Page 1

OPERATING MANUAL HPC & UMC4

Page 1 of 105

Coriolis – Mass-Flow Meter

HPC

UMC4

Operating manual

Please read the instructions carefully and store them in a safe place for future use!

Page 2

Page 2 of 105

OPERATING MANUAL HPC & UMC4

Contents

INTRODUCTION ............................................................................................................ 8

I. Shipping and storage; product inspection ............................................................................................. 8

II. Warranty ................................................................................................................................................ 8

III. Application domain the operating manual ......................................................................................... 8

IV. Measures to be taken before sending your device to the manufacturer for repair ............................ 8

V. Supplementary operating instructions regarding the HART interface ............................................ 8

VI. Operating manual of explosion-proof flow meters ............................................................................. 8

1. STEPS PRIOR TO OPERATION ........................................................................... 9

1.1 Safety advisory for the user ............................................................................................................. 10

1.2 Hazard warnings .............................................................................................................................. 10

1.2.1 Danger ...................................................................................................................................... 10

1.2.2 Warning .................................................................................................................................... 10

1.2.3 Caution ..................................................................................................................................... 10

1.2.4 Note .......................................................................................................................................... 10

1.3 Proper use of the device .................................................................................................................. 11

1.4 Installation and servicing ................................................................................................................. 11

1.5 Returning your flow meter for servicing or calibration ..................................................................... 12

1.6 Replacement of the transmitter electronics ..................................................................................... 12

2. MAINTENANCE .................................................................................................. 13

2.1 Transmitter ....................................................................................................................................... 13

2.2 Coriolis mass flow sensor ................................................................................................................ 13

3. IDENTIFICATION ................................................................................................ 13

4. THE HPC SENSOR ............................................................................................. 14

4.1 Application domain of the HPC sensor ............................................................................................ 14

4.2 Mode of operation ............................................................................................................................ 14

4.2.1 Measuring principle .................................................................................................................. 14

4.2.2 System configuration ................................................................................................................ 14

4.2.3 Measured variables .................................................................................................................. 14

Page 3

OPERATING MANUAL HPC & UMC4

Page 3 of 105

4.3 Performance characteristics of the HPC sensor ............................................................................. 15

4.3.1 Reference conditions ................................................................................................................ 15

4.3.2 HPC flow ranges....................................................................................................................... 15

4.3.3 Density measurement .............................................................................................................. 15

4.3.4 Accuracy ................................................................................................................................... 16

4.3.5 Pressure loss HPC ................................................................................................................... 16

4.3.6 Ambient temperature range ...................................................................................................... 16

4.3.7 Storage temperature ................................................................................................................ 16

4.3.8 Climatic category ...................................................................................................................... 16

4.3.9 Ingress protection ..................................................................................................................... 16

4.4 Operating conditions ........................................................................................................................ 17

4.4.1 Installation ................................................................................................................................ 17

4.4.2 Installation positions ................................................................................................................. 18

4.4.3 Pressure surges ....................................................................................................................... 19

4.4.4 Using the device with hazardous fluids .................................................................................... 20

4.4.5 Vibration stability ...................................................................................................................... 20

4.5 Process conditions ........................................................................................................................... 21

4.5.1 Process temperature ................................................................................................................ 21

4.5.2 Physical state ........................................................................................................................... 21

4.5.3 Viscosity ................................................................................................................................... 21

4.5.4 Gas content .............................................................................................................................. 21

4.5.5 Process temperature range ...................................................................................................... 21

4.5.6 Process pressure range ........................................................................................................... 21

4.5.7 Outlet pressure ......................................................................................................................... 21

4.6 Connection to the transmitter .......................................................................................................... 21

4.7 Construction details ......................................................................................................................... 22

4.7.1 Dimensions and weight ............................................................................................................ 22

4.7.2 Dimension drawings for the types HPC-S01 to HPC-S03 ....................................................... 23

4.7.3 Material ..................................................................................................................................... 25

4.8 Sensor HPC approvals .................................................................................................................... 25

4.8.1 CE marking ............................................................................................................................... 25

5. COMMISSIONING ................................................................................................ 26

5.1 Zero point calibration ....................................................................................................................... 26

5.2 Startup conditions ............................................................................................................................ 26

6. APPLICATION DOMAIN OF THE UMC4 TRANSMITTER .................................. 27

7. UMC4 TRANSMITTER: MODE OF OPERATION AND CONFIGURATION ........ 27

7.1 Measuring principle.......................................................................................................................... 27

7.2 System configuration ....................................................................................................................... 27

7.2.1 DSB data memory module ....................................................................................................... 28

8. INPUT ................................................................................................................... 29

Page 4

Page 4 of 105

OPERATING MANUAL HPC & UMC4

8.1 Measured variable ........................................................................................................................... 29

8.2 Measuring range .............................................................................................................................. 29

9. OUTPUT .............................................................................................................. 29

9.1 Output signal .................................................................................................................................... 29

9.2 Failure signal .................................................................................................................................... 30

9.3 Load ................................................................................................................................................. 30

9.4 Damping ........................................................................................................................................... 30

9.5 Low flow cutoff ................................................................................................................................. 30

10. UMC4 PERFORMANCE CHARACTERISTICS................................................... 31

10.1 Reference conditions ................................................................................................................... 31

10.2 Measured error ............................................................................................................................. 31

10.3 Repeatability error ........................................................................................................................ 31

10.4 Influence of ambient temperature ................................................................................................ 31

11. UMC4 OPERATING CONDITIONS ................................ ................................ ..... 32

11.1 Installation conditions and cable glands ...................................................................................... 32

11.2 NPT cable glands ......................................................................................................................... 32

11.3 Environmental conditions ............................................................................................................. 32

11.3.1 Ambient temperature ................................................................................................................ 32

11.3.2 Ambient temperature range ...................................................................................................... 32

11.3.3 Storage temperature ................................................................................................................. 32

11.3.4 Ingress protection ..................................................................................................................... 32

11.4 Process conditions ....................................................................................................................... 33

11.4.1 Integrally Mounted transmitter .................................................................................................. 33

11.4.2 Remote mounted transmitter .................................................................................................... 33

12. CONSTRUCTION DETAILS ................................................................................ 34

12.1 Type of construction/dimensions.................................................................................................. 34

12.2 Weight .......................................................................................................................................... 36

12.3 Material ......................................................................................................................................... 36

12.4 End connection............................................................................................................................. 36

12.5 Electrical connections and their protection classes ..................................................................... 36

Page 5

OPERATING MANUAL HPC & UMC4

Page 5 of 105

12.5.1 Wiring diagrams........................................................................................................................ 36

12.5.2 The output signals .................................................................................................................... 39

12.5.3 HART® ...................................................................................................................................... 39

12.5.4 Communication via Siemens PDM® ......................................................................................... 39

13. CONTROL UNIT BE4 ........................................................................................... 40

13.1 Introduction .................................................................................................................................. 40

13.2 Display ......................................................................................................................................... 40

13.3 Operating modes .......................................................................................................................... 41

13.4 Operation ..................................................................................................................................... 41

13.4.1 Operator interface .................................................................................................................... 41

13.4.2 The keys and their functions .................................................................................................... 42

13.4.3 Functional classes, functions and parameters ......................................................................... 43

14. UMC4 TRANSMITTER FUNCTIONS ................................................................... 45

14.1 MEASURED VALUES functional class ........................................................................................ 46

14.1.1 Mass flow .................................................................................................................................. 47

14.1.2 Volume flow .............................................................................................................................. 47

14.1.3 Counter forward ........................................................................................................................ 47

14.1.4 Counter reverse ........................................................................................................................ 47

14.1.5 Density ...................................................................................................................................... 48

14.1.6 Temperature ............................................................................................................................. 48

14.1.7 Elapsed time ............................................................................................................................. 48

14.1.8 Mass flow + Counter forward ................................................................................................... 48

14.1.9 Mass flow + Density ................................................................................................................. 49

14.1.10 Mass flow + Temperature ..................................................................................................... 49

14.1.11 Volume flow + Counter forward ............................................................................................ 49

14.1.12 Volume flow + Density .......................................................................................................... 49

14.1.13 Display mode during startup ................................................................................................. 50

14.1.14 Raw values ........................................................................................................................... 50

14.2 PASSWORD functional class ...................................................................................................... 51

14.2.1 Customer password ................................................................................................................. 51

14.2.2 Change customer password ..................................................................................................... 52

14.2.3 Service password ..................................................................................................................... 52

14.3 COUNTER functional class .......................................................................................................... 53

14.3.1 Unit of counters ........................................................................................................................ 54

14.3.1 Reset counters ......................................................................................................................... 54

14.4 MEASUREMENT PROCESSING functional class ...................................................................... 55

14.4.1 Damping ................................................................................................................................... 56

14.4.2 Low flow cut-off......................................................................................................................... 56

14.4.3 Low flow cut-off hysteresis ....................................................................................................... 56

14.4.4 Zero point calibration ................................................................................................................ 57

14.4.5 Filter .......................................................................................................................................... 57

14.5 FLOW functional class ................................................................................................................. 58

14.5.1 Mass flow QM unit .................................................................................................................... 59

14.5.2 Factor mass flow QM programmable unit ................................................................................ 59

Page 6

Page 6 of 105

OPERATING MANUAL HPC & UMC4

14.5.3 Mass flow QM range ................................................................................................................. 60

14.5.4 Mass flow QM limit MIN ............................................................................................................ 60

14.5.5 Mass flow QM limit MAX ........................................................................................................... 60

14.5.6 Mass flow QM limit hysteresis .................................................................................................. 61

14.5.7 Volume flow QV unit ................................................................................................................. 61

14.5.8 Factor volume flow QV programmable unit .............................................................................. 62

14.5.9 Volume flow QV range .............................................................................................................. 62

14.6 DENSITY functional class ............................................................................................................ 63

14.6.1 Density measurement on/off ..................................................................................................... 64

14.6.2 Density unit ............................................................................................................................... 64

14.6.3 Factor programmable density unit ............................................................................................ 65

14.6.4 Density lower-range value ........................................................................................................ 65

14.6.5 Density upper-range value ....................................................................................................... 65

14.6.6 Density limit MIN ....................................................................................................................... 65

14.6.7 Density limit MAX ..................................................................................................................... 66

14.6.8 Density limit hysteresis ............................................................................................................. 66

14.6.9 Density limit for empty pipe ...................................................................................................... 66

14.6.10 Fixed density ......................................................................................................................... 66

14.6.11 Reference/process density display ....................................................................................... 67

14.6.12 Temperature coefficient ........................................................................................................ 67

14.6.13 Reference temperature ......................................................................................................... 67

14.6.14 Operating pressure ............................................................................................................... 68

14.6.15 Density calibration hot medium ............................................................................................. 68

14.6.16 Measured values hot medium ............................................................................................... 68

14.6.17 Finish density calibration ....................................................................................................... 68

14.7 TEMPERATURE functional class ................................................................................................ 69

14.7.1 Temperature unit ...................................................................................................................... 70

14.7.2 Temperature lower-range value ............................................................................................... 70

14.7.3 Temperature upper-range value ............................................................................................... 70

14.7.4 Temperature limit MIN .............................................................................................................. 71

14.7.5 Temperature limit MAX ............................................................................................................. 71

14.7.6 Max. measured temperature .................................................................................................... 71

14.8 PULSE OUTPUT functional class ................................................................................................ 72

14.8.1 Pulse or frequency output ......................................................................................................... 73

14.8.2 Pulse output unit ....................................................................................................................... 73

14.8.3 Pulse value ............................................................................................................................... 74

14.8.4 Pulse width ............................................................................................................................... 74

14.9 STATUS functional class ............................................................................................................. 75

14.9.1 Status output active state ......................................................................................................... 75

14.9.2 Status output 1 assignment ...................................................................................................... 76

14.10 CURRENT OUTPUTS functional class ........................................................................................ 77

14.10.1 Current output I1 4 to 20 mA................................................................................................. 78

