Page 1

USA

Canada

1801 Parkway View Drive

Pittsburgh, PA 15205

PH: 412-788-2830

FAX: 412-788-4890

www.kobold.com

9A Aviation

Point-Claire, QC H9R 4Z2

PH 514-428-8090

Fax: 514-428-8899

Precautions

• User's Responsibility for Safety: KOBOLD manufactures

a wide range of process sensors and technologies. While

each of these technologies are designed to operate in a

wide variety of applications, it is the user's responsibility to

select a technology that is appropriate for the application, to

install it properly, to perform tests of the installed system,

and to maintain all components. The failure to do so could

result in property damage or serious injury.

• Proper Installation and Handling: Use a proper sealant

with all installations. Never overtighten the sensor within its

fittings. Always check for leaks prior to system start-up.

• Wiring and Electrical: This is an electrically operated

device and only properly trained personnel should install

and maintain this product. Be sure that the power supplied

to the sensor is appropriate for the electronics supplied.

Electrical wiring should be performed in accordance with all

applicable national, state and local codes.

• Temperature and Pressure: The DRG is available in

several material combinations. Temperature and pressure

maximums vary depending upon the material selected.

Operation outside these limitations will cause damage to

the unit.

Series DRG

Paddle Flow Sensor

• Material Compatibility: The DRG process wetted

parts for the various body materials are stated below.

Make sure that the DRG is chemically compatible with

the application liquids. While the sensor’s outer housing

is liquid resistant when installed properly, it is not

designed to be immersed. It should be mounted in such

a way that it does not normally come into contact with

fluid.

• Flammable, Explosive and Hazardous Applications:

The DRG is not an explosion-proof design. It should not

be used in applications where an explosion-proof

design is required.

• Make a Fail-Safe System: Design a fail-safe system

that accommodates the possibility of sensor or power

failure. In critical applications, KOBOLD recommends

the use of redundant backup systems and alarms in

addition to the primary system.

Specifications

Accuracy: ±3.0% of full scale

Wetted Parts

DRG-11: Bronze, Acrylic, PTFE, Ceramic, NBR

DRG-12: Bronze, PTFE, Ceramic, NBR

DRG-14: 316SS, Acrylic, PTFE, Ceramic, FKM

DRG-15: 316SS, PTFE, Ceramic, FKM

DRG-18: PP, PTFE, Ceramic, NBR

Max. Pressure:

DRG-18: 100 PSIG

DRG-11, 14: 230 PSIG

DRG-12, 15: 580 PSIG

Temperature Range:

-10°F to +176°F

Electrical Protection (all versions):NEMA 4X/IP 65

Electrical (refer to model number table for model codes and

descriptions for each output type)

Output F300

PNP Pulse Output: PNP open collector, 25mA max.

Input Power: 14-28 VDC

Connection: 4 pin, M-12 Micro-DC plug, male

Electrical (continued)

Output L342: 4-20 mA, 2-wire, Rmax < 500 ohms, 24 VDC

Connection: 4 pin, M-12 Micro-DC plug, male

Output L343: 4-20 mA, 3-wire, Rmax < 500 ohms, 24 VDC

Connection: 4 pin, M-12 Micro-DC plug, male

Output L442: 4-20 mA, 2-wire, Rmax < 500 ohms, 24 VDC

Connection: DIN 43650 (Hirschmann) plug

Outputs C34P & C30R

Output C34P: 4-20 mA, 3-wire, Rmax < 500 ohms + 1 PNP

switch

Output C30R: 2 PNP switches

Power Supply: 24 VDC ±20%, 80 mA max.

Display: 3-digit LED

Switch Type: PNP open collector, 24 VDC, 300 mA max.

