Page 1

Operating Instructions

for

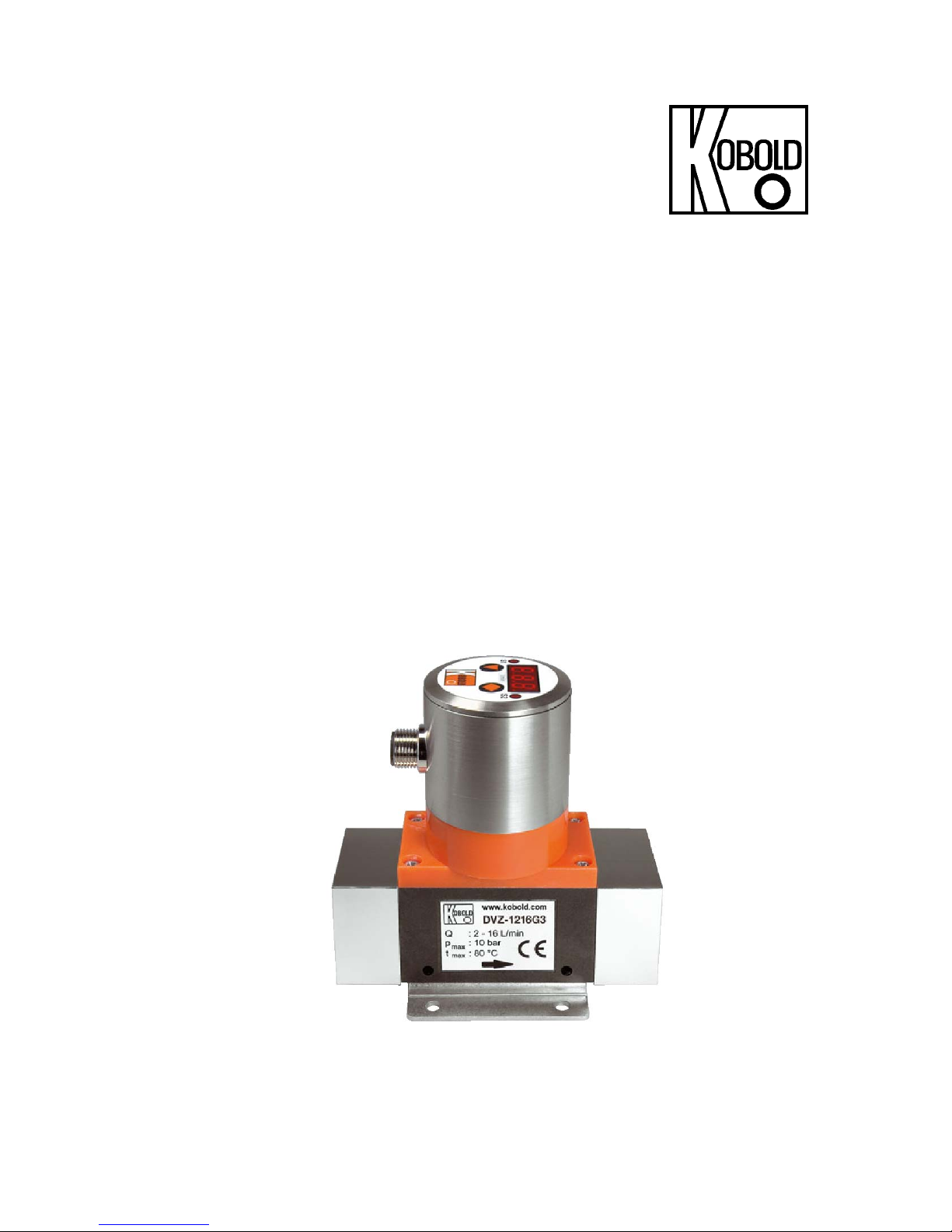

Compact Vortex Flow Meter

Model: DVZ

Page 2

DVZ

page 2 DVZ K04/0810

1. Contents

1. Contents ........................................................................................................ 2

2. Note .............................................................................................................. 3

3. Instrument Inspection .................................................................................... 3

4. Regulation Use .............................................................................................. 3

5. Operating Principle ........................................................................................ 4

6. Mechanical Connection ................................................................................. 4

6.1 Check operating conditions: ................................................................. 4

6.2 Installation ............................................................................................ 4

7. Electrical Connection .................................................................................... 5

7.1 General ................................................................................................ 5

7.2 DVZ-...S300 ......................................................................................... 6

7.3 DVZ-...S30D ........................................................................................ 6

7.4 DVZ-...F300; DVZ-...L3x3 .................................................................... 6

7.5 DVZ-...L443 ......................................................................................... 7

7.6 DVZ-...C30 ........................................................................................... 7

7.7 DVZ-...C34 ........................................................................................... 7

7.8 DVZ-...Ex4R, DVZ-...Gx4R .................................................................. 8

8. Operation ...................................................................................................... 9

8.1 Switch point setting DVZ-...S300, DVZ-…S30D .................................. 9

8.2 Counter electronics DVZ-…Ex4R ........................................................ 9

8.3 Dosing electronics DVZ-…Gx4R ......................................................... 9

9. Adjustments – Compact Electronic DVZ-...C3.. .......................................... 10

9.1 Button function ................................................................................... 10

9.2 Settings .............................................................................................. 10

9.3 Value setting ...................................................................................... 11

9.4 Set-up mode ...................................................................................... 12

9.5 Main menu items ............................................................................... 14

10. Maintenance ............................................................................................... 16

11. Technical Information .................................................................................. 17

12. Order Codes ............................................................................................... 20

13. Dimensions ................................................................................................. 22

13.1 Dimensions - Sensor.......................................................................... 22

13.2 Dimensions - Electronics ................................................................... 28

14. Declaration of Conformance ....................................................................... 31

Manufactured and sold by:

Kobold Messring GmbH

Nordring 22-24

D-65719 Hofheim

Tel.: +49(0)6192-2990

Fax: +49(0)6192-23398

E-Mail: info.de@kobold.com

Internet: www.kobold.com

Page 3

DVZ

DVZ K04/0810 page 3

2. Note

Please read these operating instructions before unpacking and putting the unit

into operation. Follow the instructions precisely as described herein.

The devices are only to be used, maintained and serviced by persons familiar

with these operating instructions and in accordance with local regulations

applying to Health & Safety and prevention of accidents.

When used in machines, the measuring unit should be used only when the

machines fulfil the EWG-machine guidelines.

as per PED 97/23/EG

In acc. with Article 3 Paragraph (3), "Sound Engineering Practice", of the

PED 97/23/EC no CE mark.

