Page 1

Thermal Flow Switch

for Water-Based Liquids

measuring

•

monitoring

•

analyzing

KAL-K

• Flow Velocities from 0.04...2 m/s

• T

: 250 °F, P

max

: 1450 PSIG

max

• NPT and 3-A Compliant Sanitary Fittings

• No Moving Parts

• Intelligent Temperature Compensation

• Extremely Low Pressure Loss

• Easy to Operate

• Insensitive to Dirt

KOBOLD companies worldwide:

ARGENTINA, AUSTRALIA, AUSTRIA, BELGIUM, BULGARIA, CANADA, CHILE, CHINA, COLOMBIA,

CZECH REPUBLIC, EGYPT, FRANCE, GERMANY, HUNGARY, INDIA, INDONESIA, ITALY, MALAYSIA,

MEXICO, NETHERLANDS, PERU, POLAND, REPUBLIC OF KOREA, ROMANIA, SINGAPORE, SPAIN,

SWITZERLAND, TAIWAN, THAILAND, TUNISIA, TURKEY, UNITED KINGDOM, USA, VIETNAM

05/07-15-2019

KOBOLD Instruments, Inc.

1801 Parkway View Drive

Pittsburgh, PA 15205

Main Ofce:

1.800.998.1020

1.412.788.4890

info@koboldusa.com

www.koboldusa.com

Page 2

Temperatur (C)

0

80

2

Thermal Flow Switch Model KAL-K

Description

The KAL-K thermal flow switch utilizes KOBOLD’s temperature

compensating electronics. This compact, one-piece unit

provides reliable readings unaffected by temperature or physical

characteristics of non-viscous water-based liquids. This is made

possible through the use of state-of-the-art microprocessor

technology. The microprocessor can be field calibrated to both

the liquid properties and operating range in a simple, five minute

set-up procedure. This intelligence, coupled with a “no moving

parts” design, make the KAL a superior performer in virtually all

applications. The KAL-K is also offered in a 3-A compliant version.

The KAL-K incorporates an 8 segment bar-graph LED flow

trend indicator and one flow alarm setpoint. The setpoint is fully

configurable as NPN, PNP, normally open or normally closed.

Operation

The KAL design is based on the time proven calorimetric

principle. The sensor is internally heated to a few degrees above

the temperature of the media. Flow causes removal of heat from

the sensor, resulting in a cooling effect. The rate of cooling is a

measure of the flow velocity. The microprocessor based design

of the KAL distinguishes it from the competition. Full temperature

compensation of the flow rate is readily obtained through a simple,

one-time, calibration procedure. This assures elimination of flow

rate reading drift caused by temperature variations in the process

liquid.

