Page 1

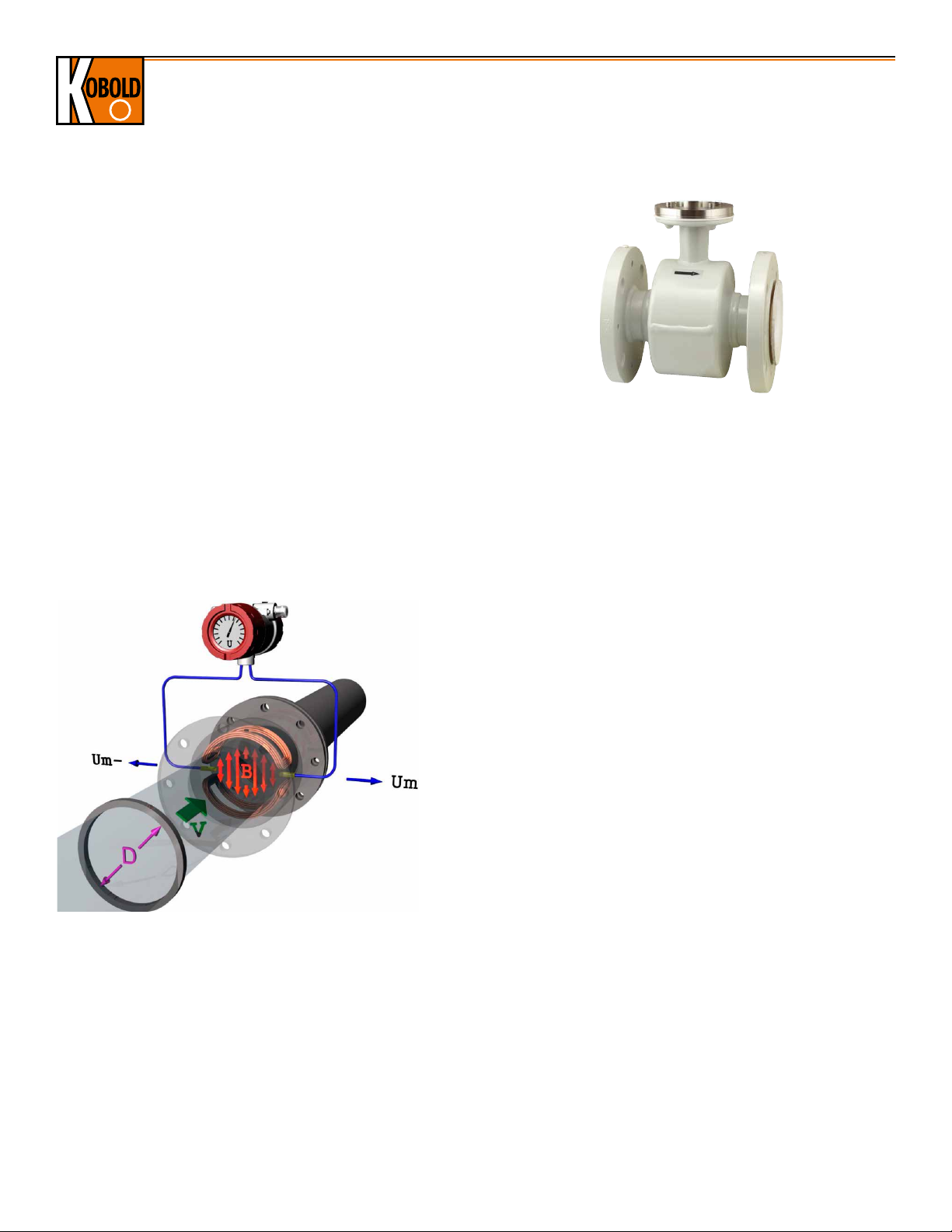

Magnetic Inductive Flowmeter

for Conductive Liquids

measuring

•

monitoring

•

analyzing

EPS / UMF2

●● High Accuracy:

0.3 % of Actual Flow

●● Maintenance-free

●● No Pressure Drop

●● Wide Variety of Lining and Electrode

Materials

KOBOLD companies worldwide:

ARGENTINA, AUSTRALIA, AUSTRIA, BELGIUM, BULGARIA, CANADA, CHILE, CHINA, COLOMBIA,

CZECH REPUBLIC, EGYPT, FRANCE, GERMANY, HUNGARY, INDIA, INDONESIA, ITALY, MALAYSIA,

MEXICO, NETHERLANDS, PERU, POLAND, REPUBLIC OF KOREA, ROMANIA, SINGAPORE, SPAIN,

SWITZERLAND, TAIWAN, THAILAND, TUNISIA, TURKEY, UNITED KINGDOM, USA, VIETNAM

01/12-17-2018

KOBOLD Instruments, Inc.