Diagram 8, Pipelines, Group 1, dangerous fluids

3. Instrument Inspection

Instruments are inspected before shipping and sent out in perfect condition.

Should damage to a device be visible, we recommend a thorough inspection of

the delivery packaging. In case of damage, please inform your parcel service /

forwarding agent immediately, since they are responsible for damages during

transit.

Scope of delivery:

The standard delivery includes:

• Compact Vortex Flow Meter model: DVZ

• Operating Instructions

4. Regulation Use

Any use of the Compact Vortex flow meter, model: DVZ, which exceeds the

manufacturer’s specifications, may invalidate its warranty. Therefore, any

resulting damage is not the responsibility of the manufacturer. The user assumes

all risk for such usage.

Page 4

DVZ

page 4 DVZ K04/0810

5. Operating Principle

The compact KOBOLD Vortex flow meter, model DVZ, is used for measuring and

monitoring smaller and medium-sized flow of low viscosity, water-like fluids in

pipes.

The device works using the vortex process, making it virtually maintenance-free.

This involves the installation of a sharp-edged object (the vortex generator) in the

flow duct. A vortex is created behind the object whose frequency is proportional

to the flow velocity of the fluid.

The flow volume can be determined with a very great degree of accuracy by

measuring the vortex frequency. This achieves a very high linearity across the

whole measuring range.

The device can be fitted with switching, frequency or analogue outputs. There is

also an optional compact electronics package that includes a digital display, and

both a switching and analogue output.

6. Mechanical Connection

6.1 Check operating conditions:

• Flow rate

• max. operating pressure

• max. operating temperature

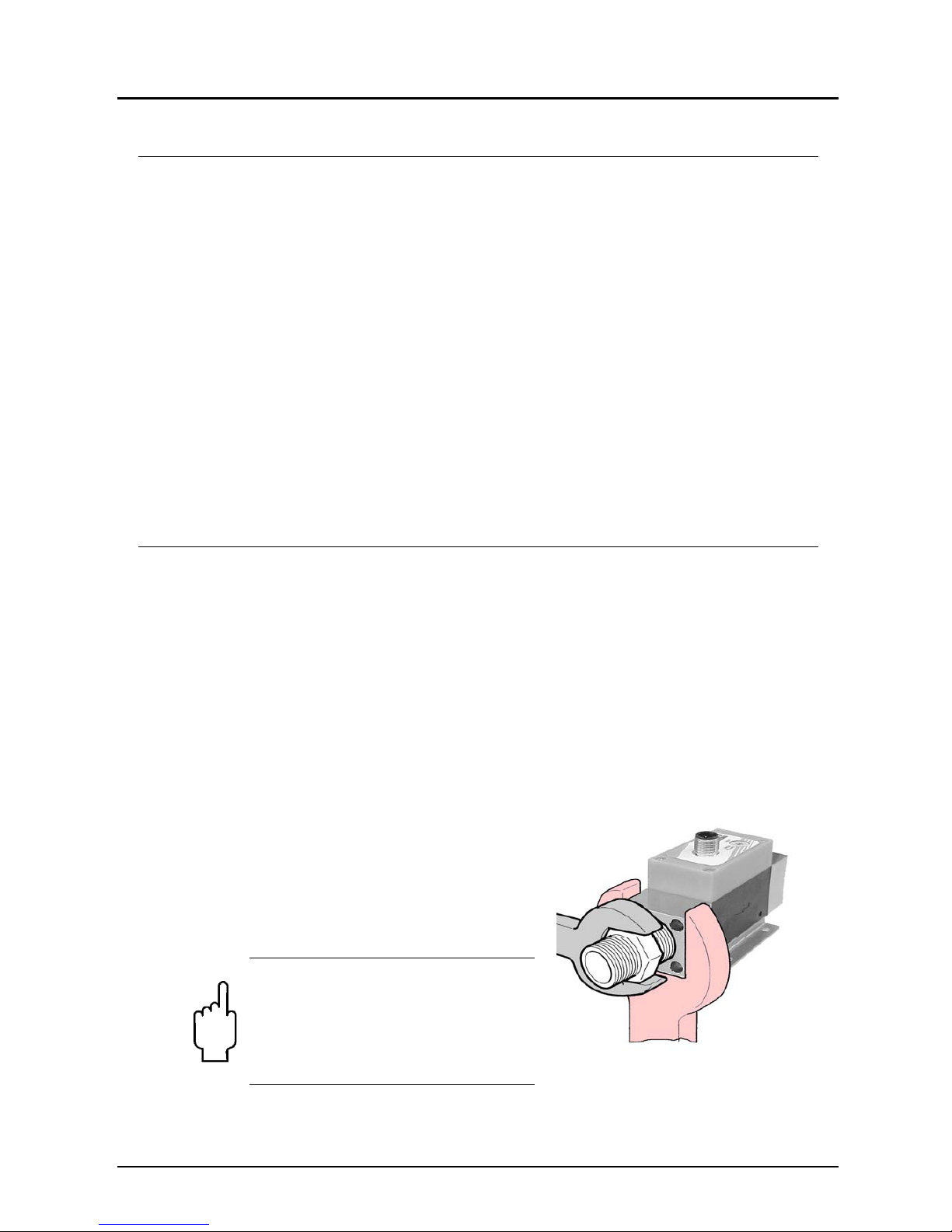

6.2 Installation

• Remove all packing materials and transport retainers and ensure that no such

materials remain in the device.

• Install with flow in direction of arrow

(universal mounting)

• Avoid pressure and radial tension

• Fasten the pipe at up stream and down

stream at a distance of 50 mm from the

connections

Attention! Retransfer the unit on

the metal bolting (not on the

plastic housing!) Mount switches

using the proper tightening

torque according the following

table!

