual

STEP 4 A

DJUSTING LINEARITY: First gain access to the printed

circuit board inside the MAS enclosure by using the procedure

described in Section 2.5.3, OEM E

LECTRICAL C ONNECTIONS. Orient

the meter so that the component side of the circuit board is facing

you. Plug in the meter and allow it to warm up for at least 15

minutes.

STEP 5 Z

ERO A DJUST: Connect a voltmeter to the meter output pins

and adjust the zero potentiometer (R5) for zero volts at zero flow (4

mA for 4-20 mA outputs).

___________________________________________________________________________________

_________________________________________________________________________________

INC. DEC. INC. DEC.

J1 0 0 0 J1 [XXXXX] 0 Adjust R25 (50%)

J2 0 0 0 J2 0 [XXXXX] Adjust R27 (75%)

J3 0 0 0 J3 [XXXXX] 0 Adjust R29 (100%)

Linearizer Jumper Array Jumpers Installed

_________________________________________________________________

Linearizer Jumper Array

STEP 6 CALIBRATE 25%: Use the calibration standard to set a flow

rate of 25% of full scale. Adjust the span potentiometer (R21) for

1.25 volts (8 mA for 4-20 mA outputs) at the output of the meter.

Figure 5-1

STEP 7 C

ALIBRATE 50%: Increase the flow rate to 50% of full scale.

If the output is within ± 100 mV, no adjustment is necessary. If the

output is beyond these limits, install a jumper block at J1 in the

appropriate position (increment (INC.) or decrement (DEC.); see

Figure 5-1) and adjust R25 for the proper reading.

STEP 8 C

ALIBRATE 75% AND 100%: Set the flow to 75% of full scale.

If the output is outside the limits set in STEP 7, install a jumper

block in J2 in the proper location and adjust R27 for the correct

reading. Repeat this procedure for 100% flow, using J3 and R9 if

necessary.

NOTE: If the curve being linearized is not monotonic (e.g., jumpers

are in both increment and decrement positions), repeat STEPS 6

through 8 at least one more time.

Page 21

Page 23

MAS Instruction Manual

5.3

Flow Calibration

Over a Different Flow

Range and/or Gas

The procedure for calibrating your MAS over a different flow range

and/or gas is identical to that described in Section 5.2, R

ECALIBRATION

OVER THE S AME F LOW R ANGE, except that the range of the laminar

flow element (LFE) may need changing.

The first step is to determine the equivalent nitrogen flow rate. To

do so, you must first determine your “standard” gas conditions.

21°C (or 70°F) and 760 mm of mercury (1 atmosphere) is standard

for Kobold Instruments. Appendix C is helpful in this regard. You

must then use the K-factor tables in Appendix D.

The next step is to procure from Kobold Instruments the Model EL

Laminar Flow Bypass Set. This set of two patented Model EL

LFE’s covers all ranges from 0-10 SCCM to 0-40 SLM, when the

proper combination of “gates” to the individual laminar flow

channels have been opened (see Section 1.2, P

RINCIPLE OF O PERATION).

The instruction manual for the Model EL LFE’s describes this

procedure in detail.

NOTE: Potentiometer R15 shown in Appendix B is for speed of

response and does not require any adjustment.

Page 22

Page 24

MAS Instruction Manual

When it is suspected that your MAS is not operating correctly, a

few simple checks can be made before dismantling for repair:

1. Make sure there are no leaks in the line.

2. Check that all cables are plugged in and are in good condition.

3. Check that the power supply is in the correct range.

4. Double-check connector pinouts.

This guide is provided to help locate the section of the MAS at

fault. It is not intended to be an all-inclusive repair manual. In the

case of most repairs, your MAS should be returned to the factory

for service.

