Kobold DRG Series, DRG-F Series, DRZ-**Z Series, DRG-**L442, DRG***L3 Series Operating Instructions Manual

...Page 1

Operating Instruction

for

Rotating Vane Flow Meter

Model: DRG-...

Page 2

DRG

Page 2 DRG K02/0316

1. Contents

1.

Contents ........................................................................................................ 2

2. Note .............................................................................................................. 3

3. Regulation Use .............................................................................................. 3

4. Operating Principle ........................................................................................ 3

5. Instrument Inspection .................................................................................... 4

6. Mechanical Connection ................................................................................. 4

7. Electrical Connection .................................................................................... 5

8. Commissioning – Evaluation Electronics ...................................................... 8

9. Technical Information .................................................................................... 8

10.Order Details ............................................................................................... 10

11.Maintenance ............................................................................................... 11

12.Dimensions ................................................................................................. 11

13.EU Declaration of Conformance .................................................................. 14

Manufactured and sold by:

Kobold Messring GmbH

Nordring 22-24

D-65719 Hofheim

Tel.: +49(0)6192-2990

Fax: +49(0)6192-23398

E-Mail: info.de@kobold.com

Internet: www.kobold.com

Page 3

DRG

DRG K02/0316 Page 3

2. Note

Please read these operating instructions before unpacking and putting the unit

into operation. Follow the instructions precisely as described herein.

The devices are only to be used, maintained and serviced by persons familiar

with these operating instructions and in accordance with local regulations

applying to Health & Safety and prevention of accidents.

When used in machines, the measuring unit should be used only when the

machines fulfil the EG-machine guidelines.

PED 2014/68/EU

In acc. with Article 4 Paragraph (3), "Sound Engineering Practice", of the

PED 2014/68/EU no CE mark.

Table 8, Pipe, Group 1 dangerous fluids

3. Regulation Use

The Model DRG-..., rotating vane flow meter is to be installed only in applications

that are within the specified operating limits. An use which exceeds the

specifications is prohibited. Any damages resulting therefrom are not the

responsibility of the manufacturer. The user assumes all risk for such usage. The

application specifications include the installation, start-up and service

requirements specified by the manufacturer.

4. Operating Principle

KOBOLD rotating vane flow meters series DRG are used for measuring and

monitoring low viscosity liquids. Series DRG flow meters are working according

the well known rotating vane principle. A magnet fitted in the vane and

hermetically sealed from the medium transfers the rotary motion of the vane to a

Hall-effect sensor mounted in the housing. The sensor converts the rotary motion

which is proportional to the flow to a frequency signal. The frequency is therefore

proportional to flowrate. A series-connected electronics unit converts the signal to

an analogue output, limit contacts or display.

Page 4

DRG

Page 4 DRG K02/0316

5. Instrument Inspection

These devices are checked before dispatch and sent away in perfect condition.

Should the damage to a device be visible, we recommend a thorough inspection

of the delivery packing. In case of damage, please inform your parcel service/

forwarding agent immediately, since they are responsible for damages during

transit.

Scope of delivery:

Rotating Vane Flow Meter model: DRG

Operating Instructions

6. Mechanical Connection

6.1. Operational conditions check up:

Max. flowrate

Max. operational pressure

Max. operational temperature

Attention! In case, specified range is over-violated, bearings may get

damaged and considerable measurement errors may result.

