Page 1

Operating Instructions

for

Handheld Digital Pressure Meter

with internal pressure sensor

Model: HND-P239

Page 2

HND-P239

page 2 HND-P239 K01/0307

1. Contents

1. Contents........................................................................................................2

2. Note ..............................................................................................................3

3. Instrument Inspection....................................................................................3

4. Regulation Use..............................................................................................3

5. Operating Principle........................................................................................4

6. Safety Requirements.....................................................................................4

7. Electrical Connection ....................................................................................5

8. Operation ......................................................................................................6

9. Configuration................................................................................................. 7

9.1 Different Kinds Of Measuring: „rAtE-Slo, -P.dEt, -FASt“ ......................8

9.2 Sea Level Correction ...........................................................................8

9.3 Averaging Function..............................................................................9

9.4 Power Off Time....................................................................................9

9.5 Address................................................................................................9

9.6 Alarm ...................................................................................................9

9.7 Real Time Clock ................................................................................10

10. Operation Of Logger ...................................................................................10

10.1 „Func-Stor“: Storing Single Measurements........................................10

10.2 „Func-CYCL“: Automatic Recording With Selectable Logger-Cycle-Time

11

11. The Serial Interface.....................................................................................13

12. Error And System Messages ......................................................................14

13. Calibration Services ....................................................................................14

14. Maintenance ...............................................................................................15

14.1 Battery Operation...............................................................................15

15. Technical Information..................................................................................15

16. Order Codes ...............................................................................................17

16.1 Accessories for HND-P ......................................................................17

17. Declaration of Conformance .......................................................................18

Manufactured and sold by:

Kobold Messring GmbH

Nordring 22-24

D-65719 Hofheim

Tel.: +49(0)6192-2990

Fax: +49(0)6192-23398

E-Mail: info.de@kobold.com

Internet: www.kobold.com

Page 3

HND-P239

HND-P239 K01/0307 page 3

2. Note

Please read these operating instructions before unpacking and putting the unit

into operation. Follow the instructions precisely as described herein.

The devices are only to be used, maintained and serviced by persons familiar

with these operating instructions and in accordance with local regulations

applying to Health & Safety and prevention of accidents.

When used in machines, the measuring unit should be used only when the

machines fulfil the EWG-machine guidelines.

3. Instrument Inspection

Instruments are inspected before shipping and sent out in perfect condition.

Should damage to a device be visible, we recommend a thorough inspection of

the delivery packaging. In case of damage, please inform your parcel service /

forwarding agent immediately, since they are responsible for damages during

transit.

Scope of delivery:

The standard delivery includes:

• Handheld Digital Pessure Meter with internal pressure sensor

model: HND-P239

• Operating Instructions

4. Regulation Use

Any use of the Handheld Digital Pressure Meter, model: HND-P239, which

exceeds the manufacturer’s specification may invalidate its warranty. Therefore,

any resulting damage is not the responsibility of the manufacturer. The user

assumes all risk for such usage.

Page 4

HND-P239

page 4 HND-P239 K01/0307

5. Operating Principle

The KOBOLD Handheld Digital Pressure Meters HND-P239 have an integrated

pressure sensor for absolute pressure measurement. The measuring device is

connected to the measuring point by means of a stable, metal connection on the

top of the housing and an optional plastic hose. This device design offers the

possibility of also displaying the barometric air pressure in relation to sea level

»zero«. In this case, air pressure is corrected by entering the height above

»zero« in meters. Naturally, these devices also have the minimum/maximum

value memory, a hold function, a tare function, automatic self-shut-off function,

and zero point adjustment. The HND-P239 devices also offer additional functions

like the logger function, peak value memory, minimum/maximum alarm, an

adjustable measuring cycle, and averaging.

6. Safety Requirements

This device has been designed and tested in accordance with the safety

regulations for electronic devices.

However, its trouble-free operation and reliability cannot be guaranteed unless

the standard safety measures and special safety advises given in this manual will

be adhered to when using the device.