Connection: 5 pin, M-12 Micro-DC plug, male

PDF Rev. 12/15

DRG_manual_12-15

Page 2

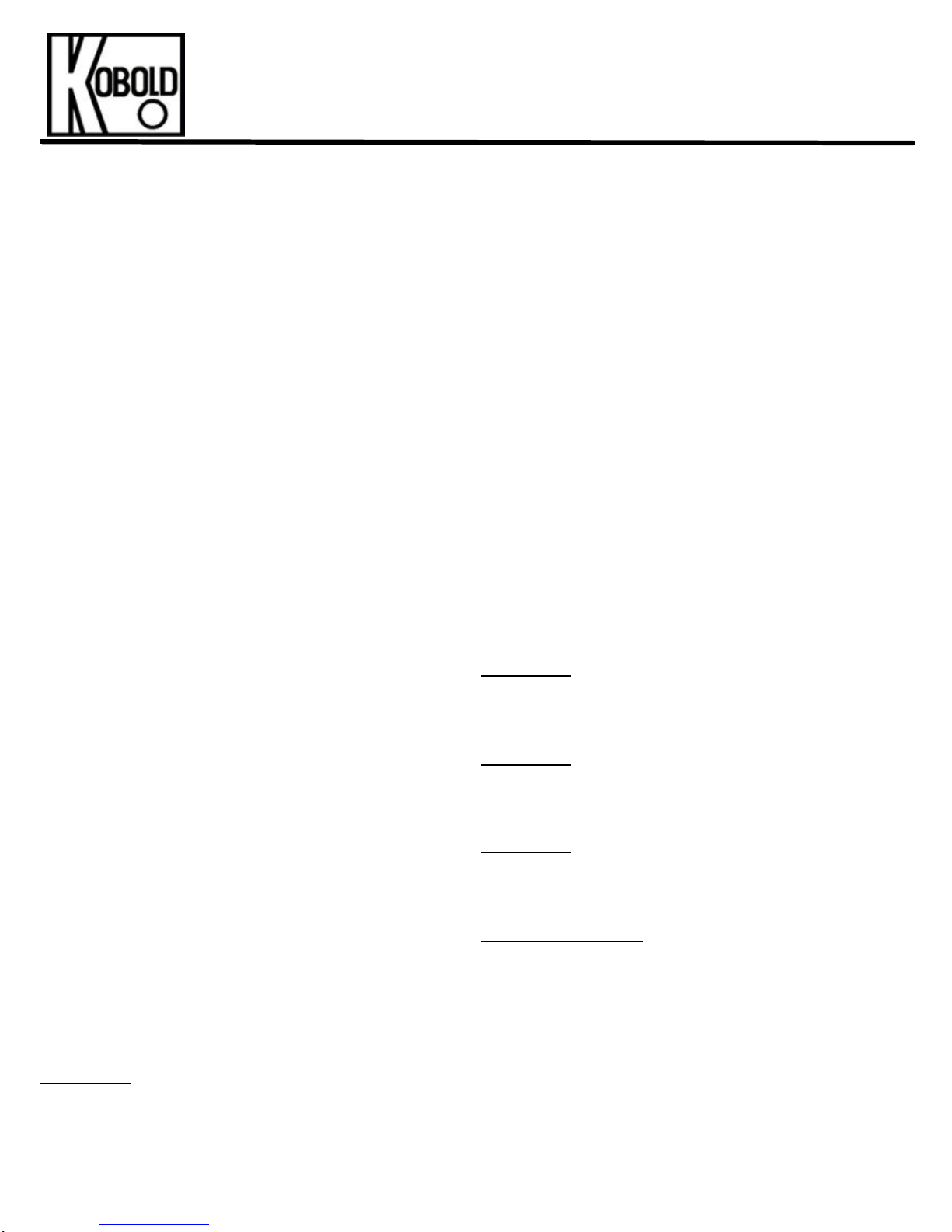

Part Number Decoding

Switch out 2

+ (0)4

-

20 mA

Switch out 1

Switch out 1

Flow Range

GPM Water

0.15 - 3

0.15 - 6.6

0.3 - 8

0.6 - 12

0.8 - 23

1.5 - 37

3 - 37

Part Number 807.037=Mating 4-pin Micro-DC plug with 6 ft. cable for output F300, L342, & L343