14.10.2 Current output I1 alarm ......................................................................................................... 78

14.10.3 Current output I1 assignment................................................................................................ 79

14.10.4 Current output I2 4 to 20 mA................................................................................................. 79

14.10.5 Current output I2 alarm ......................................................................................................... 79

14.10.6 Current output I2 assignment................................................................................................ 80

14.11 SIMULATION functional class ...................................................................................................... 81

14.11.1 Simulation on/off ................................................................................................................... 82

14.11.2 Direct simulation ................................................................................................................... 82

Page 7

OPERATING MANUAL HPC & UMC4

Page 7 of 105

14.11.3 Measured value simulation ................................................................................................... 83

14.11.4 Direct simulation of outputs .................................................................................................. 84

14.12 SELF-TEST function class ........................................................................................................... 85

14.12.1 Sensor test on/off .................................................................................................................. 86

14.12.2 Max. deviation of excitation .................................................................................................. 86

14.12.3 Self-test calibration ............................................................................................................... 86

14.12.4 Monitoring of sensor amplitude and excitation current ......................................................... 86

14.12.5 Display of sensor amplitudes ................................................................................................ 87

14.13 UMC TRANSMITTER SETTINGS functional class ..................................................................... 88

14.13.1 Language .............................................................................................................................. 89

14.13.2 Serial number........................................................................................................................ 89

14.13.3 Software version ................................................................................................................... 89

14.13.4 Reset system error ............................................................................................................... 90

14.13.5 Profibus/Modbus device address.......................................................................................... 90

14.14 SENSOR SETTINGS functional class ......................................................................................... 91

14.14.1 Sensor constant C ................................................................................................................ 92

14.14.2 Sensor material ..................................................................................................................... 92

14.14.3 Flow direction ........................................................................................................................ 93

15. DENSITY CALIBRATION .................................................................................... 94

15.1 Conditions .................................................................................................................................... 94

15.2 Procedure ..................................................................................................................................... 94

16. UMC4 FOR CUSTODY TRANSFER APPLICATIONS ........................................ 96

17. UMC4 TRANSMITTER ERROR MESSAGES ...................................................... 97

17.1 Standard operating mode ............................................................................................................ 97

17.2 Custody transfer mode ................................................................................................................. 97

17.3 List of error messages.................................................................................................................. 97

17.3.1 Display of self-test errors .......................................................................................................... 97

17.3.2 Display of system error ........................................................................................................... 100

18. DECLARATION OF CONFORMITY ................................................................... 102

19. DECONTAMINATION CERTIFICATE FOR DEVICE CLEANING ..................... 104

Page 8

Page 8 of 105

OPERATING MANUAL HPC & UMC4

Warning

Only sensors and transmitters signed as Ex-proofed on their rating plates must be

used in ex hazardous areas!

Standard equipment is not allowed to be used in ex hazardous areas.

Introduction

I. Shipping and storage; product inspection

Shipping and storage

The device is to be safeguarded against dampness, dirt, impact and damage.

Product inspection

Upon receipt of the product, check the contents of the box and the product particulars against the information on the delivery slip and order form so as to ensure that all ordered components have been supplied. Notify us of any shipping damage immediately upon receipt of the product. Any damage claim received at a later time will not be honored.

II. Warranty

Your flow meter was manufactured in accordance with the highest quality standards and was thoroughly

tested prior to shipment. However, in the event any problem arises with your device, we will be happy to

resolve the problem for you as quickly as possible under the terms of the warranty which can be found in

the terms and conditions of delivery. Your warranty will only be honored if the device was installed and

operated in accordance with the instructions for your device. Any mounting, commissioning and/or

maintenance work is to be carried out by qualified and authorized technicians only.

III. Application domain the operating manual

The present manual applies to Coriolis mass flow meters that are operated in conjunction with the UMC4

transmitter.

IV. Measures to be taken before sending your device to the manufacturer for repair

It is important that you do the following before shipping your flow meter to Heinrichs Messtechnik GmbH

for repair:

Enclose a description of the problem with your device. Describe in as much detail as possible the

application and the physical and chemical properties of the fluid.

Remove any residues from the device and be sure to clean the seal grooves and recesses thorough-

ly. This is particularly important if the fluid is corrosive, toxic, carcinogenic, radioactive or otherwise

hazardous.

The operator is liable for any substance removal or personal damage costs arising from inadequate

cleaning of a device that is sent for repair.

V. Supplementary operating instructions regarding the HART interface

For information regarding operation of the transmitter using the HART hand-held terminal, see “Operation of the UMC4 transmitter using the HART hand-held terminal.”

VI. Operating manual of explosion-proof flow meters

For installation of the sensor and transmitter within hazardous areas read „Operation manual of explosion-proof flow meters “. It contains also all ex-relevant characteristic values for the sensors and the

transmitter UMC4.

Page 9

OPERATING MANUAL HPC & UMC4

Page 9 of 105

1. Steps prior to operation

It is essential that you read these operating instructions before installing and operating the device. The device is to be installed and serviced by a qualified technician

only. The UMC4 transmitter is to be used exclusively to measure mass and volume

flow, as well as liquid and gas density and temperature, in conjunction with a Heinrichs Messtechnik Coriolis mass-flow sensor.

Downloading of the present document from our web site www.heinrichs.eu and

printing out this document is allowed only for purposes of using our mass flow meters. All rights reserved.

No instructions, wiring diagrams, and/or supplied software, or any portion thereof, may be produced,

stored, in a retrieval system or transmitted by any means, electronic, mechanical, photocopying or otherwise, without the prior written permission of Heinrichs Messtechnik GmbH.

Although the materials in the present document were prepared with extreme care, errors cannot be ruled

out. Hence, neither the company, the programmer nor the author can be held legally or otherwise responsible for any erroneous information and/or any loss or damage arising from the use of the information

enclosed.

Heinrichs Messtechnik GmbH extends no express or implied warranty concerning the applicability of the

present document for any purpose other than that described.

We plan to optimize and improve the products described and in so doing will incorporate not only our own

ideas but and in particular, any suggestions for improvement made by our customers. If you feel that

there is any way in which our products could be improved, please send your suggestions to the following

address:

Company:

Heinrichs Messtechnik GmbH

HM-E (R&D Department)

Headword: HPC for the sensor

Headword: UMC4 for the transmitter

Robert-Perthel-Strasse 9

D-50739 Cologne

Germany

or:

via fax: +49 (221) 49708-178

via E-mail: info@heinrichs.eu

We reserve the right to change the technical data in this manual in the light of any technical

progress that might be made. For updates regarding this product, visit our website at

www.heinrichs.eu, where you will also find contact information for the Heinrichs Messtechnik distributor

nearest you. For information regarding our own sales operations, contact us at info@heinrichs.eu.

Page 10

Page 10 of 105

OPERATING MANUAL HPC & UMC4

1.1 Safety advisory for the user

The present document contains the information that you need in order to operate the product described

herein properly. The document is intended for use by qualified personnel. This means personnel who are

qualified to operate the device described herein safely, including

electronics engineers,

electrical engineers, or

service technicians

who are conversant with the safety regulations pertaining to the use of electrical and automated technical

devices and with the applicable laws and regulations in their own country.

Such personnel must be authorized by the facility operator to install, commission and service the product

described herein, and are to read and understand the contents of the present operating instructions before working with the device.

1.2 Hazard warnings

The purpose of the hazard warnings listed below is to ensure that device operators and maintenance

personnel are not injured and that the flow meter and any devices connected to it are not damaged.

The safety advisories and hazard warnings in the present document that aim to avoid placing operators

and maintenance personnel at risk and to avoid material damage are prioritized using the terms listed

below, which are defined as follows in regard to these instructions herein and the advisories pertaining to

the device itself.

1.2.1 Danger

means that failure to take the prescribed precautions will result in death, severe bodily injury, or substantial material damage.

1.2.2 Warning

means that failure to take the prescribed precautions could result in death, severe bodily injury, or substantial material damage.

1.2.3 Caution

means that failure to take the prescribed precaution could result in bodily injury, or a material damage.

1.2.4 Note

means that the accompanying text contains important information about the product, handling the product

or about a section of the documentation that is of particular importance.

Page 11

OPERATING MANUAL HPC & UMC4

Page 11 of 105

Warning

The operator is responsible for ensuring that the material used in the sensor

and housing is suitable and that such material meets the requirements for

the fluid being used and the ambient site conditions.

The manufacturer accepts no responsibility in regard to such material and housing.

Warning

In order for the device to perform correctly and safely, it must be shipped, stored,

set up, mounted operated and maintained properly.

Warning

Only sensors signed as Ex-proofed on their rating plates must be used in ex

hazardous areas!

Standard equipment is not allowed to be used in ex hazardous areas.

For installation of the sensor and transmitter within hazardous areas read „Opera-

tion manual of explosion-proof flow meters “. It contains also all ex-relevant characteristic values for the sensors and the transmitter UMC4.

1.3 Proper use of the device

A Coriolis Mass Flow Sensor is intended for use solely for direct and continuous mass flow measurement

of liquids and gases, irrespective of their conductivity, density, temperature, pressure, or viscosity. The

sensor is also intended for use for the direct and continuous mass flow measurement of chemical fluids,

suspensions, molasses, paint, varnish, lacquer, pastes and similar materials.

1.4 Installation and servicing

The devices described in this manual are to be installed and serviced only by qualified technical personnel such as a qualified Heinrichs Messtechnik electronics engineer or service technician.

Warning

Before servicing the device, it must be completely switched off, and disconnected from all peripheral devices. The technician must also check to ensure

that the device is completely off-circuit. Only original replacement parts are to be

used.

Heinrichs Messtechnik GmbH accepts no liability for any loss or damage of any kind arising from

improper operation of any product, improper handling or use of any replacement part, or from

external electrical or mechanical effects, overvoltage or lightning. Any such improper operation,

use or handling shall automatically invalidate the warranty for the product concerned.

In the event a problem arises with your device, please contact us at one of the following numbers to arrange to have your device repaired:

Phone: +49 221 49708-0

Fax: +49 221 49708-178

Contact our customer service department if your device needs repair or if you need assistance in diagnosing a problem with your device

Page 12

Page 12 of 105

OPERATING MANUAL HPC & UMC4

Warning

The operator is liable for any loss or damage of any kind, including personal injury,

decontamination measures, removal operations and the like that are attributable to

inadequate cleaning of the device.

Any device sent in for servicing is to be accompanied by a certificate as

specified in Section 19 “Decontamination certificate for device cleaning”.

Caution

The complete insert is to be replaced with all of its printed boards (except for

the memory module). This is particularly important for the explosion-proof

transmitter. The specified precision and interchangeability of the electronics are

only guaranteed if the complete insert is replaced.

1.5 Returning your flow meter for servicing or calibration

Before sending your flow meter back to us for servicing or calibration, make sure it is completely clean.

Any residues of substances that could be hazardous to the environment or human health are to be removed from all crevices, recesses, gaskets, and cavities of the housing before the device is shipped.

The device is to be accompanied by a document describing the problem with the device. Please include

in this document the name of a contact person that our technical service department can get in touch with

so that we can repair your device as expeditiously as possible and therefore minimize the cost of repairing it.

1.6 Replacement of the transmitter electronics

Before replacing the transmitter electronics, read the safety instructions in Section 1.4 Installation and

servicing on page 11.

The data memory chip (DAB) with the calibrating data of the sensor is an integral component of the control unit (display BE4). Removal and installation is described in chapter 7.2.1 DSB data memory module

on page 28.

At an exchange of transmitter electronics, all electronics board must be exchanged. That comprises all

circuit boards in the electronic compartment and in the terminal compartment. The overall accuracy of the

measurement up to the analogous outputs is only guaranteed in such a way. Only the control unit with the

integrated memory for the calibrating data of the sensor remains in the device.