1. Trouble-free operation and reliability of the device can only be guaranteed if

the device is not subjected to any other climatic conditions than those stated

under "Technical Information".

2. If the device is transported from a cold to a warm environment condensation

may cause in a failure of the function. In such a case make sure the device

temperature has adjusted to the ambient temperature before trying a new

start-up.

3. If device is to be connected to other devices the circuitry has to be designed

most carefully. Internal connection in third party devices (e.g. connection

GND and earth) may result in not-permissible voltages impairing or

destroying the device or another device connected.

Warning! If device is operated with a defective mains power

supply (e.g. short circuit from mains voltage to output voltage)

this may result in hazardous voltages at the device (e.g. at sensor

socket or interface).

Page 5

HND-P239

HND-P239 K01/0307 page 5

4. If there is a risk whatsoever involved in running it, the device has to be

switched off immediately and to be marked accordingly to avoid re-starting.

Operator safety may be a risk if:

- there is visible damage to the device

- the device is not working as specified

- the device has been stored under unsuitable conditions for a longer

period of time.

In case of doubt, please return device to manufacturer for repair or maintenance.

7. Electrical Connection

By operation with external power supply:

When using a power supply please note that operating voltage has to be 10.5 to

12 VDC. Do not apply overvoltage!!! Cheap 12V-power supplies often have

excessive no-load voltage. We, therefore, recommend using regulated voltage

power supplies. Trouble-free operation is guaranteed by our power supply HNDZ002. Prior to connecting the power supply to the mains make sure that the

operating voltage stated at the power supply is identical to the mains voltage.

Page 6

HND-P239

page 6 HND-P239 K01/0307

8. Operation

When switching on the device and the logger function is not off the time of the

integrated clock will shortly be displayed.

After changing the battery the clock-setting menu is activated automatically

(‚CLOC‘). Check the clock and adjust, if necessary (see chapter 9. Configuration).