1801 Parkway View Drive

Pittsburgh, PA 15205

Main Ofce:

1.800.998.1020

1.412.788.4890

info@koboldusa.com

www.koboldusa.com

Page 2

Magnetic Inductive Flowmeter Model EPS

Description

The EPS magnetic-inductive flow sensor is used to measure

the volumetric flow of liquids, slurries, pastes and other

electrically conductive media without any pressure drop.

Pressure, temperature, density and viscosity do not affect

the volume measurements. Solid particles and small gas

bubbles should be avoided. The EPS sensor can be used

in combination with the KOBOLD UMF2 transmitter. The

transmitter is available in a compact version or a remote

version.

Operation

An electrically conductive media flowing through a magnetic

field, in accordance to Faraday's law of induction, will induce

a voltage proportional to the mean flow velocity rate and

hence the volumetric flow. A magnetic inductive flowmeter

consists of a lined flow body, through which a conductive

liquid flows, a magnetic field coil and two electrodes. The

electrode voltage is detected by a transmitter and converted

into standardized electrical signal such as 4-20 mA or pulse

output.

Advantages

●● Wide Variety of Lining Materials

●● Electrodes in Stainless Steel, Hastelloy

®

, Tantalum,

Platinum-Iridium, Titanium

●● Large Selection of Process Connections

●● For Use in Harsh Environments

Technical Details for EPS Sensor

Flow Body: Painted Steel (Standard)

Stainless Steel Tri-Clamp®, Ceramic Models

Nominal Sizes: 1/12" , 1/8", 1/4", 3/8" Inside Diameter

Process Connection in ½" NPT,

ANSI ½" ... 24" (Other Nominal Sizes on

Request)

Connection: Flanges of Steel or 304 Stainless Steel

(ASME B16.5), 1/2" NPT of 316L Stainless

Steel or Hastelloy®, or Tri-Clamp®

(Other Connections on Request)

Lining Material: Hard Rubber, Soft Rubber, EPDM, PTFE, or

Ceramic

Electrode Material: 316-Ti Stainless Steel, Hastelloy® C276,

Titanium, Tantalum or Platinum-Iridium

Grounding Rings: On Request

Nominal Pressure (ANSI Flange) per ASME B16.5:

(verify flange material, rating, & temperature)

1/2" to 24": Class 150, 230 PSI

1/2" to 12": Class 300, 580 PSI

(Higher Pressures on Request)

Process Temperature:

EPDM Lining: 14...158 °F

PTFE Lining: -4...302 °F

Ceramic Lining: -4...302 °F

Hard Rubber: 32...203 °F

Soft Rubber: 32...158 °F

Ambient Temp: -4...140 °F, Depending on Process

Temperature

Conductivity: ≥ 5 µS/cm

≥ 20 µS/cm with Demineralized Water

Measuring Ranges: 0.5 m/s ... 10 m/s

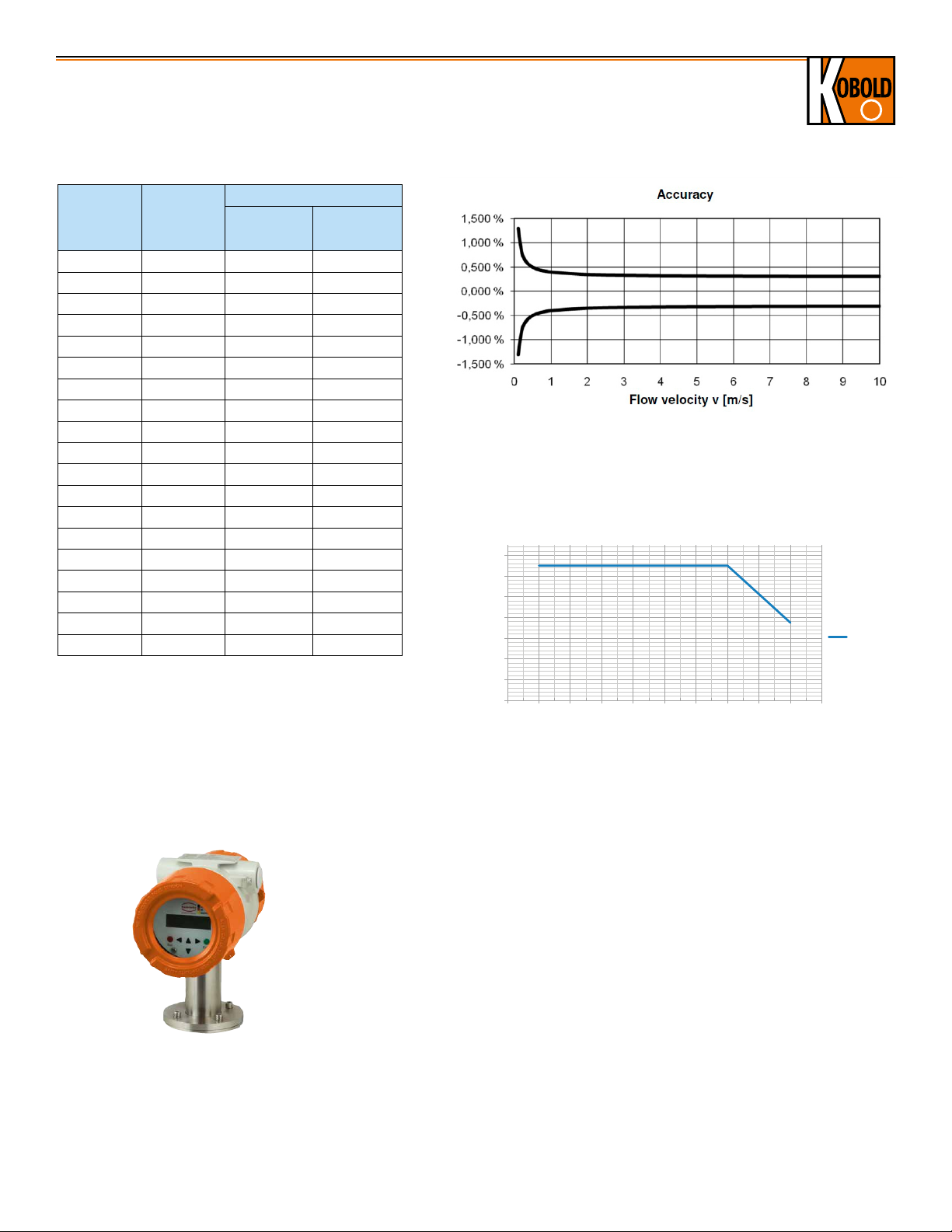

Accuracy: ± 0.3 % of Measured Value

± 0.01 % * (Q at 10 m/s)

(Under Reference Conditions)

Repeatability: ± 0.15 % of Measured Value

± 0.005 % * (Q at 10 m/s)

(Under Reference Conditions)

Protection: IP67 or IP68 (EN60529)

2

www.koboldusa.com

No responsibility taken for errors;

subject to change without prior notice.

Page 3

Magnetic Inductive Flowmeter Model EPS

Material load curves

For stainless steel flanges (1.4404 / 316L) according to EN1092-1

0

5

10

15

20

25

30

35

40

45

50

-40-20 020406080100 120140

[bar]

PN6

PN10

PN16

PN40

[°C]

[°F]

Flow Ranges

Inner

Diameter of

Measuring

Connection

Size

Tube

1/12" 1/2" 0.03 0.49

1/8" 1/2" 0.06 1.11

1/4" 1/2" 0.23 4.48

3/8" 1/2" 0.63 12.4

1/2" 1/2" 1.47 29.0

1" 1" 4.21 84.0

1-1/2" 1-1/2" 8.5 168.0

2" 2" 15.5 309.0

3" 3" 38.0 747.0

4" 4" 61.0 1,205

6" 6" 140 2,780

8" 8" 245 4,890

10" 10" 395 7,865

12" 12" 565 11,270

14" 14" 705 14,050

16" 16" 925 18,450

18" 18" 1,170 23,375

20" 20" 1,470 29,360

24" 24" 2,110 42,115

Technical Details for UMF2 Transmitter

GPM

Q

min

Mounting Options: Compact or Remote

Housing: Die Cast Aluminum, Painted

Power Supply: 115 / 230 VAC 50/60 Hz, 10 VA

24 VDC 10 W

Accuracy/Repeatability

Q

max

Accuracy: ± 0.3% of Measured Value + 0.0001 * (Q at 10 m/s)

Repeatability: ± (0.15% of Measured Value + 0.00005 * (Q at 10 m/s)

Material Load Curve

[psi g]

240

220

200

180

class 150

160

140

120

100

-40-20 020406080100 200280 300

For stainless steel flanges (1.4404 / 316L) according to ASME B16.5

Indication: LCD, 2-lines, 16 Digits,

Back-lit

Interface Language: English, German

Output

Analog: 1 x 4-20 mA HART®, Active,

Galvanically Isolated

Pulse: Passive, Galvanically Isolated

24 V, 60 mA

Status: Passive, Galvanically Isolated

24 V, 60 mA

Ambient Temp: -4...140 °F (-20 °C...60 °C),

Depending on Process Temperature

Protection: IP67 or IP68 (EN60529)