______________________________________________________________

Possible Corrective

Symptom Cause Action

______________________________________________________________

No output No power Plug in power supply

Clogged sensor Clean or replace sensor

PCB defective Repair or replace PCB

Inlet filter Clean or replace

screen clogged

6

TROUBLE-

SHOOTING

6.1

General

6.2

Troubleshooting Guide

Will not zero Gas leak Find and correct leaks

Application Re-zero meter

requires high

pressure and nonhorizontal mounting

PCB defective Repair or replace

Reads full scale Defective sensor Return to factory

with zero flow for replacement

Gas leak Find and correct leaks

Out of Dirty or clogged Clean or replace sensor

calibration sensor

Change in See “K” factor tables

composition of gas in Appendix D

Gas leak Find and correct leaks

PCB defective Repair or replace

LFE dirty Clean

Inlet filter screen Clean or replace

______________________________________________________________

clogged

Page 23

Page 25

MAS Instruction Manual

Kobold Instruments will provide technical assistance over the

phone to qualified repair personnel. Please call Customer Service

Department, Technical Assistance, (412) 788-2830, Fax (412) 788-

4890. European customers can contact Kobold Messring GmbH for

customer service and technical assistance at 49(0)61-92-29-90,

Fax 49(0)61-92-23-398. Please have your Serial Number and

Model Number when you call.

Page 24

Page 26

MAS Instruction Manual

If your MAS requires servicing or recalibration, please refer to the

following ordering numbers. Kobold’s current Price List gives the

respective prices.

IMPORTANT NOTE: For all servicing and recalibration, please

return the entire MAS flow body to the factory.

R1 Standard Recalibration (1.5%) and Cleaning

R2 Standard Recalibration (1.5%), Cleaning and Repair

R3 Replacement Sensor and Standard Recalibration (1.5%)

If you wish to have Kobold calibrate with a different flow range

and/or gas, please take note of the following.

NOTE 1 F

The standard flow ranges given in Section 1.3, S

for nitrogen at standard conditions of 1 atmosphere and 21°C

(70°F). For a given MAS Flowmeter, the range may vary for other

gases depending on their molecular weight and thermal properties.

NOTE 2 C

Please specify the actual gas you intend to use. If you are using

several gases, inform us and we will give you the required conversion

factors. Unless otherwise specified, “standard” conditions shall be

1 atmosphere pressure and 21°C (70 °F) temperature. For example,

if you require a 0°C (32°F) “standard” temperature, please specify

when ordering.

LOW RANGE:

PECIFICATIONS, are

ALIBRATION:

7

STANDARD

SERVICING AND

RECALIBRATION

Page 25

Page 27

MAS Instruction Manual

Exploded View of MAS Transducers and Parts Lists

APPENDIX A

Page 26

Page 28

MAS Instruction Manual

Aluminum Assembly

High-Flow, MAS-1100/2100

M82-0022

Page 27

Page 29

MAS Instruction Manual

Aluminum Flowbody

High-Flo, MAS-1100/2100

M82–0017–X

Parts List M82-0017–XParts List M82-0017–X

Parts List M82-0017–X

Parts List M82-0017–XParts List M82-0017–X

ITEM:PIN

1 41-0175 Body, 820, Hi-Flow, Al

2 41-0176 Cap. End. 820. High Flow

3 40-0037 Holder. LFE. Mod 820

4 35-0084 Washer, Split, #06

5 35-0326 N u t , Hex. 6-32, SS

*6 35-0174 Rod. Threaded, 6-32 X 5"L

7 42-0098 LFE, Hi-Flow, Mod 820

8 40-0127 Bracket, Mounting, 820H

Page 28

:

DESCRIPTION

:

Page 30

MAS Instruction Manual

MAS Assembly

MAS-1000/2000

M82–0023

Page 29

Page 31

MAS Instruction Manual

Polyamide

Flowbody

MAS-1000/2000

M82–0018 A

Parts List M82-0018–XParts List M82-0018–X

Parts List M82-0018–X

Parts List M82-0018–XParts List M82-0018–X

ITEM:PIN

1 42-0053

2 40-0043

3 31-0001-906

4 42-0105

5 40-0042

6 42-0041

7 31-0001-908

Page 30

:

DESCRIPTION

Body, 820, Black

Screen. Mod 820 (for > 10 SLPM Flows)

O-Ring, FKM 3-906

Adaptor. Numb. Mod 850, 3⁄4-16 to 0.250 FNPT

Screen. Inlet. Mod 820

Hold Down, LFE

O-Ring,FKM, 3-908, Brown

:

