Page 1

Operating Instructions

for

Digital Thermometers

Model: DTM

Page 2

DTM

page 2 DTM K01/0117

1. Contents

1.

Contents ........................................................................................................ 2

2. Note .............................................................................................................. 3

3. Instrument Inspection .................................................................................... 3

4. Regulation Use .............................................................................................. 3

5. Operating Principle ........................................................................................ 4

6. Mechanical Connection ................................................................................. 5

7. Electrical Connection .................................................................................... 5

8. Operation ...................................................................................................... 7

9. Key Function ................................................................................................. 8

10.Technical Information .................................................................................... 9

11.Order Codes ............................................................................................... 10

12.Maintenance ............................................................................................... 10

13.Dimensions ................................................................................................. 10

14.EU Declaration of Conformance .................................................................. 13

15.Annex .......................................................................................................... 14

Manufactured and sold by:

Kobold Messring GmbH

Nordring 22-24

D-65719 Hofheim

Tel.: +49(0)6192-2990

Fax: +49(0)6192-23398

E-Mail: info.de@kobold.com

Internet: www.kobold.com

Page 3

DTM

DTM K01/0117 page 3

2. Note

Please read these operating instructions before unpacking and putting the unit

into operation. Follow the instructions precisely as described herein.

The devices are only to be used, maintained and serviced by persons familiar

with these operating instructions and in accordance with local regulations

applying to Health & Safety and prevention of accidents.

When used in machines, the measuring unit should be used only when the

machines fulfil the EC-machine guidelines.

3. Instrument Inspection

Instruments are inspected before shipping and sent out in perfect condition.

Should damage to a device be visible, we recommend a thorough inspection of

the delivery packaging. In case of damage, please inform your parcel service /

forwarding agent immediately, since they are responsible for damages during

transit.

Scope of delivery:

The standard delivery includes:

Digital Thermometers, model: DTM

Operating Instructions

4. Regulation Use

Any use of the Digital Thermometers, model: DTM, which exceeds the

manufacturer’s specifications, may invalidate its warranty. Therefore, any

resulting damage is not the responsibility of the manufacturer. The user assumes

all risk for such usage.

