Page 1

KOBOLD DSF26 Digital Pressure Gauge

User Instructions

KOBOLD Instruments Inc. 1801 Parkway View Drive Pittsburgh PA 15205

Phone (412) 788-2830 • Fax (412)-788-4890 • www.koboldusa.com

Manual-DSF26_12-13

Page 2

Page 3

DSF26

Table Of Contents

KOBOLD DSF26 DIGITAL PRESSURE GAUGE

1.0 General . . . .. . . . . . . . . . . . . . . . .. . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . 1

2.0 Specifications . . . . . . . . . . . . . . . .. . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . 2

3.0 Installation Instructions . . . . . . . . .. . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . 5

4.0 Operation . . .. . . . . . . . . . . . . . . . .. . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . 6

4.1 Turning the Unit On . . . . . .. . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . 6

4.2 Flow Measurement . . . . . .. . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . 6

5.0 Arrival of Damaged Equipment . .. . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . 6

6.0 Maintenance .. . . . . . . . . . . . . . . . .. . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . 6

7.0 Need Help With Your DSF26?. . . .. . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . 6

List of Diagrams

Diagram 2.4: Sensor Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Diagram 3.1: Wiring . . . . . . . . . .. . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . 5

List of Tables

Table 2.1: Material Combinations and Maximum Limits . . . . . . . . . . . . . . . . . . . 2

Table 2.2: Electrical Data. . . . . . . . . .. . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . 3

Table 2.3: Flow Ranges and Fitting Sizes . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . 3

FM Rev. 12/03/13

Page 4

Page 5

DSF26

KOBOLD DSF26 DIGITAL PRESSURE GAUGE

User Instructions

CAUTION: For safety reasons, please read the cautionary information located at

the end of the manual, before attempting installation.

1.0 General

The DSF26 employs a piezo-resistive strain gauge element whose resistance varies in

proportion to an applied force (pressure). This variable resistance signal is conditioned to

provide an LED display and analog output. Optionally this meter can be provided with up

to 4 switches whose switch points and hysteresis are programmable.

2.0 Specifications

Table 2.1: General Specifications

Ranges: -14.7 to 5800 PSIG (see table 2.1 for

model numbers)

Over Pressure Protection:

To 3000 PSIG: 2X range Max.

Above 3000 PSIG: 1.5X range Max.

Sensor Type: Piezoresistive

Accuracy: ±0.5% of full scale ± 1 digit

Linearity: ±0.2% of full scale

Repeatability: ±0.1% of full scale

Operating Temperature:

Medium: -5°F to 220°F

Ambient: -5°F to 140°F

Storage: -40°F to 160°F

Temperature Drift Coefficients

Zero: < 0.05% of full scale/°F

Span: < 0,05% of full scale/°F

Sensing Membrane Location: Internal

Optional: Flush

Materials of Construction:

Wetted Parts: 316 Ti-Stainless Steel, Sapphire

Housing: 304 Stainless Steel, Polyamide

FM Rev. 12/03/13

Page 6

DSF26 2

Table 2.2: Electrical Data

Power Supply: 15-30 VDC, 300 mA Max. steady state,

Analog Output:

Current: 0-20 mA or 4-20mA into 500 ohms Max.

Voltage: 0-10 VDC into 500 Ohms Min.

Zero Adjust: ±25% of full scale

Relays (Optional):

Type: SPDT

Setpoints: Field Adjustable

Hysteresis: Field Adjustable

Max. Voltage: 250 VAC, 220 VDC

Max. Current: 3 Amps

Max. Power: 50 VA, 60 Watts

Displays:

Pressure: 4 digit, 0.5”, Green LED

Switch Setpoints: 4 Digit Backlit LCD

1 Amp inrush

Electrical Connections: Via Terminal St rip

Operating Temperatures:

Medium: -5° to 220°F

Ambient: -5° to 140°F

Storage: -40° to 160°F

Environmental Protection: IP65 (equivalent to NEMA 4)

