Page 1

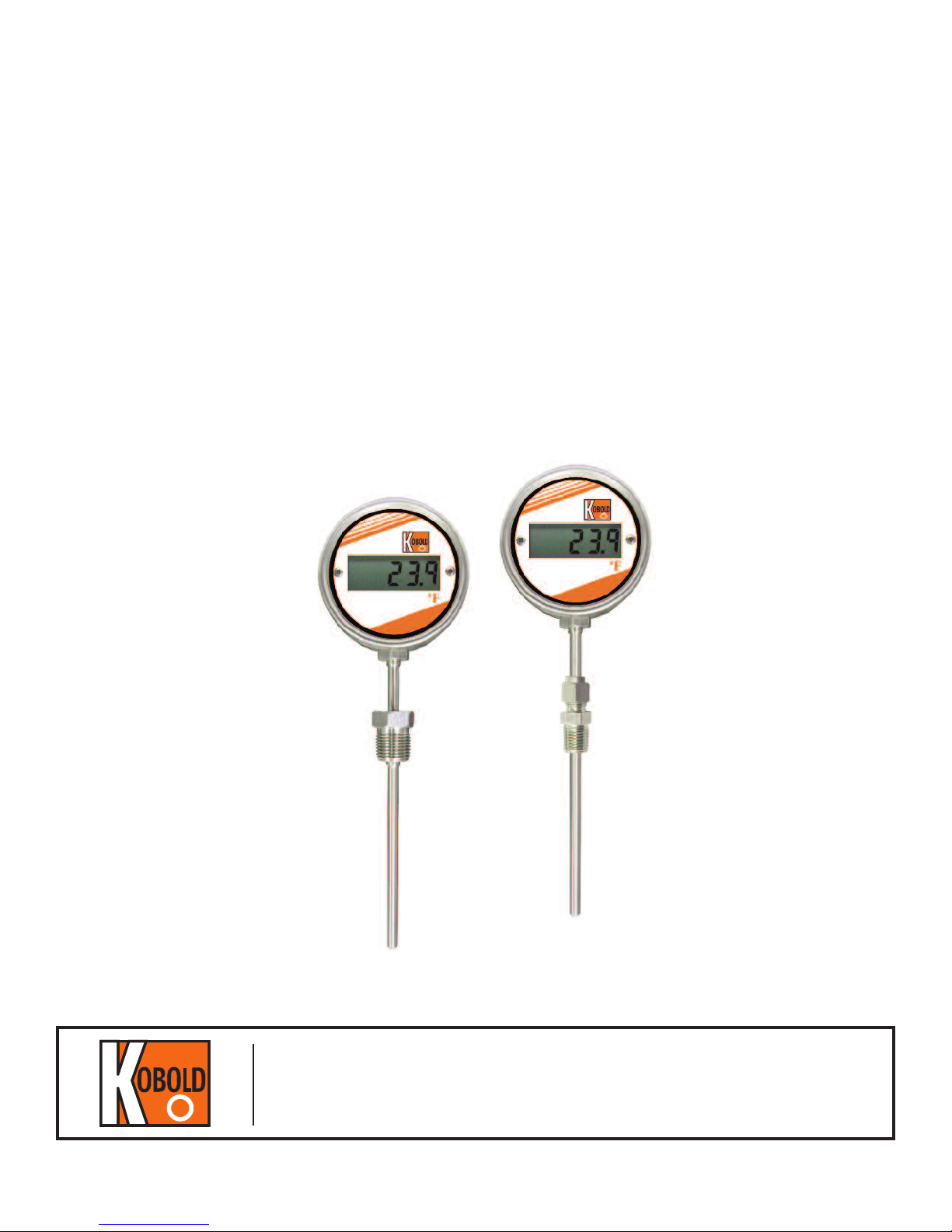

DTB Series

Battery Powered

Digital Thermometer

USER MANUAL

KOBOLD Instruments Inc.

1801 Parkway View Drive

Pittsburgh, PA 15205

Phone: 412-788- 28 30 Fax: 412-788- 48 90

www.koboldusa.com

Rev. 2-11/2013

Page 2

1. Description

F

F

F

F

F

F

The DTB series Digital Temperature Gauges are a complete solution for most industrial temperature monitoring

and temperature indicating applications. Of high quality

construction, these gauges features a large 4-digit LCD

display. They are designed for optimum accuracy and

performance. The series DTB are an ideal replacement

for bi-metal, liquid bulb and gas thermometers. They

are also a suitable replacement for Mercury reduction

programs.