Part Number 807.007=Mating 5-pin Micro-DC plug with 6 ft. cable for output C34P, & C30R

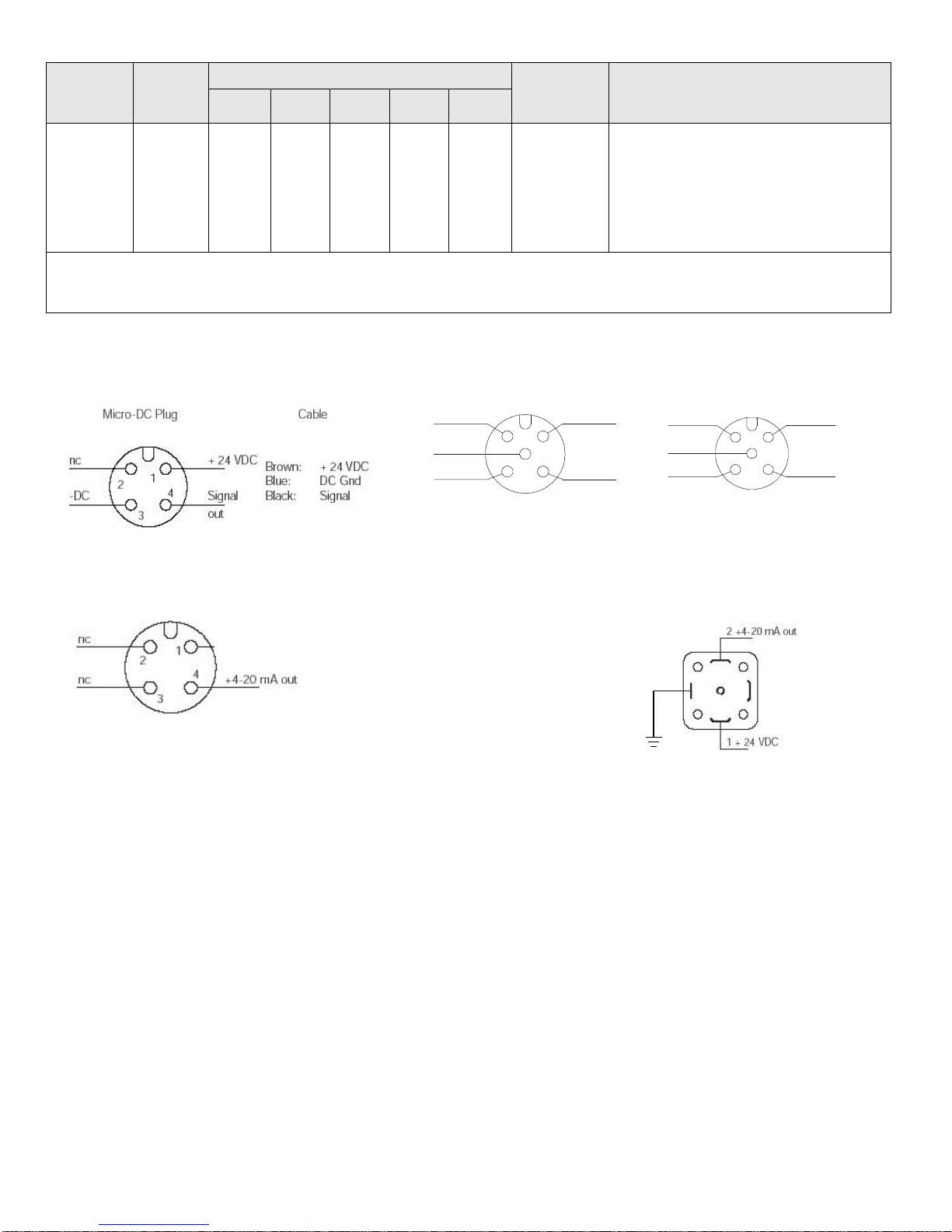

Electrical Connection for Output F300 and L343

Nominal

freq. at

f.s. (Hz)

