Page 1

Operating Instruction

for

Turbine-wheel Flow Meter

Model: DRB-...

Page 2

DRB

Page 2 DRB K04/0318

1. Contents

1. Contents ........................................................................................................ 2

2. Note .............................................................................................................. 3

3. Instrument Inspection .................................................................................... 3

4. Regulation Use .............................................................................................. 3

5. Operating Principle ........................................................................................ 4

6. Mechanical Connection ................................................................................. 4

7. Electrical connection ..................................................................................... 7

8. Commissioning – Evaluation Electronics .................................................... 10

9. Maintenance ............................................................................................... 10

10.Technical Data ............................................................................................ 11

11.Order Details ............................................................................................... 14

12.Dimensions (mm) ........................................................................................ 15

13.EU Declaration of Conformance .................................................................. 18

Manufactured and sold by:

Kobold Messring GmbH

Nordring 22-24

D-65719 Hofheim

Tel.: +49(0)6192-2990

Fax: +49(0)6192-23398

E-Mail: info.de@kobold.com

Internet: www.kobold.com

Page 3

DRB

DRB K04/0318 Page 3

2. Note

Please read these operating instructions before unpacking and putting the unit

into operation. Follow the instructions precisely as described herein.

The devices are only to be used, maintained and serviced by persons familiar

with these operating instructions and with the prevailing regulation applying to

safety and the prevention of accidents.

When used in machines, the measuring unit should be used only then when the

machines fulfil the EC-machine guide lines.

PED 2014/68/EU

In acc. with Article 4 Paragraph (3), "Sound Engineering Practice", of the

PED 2014/68/EU no CE mark.

Table 8, Pipe, Group 2 dangerous fluids

3. Instrument Inspection

These devices are checked before shipping and sent out in perfect condition.

Should damage to a device be visible, we recommend a thorough inspection of

the delivery packing. In case of damage, please inform your parcel service/

forwarding agent immediately, since they are responsible for damages during

transit.

Scope of delivery:

Turbine-wheel Flow Meter, Model: DRB

Operating Instructions

4. Regulation Use

The “turbine-wheel flow meter, model DRB“, is to be installed only in specified

applications. Any usage which exceeds the specifications is considered to be nospecified, and would also invalidate the warranty. Any damages resulting

therefrom are not the responsibility of the manufacturer. The user assumes all

risk for such usage. The application specifications include the installation, start-up

and service requirements specified by the manufacturer.

Page 4

DRB

Page 4 DRB K04/0318

5. Operating Principle

The KOBOLD flow meter model DRB is used for measuring and monitoring

liquids. The device works according the well-known paddle wheel principle.

The four vane paddle wheel is retained radially in a high quality sapphire bearing.

The sensor is supplied ready-to-install with pipe fittings or with weld-on sleeves.

The paddle wheel is set in motion by the flowing medium. Magnets are

embedded hermetically sealed in the ends of the blades. The magnets generate

electrical pulses in a Hall-effect sensor mounted outside the flow area. Various

electronics units can be used to display and monitor the volumetric flow.

6. Mechanical Connection

6.1. Examine operating conditions:

Flow volume

Max. operating pressure

Max. operating temperature

Ensure that they are all within the limits of the device

Attention! Over-ranging may cause bearing damage and considerable

measurement errors.

6.2. Installation

Flow in the direction of the pointing arrow (position independent)

Pressure and tensile loading should be avoided

The inlet and outlet should be secured at a distance of 50 mm mechanically

from the connection.