Page 13

OPERATING MANUAL HPC & UMC4

Page 13 of 105

Manufacturer

Heinrichs Messtechnik GmbH

Robert-Perthel-Straße 9

D-50739 Cologne

Phone: +49 221 49708-0

Fax: +49 221 49708-178

Internet: www.heinrichs.eu

E-mail: info@heinrichs.eu

Product type

Mass-flow meter for liquid and gaseous products

Product name

Sensor type HPC

Transmitter type UMC4, suitable for use with Heinrichs Messtechnik Coriolis

mass-flow sensors

Version no.

1.0, dated January 31, 2019

2. Maintenance

2.1 Transmitter

The transmitter is maintenance-free.

We recommend cleaning the sight-glass in regular intervals; check the enclosure for corrosion damages

and the solid seat of the cable glands.

2.2 Coriolis mass flow sensor

The sensor is generally maintenance-free. The function only is influenced by corrosion or by deposits

inside the inside of the measuring pipes. Therefore both have to be avoided mandatorily. Deposits have

to be removed by suitably washing up or cleaning the internal pipes and splitter. Otherwise the measuring

precision cannot be obtained.

Danger

In the case of a loop breakage, e. g. due to corrosion, medium leaks, fills the enclosure. Medium can get into the mounted transmitter or terminal box also (particularly at

high process pressures)!

The transmitter can stand under pressure, too.

Take care if there are:

Visible discolourations or humidity condensation at the sight-glass of the transmitter,

corrosion damages to the enclosure,

deformation of the sensor enclosure.

3. Identification

Page 14

Page 14 of 105

OPERATING MANUAL HPC & UMC4

mFC2

4. The HPC sensor

4.1 Application domain of the HPC sensor

The HPC sensor is intended for use solely for direct and continuous mass flow measurement of liquids

and gases, irrespective of their conductivity, density, temperature, pressure, or viscosity. The sensor is

also intended for use for the direct and continuous mass flow measurement of chemical fluids, suspensions, molasses, paint, varnish, lacquer, pastes and similar materials.

4.2 Mode of operation

4.2.1 Measuring principle

The Coriolis mass flow meter is based on the

principle whereby in a rotating system a force

(known as the Coriolis force) is exerted on a

mass at a rotation point that is moving towards

or away from this point.

4.2.2 System configuration

The flow meter consists of a sensor that is

mounted in a pipe, and a transmitter (see Section 6 Application domain of the UMC4 on pp. 27), that

can be directly mounted on the sensor or installed separately (e.g. on a wall).

The transmitter oscillates the flow tubes in the sensor over a excitation coil and picks up, via the sensor coil, the measuring signal which is proportional to the mass flow. After being temperature compensated, the measuring signal is converted into an analog output signal that is consistent with the measuring range setting.

4.2.3 Measured variables

Measured variables: mass flow, density, temperature;

Calculated: Volume flow is calculated from the mass-flow and density

Page 15

OPERATING MANUAL HPC & UMC4

Page 15 of 105

Mass-flow

min.

Measuring range

max.

Measuring range

Nominal

(=1bar)

Zero point stability

(of range)

Model

kg/h

[lbs/min]

kg/h

[lbs/min]

kg/h

[lbs/min]

kg/h

[lbs/min]

HPC-S01

2,0

[0,1]

20

[0,7]

6

[0,2]

0,004

[0,000]

HPC-S02

5

[0,2]

50

[1,8]

15

[0,6]

0,01

[0,000]

HPC-S03

16

[0,6]

160

[5,9]

48

[1,8]

0,032

[0,001]

*

(=0,5bar)

Density accuracy

Model

3-Point

5-Point

HPC-S01

5 g/l

3 g/l

HPC-S02

5 g/l

3 g/l

HPC-S03

5 g/l

3 g/l

4.3 Performance characteristics of the HPC sensor

4.3.1 Reference conditions

Established flow profile

Inlet section corresponds to the mounting length

Operation is to be performed with downstream control valves

Measurement is to be performed in the absence of any gas bubbles

Flow tubes are to be kept clean at all times

Process temperature is to be regulated as specified in Section 4.5.1 Process temperature

on page 21

Process pressure is to be regulated as specified in Section 4.5.6 Process pressure range

on page 21

Ambient temperature is to range from + 10 °C to + 30 °C (50 °F to 86 °F)

Warm-up period: 15 minutes

Standard calibration shall be performed at 20 %, 50 % and 100 % (three times each)

High-frequency interference is to be regulated as specified in section 4.8.1 CE marking

on page 25.

4.3.2 HPC flow ranges

Reference conditions: in conformity with IEC 770:

Temperature: 20 °C, relative humidity: 65 %, air pressure: 101.3 kPa

Fluid: water

4.3.3 Density measurement

The attainable accuracy depends on the selected calibration type.

With density measurement is deactivated in the density menu, no density measurement is possible and empty pipe monitoring is not available!

Page 16

Page 16 of 105

OPERATING MANUAL HPC & UMC4

Mass flow

Fluids

Accuracy HPC-S01 to HPC-S03

± 0.1 % of actual flow ± zero point stability (see Section 4.3.2

HPC flow ranges)

± 0.05 % of actual flow ± zero point stability with special calibration (see Section 4.3.2 HPC flow ranges)

Repeatability error

± 0.05% of actual flow (sensor with transmitter) ± ½ zero point

stability (see Section 4.3.2 HPC flow ranges)

Mass flow

Gases

Accuracy HPC-S01 to HPC-S03

± 0.5 % of actual flow ± zero point stability (see Section 4.3.2

HPC flow ranges)

Repeatability error

± 0.25 % of actual flow (sensor with transmitter) ± ½ zero point

stability (see Section 4.3.2 HPC flow ranges)

Additional measured values

Volume flow

± 0.2 % of actual value + zero point stability

Temperature

± 0.5 °C

Hysteresis

n/a

Settling time

1 to 15 seconds

Startup drift

15 minutes

Long-term drift

± 0.02 % of upper-range value per year

Influence of ambient temperature

± 0.005 % per K

Influence of fluid temperature

Compensated

Influence of fluid pressure

For fluids: too small to be relevant

Model

min. range

max. range

Pressure loss (Water (20°C), 1 mPas)

HPC-S01

2 kg/h

20 kg/h

2 kg/h

6 kg/h

10 kg/h

16 kg/h

20 kg/h

[0,1 lbs/min]

[0,7 lbs/min]

[0,1 lbs/min]

[0,2 lbs/min]

[0,4 lbs/min]

[0,6 lbs/min]

[0,7 lbs/min]

0,03 bar

0,09 bar

0,15 bar

0,16 bar

0,25 bar

HPC-S02

5 kg/h

50 kg/h

5 kg/h

15 kg/h

25 kg/h

35 kg/h

50 kg/h

[0,2 lbs/min]

[1,8 lbs/min]

[0,2 lbs/min]

[0,6 lbs/min]

[0,9 lbs/min]

1,3 lbs/min]

[1,8 lbs/min]

0,01 bar

0,04 bar

0,05 bar

0,10 bar

0,20 bar

HPC-S03

16 kg/h

160 kg/h

16 kg/h

48 kg/h

80 kg/h

128 kg/h

160 kg/h

[0,6 lbs/min]

[5,9 lbs/min]

[0,6 lbs/min]

[1,8 lbs/min]

[2,9 lbs/min]

[4,7 lbs/min]

[5,9 lbs/min]

0,01 bar

0,11 bar

0,30 bar

0,73 bar

1,13 bar

4.3.4 Accuracy

4.3.5 Pressure loss HPC

4.3.6 Ambient temperature range

− 20 °C to + 60 °C (-4 °F to 140 °F)

4.3.7 Storage temperature

− 40 °C to + 80 °C (-40 °F to 140 °F)

4.3.8 Climatic category

In conformity with IEC 654-1. Unsheltered class D locations with direct open-air climate.

4.3.9 Ingress protection

Standard version: IP 65 (NEMA 4) DIN EN 60529.

Page 17

OPERATING MANUAL HPC & UMC4

Page 17 of 105

Do not secure the screws of the flanges by using an Impact screwdriver!

Sensor may be damaged by the shocks!

Under no circumstances is the

sensor to be used to support a

pipe.

Do not install the sensor in suspended pipes.

Do not adjust the position of a

pipe by pulling or grasping the

sensor.

4.4 Operating conditions

4.4.1 Installation

The sensor is to be protected, wherever possible, against valves, manifolds and similar fittings that

generate turbulence. The sensor is to be installed in accordance with the following instructions.

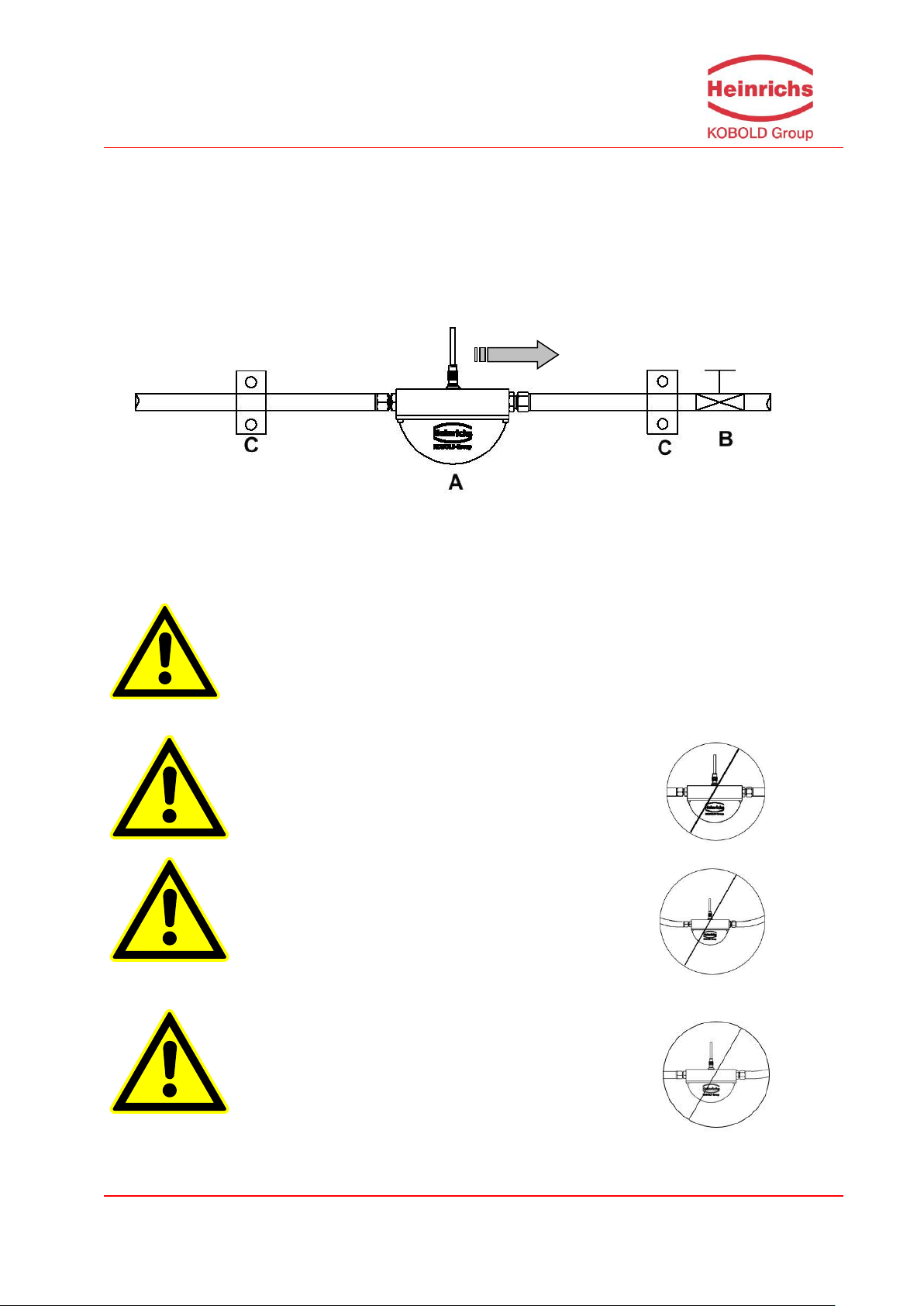

Diagram showing flow meter installation

Flow meter installation: A = sensor, B = valve, C = pipe clamps and supports

Warnings:

Page 18

Page 18 of 105

OPERATING MANUAL HPC & UMC4

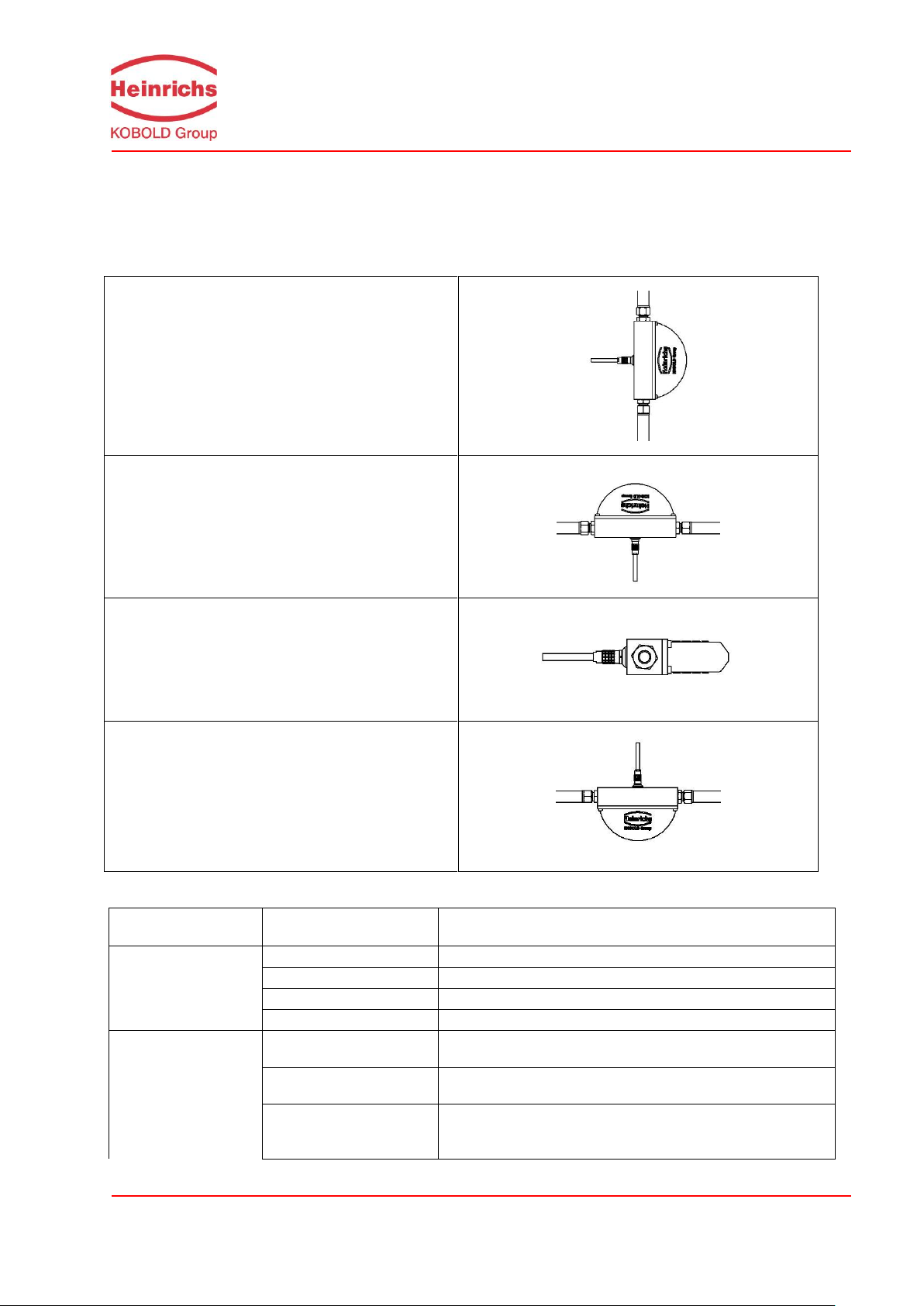

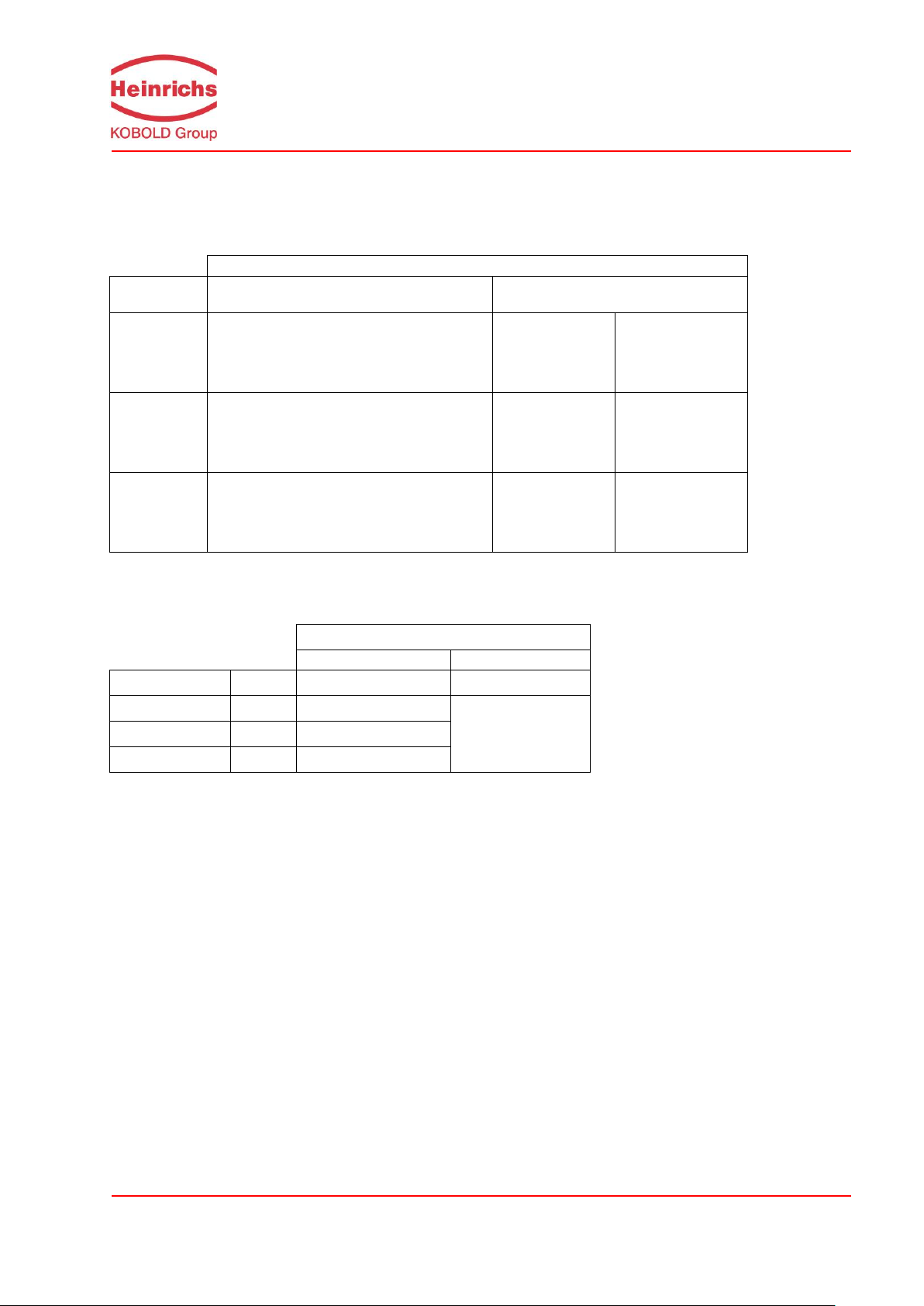

Standard Installation position A

Installation position B

Installation position C

Installation position D

Type of fluid

Position

Assessment

Pure liquids

Standard Position A

Self-draining flow tubes, recommended position

Position B

OK Position C

OK

Position D

Liquid residue remains in pipe

Liquids with gas bubbles

Standard Position A

Self-draining flow tubes, gas bubbles will not accumulate

in the tubes

Position B

Not recommended owing to gas bubble accumulation in

the tubes

Position C

Gas bubbles may accumulate in the presence of low flow

velocities

4.4.2 Installation positions

The HPC may be installed and will be fully functional in any number of positions. The following images

demonstrate the most common means of pipe installation as well as delivering tips for preventing the

orientation of the mounted device from influencing the measurement.

4.4.2.1 Assessment of the installation position

Page 19

OPERATING MANUAL HPC & UMC4

Page 19 of 105

Type of fluid

Position

Assessment

Position D

No gas bubble accumulation in the tubes, liquid residues

may however remain in the sensor after discharge

Liquids containing

substances that could

form deposits

Standard Position A

Self-draining flow tubes, no deposit formation

Position B

OK

Position C

Substances in the liquid could form deposits at low flow

velocities

Position D

Not recommended owing to the presence of substances

that could form deposits in the tubes

Liquids containing

gas bubbles, as well

as substances that

could form deposits

Standard Position A

Self-draining flow tubes, no accumulation of gases or

forming of substance deposits in the tubes

Position B

Not recommended owing to gas bubble accumulation in

the tubes

Position C

Gas bubbles or substances could form deposits at low

flow velocities

Position D

Not recommended, substances could form deposits in

the tubes

Gases that do not

form a condensate

Position A, B, C or D

Any of the installation positions may be used

Gas, condensateforming gas/liquid,

moisture

Standard Position A

Flow direction should be from top to bottom to ensure

forming condensate can flow out efficiently

Position B

OK

Position C

Condensate might form in the tubes

Position D

Not recommended owing to condensate accumulation in

the tubes

Slurries

Standard Position A

Optimal installation position

Position B

High density substances could accumulate in the tubes

Position C

Gas bubbles could accumulate

Position D

Gas bubbles or high density substances could accumulate in the tubes

4.4.3 Pressure surges

Pressure surges in a pipe could be provoked by a sudden decrease in flow caused by rapid closing of

a valve or similar factors. This change in pressure can lead to negative pressure downstream from a

valve that has been closed rapidly, and to outgassing. If the valve is mounted directly on the inlet section of the flow meter, a gas bubble can form in the flow tube that can cause a measuring signal disturbance which would shift the zero point of the output signal. In extreme cases, a pressure surge

could cause mechanical damage to the sensors and/or flow tubes.

Whenever possible, quick-closing valves should be mounted downstream from the sensor. If this is not

feasible, such valves are to be mounted a minimum of 10 x DIA (Φ) from the nearest sensor. Alternatively, valve closing speed can be reduced.

Page 20

Page 20 of 105

OPERATING MANUAL HPC & UMC4

4.4.4 Using the device with hazardous fluids

The sealing technology used in the standard HPC mass flow meter renders the device unsuitable for

use with hazardous fluids. Only sensors that meet the standards for safety instruments are suitable for

use with hazardous fluids.

The pathway between the sensor and transmitter must be pressure-tight so as to prevent fluid from

leaking out of a sensor in the event a sensor develops a defect.

In the case of welded components, a colored liquid penetration test may be performed on the welds, or

one joint (only the foremost seam) may be x-rayed. Alternatively, an internal pressure monitoring device can be used to detect any defect.