Page 32

MAS Instruction Manual

Electronics Enclosure

Sub-Assembly MAS

M82–0019–XXXX B

Page 31

Page 33

MAS Instruction Manual

Parts List M82-0019–XXXXParts List M82-0019–XXXX

Parts List M82-0019–XXXX

Parts List M82-0019–XXXXParts List M82-0019–XXXX

ITEM:PIN

1 42-0033 Encl, 820, Front, White

2 42-0034 Encl, 820, Back, White

*3* 52-0038-11 PCA, 820 Flow Meter: 110/220 VAC; 0-5 VDC

4 42-0038 Bracket, PCB, 820

5 42-0044 Slides, Zero & Span

6 35-0346 Scr, FLH, Phl, #4 x 0.500"L, SLF TPG, Zinc

*7* 42-0052 Cover, Top, Mod 820

*8* 40-0038 Bracket, Adapter, 820 Display to 830 Body

*9* 35-0288 Scr, FLH, Phl. 4-40 X 0.750"L, Type "B" Zinc

10* 82-0021 Display Sub-Assy: 820

11* 35-0024 Scr, Flh, Sch, 4-40 X 0.375"L

12* 55-0018 Conn, Kit, "DCD" Vend# TGA-46-00633

13* 35-0075 Scr, Pnh. Phl. 4-40 X 0.250"L

14* 35-0037 Washer, Split, #04

15* 39-0211 D-Connector Cover, 9-Pin

*Change with application, consult factory for specifics.

Page 32

:

DESCRIPTION

:

Page 34

MAS Instruction Manual

Sensor Compartment

Assembly: MAS

M82–0020–X B

Page 33

Page 35

MAS Instruction Manual

Parts List M82-0020–XParts List M82-0020–X

Parts List M82-0020–X

Parts List M82-0020–XParts List M82-0020–X

ITEM:PIN

1 41-0207 Plate, Sensor Mounting (Die Cast)

*2* 41-0173 Heat Sink (Die Cast)

3 43-0037-01 Sensor, Flow Capillary

4 41-0171 Bushing, Sensor O-Ring (Die Cast)

5 41-0170 Plate, Sensor Ring, 820 (Die Cast)

6 35-0130 Scr, Flh, Phl. 4-40 X 0.250"L

*7* 35-0092 Scr, Pnh, Phl. #4 X 0.562"L, Zinc, Type "B"

*9* 35-0142 Scr, Flh, Phl, #4 X .375 L, Self Tpg, Zinc Type "B"

10* 39-0149 Insulation, Pcf. 1.2 for Sensor Compartment

11* 45-0052 Plate, Sensor Feed Thru Mod 820

*Change with application, consult factory for specifics.

:

DESCRIPTION

:

Page 34

Page 36

MAS Instruction Manual

Stainless Steel Low Flow

Dimensional Drawing

Side View

Bottom View

Tables

1

/4" O.D. Tube

Fitting Type VCO VCR

(9/16"-18 Thd.) Comp. (male) (male)

Dim.“L” 4.8 5.0 4.8

Outlet End View

Page 35

Page 37

MAS Instruction Manual

Stainless Steel Medium Flow

Dimensional Drawing

Tables

Flow Range 0-20 0-30 0-50

SLM

Tube O.D.,1/4", 3/8"1/4", 3/8"1/4", 3/8"

Inches

Flow Range, 0.706 1.06 1.77

SCFM

Tube O.D.,3/8"3/8"

Inches

Fitting Type1/4"1/4" VCO1/4" VCR

(9/16"-18 Thd.) Comp. (male) (male)

Dim. “L” 6.27 6.01 6.13

Fitting Type3/8"3/8" VCO3/8" VCR

(9/16"-18 Thd.) Comp. (male) (male)

Dim. “L” 6.39 5.25 6.43

3

/8"

Side View

Bottom View

Outlet End View

Page 36

Page 38

MAS Instruction Manual

Stainless Steel High Flow

Dimensional Drawing

Side View

Bottom View

Tables

Flow Range 0-100 0-200 0-300

SLM

Tube O.D.,3/8", 1/2"3/8", 1/2"1/2"

Inches

Flow Range, 3.53 7.06 10.6

SCFM

Tube O.D.,1/2"

Inches

Fitting Type3/8"3/8" VCO3/8" VCR

(3/4"-16 Thd.) Comp. (male) (male)

Dim. “L” 11.36 11.81 11.93

Fitting Type1/2"— —

(3/4"-16 Thd.) Comp.