Communication: HART

®

Diagnostics: Empty Pipe Detection, Coil Current

Monitoring

Electromagnetic

Tolerance: EMC-Directive 2014/30/EU (EMC)

No responsibility taken for errors;

subject to change without prior notice.

www.koboldusa.com

3

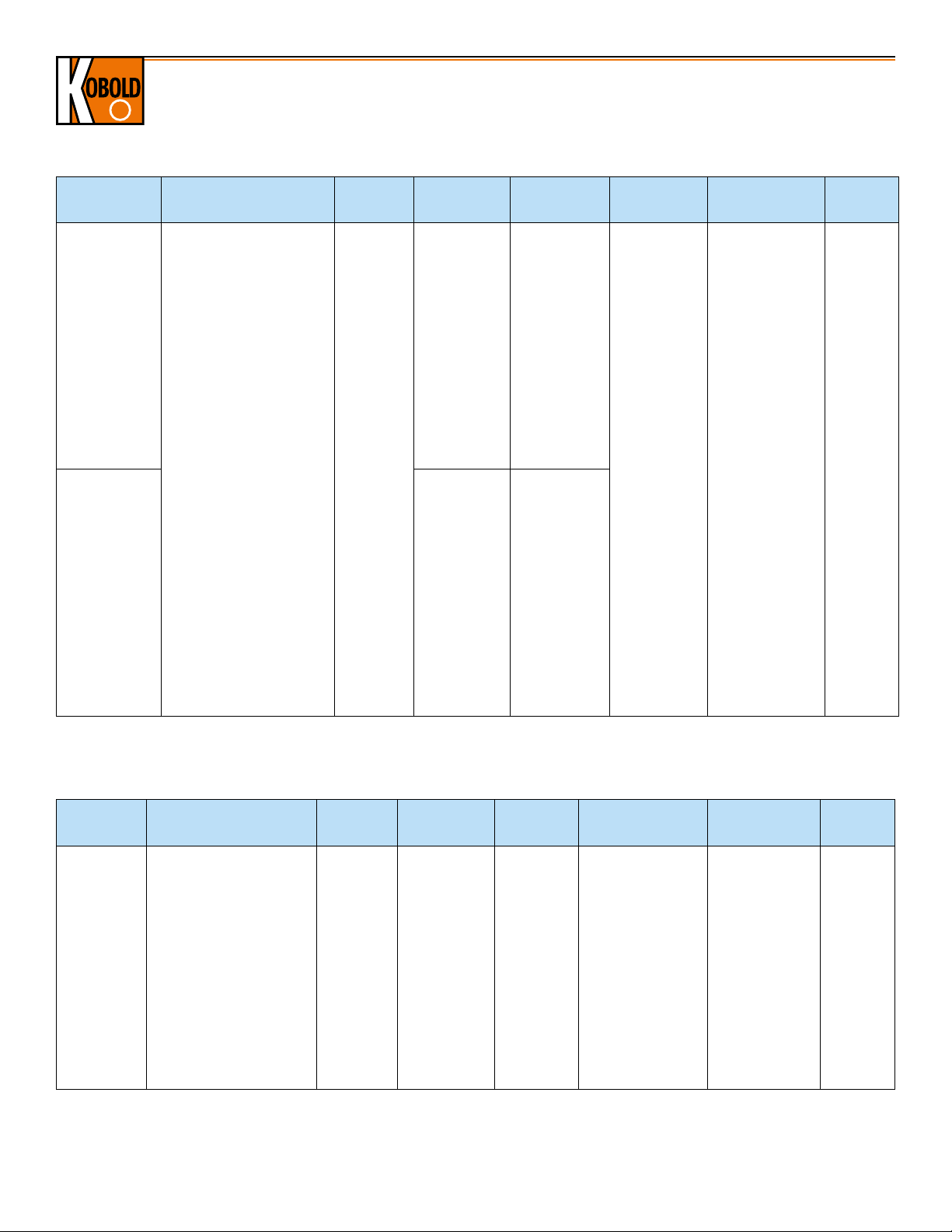

Page 4

Magnetic Inductive Flowmeter Model EPS

Order Details for Models EPS-H and EPS-W: Sensor with Hard Rubber (Ebonite) or Soft Rubber Lining

Model

Liner Material

Connections*

..203R.. = 1" ANSI Class 150*

Process

Connection

Material

Electrode

Material

Grounding

Electrode

Transmitter

Mounting

Certificates Transmitter

..205R.. = 1-1/2" ANSI Class 150*

EPS-H.. = Hard

Rubber

(Ebonite)