FM Rev. 12/03/13

Page 7

3DSF26

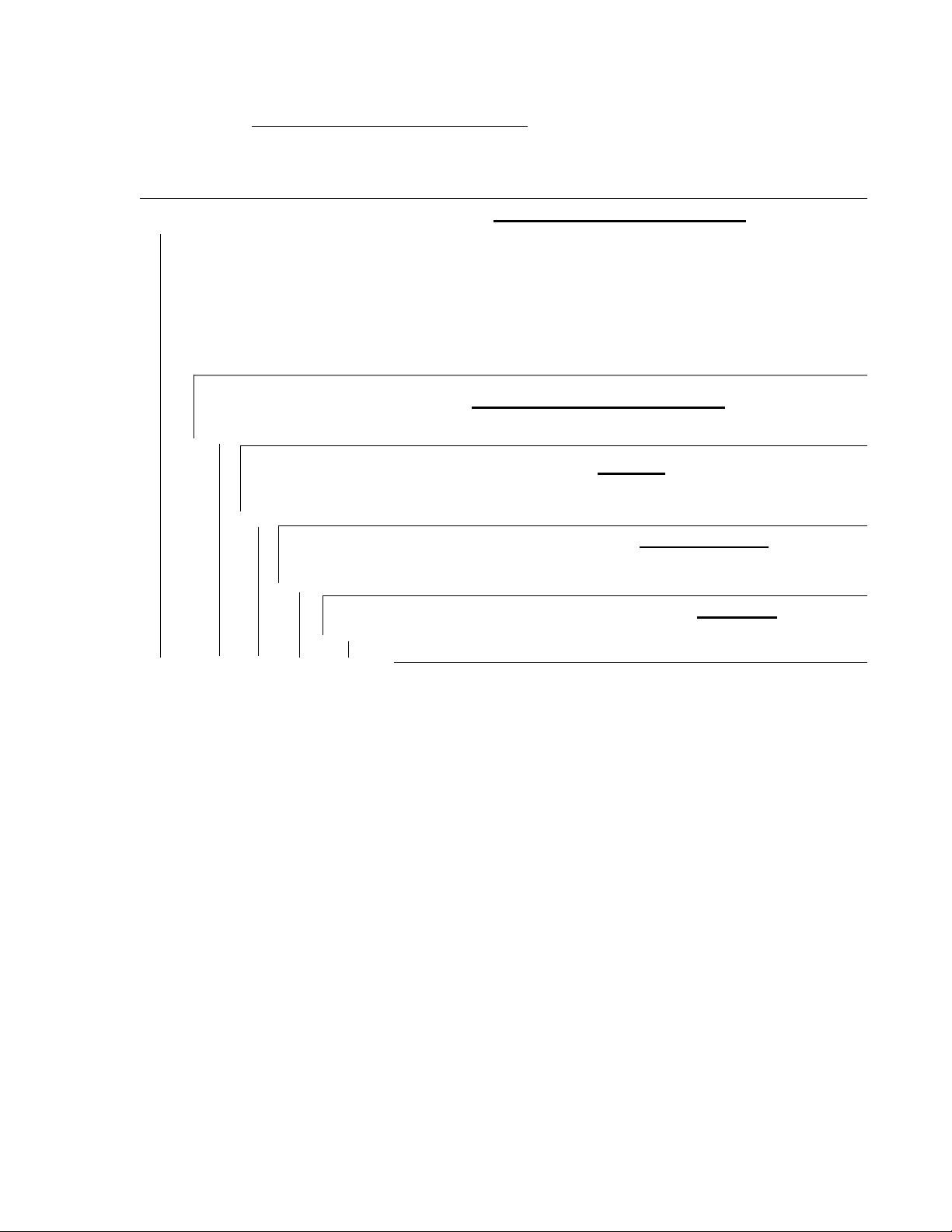

Table 2.3: Part Number Decoding

DSF26 Digital Pressure Gauge with Analog Output

Range = Pressure Range Abbreviation

V15 = -14.7 to 0 PSIG 210 = 100 PSIG 270 = 700 PSIG 350 = 50

050 = 5 PSIG 215 = 150 PSIG 275 = 750 PSIG 358 = 58

110 = 10 PSIG 220 = 200 PSIG 310 = 1000 PSIG

115 = 15 PSIG 230 = 300 PSIG 315 = 1500 PSIG

130 = 30 PSIG 250 = 500 PSIG 320 = 2000 PSIG

160 = 60 PSIG 260 = 600 PSIG 330 = 3000 PSIG

Sensing Membrane Location

1 = Internal Membrane

1 = 1/4” NPT

2 = 1/2” NPT

3 = 3/4” NPT

4 = 4-20 mA Output

0 = 0-20 mA Output

1 = 0-10 VDC Output

G = 2 SPDT Limit Switches

H = 4 SPDT Limit Switches

Available Measuring Ranges

Fittings

Analog Output

Switches

-115

1 24