Page 4

DTM

page 4 DTM K01/0117

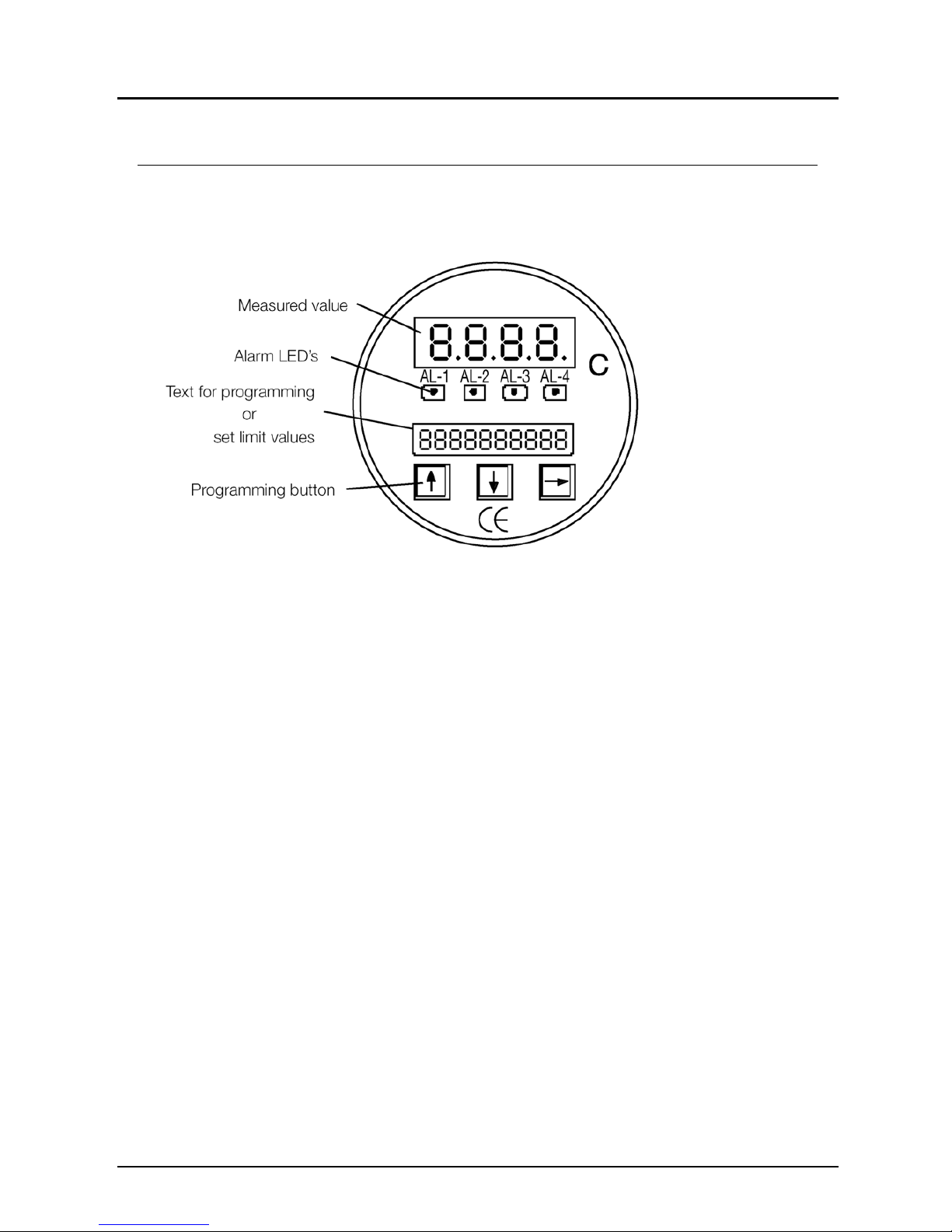

5. Operating Principle

Digital thermometers with intelligent electronics serve to display, monitor, control

and transmit temperatures in production processes and equipment.

The new device series DTM... is remarkable for its easy operation and adaptation

to the most demanding measurement applications.

A 4-segment 14 mm LED display provides clearly visible indication, the device is

programmed with three arrow keys beneath the lower back-lit LCD display.

The devices are fitted with an analogue output as standard. Other interfaces are

available as options. Up to four limit values can be adjusted in the relay version.

The temperature to be measured is sensed by a platinum resistance thermistor

and converted by the electronics to an analogue signal proportional to the

temperature. The digital thermometer can be supplied in a compact shaft version

for a maximum indicating range of a 200°C. Above 200°C the temperature sensor

should be connected externally to the basic device with a cable.

Page 5

DTM

DTM K01/0117 page 5

6. Mechanical Connection

Before installation:

Be sure the maximum allowable working pressure and temperature specified

for the unit are not exceeded.

Make sure there are no packaging residues left inside the unit.

Installation:

Make sure the device into which the thermometer is to be installed has been

depressurised.

Mount the DTM where it may be easily connected according to applicable

codes and standards.

Do not screw in the unit using its housing, but rather on its hexagon (size 24

spanner).

If feasible, check the connection between the unit and the process or plant for

leaks as early as after mechanical installation.

7. Electrical Connection

Attention! Make sure that the voltage values of your system

correspond with the voltage values of the Digital Thermometers.

Make sure that the electrical supply wires are de-energized.

Remove the plastic cover

from the unit’s rear.

Insert the cable in the screw

terminal, and fix. Make sure

the PG connection is tight.

Pull off the terminal strip and

connect the cable as shown

in the terminal diagram.