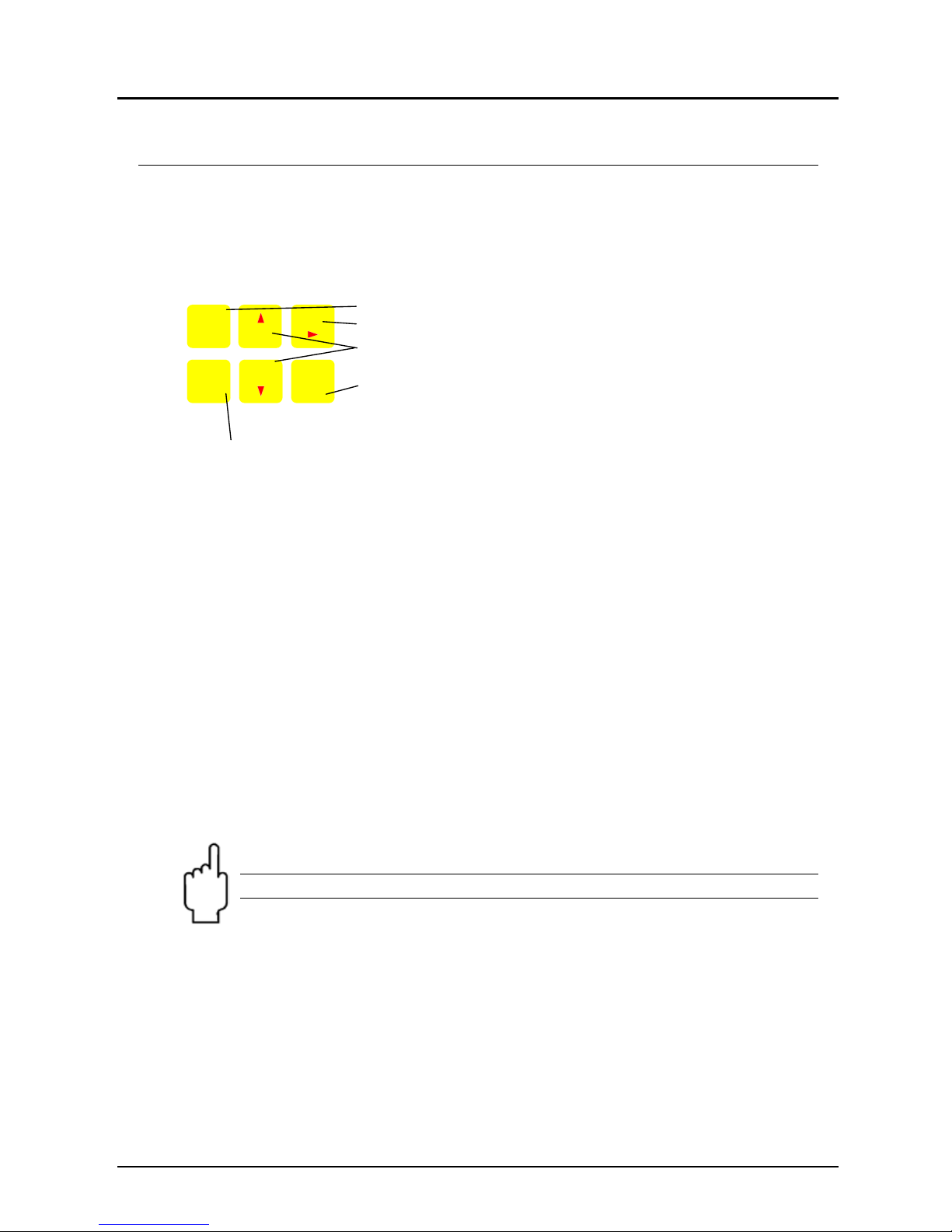

On-/Off-Switch

Tara: Calling of tara function, zero point adjustment

min/max: Showing the min- resp. max-memory in sec.

display

Store/Quit: Calling of hold function resp. calling of logger

functions

(please refer to chapter 10. “Operation Of Logger”)

Set/Menu: Calling of configuration

Max Memory: Pressing “max“ (key 2) shows the maximum of the measured

values. Pressing it again hides it. To clear the max memory press key „max“ for

>2 seconds.

Min Memory: Pressing “min“ (key 5) shows the minimum of the measured

values. Pressing it again hides it. To clear the min memory press key „min“ for >2

seconds.

Hold Function: By pressing “Store/Quit“ (key 6) the last measuring value

will be held in the secondary display. Pressing it again hides it. (only when logger

= ‚off‘).

Tare Function: By pressing ”Tara“ (key 3) the display will be set to 0. All

measurings from then on will be displayed relatively to the set tare value. When

tara function is activated, the arrow "Tara" appears in the display. To deactivate

tare function press ”Tara“ for >2 seconds.

Note: Activating/deactivating tara clears the max- & min-memories.

123

456

ON

OFF max

Tar a

Sto remin

Set

Menu Quit

Page 7

HND-P239

HND-P239 K01/0307 page 7

9. Configuration

To change device settings, press “Menu” (key 4) for 2 seconds. This will call the

configuration menu (main display: „SEt“).

Pressing key “Menu” changes between the menu, pressing “4“ (key 3) jumps to

the referring parameters, which can be selected with key “4“ (key 3).

The parameters can be changed with “5“ (key 2) or “6“ (key 5).

Pressing “Menu” again jumps back to the main configuration menu and saves

the settings.

“Quit” (key 6) finishes the configuration and returns to standard measuring

operation.

Menu Param. Values Meaning

‚Menu‘

4 5or6

Set Configuration: Generic Configuration

Unit

mbar,bar..