G

Sample DSF26 Specification

FM Rev. 12/03/13

Page 8

DSF26 4

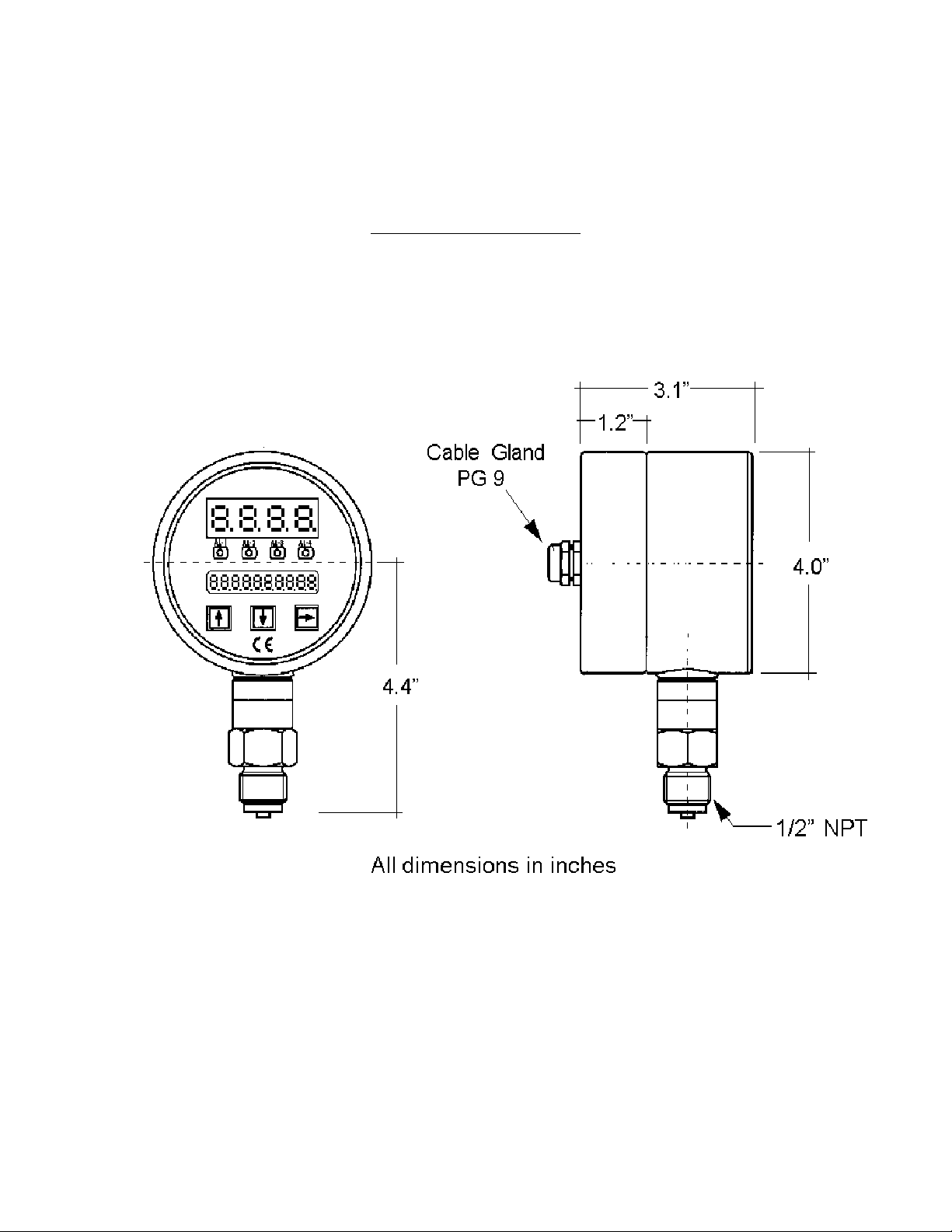

Diagram 2.4: Dimensions

FM Rev. 12/03/13

Page 9

5DSF26

3.0 Installation Instructions

CAUTION: For safety reasons, please read the cautionary information located at

the end of the manual, before attempting installation.

The following instructions and recommendations must be adhered to in order to ensure

proper pressure gauge installation:

1. When installed in horizontal piping runs, the gauge should be installed in the

upper hemisphere of the pipe, at the 12 O’clock position or within ±45° of the 12

O’clock position. This will ensure that sediments which may build up at the bottom of

the pipe will not clog the pressure sensing port (see Diagram 3.1).