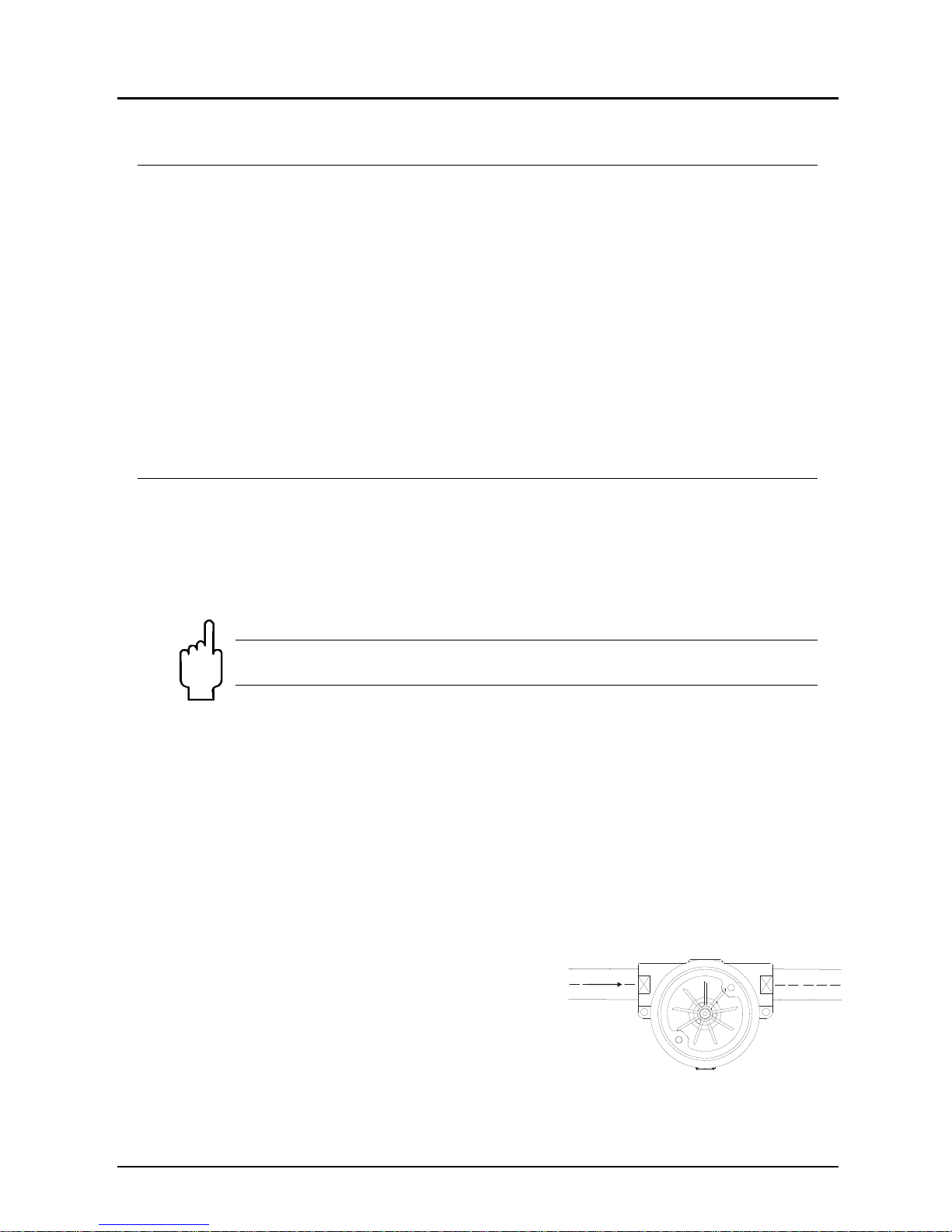

6.2. Installation

It must be ensured that the instrument housing is continuously filled with the

flow medium, especially for flows from top to bottom. No straight lengths are

necessary at inlet and outlet connections.

Flow in the direction of arrow pointer (position independent), front side of the

unit must stand in a vertical plane.

Pressure and tensile loading should be avoided.

Inlet and outlet (piping) should be braced at a distance of 50 mm from the

connection location.

Sealing of connections should be checked.