Unit: Unit of display

*

SL

oFF/on

Sea-Level: on or off

*

Alti

-2000..9999

Altitude: Input of altitude above sea level [m] (only if SL on)

*

Rate: Measuring rate (see chapter 9.1 Different Kinds Of

Measuring: „rAtE-Slo, -P.dEt, -FASt“)

*

Slo

Slow: measuring rate (4 Hz filtered, low power consumption)

*

FASt

Fast: measuring rate, filtered (>100 Hz)

*

rAtE

P.dEt

Peak detection: fast measuring rate, unfiltered (>100 Hz)

*

1-120

Averaging period in seconds, used by the averaging function

t.AVG

oFF

Averaging function deactivated

1-120

Auto Power-Off time in minutes

P.oFF

oFF

Auto Power-Off deactivated

SEt

ConF

Adr.

01,11..91

Base address of interface

Set Alarm: Settings Of Alarm Function

AL.

On

Alarm on, with horn-sound

no.So

Alarm on, without horn-sound

oFF

Alarm deactivated

AL.Lo

0 bar ... AL.Hi Min alarm rail (not when AL. oFF. Sensor-Min is the lower display

range of connected sensor)

SEt

AL.

AL.Hi

AL.Lo ...1.3 bar Max alarm rail (not when AL. oFF. Sensor-Max is the upper

display range of connected sensor)

Set Logger: Configuration Of Logger Function

*

Func

CYCL

Store: logger function, ‚cyclic logger’

*

Stor

Cyclic: logger function ‚individual value logger’

*

oFF

no logger function *

CYCL

1..3600

Cycle time of cyclic logger [seconds] *

SEt

LoGG

Lo.Po

on/oFF

Low-power logger with very low power consumption

(only for cyclic logger and slow measuring rate)

*

Set Clock: Setting Of Real Time Clock

CLOC

HH:MM

Clock: Setting of time hours: minutes

dAtE

TT.MM

Date: day. month

SEt

CLOC

YEAr

YYYY

Year:

Note! If the logger memory contains data already, the

menus/parameters marked with (*) can not be invoked! If these

should be altered the logger memory has to be cleared before! (key

6, please refer to. chapter 10. “Operation Of Logger”)

Page 8

HND-P239

page 8 HND-P239 K01/0307

9.1 Different Kinds Of Measuring: „rAtE-Slo, -P.dEt, -FASt“

Three different kinds of measuring pressure are supported. Two of them are

working with high measuring frequency of more than 100 measurings per second.

If one of them was chosen in the configuration (see above), this will be displayed

in the secondary display: „P.dEt“ or „FASt“.

9.1.1 rAtE-Slo: Standard Measuring

Measuring rate 4Hz, averaging and filter functions are active.

Application: Measuring of slowly changing or static pressures, e.g. measuring of

leak proofness, atmospheric pressure...

Highest accuracy, high noise immunity (EMI and unstable measuring signals),

low power consumption.

9.1.2 rAtE-P.dEt: Peak detection

Measuring rate >100Hz, the value is displayed unfiltered.

Application with logger function: Measuring of short pressure peaks or fast

changing pressures with a resolution of <10ms. The cyclic logger function records

the arithmetic mean value, the highest and the lowest peak of the referring time

interval.

Attention: higher power consumption, measuring is sensitive to noise (EMI,..).

9.1.3 rAtE-FASt: Fast filtered measuring

Measuring rate >100Hz, the value is filtered slightly (higher noise immunity than

P.dEt, small peaks will be filtered out), apart from that identical behaviour like

P.dEt.

9.2 Sea Level Correction

The device displays the absolute pressure measured at the sensor. This is not

necessarily the same like the values given by weather stations! The weather

stations‘ values are giving the pressure at sea level. Usually the sensor is placed

above sea level and therefore, if the value at sea level(zero) is to be measured,

the pressure loss resulting from the actual level above sea level has to be

considered! To correct the measuring display activate the „Sea-Level-Function“

(SL, please refer to chapter 9. “Configuration”). Then enter the altitude above sea

level of the sensor‘s location in meters (Alti, please refer to chapter 9.

Configuration). When activated, the display shows the SL-arrow and the device

displays the pressure value at sea level.

Page 9

HND-P239

HND-P239 K01/0307 page 9

9.3 Averaging Function

The averaging function concerns the display values (LCD and interface). It is

completely independent from the averaging of the logger function, please don’t

mix them up!