Diagram 3.1: Pressure Gauge Installation

2. Install the gauge into a properly sized female port. Use of a thread sealant such

as PTFE tape is recommended to ensure a leak-tight seal.

3. When tightening the gauge into the piping system use a properly sized wrench on

the hex just above the threaded portion of the fitting. Do not use the case of the

gauge to apply torque or make or break the pressure connection.

FM Rev. 12/03/13

Page 10

DSF26 6

4.0 Electrical Connections

1. The DSF26 requires a 15-30 VDC power supply with at least 300 mA steady state

current capability. The unit has an inrush current of up to 1 Amp during the initial

startup transient. It is therefore necessary to ensure that the power supply used with

the DSF26 has a transient short-time current capability of at least 1 Amp.

2. The analog output signal wiring (if used) is made using either a 3-wire or 4-wire

connection as specified by the following wiring diagram:

CAUTION: THE DSF26 IS NOT A LOOP POWERED (2-WIRE) DEVICE.

DO NOT ATTEMPT TO USE A 2-WIRE CONNECTION AS THE

INTERNAL ELECTRONICS WILL BE DAMAGED IMMEDIATELY!!!

Diagram 4.1: Wiring

Note 1: Relays shown are optional

Note 2: Terminal blocks may be unplugged for wiring ease

Diagram 4.2: Power and Analog Output Connections

Terminal 10: DC Power (+)

Terminal 9: DC Power (-)

Terminal 8: Analog Output (+)

Terminal 7: Analog Output (-)

