Page 1

Operating Instructions

for

Plastic Flow Meter

Model: KSM

Page 2

KSM

1. Contents

1. Contents ........................................................................................................ 2

2. Note .............................................................................................................. 3

3. Regulation Use .............................................................................................. 3

4. Operating Principle ........................................................................................ 4

5. Instrument Inspection .................................................................................... 4

6. Mechanical Connection ................................................................................. 4

7. Electrical Connection .................................................................................... 5

8. Operation ...................................................................................................... 6

9. Technical Data .............................................................................................. 7

10.Order Codes ................................................................................................. 8

11.Maintenance ............................................................................................... 10

12.Dimensions ................................................................................................. 11

13.EU Declaration of Conformance .................................................................. 12

Manufactured and sold by:

Kobold Messring GmbH

Nordring 22-24

D-65719 Hofheim

Tel.: +49(0)6192-2990

Fax: +49(0)6192-23398

E-Mail: info.de@kobold.com

Internet: www.kobold.com

page 2 KSM K08/0818

Page 3

KSM

2. Note

Please read these operating instructions before unpacking and putting the unit

into operation. Follow the instructions precisely as described herein.

The devices are only to be used, maintained and serviced by persons familiar

with these operating instructions and in accordance with local regulations

applying to Health & Safety and prevention of accidents.

When used in machines, the measuring unit should be used only when the

machines fulfil the EC-machine guidelines.

