Page 1

Operating Instructions

for

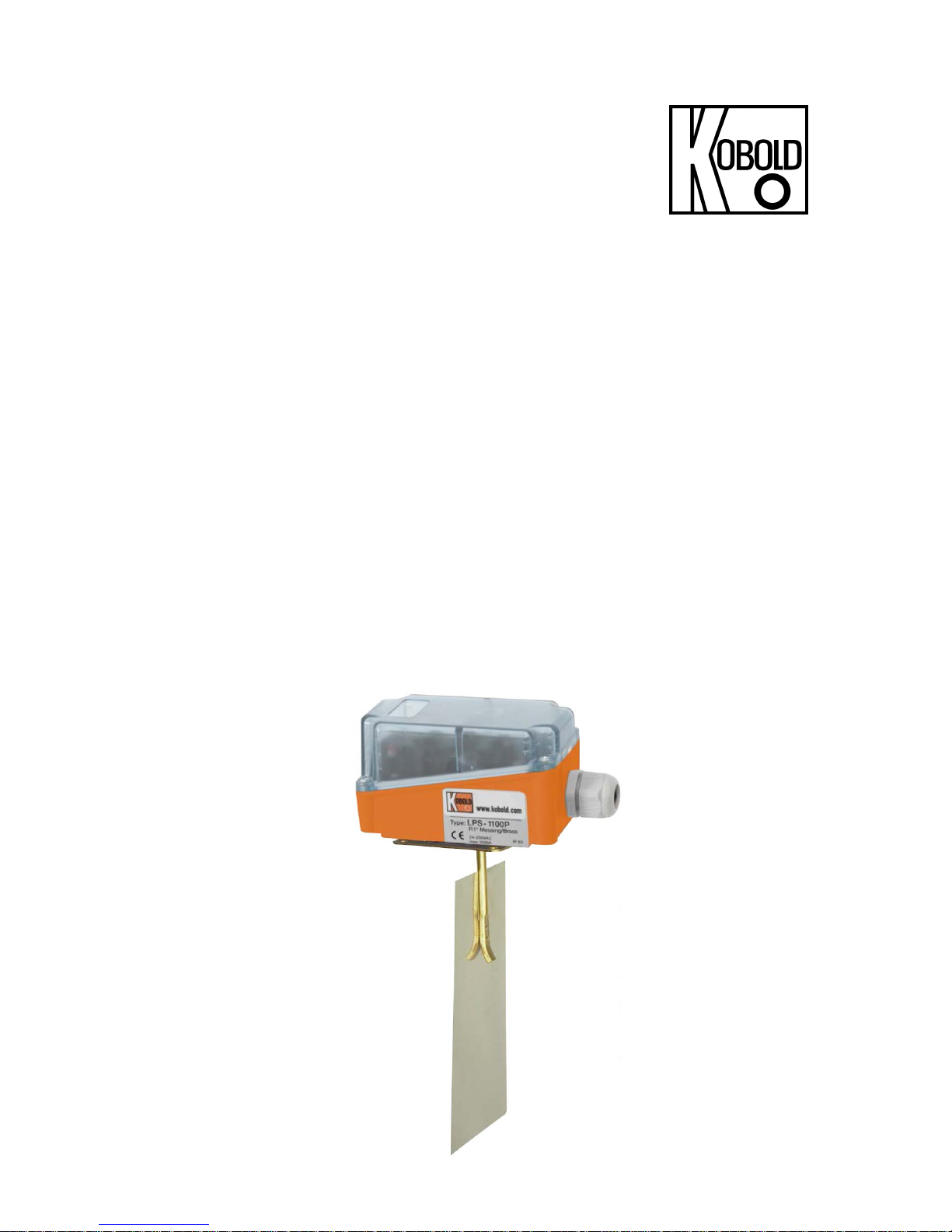

Air-Flow Monitor

Model: LPS-P

Page 2

LPS-P

Page 2 LPS-P K01/1116

1. Contents

1. Contents ........................................................................................................ 2

2. Note .............................................................................................................. 3

3. Regulation use .............................................................................................. 3

4. Operating Principle ........................................................................................ 3

5. Instrument Inspection .................................................................................... 4

6. Mechanical connection .................................................................................. 4

7. Electrical Connection .................................................................................... 5

8. Commissioning .............................................................................................. 6

9. Technical Information .................................................................................... 7

10.Order Codes ................................................................................................. 7

11.Maintenance ................................................................................................. 7

12.Dimensions ................................................................................................... 8

13.EU Declaration of Conformance .................................................................... 9

Manufactured and sold by:

Kobold Messring GmbH

Nordring 22-24

D-65719 Hofheim

Tel.: +49(0)6192-2990

Fax: +49(0)6192-23398

E-Mail: info.de@kobold.com

Internet: www.kobold.com

Page 3

LPS-P

LPS-P K01/1116 Page 3

2. Note

Please read these operating instructions before unpacking and putting the unit

into operation. Follow the instruction precisely as described herein.

The devices are only to be used, maintained and serviced by persons familiar

with these operating instructions and in accordance with local regulations

applying to Health & Safety and prevention of accidents.

By usage in machines, the measuring unit should be used only then when the

machines fulfil the EC-machine guidelines.