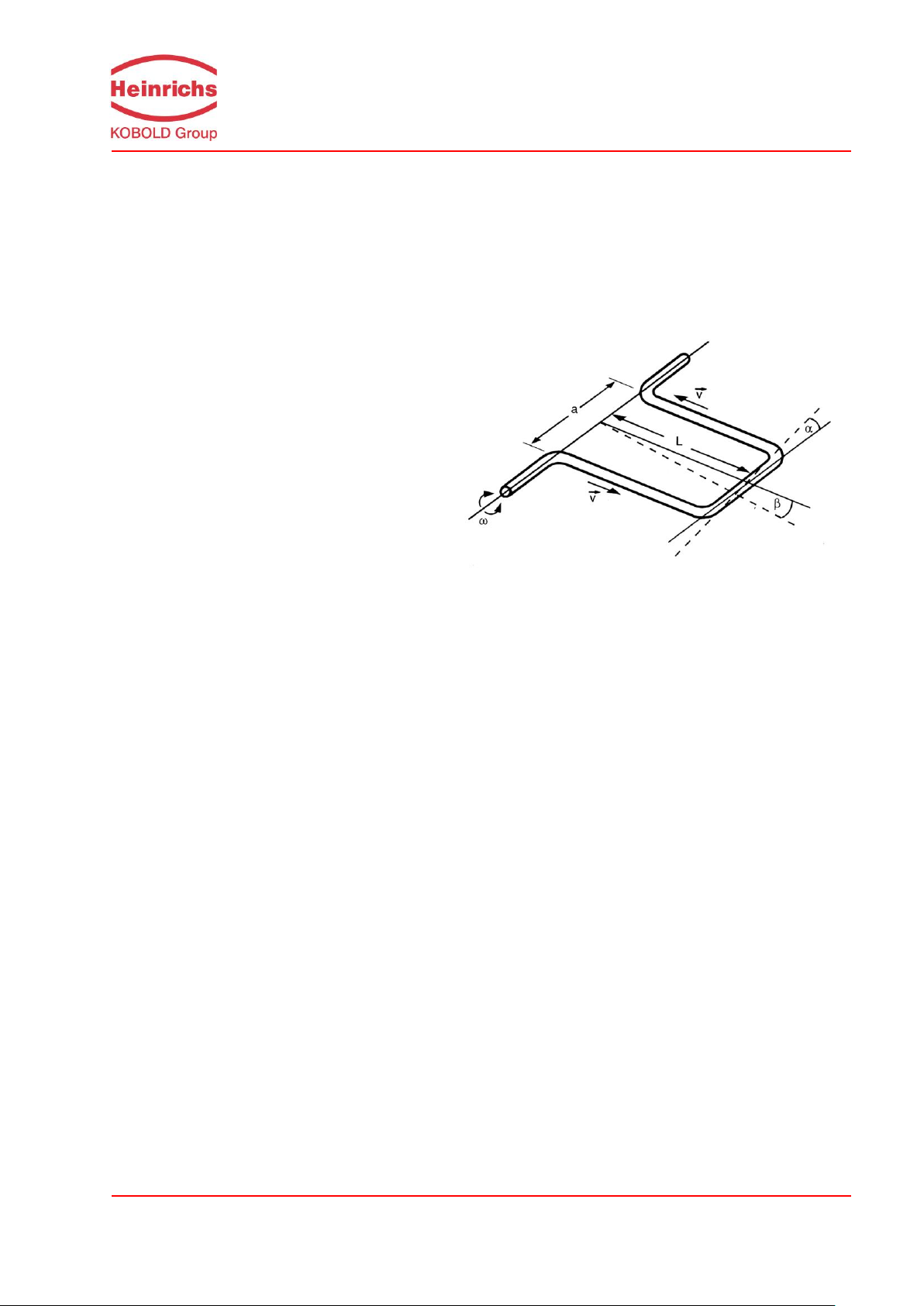

4.4.5 Vibration stability

The sensors are insensitive to vibration; vibration stability has been validated in accordance with

DIN IEC 68-2-6, for up to 1 g at 10 to 150 Hz.

If pipe vibration is greater than 1 g in the 5-2000 Hz range, additional mounting supports are to be

installed as shown in the following drawing. These supports will prevent vibration from affecting the

device’s mechanical configuration and/or measurement readings.

Installation example

The above example represents a pipeline installation. The table and wall variant, with their accessories, are not affected by the representation.

Page 21

OPERATING MANUAL HPC & UMC4

Page 21 of 105

4.5 Process conditions

4.5.1 Process temperature

− 40 °C to 180 °C (-40 °F to 356 °F); rating plate specifications are to be observed

4.5.2 Physical state

Liquid product (maximum density 2 kg/l)

Gaseous product (minimum density 0.002 kg/l in operating state)

4.5.3 Viscosity

0.3 to 2,000 mPas (0.3 to 2,000 cP)

4.5.4 Gas content

The use of products containing gas will increase the measurement error. To have any chance of

achieving an acceptable measurement of a gaseous liquid, it is essential that the gas bubbles are as

small as possible and that they are homogeneously distributed in the fluid. Large gas bubbles will provoke grave measurement errors, and may also shift the zero point. Thus, the process conditions

gravely influence the measurement accuracy of the meter. With this in mind, a rule of thumb is: 1 %

gas component will increase false readings by 1 %. The gas component to exceed 5 %.

4.5.5 Process temperature range

+ 180 °C (356 °F)

4.5.6 Process pressure range

According to PN100 pressure rating = 100 bar / PN 320 320bar / PN400 = 400 bar

4.5.7 Outlet pressure

Outlet pressure must be greater than the vapor pressure ps of the measured product.

4.6 Connection to the transmitter

In consideration of its small dimensions, the transmitter cannot be mounted directly onto the

HPC sensor.

The connection to the sensor is achieved by means of a detachable cable connector.

During installation, regulations and applicable legal standards are to be adhered to.

The maximum cable length is 300 m (1000ft). See Section 12.5.1.2 “Connection of the sensor” on

page 37 for information regarding the connection and cable specifications.

Page 22

Page 22 of 105

OPERATING MANUAL HPC & UMC4

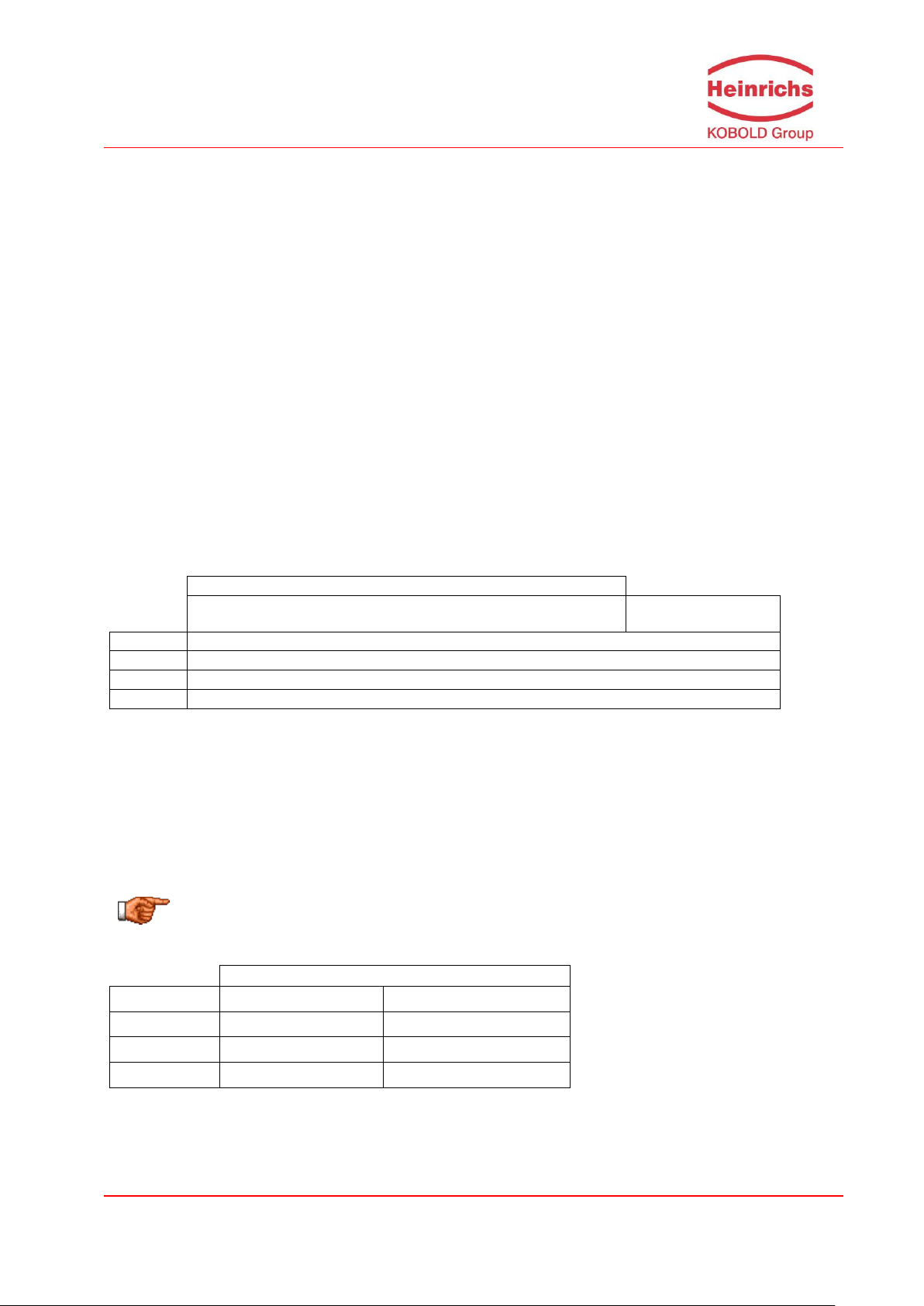

A

Model

Process connection

Sensor length (without connector)

mm [inch]

HPC-S01

G1/2 AG,

½ NPT(F),

Gyrolok 6/8/10 mm,

Swagelok 6/10/12 mm

150

[5,9]

HPC-S02

G1/2 AG,

½ NPT(F),

Gyrolok 6/8/10 mm,

Swagelok 6/10/12 mm

150

[5,9]

HPC-S03

G1/2 AG,

½ NPT(F),

Gyrolok 6/8/10 mm,

Swagelok 6/10/12 mm

150

[5,9]

Weight

Sensor

Transmitter

Model

DN

kg

[lbs]

kg

[lbs]

HPC-S01

G 1/2

1,8

[4,0]

HPC-S02

G 1/2

1,8

[4,0]

4,5

[9,9]

HPC-S03

G 1/2

1,8

[4,0]