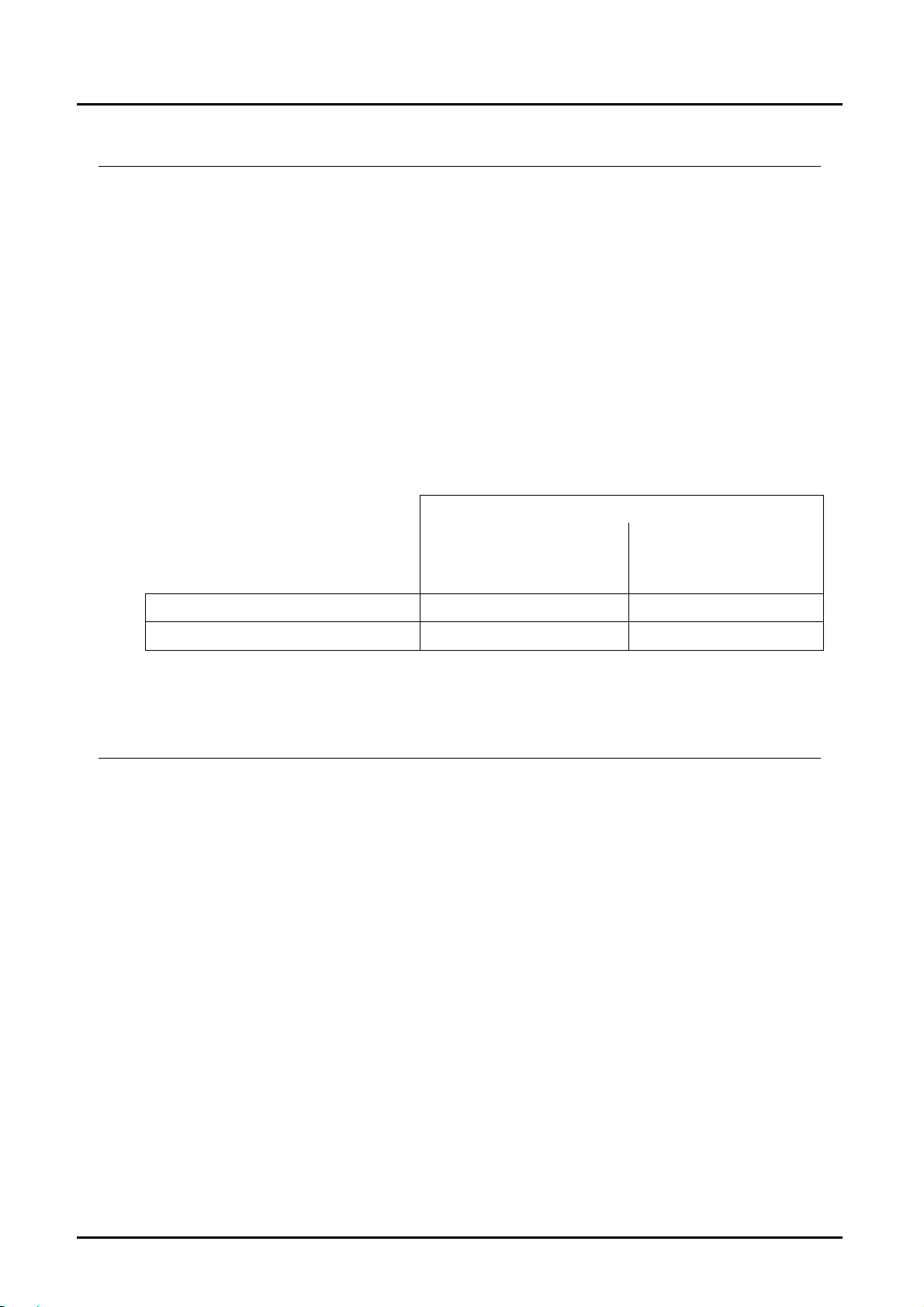

PED 2014/68/EU

In acc. with Article 4 Paragraph (3), "Sound Engineering Practice", of the

PED 2014/68/EU no CE mark.

Pipe

Table 8

Group 1

dangerous fluids

KSM-x001 – KSM-x010 Art. 4, § 3 Art. 4, § 3

KSM-x020 – KSM-x600 Kat. I Art. 4, § 3

no dangerous fluids

Table 9

Group 2

3. Regulation Use

Any use of the Plastic Flow Meter, model: KSM, which exceeds the

manufacturer’s specification, may invalidate its warranty. Therefore any resulting

damage is not the responsibility of the manufacturer. The user assumes all risk

for such usage.

KSM K08/0818 page 3

Page 4

KSM

4. Operating Principle

The Plastic Flow Meter model: KSM operates according to the variable area

principle, in which the float is free to move without friction inside the measuring

tube. The reading edge corresponds to the larger diameter of the float. The

standard flow meter is equipped with a scale for water (+20°C), a percentage

scale, O-rings, 2 adjustable set-point indicators and a rail for accessories; on

each end, two threaded cap-screws accommodate various connectors (see

Section 9: Technical Data; Connections). For the operation with bistable reed

switches the float will be supplied with internal magnets.

5. Instrument Inspection

Instruments are inspected before shipping and sent out in perfect condition.

Should damage to a device be visible, we recommend a thorough inspection of

the delivery packaging. In case of damage, please inform your parcel service /

forwarding agent immediately, since they are responsible for damages during

transit.

Scope of delivery:

The standard delivery includes:

Plastic Flow Meter model: KSM

Operating Instructions

6. Mechanical Connection

Before Installation:

Remove all transportation safety locks and ensure that no packing material

remains within the unit.

Be sure that the maximum allowable operating pressure and temperature is

not exceeded (see Technical Data).

Install the flow meter in the piping system, making certain the instrument is

under no mechanical stress/tension (install support bracing if necessary).

page 4 KSM K08/0818

Page 5

KSM

Protect the measuring tube from external damage.

Avoid pressure peaks in the measuring tube, e.g. from sudden surges or

stoppage of flow.

The units with bistable reed switch may not be installed within an inductive

field.

If possible, immediately after making mechanical connections, check whether

the connections are properly sealed with no evidence of leakage.

Detailed information regarding installation of float flow meters is available

in VDI/VDE guidelines 3513.

7. Electrical Connection

Reed contact, bistable (option)

Ensure that the electrical supply lines are

disconnected from power.

Loosen the plug-cap holding screw and remove the

cap from the switch housing.

Connect the supply lines inside the plug-cap in

accordance with the connection diagram opposite.

If the set point has not yet been adjusted, it may be

done at this point. (see section 8, 'Operation').

Set the plug to the socket and fix it with the safety

screws.

Attention! The stated electrical parameters of the reed switch may not be

exceeded, even for a short period of time. For switching higher power

ratings, we recommend a contact protection relay (e.g. our model MSR) or

any other interposing relay.

After connecting the external devices, and adjusting the switch housing to the

desired switch points, all the connection work is completed. The unit is ready for

operation.

KSM K08/0818 page 5

Page 6

KSM

8. Operation

In order to initialise the bistable switching function, it is essential that the

float-travel activates the contact once in each direction.

Adjustment of limit-values

The switch-point can be adjusted to the desired levels by using both red sliders

as reference points.

Reference edge for falling flow: bottom-edge, switch housing

Reference edge for rising flow: approx. 5 mm above the bottom-edge of

switch housing.

Slide the switch housing up or down until the reference edge coincides with the

desired switch-point scale reading.

