Page 1

Operating Instruction

for

Electronic Flow Meter / Monitor

Compact Version

Model: KAL-A

KAL-AK

Page 2

KAL-A(K)

1. Contents

...Contents ........................................................................................................ 2

1.

2....Note .............................................................................................................. 3

3....Instrument Inspection .................................................................................... 3

4....Regulation Use .............................................................................................. 3

5....Operating Principle ........................................................................................ 4

6....Mechanical Connection ................................................................................. 5

7....Electrical Connection .................................................................................... 5

8....Output ........................................................................................................... 8

9....Commissioning .............................................................................................. 9

10..Maintenance ............................................................................................... 12

11..Diagnostics ................................................................................................. 12

12..Technical Information .................................................................................. 12

13..Order Codes ............................................................................................... 13

14..Dimensions ................................................................................................. 14

15..EU Declaration of Conformance .................................................................. 15

Manufactured and sold by:

Kobold Messring GmbH

Nordring 22-24

D-65719 Hofheim

Tel.: +49(0)6192-2990

Fax: +49(0)6192-23398

E-Mail: info.de@kobold.com

Internet: www.kobold.com

Page 2 KAL-A(K) K05/1116

Page 3

KAL-A(K)

2. Note

Please read these operating instructions before unpacking and putting the unit

into operation. Follow the instructions precisely as described herein.

The devices are only to be used, maintained and serviced by persons familiar

with these operating instructions and in accordance with local regulations

applying to Health & Safety and prevention of accidents.

When used in machines, the measuring unit should be used only when the

machines fulfil the EC-machine guidelines.

3. Instrument Inspection

Instruments are inspected before shipping and sent out in perfect condition.

Should damage to a device be visible, we recommend a thorough inspection of

the delivery packaging. In case of damage, please inform your parcel service /

forwarding agent immediately, since they are responsible for damages during

transit.

4. Regulation Use

The KOBOLD KAL-A.. Flow Meter is intended for use in measuring moderate

flow rates of low-viscous or dirty liquids.

The KOBOLD KAL-AK.. Flow Meter is intended for use in measuring and

monitoring moderate flow rates of low-viscous or dirty liquids.

Analogue Output / Limiting Signal

For measuring the flow rate of the liquids the device is equipped with a 4-20 mA

output signal. Additionally the model KAL-AK.. is equipped with a limit switch

(NPN or PNP).

Trend Display

A LED bar graph display indicates the current flow rate and the set point

(KAL-AK) via a flashing LED.

Sensor

The model KAL-A and KAL-AK consists of a sensor with integrated electronic.

The devices may only be used for liquids to which the probe material is resistant.

With proper installation and maintenance, the probes are not sensitive to soiling

and cause practically no pressure loss.

KAL-A(K) K05/1116 Page 3

Page 4

KAL-A(K)

Materials

Sensor Stainless steel (1.4301, 1.4305, 1.4571)