Dim. “L” 11.36 — —

1

/2"1/2"

Outlet End View

Page 37

Page 39

MAS Instruction Manual

APPENDIX B

Conversion of Flow

Rate to Other T and P

Conditions

The flow rate of your MAS is referenced to certain “standard”

conditions of temperature and pressure. Unless otherwise specified

in your order, these standard conditions are 21°C (70°F) and 760

mm of mercury (1 atmosphere). If you wish to convert to other

“standard” conditions or to find the “actual” conditions in the pipe

where your MAS is installed, use the following relationship:

P

T

2

=

2

1

P

2

Q

1

T

1

(1)

Q

()

= Refers to the standard conditions with which your MAS was

1

calibrated,

= Refers to the new standard conditions or to the actual

()

2

temperature and pressure conditions in the pipe,

= The gas mass flow rate referenced to the calibrated stan-

Q

1

dard conditions (SCCM or SLM),

= The gas mass flow rate referenced to the new standard or

Q

2

actual conditions (SCCM or SLM–“S” means “standard”;

ACCM or ALM–“A” means “actual”),

P = Absolute pressure (kg/cm2 or psia), and

T = Absolute temperature (°D or °R) °K = °C + 273; °R = °F +

460)

EXAMPLE 1 C

HANGING “STANDARD” CONDITIONS:

If your MAS has a flow rate reading of 10.00 SLM and was

calibrated at standard conditions of 70°F (21°C) 1 atmosphere

(14.7 psia) and if you wish to convert this reading to standard

conditions of 32°F (0°C) and 1 atmosphere, then you would use

Equation (1) as follows:

14 7

.

Q

=

2

14 7

.

460 + 32

460 + 70

(10.00) = 9.28 SLM

So, you can see that the flow rate referenced to 0°C will be

approximately 7% lower than when referenced to room conditions

of 21°C.

EXAMPLE 2 F

INDING THE “ACTUAL” FLOW RATE:

If the flow rate and calibrated standard conditions are as given in

Example 1 and you wish to find the actual flow rate at 100°F and

30 psig, then you would use Equation (1) as follows:

14 7

Q

=

2

.

14 7 30

+

.

460 + 100

460 + 70

(10.00) = 3.47 ALM

Page 38

Page 40

MAS Instruction Manual

The following tables provide K-factors and thermodynamic

properties of gases commonly used with mass flow controllers and

meters. The purpose of these tables is two-fold:

1. Calibrating an “actual” gas with a reference gas. This is

particularly useful if the actual gas is not a common gas or if it

is a so-called “nasty” gas (i.e., toxic, flammable, corrosive, etc.).

2. Interpreting the reading of a flow meter or flow controller

which has been calibrated with a gas other than the actual gas.

In applying the tables, the following fundamental relationship is

used:

Q

1/Q2

= K1/K

2

(1)

Where:

Q = The volumetric flow rate of the gas referenced to standard

conditions of 0°C and 760 mm Hg (SCCM or SLM),

K = The “K” factor defined in equation (6),

()

= Refers to the “actual” gas, and

1

()

= Refers to the “reference” gas

2

The K-factor is derived from the first law of thermodynamics

applied to the sensor tube, as described in Section 1.2, P

RINCIPLE OF

OPERATION:

˙

∆

C T

P

N

(2)

where:

H

m

=

APPENDIX C

K Factors and

Gas Tables

For a Single Gas

H = The constant amount of heat applied to the sensor tube,

˙

m

= The mass flow rate of the gas (gm/min),

C

= The coefficient of specific heat of the gas (Cal/gm); CP is given

P

in the Tables (at 0 °C),

∆T = The temperature difference between the downstream and

upstream coils,

N = A correction factor for the molecular structure of the gas

given by the following table:

________________________________________________________________

Number of Atoms in the Gas Molecule N

______________________________________________________________

Monatomic 1.040

Diatomic 1.000

Triatomic 0.941

Polyatomic 0.880

______________________________________________________________

Page 39

Page 41

MAS Instruction Manual

˙

The mass flow rate,

m

, can also be written as:

˙

m

= ρQ (3)

where:

ρ = The gas mass density at standard conditions (g/1); ρ is given

in the tables (at 0 °C, 760 mm Hg).

Furthermore, the temperature difference, DT, is proportional to

the output voltage, E, of the mass flow meter, or

∆T = aE (4)

where:

a = A constant.