The averaging integrates the measuring values during a selectable period of time

and then calculates the average display value. It is independent from the selected

kind of measuring (slow, fast, peak detect)

As long as not enough values are collected (selected averaging time) to calculate

a average value, the upper display shows “----“, the lower display a ‘countdown‘.

During an active low-power-logging procedure the averaging is always

deactivated.

Function of min/max-value memory during averaging:

• If averaging is activated and slow measuring is selected (rAtE-Slo),

the min-/max-value memory refers to the average display value.

• If averaging is activated and fast measuring is selected (rAtE-FASt or P.dEt) ,

the min-/max-value memory refers to the internal measured values (fast peaks

can be detected).

9.4 Power Off Time

If there won’t be pressed any key and no interface communication takes place for

the time of the power off time setting (P.Off), the device will be switched off

automatically to save battery power.

If P.oFF = oFF then the automatic switch off is deactivated.

9.5 Address

Up to 10 devices of the GMH3xxx- handheld-family can be connected to a serial

interface at once (depending on interface converter, e.g. GRS3105: 5 devices).

To get access to each device the base addresses of the devices have to be

different. For example choose 01 for the first, 11 for the second device and so on.

See also chapter 11. “The Serial Interface”.

9.6 Alarm

There are three possible settings: Alarm off (AL. oFF), on with horn sound (AL.

on), on without horn sound (AL. no.So).

Following conditions will display an alarm, when the function is activated (on or

no.So):

- Value is below lower (AL. Lo) or above upper alarm rail (AL.Hi).

- Sensor error (Sens Erro)

- Low battery (bAt)

- Fe 7: System error (always with sound)

In case of an alarm and when polling the interface the prio-flag is set in the

returned interface message.

Page 10

HND-P239

page 10 HND-P239 K01/0307

9.7 Real Time Clock

The real time clock is used for the logger function: Recorded values are also

containing the point of time, when they were measured. Please check the settings

when necessary.

If the battery was replaced the referring menu ‚CLOC‘ will automatically be

started.

10. Operation Of Logger

The device supports two different logger functions:

„Func-Stor“:

each time when „store“ (key 6) is pressed a measurement will be recorded.

„Func-CYCL“:

measurements will automatically be recorded each interval, which was set in the

logger menu ‚CYCL‘ until the logger will be stopped or the logger memory is full.

The recording is started by pressing „Store“ 2 seconds.

The logger records 3 measurement results each time:

Current or mean value (depending on logger setting, see below), min peak and

max peak.

Min and max peak are the minimum resp. the maximum of the measured values

since the last recording.

Using them allows f.e. analysis of fluctuating pressures.

For the evaluation of the data the software HND-Z034 has to be used. The

software also allows easy configuration and starting of the logger.

When the logger is activated (Func Stor or Func CYCL) the hold function is no

more available, the key 6 is solely used for the operation of the logger functions.

10.1 „Func-Stor“: Storing Single Measurements

Each time when „store“ (key 6) is pressed a measurement and its time stamp will

be recorded.

The recorded data can be viewed either in the display (when calling the

configuration an additional menu „REAd LoGG“ is displayed, see below) or by

means of the interface and a PC with GSOFT3050-software.

Max. number of measurings: 99

A measuring contains:

- current measuring value at the time of recording

- min peak, max peak since the last recording

- - time and date of the recording

Page 11

HND-P239

HND-P239 K01/0307 page 11

After each recording „St. XX“ will be displayed for a short time. XX represents the

number of the recording.

If logger memory contains recordings already:

When „Store“ is pressed for 2 seconds, the choice for clearing the logger memory

will be displayed:

The selection can be made by “5“ (key 2) and “6“ (key 5). "Quit" (key 6) enters

the choice.

If the logger memory is full, the display will show:

Viewing Recorded Measurements

Within the „LoGG Stor“ function the measurements can be viewed directly in the

display not only by means of a computer (like at „Func CYCL“): press 2 seconds

„Set“ (key 4): The first menu displayed now is „rEAd LoGG“ (read logger data).