Terminals 1-6:Factory programming use only

FM Rev. 12/03/13

Page 11

5.0 Operation

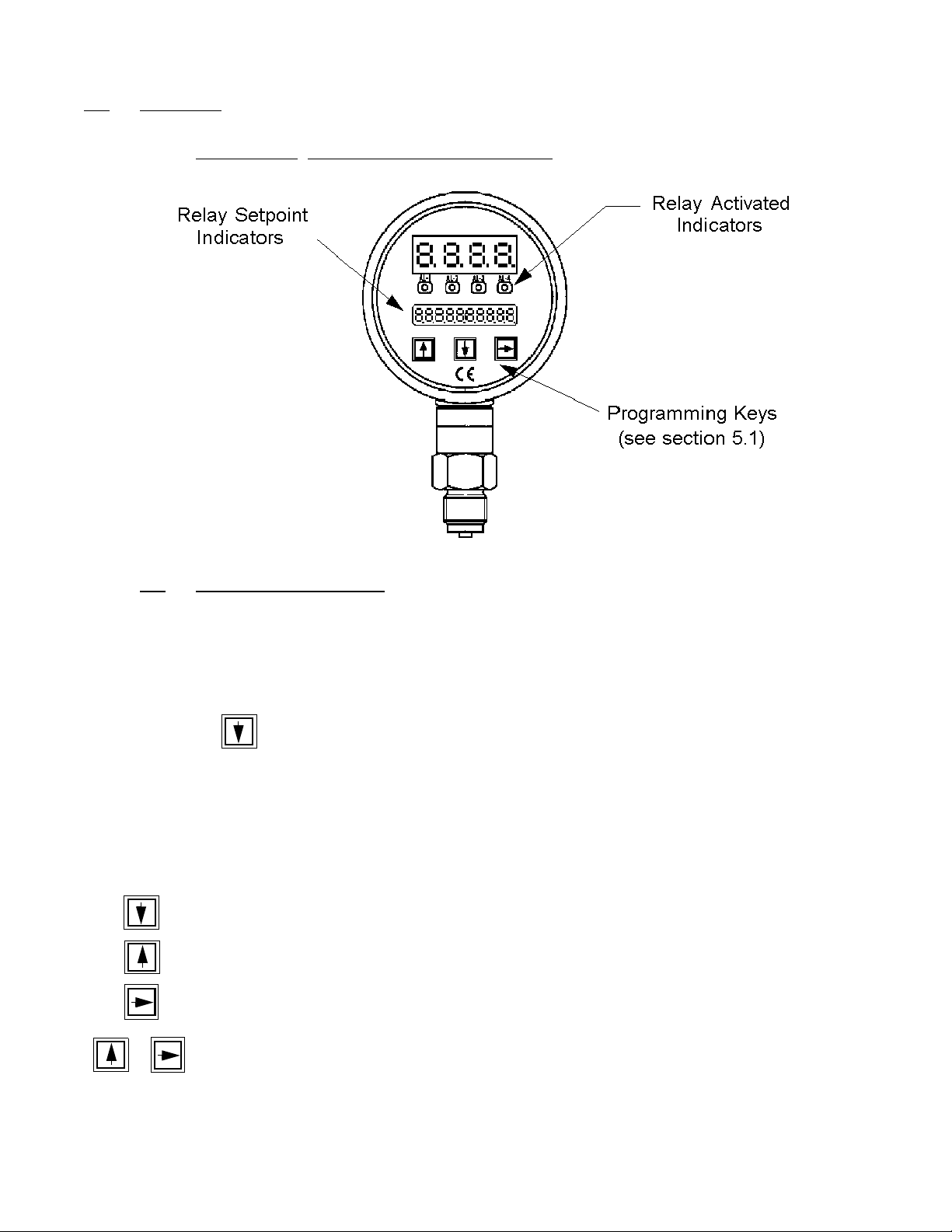

Diagram 5.1 DSF26 Displays and Controls

7DSF26

5.1 Programming, General

Programming is required in order to set the relay parameters and auto-zero the display if

needed. The programming menu items are displayed on the LCD display below the main

pressure display. The arrow keys on the front of the DSF26 are used to perform the

programming as follows:

Depressing the will place the DSF26 in the programming mode. EO - EbEnE will

be displayed on the LCD display. There are 4 branches in the programming mode (see

Diagram 5.2). Branch 1 sets Relay 1 parameters (setpoint, hysteresis etc.); Branch 2

sets the Relay 2 parameters; Branch three is used for auto- zeroing the display and

branch four is used only by the factory for initial setup. Menu items in branch 4 are locked

and cannot be altered by the user.

Programming key functions when in the programming mode (refer to Diagram 5.2)

Move to the next menu item

Move to the previous menu item

Move to the next branch. (only when at the first menu item in a branch)

Go back to the operating mode

FM Rev. 12/03/13

Page 12

DSF26 8

5.1 Programming, General (cont.)

When the numerical value of a menu item needs to be changed (e.g. changing relay

setpoint value) pressing the key will release the previous value to allow changing it.

the far right digit will be flashing to signify that the setting has been released to be

changed. Use or to change the value of that digit. Use to toggle to the next

digit. When the proper value is set, press & to enter the new value.

5.2 Programming Code Descriptions

The following is a listing of each programming code for the DSF26 along with a

description of its function. Diagram 5.2 shows a flow chart of the programming process:

E0 - EbEne Programming mode enabled. Pressing will toggle through each of

the 4 programming branches (see Diagram 5.2).

E0 - rELAiS1 Branch 1 for setting Relay 1 parameters. Use to move to the next

programming branch. Use to move down through the Relay 1

branch and set the Relay 1 parameters of setpoint, hysteresis, and

delay time.

SPt1 XXXX Relay 1 activation setpoint. To adjust the setpoint value, press the

key to release the previous setpoint value. the far right digit will be

flashing to signify that the setting has been released to be changed.

Use or to change the value of the flashing digit. Use to

toggle to the next digit. When the setpoint value is set, press &

to enter the new value.

HYS1 XXXX Relay 1 hysteresis. Hysteresis is defined in this as the temperature

setpoint where the relay de-activates. It is designed to allow for a

temperature “deadband” between the relay activation and de-activation.

To adjust the setpoint value, press the key to release the previous

setpoint value. the far right digit will be flashing to signify that the setting

FM Rev. 12/03/13

has been released to be changed. Use or to change the value

of the flashing digit. Use to toggle to the next digit. When the

setpoint value is set, press & to enter the new value.

Page 13

9DSF26

6.0 Maintenance

The DSF26 is an electronic device with no wear parts other than the relay contacts which

if properly connected will last for several hundred thousand cycles. The only

maintenance required on this device may be an occasional cleaning of the sensing port if

a coating or dirty process media exists. A possible indication of a dirty sensing port

would be a sluggish response to changes in process pressure.

Do NOT tamper with the electronics as this voids your warranty.

7.0 Need help with your DSF26?

Call one of our friendly engineers at 412-788-2830.

FM Rev. 12/03/13

Page 14

DSF26 10

Caution

PLEASE READ THE FOLLOWING GENERAL FLOW METER / MONITOR

WARNINGS BEFORE ATTEMPTING INSTALLATION OF YOUR NEW

DEVICE. FAILURE TO HEED THE INFORMATION HEREIN MAY

RESULT IN EQUIPMENT FAILURE AND POSSIBLE SUBSEQUENT

PERSONAL INJURY.