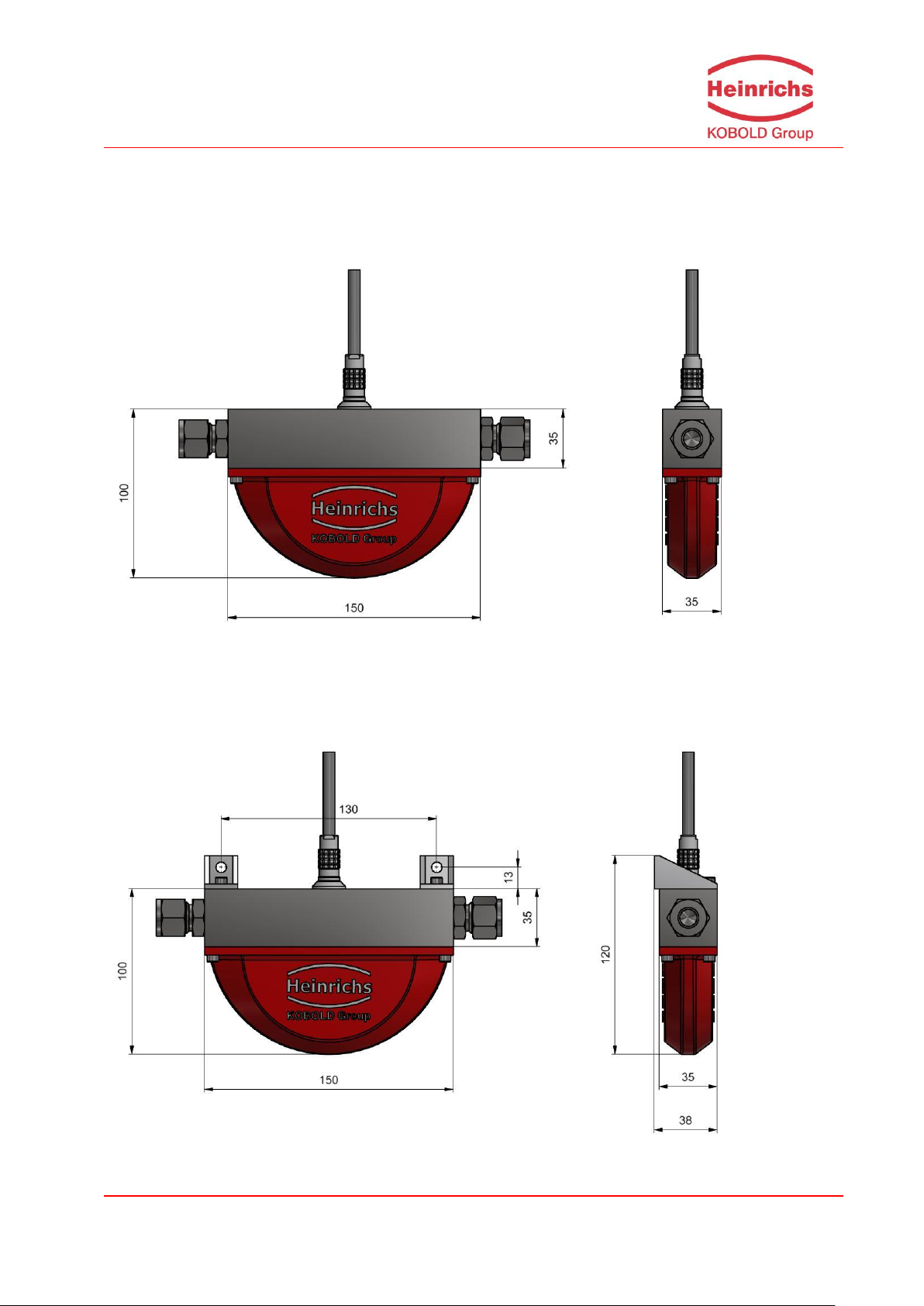

4.7 Construction details

4.7.1 Dimensions and weight

Dimensions:

Weight:

Page 23

OPERATING MANUAL HPC & UMC4

Page 23 of 105

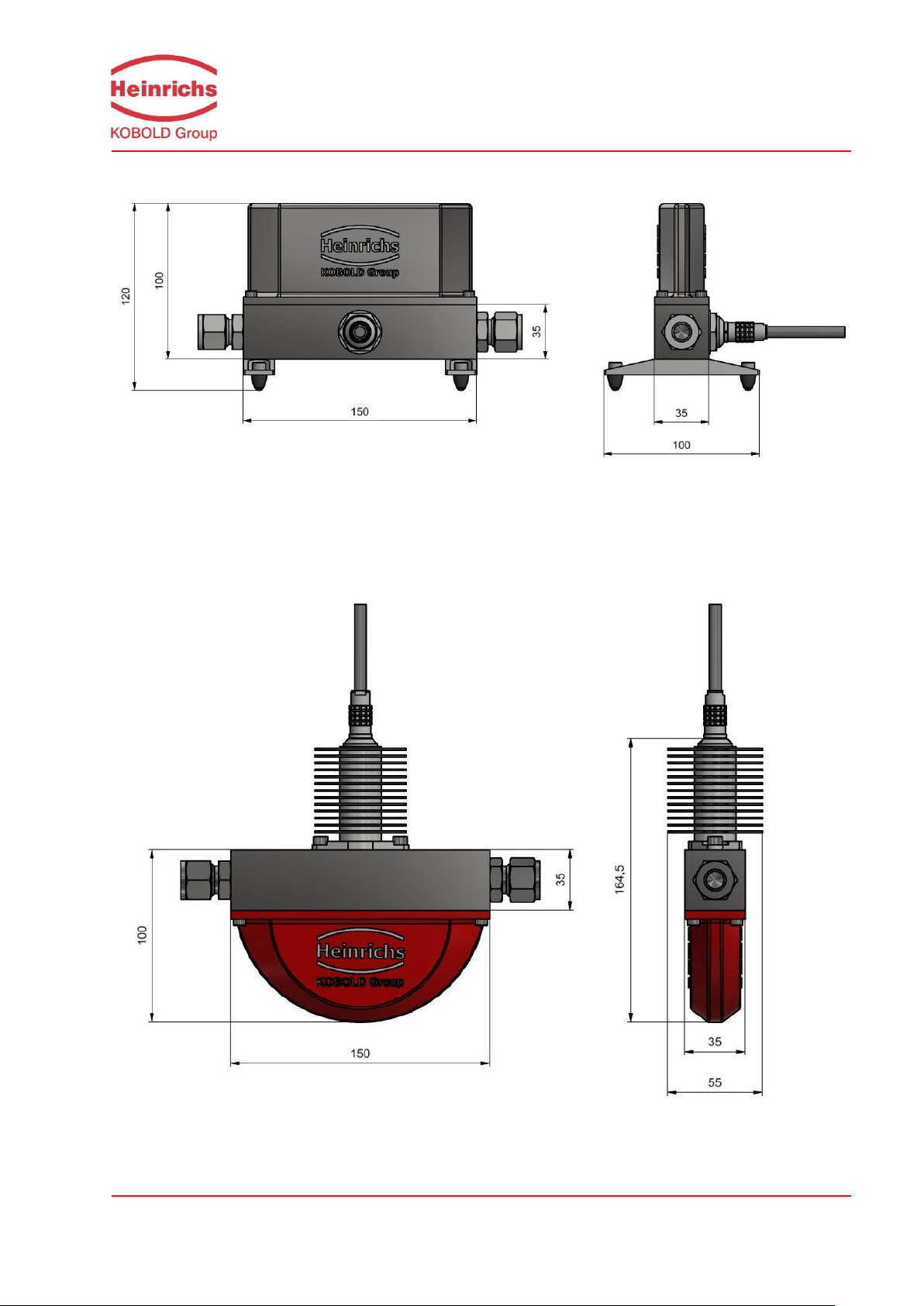

4.7.2 Dimension drawings for the types HPC-S01 to HPC-S03

4.7.2.1 Dimensional drawing of the pipe mounted version

For all dimensions and weight, see Section 4.7.1 Dimensions and weight on page 22.

4.7.2.2 Dimensional drawing of the wall mounted version

For all dimensions and weights, see Section 4.7.1 Dimensions and weight on page 22.

Page 24

Page 24 of 105

OPERATING MANUAL HPC & UMC4

4.7.2.3 Dimensional drawing of the Table top version

For all dimensions and weights, see Section 4.7.1 Dimensions and weight on page 22.

4.7.2.4 Dimensional drawing of the 180°C high temperature version

For all dimensions and weights, see Section 4.7.1 Dimensions and weight on page 22.

Page 25

OPERATING MANUAL HPC & UMC4

Page 25 of 105

4.7.3 Material

Sensor Containment:

HPC-S01 to HPC-S03: Stainless steel 1.4571 (316Ti)

Stainless steel 1.4404 (316L)

Sensor lid:

HPC-S01 bis HPC-S03: Aluminum, Eloxated aluminium, Stainless Steel

Flow tubes: 1.4571 (316Ti),

Flow distribution block: 1.4404 (316L)

or Hastelloy, Tantalum, or other materials on

request

4.8 Sensor HPC approvals

4.8.1 CE marking

See also section 18 “Declaration of Conformity” on page 102

Pressure Equipment Directive 2014/68/EU

EMC Directive 2014/30/EU

EN 61000-6-3:2011 Störaussendung

EN 61000-6-2:2011 Störfestigkeit

Page 26

Page 26 of 105

OPERATING MANUAL HPC & UMC4

5. Commissioning

5.1 Zero point calibration

In order to ensure that precise measurements are obtained, zero point calibration is to be Performed the

first time the device is put into operation and before any regular operations are carried out. Zero point

calibration is to be performed using a fluid.

The zero calibration procedure is as follows:

Install the sensor as described in the manufacturer’s instructions.

Check to ensure that the sensor is completely filled with fluid and that there are no gas bub-

bles in the flow tubes.

Define the process conditions such as pressure, temperature and density.

Close a potential shut-off device behind the sensor.

Operate the transmitter in accordance with the instructions in Section 14.4.4 Zero point cal-

ibration on page 57.

Make sure that sufficient time is allowed for the electronics to warm up.

Allowing fluid to flow through the sensor during the zero calibration procedure will skew the

zero point and result in false readings, especially during low flow conditions.

5.2 Startup conditions

The device is not subject to specific startup conditions. However, pressure surges should be avoided.

Page 27

OPERATING MANUAL HPC & UMC4

Page 27 of 105

Warning

Only sensors and transmitters marked as Ex-proofed on their rating plates may be

used in Ex hazardous areas!

Standard equipment is prohibited for use in Ex hazardous areas.

6. Application domain of the UMC4 transmitter

The microprocessor controlled UMC4 transmitter (hereinafter referred to as UMC4) for use with TM, TME

TMR, TMU and HPC sensors is a programmable transmitter which processes measurement data and

displays and transmits various types of measurement results.

The UMC4 is capable of communication and supports the HART® protocol. The device can be customized using the standard installed control unit BE4. Although basic configuration settings such as transmitter calibration are carried out at the factory, other settings such as those for measurement data processing, analysis, display and output are user definable.

User settings are protected by a user definable password. The user password can be changed by the

customer.

Settings that are essential for proper operation of the transmitter in conjunction with the sensor (e.g. calibration and initialization values) are accessible only to service technicians via a password that is not provided to customers.

7. UMC4 transmitter: mode of operation and configuration

7.1 Measuring principle

The Coriolis mass flow meter is based on the principle that in a rotating system a force (known as Coriolis

force) is exerted on a mass at a rotation point that is moving towards or away from this point. By configuring the sensor in a specific fashion, this force can be used to measure mass flow directly. The UMC4

transmitter evaluates the sensor signal (see Section 4.2.1 Measuring principle on page 14).

7.2 System configuration

Transmitter:

The UMC4 transmitter regulates the excitation of the sensor vibration system and processes the sensor

signals. The standard model is equipped with two analog, passive 4 to 20 mA outputs, an impulse or frequency output and a status output, and is enabled for digital data transfer via the HART® protocol.

Sensor:

The sensors measure mass-flow, density and temperature of fluids or gases. The device can be used to

perform measurements with any liquid or gaseous product providing that the sensor material is suitable

for the product being used.

Page 28

Page 28 of 105

OPERATING MANUAL HPC & UMC4

Warning

Make sure that you abide by the applicable standards and regulations pertaining to electrical devices, device installation and process technology when replacing the transmitter electronics. The highly integrated electronic components

in the device carry the risk of ESD hazards and are only protected when installed in the device pursuant to EMC standards.