Electronic cover Glass fibre reinforced polyamide

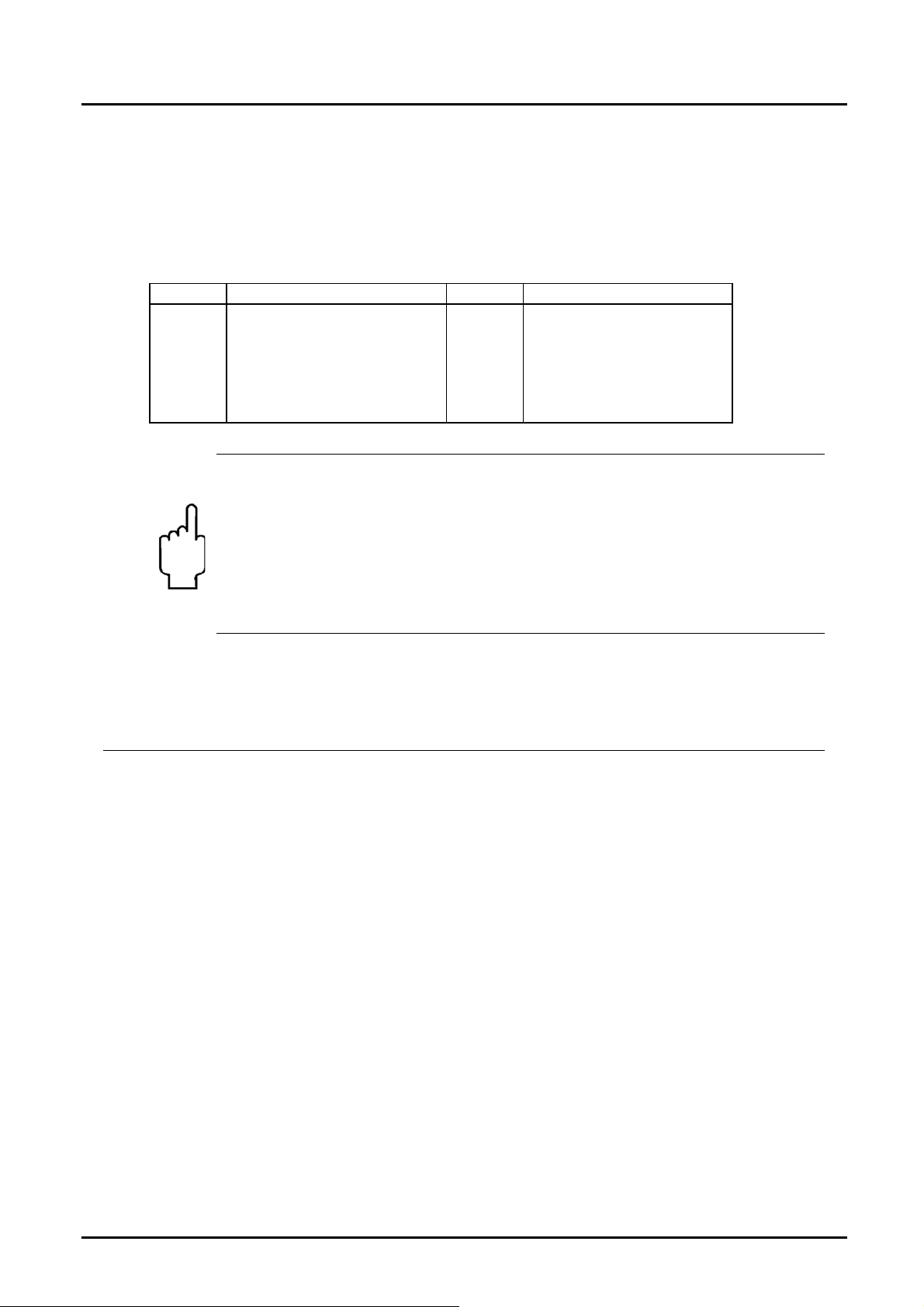

Setting ranges

in relation to nominal tube diameter

ID (mm) Meas. range (L/min) water ID (mm) Meas. range (L/min) water

8 0.12 - 6.0 40 3.0 - 150

10 0.19 - 9.4 50 4.7 - 235

15 0.42 - 21.8 60 6.8 - 340

20 0.75 - 37.7 80 12.0 - 603

25 1.18 - 59.0 100 18.8 - 942

30 1.7 - 84.8 150 42.4 - 2120

Attention! The flow ranges specified in the table above have been

calculated for each pipe diameter based on the known velocity

range of the KAL-A(K). It must be noted that flow in pipes is nonuniform across the pipe cross section, and approaches zero at the

pipe wall. This means that, in practice, the depth of installation of

the probe, the internal pipe diameter, and the flow profile of the

liquid in the pipe can interact to produce significant deviations from

the flow ranges in the above table.

5. Operating Principle

The KAL-A... Flow Meter/ -Monitor uses the proven thermal dispersion principle

and operates as follows: The probe is heated internally to a few degrees above

the temperature of the medium into which it extends. The flowing medium takes

this heat off the probe, i.e. the probe is cooled down. The cooling rate is

proportional to the flow rate. The electronic converts the signal into a proportional

current signal (4-20 mA) linear to the flow rate. With model KAL-AK the requested

flow rate will be compared with the flow rate existing and if the set- point is

reached a PNP/NPN switch is activated. The microprocessor-controlled design

permits simple calibration and set-up. The compact probe design permits

monitoring of flow rate with minimum pressure loss.