Page 5

DRG

DRG K02/0316 Page 5

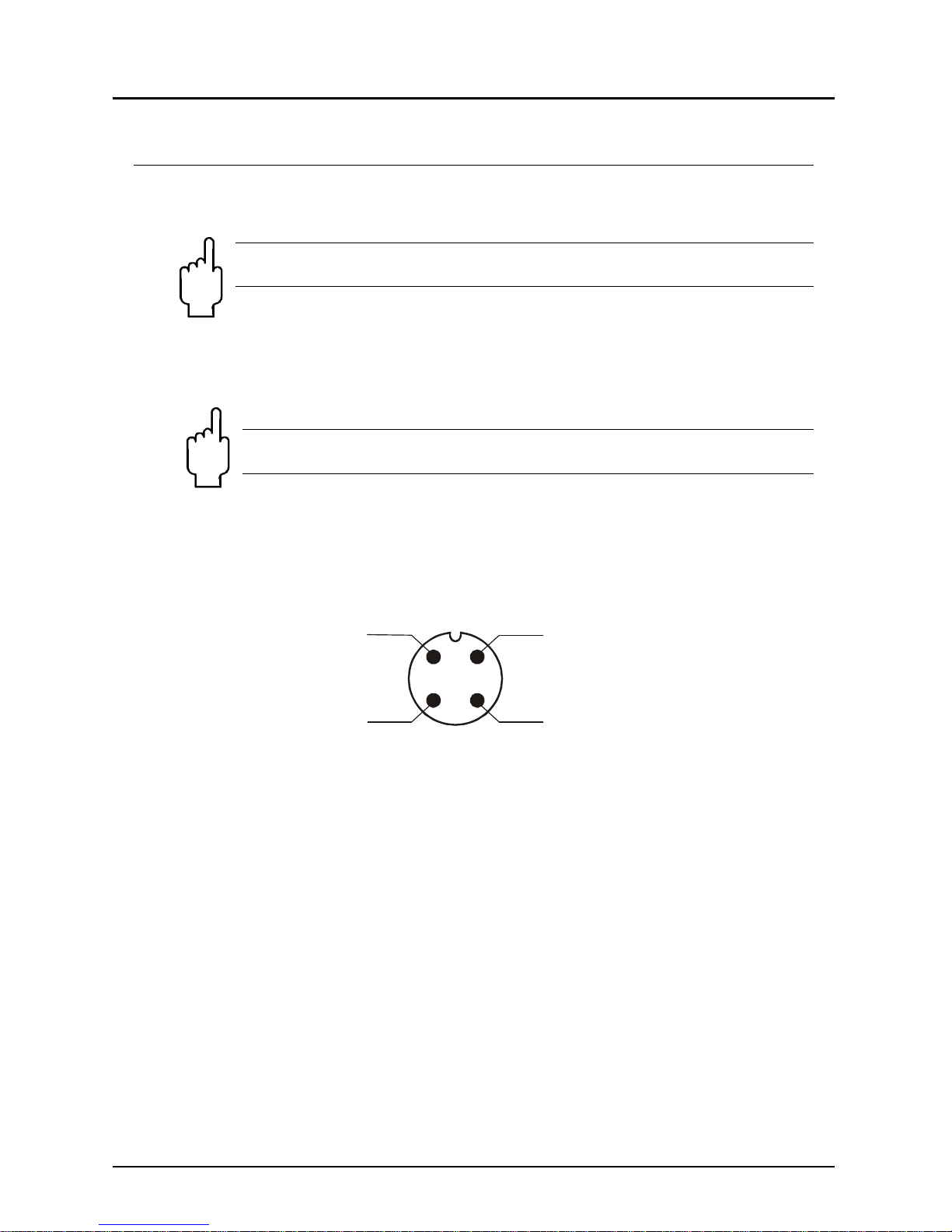

7. Electrical Connection

7.1. General

Attention! Please ensure that the voltage levels of your system are

in agreement with that of the flow meter.

Make sure that the electric supply lines are de-energized.

Connect the power supply and output signal on the plug-pins as shown below.

We recommend a cross-sectional area of 0.25 mm² of power supply cable.

Attention! A wrong plug-connection can lead to destruction of

unit’s electronics.

7.2. Evaluation electronics: Frequency output (..F300; ..F320,

..F340)

1

2

3

4

+Vs

Signal

Out

n.c.

GND

Page 6

DRG

Page 6 DRG K02/0316

7.3. Evaluation electronics:

Analogue output (..L303, ..L342, ..L343, ..L442)

3-wire (..L303, ..L343)

1

2

3

4

+Vs

Signal

Out

n.c.

GND

+Vs

GND

2-wire (..L342)

1

2

3

4

S+

S-

n.c.

n.c.

+Vs

GND

2-wire, DIN-plug (..L442)

+Vs

GND

1

2

3

S+

S-

PE

n.c.

Page 7

DRG

DRG K02/0316 Page 7

7.4. Compact electronics:

(..C30R, ..C30M, ..C34P, ..C34N)

Please see

Instruction Manual-Supplement

for Compact Electronics

7.5. Evaluation electronics: Pointer display (..Z300, ..Z340)

Attention! If the current output is not needed, PIN 4 (Signal Out) must

be connected permanently with Ground (GND) (Short Circuit Link).

mA

+Vs

GND

Power

1

2

3

4

+Vs

Signal

Out

n.c.

GND

Plug M12

Page 8

DRG

Page 8 DRG K02/0316

8. Commissioning – Evaluation Electronics

8.1. General

The measuring units are pre-adjusted and ready for use after electrical

connection.