FM Rev. 12/03/13

Page 15

11 DSF26

• User's Responsibility for Safety: KOBOLD manufactures a wide range of

process sensors and technologies. While each of these technologies are

designed to operate in a wide variety of applications, it is the user's

responsibility to select a technology that is appropriate for the application,

to install it properly , to perform test s of the installed system, and to maintain

all components. The failure to do so could result in property damage or

serious injury.

• Inspect instrument for damage upon arrival: Cracked, fractured, bent or

otherwise damaged instruments must not be put into use, since the device

is weakened to an unknown extent. Refer to Section 5.0, Arrival of

Damaged Equipment, for additional information.

• Media and Chemical Compatibility: The maximum tolerances of the

device have been determined using water. If using other media, especially

corrosive media, it is critically important that the user determine chemical

compatibility with our instruments. KOBOLD Instruments Inc. cannot

accept responsibility for failure and consequences resulting from use of

media other than water.

• Material Compatibility: Make sure that the model which you have

selected is chemically compatible with the application liquids. While the

meter is liquid and spray resistant when installed properly, it is not

designed to be immersed.

• Proper Installation in Flow System: Install the device in a fully supported

position within your flow system. This avoids excessive stresses which may

damage the instrument. In particular:

a.) Ensure that the plumbing leading to and from the instrument is fully

supported and that the instrument does not perform the physical function of

a joint.

b.) When calculating stress on the device caused by plumbing, the weight

of the medium in the pipes must be considered as well.

c.) Misaligned runs of rigid piping can cause large stresses when

connected to the instrument. Do not connect in such a fashion.

d.) When connecting fittings, hold the instrument fittings rigid with a

correctly sized wrench. Do not install by twisting the instrument into the

pipe fittings.

e.) Do NOT install by holding the device housing to provide counter-torque

to the pipe fitting.

f.) Use an appropriate amount of PTFE tape on male threads of fitting. This

reduces the twisting stresses produced by tightening the fittings into each

other.

g.) Do not use pliers or wrenches on the housing, as this may damage it.

FM Rev. 12/03/13

Page 16

DSF26 12

h.) Do not overtighten, as this may fracture the fittings.

• While Operating the Flow System: During operation, there are a number

of situations to avoid:

a.) The sudden cessation of fluid flow causes what is typically referred to

as "water hammer". Most people are familiar with this phenomenon from

their home experience - it is the cause behind the loud clank of water pipes

which occurs when faucets are turned off too suddenly. The cause behind

this "water hammer" is quite easy to visualize. Water is fairly massive. The

amount of water in long runs of pipe is quite substantial. When the faucets

are turned off suddenly, especially from a full on condition, the water has

considerable momentum and does not want to stop flowing. The situation

is similar to stopping a car by running into a wall, rather than by applying

brakes. Both are sudden rather than gradual. The damage to the wall can

be substantial (not to mention the car).

b.) The "water hammer" causes surges in fluid pressure which could cause

the measurement instrument's pressure limit to be exceeded, resulting in

failure and possible personal injury.

c.) Fluid surges, as well as the water hammer, can be particularly

damaging to empty flowmeters since there is no back pressure in the

device. The damage is caused, once again, by momentary excess

pressure. To avoid these surges, fluid lines should remain full (if possible)

and water flow should be introduced to the device slowly.

d.) If the instrument is isolated with inlet and outlet valves, the flowmeter

must be completely drained when said valves are both closed. Failure to

do so could result in damage to the device caused by thermal expansion of

fluid.

e.) Freezing of water in the instrument must be avoided since the resultant

expansion will damage the flowmeter and make it unsafe for use.

• Wiring and Electrical: Section 2.0, Specifications and Section 3.0,

Installation Instructions, provide the voltage and current limitations and the

wiring for the various sensor types. The sensor electrical ratings should

never be exceeded. Electrical wiring of the sensor should be performed in

accordance with all applicable national, state and local codes.

• Temperature and Pressure: Section 2.0, Specifications, provides the

temperature and pressure limits for each model. Operation outside these

limitations will cause damage to the unit and can potentially cause personal

injury. Fluid should never be allowed to freeze inside the sensor.

• Make a Fail-safe System: Design a fail-safe system that accommodates

the possibility of switch or power failure. In critical applications, KOBOLD

recommends the use of redundant backup systems and alarms in addition

to the primary system.

FM Rev. 12/03/13

Loading...

Loading...