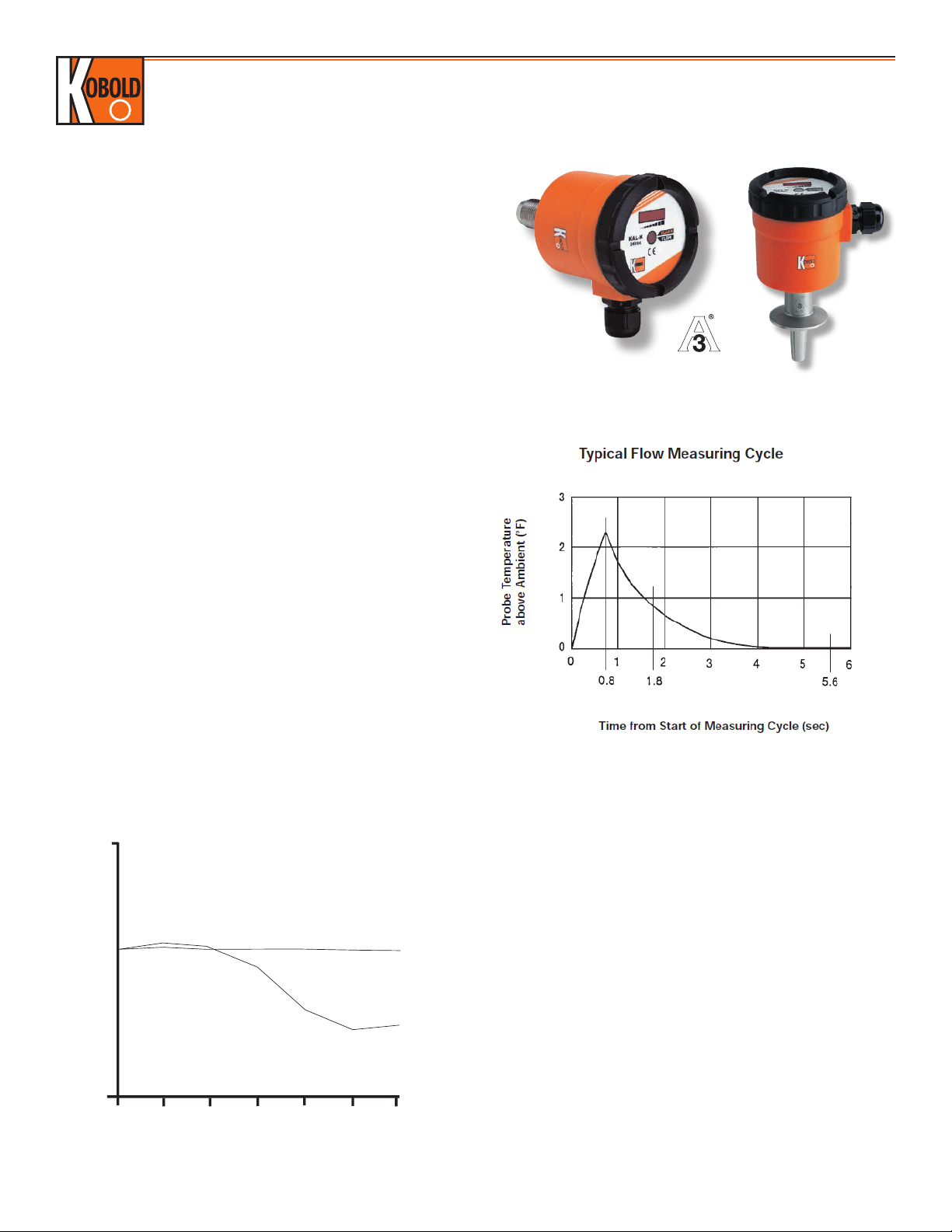

KAL Timing - Heating and Measuring Cycle

Temperature Compensation

The KOBOLD KAL flow products use a microprocessor to

compensate for temperature changes through use of an internal

look-up table. End-users can easily adapt the equipment to the

requirements of their unique installations. Unlike conventional

calorimetric flow switches, the technically advanced design of the

KAL provides a flow reading which is unaffected by temperature.

Operating Behavior

1. At t=0, the probe temperature is recorded. This reading

represents the ambient liquid temperature.

Schaltpunktveränderung über Temperatur

2. Still at t=0, the KAL begins heating the probe.

3. At t=0.8 seconds, the heating cycle ends and the KAL begins

monitoring the probe temperature.

KAL-... with compensation

KAL-... mit Kompensation

4. At t=1.8 seconds, a temperature reading is taken and

compared to the t=0.8 second temperature. The rate of cooling

Schaltpunkt (m/s)

Switch point (m/s)

Standard without

Herkömmlich

compensation

ohne Kompensation

is calculated and compared to a Cooling Rate vs Flow Rate

table specific to the ambient temperature recorded at t=0.

5. The probe is allowed to cool until t=5.6 seconds. A

temperature reading is taken and compared to the initial t=0

reading. If the temperatures are equal (or nearly so), the flow

reading is determined valid and passes through to the KAL

output. If the temperatures are not equal, the KAL waits

20 30

40

Temperature °C

50

60

70

another 5.6 sec, and Step 5 repeats.

2

www.koboldusa.com

No responsibility taken for errors;

subject to change without prior notice.