Hysteresis

Hysteresis is the difference between the level at which “switch-on” occurs during

rising flow and the level at which “switch-off” occurs during decreasing flow. The

hysteresis is approximately 5 mm on the float scale.

Overranging

With non-pulsating flow, the maximum flow rate can be exceeded. Only an

increase in pressure loss will result (max. permissible operating pressure must

not be exceeded!)

page 6 KSM K08/0818

Page 7

KSM

9. Technical Data

Housing: KSM-1...: Trogamide-T (PA)

KSM-2...: Polysulfone

Connections: ½”...3½”, see order codes

Float: PVDF

Guide rod: PVDF/stainless steel for the three largest sizes

Seals: EPDM (KSM-1.../KSM-2...)

FPM (KSM-3...)

Max. temperature: KSM-1...: 0-60 °C

KSM-2...: 0-100 °C

with contact: 85 °C

Max. pressure: KSM-x0xx, KSM-x1xx: 16 bar

KSM-x201, KSM-x301, KSM-x601: PN 10

Accuracy: ±4% F.S.

Repeatability: 1%

Reed contact (optional):

Bistable Reed contact (N/O) on rising flow

Max. ambient temperature: 0...55°C

Max. power: 230 V

Hysteresis: approx. 3 ...12 mm span

Protection: IP 65

(While upgrading a unit with contact, the float must be replaced by a float with

integrated magnet.)

Connections (optional):

(only KSM-1... and KSM-2...)

Following connections are available with cap-screws:

Glue-in connection made of PVC (max. 60°C; PN 10)

Female thread made of PVC (max. 60°C; PN 10)

Female thread made of cast iron

Respective connection sizes are listed in the tables in Section 10 “Ordering

Information”

10 W / 12 VA; 0.5 A

AC;

KSM K08/0818 page 7

Page 8

KSM

10. Order Codes

Medium liquids

The following scales are available for liquids

Model Standard

KSM-..001 15-150 19 - - 0.25-2.5 3-46 0.5-7 20-130

KSM-..005 50-500 19 - - 0.8-8 10-270 2.5-70 60-460

KSM-..010 100-1000 19 0.1-1 - 1.7-17 40-600 6-220 120-900

KSM-..020 200-2000 26 0.2-2 0.056-0.56 3.3-33 100-1400 20-600 200-1900

KSM-..030 300-3000 26 0.3-3 0.08-0.8 5-50 200-2000 50-1200 300-2700

KSM-..060 600-6000 26 0.6-6 0.17-1.7 10-100 400-4600 200-3400 800-5600

KSM-..120 1200-12000 26 1.2-12 0.34-3.4 20-200 800-8400 300-5600 1200-10000

KSM-..201 2000-20000 26 2.0-20 0.55-5.5 33-330 1400-15000 500-11000 2000-18000

KSM-..301 3000-30000 26 3.0-30 0.83-8.3 50-500 2000-20000 1000-14000 3000-25000

KSM-..601 8000-60000 34 8.0-60 - - - - -

* for KSM-2… and KSM-3… only

Order Details (Example: KSM-1005H K32 R1)

Measuring

range water

[L/h]

15 - 150

50 - 500

100 - 1000

200 - 2000

300 - 3000

600 - 6000

1200 - 12000

2000 - 20000

3000 - 30000

8000 - 60000

Water

[L/h]

Order no.

Trogamide

KSM-1001... KSM-2001...

KSM-1005… KSM-2005…

KSM-1010… KSM-2010…

KSM-1020… KSM-2020…

KSM-1030... KSM-2030...

KSM-1060... KSM-2060...

KSM-1120... KSM-2120…

KSM-1201... KSM-2201...

KSM-1301… KSM-2301…

KSM-1601… KSM-2601…

Pressure

loss

[mbar]

Order no.

PSU

Water

3

[m

/h]

H= L/h water

Q= m³/h water

M= L/h water min

S= L/h water s

H= L/h water

Q= m³/h water

M= L/h water min

S= L/h water s

H= L/h water

Q= m³/h water

M= L/h water min

S= L/h water s

H= L/h water

Q= m³/h water

M= L/h water min

S= L/h water s

Water

Scale Option

[L/s]

Special scale

Water

[L/min]

(for KSM-1..., KSM2...only)

000 = without auxiliary screwed fitting

K32= glue-in connection Da32 (PCV)

P15= PVC G 1/2 IG

P20= PVC G 3/4 IG

P25= PVC G 1 IG

T25= malleable cast iron G 1 IG

V32= PVDF (Welding sleeve) Da32

F25= PVC flange DN 25

000= without auxiliary screwed fitting

K50= glue-in connection Da50 (PVC)