Check the sealing of connections/joints

Page 5

DRB

DRB K04/0318 Page 5

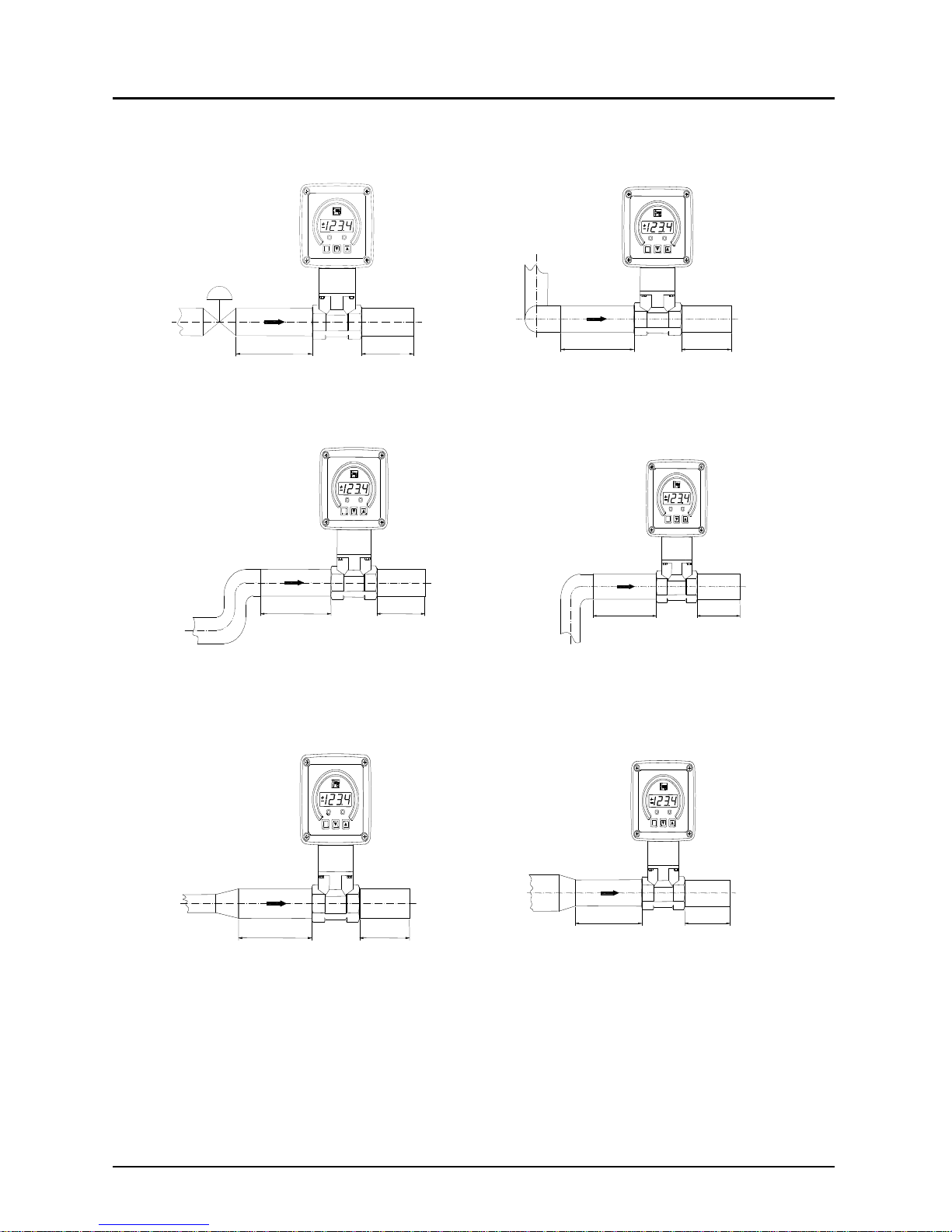

6.3. Inlet and outlet path straight piping requirements

P

50 x D 5 x D

Control valve

P

40 x D

5 x D

3 - dimensi onal

2 x 90°- el bow

P

25 x D 5 x D

2 x 90°- elbow

P

20 x D 5 x D

90°- el bow or

T - pi ece

P

18 x D 5 x D

Ext ent i on

P

15 x D 5 x D

Reducti on

Page 6

DRB

Page 6 DRB K04/0318

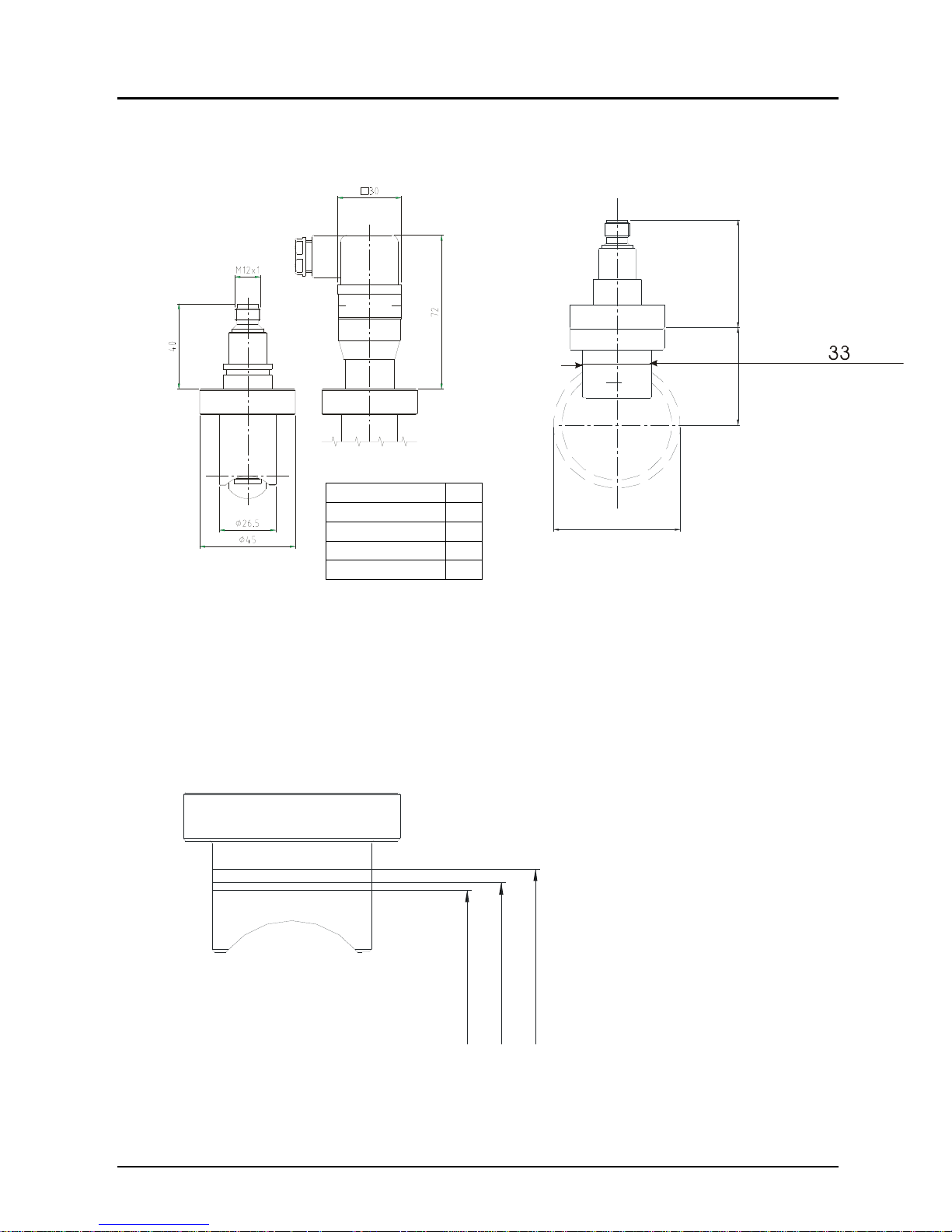

Version with weld-on mounting adapter

Weld the mounting adapter in the piping according to the sketch given below.

Position and weld-in the mounting adapter according to the nominal diameter

suitable marking. The marking on the adapter must be in line with the outer

diameter of the pipe. Also pay attention to the later position of the rotating vane

(shaft of the vane shifted by 90° to the direction of flow).

for DN 40

for DN 80

for DN 50

Nominal Size H

DN 25 30

DN 40 44

DN 50 46

DN 80 63

51

H

Nominal diameter

A

dapter

Ø

±

0,3

Page 7

DRB

DRB K04/0318 Page 7

7. Electrical connection

7.1. General

Attention! Make sure that the power supply voltage corresponds with the

voltage requirement of the flow meter.

Ensure that power supply is de-energized

Connect the power supply and the output signal to the plug-pins, as shown

below.

We recommend a cross-section of 0.25 mm² for the power supply cable.

Attention! Incorrect wiring may cause permanent damage to the sensor.