EPS-W.. = Soft

Rubber

* 300 LB ANSI available upon request

..206R.. = 2" ANSI Class 150*

..208R.. = 3" ANSI Class 150*

..210R.. = 4" ANSI Class 150*

..212R.. = 6" ANSI Class 150*

..213R.. = 8" ANSI Class 150*

..214R.. = 10" ANSI Class 150*

..215R.. = 12" ANSI Class 150*

..216R.. = 14" ANSI Class 150*

..217R.. = 16" ANSI Class 150*

..218R.. = 18" ANSI Class 150*

..219R.. = 20" ANSI Class 150*

..220R.. = 24" ANSI Class 150*

..1.. = Flange,

Steel,

Painted

..2.. = 304 SS

Flange

..S.. = 316-Ti SS

..H.. = Hastelloy®

..M.. = Titanium

..S.. = 316-Ti SS

..H.. = Hastelloy®

..T.. = Tantalum

..N.. = Platinum/

Iridium

..S.. = 316-Ti SS

..H.. = Hastelloy®

..M.. = Titanium

..S.. = 316-Ti SS

..H.. = Hastelloy®

..T.. = Tantalum

..N.. = Platimum/

Iridium

..1.. = Integrated

Transmitter,

IP67

..2.. = Remote

Transmitter,

IP 67,

Terminal

Box via

M20x1.5,

(Cable >10

m, add

Junction

Box at

Transmitter)

..3.. = Remote

Transmitter,

IP 68,

Terminal

Box via

M20x1.5,

Encaps.

(Add

Juntion

Box at

Transmitter)

..0 = without

..1 = Certificate of

Compliance with

Order 2.1

..2 = Test Report 2.2

..B = Inspection/

Material

Certificate

3.1 DIN/

EN10204:2008

..C = I nspection/

Material

Certificate

3.2 DIN/

EN10204:2008

To Complete

the Order,

Refer to the

Order Table

on Page

Six to Order

Transmitter

UMF2

Order Details for Model EPS-P: Sensor with PTFE Lining

Model

Liner Material

..201R.. = 1/2" ANSI Class 150

..203R.. = 1" ANSI Class 150

..205R.. = 1-1/2" ANSI Class 150

..206R.. = 2" ANSI Class 150

EPS -P.. = PTFE

* Grounding Rings are available upon request

4

..208R.. = 3" ANSI Class 150

..210R.. = 4" ANSI Class 150

..212R.. = 6" ANSI Class 150

..213R.. = 8" ANSI Class 150

..214R.. = 10" ANSI Class 150

..215R.. = 12" ANSI Class 150

Connections

Process

Connection

Material

..1.. = Flange,

Steel,

Painted

..2.. = 304 SS

Flange

Electrode

Material

..H.. = Hastelloy®

..T.. = Tantalum

..N.. = Platinum/

Iridium

..M.. = Titanium

www.koboldusa.com

Grounding

Electrode*

..0.. = without *

Transmitter Mounting Certificates Transmitter

..1.. = Integrated

Transmitter, IP67

..2.. = Remote

Transmitter, IP 67,

Terminal Box via

M20x1.5, (Cable

>10 m, add

Junction Box at

Transmitter)

..3.. = Remote

Transmitter, IP 68,

Terminal Box via

M20x1.5, Encaps.

(Add Juntion Box

at Transmitter)

..0 = without

..1 = Certificate of

Compliance

with Order 2.1

..2 = Test Report 2.2

..B = Inspection/

Material

Certificate

3.1 DIN/

EN10204:2008

..C = Inspection/

Material

Certificate

3.2 DIN/

EN10204:2008

No responsibility taken for errors;

subject to change without prior notice.

To Complete

the Order,

Refer to the

Order Table

on Page

Six to Order

Transmitter

UMF2

Page 5

Magnetic Inductive Flowmeter Model EPS

Order Details for Model EPS-E: Sensor with EPDM Lining

Model

Liner Material

EPS -E.. = EPDM

Connections

..201R.. = 1/2" ANSI Class 150

..203R.. = 1" ANSI Class 150

..205R.. = 1-1/2" ANSI Class 150

..206R.. = 2" ANSI Class 150

..208R.. = 3" ANSI Class 150

..210R.. = 4" ANSI Class 150

..212R.. = 6" ANSI Class 150

..213R.. = 8" ANSI Class 150

..214R.. = 10" ANSI Class 150

..215R.. = 12" ANSI Class 150

..216R.. = 14" ANSI Class 150

..217R.. = 16" ANSI Class 150

..218R.. = 18" ANSI Class 150

..219R.. = 20" ANSI Class 150

..220R.. = 24" ANSI Class 150

Process

Connection

Material

..1.. = Flange,

Steel,

Painted

..2.. = 304 SS

Flange

..H.. = Hastelloy® ..H.. = Hastelloy®

Electrode

Material

Grounding

Electrode

Transmitter

Mounting

..1.. = Integrated

Transmitter,

IP67

..2.. = Remote

Transmitter,

IP 67,

Terminal

Box via

M20x1.5,

(Cable >10

m, add

Junction

Box at

Transmitter)

..3.. = Remote

Transmitter,

IP 68,

Terminal

Box via

M20x1.5,

Encaps.