P25= PVC G 1 IG

P32= PVC G 1 1/4 IG

P40= PVC G 1 1/2 IG

T40= malleable cast iron G 1 1/2 IG

V50= PVDF (Welding sleeve) Da50

F40= PVC flange DN 40

000= without auxilary screwed fitting

K63= glue-in connection Da63 (PVC)

P25= PVC G 1 IG

P40= PVC G 1 1/2 IG

P50= PVC G 2 IG

T50= malleable cast iron G 2 IG

V63= PVDF (Welding sleeve)Da63

F50= PVC flange DN 50

000= without auxiliary screwed fitting

K75= glue-in connection Da75(PVC)

P40= PVC G 1 1/2 IG

P50= PVC G 2 IG

T65= malleable cast iron G 2 1/2 IG

V75= PVDF (Welding sleeve) Da75

F65= PVC flange DN 65

NaOH

30 %

[L/h]

screwed fitting

NaOH

50 %

[L/h]

HCI*

30-33 %

[L/h]

Option

contact

R0= without

contact

R1= 1 contact

R2= 2 contacts

R0= without

contact

R1= 1 contact

R2= 2 contacts

R0= without

contact

R1= 1 contact

R2= 2 contacts

R0= without

contact

page 8 KSM K08/0818

Page 9

KSM

Medium air

The following scales are available for air

Typ

KSM-..001 0.8 - 5 1.2 - 7 1.4 - 9 1.6 - 10 2 - 12 2 - 13 2 - 14 2.5 - 14 2.5 - 15

KSM-..005 2 - 18 3 - 25 4 - 30 5 - 35 5 - 40 6 - 43 6 - 45 7 - 50 6 - 52

KSM-..010 4 - 34 6 - 50 8 - 60 8 - 70 10 - 74 10 – 84 10 - 90 12 - 96 12 - 100

KSM-..020 10 - 70 12 - 90 14 - 120 15 - 130 20 - 150 20 - 160 20 - 170 20 - 190 20 - 200

KSM-..030 10 - 90 15 - 130 20 - 160 20 - 190 25 - 210 25 - 230 30 - 250 30 - 260 30 - 280

KSM-..060 22 - 190 30 - 260 40 - 380 40 - 400 50 - 450 50 - 480 75 - 500 70 - 550 75 - 550

KSM-..120 45 - 370 60 - 520 80 - 660 100 - 760 100 - 840 100 - 900 100 - 1000 120 - 1000 140 - 1100

KSM-..201 60 - 580 90 - 800 100 - 1060 120 - 1200 150 - 1300 150 - 1500 150 - 1500 200 - 1700 200 - 1800

KSM-..301 100 - 860 140 - 1200 200 - 1500 200 - 1700 250 - 1900 250 - 2100 300 - 2200 300 - 2400 300 - 2500

Order Details (Example: KSM-1010 2 P15 R0)

Meas. range

air m³

(0 bar rel.)

0.8 - 5

10 - 70

10 - 90

22 - 190

45 - 370

55 – 545

80 - 758

2 - 18

4 - 34

m³N/h

(0 bar rel.)

m³N/h

(1 bar rel.)

m³N/h

(2 bar rel.)

m³N/h

(3 bar rel.)

m³N/h

(4 bar rel.)

(5 bar rel.)

Order no.

/h

N

Trogamide

KSM-1001… KSM-2001…

KSM-1005… KSM-2005…

KSM-1010… KSM-2010…

KSM-1020… KSM-2020… 000 = without auxiliary screwed fitting

KSM-1030… KSM-2030…

KSM-1060... KSM-2060... 000 = without auxiliary screwed fitting

KSM-1120… KSM-2120…

KSM-1201… KSM-2201…

KSM-1301… KSM-2301…

Order no.

PSU

Scale

Range

see Table

0 = 0 bar rel.

1 = 1 bar rel.

2 = 2 bar rel.

3 = 3 bar rel.

4 = 4 bar rel.

5 = 5 bar rel.

6 = 6 bar rel.

7 = 7 bar rel.

8 = 8 bar rel.

