Page 1

KOBOLD KAL-L (KAL-8000 Series)

Thermal Air Flow Switch

User Instructions

KOBOLD Instruments Inc. 1801 Parkway View Drive Pittsburgh PA 15205

Phone (412) 788-2830 • Fax (412)-788-4890

Manual-KAL-L_5-12

Page 2

Page 3

KAL-L

Table Of Contents

1.0 General .......................................................................................................1

2.0 Specifications..............................................................................................1

3.0 Mechanical Installation................................................................................3

3.1 Installation General ..........................................................................3

3.2 Installation of Units with NPT Thread Connection............................5

3.3 Installation of Units with HVAC Flange Connection..........................5

4.0 Electrical Connections ................................................................................5

5.0 Operation ....................................................................................................6

5.1 Flow Setpoint Adjustment ................................................................ 6

5.2 Adjustment of the Start-up Time Delay ............................................8

6.0 Maintenance ............................................................................................... 9

7.0 Need Help with Your KAL-L Flow Switch? ..................................................9

List of Diagrams

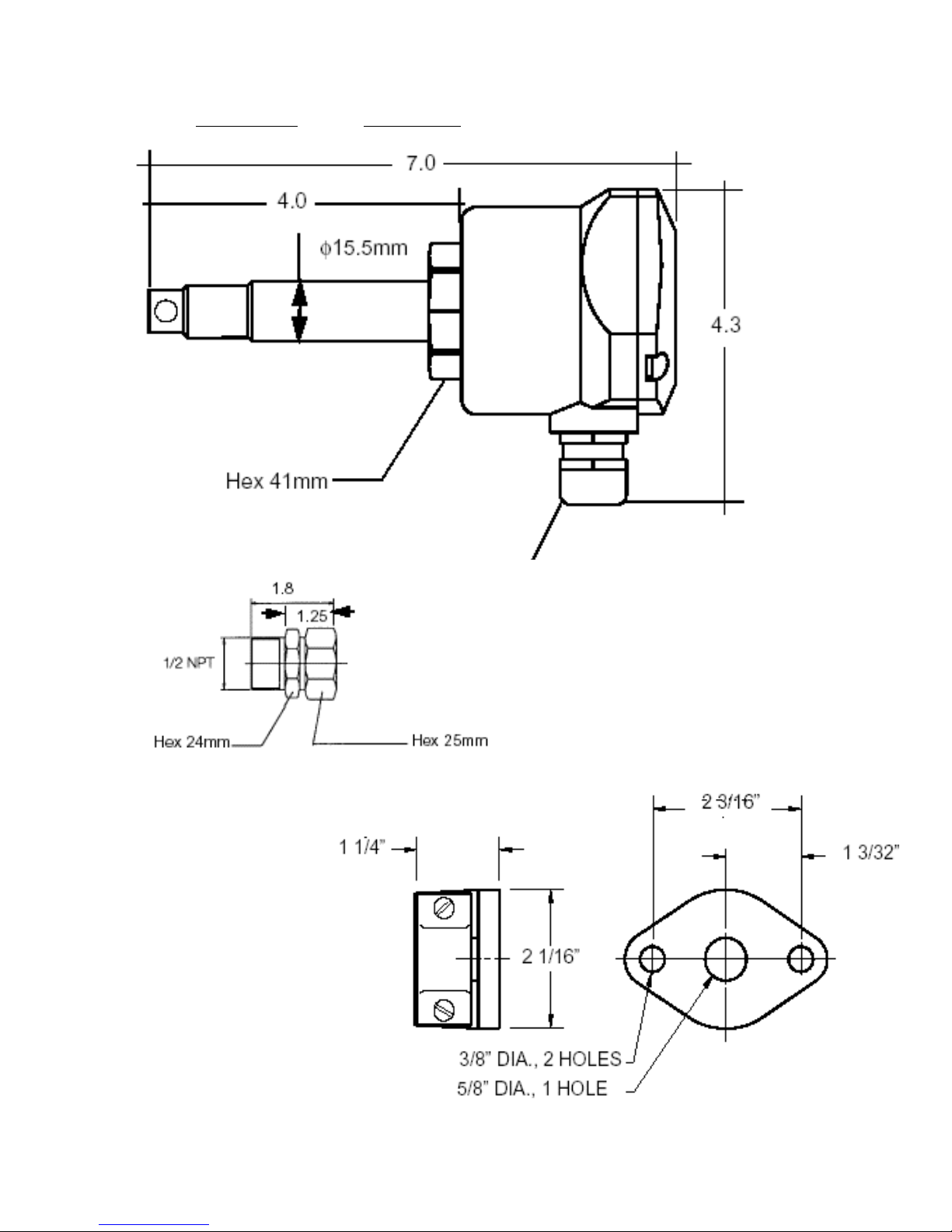

Diagram 2.1: Dimensions............................................................................2

Diagram 3.1: General Installation ............................................................... 4

Diagram 3.2: Required Straight Pipe Runs.................................................4

Diagram 4.1: Electrical Connections...........................................................5

Diagram 5.1: Interior Controls Layout for the KAL-L...................................6

List of Tables

Table 2.1: Model Number Codes ........................................................... 3

FM Rev. 5/17/12

Page 4

Page 5

KAL-L

CAUTION: For safety reasons, please read the cautionary information located at

the end of the manual, before attempting installation.

1.0 General

The KAL-L (KAL-8000 Series) Thermal Air Flow Switch uses the proven calorimetric