Page 6

DTM

page 6 DTM K01/0117

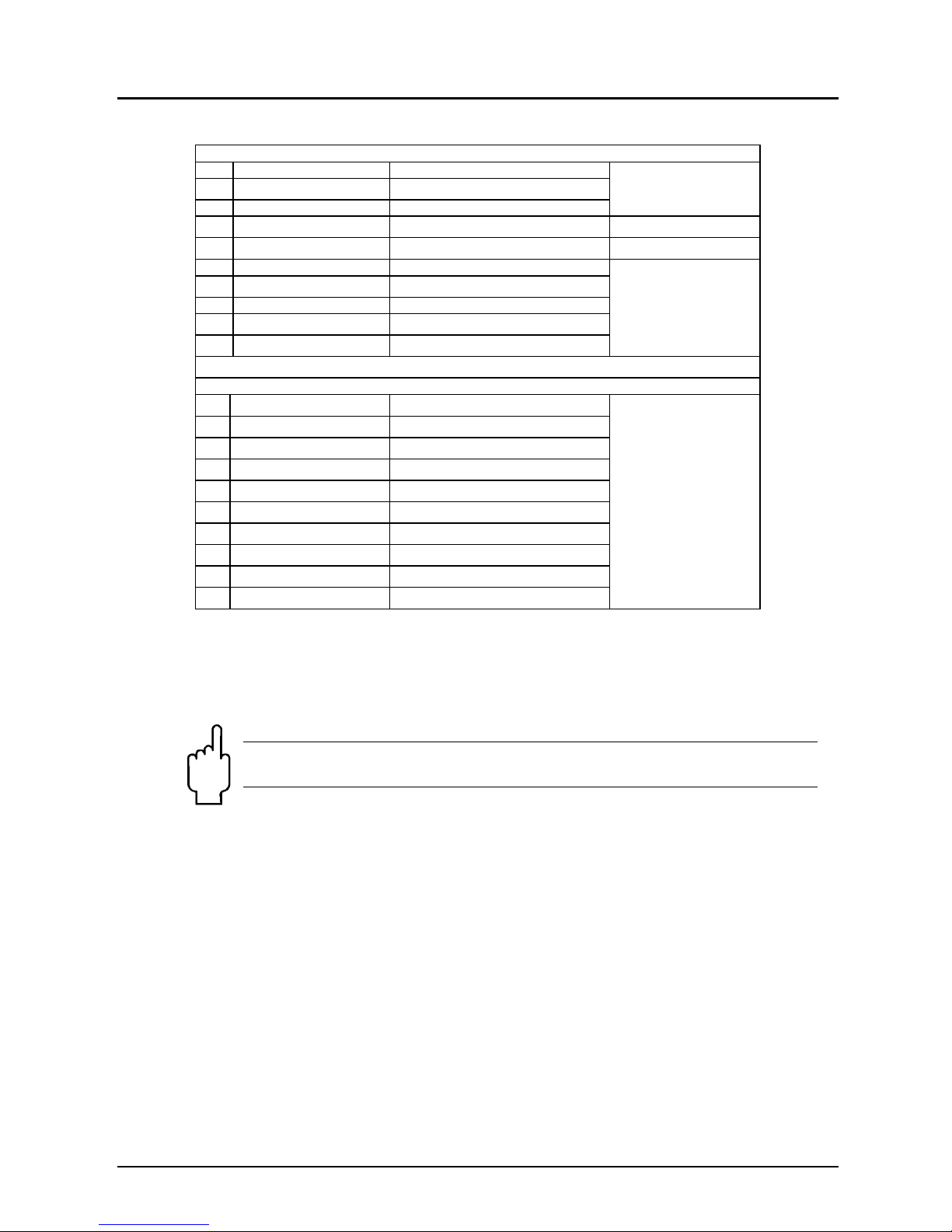

X103

1 Supply + channel-2 /external (option)

For external sensor

4 to 20 mA only

2 Not used

3 Supply - channel-2 /external (option)

4 Not used

5 Not used

6 Supply + channel-1 /external (option)

for external sensor

4 to 20 mA only

7 Not used

8 Supply - channel-1 /external (option)

9 Not used

10 Not used

X113

1 Not used

2 Not used

3 Not used

4 Data transfer RS 232 (option)

5 Data receive RS 232 (option)

6 Earth RS 232 (option)

7 Earth output (-)

8 Signal output (+)

9 Earth supply (-)

10 24 VDC supply (+)

Plug the terminal strip onto the plug base on the unit.

Slip on the plastic cap, and bolt in place.

Be sure the packing ring inside the plastic cap fits tightly.

Attention! Incorrect wiring will lead to damage of the unit’s

electronics.

Page 7

DTM

DTM K01/0117 page 7

8. Operation

The various functions and parameters are distributed over three (3) levels.

LEVEL 0- operator level

This level is accessible to anyone (without a password).

It will be possible to set the following functions if they are enabled.

Zero balance of the display unit (inPUt ¯ S-ZEro),

Servicing (SErVicE), always enabled:

View serial number (SErVicE ¯ n),

Enter master password to view passwords,

(SErVicE MAStr) (see 10.3),

Limit contacts (option) (rELAiS 1-4) :

Switching points (rELAiS 1-4 SPt1-4),

Switching point hysteresis (rELAiS 1-4 HyS1-4),

Switching point lag time (rELAiS 1-4 dEL1-4),

Additional functions (option):

Scaling of analogue output (outZP),

Scaling of display unit (diSPLAY),

Setting the peak memory (Pdu),

Setting the relay rotation (rotAtE),

Setting the RS 232 interface (S232).

All the menu items of LEVEL 1 and LEVEL 2 (except for the servicing menu item)

may be enabled or blocked respectively for LEVEL 0.