8.2. Adjustment – Evaluation Electronics

Please see

Instruction Manual-Supplement

for Compact Electronics with frequency output

9. T echnical Information

9.1. Sensor data

Material combinations: see order details

Max. operating pressure: see order details

Max. temperature: see order details

Measuring accuracy: ±3% f. s.

Electrical connection: plug connector DIN 43 650,

plug connector M12x1

Pressure loss: max. 1 bar at max. range value

Protection: IP 65

Unit parts Ordering

code:

1

Ordering

code:

2

Ordering

code:

4

Ordering

code:

5

Ordering

code:

8

Ordering

code:

9

Housing

Brass

casting

Brass

casting

1.3955 1.3955 PP PP

Housing cover

PSU Brass

casting

PSU 1.4404 PP PSU

Sealing

NBR NBR FPM FPM NBR NBR

Vane

PTFE PTFE PTFE PTFE PTFE PTFE

Axle

Ceramic Ceramic Ceramic Ceramic Ceramic Ceramic

Bearings

PTFE PTFE PTFE PTFE PTFE PTFE

Max. Pressure

16 bar 40 bar 16 bar 40 bar 7 bar 7 bar

Max. Temp.

80°C 80°C 80°C 80°C 80°C 80°C

Sensor Weight

580 g 580 g 480 g 480 g 120 g 120 g

Page 9

DRG

DRG K02/0316 Page 9

9.2. Evaluation electronics

Frequency output (...F300)

Supply voltage: 12 - 28 VDC

Current intake: 10 mA

Pulse output: PNP, open collector, max. 25 mA

Electrical connection: Plug M12x1

Frequency output with frequency divider

Supply voltage: 24 VDC ±20%

Current intake: 15 mA

Pulse output: PNP, Open Collector, max. 25 mA

Electrical connection: Stecker M12x1

Dividing factor: 1...1/128, factory setting

Analogue output (option: on-plug display)

Supply voltage: 24 VDC ±20%

Output: 0-20 mA or 4-20 mA,

2- or 3-wire

Max. load: 500 Ohm

Electrical connection: Plug M12x1 or DIN 43 650

Option: plug-on display

(only with plug DIN 43 650

and 4-20 mA output), 2 conductor

Compact electronics

Display: 3-digit LED

Analogue output: (0)4 -20 mA adjustable, max. 500 Ω

Switching outputs: 1 (2) semiconductor PNP or NPN,

factory set

Contact operation: N/C / N/O contact frequency

programmable

Setting: with 2 buttons

Supply: 24 V

DC ±20%, 3-wire technology,

approx. 100 mA

Electrical connection: plug connector M12x1

Pointer display with analogue output

Housing: Aluminium

Display: Moving-coil instrument, 240° display

Suppkly voltage: 24 V

DC ±20%

Output: 0-20 mA or 4-20 mA

3-conductor

Max. load: 250 Ohm

Electr. connection: Plug M12x1

Page 10

DRG

Page 10 DRG K02/0316

10. Order Details

(example: DRG-1105 G1 F300)

Measuring range

Orifice

diameter

durch-

[mm]

Model

Connection

Evaluating electronics

L/min

water

approx.

frequency

(Hz)

at f.s.

Standard

fem. thread

Special

fem. thread

0,5-12 120 6

DRG-1X05... ..G1..=G 1/8 ..N1..=1/8 NPT

Frequency output

..F300= Frequency output, plug connector M12x1

..F320= Frequency divider 1:2, plug connector M12x1

..F340= Frequency divider 1:4, plug connector M12x1

..F390= Frequency divider 1...

1

/128, plug connector M12x1

Analogue output

..L303= 0-20 mA output, 3-wire, plug connector M12x1

..L342= 4-20 mA output, 2-wire, plug connector M12x1

..L343= 4-20 mA output, 3-wire, plug connector M12x1

..L442= 4-20 mA output, 2-wire, plug connector DIN 43 650

Compact electronics*

..C30R= LED display, 2x open coll., PNP, plug con. M12x1

..C30M= LED display, 2x open coll., NPN, plug con. M12x1

..C34P= LED display, 4-20 mA, 1x open coll., PNP,

plug connector M12x1

..C34N= LED display, 4-20 mA, 1x open coll., NPN,

plug connector M12x1

Pointer indication*

..Z300= 240° - pointer indication, 0-20 mA, plug con. M12x1

..Z340= 240° - pointer indication, 4-20 mA, plug con. M12x1

0,5-25 217 6

DRG-1X10... ..G2..=G ¼ ..N2..=1/4 NPT

1-30 217 8

DRG-1X15... ..G2..=G ¼ ..N2..=1/4 NPT

1-30 190 7

DRG-1X15... ..G4..=G ½ ..N4..=1/2 NPT

2-45 215 8

DRG-1X20...