(Add

Juntion

Box at

Transmitter)

Certificates Transmitter

..0 = without

..1 = Certificate of

Compliance

with Order 2.1

..2 = Test Report 2.2

..B = Inspection/

Material

Certificate

3.1 DIN/

EN10204:2008

..C = Inspection/

Material

Certificate

3.2 DIN/

EN10204:2008

To Complete

the Order,

Refer to the

Order Table

on Page

Six to Order

Transmitter

UMF2

Order Details for Model EPS-A: Sensor with Ceramic Lining

Model

Liner Material

EPS-A.. = Ceramic

Connection Type, Material, Seal

..002A.. = 1/2" NPT Male, 1/12" I.D.

Stainless Steel with EPDM

..003A.. = 1/2" NPT Male, 1/8" I.D.

Stainless Steel with EPDM

..006A.. = 1/2" NPT Male, 1/4" I.D.

Stainless Steel with EPDM

..010A.. = 1/2" NPT Male, 3/8" I.D.

Stainless Steel with EPDM

..H02A.. = 1/2" NPT Male, 1/12" I.D.

Hastelloy® with PTFE

..H03A.. = 1/2" NPT Male, 1/8" I.D.

Hastelloy® with PTFE

..H06A.. = 1/2" NPT Male, 1/4" I.D.

Hastelloy® with PTFE

..H10A.. = 1/2" NPT Male, 3/8" I.D.

Hastelloy® with PTFE

..7000.. = 1/2" Tri-Clamp®, Stainless

Steel

..7010.. = 1" Tri-Clamp®, Stainless

Steel

..7020.. = 1-1/2" Tri-Clamp®, Stainless

Steel

..7030.. = 2" Tri-Clamp®, Stainless

Steel

..7050.. = 3" Tri-Clamp®, Stainless

Steel

..7060.. = 4" Tri-Clamp®, Stainless

Steel

Process

Connection

Material

..0.. = without

Electrode

Material

..N.. = Platinum/

Iridium

Grounding

Electrode*

..0.. = without*

Transmitter

Mounting

..1.. = Integrated

Transmitter,

IP67

..2.. = Remote

Transmitter,

IP 67,

Terminal

Box via

M20x1.5,

(Cable >10

m, add

Junction

Box at

Transmitter)

..3.. = Remote

Transmitter,

IP 68,

Terminal

Box via

M20x1.5,

Encaps.

(Add

Juntion

Box at

Transmitter)

Certificates Transmitter

..0 = without

..1 = Certificate of

Compliance

with Order 2.1

..2 = Test Report 2.2

..B = Inspection/

Material

Certificate

3.1 DIN/

EN10204:2008

..C = Inspection/

Material

Certificate

3.2 DIN/

EN10204:2008

To

Complete

the Order,

Refer to the

Order Table

on Page

Six to Order

Transmitter

UMF2

* Grounding Rings are available upon request

No responsibility taken for errors;

subject to change without prior notice.

www.koboldusa.com

5

Page 6

Magnetic Inductive Flowmeter Model EPS

Order Details for UMF2 Transmitter

Model Mount and Connections LCD Display Power Supply Output Signal

..A.. = IP 67, Integral

Transmitter, 1/2" NPT

..B.. = IP67, Integral

Transmitter, M20x1.5

..C.. = IP67, Remote

Transmitter, Includes

2.5 m Cable and C/W

Pipe/Wall Mounting

Bracket, (Cable > 10m

Add Junction Box at

UMF2-

Transmitter), 1/2" NPT

..D.. = IP67, Remote

Transmitter, Includes

2.5 m Cable and C/W

Pipe/Wall Mounting

Bracket, (Cable > 10m

Add Junction Box at

Transmitter), M20x1.5

..G.. = IP68, Remote

Transmitter, Includes 2.5

m Cable and C/W Pipe/

Wall Mounting Bracket,

(Transmitter C/W

Terminal Connection

Box), 1/2" NPT

..H.. = IP68, Remote

Transmitter, Includes 2.5

m Cable and C/W Pipe/

Wall Mounting Bracket,

(Transmitter C/W

Terminal Connection

Box), M20x1.5

..1.. = with

..1.. = 230 VAC (+10%, -15%)

