Page 1

KPA Series

Industrial/OEM

Pressure Sensor

USA

KOBOLD Instruments, Inc

1801 Parkway View Drive

Pittsburgh, PA 15205

Tel: 412-788-2830

• 0.25% of Full Scale Accuracy

• Precision Machined Diaphragm with no Welds

or O-ring Seals

• Pressure Ranges 0-50 through 0-10,000 PSIG

• All Stainless Steel Wetted Parts

• Unique Sensor Fusing Technology for

Exceptional Cycle Life at Low Cost

• All of the Features with None of the Cost

The Kobold KPA series Industrial/OEM pressure sensors

are a breakthrough that combin

e unique features, yielding

an exceptionally tough and accurate sensor at a low cost.

The fitting and pressure sensing diaphragm are precision

machined out of a single piece of 17-4 PH stainless steel.

There are no welds or O-ring seals which results in an

exceptionally high cycle life. The semiconductor strain

gauges are kiln fused to the diaphragm making a highly

stable molecular bond. Molecular bonding of the sensing

element produces a pressure sensor that will have

exceptional long term stability in demanding applications

characterized by high pulsations. The KPA series has a

4-20 mA, 2-wire transmitter and 1/4” NPT fitting as

standard. Other outputs and fitting options are available in

OEM quantities. The KPA also provides significant levels of

RFI, EMI and ESD protection to make the KPA and

excellent choice for industrial and mobile applications.

Canada

9A Aviation

Pointe-Claire, QC

H9R 4Z2

Tel: 514-428-8090

www.kobold.com

Specifications

Pressure Ranges: 0-

Accuracy:

Temp. Drift Coefficient: ±0.0065% of full scale/°F over the

Process Temp. Range: -40 to 250°F

Compensated Temp.

Range: 0 to 185°F

Wetted Materials: 17-

50 PSIG through 0-10,000 PSIG

0.25% of full scale BFSL

compensated temperature range

4 PH Stainless Steel

Ordering Information

Range

(PSIG)

0-50 KPA-565P055 0-1000 KPA-565P115

0-100 KPA-565P065 0-3000 KPA-565P140

0-200 KPA-565P085 0-5000 KPA-565P150

0-300 KPA-565P090 0-10000 KPA-565P175

0-500 KPA-565P100

Model Number Range

(PSIG)

Model Number

Proof Pressure: 2X measuring range

Burst Pressure: 5X measuring range

Vibration Resistance: 20G at 20-200 Hz

Shock Resistance: 11G / 11

ms

Output:

Standard: 4-20 mA, 2-wire, 9-30 VDC

Optional: Others available in OEM quantities

Electrical Connection

Standard: Mini-DIN 43650C

Optional: Others available in OEM quantities

Electrical Protection: NEMA 4X/ IP 65

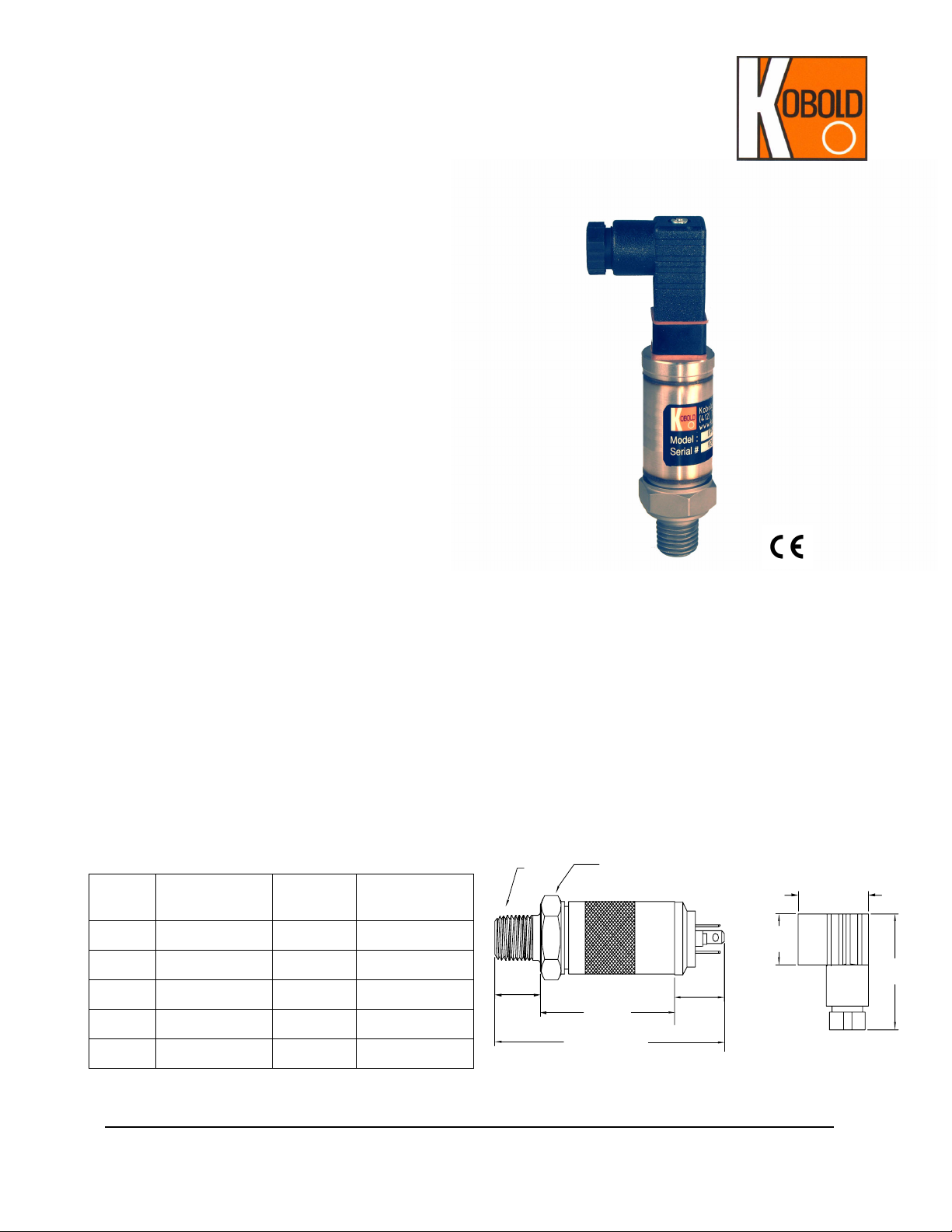

1/4” NPT

0.64”

7/8” HEX

1.89”

3.23”

0.70"

REF

0.61"

REF

1.00"

REF

1.38"

REF

When quality counts, count on KOBOLD

Argentina, Austria, Belgium, Brazil, Canada, Chile, Czech Republic, France, Germany, Indonesia, Italy, Malaysia

Mexico, Netherlands, Peru, Slovakia, Switzerland, Thailand, United Kingdom, USA, Venezuela, Vietnam