Page 5

DVZ

DVZ K04/0810 page 5

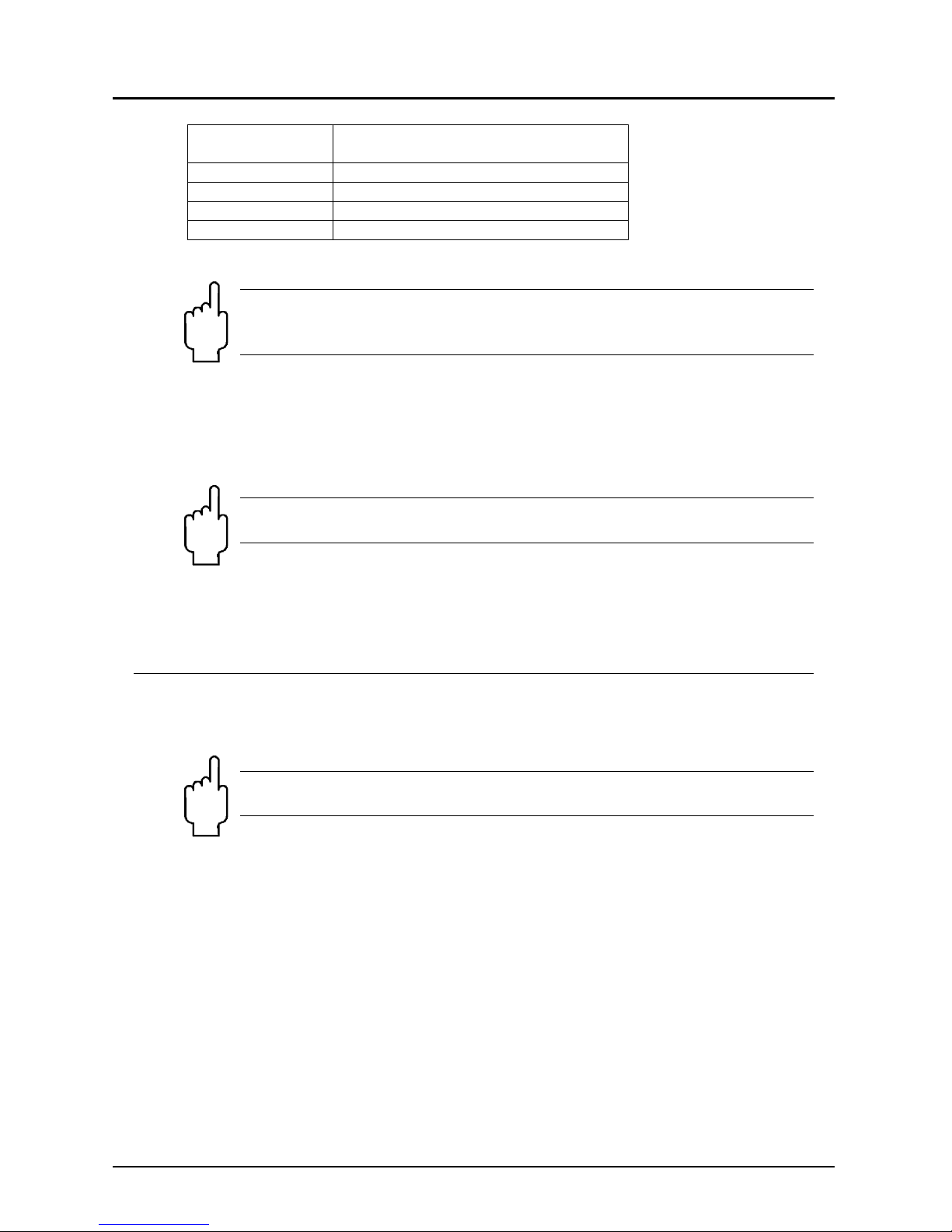

Nominal size of

threads

Proper tightening torque

3/8” 22 bis 24 Nm

1/2” 28 bis 30 Nm

3/4” 28 bis 30 Nm

1” 36 bis 38 Nm

Note! The switch may be damaged if it is tightened above the

tightening torque range. Also, if it is tightened below the tightening

torque range, the connecting thread section may loosen.

• Ensure inlet section of 10xDN and outlet section of 10xDN

• Avoid valves or large reduction on the inlet section (this increases the

inaccuracy of measurements)

• Check the seals of the connections

Attention! When used with an open output side, there is a danger of

cavitation.

7. Electrical Connection

7.1 General

Attention! Make sure that the voltage values of your system

correspond with the voltage values of the measuring unit.

• Make sure that the supply wires are de-energised.

• Connect the supply voltage and the output signal to the plug PIN’s as stated

below.

• We recommend the use of wires with cross sectional area of min. 0,25 mm².