50/60 Hz

..2.. = 115 VAC (+10%, -15%)

50/60 Hz

..4.. = 24 VDC (± 15%)

..F0BK = Current Output of

4-20 mA, Pulse

Output Passive Um =

24 VDC, Status Output

Passive Um = 24 V

..G0BK = Current Output of

4-20 mA with HART®

Protocol, Pulse

Output Passive Um =

24 VDC, Status Output

Passive Um = 24 V

Optional Longer Cable Length

(Junction Box)

..1 = IP67, 16' (5m), Breakout

Cable

..2 = IP67, 32' (10m), Breakout

Cable

..3 = IP67, 49' (15m)

..4 = IP67, 65' (20m)

..5 = IP67, 98' (30m)

..6 = IP67, 130' (40m)

DC

..7 = IP67, 164' (50m)

..B = IP68, 16' (5m)

..C = IP68, 32' (10m)

DC

..D = IP68, 49' (15m)

..E = IP68, 65' (20m)

..F = IP68, 98' (30m)

..G = IP68, 130' (40m)

..H = IP68, 164' (50m)

6

www.koboldusa.com

No responsibility taken for errors;

subject to change without prior notice.

Page 7

Electrical Connections

Mounting Types

Magnetic Inductive Flowmeter Model EPS

Compact IP67 according to

DIN/EN 60529

Dust tight, short time

submersible.

Remote IP67 according to

DIN/EN 60529

Dust tight, short time submersible.

(With 2.5 m, 5 m and 10 m factory

mounted cable on transmitter.)

Remote IP68 according to DIN/EN

60529

Dust tight, suitable for continuous

immersion.

(For distances >10 m, factory

mounted cable on transmitter, junction

box on sensor resin filled.)

Remote version up to 10 m cable Remote version > 10 m cable

No responsibility taken for errors;

subject to change without prior notice.

www.koboldusa.com

7

Page 8

Magnetic Inductive Flowmeter Model EPS

Emptying possible

Emptying avoided

Emptying possible

Upstream of pump, vacuum possible

Mount in ascending main

Upstream of pump, vacuum possible

Mount in ascending main

Do not mount downstream of a valve

Upstream of pump, vacuum possible

Mount in ascending main

Do not mount downstream of a valve

ns Pipe narrowing with maximum 8° angle

Mount in ascending main

Installation Conditions

To avoid vacuum, emptying of pipes, or gas aggregation please take notice of the following mounting advice.

Upstream of pump, vacuum possible

support to prevent vibratio

Pipe narrowing with maximum 8° angle

8

www.koboldusa.com

No responsibility taken for errors;

subject to change without prior notice.

Page 9

Magnetic Inductive Flowmeter Model EPS

M°

20

25

30

35

40

45

50

55

60

65

70

60 70 80 90 100110 120130 140

[erutarepmet tneibma .xaM°C]

Max. medium temperature [°C]

M°

Ambient Conditions

As the flowmeter becomes an element of the piping, they are

sometimes thermally insulated when installed to save energy

and prevent accidental physical contact. The heat of the process

temperature will be transferred through the support neck of the

integrally mounted transmitter or terminal box. For this reason the

thermal insulation of the flowmeter should only extend half way

up the support of the transmitter. It is essential not to include the

transmitter or the terminal box as part of the thermal insulation.

The maximum permissible liquid temperature limits are stated on

the rating plate of the respective flowmeter version.

Maximum Ambient Temperature According to Media Temperature with a Direct Mounted Transmitter

70

65

C]

60

[erutarepmet tneibma .xa

55

50

45

40

35

30

25

20

60 70 80 90 100110 120130 140

Max. medium temperature [°C]

Maximum Ambient Temperature According to Media Temperature with a Mounted Terminal Box

70

65

C]

[erutarepmet tneibma .xa

60

55

50

45

40

Remember to also consider the liner material max temperature limit.

Potential Equalization

The potential equalization is achieved via the grounding terminal of the junction box.

Pipe

Gasket

70 80 90 100110 120130 140

Ground Wire

min. 4mm2 Cu

Pipe

FE/PE

Gasket

Max. medium temperature [°C]

Pipe

Gasket

Grounding

Ring

Ground Wire

min. 4mm2 Cu

Grounding

Ring

Pipe

FE/PE

For metallic pipelines we recommend connecting the

grounding terminal to the pipe.

No responsibility taken for errors;

subject to change without prior notice.

www.koboldusa.com

Gasket

For non-metallic pipelines we recommend connecting

the grounding terminal to the grounding rings.