After pressing “4“ (key 3) the measurement recorded last will be displayed,

changing between the different values referring to the measurement also is done

by pressing “4“.

Changing the measurement is done by pressing the keys “5“ or “6“.

10.2 „Func-CYCL“: Automatic Recording With Selectable

Logger-Cycle-Time

The Logger-Cycle-Time is settable (please refer to Configuration). For example

„CYCL“ = 60: A measuring is recorded after each 60 seconds.

When the slow measurement "rAtE-Slo" is chosen, additionally a low power

function is available: „Lo.Po“.

If „Lo.Po“ is on, the device only will take a measurement at the point of time of the

recording. In between the recordings the measuring shuts down. This decreases

the power consumption enormously and therefore is recommended e.g. for long

time recordings where no mains adapter is available.

Max. number of measurings: 9999

Cycle time: 1...3600 seconds (=1h), selectable in the configuration

A measurement comprises of:

by slow measurements (rAtE Slo):

• current measuring value at the time of recording

• min peak, max peak since the last recording

by fast measurements (rAtE FASt,P.dEt)

Clear all

recordings

Clear the last

recording

Clear nothing

(Cancel menu)

Page 12

HND-P239

page 12 HND-P239 K01/0307

• arithmetic mean value since the last recording

• min peak, max peak since the last recording

Starting a recording:

By pressing "Store" (key 6) for 2 seconds the recording will be initiated. After that

the display shows ‘St.XXXX‘ for a short time whenever a measuring is recorded.

XXXX is the number of the measuring 1..9999.

If the logger memory is full, the display will show: The recording

automatically will be stopped.

If Low-Power-Logger-Function „Lo.Po = on“ the device switches itself off as soon

as the memory gets filled.

Stopping the recording manually:

By pressing "Store" (key 6) the recording can be stopped manually. Then the

following choice appears:

The selection can be made by “5“ (key 2) and “6“ (key 5). "Quit" (key 6) enters

the choice.

Note: If you try to switch off the instrument in the cyclic recording

operation You will be asked once again if the recording is to be

stopped. The device can only be switched off after the recording

has been stopped!

The Auto-Power-Off-function is deactivated during recording!

Clear Recordings:

When „Store“ is pressed for 2 seconds, the choice for clearing the logger memory

will be displayed:

The selection can be made by “5“ (key 2) and “6“ (key 5). "Quit" (key 6) enters

the choice.

Stop the

recording

Do not stop the

recording

Clear all

recordings

Clear nothing (cancel menu)

Page 13

HND-P239

HND-P239 K01/0307 page 13

11. The Serial Interface

With an electrically isolated interface converter HND-Z031 (accessories) the

device can be directly connected a RS232 interface of a computer (HND-Z032

complies with USB-interface). To avoid transmission errors, there are several

security checks implemented (CRC).

The following standard software packages are available:

HND-Z034: Operation and read out of logger function, data display in

diagrams and tables

The device has 3 channels:

Channel 1: current measuring value (base address)

Channel 2: min peak (please refer to chapter 10. Operation Of Logger)

Channel 3: max peak (please refer to chapter 10. Operation Of Logger)

Note! The measuring-/ alarm- and display range values read back

from the interface are always in the selected measurement unit

(mbar, bar...)!

Supported functions:

Channel Code Name/Function Channel Code Name/Function

1 2 3 1 2 3

x x x 0 Read measurement value x x x 199 Read kind of measuring of display

x x x 3 Read system state x x x 200 Read min display range

x 6 Read min memory x x x 201 Read max display range

x 7 Read max memory x x x 202 Read display range - unit

x x x 12 Read ID number x x x 204 Read display range – decimal point

x 22 Read min alarm rail (AL. - AL.Lo) x 208 Read # of channels

x 23 Read max alarm rail (AL. - AL.Hi) x 220 Read altitude (only abs. press sensors)

x 221 Set altitude (only abs. press sensors)

x 222 Read power off time (Conf-P.oFF)

x 223 Set power off time (Conf-P.oFF)

x x x 224 Logger: Read data of CYCL- Logger

x 32

Read configuration flag

BitAlarmOn:1; BitAlarmSound:3;