Page 8

DRB

Page 8 DRB K04/0318

7.2. Output Electronics:

Frequency output (..F300; ..F320, ..F340)

1

2

3

4

+Vs

Signal

Out

n.c.

GND

7.3. Output Electronics:

Analogue output (..L303, ..L342, ..L343, ..L442)

3-wire (..L303, ..L343)

1

2

3

4

+Vs

Signal

Out

n.c.

GND

+Vs

GND

2-wire (..L342)

1

2

3

4

S+

S-

n.c.

n.c.

+Vs

GND

Page 9

DRB

DRB K04/0318 Page 9

2-wire, DIN-plug (..L442)

+Vs

GND

1

2

3

S+

S-

PE

n.c.

7.4. Compact Electronics:

(..C30R, ..C30M, ..C34P, ..C34N)

see

Instruction Manual-Supplement

for Compact Electronics

7.5. Evaluation electronics: Pointer indication (..Z300, ..Z340)

1

2

3

4

+Vs

Signal

Out

n.c.

GND

+Vs

GND

Caution! If the current output is not needed, PIN 4 (signal out) shall be

permanently connected to ground (GND) (short circuit).

Page 10

DRB

Page 10 DRB K04/0318

7.6. ADI electronics

see

Instruction Manual-Supplement

for ADI-electronics

8. Commissioning – Evaluation Electronics

8.1. General

The Measuring units factory are pre-set and are ready for use after electrical

connections are made.

8.2. Adjustment – Compact electronics

see

Instruction Manual-Supplement

for Compact electronics with Frequency output

8.3. Adjustment – ADI display/controller

see

Instruction Manual-Supplement

for ADI-series display/controller

9. Maintenance

The measuring unit is maintenance-free if the medium to be measured does not

cause deposition of impurities. In order to avoid problems, we recommend

installation of a filter, such as magnet filter, model MFR.

Should cleaning of the sensor becomes inevitable, after opening the sensor the

inner parts may be accessed. Note the direction that the turbine points during

removal and re-install in the same direction. Please be careful to avoid any

damage to the sensor and in particular, to the turbine blades. Repair work

regarding electronics may only be carried out by the supplier. Any access or work

on the electronics voids the warranty.

Page 11

DRB

DRB K04/0318 Page 11

10. T echnical Data

10.1. Sensor data

Measuring range: 50-30...50-750 L/min Water

Measuring accuracy: ±3% of. f.s.

Process temperature: max. 80 °C

Ambient temperature: max. 80 °C

Max. operating pressure: PN 16 / 20 °C

Max. pressure loss: DRB-...05: 0.05 bar

DRB-...10. DRB-..15: 0.03 bar

DRB-...20: 0.04 bar

DRB-...25: 0.02 bar

DRB-...30: 0.01 bar

Protection: IP65

Materials

Housing: brass casting

st. steel 1.4581

st. steel 1.3955 (DRB...W)

Sealings: brass casting version: NBR

st. steel version: FPM

Turbine-wheel: PVDF

Axle: hard metal (DRB-11... and DRB-12...)

ceramic (DRB-1300...)

Bearing: ceramic (DRB-11... and DRB-12...)

ceramic/PEEK (DRB-1300...)

10.2. Evaluation electronics

Frequency output (F...300)

Power supply: 12 – 28 V

DC

Power consumption: 10 mA

Pulse output: PNP, open collector, max. 25 mA

Electrical connection: plug connector M12x1

Frequency output with frequency divider

Power supply: 24 V

DC

±20 %

Power consumption: 15 mA

Pulse output: PNP, open collector, max. 25 mA

Electrical connection: Plug M12x1

Division ratio: 1...1/128, factory set

Page 12

DRB

Page 12 DRB K04/0318

Analogue output (plug-on display option)

Power supply: 24 VDC ±20%

Output: 0-20 mA or 4-20 mA, 2-wire or 3-wire

Max. load: 500

Electrical connection: plug connector M12x1 or DIN 43 650

Option: plug-on display

(with plug connection DIN 43 650, 2-wire)