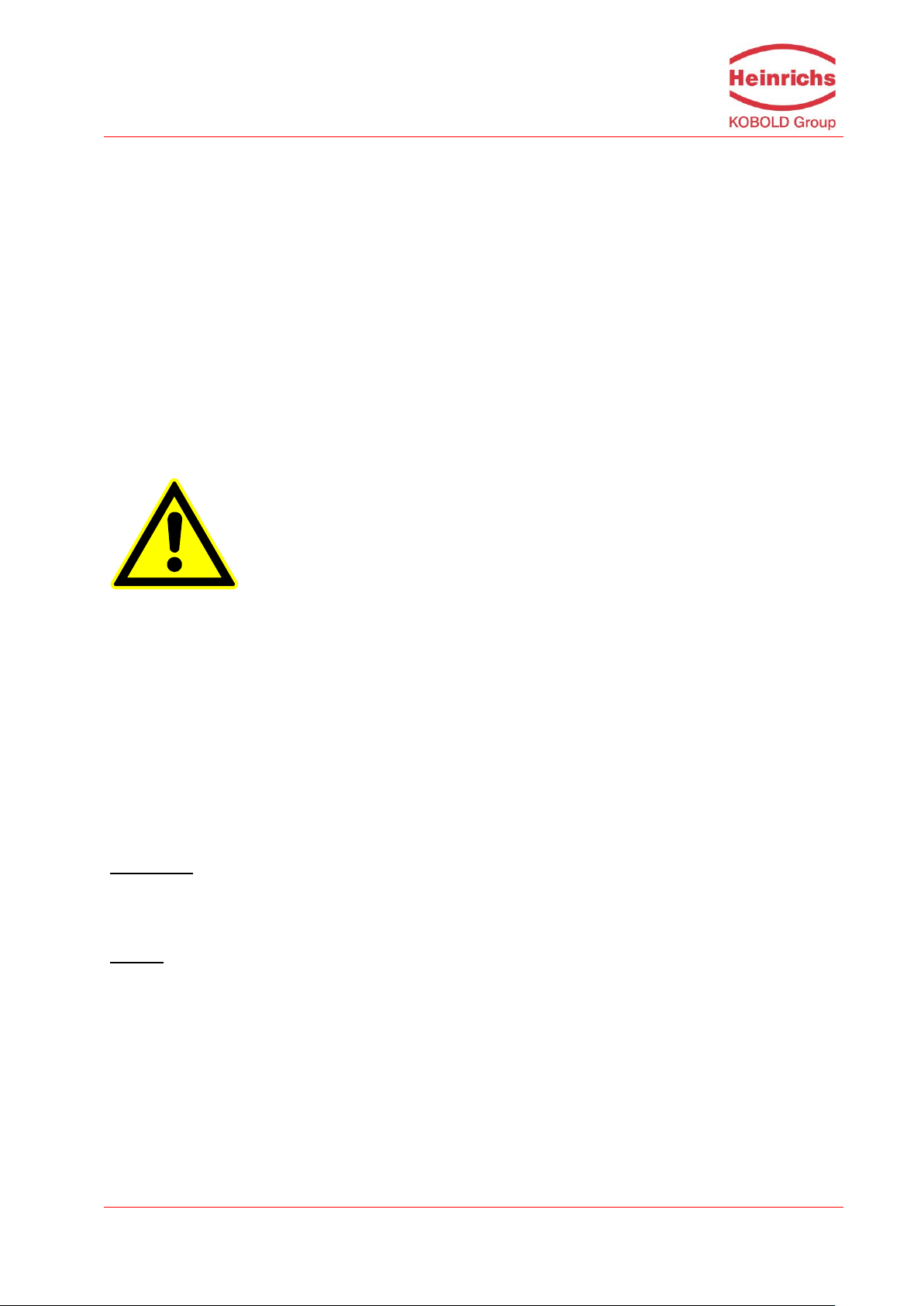

7.2.1 DSB data memory module

The replaceable plug and play memory device is integrated on the PCB of the control unit where all sensor data such as sensor constants, model numbers, serial numbers, and so on are stored. Consequently,

the memory module is linked to the sensor. If the transmitter’s electronics are exchanged for any reason,

the control unit BE4 must be removed from the old and placed onto the new electronic stack.

The removal and insertion of the control unit is performed as can be seen in the following sketch.

After removing 4 screws, the control unit with the display can be detached.

If the transmitter is replaced, the control unit should be transferred to the new transmitters electronic

stack. When the flow meter is powered up, the device continues using the values stored in the memory

device. Thus, the DSB memory device provides maximum safety and comfort when device components

are replaced.

The control units are not interchangeable arbitrarily between identically constructed transmitters

due to the memory device. Replaceable circuit boards must be ordered from Heinrichs using the trans-

mitter’s serial number specification. The calibration data of the sensor are programmed into the delivered

BE4 control panel directly by the manufacturer.

Page 29

OPERATING MANUAL HPC & UMC4

Page 29 of 105

8. Input

8.1 Measured variable

Mass flow rate, temperature, density and volume flow (calculated from the preceding measured variables).

8.2 Measuring range

The measuring range, which varies according to the used sensor, can be found on the relevant data

sheet or rating plate (see Section 4.3.2 HPC flow ranges on page 15).

9. Output

9.1 Output signal

All signal outputs Electrically isolated from each other and to ground

Analog outputs 2 x 4 to 20 mA passive

Current output 1:

Mass flow, volume flow, density, temperature

(when using the HART® protocol, output 1 is assigned to mass

flow)

Current output 2:

Mass flow, volume flow, density, temperature

Pulse output Pulse duration: default value 50 ms

(Binary output 1) Pulse duration: adjustable range is 0.1 to 2000 ms

Mark-to-space ratio is 1:1 if the set pulse duration is not reached.

As a frequency output 1 kHz

passive via optocoupler

U

= 24 V

nom

U

= 30 V

max

I

= 60 mA

max

P

= 1,8 W

max

Pulse value settable in decade increments of selected pulse unit,

e.g. kg or m³.

Status output For: forward and reverse flow, MIN flow rate, MAX flow rate, MIN

density, MAX density, MIN temperature, MAX temperature, alarm

Second pulse output (out of phase by 90°)

Passive via optocoupler

U

= 24 V

nom

U

= 30 V

max

I

= 60 mA

max

P

= 1,8 W

max

Page 30

Page 30 of 105

OPERATING MANUAL HPC & UMC4

500

23

110

max

mA

VU

R

0 Ohm

100 Ohm

200 Ohm

300 Ohm

400 Ohm

500 Ohm

600 Ohm

0 V 5 V 10 V 15 V 20 V 25 V 30 V

load

external power supply voltage

maximum load

Rmax

9.2 Failure signal

A failure in the meter can be indicated via the current outputs or the status output. The current outputs

can be set to a failure signal (alarm) of I < 3.8 mA or I > 22 mA. The status output can be configured as

make or break contact.

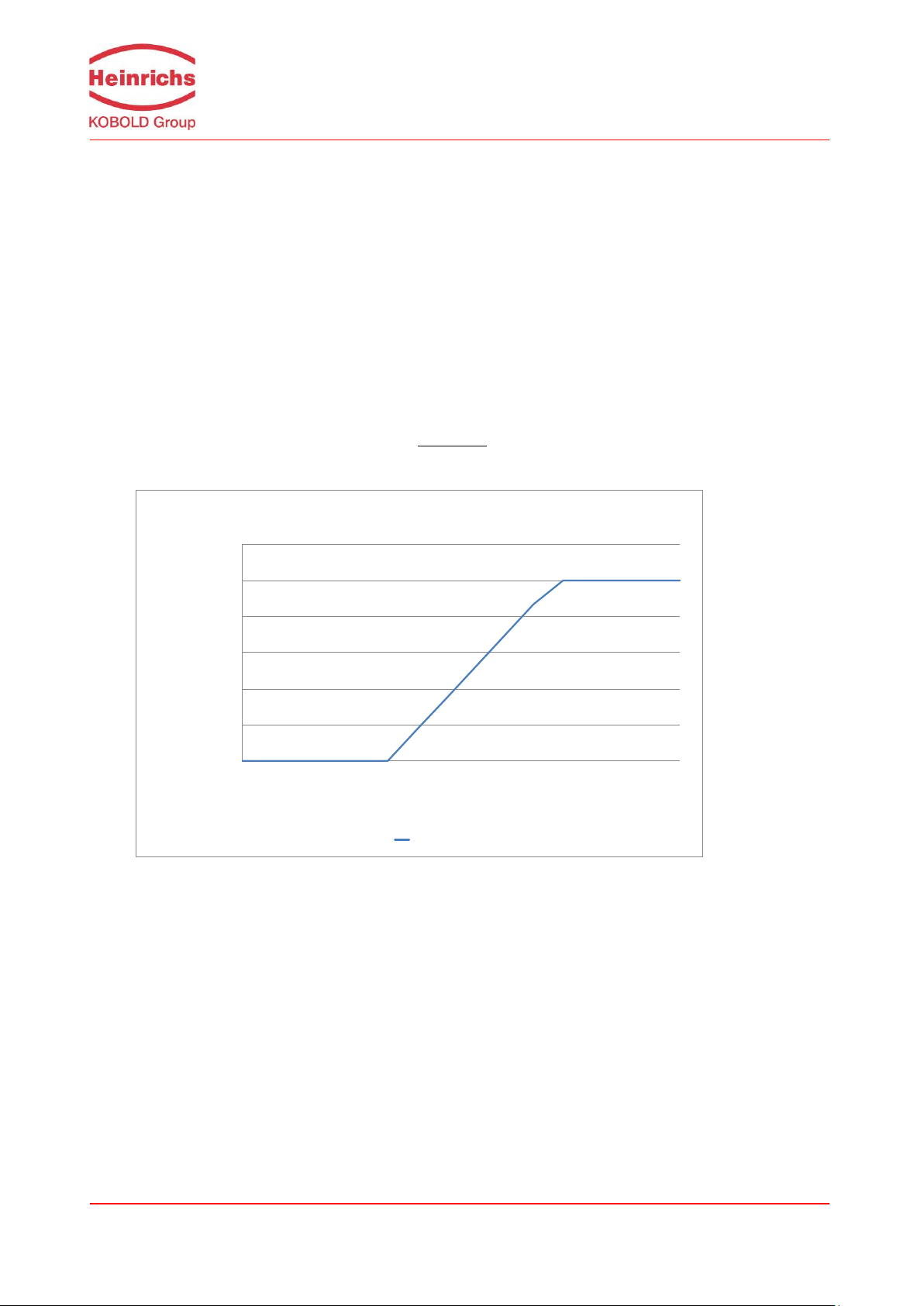

9.3 Load

Standard version: 500 ohms

Explosion-proof version: 500 ohms

HART minimum load: > 250 ohms

10 V is the minimal needed voltage at passive current output terminals. The maximum voltage of 30 V

must never be exceeded. The maximum load is calculated according to the equation:

9.4 Damping

Programmable from 1 to 60 seconds

9.5 Low flow cutoff

The low flow cutoff can be set to values between 0 and 20% using the software. The set value refers to

the upper-range value. If the measured value is lower than the set volume, the flow rate will set to 0.0

(kg/h). This results in the analog output being set to 0/4 mA, and the pulse output will stop generating

pulses.

Page 31

OPERATING MANUAL HPC & UMC4

Page 31 of 105

10. UMC4 performance characteristics

10.1 Reference conditions

In conformity with IEC 770

Temperature: 20 °C (68 °F), relative humidity: 65 %, air pressure: 101.3 kPa (14.7 psi)

10.2 Measured error

Measured error and zero point stability see sensor data sheet or Section 4.3.2 HPC flow ranges on

page 15.

10.3 Repeatability error

0.05 % of actual value (sensor with transmitter). See section 4.3.2 HPC flow ranges on page 15.

10.4 Influence of ambient temperature

0.05 % per 10 K

Page 32

Page 32 of 105

OPERATING MANUAL HPC & UMC4

Warning:

Additional cable glands:

They are not contained in the scope of supply. The operator is responsible

for guaranteeing that cable glands or screws according to the enclosures

certification are used. The type of thread present is stated on the rating

plate.

For the connection between sensor and transmitter a metalized cable gland

must be used for the screen.

(See 12.5.1.2 “Connection of the sensor” page 37)

Danger:

It is the customer’s responsibility to ensure the NPT adapters are mounted

securely! Only correctly tightened adapters will guarantee the Ex-d protection

class of the enclosure!

Warning:

Ingress protection IP 68 can only be achieved if suitable and sufficiently tightened cable glands or conduits are used. If the cable glands are only tightened

sufficiently, water may leak into the terminal compartment of the enclosure.

Danger:

Particular care must be taken if the enclosure’s window becomes fogged or

discolored. This could mean that moisture, water or product is seeping through

the wire sheath into the transmitter’s housing.

11. UMC4 operating conditions

11.1 Installation conditions and cable glands

When mounting the UMC4 transmitter, a vibration-free installation site must be guaranteed.