Page 3

Thermal Flow Switch Model KAL-K

Specifications

Switching Range: 0.04...2 m/s

Media: Water-Based Liquids (Water

Content at least 90%);

not Suitable for Oils or Fuels

Response Time

Typical: 5.6 seconds

Optional w/"F": 1.2 seconds

Fittings

Standard: 1/2" or 3/4" NPT

Sanitary: 1-1/2" Tri-Clamp®

Flow Trend Indicator: 8 Red LEDs

Temperature Rating

Operating: 32...250 °F

CIP: 280 °F (non-operating)

Maximum Pressure

Threaded: 1450 PSIG

Approximate Switch Points at Various Pipe Diameters

Sanitary: 600 PSIG or per Clamp Rating

Wetted Parts

Standard NPT: 304 SS

Optional NPT: 316-Ti SS

Sanitary: 316L SS

Housing

Standard: IP 65

Sanitary: IP 65

Power Requirements

Supply Voltage: 24 VDC ± 10%

Optional: 110 V

Current Draw: 300 mA Max.

AC

Switch Characteristics

Adjustment: By Potentiometer

Status Indicator: Bi-colored LED

24 VDC Units

Type: PNP or NPN, Open Collector

Switch Rating

DC Only: 400 mA at 24V

110 VAC Units:

Type: N/O Dry Contact

Switch Rating

AC Only: 5A at 240 V

Nominal ID

(inch)

1/2 0.08...4.0

3/4 0.2...9.0

1 0.4...16

1 1/4 0.5...25

1 1/2 0.8...36

2 1.3...64

2 1/2 2.0...100

3 3.0...140

Note:

The approximate flow ranges specified in the table above have

been calculated for each pipe diameter from the known flow

velocity range of the KAL. It must be noted that flow in pipes is

non-uniform across the pipe cross-section and approaches zero at

the pipe wall. This means that, in practice, the depth of installation

of the probe, the internal pipe diameter, and the flow profile of the

liquid in the pipe can interact to produce very significant deviations

from the flow ranges in this data sheet.

Range Water

(GPM)

Nominal ID

Range Water

(inch)

4 6.0...250

6 12...575

8 20...1025

10 35...1600

12 50...2300

16 85...4100

20 130...6400

(GPM)

DC Only: 0.2 A at 110V

For correct operation of the KAL-K thermal flow switch, the tip of the flow sensor must be located sufficiently into the flow stream of the

process to sense the liquid flow. Therefore it is very important to consider the sensor's insertion depth and how it is installed in the process

pipe. If the sensor tip is not adequately immersed into the flow stream, the sensor will not measure flow rate correctly, or worst case will not

detect any flow at all. Ideally for correct detection, we recommend the sensor tip be located at a distance from the pipe wall equal to 20% of

the internal cross-section diameter of the pipe. Note that NPT fittings are tapered, and consideration should be given to the fact that when

installed together, NPT mating fittings will not fully thread down to the bottom of the female connection.

KAL-K Order Details (Example: KAL-4315C)

Fitting

Model

(304 SS)

Model

(316-Ti SS)

1/2" NPT KAL-4215 KAL-4315 -

3/4" NPT - KAL-4320 -

1-1/2"

Tri-Clamp®

- - KAL-4340S

*specify probe length on your order (NPT models only)

No responsibility taken for errors;

subject to change without prior notice.

Model

(316 L SS)

www.koboldusa.com

Options

..C = 1/2" NPT Conduit Electrical Connection

..EP = Extended Probe*

..F = Fast Response Time (24 VDC Units Only)

..K = N/C Switch Logic

..M12 = Plug Connector w/6 ft Cable for 24 VDC Units

..P03R = 110 VAC Version with Dry Contact

3

Page 4

Dimensions

Standard Version

Thermal Flow Switch Model KAL-K

1/2" Model

3/4" Model

Sanitary Version

4

www.koboldusa.com

No responsibility taken for errors;

subject to change without prior notice.

Loading...

Loading...