The DTB arrives factory calibrated. No costly field

calibration is required.

Housing, probe and fitting material is all fabricated from

stainless steel 316. The DTB is rated to NEMA 4X ( IP65).

Many mounting configurations are available to meet

customer requirements.

The DTB has a five year battery life with a low battery

indication “batt” on the LCD.

3.2.2. Installation: these devices must be installed by

qualified personel taking all necessary precautions. The

installation should adhere to all local regulations.

3.2.3. Ensure that the label on the DTB is correct and

that the model is appropriate for the particular application.

3.2.4. These devices are repairable. In the event of failure they should be returned to the factory for repair and

recalibration. Please ensure the unit is clean and has no

contaminants before returning.

3.2.5. If the installation will occur in a hazardous

⚠

location or near hazardous materials all necessary

precautions should be taken.

3.2.6. Mounting locations should be chosen to avoid

⚠

high voltage electrical lines and for ease of installation and future maintenance.

2. Function

The DTB line of thermometers uses a Pt1000 Platinum

RTD sensor which is read by our embedded processor

and displayed on the LCD display.

The LCD based DTB is battery powered and needs no

wiring .

3. Safety Instruction

Read the instruction manual completely before installing

the DTB temperature sensor. All safety guidelines should

be followed and the sensor should only be installed by

qualified personnel following all local codes and regulations.

3.1. Safety Conventions

The following symbols should be noted in this instruction

manual.

⚠

Attention: this symbol indicates an instruction

that if not followed properly could lead to injury

or death.

4. Installation

4.1. Unpacking

If there is any visible damage to the unit check the packaging and notify the shipper immediately. Included in the

package should be one DTB and one instruction manual.

4.2. Storage

Note that the device should be stored at a temperature

between -20 º C to +70 ºC (-4ºF to 160 ºF ) in a location

that is reasonably dry and clean.

4.3. Orientation

See figure 1.

There are no restrictions on the orientation of the probe

location, but if there is a requirement for the pipe to be

self draining the seating should be angled such that it will

drain properly.

F

F

Note: this symbol indicates an action that could

lead to damage or contamination if not followed.

3.2. Proper Use

3.2.1. Designated use: These devices are intended for

specific industrial applications. Appropriate fittings,

materials and form must be chosen depending on the

use. Proper specification must be done to conform with

temperature, pressure and flow velocity requirements.

2 of 4

Page 3

4.5. Wiring

F

F

F

Figure 1

The probe should be centered in the process flow no

matter what the orientation. Angled inserts should have

the probe pointing into the direction of flow as shown.

Ensure that during installation all necessary precautions

are taken. If this is a sanitary installation ensure that

the probe has been properly cleaned in advance of

installation and ensure that it is transported to the site

of installation in a way that will maintain it’s sanitary

condition.

If there are flammable or explosive fluids or gasses

⚠

present at the site of installation ensure that proper

grounding procedures are taken. Unwrapping a probe

from bubble wrap or other packaging can impart a static

charge on the probe which may discharge upon insertion

into the mounting location.

If the function demands it, seal the process connection

with PTFE tape.

Note: NPT connections should be hand tightened

and then turned only 1-1/2 turns further with an appropriate wrench. This value may change according to what

type of sealant is used and the quality of the process

thread. Do not use the display body to tighten the probe

into the mounting location. Doing so may damage the

probe. Use only the lower hex portion of the process

fitting to tighten.

Note: Compression fittings of 1/4” ( 6mm ) and high-

er should be hand tightened and then turned only 1-1/4

turns further with an appropriate wrench. Compression

fittings of 3/16”(4mm) and lower should be hand tightened and then turned only 3/4 of a turn further with an

appropriate wrench.

F

Note that the LCD based DTB is a battery powered

device and needs no wiring.

5. Limits

5.1. Pressure Limits

The pressure limits for the probe is 500 psig, but the

pressure limits for the process connection could be

considerably less. Ensure the appropriate process

connection is used for the desired pressure limits.