Page 6

DVZ

page 6 DVZ K04/0810

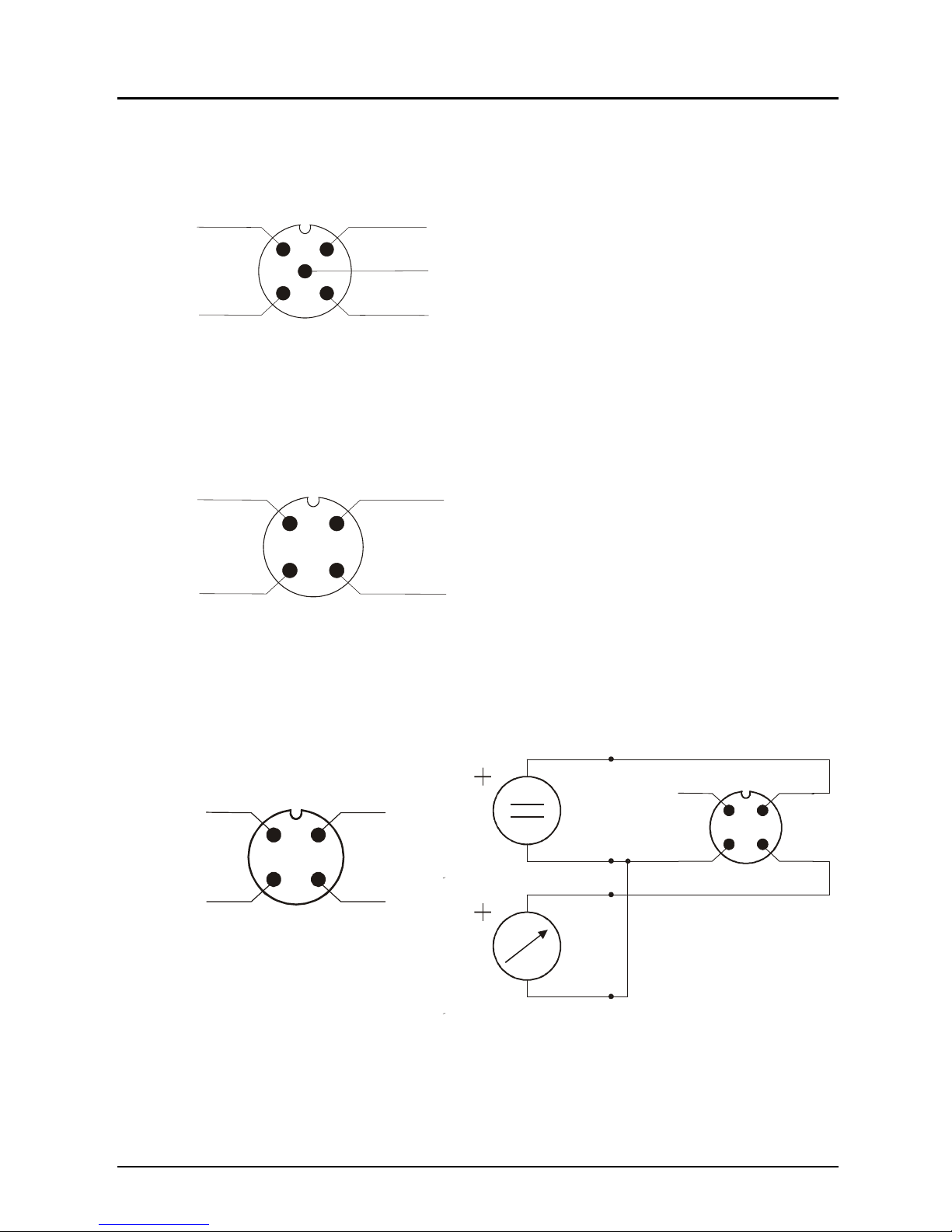

7.2 DVZ-...S300

7.3 DVZ-...S30D

1

2

3

4

Output

N/C

Output

N/O

+Vs

GND

7.4 DVZ-...F300; DVZ-...L3x3

Connection example DVZ-...L3x3

1

2

3

4

+Vs

Signal

Out

n.c.

GND

1

2

3

4

+Vs

Signal

Out

n.c.