Page 4 KAL-A(K) K05/1116

Page 5

KAL-A(K)

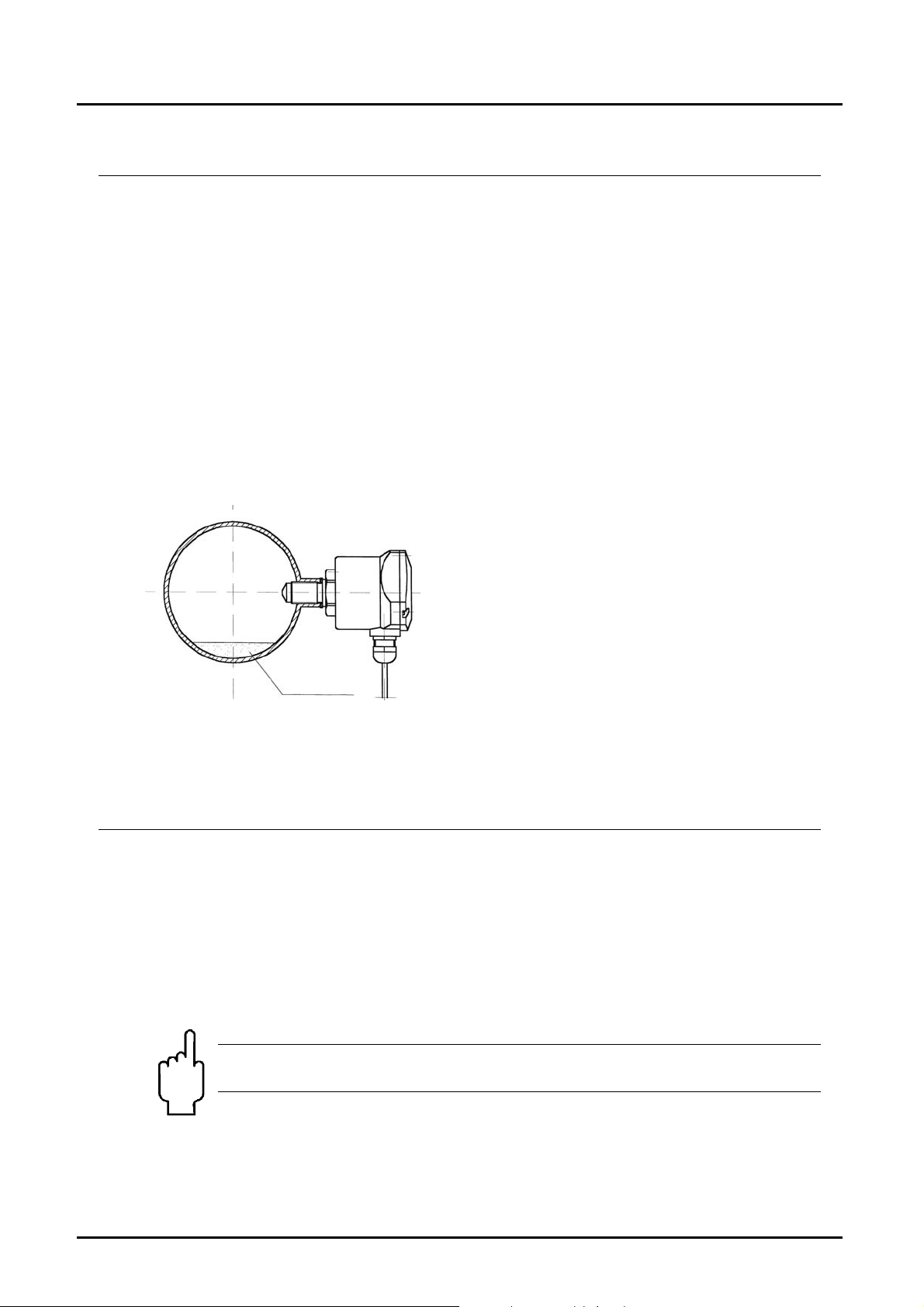

6. Mechanical Connection

Prior to installation

Ensure that the actual system flow rate the is within the measuring range of

the KAL-A(K).

Ensure that the maximum system temperature and pressure are within the

limits specified per section (see section 12. Technical Information)

Fitting

Mount the sensor into the piping and make sure that it is completely filled with

fluid. The probe tip has to reach at least 5 mm (better > 5 mm) into the pipe (see

below).

Fitting position

The sensor can be mounted in any orientation

as long as the piping is completely filled with

fluid. The mounting position has to be smooth

and free of turbulence.

(Recommended input and output length: 5 x

pipe diameter, of straight - run piping both

upstream and downstream of the flow switch).

In case of sediments in the pipe the shown

Se dim e nts

mounting position is recommended.

7. Electrical Connection

Screw in sensor.

Remove electronic cover.

(The fixing screws are secured against falling out)

Strip 4-wire cable (approx. 40-60 mm) and pull through cable gland.

