Page 1

Operating Instructions

for

Piston Flow Meters

Model: DRZ

Page 2

DRZ

1. Contents

1. Contents ........................................................................................................ 2

2. Note .............................................................................................................. 3

3. Instrument Inspection .................................................................................... 3

4. Regulation Use .............................................................................................. 3

5. Operating Principle ........................................................................................ 4

6. Mechanical Connection ................................................................................. 5

7. Electrical Connection .................................................................................... 5

7.1 General ................................................................................................ 5

8. Technical Information .................................................................................... 7

9. Order Codes ................................................................................................. 8

10.Dimensions ................................................................................................... 9

11.Pressure Loss Diagram ............................................................................... 12

12.EU Declaration of Conformance .................................................................. 13

Manufactured and sold by:

Kobold Messring GmbH

Nordring 22-24

D-65719 Hofheim

Tel.: +49(0)6192-2990

Fax: +49(0)6192-23398

E-Mail: info.de@kobold.com

Internet: www.kobold.com

page 2 DRZ K03/0418

Page 3

DRZ

2. Note

Please read these operating instructions before unpacking and putting the unit

into operation. Follow the instructions precisely as described herein.

The devices are only to be used, maintained and serviced by persons familiar

with these operating instructions and in accordance with local regulations

applying to Health & Safety and prevention of accidents.

When used in machines, the measuring unit should be used only when the

machines fulfil the EC-machine guidelines.

as per PED 2014/68/EU

In acc. with Article 4, Paragraph (3), "Sound Engineering Practice", of the

PED 2014/68/EU no CE mark.

Diagram 8, Pipe, Group 1 dangerous fluids

3. Instrument Inspection

All Instruments are inspected before shipping and sent out in perfect condition.

Should damage to a device be visible, we recommend a thorough inspection of

the delivery packaging. In case of damage, please inform your parcel service /

forwarding agent immediately, since they are responsible for damages during

transit.

Scope of delivery:

The standard delivery includes:

Piston Flow Meters model: DRZ

Operating Instructions

4. Regulation Use

Any use of the Piston Flow Meters, model: DRZ, which exceeds the

manufacturer’s specification, may invalidate its warranty. Therefore, any resulting

damage is not the responsibility of the manufacturer. The user assumes all risk

for such usage.