..G4..=G ½

..G5..=G ¾

..G6..=G 1

..N4..=1/2 NPT

..N5..=3/4 NPT

..N6..=1 NPT

5-90 265 12

DRG-1X25...

..G4..=G ½

..G5..=G ¾

..G6..=G 1

..N4..=1/2 NPT

..N5..=3/4 NPT

..N6..=1 NPT

5-140 116 16

DRG-1X30... ..G5..=G ¾ ..N5..=3/4 NPT

10-140 180 16

DRG-1X35... ..G6..=G 1 ..N6..=1 NPT

* Please specify flow direction in writing

Plug-on display

For Model DRG... L342 (with 4-20 mA output and DIN plug connector)

Page 11

DRG

DRG K02/0316 Page 11

11. Maintenance

If the medium to be measured is not contaminated, the measuring unit is

maintenance-free. In order to avoid problems, we recommend installation of a

filter, such as magnet filter, model MFR.

Should cleaning of sensor be deemed necessary, the sensor may be opened and

inner parts may be accessed. Please be attentive during dismantling so that the

sensor and in particular, the vane is not damaged. During assembly the right

placement and the mounting direction of the vane should not be overlooked.

Electronic repairs may only be carried out by the manufacturer to prevent voiding

of warranty.

12. Dimensions

Model: DRG – F... (frequency output) DRG...L3...

(with analogue output)

O

B

O

L

D

E

4,5

ca.107

50

SWA

B

M12x1

60

G

C

G/NPTABCESW

1/8 80 16,5 63,0 72,5 24

1/4 80 16,5 63,0 72,5 24

1/2 80 16,5 63,0 72,5 24

3/4 100 25,0 69,5 90,0 38

1 100 25,0 69,5 90,0 38

Page 12

DRG

Page 12 DRG K02/0316

Model: DRG-..L442

(analogue output and option plug-on display)

OBOLD

A

E

4,5

12 117

50

SW

C

B

42

G

60

G/NPT A B C E SW

1/8 80 16,5 63,0 72,5 24

1/4 80 16,5 63,0 72,5 24

1/2 80 16,5 63,0 72,5 24

3/4 100 25,0 69,5 90,0 38

1 100 25,0 69,5 90,0 38

Model: DRG-..C.. (with Compact Electronics)

A

E

4,5

M12x1

SW

50

120,5

C

+2

B

44,5

60

G

GA B C ESW

1/8 80 16,5 63,0 72,5 24

1/4 80 16,5 63,0 72,5 24

1/2 80 16,5 63,0 72,5 24

3/4 100 25,0 69,5 90,0 38

1 100 25,0 69,5 90,0 38

Page 13

DRG

DRG K02/0316 Page 13

Model: DRG-..Z.. (with pointer display)

A

M12x1

E

133,5

99

50

SW

C

+2

B

4,5

79,7

65

60

G

G/NPT A B C E

1/8 80 16,5 63,0 72,5

1/4 80 16,5 63,0 72,5

1/2 80 16,5 63,0 72,5

3/4 100 25,0 69,5 90,0

1 100 25,0 69,5 90,0

Page 14

DRG

Page 14 DRG K02/0316

13. EU Declaration of Conformance

We, KOBOLD-Messring GmbH, Hofheim-Ts, Germany, declare under our sole

responsibility that the product:

Rotating Vane Flow Meter Model: DRG -...

to which this declaration relates is in conformity with the standards noted below:

EN 61000-6-4:2011

Electromagnetic compatibility (EMC) - Part 6-4: Generic standards - Emission

standard for industrial environments

EN 61000-6-2:2005

Electromagnetic compatibility (EMC) - Part 6-2: Generic standards - Immunity for

industrial environments

EN 61010-1:2010

Safety requirements for electrical equipment for measurement, control and

laboratory use - Part 1: General requirements

EN 60529:2014

Degrees of protection provided by enclosures (IP Code)

Also the following EU guidelines are fulfilled:

2014/35/EU Low Voltage Directive

2014/30/EU EMC Directive

2011/65/EU RoHS (category 9)

Hofheim, 27. Apr. 2016

H. Peters M. Wenzel

General Manager Proxy Holder

Loading...

Loading...