Option

screwed fitting

000 = without auxiliary screwed fitting

K32 = glue-in connection Da32 (PVC)

P15 = PVC G 1/2 IG

P20 = PVC G 3/4 IG

P25 = PVC G 1 IG

T25 = malleable cast iron G 1 IG

V32 = PVDF (Welding sleeve) Da32

F25 = PVC flange DN 25

K50 = glue in connection Da50 (PVC)

P25 = PVC G 1 IG

P32 = PVC G 1 1/4 IG

P40 = PVC G 1 1/2 IG

T40 = malleable cast iron G 1 1/2 IG

V50 = PVDF (Welding sleeve) Da50

F40 = PVC flange DN 40

K63 = glue in connection Da63 (PVC)

P25 = PVC G 1 IG

P40 = PVC G 1 1/2 IG

P50 = PVC G 2 IG

T50 = malleable cast iron G 2 IG

V63 = PVDF (Welding sleeve) Da63

F50 = PVC flange DN 50

000 = without auxiliary screwed fitting

K75 = glue in connection Da75 (PVC)

P40 = PVC G 1 1/2 IG

P50 = PVC G 2 IG

T65 = malleable cast iron G 2 1/2 IG

V75 = PVDF (Welding sleeve) Da75

F65 = PVC flange DN 65

m³N/h

m³N/h

(6 bar rel.)

m³N/h

(7 bar rel.)

Option

contact

R0 = without contact

R1 = 1contact

R2 = 2 contacts

R0 = without contact

R1 = 1 contact

R2 = 2 contacts

R0 = without contact

R1 = 1 contact

R2 = 2 contacts

R0 = without contact

m³N/h

(8 bar rel.)

KSM K08/0818 page 9

Page 10

KSM

11. Maintenance

If the medium to be measured is clean, the series KSM is virtually maintenancefree. If deposits form on the inner housing or parts, periodic cleaning of the unit is

recommended. Remove the units from the piping with a suitable tool; clean the

flow meter with a suitable cleaning agent or make use of an ultrasonic bath.

If using the setpoint switch, it is particularly important to guard against

contamination by ferritic (metal) contaminants. These can be eliminated by using

the KOBOLD model MF magnetic filter (or equivalent).

page 10 KSM K08/0818

Page 11

KSM

12. Dimensions

Da

DN

L

L2

L1

G

D

DN G Da L L1 L2 (mm) approx. D

Model [mm] [mm] [mm]

approx.

KSM-..001 25 R 1 1/2 32 335 341 390 385 432 441 480 -- -- -- 385 60

KSM-..005 25 R 1 1/2 32 335 341 390 385 432 441 480 -- -- -- 385 60

KSM-..010 25 R 1 1/2 32 335 341 390 385 432 441 480 -- -- -- 385 60

KSM-..020 40 R 2 1/4 50 335 341 401 403 -- -- 467 477 525 -- 403 83

KSM-..030 40 R 2 1/4 50 335 341 401 403 -- -- 467 477 525 -- 403 83

KSM-..060 50 R 2 1/4 63 335 341 411 417 -- -- 482 -- 498 558 417 103

KSM-..120 50 R 2 3/4 63 335 341 411 417 -- -- 482 -- 498 558 417 103

KSM-..201 65 R 2 3/4 75 335 342 412 457 -- -- -- -- 510 570 429 122

KSM-..301 65 R 3 1/2 75 335 342 412 457 -- -- -- -- 510 570 429 122

KSM-..601 65 R 3 1/2 75 335 342 412 457 -- -- -- -- 510 570 -- 122

Annealed-

cast-iron

Glue

conn.

PVC

G 1/2

PVC

G 3/4

PVC

G 1

PVC

G1 1/4

PVC

G 1 1/2

PVC

G 2

PVDF

welded

[mm]

approx.

KSM K08/0818 page 11

Page 12

KSM

13. EU Declaration of Conformance

We, KOBOLD-Messring GmbH, Hofheim-Ts, Germany, declare under our sole

responsibility that the product:

Plastic Flow Meter with Contact Model: KSM -...R1/R2

to which this declaration relates is in conformity with the standards noted below:

EN 61010-1:2011

Safety regulations for electrical measurement, control, regulation and Laboratory

equipment

EN 60529:2014

Protection through housing (IP-Code)

EN 50581:2012 Technical documentation for the assessment of electrical

and electronic products with respect to the restriction of hazardous substances

Also the following EC guidelines are fulfilled:

2014/35/EU Low Voltage Directive

2011/65/EU RoHS (category 9)

2014/68/EU PED

Category III (IV) Diagram 1, vessel, group 1 dangerous fluids

Module D, marking CE0575

Notified body: DNV GL

Certificate No. PEDD000000R

Hofheim, 02. Aug. 2018

H. Peters M. Wenzel

General Manager Proxy Holder

page 12 KSM K08/0818

Loading...

Loading...