If we combine Equations (3) and (4), insert them into Equation (2),

and solve for Q, we get:

Q = (bN/ρC

) (5)

P

where:

b = H/aE = A constant if the output voltage is constant.

For our purposes, we want the ratio of the flow rate, Q

actual gas to the flow rate of a reference gas, Q

, to produce the

2

, for an

1

same output voltage in a particular mass flow meter or controller.

We get this by combining Equations (1) and (5):

Q

= K1/K2 = (N

1/Q2

1/ρ2CP2

) (6)

Please note that the constant b cancels out. Equation (6) is the

fundamental relationship used in the accompanying tables. For

convenience, the tables give “relative” K-factors, which are the

ratios K

In the third column of the tables, the relative K-factor is K

K

references

, instead of the K-factors themselves.

1/K2

actual

, where the reference gas is a gas molecularly equivalent

to the actual gas. In the fourth column, the relative K-factor is

/KN2, where the reference gas is the commonly used gas,

K

actual

nitrogen (N

). The remaining columns give CP and r, enabling you

2

to calculate K1/K2 directly using Equation (6). In some instances,

K1/K2 from the tables may be different from that which you

calculate directly. The value from the tables is preferred because

in many cases it was obtained by experiment.

/

Kobold calibrates every MAS mass flowmeter and controller with

primary standards using the actual gas or a molecularly equivalent

reference gas. The calibration certificate accompanying your MAS

Page 40

Page 42

will cite the reference gas used. When a reference gas is used, the

actual flow rate will be within 2-4% of the calculated flow rate.

EXAMPLE 1:

A MAS is calibrated for nitrogen (N2), and the flow rate is 1000

SCCM for a 5.000 VDC output signal. The flow rate for carbon

dioxide at a 5.000 VDC output is:

//,

QQ KK

CO N CO N

22 2 2

0 74 1 000 1000 740

./.

=

Q SCCM

CO

(

2

=

)

or

=

EXAMPLE 2:

A MAS is calibrated for hydrogen (H

), and the flow rate is 100

2

SCCM for a 5,000 VDC output signal. The flow rate for nitrous

oxide (N

0) is found as follows:

2

QQ K K

//,

NH N H

00

22 2 2

0 71 1 01 100 70 3

=

Q SCCM

N0

2

(

=

./. .

=

)

or

Please note that the K-factors relative to nitrogen must be used in

each case.

MAS Instruction Manual

EXAMPLE 3:

We want a MAS to be calibrated for use with dichlorosilane

(SiH

preferred reference gas Freon-14 (CF

) at a 100 SCCM full scale flow. We wish to use the

2CL2

). What flow of CF4 must we

4

generate to do the calibration?

QQKK

SiH CL CF SiH CL CF

//

24224

2

100 0 869

== SCCM

Q

100 0 869 115

CF

4

=

Q

CF

=

4

/.

/.

Equation (6) is used for gas mixtures, but we must calculate N/rC

for the mixture. The equivalent values of r, CP, and N for a dual gas

mixture are given as follows:

The equivalent gas density is:

˙/˙˙

mm mm

ρρ ρ=

(

+

)

TT12

12

(

˙

/

)

(7)

where:

˙˙˙

mmm

=+=

T

12

Total mass flow rate (gm/min),

()1= Refers to gas #1, and

()

= Refers to gas #2.

2

P

For Dual-Gas Mixtures

The equivalent specific heat is:

C

= F1 CP1 + F2 C

P

P2

Page 41

Page 43

MAS Instruction Manual

where:

˙

Fm m

=

(

111

F

The equivalent value of N is:

The equivalency relationships for r, CP, and N for mixtures of more

than two gases have a form similar to the dual-gas relationship

given above.

IMPORTANT NOTE ABOUT K-FACTORS:IMPORTANT NOTE ABOUT K-FACTORS:

IMPORTANT NOTE ABOUT K-FACTORS:

IMPORTANT NOTE ABOUT K-FACTORS:IMPORTANT NOTE ABOUT K-FACTORS:

Please note that if you have a mass flowmeter calibrated for a gas

such as methane and wish to use the K-factors to measure a gas

such as air, that the inaccuracy of the measurement can range from

±5 to 10%. The use of K-factors is, at best, only a rough approximation

and should not be used in applications that require better than ±

5 to 10% accuracies.