5.2. Temperature Limits

The ambient temperature range for the exterior housing

enclosing the processor should not exceed 50ºC ( 120ºF ).

The temperature limits for the probe should conform to

the limits outlined in the technical specifications.

Note that the temperature will affect the pressure and

flow velocity limits of the probe.

5.3. Thermal Characteristics

For some RTD temperature indicators there is self

heating from the measurement current. With the DTB

line of products, the self heating is negligible. Any self

heating error will be compensated for during factory

calibration.

Calibration of all DTB products takes place after the RTD,

probe and electronics are assembled and immersed up

to the process connection or a minimum of 10X the

probe diameter. There should be no discrepancy in the

measurement due to the thermal characteristics of the

probe or process fitting.

5.4. Response Time

Warm up is approximately 30 seconds, then response

time is typically 3 seconds due to the display refresh

rate.

6. Calibration

Calibration is performed at the factory. For recalibration

return the unit to the factory. Please ensure that the unit

is clean and free of contaminants before shipping. On

site calibration may only be conducted by factory trained

professionals.

7. Long-Term Stability

4.4. Troubleshooting

If the unit fails to function properly there are no user serviceable parts inside. If returning the unit to the factory

please ensure that the unit is clean and free from any

contaminants before shipping.

The electronics and RTD should not deviate more than

0.05% per year if sized and installed properly. Regularly

scheduled verification should be done to ensure that the

unit is within accepted norms.

3 of 4

Page 4

8. Error Codes

FF

FF

The DTB is programmed to display the following error

conditions.

9. Dimensions

1.86 ”

Code Description

Err1

Err2

Err3”

LO

Hi

Open RTD condition

Shorted RTD condition

General Error

Valid reading, but out of display range low

Valid reading, but out of display range hi

Battery voltage is low - return to

bAtt

factory for battery replacement and

recalibration.

ompression

C

fitting

F

F

“C”

1.25”

“L”

3.19 ”

NPT “C”

1/4”

3/ 8”

1/4”

10. Technical Specifications

1/ 2”

3/4”

Sensing Element: RTD, Type Pt1000 Ohm, Class A

Measuring Temperature Ranges: –50 º C to 200 º C or –50 ºF to 400 ºF

Accuracy : ±( 0.2 + 0.002 x | T|) ºC, factory,

±( 0.36 + 0.002 x | T-32 | ) ºF, factory,

|T|=Absolute value of temperature, ie. -10C=10, 10C=10

Refresh Rate : 3 seconds

Display : 4-digit LCD, 1/2” high ( 12.7 mm ), decimal point selectable by software

Display Resolution : See table 1

Display Error Messages : See operational manual

RFI effect : 1 % or less typical

Temp. Effect : < 0.01 % FS/ ºC

Ambient Temp. Range : 0ºC to 50 º C ( 32 º F to 122 ºF)

Storage Temp. Range : - 20 º C to 70 º C ( -4 º F to 158 ºF)

Max. Pressure : 500 PSIG ( on probe )

Housing Material : Stainless steel 316

Probe Material : Stainless steel 316 standard

Cable Materials : PVC, PTFE, Silicone, SS armored PTFE ( with RTD output only )

Weight : 350 grams (12 ounces)

Environmental Protection : NEMA 4X/ IP 67

Power : 2 x 3.6 V “AA Cells”

Battery Life : 5 years min. in continous mode ( low power battery indication )

Shipping Volume : Imperial Volume = 3.5” W X 3” H X ( 4.7” + L “of probe )

Metric Volume = 9.0 cm W X 8 cm H X ( 12 cm + L cm of probe )

3.10 ”

1.50” ( 38 mm )

1.50” ( 38 mm )

1.75” ( 45 mm )

1.82” ( 46 mm )

Table 1: Display Resolution

Factory Settings Optional Settings

Model Range

-50 º C to 200

( -50 º F to 400

Setting Viewable Range Setting Viewable Range Setting Viewable Range

º C

ºF)

0.1

-50.0º C to 200.0º C

(

-50.0 ºF to 400.0 ºF)

0.01

-50.00 º C to 99.99º C

( -50.00 º F to 99.99 ºF)

1

-50 º

( -50º

C to 200º C

F to 400 ºF)

4 of 4

Loading...

Loading...