9

Page 10

Dimensions of the Transmitter UMF2

Transmitter Integral Mounted

Magnetic Inductive Flowmeter Model EPS

8.07"

7.87"

Transmitter for Remote Mounting

4.53"

4.53"

5.91"

4.25"

8.07"

Ø 4.33"

5.35"

Junction Box (Sensor) for Remote Mounting

Ø 4.09"

2.48"

10

4.72"

4.72"

2.44"

Ø 0.41"

2.44"

2.44"

www.koboldusa.com

1.38"

4.13

No responsibility taken for errors;

subject to change without prior notice.

Page 11

EPS Sensor Dimensions

Magnetic Inductive Flowmeter Model EPS

8.07"

ANSI

Connection

150 lbs 300 lbs 150 lbs 300 lbs 150 lbs 300 lbs 150 lbs 300 lbs

½" 3.50" 3.75" 4.10" 6.26" 6.26" 12.28" 12.28" 8.88" 8.88" 2.32" 7.9" 8.8

1" 4.25" 4.88" 4.10" 6.34" 6.65" 12.36" 12.68" 8.96" 9.27" 2.32" 7.9" 11.0

1½" 5.00" 6.12" 4.88" 7.11" 7.67" 13.13" 13.69" 9.72" 10.28" 3.23" 7.9" 17.6

2" 6.00" 6.50" 5.47" 7.90" 8.15" 13.93" 14.18" 10.52" 10.77" 2.83" 7.9" 19.8

3" 7.50" 8.25" 6.85" 9.34" 9.72" 15.37" 15.74" 11.96" 12.33" 2.83" 7.9" 26.5

4" 9.00" 10.00" 8.43" 10.88" 11.38" 16.90" 17.40" 13.50" 14.00" 3.35" 9.8" 35.3

6" 11.00" 12.50" 11.10" 13.22" 13.97" 19.24" 19.99" 15.83" 16.59" 3.35" 11.8" 59.5

8" 13.50" 15.00" 13.31" 15.57" 16.32" 21.59" 22.34" 18.19" 18.94" 5.39" 13.8" 88.2

10" 16.00" 17.50" 15.47" 17.90" 18.65" 23.93" 24.68" 20.52" 21.27" 6.18" 17.7" 132.3

12" 19.00" 20.50" 17.48" 20.41" 21.16" 26.43" 27.18" 23.02" 23.78" 6.18" 19.7" 176.4

14"

16" 23.50" 25.50" 19.76" 23.80" 24.80" 29.82" 30.82" 26.42" 27.42" 10.63" 23.6" 275.6

18" 25.00" 28.00" 22.17" 25.75" 27.25" 31.77" 33.27" 28.37" 29.87" 12.20" 23.6" 385.8

20" 27.48" 30.50" 24.17" 28.00" 29.50" 34.02" 35.53" 30.61" 32.12" 13.78" 23.6" 440.9

24" 32.00" 36.00" 28.15" 32.24" 34.24" 38.26" 40.26" 34.86" 36.86" 12.60" 23.6" 632.7

D

ANSI ANSI ANSI with Transmitter ANSI with Junction Box

21.00" 23.00" 17.76" 21.54" 22.54" 27.57" 28.57" 24.16" 25.16" 10.63" 21.7" 242.5

D1

E A

B L

Weight*

lb

* Weights are approximate and are for 150 lb ANSI versions without a transmitter/display. Units with an integral transmitter/display carry an additional

weight of 5.3 lbs.

No responsibility taken for errors;

subject to change without prior notice.

www.koboldusa.com

11

Page 12

Dimensions

6 x M4

Ceramic Version with 1/2" NPT Connections

Magnetic Inductive Flowmeter Model EPS

20

0.79"

35

1.38" 2.05"

Dimensions

Tri-Clover® (BS4825-1) Version

G ½ (ISO) or ½“ NPT

1/2" NPT

Size

1

⁄12

1

⁄8

¼

52 mm

3

⁄8

Size A L

3

⁄8" 3.90" 5.75"

½" 3.90" 5.75"

1" 4.45" 6.34"

1½" 4.96" 6.93"

2" 6.06" 7.32"

3" 7.87" 10.16"

4" 8.86" 11.34"

Lenth Dimension L

EPDM PTFE

5.9" 6.1"

Size

L

[mm]

Tri-Clover® (BS4825-1)

Di [mm] Do [mm]

1/2" 40 9.4 12.7

3/4" 40 15.75 19,05

1" 40 22.1 25.4

1-1/2" 40 34.8 38.1

2" 40 47.5 50.8

3" 50 72.9 76.2

* For BS 4825-1 see ISO 2037

12

www.koboldusa.com

4" 50 97.38* 101.6*

No responsibility taken for errors;

subject to change without prior notice.

Loading...

Loading...