BitCorrectToSealevel:32 (only abs. press. Sensors);

BitPeakDetection:33; BitFastFiltered:34;

BitLoggerOn:50; BitCyclicLogger:51;

BitLowPowerLogger:52

x 225 Logger: Read cycle time (LoGG - CYCL)

x 102 Set min alarm rail (AL. - AL.Lo) x 226 Logger: set cycle time (LoGG - CYCL)

x 103 Set max alarm rail (AL. - AL.Hi) x 227 Logger: start recording

x 160 Set configuration flag (refer to 32) x 228 Logger: Read # of recordings made

x 174 Clear min memory x 229 Logger: Read state

x 175 Clear max memory x 231 Logger: Read stop time

x x x 176 Read min measuring range x 233 Read real time clock (CLOC)

x x x 177 Read max measuring range x 234 Set real time clock (CLOC)

x x x 178 Read measuring range – measuring unit x 236 Read logger memory size

x x x 179 Read measuring range – decimal point x 240 Reset

x x x 180 Read kind of measuring of sensor x 254 Program version

x 194 Set display unit x 260 Logger: read data of STOR Logger

Page 14

HND-P239

page 14 HND-P239 K01/0307

12. Error And System Messages

Display Meaning What to do?

Low battery power, device will only

continue operation for a short period of

time

Replace battery

Battery empty Replace battery

Mains operation without battery: wrong

voltage

Check power supply, replace it

when necessary

Logger data are read by the interface When transfer completed the device

will automatically return to normal

measuring display, no remedy

necessary

Battery empty Replace battery

Mains operation without battery: wrong

voltage or polarity

Check power supply, replace it when

necessary

System error Disconnect battery and power

supplies, wait shortly, then reconnect

No display

or confused

characters,

device does

not react on

keypress

Device defective Return to manufacturer for repair

Measured value above allowable range Check: pressure above 1300 mbar?

-> measuring value to high

Err.1

Sensor defective Return to manufacturer for repair

Measured value below allowable range -> measuring value to low

Err.2

Sensor defective Return to manufacturer for repair

Err.4

Value is too low to be displayed, tara is

set

Check: display below -2000 (tara?)?

Err.9

Measured value far out of allowable

range

Check: pressure not within sensor

range?

Err.7

System error Return to manufacturer for repair

13. Calibration Services

Calibration certificates – DKD-certificates – other certificates:

If device should be certificated for its accuracy, it is the best solution to return it to

the manufacturer.

Only the manufacturer is capable to do efficient recalibration if necessary to get

results with highest accuracy!

Page 15

HND-P239

HND-P239 K01/0307 page 15

14. Maintenance

14.1 Battery Operation

If and ´bAt´ are shown in the secondary display, the battery has been used up

and needs to be replaced. The device will, however, operate correctly for a

certain amount of time. If ´bAt´ is shown in the upper display the voltage is too

low to operate the device; the battery has been completely used up.

The battery has to be taken out, when, the device is stored above 50°C.

We recommend to take out battery if device is not used for a longer

period of time!

15. Technical Information

Measuring range: 0 to 1300 mbar

Accuracy: ±0,2 % F.S.

(hysteresis and linearity)

±0.4 % F.S.

(temperature dependency 0-50 °C)

Resolution: 1 mbar

Pressure units: mbar, bar, kPa, MPa, mmHg, PSI, m

(switchable)

Overload: max. 4 bar absolute

Measuring input: by means of a metal-hose stem

Sensor: piezo-resistive absolute pressure sensor,

for air or non-corrosive and

non-ionising gases and liquids,

not for water!