11.2 NPT cable glands

The transmitter housing SG4 is designed with M20x1.5 threads for cable glands. For cable glands with

NPT thread, a certified matching NPT adapter may be ordered directly from the manufacturer. These

NPT adapters are to be directly mounted onto the UMC4’s transmitter housing.

11.3 Environmental conditions

11.3.1 Ambient temperature

− 20 °C to + 60 °C (-4 °F to 140 °F), below 0 °C (32 °F) the readability of the LC display will be limited

11.3.2 Ambient temperature range

− 20 °C to + 60 °C (-4 °F to 140 °F)

11.3.3 Storage temperature

−25 °C to + 60 °C (-13 °F to 140 °F)

11.3.4 Ingress protection

Standard enclosure SG4, IP 68 (NEMA 6P)

Explosion-proof Ex d electronics enclosure

Terminal compartment: with terminals and Ex e “Increased safety” type of protection, or alternatively

Ex d

Page 33

OPERATING MANUAL HPC & UMC4

Page 33 of 105

Warning

Electromagnetic compatibility is only achieved if the electronics enclosure is

closed. Leaving the enclosure open can lead to electromagnetic disturbances.

Warning

In Ex hazardous areas, only sensors and transmitters with approvals marked

on the rating plates may be used!

11.4 Process conditions

11.4.1 Integrally Mounted transmitter

In combination with the HPC sensors, the UMC4 transmitter is always mounted separately (remote)

from the sensor. For the TM* series of sensors, the following parameters are valid

11.4.1.1 Process fluid temperature

− 40 °C to + 180 °C (-40 °F to 356 °F)

The data sheet/rating plate of the connected transmitter must be observed.

11.4.1.2 Fluid temperature limit

180 °C (356 °F)

The data sheet of the connected transmitter must be observed.

11.4.1.3 Vibrations

In accordance with DIN IEC 68-2-6, for up to 1 g at 10 to 150 Hz.

11.4.2 Remote mounted transmitter

In the remote mounted configuration, the process conditions of the sensor have no influence on the

transmitter

Page 34

Page 34 of 105

OPERATING MANUAL HPC & UMC4

12. Construction details

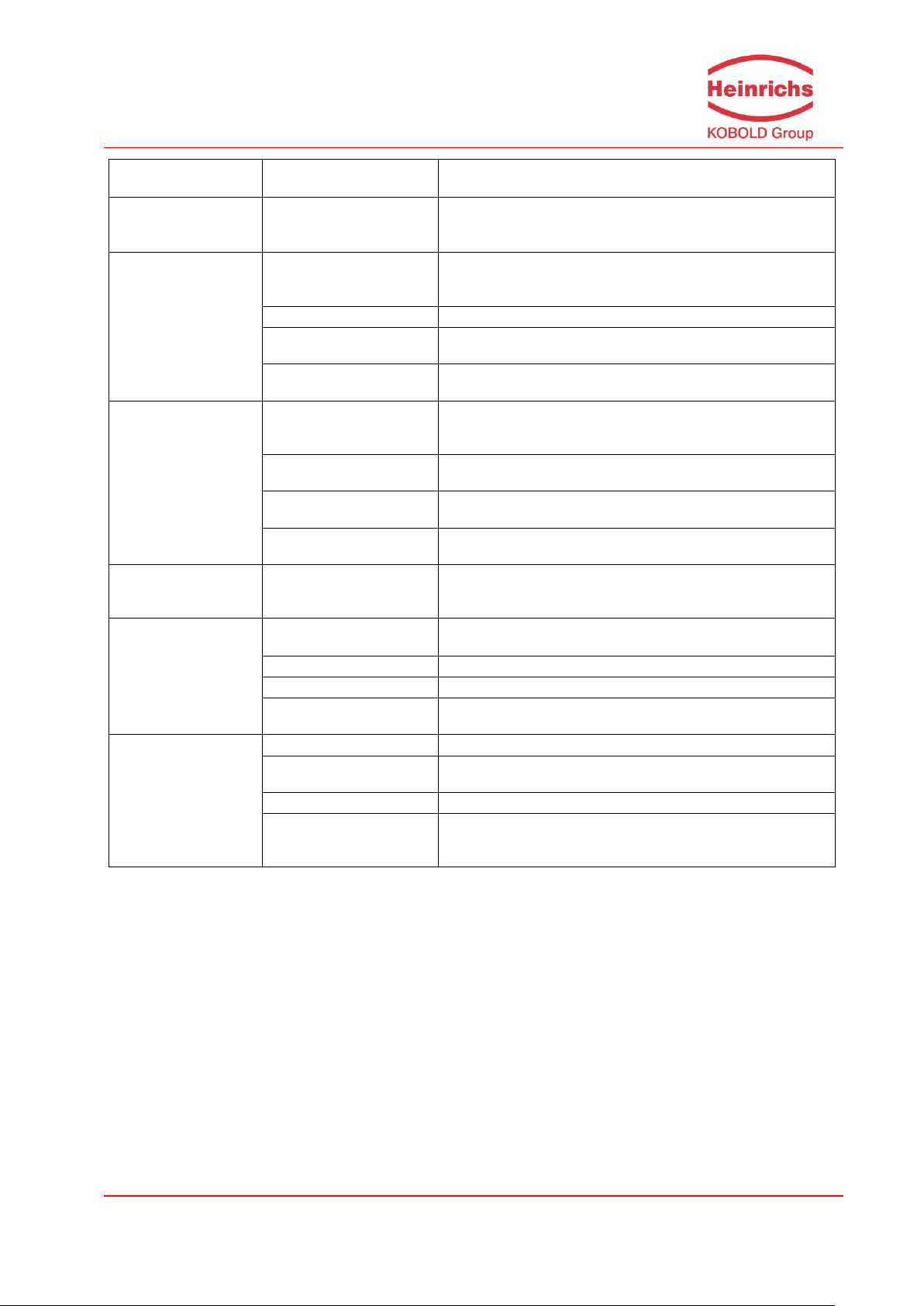

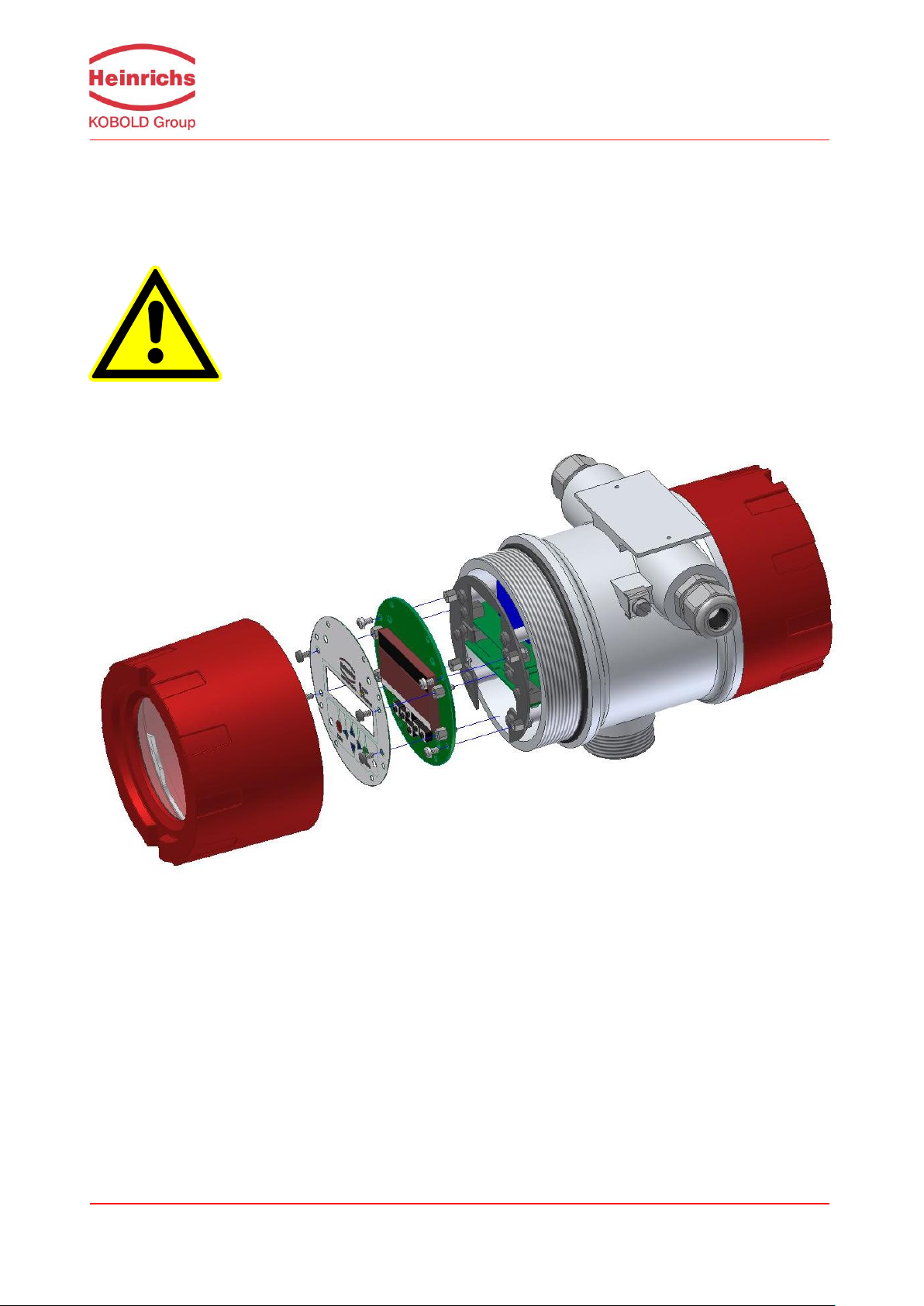

12.1 Type of construction/dimensions

Horizontal pipe mounting – SG4

Vertical pipe mounting – SG4

Page 35

OPERATING MANUAL HPC & UMC4

Page 35 of 105

Wall mounting

Pipe mounting with a junction box

Page 36

Page 36 of 105

OPERATING MANUAL HPC & UMC4

Main voltage rated Current rated voltage breaking capacity

90V ... 265V AC 250mAT 250V AC 1500A / 250V AC

24V AV 250mAT 250V AC 1500A / 250V AC

19V ... 36V DC 250mAT 250V AC 1500A / 250V AC

Designation

Terminal / Pin designation

Type of protection

Standard

Ex ia

(Non Ex)

Power supply

L or “+”

L

x

N or “-“

N

x

PE

PE

x

12.2 Weight

Approx. 2.4 kg (5.5 lbs) (separate UMC4 transmitter without mounting system)

12.3 Material

Enclosure: Painted aluminum pressure die–casting, max.0.5% Mg; yellow chromating.

12.4 End connection

To connect the remote sensor to the transmitter, a special connection cable must be used.

For further details see Sections 4.6 “Connection to the transmitter” on page 21, and 12.5.1.2 Connection of the sensor on page 37.

12.5 Electrical connections and their protection classes

Auxiliary power 90 V - 265 V AC 50/60 Hz

24 V AC + 5 %, − 20 % 50/60 Hz

19 V to 36 V DC

Power input 4.5 VA

Main fuse: 5x20 mm IEC 60127-2

Supplier: Little Fuse Series 0215.250 HXP

12.5.1 Wiring diagrams

12.5.1.1 Power connections

Power connection terminals

Page 37

OPERATING MANUAL HPC & UMC4

Page 37 of 105

Designation

Terminal / Pin designation

Type of protection

Standard

Ex ia

(Non-Ex)

Sensor lines

SENSOR1 +

1

x x

SENSOR1 -

2

x x

SENSOR2 +

3

x x

SENSOR2 -

4

x x

TIk- 5 x x

Temperature sensor -

6

x x

Temperature sensor +

7

x x

TIk+ 8 x x

EXCITER1

9

x x

EXCITER2

10

x x

Shield

Shield

x x

Warning:

The colors of the sensor’s wires may differ to the colors of the connection

cable’s wires between terminal box and transmitter! The colors shown in the