It should also be noted that certain gases, in similar “families,” will

work exceptionally well with K-factors; however, those instances

are only true when similar thermal properties of the gas are

present.

˙

mm

=

(

2

22

˙

/

and

ρρ

)

(

)

T

˙

/

ρρ

)(

.

)

T

˙/˙˙

NmmN mmN

=

(

˙

/

+

)

TT

1122

(

)

Page 42

Page 44

MAS Instruction Manual

Actual Gas Chemical Ref. KFactor KFactor Cp Density Elastomer

Acetylene C2H

Air N

Allene (Propadiene) C3H

Ammonia NH

Symbol Gas Rel. to Relative (Cal/g) (g/ l ) O-Ring* Valve

2

4

3

Ref. Gas N2 @ 0°C Seat

N

N

N

.58 .4036 1.162

2

1.00 .240 1.293

2

..43 .352 1.787 KR

2

.73 .492 .760 NEO NEO

2

Argon Ar Ar 1.000 1.45 .1244 1.782

Arsine AsH

Boron Trichloride BCl

Boron Trifluoride BF

Bromine Br

Boron Tribromide Br

Bromine Pentafluoride BrF

Bromine Trifluoride BrF

Bromotrifloromethane CBrF

3

3

3

2

3

5

3

N

N

N

N

N

N

N

N

3

.67 .1167 3.478 KR

2

.41 .1279 5.227 KR KR

2

.51 .1778 3.025 KR

2

.81 .0539 7.130

2

.38 .0647 11.18 KR

2

.26 .1369 7.803 KR

2

.38 .1161 6.108 KR

2

.37 .1113 6.644

2

(Freon-13 B1)

1,3-Butadiene C4H

Butane C4H

1-Butane C4H

6

10

8

2-Butane C4H8 CIS N

2-Butane C4H8 TRANS N

Carbon Dioxide CO

Carbon Disulfide CS

2

2

Carbon Monoxide CO N

Carbon Tetrachloride CCl

Carbon Tetrafluoride CF

4

4

N

N

N

N

N

N

N

.32 .3514 2.413

2

.26 .4007 2.593 NEO KR

2

.30 .3648 .2.503 NEO KR

2

.324 .336 2.503 NEO KR

2

.291 .374 2.503

2

.74 .2016 1.964

2

.60 .1428 3.397

2

1.00 .2488 1.250

2

.31 .1655 6.860 KR

2

.42 .1654 3.926 KR

2

(Freon-14)

Carbonyl Fluoride COF

Carbonyl Sulfide COS N

Chlorine CL

Chlorine Trifluoride CIF

2

3

Chlorodifluoromethane CHClF

N

2

N

N

N

2

.54 .1710 2.945

2

.66 .1651 2.680

2

.86 .114 3.163 KR

2

.40 .1650 4.125 KR

2

.46 .1544 3.858 KR

2

(Freon-22)

Chloroform CHCI

Chloropentafluoroethane C2CIF

N

3

N

5

.39 .1309 5.326 KR

2

.24 .164 6.892 KR

2

(Freon-115)

Chlorotrifluromethane CCIF

N

3

.38 .153 4.660 KR

2

(Freon-13)

Cyanogen C2N

2

Cyanogen Chloride CICN N

Cychlopropane C3H

Deuterium D

Diborane B2H

5

2

6

Dibromodifluoromethane CBr2F

Dibromethane N

Dichlorodifluoromethane CCI2F

N

N

N

N

N

2

N

2

.61 .2613 2.322

2

.61 .1739 2.742 KR

2

.46 .3177 1.877 KR

2

1.00 .1722 1.799

2

.44 .508 1.235 KR

2

.19 .15 9.362 KR

2

.47 .075 7.76 KR

2

.35 .1432 5.395 KR

2

(Freon-12)

Dichlorofluoromethane CHCl2FN2.42 .140 4.952 KR

(Freon-21)

Dichloromethylsilane (CH3)2SiCl2N

Dichlorosilane SiH2Cl

Dichlorotetrafluoroethane C2Cl2F

2

4

N

N

.25 .1882 5.758 KR

2

.40 .150 4.506 KR

2

.22 .1604 7.626 KR

2

(Freon-114)

1,1-Difluoroethylene C2H2F

N

2

.43 .224 2.857 KR

2

(Freon-1132A)

Dimethylamine (CH3)2NH N

.37 .366 2.011 KR

2

DRAWING NO. REV. SHEET

99-0224 D 1 of 3

12/95

*NOTE: If no O-Ring is

specified then O-Ring

to be used is FKM.