Display: 2 x 4-digit LC-displays

Operating temperature: 0…50 °C

Storage temperature: -20…+70 °C

Relative humidity: 0...95 % r.H. (non-condensing)

Output: serial interface

(via 3-pin jack, transformer on

RS232 or USB optional)

Power supply: 9V-monobloc battery

(included in scope of delivery),

external 10.5 - 12VDC via jack

Current consumption: max. 3 mA (HND-P239)

Materials: housing made of impact-resistant ABS plastic

Protection: IP65, front side

Dimensions: 142 x 71 x 26 mm (L x W x D)

Weight: approx. 160g

!

Page 16

HND-P239

page 16 HND-P239 K01/0307

Scope of functions:

• Min-/Max-value memory

• Hold function: »freezing« of the current value

• Automatic-off function: 1...120 min (can be deactivated)

• Zero point adjustment via keyboard possible

• Tare function: Display, minimum/maximum values are set to zero

• Battery change notification

Additional functions for the HND-P239:

• Minimum/maximum alarm can be deactivated

• Alarm (3 alarm settings)

Off: Alarm function inactive

On: Alarm notification via display, internal horn

and serial interface

No Sound: Alarm notification only via display

and interface

• Averaging

• Peak value memory unfiltered pressure peaks ≥ 10 msec

• Adjustable measuring cycle:

»slow« 4 measurements/sec

»fast« ≥ 100 measurements/sec (filtered)

»peak-detect« ≤ 100 measurements/sec

• Power saving mode in the measuring cycle »slow«

• Real-time clock: current time

• Logger functions:

Manual: 99 datasets

Cyclic: 9999 datasets

Adjustable cycle time: 1sec...1h

Page 17

HND-P239

HND-P239 K01/0307 page 17

16. Order Codes

Order-No. Design

HND-P 239

1x pressure sensor input, with additional functions

(see Technical Information)

16.1 Accessories for HND-P

Order-No. Description

HND-Z002

Plug power supply unit (220/240 V, 50/ 60 Hz), 10,5 V/10 mA

HND-Z011

Equipment protective housing bag, nappa leather, with 1 cut-out for

round sensor connection

HND-Z012

Equipment protective housing bag, nappa leather, with 2 cut-outs for

round sensor connection of the HND- series with logger function

HND-Z021

Case with recess (275 x 229 x 83 mm)

HND-Z022

Universal case with egg crate foam (275 x 229 x 83 mm)

HND-Z023

Large case with recess (394 x 294 x 106 mm)

HND-Z031

Interface converter on RS232, galvanically isolated

HND-Z032

Adapter RS232 converter on USB- interface

HND-Z033

Interface converter on USB, galvanically isolated

HND-Z034

Windows software for setting, data read-out, and printing of the data of

housings of the HND- series with logger function

HND-Z081

Double nozzle for hose

6

/4 on hose 6/

4

HND-Z082

Hose clamp for hose

6

/

4

HND-Z083

Adapter made of brass for G ¼ internal threads on hose

6

/4

HND-Z084

PVC-hose (5 bar), 6 mm external / 4 mm internal

HND-Z085

PE-hose (10 bar), 6 mm external / 4 mm internal

HND-Z086

PU-hose (9 bar), 6 mm external / 4 mm internal

HND-Z087

PA-hose (25 bar), 6 mm external / 4 mm internal

Additional accessories on request.

Page 18

HND-P239

page 18 HND-P239 K01/0307

17. Declaration of Conformance

We, KOBOLD Messring GmbH, Hofheim-Ts, Germany, declare under our sole

responsibility that the product:

Handheld Digital Pressure Meter

with external pressure sensor Model: HND-P239

to which this declaration relates is in conformity with the standards noted below:

Also the following EEC guidelines are fulfilled:

93/38/EEC, 2004/108/EC Electromagnetic compatibility

73/23/EEC, 93/68 EEC Low voltage guideline (for usage of the external

power supply HND-Z002)

Hofheim, 28. Jul. 2005

H. Peters M. Wenzel

General Manager Proxy Holder

Loading...

Loading...