GND

+Vs

GND

1

2

3

4

5

Output

N/O

Output

Common

Output

N/C

+Vs

GND

Page 7

DVZ

DVZ K04/0810 page 7

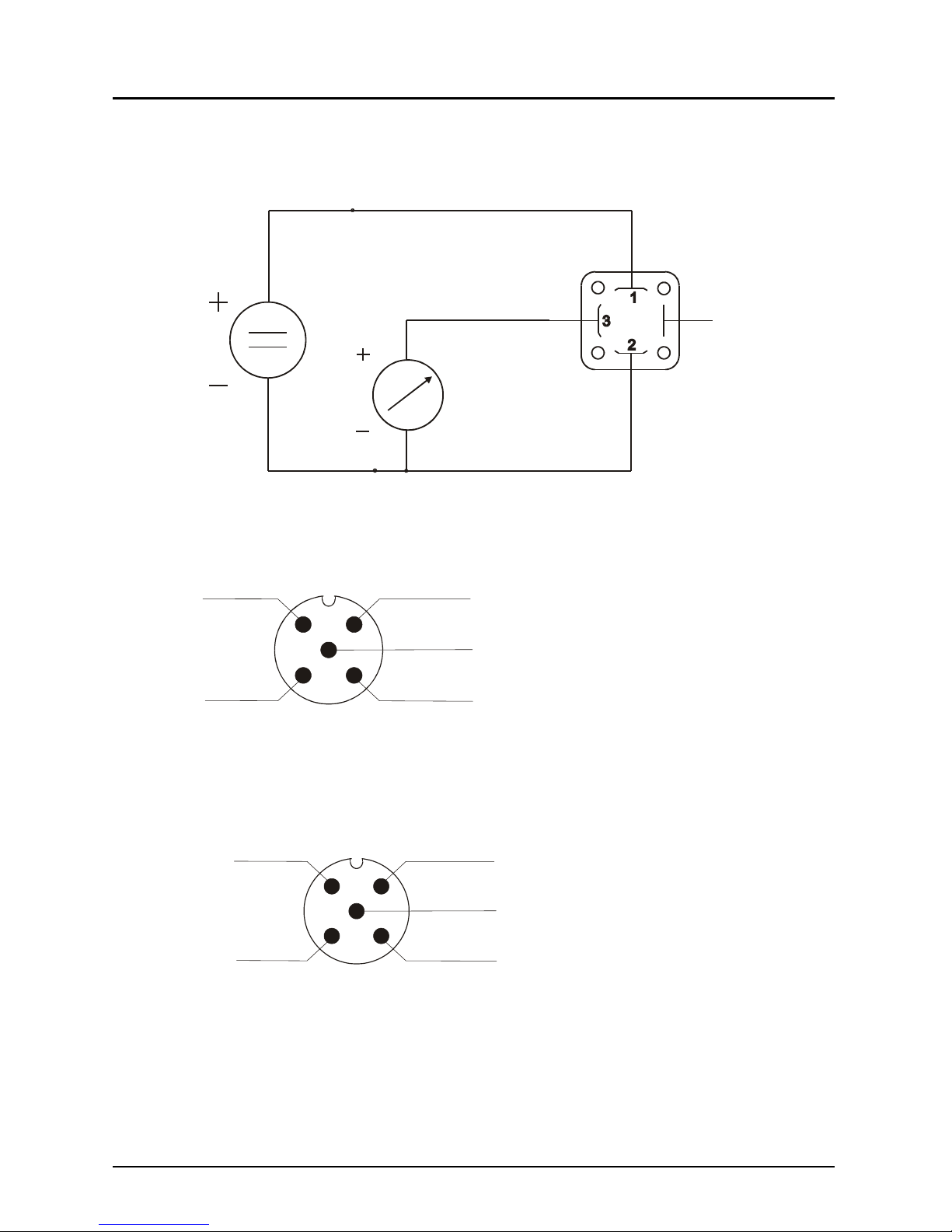

7.5 DVZ-...L443

7.6 DVZ-...C30

7.7 DVZ-...C34

1

2

3

4

5

Switch

Out 2

Switch

Out 1

+Vs

GND

GND

+Vs

Signal

Out

+Vs

GND

GND

1

2

3

4

5

+Vs

GND

GND

Switch out

1

0(4)-20 mA

Page 8

DVZ

page 8 DVZ K04/0810

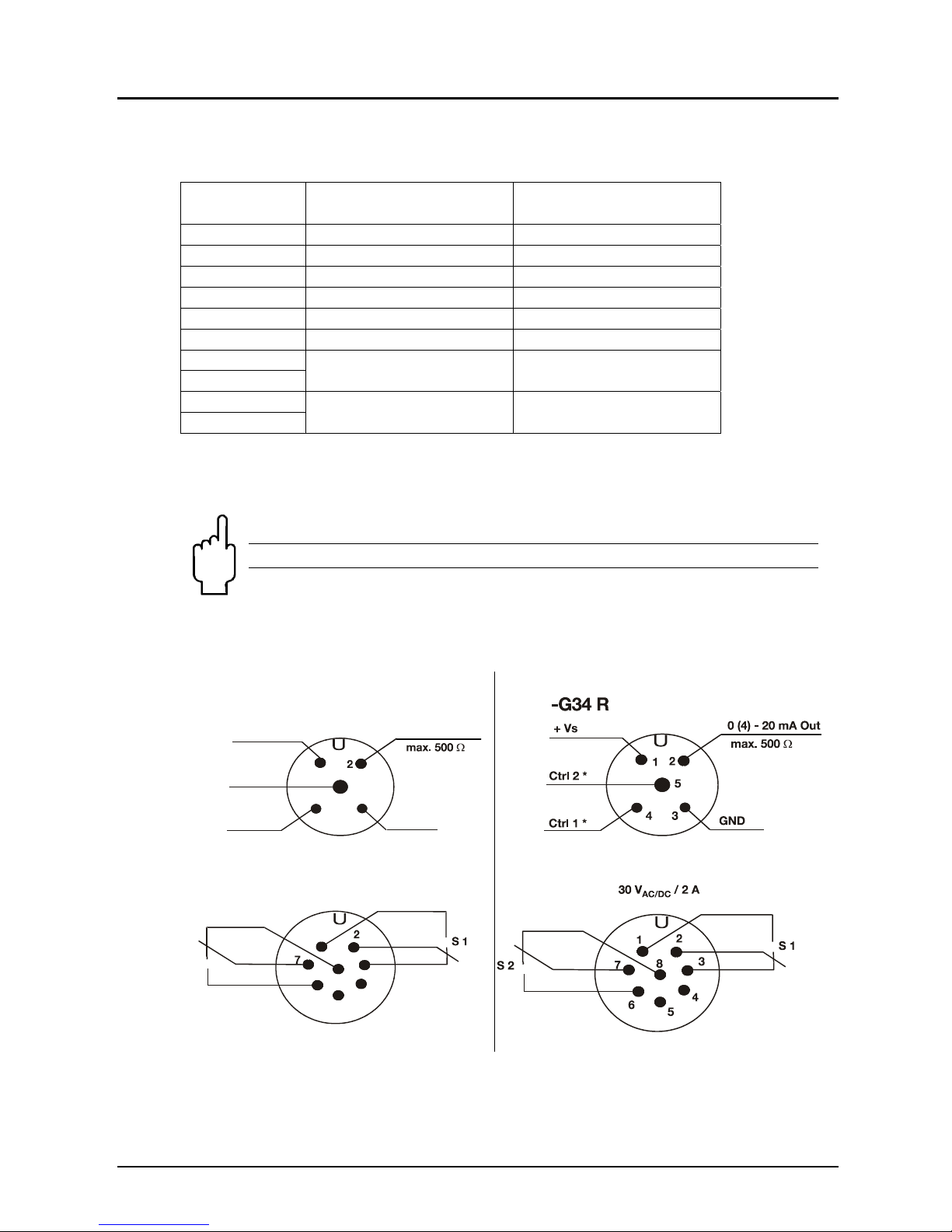

7.8 DVZ-...Ex4R, DVZ-...Gx4R

Cable connection

Wire number

DVZ-...E14R

Counter electronics

DVZ-...G14R

Dosing electronics

1 +24 VDC +24 VDC

2 GND GND

3 4-20 mA 4-20 mA

4 GND GND

5 n. c. control 2*

6 reset part quantity control 1*

7 relay S1

normally open

relay S1

normally open

8

9 relay S2

normally open

relay S2

normally open

10

*Start-dosing: Control 1 connect with GND

Stop-dosing: Control 2 connect with GND

Reset-dosing: Control 1 and Control 2 at the same time with GND

Do not connect any external voltage to the control units!

Plug connection

-E34 R

+ Vs

Reset TM

0 (4) - 20 mA

GND

1

30 V / 2 A

AC/DC

34

5

1

3

4

5

6

S 2

8

d.c. *)

Output

d.c.*) Don't connect!

Page 9

DVZ

DVZ K04/0810 page 9

8. Operation

The units are preset and after electrical connection ready for operation.

8.1 Switch point setting DVZ-...S300, DVZ-…S30D

Switch setting Switch point

0 switch function deactivated

1 start of measuring range

2 20% of f.s.

3 30% of f.s.

4 40% of f.s.

5 50% of f.s.

6 60% of f.s.

7 70% of f.s.

8 80% of f.s.

9 90% of f.s.

Flow above switch point: DUO-LED green

Flow below switch point: DUO-LED red

Measuring range overflow: DUO-LED orange flashing

8.2 Counter electronics DVZ-…Ex4R

Operating please see Operating Instructions ZED-Z

8.3 Dosing electronics DVZ-…Gx4R

Operating please see Operating Instructions ZED-D

Page 10

DVZ

page 10 DVZ K04/0810

9. Adjustments – Compact Electronic DVZ-...C3..

Connect the compact electronic according to previous connection diagram. After

power on, the measuring range (end current) will be shown for 3 seconds.

9.1 Button function

In the normal mode (measuring mode)

In the set-up mode

9.2 Settings

The following values can be changed at the temperature transmitter:

Scale range Factory setting

Switch point (SPo, SP1, SP2)

0...999 0,00

Hysteresis (HYS)

-199...0 -0,00

Window point (duo point) (duo)

Switch point ...999 --- (inactive)

contact-type (Con, Co1, Co2) N/O, N/C or Frequency (Fr)** N/O

Start current (S-C)*

000...999 000

End current (E-C)*

000...999 f.s.

Start current selection (SCS)

0-- (0 mA), 4-- (4 mA) 4 mA

Change Code (CCo)

000...999 000

* Start- and end value of flow relating to 0/4-20 mA.

** not calibrated, frequency at f.s. approx. 500 -600Hz

: Press 3 sec. Setup mode

: Switch point/Window point

: Next Step

: Change Value

3 sec

Standard mode

Any time

or do not press

a button for 20 sec

Page 11

DVZ

DVZ K04/0810 page 11

9.3 Value setting

From the main menu item (for example: switch point, "SPo"), press the ""

button to set the value. The flow chart below illustrates the universal routine for

changing individual parameters.

[From the main menu item]

1. Adjust position

2. Adjust position

3. Adjust position

Adjust decimal point

Save selected value

or

enter new value.

[To the next main menu item]

save

Page 12

DVZ

page 12 DVZ K04/0810

9.4 Set-up mode

Compact electronic DVZ-...C30..