Page 43

Page 45

MAS Instruction Manual

DRAWING NO. REV. SHEET

99-0224 D 2 of 3

*NOTE: If no O-Ring is

specified then O-Ring to

be used is FKM.

Actual Gas Chemical Ref. KFactor KFactor Cp Density Elastomer

12/95

Symbol Gas Rel. to Relative (Cal/g) (g/ l ) O-Ring* Valve

Ref. Gas N2 @ 0°C Seat

Dimeyl Ether (CH3)2ON2.39 .3414 2.055 KR

2,2-Dimethylpropane C3H

Ethane C2H

12

6

N

N

.22 .3914 3.219 KR

2

.50 .4097 1.342

2

Ethanol C2H6ON2.39 .3395 2.055 KR

EthylAcetylene C4H

6

Ethyl Chloride C2H5CI N

Ethylene C2H

4

Ethylene Oxide C2H4O) N

Fluorine F

2

Fluoroform (Freon-23) CHF

N

N

N

N

3

.32 .3513 2.413 KR

2

.39 .244 2.879 KR

2

.60 .1365 1.251

2

.52 .268 1.965 KR

2

.980 .1873 1.695 KR

2

.50 .176 3.127 KR

2

Freon-11 CCI3FN2.33 .1357 6.129 KR

Freon-12 CCI2F

Freon-13 CCIF

Freon-13 B1 CFrF

Freon-14 CF

4

N

2

N

3

N

3

N

.35 .1432 5.395 KR

2

.38 .153 4.660 KR

2

.37 .1113 6.644 KR

2

.42 .1654 3.926

2

Freon-21 CHCI2FN2.42 .140 4.952 KR

Freon-22 CHCIF

Freon-113 CCI2FCCIF2N

Freon-114 C2Cl2F

Freon-115 C2ClF

Freon-C318 C4F

6

Germane GeH

Germanium Tetrachloride GeCL

N

2

N

4

N

5

N

N

4

N

4

.46 .1544 3.858 KR

2

.20 .161 8.360 KR

2

.22 .160 7.626 KR

2

.24 .164 6.892 KR

2

.17 .185 8.397 KR

2

.57 .1404 3.418

2

.27 .1071 9.565 KR

2

Helium He He 1.000 1.454 1.241 .1786

Hexafluoroethane C2F

6

N

.24 .1834 6.157 KR

2

(Freon-116)

Hexane C6H

Hydrogen H

14

2

Hydrogen Bromide HBr N

Hydrogen Chloride HCl N

Hydrogen Cyanide HCN N

Hydrogen Fluoride HF N

Hydrogen Iodide HI N

Hydrogen Selenide H2Se N

N

H

.18 .3968 3.845 KR

2

1.000 1.01 3.419 .0899

2

1.000 .0861 3.610 KR

2

1.000 .1912 1.627 KR KR

2

1.070 .3171 1.206 KR

2

1.000 .3479 .893 KR KR

2

1.000 .0545 5.707 KR

2

.79 .1025 3.613 KR

2

Hydrogen Sulfide H2SN2.80 .2397 1.520 KR

Iodine Pentafluoride IF

5

Isobutane CH(CH3)