3. Regulation use

These units (type LPS) are employed in order to monitor the air-flow in air and

environment industry. All these units are equipped with adjustable limit-contacts.

Monitoring of fluids is suitable only for those gases and air, which would not

attack the materials used in flow monitor.

This air-flow monitor should not be used for monitoring of flammable and

explosive gases.

Material Combination

Housing Galvanised base-plate

/Cover (ABS)

Paddle St. Steel (AISI)

Paddle arm Brass (Ms 58)

Connection- plate Galvanised iron

Flat Gasket Flexoid

Switch Off/On (adjustable)

Switch-off values (min) 1.5 m / sec.

(max) 8.0 m / sec. (with shortened paddle)

Switch-on values (min) 2.5 m / sec.

(max) 9.2 m / sec. (with shortened paddle)

4. Operating Principle

The air flow being controlled presses against the paddle, which is mechanically

linked to a dust-tight changeover microswitch. The latter will signal whether or not

the minimum or maximum preset air flow exists.

The switching point is adjustable over a wide range of values.

Page 4

LPS-P

Page 4 LPS-P K01/1116

5. Instrument Inspection

Instruments are checked before dispatch and should arrive in perfect condition.

In case of damage, please inform your local Kobold office or if you had the parcel

transport your parcel service / forwarding agent immediately, since they are

responsible for damages during transit. Should the damage to a device be visible,

we recommend a thorough inspection of the delivery packing.

Scope of delivery:

Air-Flow Monitor Model: LPS-P

Flat Gasket

Operating Instructions

6. Mechanical connection

Before mounting

Please ensure that the actual flow value remains within the switching range of

the unit.

Make sure that the permitted max. operational pressure and temperature limits

of this unit are not exceeded.

Please ensure a minimum run inner pipe diameter of 5 x D upstream and

downstream of the switch.

Assembly

Drill a hole and a slit in your air-channel as shown in the adjacent

drawing.

Fix the flow-monitor over the air-channel and secure it with 4 metal

screws (D=3.5 mm).

The paddle can also be mounted after the installation, it is

then sufficient to drill a 20 mm diameter hole.

Sealing is carried out by means of supplied flat gasket.

Mounting of this unit is position independent. The affixed arrow sign

on housing must point in the direction of the flow. The upper part of

the flow-monitor must be vertical with respect to the pipe axis.

With vertical mounting, the switching point must be adjusted in

order to compensate for the paddle-weight.

For gases containing dust particles, the flow monitor must be positioned in

such a way that no dust particles can deposit inside the connection head (e.g.

mounting on the upper side of the air-channel).

Page 5

LPS-P

LPS-P K01/1116 Page 5

blau

blue

weiß

whit

e

Erde

ground

rot

red

7. Electrical Connection

Please ensure that the voltage as well as the current

values of your power supply does not exceed the

permitted values specified for the flow monitor.

Before making connections, be assured that the

power supply lines are not active.

Remove the housing of the flow monitor by loosening

4 screws

Make connections to the flow monitor as shown in the adjoining figure.

After making connections between external units and the limit-contact, the unit is

ready for operation.

Page 6

LPS-P

Page 6 LPS-P K01/1116

8. Commissioning

These units are supplied along with an adjustable micro-switch. The contact is

change-over type, which, depending on connections, may be used as normallyclosed or normally-open switch.

These units are factory-set at a switch-off value of 1.5 m / sec.

A higher "switch-off" value is set by rotating the range-screw in the clockwise

direction.

In case a switching value over 5 m / sec. is desired, then the paddle must be

truncated at the marked position.

By paddle-truncation, the factory-set value changes to 2.5 m/sec.

Page 7

LPS-P

LPS-P K01/1116 Page 7

9. T echnical Information

Max. Switching Current: 15 (8) A

Max. Switching Voltage: 24 - 250 VAC

Protection Cat.: IP 65 (from external channel)

Max. Medium Temp.: +85 °C

Ambient Temperature: -40 °C ...+85 °C

10. Order Codes

Description

Order number

Air-flow indicator

LPS-1100P

11. Maintenance

In case, the medium to be measured is not polluted, LPS-P flow-monitor is

regarded as maintenance-free. Otherwise, presence of large-size dust-particles

may lead to the jamming of paddle arm. Depending upon the degree of pollution,

a routine check after regular intervals is recommended.

Page 8

LPS-P

Page 8 LPS-P K01/1116

12. Dimensions

Page 9

LPS-P

LPS-P K01/1116 Page 9

13. EU Declaration of Conformance

We, KOBOLD Messring GmbH, Hofheim-Ts, Germany, declare under our sole

responsibility that the product:

Air-Flow Monitor Model: LPS-P

to which this declaration relates is in conformity with the standards noted below:

EN 60730-2-15:2010 Automatic electrical controls for household and

similar use - Part 2-15: Particular requirements for automatic electrical air flow,

water flow and water level sensing controls

Also the following EC guidelines are fulfilled:

2014/30/EU EMC Directive

2014/35/EU Low Voltage Directive

2011/65/EU RoHS (category 9) industrial monitoring and control

instruments, compliant, no CE-marking for the transitional

period until 2017

Hofheim, 01. Dec. 2016

H. Peters M. Wenzel

General Manager Proxy Holder

Loading...

Loading...