principle to monitor the flow of air or non-hazardous gases. A sensing resistive thermal

device (RTD) is heated to a few degrees above the temperature of the flow medium. As

the medium flows across the sensing RTD it cools the RTD. The rate of cooling is

proportional to flowrate. A second RTD measures medium temperature and the KAL-L

electronics uses this measurement to compensate for changes in medium temperatures

thus preventing false readings due to medium temperature transients. If the measured

flow value drops below the setpoint value, an output relay is activated providing an alarm

or control input.

2.0 Specifications

Switching Range: 3.3 to 66 feet/second @ 68°F/14.5 PSIA

Restricted span for other pressure and

temperature conditions

Accuracy: ±10% of flow rate

Repeatability: ±1% of flow rate

Display

Flowrate: 8 LED trend indicator

Switchpoint: Flashing LED in trend indicator

Switch Status: Dual colored LED

RED = Flow below switchpoint

GREEN = Flow above switchpoint

Max. Temperature Gradient: 30°K(°C)/Min. @ 25 feet/sec and 190°F

Response Time: Adjustable 1 to 60 seconds

Warm-up Time: 30 seconds

Max. Pressure: 120 PSIG

Temperature Range

Process: -10 to +250°F

Ambient: +15 to +140°F

Wetted Parts: Ni-Plated brass

Housing: Polyamide

Electrical Data

Power Requirements: 24 VDC/VAC +10%/-15%

Switch Characteristics: 1-SPDT relay Max. 250 VAC/4 A/1000

VA

Electrical Connection

Standard: Cable gland

Optional: 1/2” NPT Conduit or M-12 plug

Protection: NEMA 4/IP 65

FM Rev. 5/17/12

Page 6

KAL-L 2

Diagram 2.1 Dimensions

7.0

4.0

φ15.5mm

Hex 41mm

4.3

HVAC Duct Mount

Flange

PG 13.5

Cable Gland

1/2” NPT

Compression Fitting

FM Rev. 5/17/12

All dimensions in inches

Unless otherwise noted

Page 7

3 KAL-L

Table 2.1 Model Number Codes

Model Code Description

KAL-8115 15mm smooth bore probe with 1/2” NPT compression fitting

KAL-8115FL 15mm diameter probe with clamping flange per DIN 43 743

Options

Option Suffix Description

-M12 NEMA 4 electrical plug connector

-C 1/2” NPT conduit connection

3.0 Mechanical Installation

CAUTION

Prior to mechanical installation, ensure that the process flow velocity to be monitored is

within the switching range of the device. Also ensure that system temperature and

pressure are within the limit of the device. See Section 2.0 ”Specifications”.