Page 2

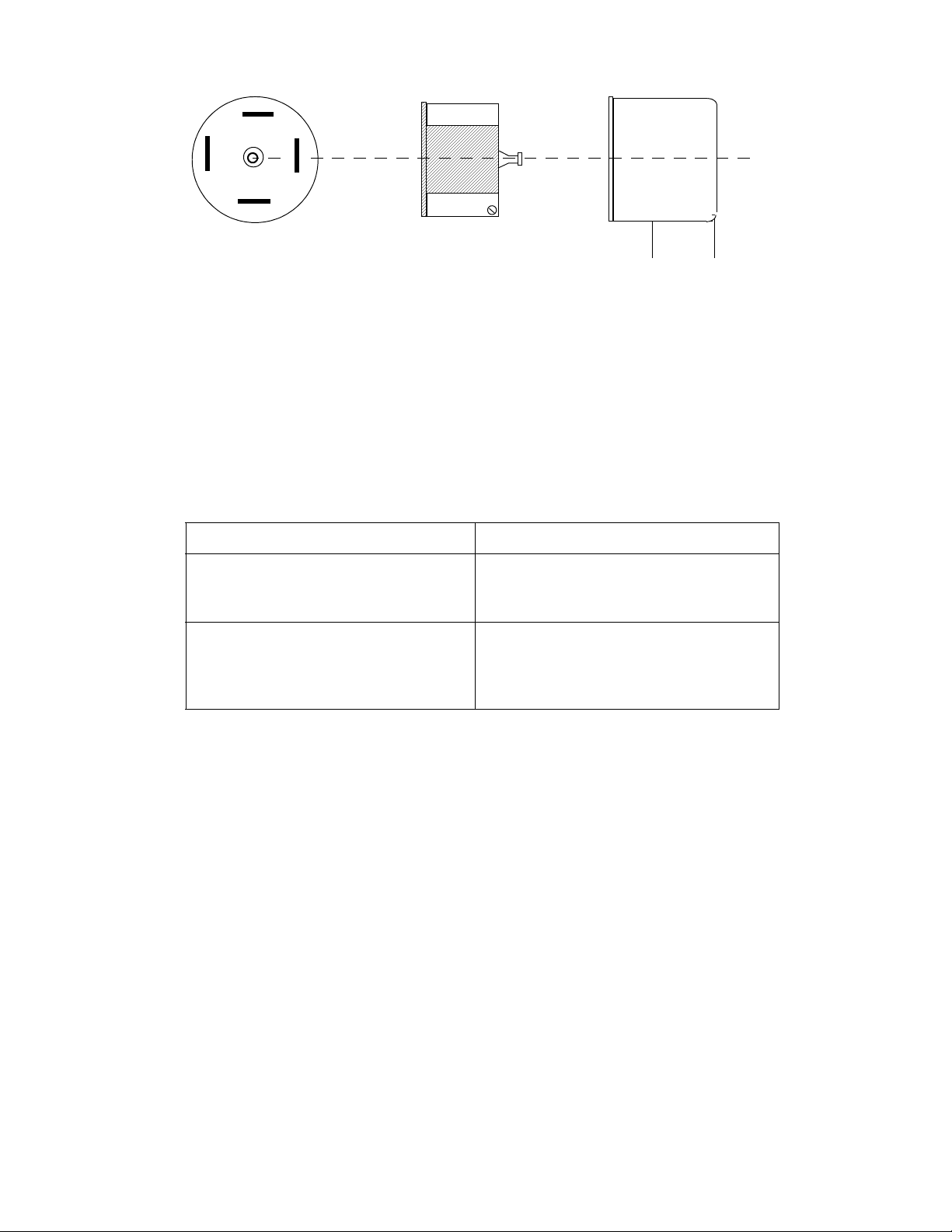

Wiring - Standard DIN 43650C P

lug

1

3

4

2

Pin Assignments

Standard 4-

20 mA Output (2-wire)

P

in 1 = +9-30 VDC

Pin 2 = 4-20 mA Out

Pin 3 = Not Connected

Pin 4 = Not Connected

Optional 0-5 VDC, 0-10 VDC, 1-5 VDC, 0.5-4.5 VDC Outputs (3-wire)

Wiring - w/Optional Integral Cable

Output Type Wiring

4-20 mA Output (2-wire)

0-5 VDC, 0-10 VDC, 1-5 VDC & 0.5-4.5

VDC Outputs (3-wire)

• User's Responsibility for Safety: KOBOLD manufactures

a wide range of process sensors and technologies. While

each of these technologies are designed to operate in a

wide variety of applications, it is the user's responsibility to

select a technology that is appropriate for the application,

to install it properly, to perform tests of the installed system,

and to maintain all components. The failure to do so could

result in property damage or serious injury.

• Proper Installation and Handling: Use a proper sealant

with all installations. Never overtighten the sensor within its

fitting. Always check for leaks prior to system start-up.

• Wiring and Electrical: Because this is an el

operated device, only properly trained personnel should

install and maintain this product. Be sure that the power

supplied to the sensor is appropriate for the electronics

version supplied. Electrical wiring of the sensor should be

performed in accordance with all applicable national, state

and local codes.

ectrically

Pin 1 = +8-30 VDC

Pin 2 = + Signal Out

Pin 3 = - VDC

Pin 4 = Not Connected

Red = + 9-30 VDC Supply

Black = 4-20 mA Out

Red = + 8-30 VDC Supply

White = + Signal Out

Black = - DC Supply

• Material Compatibility: The wetted parts are all 17-4 PH

stainless steel. Make sure that the unit is chemically

compatible with the application fluids. While the sensor’s

outer housing is liquid and spray resistant when installed

properly, it is not designed to be immersed. It shoul

mounted in such a way that it will not be submerged in

liquid.

• Flammable, Explosive and Hazardous Applications:

The KPA is not an explosion-proof design. It should not be

used in applications where an explosion-proof desig

required.

• Make a Fail-Safe System: Design a fail-safe system that

accommodates the possibility of sensor or power failure.

critical applications, KOBOLD recommends the use

In

redundant backup systems and alarms in addition to the

primary system.

d be

n is

of

• Temperature and Pressure: The KPA is designed for use

in process temperatures from -40°F to 250°F. Operation

outside these limitations will cause damage to the unit.

KPA_manual_08-

16

Loading...

Loading...