Tighten cable gland.

Connect wires to terminal connector block according to their functions.

Ensure that the power is disconnected during the connection of the cable.

Attention! SET-pushbutton must not be pressed while switching

supply voltage on.

After connection, apply supply voltage of 24 VDC ± 20% (see Technical

Information)

KAL-A(K) K05/1116 Page 5

Page 6

KAL-A(K)

Flood piping in which the sensor has been mounted with medium.

Check the sensor thread for tightness.

Check function of electronic (set-point LED must flash)

Calibrate flow switch (see 9. Commissioning)

Function elements

Output Selector Switch

NPN/PNP

Attention! Ensure that the voltage of your installation corresponds

to the voltage values given on the device's specification plate.

Trend Indicator

(8 LEDs)

Set point Potentiometer

P1

Terminal Strip

1: Output NPN/PNP

2: GND

3: +24 VDC

4: 4...20 mA

LED Trend Indicator

The LED Trend Indicator (8 LEDs) is used to indicate the flow rate (LED,

starting left). For model KAL-AK the adjusted switching point is additionally

indicated by a flashing LED.

If the flow rate has reached the set point value selected by the user, then the

LED is flashing.

Bi-coloured LED (KAL-A)

If bi-coloured LED is green: Instrument is in operation mode.

If bi-coloured LED is flashing green: Instrument is in calibration mode.

If bi-coloured LED is flashing red: Instrument signal an error (check the

temperature of the liquid).

SET-Push button

(calibration)

Bi-coloured LED

red = ALARM

green = FLOW

(above set point)

Cable gland

Page 6 KAL-A(K) K05/1116

Page 7

KAL-A(K)

Bi-coloured LED (KAL-AK)

The bi-coloured LED serves to additionally display a switching point (KAL-AK).

RED = ALARM (flow below the set point)

GREEN = (flow above the set point)

If bi-coloured LED is flashing green: Instrument is in calibration mode.

If bi coloured LED is flashing red: Instrument signal an error (check the

temperature of the liquid ).

Terminal strip

The terminal strip serves the electrical connection.

The device only operated with 24 VDC (DC ± 20%)

Terminal 1: Output NPN/PNP (only KAL-AK)

Terminal 2: GND

Terminal 3: + 24 VDC

Terminal 4: Analogue output

Plug connector M12

Output NPN/PNP

(only for KAL-AK)

2

1

3

GND

4

SET pushbutton

The calibration switch is used to start the flow calibration procedure

Potentiometer

a.) Calibration: left-hand stop = zero flow calibration

right-hand stop = maximum flow calibration

b.) Switching point adjustment (KAL-AK)

The set point potentiometer is used to adjust the flow set point. You will

notice that the flashing LED moves along the trend indicator scale as the set

point potentiometer is adjusted.

Output Selector Switch

The output selector switch is used to select between the output logic NPN and

PNP. This adjustment is factory-made and needs not to be changed anymore

under normal conditions.

Output selector switch right: NPN-output

Output selector switch left: PNP-output

24 V

DC

4-20 mA

KAL-A(K) K05/1116 Page 7

Page 8

KAL-A(K)

8. Output

Analogue output

The analogue output supplies a current signal proportional to the flow rate

(0-100% = 4-20 mA). Terminal 2 is the bench mark of the analogue output

GROUND (0 VDC).

Switching point (KAL-AK)

The output characteristics of the switch logic will be customised by the factory.

NPN-output

The semiconductor output switches to GND (GROUND = 0 VDC) or is highly

resistant. The maximum output current is 400 mA.

The reference point for the NPN-output is +24 VDC.

PNP-output

The semiconductor output switches to +24 VDC or is highly resistant. The

maximum output current is 400 mA.

The reference point for the PNP-output is GND (GROUND = 0 VDC).

Page 8 KAL-A(K) K05/1116

Page 9

KAL-A(K)

N/O function (KAL-AK)

In the N/O function the output is switching into the low resistance state

(PNP +24 VDC impress on the output; NPN GND 0 VDC impresses on the

output), if the actual value has reached or exceeded the set point

At the same time the green LED is flashing.

If the actual value is falling below the set point, then the output will become highly

resistant and the red LED will flash ( = ALARM-condition).

In case of a break-down of the power supply the output will be switched to highly

resistant (ALARM-condition).

9. Commissioning

The use of this meter in machines according to directive 89/392/EWG is

prohibited until the complete machine complies to this directive.