DRZ K03/0418 page 3

Page 4

DRZ

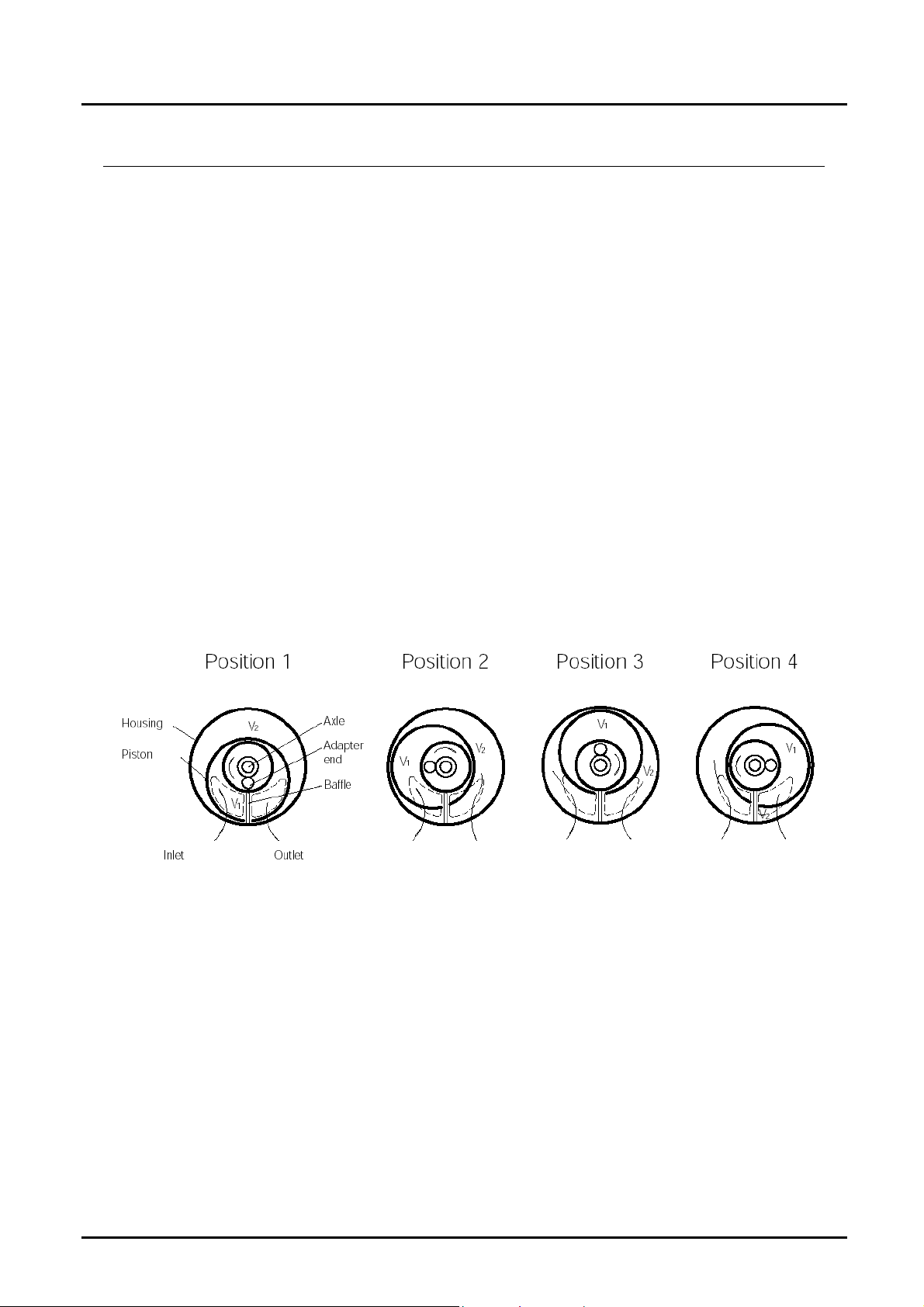

5. Operating Principle

KOBOLD Piston Flow Meters are direct volume counters, also called

displacement counter (positive displacement meter).

Its function is based on continuous limitation of a definite part-volume of the flow

in a measuring cell through continuous filling and emptying of this measuring cell.

The measuring cell consists of the measuring chamber and the moving part, the

piston.

The piston is driven by the pressure difference between inlet and outlet of the

measured media. The counter is a pure mechanical instrument. The revolution is

carried forward via a magnet and a magnet field sensor. In cross section the uformed piston is guided with its piston and guiding-adapter in a ring chamber at

the bottom and top of the measuring-body and with its slot at the baffle. The inlet

and outlet openings are located on both sides of the chamber’s wall. They are

constantly sealed by the piston and the baffle. The incoming measured media fills

up the sickle shaped spaces, it wants to increase these spaces and therefore

turns the piston. Until one after the other the volumes V1 and V2 are reached.

While moving ahead, these filled spaces are connected with the outlet and are

emptied. Since both sickle shaped spaces - the inner and the outer - are

displaced to one another, the piston movement will not have a dead centre. The

piston moves continuously depending to the measured flow.

One complete turn of the piston adapter end is equal to the flow of the measuring

chamber content (V1+V2). With the help of a located magnet and a Hall-type

sensor, it is possible to create a digital signal, which can be evaluated.

page 4 DRZ K03/0418

Page 5

DRZ

6. Mechanical Connection

Before installation:

Remove all packing materials, transport retainers and ensure that no such

materials remain in the device.

Make sure that the maximum operating pressure and temperature of the device

are not exceeded.

Please ascertain, that the pipe system is free of any welding bead, ferrite

particles or other pollution.

Make sure that the application flow amount corresponds with the flow range of

the instruments.

Installation

The mounting position of the piston is free of choice. The flow direction must

be in the direction as indicated by the arrow.

In- and outlet flow sections are not necessary.

The sealing of the connection threads is done with sealing tape or something

similar.

During installation, please pay attention that the DRZ-instrument is not

exposed to mechanical stress or tension. We recommend to mechanically

fastening the connection pipes approximately 50 mm away from the

connection thread.

If possible, after completing the mechanical installation, check the thread

connection between the device and the piping for leakage immediately.

7. Electrical Connection

7.1 General

Make sure that the supply wires are de-energised.

Connect the power supply and the evaluation of the output signal to the pins of

the plug described as follows.

Warning! Incorrect wiring of the connections in the coupling plug

can lead to the electronics being destroyed. Make sure that the

voltage values of your installation correspond with the voltage

values of the measuring instrument.

DRZ K03/0418 page 5

Page 6

DRZ

DRZ-..F3..; DRZ-..L3..

DRZ-..0000

DRZ-..C3..

page 6 DRZ K03/0418

Page 7

DRZ

8. Technical Information

Measuring range: 6-420 L/h

Max. flow rate: 600 L/h

Measuring accuracy: ± 1.0% of reading

± 2.5% of reading

Repeatability: ± 0.2%

Standard viscosity range: 5-100 mm2/s

Process temperature: max. 80 °C

Ambient temperature: -10 to +60 °C

Max. pressure: 40 bar

Max. pressure loss: 1.5 bar

Connection: female thread G 1/8; G 1/4;

1/8 NPT; 1/4 NPT

Mounting position: independent

Recom. filter fineness: 100 µm

Protection type: IP 65

Weight: approx. 0.7 kg

(DRZ-..F.., DRZ-..L..)

approx. 1.0 kg (DRZ-..C..)

