Page 1

K03/1213

Manufactured and sold by:

Kobold Messring GmbH

Nordring 22-24

D-65719 Hofheim

Tel.: +49(0)6192-2990

Fax: +49(0)6192-23398

BI-DIRECTIONAL INSERTION FLOW TRANSDUCER

Model DOR

INSTRUCTION MANUAL

KOBOLD

LOCK

Page 2

IMPORTANT INFORMATION

Thank you for purcha

sing a Kobold Insertion Flowmeter. It is important that you

read this manual to gain a full understanding of the capability and operational

aspects of the equipment you are about to install.

This information is provided only to assist in the installation of the product and

does not diminish your obligation to read the manual.

1. Select a location that meets the requirements as illustrated on the guideline

sheet (please see the data sheet/order codes). An ideal installation would provide

for 25 diameters of straight pipe upstream from the meter and 10 diameters

downstream.

You will also need to know the pipe internal diameter (NB) and pipe wall thickness

for calculation of the insertion depth. (refer page 5.) Non ideal installations may

require in-situ calibration (refer to the factory for details).

2. After screwing the flowmeter in place ensure the flow alignment mark located

on the top positioning collar of the meter aligns with the flow in the pipe (refer

page 5). This ensures the paddle is correctly aligned to the flow.

Note. the meter is bi-directional so a flow direction arrow is not provided.

3. Calculate and adjust the height of the flowmeter (refer page 5).

4. Electrical Installation depends on the model you have purchased.

If the dualpulse is fitted or supplied with a receiving instrument such as a totaliser

or rate totaliser please refer to the appropriate manual and page 10 of this

manual. For pulse output meters, select the appropriate output and wire to your

receiving device. (refer pages 7 to 9).

5. Calculate the flowmeter K (scale) factor to suit the installation. For ideal

installations refer to page 11 or 12 or 13 of the flowmeter Manual. For non ideal

installations the K-factor may be calculated by performing an in-situ calibration.

Enter the appropriate K-factor into your receiving instrument.