After mechanical (“Mechanical Connection”) and electrical (“Electrical

Connection”) installation of the sensor the flow meter has to be put into operation

as described in this section.

Calibration

a) Zero flow calibration

Stop the flow of the liquid in the piping in which the sensor is installed. It is

important that the sensor tip be immersed in the liquid. There should be no

bubbles around the sensor tip.

Turn set point adjustment potentiometer counter clockwise to its far left-hand

stop and now briefly press the SET button.

The bi-coloured LED will flash green.

Do not make any changes (potentiometer setting, etc.) while the bi-coloured

LED is blinking. This adjustment phase will last approx. 5-15 sec.

When the bi-coloured LED stops flashing, the zero flow calibration is set.

The device now switches automatically to the monitoring mode and displays

no flow. The LED strip is not illuminated; only the threshold value LED is

flashing.

KAL-A(K) K05/1116 Page 9

Page 10

KAL-A(K)

b) Calibration of the maximum flow

The flow monitor is factory pre-set at its maximum span. This span corresponds

to a water flow velocity of 2 m/s. If fluid is running through the pipe the trend

indicator is showing the actual system flow. At lower flow speeds, not all 8 LEDs

will illuminate. To achieve finer monitoring resolution, the measuring range can

(should) be adapted to better fit the actual flow speed.

Rotate the potentiometer clockwise as far as it will go (to the right-hand

stop). The extreme right-hand LED in the LED strip will blink. The maximum

flow speed must be present.

Now press the SET button. The bi-coloured LED blinks green.

Do not make any changes (potentiometer setting, etc.) while the bi-coloured

LED is blinking. This adjustment phase will last approx. 5-15 sec.

The setting procedure is now complete. The device now switches

automatically to the monitoring mode. This adjustment has set the device

measuring range so that it now extends across the entire analogue output

range (0-100% = 4-20 mA) and the LED trend indicator (8-LEDs).

The adjustment procedure is now complete. It may be repeated as often as

necessary.

c) Measuring mode

After adjustment, the flow monitor is once again in measuring mode.

The flow is constantly monitored and the actual value of the flow speed is

displayed on the LED strip.

Page 10 KAL-A(K) K05/1116

Page 11

KAL-A(K)

Switching point adjustment (KAL-AK)

The potentiometer is now used to set the switching point (threshold) of the flow

switch. The switching point is displayed as a blinking LED. If the flow rate

increases to the point that illuminated LEDs (actual flow value) reaches the

position of the blinking LED (set point), the flow monitor switches over from

ALARM to FLOW. This can be seen at the display: the bi-coloured LED that was

showing a steady red light now switches to a steady green light. The output is

also switched at the same time.

slowly flashing switching point-LED (set point)

Actual value < set point

Bi-coloured LED = red

slowly flashing switching point-LED (set point)

LED

Actual value

fast flashing switching point-LED (set point)

LED

Actual value

slowly flashing switching point-LED

LED actual value

Bi-coloured LED = red

Bi-coloured LED = green

Alarm status

Actual value = 0: no flow present

Actual value < set point

Alarm status

Actual value too low

Actual value = set point

Flow status currently being switched

Actual value has just reached set

point

Actual value > set point

Flow status (ideal conditions)

This is the most desirable status.

Bi-coloured LED = green

After the settings are completed, screw the cover tightly back on the housing

KAL-A(K) K05/1116 Page 11

Page 12

KAL-A(K)

10. Maintenance

The unit is maintenance free. The sensor should be inspected in monthly

intervals for deposits (calcination etc.) and if necessary be cleaned.

11. Diagnostics

The KAL-A(K) continuously self monitors the sensing probe and the microprocessor system upon short-circuit and circuit breaking. Any fault in these parts

of the electronics will be signalled by a flashing red bi-coloured LED and a

simultaneous flashing LED-bar ( KOBOLD Service).

12. T echnical Information

Power Supply: 24 VDC ± 20 %,

Power Consumption: max. 3,6 W (typically 1.2 W) at rated voltage

Output Characteristics: 4-20 mA (optional 0-20 mA)

Max. load 500 Ohm

Switching Point Adjustment: via Potentiometer (KAL-AK)

Semi-conductor output NPN or PNP

(factory-set on customer request)

Switching Characteristics: N/O

Switching Output: max. 400 mA

Switch Status Indication: Bi-coloured LED (DUO-LED)

red = ALARM, green = FLOW

Standby Time: max. 12 sec

Ambient Temperature: -20 to +60 °C (-4 to 140 °F)

Housing Protection: IP 65

Calibration Data: stored in non-volatile memory, data retained

for at least 10 years in the event of a power

failure

Measuring range: 4 cm/s... 2 m/s

Accuracy: ± 10 % f.s.