Materials:

Housing: brass

Piston: titanium

Magnet holder: POM

Magnet: permanent magnet

O-ring/Seal: FPM

Electronics

OEM frequency output (...0000) (without CE)

Power supply: 5-24 VDC

Supply current: 10 mA

Pulse output: NPN, open collector,

max. 15 mA

Impulse rate: 405 pulses/litre

Electr. connection: plug connector DIN 43650

Option: plug-on display AUF-4000

with 4 -20 mA output

Frequency output (...F300)

Power supply: 12-28 VDC

Supply current: 10 mA

Pulse output: PNP, open collector,

max. 25 mA

Impulse rate: 432 pulses/litre

Electr. connection: plug connector M12x1

DRZ K03/0418 page 7

Page 8

DRZ

Frequency output with frequency divider (...F3X0)

Power supply: 24 VDC ± 20%

Supply current: 15 mA

Pulse output: PNP, open collector,

max. 25 mA

Electr. connection: plug connector M12x1

Division factor: 1:2, 1:4 or customer request

Analogue output (...L303; ...L343)

Power supply: 24 V

DC ±20%

Output: 4-20 mA, 0-20 mA, 3-wire

Max. load: 500 .

Electr. connection: plug connector M12x1

Compact electronics (..C3..)

Display: 3-segment LED

Analogue output: (0)4...20 mA adjustable, max. 500

Switching output: 1 (2) semiconductor PNP

or NPN, factory setting

Contact function: N/C or N/O programmable

Setting: via 2 buttons

Power supply: 24 V

DC ±20%,

3-wire technology

Electr. connection: plug connector M12x1

9. Order Codes

Example: DRZ-1110 G1 F300

Version Model Connection Evaluating electronics

Brass housing

6 - 420 L/h oil

DRZ-1110

G1 = G 1/8 IG

G2 = G 1/4 IG

N1 = 1/8 NPT

N2 = 1/4 NPT

OEM frequency output, no CE

0000 = DIN plug connector 43650, NPN

Frequency output

F300 = plug connector M12x1, PNP

F320 = plug connector M12x1, PNP, divider 1:2

F340 = plug connector M12x1, PNP, divider 1:4

F390 = plug connector M12x1, PNP, divider adjustable

Analogue output

L303 = plug connector M12x1, 0 - 20 mA, 3-wire

L343 = plug connector M12x1, 4 - 20 mA, 3-wire

Compact electronics

C30M = LED display, 2x NPN switch. output, plug con. M12x1

C30R = LED display, 2x PNP switch. output, plug con. M12x1

C34N = LED display, 4 - 20 mA, 1x NPN switching output,

plug connector M12x1

C34P = LED display, 4 - 20 mA, 1x PNP switching output,

plug connector M12x1

1)

Please specify flow direction in wiring.

1)

page 8 DRZ K03/0418

Page 9

DRZ

Plug-on display

for model DRZ...0000 (OEM version, NPN- and DIN connector)

Description Order No.

4-digit LED,

Plug connector DIN 43 650

Input: pulses of DRZ

Output: 4 - 20 mA, 3-wire

Load: max. 250

Accessories

Round plug

Model Description

ZUB-KAB-12D500 Round plug M12 x 1 socket with screw clamps, 5 pins

ZUB-KAB-12K002 Round plug M12 x 1 socket with 2 m cable, 4 pins

ZUB-KAB-12K005 Round plug M12 x 1 socket with 5 m cable, 4 pins

ZUB-KAB-12Q000 Round plug M12 x 1 socket with Quick-on, 4 pins

AUF-4000

10. Dimensions

3 x M 5-10 deep

DRZ K03/0418 page 9

Page 10

DRZ

page 10 DRZ K03/0418

Page 11

DRZ

DRZ K03/0418 page 11

Page 12

DRZ

11. Pressure Loss Diagram

page 12 DRZ K03/0418

Page 13

DRZ

12. EU Declaration of Conformance

We, KOBOLD Messring GmbH, Hofheim-Ts, Germany, declare under our sole

responsibility that the product:

Piston Flow Meters Model: DRZ

to which this declaration relates is in conformity with the standards noted below:

EN 61000-6-3:2011

Electromagnetic compatibility (EMC) - Part 6-3: Generic standards - Emission

standard for residential, commercial and light-industrial environments

61000-6-2:2006

Electromagnetic compatibility (EMC) - Part 6-2: Generic standards - Immunity for

industrial environments

EN 61010-1:2010

Safety requirements for electrical equipment for measurement, control and

laboratory use - Part 1: General requirements

EN 60529:2014

Degrees of protection provided by enclosures

EN 50581:2012

Technical documentation for the assessment of electrical and electronic products

with respect to the restriction of hazardous substances

Also the following EC guidelines are fulfilled:

2014/30/EU EMC Directive

2014/35/EU Low Voltage Directive

2011/65/EU RoHS (category 9)

Hofheim, 11. Jan. 2018

H. Peters M. Wenzel

General Manager Proxy Holder

DRZ K03/0418 page 13

Loading...

Loading...