Compact electronics

Display: 3-segment LED

Analogue output: (0)4 -20 mA adjustable, max. 500 W

Switching outputs: 1 (2) semiconductor PNP or NPN, factory set

Contact operation: N/C / N/O contact programmable

Setting: with 2 buttons

Supply: 24 VDC ±20%, 3-wire technology,

approx. 100 mA

Electrical connection: plug connector M12x1

Pointer indication with analogue output

Housing: Aluminium

Display: moving-coil instrument,

240° display

Power supply: 24 VDC ±20 %

Output: 4-20 mA or 0-20 mA/0-10 V,

3-wire

Max. load: 250

Electrical connection: plug connector M12x1

ADI electronics

Display: bar graph, 5-digit digital display; batching unit

Analogue output: (0)4...20 mA, 0-10 V

DC

2 switching outputs: relay/changeover contact

max. 250 V

AC/5 A

resistive load, max. 30 VDC/5 A

Setting: with 4 buttons

Power supply: 100...240 V

AC ±10% or

18...30 VAC/10...40 V

DC

Electrical connection: pluggable terminal block via

cable gland

Page 13

DRB

DRB K04/0318 Page 13

DRB-...Exxx (Counter elektronic)

Display: LCD, 2 x 8 digit, illuminated

total, part and flow quantities

units selectable

Analogue output: 0(4)...20 mA adjustable

Load: max. 500

Switching output: 2 relays, max. 250 V / 5 A /1000 VA

Settings: via 4 buttons

Functions: reset, MIN/MAX memory, flow monitor,

monitoring for part and total quantity,

language

Power supply: 24 VDC ± 20 %, 3-wire

Power consumption: approx. 170 mA

Electrical connection: pluggable terminal block via

cable gland

DRB-...Gxxx (Dosing electronic)

Display: LCD, 2 x 8 digit, illuminated

total, part and flow quantities

units selectable

Analogue output: 0(4)...20 mA adjustable

Load: max. 500

Switching output: 2 relays, max. 250 V / 5 A / 1000 VA

Settings: via 4 buttons

Functions: dosing (relay S2), start, stop, reset,

fine dosing, correction amount,

flow switch, total quantity, language

Power supply: 24 VDC ± 20 %, 3-wire

Power consumption: approx. 170 mA

Electrical connection: pluggable terminal block via

cable gland

Page 14

DRB

Page 14 DRB K04/0318

11. Order Details

example: DRB-1105 G4 F300

With pipe fitting

Evaluating electronics

Frequency output

..F300= Frequency output, plug connector M12x1

..F320= Frequency divider 1:2 plug connection M12x1

..F340= Frequency divider 1:4, plug connector M12x1

..F390= Frequency divider 1…1/128 plug connector M12x1

Analogue output

..L303= 0-20 mA output, 3-wire, M12x1 plug connector

..L342= 4-20 mA output, 2-wire M12x1 plug connector

..L343= 4-20 mA output, 3-wire, M12x1 plug connector

..L442= 4-20 mA output, 2-wire, plug connection DIN EN 175301

Compact electronics*

..C30R= LED display, 2xOpen Collector, PNP, plug connector M12x1

..C30M= LED display, 2xOpen Collector, NPN, plug connection M12x1

..C34P= LED display, 4-20 mA, 1x Open Collector PNP,

plug connector M12x1

..C34N= LED display, 4-20 mA, 1xOpen collector NPN,

plug connector M12x1

Pointer indication, 240°*

..Z300= 240° pointer indication, 0-20 mA, plug connector M12x1

..Z340= 240° pointer indication, 4-20 mA, plug connector M12x1

Counter electronics

..E34R = LCD, 0(4)-20 mA, 2 x relays

Dosing electronics

..G34R = LCD, 0(4)-20 mA, 2 x relays

ADI electronics*

Measuring range

max. 3 m/s

Flow rate

max. 10 m/s

Model Connection

(L/min

water)

app.

frequency

(Hz) f. s.