Contact 2

function

N/O

N/C

Save

Code entering

Value setting

Contact 1

function

N/C

Frequency

Save

Hysteresis

Value setting

Switching

point 2

Value setting

Switching

point 1

Value setting

Code=

3 sec

Code entering

Value setting

Page 13

DVZ

DVZ K04/0810 page 13

Compact electronic DVZ-...C34

Contact

function

N/O

N/C

Frequency

Save

Code entering

Window point

Hysteresis

Switching point

3 sec

Code=

End current

Start current

7sec

7sec

Value setting

Value setting

Value setting

Value setting

Value setting

Value setting

Page 14

DVZ

page 14 DVZ K04/0810

9.5 Main menu items

9.5.1 Switching point

The switching point is entered in the menu item "Spo, SP1, SP2". A setting value

between 000 and 999 can be selected. This value can also include a decimal

point. The decimal point can be set at two points (e.g. 10.0 or 1.00). If the display

value exceeds the set switch point, the electronic is activated and is signalised by

a lightning LED.

If the hysteresis is equal to zero and the window point is de-activated, the

electronic switches back whenever the indicated value falls below the switching

point.

9.5.2 Hysteresis

After the setting of the switching point, the hysteresis can be entered as a

negative value in the "

HYS" menu. The standard hysteresis value is zero. In

operation condition this can lead to ambiguous switching behaviour, if the reading

fluctuates around the switching point or window point. In this case, increasing the

hysteresis can put things right. The hysteresis relates to the switching point and

the window point (switching point minus hysteresis; window point plus

hysteresis).

Example: Switching point 100 l/min; Hysteresis: -2.5 l/min

The electronic switches when 100 l/min is exceeded and switches

back when the reading drops below 97.5 l/min.

9.5.3 Window point (duo-point)

As well as the switching point, it is also to define a "duo" (duo-point), the window

point. This must be higher than the switching point. By using the window point

and the switching point it is possible to monitor the measurement value in a

certain range. The switching point limits the measurement range to smaller

values and the window point to larger values.

Changing code

Value setting

Storing

7sec

4-20

mA

0-20

mA

Analog output

choosing

Page 15

DVZ

DVZ K04/0810 page 15

If the window point (duo-point) is less than or equal to the switching

point, an error report (Er4) will be indicated on the display and its

value is deleted and its function is invalid (in the case that the

window point and switching point out of adjustment).

The value is set in the same way as the switching point.

The window point is needed for process, in which monitoring of a certain

temperature range is necessary.

Example: Switching point: 100 L/min; window point: 150 L/min;

hysteresis: -1 L/min

The electronic switches when 100 l/min is exceeded. If the switching value

remains between 99 L/min (100-1) and 151 L/min (150+1), the contact will also

remain in active switching condition (LED on). If it exceeds 151 l/min or is below

99 l/min the electronic switches back.

Switching behaviour

The following diagram clarifies the switching behaviour of the electronic switch.

The contact closes (contact type: no) when it drops below the switching point or

the window point. It only opens again if the window point plus hysteresis is

exceeded or if it drops below the switching point minus hysteresis. An LED

indicates the switching condition of the switching point.

Time / t

Display

bar (°C)

Hysteresis

LED on

Time / t

Display

bar (°C)

Switchpoint

Hysteresis

LED on

Hysteresis

Window point

LED on

Page 16

DVZ

page 16 DVZ K04/0810

9.5.4 Contact type

The function of the transistor switching output is set in menu item "Con, Co1 or

Co2

". The switching function switches from

no - N/O contact to

nc - N/C to

Fr – frequency (only Con and Co1)

and back.

N/O contact: contact closes when switching point is exceeded

N/C contact: contact opens when switching point is exceeded

Frequency: frequency output synchronised with the vane frequency

9.5.5 Current output

The current output is selected in menu items

"S-C" Start current indicated value < > 0(4) mA

"E-C" End current indicated value < > 20 mA

"SCS" Start current selection (0-20 mA or 4-20 mA).

The indicated value at which 0(4) mA flow is entered in menu item Start current.

The indicated value at which 20 mA flow is entered in menu item End current.

9.5.6 Change Code

The change code option "CCo" secures the unit against unauthorised tampering.

If the code is different from 000, the user must input the code immediately after

entering the adjustment mode.

10. Maintenance

The measurement device requires no maintenance if the measurement medium

does not cause deposits or include fibre parts, which wrap around the sensor or

the gate. In order to avoid problems, we recommend the installation of a filter,

such as the magnetic filter, type MFR.

If it is necessary to clean the sensor, the sensor can be rinsed with a suitable

liquid. Fiber parts or large particles can be carefully removed with tweezers, etc.

Ensure that the sensor is not damaged.

Work on the electronics can only be performed by the factory, or the warranty is

otherwise voided.

Page 17

DVZ

DVZ K04/0810 page 17

11. Technical Information

Measurement process: Vortex principle

Mounting position: any, flow in direction of arrow

Response time: 1 s

Accuracy: ±2.5% of f.s.

Repeat accuracy: ±1% of f.s.

Inlet / outlet runs: 10xDN

Protection: IP 65

Media temperature: 0...80 °C

Ambient temperature: -10...+60 °C

Max. Pressure

Connection fixed rotatable

Standard version 10 bar 20 bar

Reinforced version 20 bar -

Pressure loss

Model Upper range value Pressure loss

DVZ-**04 4,5 L/min 420 mbar

DVZ-**07 6,5 L/min 650 mbar

DVZ-**10 10,0 L/min 780 mbar

DVZ-**16 16,0 L/min 600 mbar

DVZ-**22 22,0 L/min 450 mbar

DVZ-**32 32,0 L/min 370 mbar

DVZ-**40 40,0 L/min 450 mbar

DVZ-**50 50,0 L/min 400 mbar

DVZ-**63 63,0 L/min 380 mbar

DVZ-**80 80,0 L/min 400 mbar

DVZ-**99 100,0 L/min 350 mbar

Weight - Sensor

Measuring range Size Connection fixed

Connection

strengthened

Connection

rotatable

bis 32 L/min ¼", 3/8", ½" approx. 450 g approx. 600 g approx. 800 g

bis 32 L/min ¾" approx. 600 g approx. 600 g approx. 900 g

bis 32 L/min 1" approx. 1050 g approx. 950 g approx. 950 g

40...100 L/min ¾" approx. 1050 g approx. 1300 g approx. 1350 g

40...100 L/min 1" approx. 900 g approx. 1150 g approx. 1400 g

Weight - Electronics

Model Weight

DVZ-...F3x0

DVZ-...S30x

DVZ-...Lxx3

approx. 80 g

DVZ-...C3xx approx. 300 g

DVZ-...Exxx

DVZ-...Gxxx

approx. 250 g

Total weight = weight sensor + weight electronics

Page 18

DVZ

page 18 DVZ K04/0810

Wetted parts

Sensor housing: PPS, fibreglass-reinforced

Sensor: PVDF

Connections: brass (from 32 L/min nickel plated

from 40 L/min blank) or

stainless steel 1.4404

Bluff body: PPS, fibreglass-reinforced or

oxide ceramic (non-wear version)