LEVEL 1- master level

Access to this level is via password. All the functions of level 1 (for level 0) can be

enabled or blocked respectively on this level. Settings of LEVEL O may also be

made on LEVEL 1 (if LEVEL 0 is blocked, for example).

Additionally, the following functions are available:

Servicing (SErVicE):

Displaying the dialogue display in operating mode (SErVicE SEE-Lcd),

Changing the password for LEVEL 1 (SErVicE PS-1).

LEVEL 2- additional function level

Access to this level is via LEVEL 1 after entering a password.

All additional functions available as options may be blocked or enabled

respectively on this level. Settings for additional functions may also be made on

LEVEL 2 (if LEVEL 0 is blocked, for example).

In addition, the following function is available:

Servicing (SErVicE):

Changing the password for LEVEL 2 (SErVicE PS-2).

Page 8

DTM

page 8 DTM K01/0117

9. Key Function

The menu items are shown in an annexed schematic.

In measurement mode

On the levels

In the functions

A

ccess to control levels

Access to menu items

Access to the functions of the

Various menu items

Exit the level and return to

operating mode

Access to setting (r.h. digit is flashing)

Next digit with an overflow to the right

One digit down

One digit up

Reject this setting; reload previous value

and return to selected function.

Confirm setting and go to next function of

m

enu ite

m

Page 9

DTM

DTM K01/0117 page 9

10. T echnical Information

Sensor: Pt 100, class B

Casing: diameter: 100 mm

material stainless steel,

rear made of polyamide,

front side made of PAVG30 and polyester film,

Electrical connection: terminal blocks, PG cable gland,

Protection: IP 65 acc. to DIN 40 050, IEC 529

Probe: diameter 8 mm (others upon request),

material stainless steel 1.4571,

Probe length: acc. to customer specifications, min. 50 mm

Process connection: stainless steel 1.4571

Indicating range: - 30 to + 50 to 0 to 400 °C

Accuracy class: 0.5

Analogue output: 0 to 20 mA, 4 to 20 mA, 0 to 10 V (all 3-wire)

Max. load/burden: 500 for current output

500 for voltage output

Accuracy: typically ± 0.3 % (limit point setting)

(acc. to DIN 16 086)

Repeatability: ± 0.1 %

Limit value relay: Switching points adjustable as required

Switching hysteresis adjustable as required

Switching delay adjustable from 0.01 to 99.99 s

Max. switching voltage: 250 VAC, 220 VDC,

Max. switching current: 3 A

Max. breaking capacity: 50 VA, 60 W

Response time:

Display and output signal 100 ms

Relay output 30 ms

Supply: 15 to 30 VDC

Service environment:

Ambient temperature: -20 to +60 °C

Storage temperature: -40 to +70 °C

Functions (standard):

Output signal

setting of scaling and delay

Display

setting of scaling, decimal point and delay

Functions (optional):

Peak memory with effect on display, output, relay,

internal reset via adjustable timer, keyboard or RS 232

Serial interface RS 232

2 external probes (differential temperature)

Higher temperatures (on request)

Page 10

DTM

page 10 DTM K01/0117

11. Order Codes

12. Maintenance

This unit will require no maintenance or servicing unless the medium is dirty.

13. Dimensions

Page 11

DTM

DTM K01/0117 page 11

Page 12

DTM

page 12 DTM K01/0117

Page 13

DTM

DTM K01/0117 page 13

14. EU Declaration of Conformance

We, KOBOLD Messring GmbH, Hofheim-Ts, Germany, declare under our sole

responsibility that the product:

Digital Thermometers Model: DTM

to which this declaration relates is in conformity with the standards noted below:

EN 61000-6-3:2011

Electromagnetic compatibility (EMC) - Part 6-3: Generic standards - Emission

standard for residential, commercial and light-industrial environments

EN 61000-6-2:2006

Electromagnetic compatibility (EMC) - Part 6-2: Generic standards - Immunity for

industrial environments

EN 61010-1:2011

Safety requirements for electrical measuring, control and laboratory instruments –

Part 1: General requirements

EN 60529:2014

Degrees of protection provided by enclosures (IP Code)

Also the following EU guidelines are fulfilled:

2014/30/EU EMC Directive

2014/35/EU Low Voltage Directive

2011/65/EU RoHS

Hofheim, 12. Jan. 2017

H. Peters M. Wenzel

General Manager Proxy Holder

Page 14

DTM

page 14 DTM K01/0117

15. Annex

Page 15

DTM

DTM K01/0117 page 15

Page 16

DTM

page 16 DTM K01/0117

Page 17

DTM

DTM K01/0117 page 17

Loading...

Loading...