3.1 Installation General

The following general installation instructions and precautions apply to all KAL-8000

series installations:

3.1.1 The probe tip must be inserted a minimum of 3/8” beyond the

inside diameter of the pipe or duct into which it is to be installed.

Best results are obtained if the probe is inserted into the pipe or duct 1/

2” or greater.

3.1.2 In order to ensure that the sensing elements are facing directly into the

flow stream, a notch has been placed on the probe hex nut to aid in

alignment. For optimal results, the probe should be installed so that the

notch is aligned directly over the centerline of the pipe or duct.

3.1.3 In order to ensure a uniform flow profile across the probe tip, install the

probe to allow for 10 pipe diameters of straight run piping upstream and

5 downstream. This piping should be free of tees, elbows, bends,

valves, dampers or any other such appurtenances.

3.1.4 The probe should not be installed in the lower hemisphere of the pipe or

duct. Liquid and debris which collect in the lower portion of the pipe will

cause the probe to function erratically if they come in contact with the

probe.

FM Rev. 5/17/12

Page 8

KAL-L 4

Diagram 3.1 General Installation

3/8” Min. probe

insertion depth.

1/2” or greater is

optimal

Liquid and sediment

which settle at the bottom

cannot cause measuring

errors

Mount the unit

in the pipe upper

hemisphere

C

L

Mount probe such that

the notch cut into the

hex is perpendicular to

the pipe centerline to

ensure that the probe is

properly oriented in the

flow stream.

Diagram 3.2 Required Straight Pipe Runs

10XD Upstream

5XD Downstream

Flow

3.2 Installation of Units with NPT Thread Connection

FM Rev. 5/17/12

Page 9

5 KAL-L

3.2.1 Units with NPT threaded connections are best suited for round pipes or

ducts in which systems are under pressure. The NPT connection

makes a leaktight seal to 120 PSIG.

3.2.2 The threaded connection should be installed into a pipe via a 1/2” weld

coupling or a pipe tee with 1/2” connection. If a bushing is used to

reduce a larger fitting size to 1/2”, ensure that the probe insertion

requirements are met. See Section 3.1 ”Installation General”.

3.2.3 Ensure that a thread sealant such as PTFE tape is used to seal the

threads.

3.3 Installation of Units with HVAC Flange Connection

3.3.1 Units with flanged connections are best suited for square ducts in HVAC

applications where adding an NPT connection is impractical.

3.3.2 Prior to installing the flange, the flange face which contacts the surface

of the HVAC duct should be sealed using a field manufactured gasket

or RTV compound. This will minimize leakage at the flange face.

4.0 Electrical Connections

4.0.1 All electrical connections are made at the terminal blocks inside the

electronics enclosure of the KAL-L.

4.0.2 The KAL-L can operate using a power supply of 24 VAC or DC. When

DC voltage is used, the input supply is non-polarized. The polarity

of the DC input voltage does not matter and can be wired in either

direction without affecting the operation of the unit.

Diagram 4.1 Electrical Connections

Relay Output

SPDT

Max. 4A @ 250 VAC

FM Rev. 5/17/12

Page 10

KAL-L 6

5.0 Operation

Diagram 5.1 Interior Controls Layout for the KAL-L

Setpoint LED

Fixed at 3rd LED

(flashing)

Trend Indicator

8 LEDs

Span Adjustment P1

DUO-LED

Green= Flow > Setpoint

Relay Activated

Red = Flow < Setpoint

Relay Deactivated

RELAY

24V AC/DC

Start-up Time Delay P2

Holds the relay in activated

state for 0 to 60 seconds after

power-up

5.1 Flow Setpoint Adjustment

The section describes the procedures for adjustment of the flow setpoint for three

scenarios:

• Adjustment of precise setpoint on falling flow.