Seal: NBR, EPDM or FPM

DVZ-...S300, DVZ-…S30D

Display: duo-LED for switching condition

and when range limit is exceeded

Switching output: relay changeover, max. 1 A/30 V

DC

or active 24 VDC, N/C / N/O

Switch point: measuring range beginning from 90% f.s.

in 10%-steps

can be configured by the customer using a

rotary switch

Power supply: 24 V

DC

± 20%

Power consumption: 12 mA

Electrical connection: plug M12x1.5 pole

Measuring range overflow: flash of the DUO-LED (red/green)

from 105 % of f.s.

DVZ-...F300, DVZ-…F390

Impulse output: PNP, Open Collector, max. 200 mA

Frequency at f.s. 500 Hz (…F300)

50…1000 Hz (F390)

Power supply: 24 VDC ± 20%

Power consumption: 5 mA

Electrical connection: plug M12x1

Measuring range overflow: F

out

approx. 2 kHz from 105 % of f.s.

DVZ-...L303; DVZ-...L343

Output: 0(4)-20 mA, 3-wire

Max. load: 500 Ω

Power supply: 24 VDC ± 20%

Electrical connection: plug M12x1

Measuring range overflow: I

out

approx. 20,5 mA from 103 % of f.s.

DVZ-...L443 (usage with AUF-3000)

Output: 4-20 mA, 3-wire

Max. load: 500 Ω

Power supply: 24 VDC ± 20%

Electrical connection: plug DIN 43650

Measuring range overflow: I

out

approx. 20,5 mA from 103 % of f.s.

Page 19

DVZ

DVZ K04/0810 page 19

DVZ-...C3 (Compact electronics)*

Display: 3-digit LED

Analogue output: (0)4...20 mA adjustable, max. 500 Ω

(only DVZ-…C34*)

Switching output: 1 or 2 Open Collector PNP or NPN,

set at factory, max. 300 mA

Contact function: N/C, N/O, frequency, programmable

(frequency output not calibrated, frequency at

f.s. approx. 500 -600Hz)

Programming: with 2 keys

Power supply: 24 VDC ± 20%, 3-wire

Power consumption: approx. 100 mA

Electrical connection: plug M12x1

Measuring range overflow: display “OF” from 105% of f.s.

DVZ-...Exxx (Counter electronics)*

Display: LCD, 2x8 digit, illuminated

total, part and flow quantities,

units selectable

Quantity meter: 8-digit

Analogue output: (0)4...20 mA adjustable

Load: max. 500 Ω

Switching output: 2 relays, max. 30 V

AC/DC

/ 2 A / 60 VA

Settings: via 4 buttons

Functions: reset, MIN/MAX memory,

flow monitor, monitoring for part

and total quantity, language

Power supply: 24 VDC ±20 %, 3-wire

Power consumption: approx. 150 mA

Electrical connection: cable connection or M12-plug

DVZ-...Gxxx (Dosing electronics)*

Display: LCD, 2x8 digit, illuminated,

dosing, total and flow quantity,

units selectable

Quantity meter: 8-digit

Dosage: 5-digit

Analogue output: (0)4...20 mA adjustable

Load: max. 500 Ω

Switching output: 2 relays, max. 30 V

AC/DC

/ 2 A / 60 VA

Settings: via 4 buttons

Functions: dosing (relay S2), start, stop, reset, fine

dosing, correction amount, flow switch,

total quantity, language

Power supply: 24 VDC ±20 %, 3-wire

Power consumption: approx. 150 mA

Electrical connection: cable connection or M12-plug

*more technical details see data sheet ZED in the brochure Z2

Page 20

DVZ

page 20 DVZ K04/0810

12. Order Codes

Fixed connection

Order details (Example: DVZ-1 1 04 G2 S300)