Isobutylene C4H

8

N

N

3

N

.25 .1108 9.90 KR

2

.27 .3872 3.593 KR

2

.29 . .3701 2.503 KR

2

Krypton Kr Ar 1.002 1.453 .0593 3.739

Methane CH

4

Methanol CH3OH N

Methyl Acetylene C3H

4

Methyl Bromide CH2Br N

Methyl Chloride CH3Cl N

N

N

.72 .5328 .715

2

.58 .3274 1.429

2

.43 .3547 1.787 KR

2

.58 .1106 4.236

2

.63 .1926 2.253 KR

2

Methyl Fluoride CH3FN2.68 .3221 1.518 KR

Methyl Mercaptan CH3SH N

Methyl Trichlorosilane (CH3) SiCl3N

Molybdenum Hexafluoride MoF

Monoethylamine C2H5NH

Monomethylamine CH3NH

6

2

2

N

N

N

.52 .2459 2.146 KR

2

.25 .164 6.669 KR

2

.21 .1373 9.366 KR

2

.35 .387 2.011 KR

2

.51 .4343 1.386 KR

2

Neon NE Ar 1.006 1.46 .245 .900

Nitric Oxide NO N

Nitrogen N

Nitrogen Dioxide NO

2

2

N

N

.990 .2328 1.339

2

1.000 .2485 1.25

2

.74 .1933 2.052

2

Page 44

Page 46

MAS Instruction Manual

Actual Gas Chemical Ref. KFactor KFactor Cp Density Elastomer

Nitrogen Trifluoride NF

Nitrosyl Chloride NOCl N

Symbol Gas Rel. to Relative (Cal/g) (g / l ) O-Ring* Valve

3

Ref. Gas N2 @ 0°C Seat

N

.48 .1797 3.168 KR

2

.61 .1632 2.920 KR

2

Nitrous Oxide N2ON2.71 .2088 1.964

Octafluorocyclobutane C4F

6

N

.17 .185 8.397 KR

2

(Freon-C318)

Oxygen Difluoride OF

Oxygen O

Ozone O

Pentaborane B5H

Pentane C5HI

2

2

3

9

2

N

.63 .1917 2.406

2

N21.000 .2193 1.427

N

N

N

.446 .3 2.144

2

.26 .38 2.816 KR

2

.21 .398 3.219 KR

2

Perchloryl Fluoride CIO3FN2.39 .1514 4.571 KR

Perfluoropropane C3F

8

Phosgene COCl

Phosphine PH

3

Phosphorous Oxychloride POCl

Phosphorous Pentafluoride PH

Phosphorous Trichloride PCl

Propane C3H

Propylene C3H

Silane SiH

Silicon Tetrachloride SiCl

Silicon Tetrafluoride SiF

Sulfur Dioxide So

Sulfur Hexafluoride SF

5

5

8

6

4

4

4

2

6

Sulfuryl Fluoride SO2F

Teos N

Tetrafluorahydrazine N2F

4

N

N

2

.174 .197 8.388 KR

2

.44 .1394 4.418 KR

2

N21.070 .2374 1.517 KR

N

3

N

N

N

N

N

N

N

N

N

N

2

N

.36 .1324 6.843 KR

2

.30 .1610 5.620 KR

2

.30 .1250 6.127 KR

2

.36 .3885 1.967 KR

2

.41 .3541 1.877 KR

2

.60 .3189 1.433 KR

2

.28 .1270 7.580 KR

2

.35 .1691 4.643 KR

2

.69 .1488 2.858 KR

2

.26 .1592 6.516 KR

2

.39 .1543 4.562 KR

2

.090 KR KR

2

.32 .182 4.64 KR

2

Trichlorofluormethane CCl3FN2.33 .1357 6.129 KR

(Freon-11)

Trichlorisilane SiHCl

1,1,2-Trichloro-1,2,2 CCl2FCClF2N

N

3

.33 .1380 6.043 KR

2

.20 .161 8.360 KR

2

Trifluorethane (Freon-113)

Trisobutyl Aluminum ( C4H9)Al N

Titanium Tetrachloride TiCl

Trichloro Ethylene C2HCl

4

3

N

N

.061 .508 8.848 KR

2

.27 .120 8.465 KR

2

.32 .163 5.95 KR

2

Trimethylamine (CH3)3NN2.28 .3710 2.639 KR

Tungsten Hexasfuoride WF

Uranium Hexafluoride UF

6

6

Vinyl Bromide CH2CHBr N

Vinyl Chloride CH2CHCl N

N

N

.25 .0810 13.28 KR PTFE

2

.20 .0888 15.70 KR

2

.46 .1241 4.772 KR

2

.48 .12054 2.788 KR

2

Xenon Xe Ar .993 1.44 .0378 5.858

DRAWING NO. REV. SHEET

99-0224 D 3 of 3

12/95

*NOTE: If no O-Ring is

specified then O-Ring to be

used is FKM.

Page 45

Page 47

MAS Instruction Manual

Page 46

Page 48

MAS Instruction Manual

QUICK START INSTRUCTIONS .................................................................i