• Adjustment of precise setpoint on rising flow.

• Setup for flow/no flow detection.

5.1.1

Flow Setpoint Adjustment - General

The flow switch point on the KAL-L is fixed at 50% of its span. Because of the trend

indicator’s non-linear response, this corresponds to the third LED on the indicator bar.

The third LED is wired to flash permanently to allow users to judge the location of the

flow setpoint relative to system flow.

The flow switch point is set by adjusting the span potentiometer P1. Doing this increases

or decreases the span of the trend indicator thereby changing the point at which the

KAL-L switches. The next three sections describe how to set the KAL-L switchpoint in

specific situations

FM Rev. 5/17/12

Page 11

7 KAL-L

5.1.2 Adjustment of Precise Setpoint on Falling Flow

To adjust the KAL-L for a precise switchpoint on falling flow, refer to Diagram 5.1 on page

6 and proceed as follows:

5.1.2.1 With power connected to the KAL-L, adjust the span potentiometer P1 clockwise to its right hand stop.Turn time delay potentiometer P2 counter-clockwise to its far lefthand stop.

5.1.2.2 Initiate system flow and adjust it to the desired switchpoint flow

rate. Note that at this time the DUO LED should be green. If it is

red your desired flowrate is below the measuring capability of the

KAL-L.

5.1.2.3 Slowly turn P1 counter-clockwise. You will note that the LEDs on

the trend indicator will extinguish sequentially as the span is

reduced. Continue turning P1 counter-clockwise until the trend

indicator span is reduced to the third LED (which is flashing). At

this point, the DUO-LED turns red and the relay switches over.

The KAL-L is now adjusted at the desired setpoint.

5.1.2.4 Adjust system flow to normal.

5.1.3 Adjustment of Precise Setpoint on Rising Flow

To adjust the KAL-L for a precise switchpoint on rising flow, refer to Diagram 5.1 on page

6 and proceed as follows:

5.1.3.1 With power connected to the KAL-L, adjust the span potentiometer P1 counter-clockwise to its left hand stop. Turn time delay

potentiometer P2 counter-clockwise to its far lefthand stop.

5.1.3.2 Initiate system flow and adjust it to the desired switchpoint flow

rate.

5.1.3.3 Slowly turn P1 clockwise. You will note that the LEDs on the

trend indicator will light sequentially as the span is increased

from zero. Continue turning P1 clockwise until the trend indicator

span is increased to the third LED (which is flashing). At this

point, the DUO-LED turns green and the relay switches over.

The KAL-L is now adjusted at the desired setpoint.

5.1.3.4 Adjust system flow to its normal value.

FM Rev. 5/17/12

Page 12

KAL-L 8

5.1.4 Setup of the KAL for Flow/No-flow Detection

Alternatively, the KAL-L can be quickly set-up to switch on a loss of flow. Using this

procedure does not yield a precise switchpoint but is generally acceptable for flow/noflow detection. When set up in this manner, the KAL-L will switch when approximately a

50% reduction from normal flow occurs. To set the KAL-L for flow/no-flow detection, refer

to Diagram 5.1 and proceed as follows:

5.1.4.1 With power connected to the KAL-L, adjust the span potentiometer P1 counter-clockwise to its left hand stop.Turn time delay

potentiometer P2 counter-clockwise to its far lefthand stop.

5.1.4.2 Initiate system flow. Ensure that system flow rate is at normal

operating value.

5.1.4.3 Slowly turn P1 clockwise. You will note that the LEDs on the

trend indicator will light sequentially as the span is increased

from zero. Continue turning P1 clockwise just until all 8 trend

indicator LEDs are lit. As the trend indicator span is adjusted

past the third LED (which is flashing) note that the DUO LED

changes from red to green and the relay switches over.