120

217

184

215

265

180

180

Material Combination & Flow Range Fitting Output/Electronics

DRG-11 DRG-12 DRG-14 DRG-15 DRG-18

..50

..55

..60

..65

..70

..75

..80

(3-wire transmitters)

..50

..55

..60

..65

..70

..75

..80

..50

..55

..60

..65

..70

..75

..80

..50

..55

..60

..65

..70

..75

..80

Accessories

..50

..55

..60

..65

..70

..75

..80

N2=1/4” NPT

N4=1/2” NPT

N5=3/4” NPT

N6=1” NPT

F300=Frequency output, Micro-DC plug

L342=4-20 mA, 2 wire, Micro-DC plug

L343=4-20 mA, 3 wire, Micro-DC plug

L442=4-20 mA, DIN 43650 plug

C34P=Compact Electronics,

C30R=Compact Electronics,

N1=1/8” NPT

Electrical Connection for Output C30R & C34P

(5-wire Micro-DC plug)

Cable: Brown= Pin 1; White= Pin 2; Blue= Pin 3; Black= Pin 4; Gray= Pin 5

GND

GND

24 VDC power

+

1

2

3

4

5

GND

GND

C30R

4-20 mA w/1 PNP switch

2 PNP switches

+ 24 VDC power

2

3

1

4

5

C34P

Electrical Connection for Output L342

(2-wire 4-20 mA)

+24 VDC

Mechanical Installation

Piping Preparation: Piping should be rigidly supported at both

the inlet and outlet of the sensor to prevent potential damage

due to excessive stress on the sensor fittings.

Horizontal flow direction with piping positioned above the flow

body is recommended to minimize trapped air, which can

cause output fluctuations and meter inaccuracy.

Additionally, be sure that the axle is always positioned in the

horizontal plane to minimize friction, otherwise, meter

inaccuracy and excessive paddle wheel wear can result.

In order to ensure that the fluid flow profile is fully developed

and symmetrical, a minimum straight pipe run of 20 nominal

pipe diameters upstream and 5 diameters downstream of

the sensor are required. These straight runs should be free of

tees, elbows, valves, reducers and other disturbances.

Pumps: All pumps cause pulsations in the fluid. Centrifugal

pumps cause the least amount of pulsations in the fluid and

positive displacement or reciprocating pumps cause the most.

In order to minimize the effect of these pulsations on sensor

accuracy, the sensor should be located as far away from the

pump as possible. A pulsation dampener or accumulator may

be used to dampen pulsations if required. If the fluid pulsations

cannot be reduced to an acceptable level, a field calibration to

determine the new K-factor for the sensor installed in a

pulsating system may be required.

Cable

Pin 1 = Brown = +24 VDC

Pin 4 = Black = 4-20 mA out

Electrical Connection for Output L442

(2-wire 4-20 mA)

Viscosity: All flow range and calibration data assume

water as the flow media. All paddle type transducers

are affected by viscosity and higher viscosities tend to

make the paddle wheel turn slower for a given flow

rate. This results in a lower K-factor when the sensor

is used with a viscous media (i.e. viscosity > 10 cSt.)

and the calibration data provided for water flow is no

longer valid. If the sensor is to be used with viscous

media, a field calibration is required to determine the

new K-factor for the sensor.

Field calibration: For frequency output versions, a

simple field calibration may be performed to determine

a new K-factor when the sensor is to be used in a

manner in which the above specified calibration

information does not apply (i.e. use with viscous or

pulsating media, insufficient straight run, etc.). With

the sensor installed in the system, dispense a known

quantity of the fluid to be measured while using a

pulse counter to count the number of pulses

generated during the dispense. This information can

then be used to determine the new K-factor specific to

your system and fluid. 4-20mA output and / or

Compact Electronic versions have a preset output

span that is not field adjustable.

Loading...

Loading...