Repeatability: ± 1 % f.s.

Medium Temperature: -20 to +80 °C (-4 to 176 °F)

Temperature gradient: unlimited

Maximum Pressure: 100 bar

Connection: G 1/2 (G 1/4, G 3/4, M 12x1,

1/4" NPT, 1/2" NPT, 3/4" NPT)

Wetted Parts: 1.4305 (1.4301, 1.4571 on request)

Response Time: 5 sec.

Page 12 KAL-A(K) K05/1116

Page 13

KAL-A(K)

13. Order Codes

Order example: KAL-A1308A4PG

Version Connection

1

G

/

4

G 1/

2

G 3/

4-20 mA/

without contact

4

M 12 x 1

1

/4 NPT

1

/2 NPT

3

/4 NPT KAL-A5320A4 - KAL-A5420A4*

Tri-Clamp, DIN 32676

1

G

/

4

G 1/

4-20 mA/

N/O contact

NPN/PNP

switchable

2

G 3/

4

M 12 x 1

1

/4 NPT KAL-AK5308AS - KAL-AK5408AS*

1

/2 NPT KAL-AK5315AS - KAL-AK5415AS

3

/4 NPT KAL-AK5320AS - KAL-AK5420AS*

Tri-Clamp, DIN 32676

*stainless steel hexagon 1.4301

**stainless steel 1.4404

Material stainless steel / version

1.4301 1.4305 1.4571

KAL-A1308A4 - KAL-A1408A4*

KAL-A1315A4 KAL-A1215A4 KAL-A1415A4

KAL-A1320A4 - KAL-A1420A4*

KAL-A0312A4 - KAL-A5308A4 - KAL-A5408A4*

KAL-A5315A4 - KAL-A5415A4

- - KAL-A4440A4**

KAL-AK1308AS - KAL-AK1408AS*

KAL-AK1315AS KAL-AK1215AS KAL-AK1415AS

KAL-AK1320AS - KAL-AK1420AS*

KAL-AK0312AS - -

- - KAL-AK4440AS**

Electr.

connection

PG =cable gland

M16x1,5

ST = connector

M12x1

PG=cable gland

M16x1,5

ST=Connector

M12x1

KAL-A(K) K05/1116 Page 13

Page 14

KAL-A(K)

14. Dimensions

KAL-K.., KAL-A(K)

A (mm) C (mm) D (mm)

G ¼ 26 123

G ½ 40 137

G ¾ 43 140

M12x1 23 120

¼ NPT 16 123

½ NPT 27 137

¾ NPT 33 133

KAL-... Sensor

A (mm) B C (mm) D (mm)

M12x1 SW 19 23 43

G ¼ SW 19 26 43

G ½ SW 27 43 58

G ¾ SW 32 43 58

KAL-... with pipe fitting

A B C (mm) D (mm) E (mm)

G ¼ SW 27 10 50 81

G ½ SW 27 10 50 81

G ¾ SW 32 15 52 82,5

G 1 SW 39 15 56 85

G 11/4 SW 46 15 50 90

G 11/2 SW 55 15 50 92,5

KAL-..4440 with Tri clamp

Page 14 KAL-A(K) K05/1116

Page 15

KAL-A(K)

15. EU Declaration of Conformance

We, KOBOLD-Messring GmbH, Hofheim-Ts, Germany, declare under our sole

responsibility that the product:

KAL-A Electronic Flow Meter

KAL-AK Electronic Flow Meter / Monitor

to which this declaration relates is in conformity with the standards noted below:

EN 61000-6-3:2011-09

Electromagnetic compatibility (EMC) - Part 6-3: Generic standards - Emission

standard for residential, commercial and light-industrial environments

EN 61000-6-1:2007-10

Electromagnetic compatibility (EMC) - Part 6-1: Generic standards - Immunity for

residential, commercial and light-industrial environments

Also the following EC guidelines are fulfilled:

2014/30/EU EMC Directive

2011/65/EU RoHS (category 9)

Hofheim, 12. May 2016

H. Peters M. Wenzel

General Manager Proxy Holder

KAL-A(K) K05/1116 Page 15

Loading...

Loading...