5.1.4.4 The KAL-L is now adjusted for flow/no flow detection. The switch

point will occur on a flow rate reduction of approximately 50%

from normal operating value.

5.2 Adjustment of the Start-up Time Delay

The KAL-L has a start-up time delay feature which holds the output relay in the activated

state and disables flow monitoring for a period of up to 60 seconds after power-up of the

KAL-L. This feature is designed to prevent nuisance alarms during system start-up and

until steady state flow conditions are achieved.

To adjust the start-up time delay, refer to Diagram 5.1 on page 6 and proceed as follows:

5.2.1 Potentiometer P2 adjusts the start-up time delay. Turning P2 counterclockwise to its far left hand stop adjusts the time delay to zero. Turning

P2 clockwise increases the time delay to a maximum possible of 60

seconds at the far right hand stop. The time delay adjustment is approximately linear between the left and right hand stops.

FM Rev. 5/17/12

Page 13

9 KAL-L

6.0 Maintenance

The KAL-L is an electronic device which uses no moving parts. This design ensures

reliable operation and long service life. Dirt and debris which can build up on the sensing

probe over time will result in degraded performance. For this reason we strongly

recommend that the proper filtration be installed in the system. It is also recommended

that the KAL-L be occasionally removed from the system and its measuring probe

inspected for dirt buildup and cleaned as needed. The frequency of this cleaning will vary

depending on the cleanliness of the system.

7.0 Need Help with Your KAL-L Flow Switch?

Contact one of our friendly engineers at 412-788-2830.

FM Rev. 5/17/12

Page 14

Page 15

11 KAL-L

CAUTION

PLEASE READ THE FOLLOWING WARNINGS BEFORE ATTEMPTING

INSTALLATION OF YOUR NEW DEVICE. FAILURE TO HEED THE

INFORMATION HEREIN MAY RESULT IN EQUIPMENT FAILURE AND

POSSIBLE SUBSEQUENT PERSONAL INJURY.

FM Rev. 5/17/12

Page 16

KAL-L 12

• User's Responsibility for Safety: KOBOLD manufactures a wide range of

process sensors and technologies. While each of these technologies are

designed to operate in a wide variety of applications, it is the user's

responsibility to select a technology that is appropriate for the application,

to install it per these installation instructions, to perform tests of the

installed system, and to maintain all components. The failure to do so could

result in property damage or serious injury.

• Proper Installation and Handling: Use a proper sealant with all

installations. Never overtighten the unit within the fitting. Never use the

housing to thread the unit into its fitting. Always use only an

appropriate sized wrench on the hex portion of the probe. Always check for

leaks prior to system start-up.

• Wiring and Electrical: A supply voltage of 24 Volts AC or DC +10%/-15%

is used to power the KAL-L. The sensor systems should never exceed this

rating. Electrical wiring of the sensor should be performed in accordance

with all applicable national, state, and local codes.

• Temperature and Pressure: The KAL-K is designed for use in application

temperatures from -10 to 250°F, and for use at pressures up to 115 PSIG.

Operation outside these limitations will cause damage to the unit and

possible personal injury.

• Material Compatibility: The KAL-K sensor probe is made of nickel plated

brass. The housing is polycarbonate. Check your model number with the

wetted materials specification in Section 2.0 ‚"Specifications”, on page 1 of

this manual. Make sure that the model which you have selected is

chemically compatible with the application environment. While the switch

housing is liquid resistant when installed properly, it is not designed to be

immersed. It should be mounted in such a way that it does not normally

come into contact with liquid.

• Flammable, Explosive and Hazardous Applications: The KAL-L is not

an explosion-proof or intrinsically safe design. It should not be used in

hazardous areas where risk of explosion exists.

• Make a Fail-safe System: Design a fail-safe system that accommodates

the possibility of switch or power failure as well as operator error. In critical

applications, KOBOLD recommends the use of redundant backup systems

and alarms in addition to the primary system.

FM Rev. 5/17/12

Page 17

Page 18

Loading...

Loading...