(L/min water)

Mat. brass

casting

Material

st. steel

Standard

fem. Thread

Special

fem. thread

5-30

40 100

DRB-1105.. DRB-1205.. ..G4..= G 1/2 ..N4..= 1/2 NPT

10-50

40 180

DRB-1110.. DRB-1210.. ..G5..= G 3/4 ..N5..= 3/4 NPT

20-80

65 230

DRB-1115.. DRB-1215.. ..G6..= G 1 ..N6..= 1 NPT

25-250

85 600

DRB-1120.. DRB-1220.. ..G8..= G 1 1/2 ..N8..= 1 1/2 NPT

30-350

80 1000

DRB-1125.. DRB-1225.. ..G9..= G 2 ..N9..= 2 NPT

50-750

70 1600

DRB-1130.. DRB-1230.. ..GB..= G 3 ..NB..= 3 NPT

With installation adapter

not available with compact or ADI electronics

Meas.

range

(m/s)

approx.

frequency

(Hz) at

max. value

Max.

flow rate

(m/s)

Model

Connection

for nominal pipe size

..W6.. = DN 25

..W8.. = DN 40 / DN 50

..WB.. = DN 80

Material

1.3955

axle hard metal

Material

1.3955

axle ceramic

Display Power supply Output Contacts

0.7-3

0.3-3

0.3-3

0.2-3

50 (at DN 25)

85 (at DN 40)

80 (at DN 50)

70 (at DN 80)

10

DRB-1200.. DRB-1300..

K..= Bargraph/

Digital

display

0=100-240 V

AC/DC

3= 18-30 VAC,

10-40 V

DC

0= without

4= 0(4)-20 mA,

0-10 V

2= 2 change-

over contacts

*Please specify flow direction in writing

Plug-on display

For model DRB...L442 (with 2-wire, 4-20mA output and DIN plug connector)

Description Order number

4-digit LED,

connector DIN 43650,

2-wire, supply through analogue output

AUF-1000

as above

however with additional open

collector output

AUF-1001

Page 15

DRB

DRB K04/0318 Page 15

12. Dimensions (mm)

Model: DRB-...L3.. / DRB- F..

(with analogue output)

H

40

SW

51

B

G

M 12x1

Model: DRB-..L4..

(with analogue output and optional plug-on display)

G SW B H

G 1/2, 1/2 NPT 27 78 40

G 3/4, 3/4 NPT 41 78 42

G 1, 1 NPT 41 78 42

G 1 1/2, 1 1/2 NPT 55 78 57

G 2, 2 NPT 70 81 58

G 3, 3 NPT 100 106 75

Page 16

DRB

Page 16 DRB K04/0318

Model: DRB-..C.. (with Compact electronics)

Model: DRB-..Z.. (with pointer indication)

OBOLD

73

6,6

G

B

H98

SW

51

G SW B H

G 1/2, 1/2 NPT 27 78 40

G 3/4, 3/4 NPT 41 78 42

G 1, 1 NPT 41 78 42

G 1 1/2, 1 1/2 NPT 55 78 57

G 2, 2 NPT 70 81 58

G 3, 3 NPT 100 106 75

Page 17

DRB

DRB K04/0318 Page 17

Model: DRB-..K,..G.., ..E..

(with ADI evaluating electronic, counter or dosing electronic)

G SW B H

G 1/2, 1/2 NPT 27 78 40

G 3/4, 3/4 NPT 41 78 42

G 1, 1 NPT 41 78 42

G 1 1/2, 1 1/2 NPT 55 78 57

G 2, 2 NPT 70 81 58

G 3, 3 NPT 100 106 75

Page 18

DRB

Page 18 DRB K04/0318

13. EU Declaration of Conformance

We, KOBOLD-Messring GmbH, Hofheim-Ts, Germany, declare under our sole

responsibility that the product:

Turbine-wheel flow meter Model: DRB -...

to which this declaration relates is in conformity with the standards noted below:

EN 61000-6-4:2011

Electromagnetic compatibility (EMC) - Part 6-4: Generic standards - Emission

standard for industrial environments

EN 61000-6-2:2005

Electromagnetic compatibility (EMC) - Part 6-2: Generic standards - Immunity for

industrial environments

EN 61010-1:2010

Safety requirements for electrical equipment for measurement, control and

laboratory use - Part 1: General requirements

EN 60529:2014

Degrees of protection provided by enclosures (IP Code)

EN 50581:2012

Technical documentation for the assessment of electrical and electronic products

with respect to the restriction of hazardous substances

Also the following EC guidelines are fulfilled:

2014/30/EU EMC Directive

2011/65/EU RoHS

Hofheim, 08 March 2018

H. Peters M. Wenzel

General Manager Proxy Holder

Loading...

Loading...