*Reinforced version only in combination with fixed connection

**Please specify flow direction in the order

Storage body/

housing

Connection

material/seal

Measuring range

Connection

fixed

Electronics

DVZ-1.. =

PPS

DVZ-2.. =

ceramic

DVZ-3..*=

PPS/strengthened

design

DVZ-4..*=

ceramic/strengthe

ned design

..1.. = brass/ NBR

..2.. = st. steel/ NBR

..4.. = brass/ EPDM

..5.. = st. steel/ EPDM

..7.. = brass/ FPM

..8.. = st. steel/ FPM

..04.. = 0.5 - 4.5 L/min

..07.. = 0.8 - 7.0 L/min

..10.. = 1.3 - 10.0 L/min

..G2.. = G 1/4

..G3.. = G 3/8

..G4.. = G 1/2

..N2.. = 1/4 NPT

..N3.. = 3/8 NPT

..N4.. = 1/2 NPT

switching output

..S300 = relay, M12-plug

..S30D =active 24 VDC, M12-plug

frequency output

..F300 =M12-plug, 500 Hz

..F390 =M12-plug,

50…1000 Hz

analogue output

..L303 =M12-plug, 0-20 mA

..L343 =M12-plug, 4-20 mA

..L443 =DIN-plug, 4-20 mA

compact electronics**

..C30R =2xOpen Coll. PNP

..C30M =2xOpen Coll. NPN

..C34P =4-20 mA,

1xOpen Coll. PNP

..C34N =4-20 mA,

1xOpen Coll. NPN

counter electronics

..E14R =LCD, 0(4)-20 mA,

2xrelay, 1 m cable

..E34R =LCD, 0(4)-20 mA,

2xrelay, M12-plug

dosing electronics

..G14R =LCD, 0(4)-20 mA,

2xrelay, 1 m cable

..G34R =LCD, 0(4)-20 mA,

2xrelay, M12-plug

..16.. = 2.0 - 16.0 L/min

..G3.. = G 3/8

..G4.. = G 1/2

..G5.. = G 3/4

..N3.. = 3/8 NPT

..N4..= 1/2 NPT

..N5.. = 3/4 NPT

..22.. = 3.2 - 22.0 L/min

..32.. = 4.0 - 32.0 L/min

..G4.. = G 1/2

..G5.. = G 3/4

..G6.. = G 1

..N4.. = 1/2 NPT

..N5.. = 3/4 NPT

..N6.. = 1 NPT

..40.. = 4,0 - 40,0 L/min

..50.. = 5,0 - 50,0 L/min

..63.. = 6,3 - 63,0 L/min

..80.. = 8,0 - 80,0 L/min

..99.. = 10,0 - 100 L/min

..G5.. = G 3/4

..G6.. = G 1

..N5.. = 3/4 NPT

..N6.. = 1 NPT

Page 21

DVZ

DVZ K04/0810 page 21

Axial rotatable connection

*Please specify flow direction in the order

Storage body/

housing

Connection

material/

Seal

Measuring range

Connection

rotatable

Electronics

DVZ-1.. =

PPS

DVZ-2.. =

ceramic

..1.. = brass/ NBR

..2.. = st. steel/ NBR

..4.. = brass/ EPDM

..5.. = st. steel/ EPDM

..7.. = brass/ FPM

..8.. = st. steel/ FPM

..04.. = 0.5 - 4.5 L/min

..07.. = 0.8 - 7.0 L/min

..10.. = 1.3 - 10.0 L/min

..B2.. = G 1/4

..B3.. = G 3/8

..B4.. = G 1/2

..P2.. = 1/4 NPT

..P3.. = 3/8 NPT

..P4.. = 1/2 NPT

switching output

..S300 =relay, M12-plug

..S30D =active 24 VDC, M12-plug

frequency output

..F300 =M12-plug. 500 Hz

..F390 =M12-plug,

50…1000 Hz

analogue output

..L303 =M12-plug, 0-20 mA

..L343 =M12-plug, 4-20 mA

..L443 =DIN-plug, 4-20 mA

compact electronics*

..C30R =2xOpen Coll. PNP

..C30M=2xOpen Coll. NPN

..C34P =4-20 mA,

1xOpen Coll. PNP

..C34N =4-20 mA,

1xOpen Coll. NPN

counter electronics

..E14R =LCD, 0(4)-20 mA,

2xrelay, 1 m cable

..E34R =LCD, 0(4)-20 mA,

2xrelay, M12-plug

dosing electronics

..G14R =LCD, 0(4)-20 mA,

2xrelay, 1 m cable

..G34R =LCD, 0(4)-20 mA,

2xrelay, M12-plug

..16.. = 2.0 - 16.0 L/min

..B3.. = G 3/8

..B4.. = G 1/2

..B5.. = G 3/4

..P3.. = 3/8 NPT

..P4..= 1/2 NPT

..P5.. = 3/4 NPT

..22.. = 3.2 - 22.0 L/min

..32.. = 4.0 - 32.0 L/min

..B4.. = G 1/2

..B5.. = G 3/4

..B6.. = G 1

..P4.. = 1/2 NPT

..P5.. = 3/4 NPT

..P6.. = 1 NPT

..40.. = 4,0 - 40,0 L/min

..50.. = 5,0 - 50,0 L/min

..63.. = 6,3 - 63,0 L/min

..80.. = 8,0 - 80,0 L/min

..99.. = 10,0 - 100 L/min

..B5.. = G 3/4

..B6.. = G 1

..P5.. = 3/4 NPT

..P6.. = 1 NPT

Page 22

DVZ

page 22 DVZ K04/0810

13. Dimensions

13.1 Dimensions - Sensor

DVZ-sensor with fixed connection, measuring range up to 32 L/min

Meas.

range

..04/..07/..10

..04/..07/

..10/..16

..04/..07/..10/

..16/..22/..32

..16/..22/..32 ..22/..32

D 1 1/4" 3/8" 1/2" 3/4" 1"

AF 35 35 35 34 -L 1 100 100 106 120 128

L 2 -- -- -- 50 50

L 3 35 35 35 34 -L 4 -- -- -- -- 46

for

AF

Page 23

DVZ

DVZ K04/0810 page 23

DVZ-sensor with fixed connection,

measuring range from 40 L/min

A

F

o

Page 24

DVZ

page 24 DVZ K04/0810

DVZ-sensor with strengthened connection,

measuring range up to 32 L/min

Meas.

range

..04/..07/..10

..04/..07/

..10/..16

..04/..07/..10/

..16/..22/..32

..16/..22/..32 ..22/..32

D 1 1/4" 3/8" 1/2" 3/4" 1"

AF 34 34 34 34 -L 1 100 100 106 120 128

L 4 34 34 34 34 46

for

AF

Page 25

DVZ

DVZ K04/0810 page 25

DVZ-sensor with strengthened connection,

measuring range from 40 L/min

o

AF

Page 26

DVZ

page 26 DVZ K04/0810

DVZ-Sensor with rotatable connection,

measuring range up to 32 L/min

Meas.

range

..04/..07/

..10

..04/..07/

..10/..16

..04/..07/

..10/..16/

..22/..32

..16/..22/

..32

..22/..32

D 1 1/4" 3/8" 1/2" 3/4" 1"

D 2 24 28 35 40 45

AF 19 24 30 36 41

o

Page 27

DVZ

DVZ K04/0810 page 27

DVZ-Sensor with rotatable connection,

measuring range from 40 L/min

Meas.

range

..40/..50/

..60/..80/

..99

..40/..50/

..60/..80/

..99

D 1 3/4" 1"

D 2 40 45

AF 36 41

AF

o

Page 28

DVZ

page 28 DVZ K04/0810

13.2 Dimensions - Electronics

DVZ-...S30x, DVZ-...F3x0, DVZ-...L3x3

DVZ-...L443

Page 29

DVZ

DVZ K04/0810 page 29

DVZ-...C3xx

Page 30

DVZ

page 30 DVZ K04/0810

DVZ-...Exxx, DVZ-...Gxxx

Page 31

DVZ

DVZ K04/0810 page 31

14. Declaration of Conformance

We, KOBOLD Messring GmbH, Hofheim-Ts, Germany, declare under our sole

responsibility that the product:

Compact Vortex Flow Meter Model: DVZ

to which this declaration relates is in conformity with the standards noted below:

EN 61326/A1 2004-05

Electrical equipment for control and instrumentation technology and laboratory

use – EMC-requirements (industrial area)

DIN EN 61010-1 1994-03

Safety requirements for electrical measuring-, control- and laboratory

instruments.

EN 60529, DIN VDE 0470-1 1992-11

Protection type housing (IP-Code)

Also the following EEC guidelines are fulfilled:

2004/108/EC EMC Directive

Hofheim, 16. Jan. 2007

H. Peters M. Wenzel

General Manager Proxy Holder

Loading...

Loading...