page 1

CONTENTS PAGE

1.0 INTRODUCTION

1.1 Model number designation

1.2 Overview

1.3 Operating principal 3

1.4 Specifications 3

2.0 INSTALLATION

2.1 Meter location

2.2 Meter installation & orientation 4

2.3 Height adjustment 5

2.4 Flow direction orientation 5

2.5 Hot tap installations 6

3.0 ELECTRICAL CONNECTIONS

3.1 Standard outputs 7

3.2 Optional Reed switch output 7

3.3 Instrument cable installation requirements 8

3.4 Pulse output selection ( standard outputs ) 8

3.5 QP Quadrature pulse output option 9

3.6 Bi-directional flow using QP option 9

3.7 Connection to family instruments 10

4.0 K – FACTOR ( calibration factor for meter )

4.1 K-factors for common pipe ID sizes <575mm 11

4.2 K-factors for large pipe ID >460mm 11

4.3 Calculating K-factors ( metric units – litres or M3 ) 12

4.4 Calculating K-factors ( US gallons )

5.0 Declaration of Conformance

3

4

12

14

Page 3

Page 2

1.1 Model no. designation

Please see the data sheet

1.2 Overview

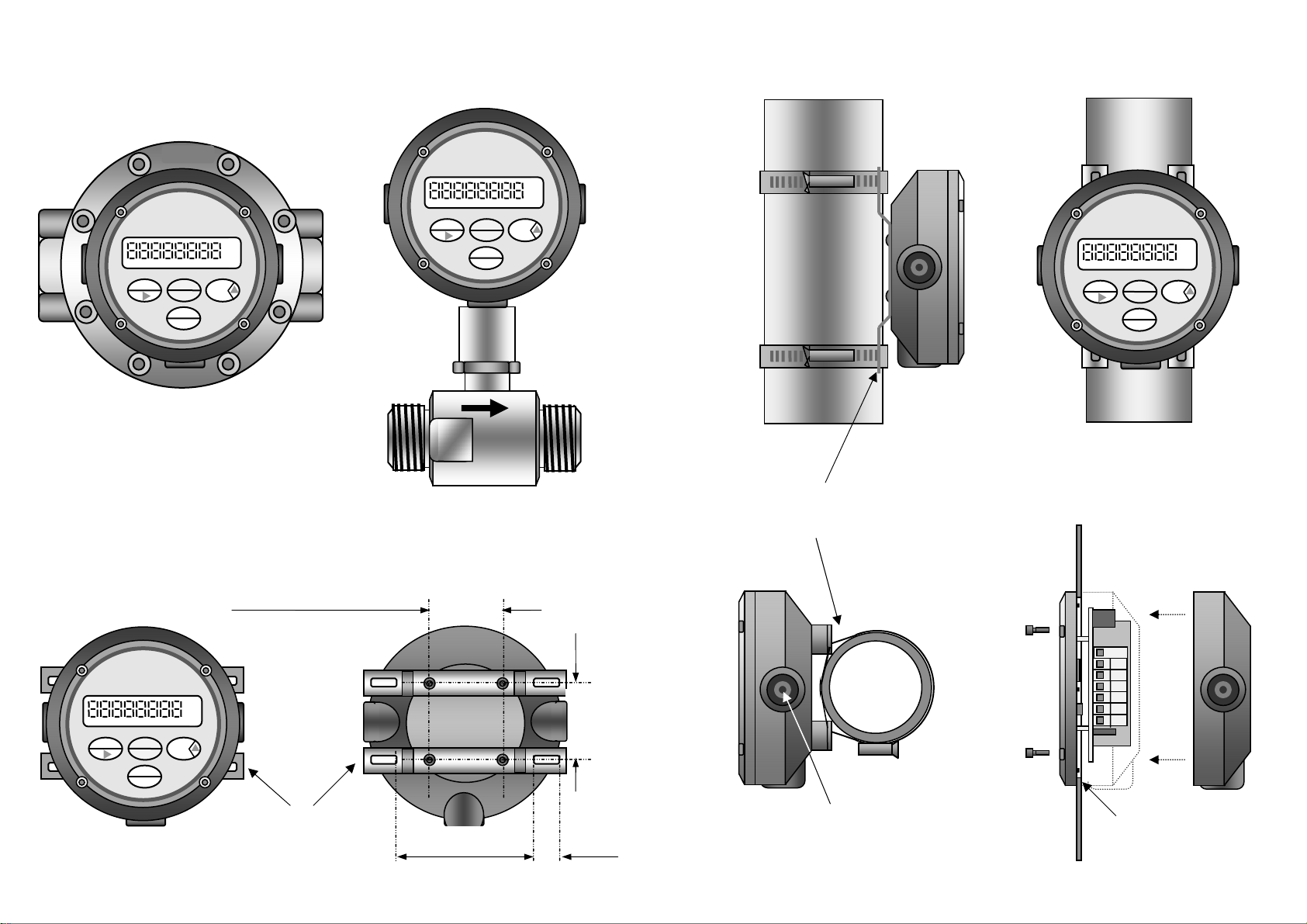

Kobold insertion flow transducers provide a cost effective and simple means of measuring

the flow of a wide range of low viscosity liquids. Installation is quick and inexpensive for

pipe diameters ranging from 40mm to 900mm (1.5-36") and up to 2500mm (100") nominal

bore for the Hot tap capable model DOR-52.

The flowmeter has a linear measuring range of 0.3~10.0 metres/sec. (1~33 ft/sec.).

Minimum detectable flow velocity is 0.15 m/sec. (0.5 ft/sec.). When used in conjunction with

the ZOD-Z3 flow rate totaliser NLC feature the linear flow range is extended down to 0.15

m/sec. (0.5 ft/sec.) with an improved linearity.

The flowmeter is constructed from 316 L (1.4404) stainless steel enabling use in many

applications for metering water and low viscosity chemicals.

Two independent pulse outputs are standard & can directly input to a wide range of

ancillary instruments, PLC’s and computers. Both pulse outputs have a high level of

immunity to electrical interference. Options include a reed switch.

1.3 Operating principle

Flow passes through a pipe causing the rotor to spin. Magnets installed in the rotor pass by

pulse sensors within the transducer body & inturn this produces frequency outputs

proportional to flow rate.

page 3

1.4 Specifications

Velocity measuring range (linear): 0.3...10 m/s equates to approx.0.25...49,000 l/s in

Linearity: ±1.5% with well est. flow profile

Repeatability: ±1% of f. s. at factory conditions and optimal straight

Max pressure: 80 bar

Temperature range: -40…+100°C standard, see max.allowable medium

Material

Body: stainless steel 1.4404 (316L)

Rotor: PVDF or PEEK (depending on model)

Rotor shaft: stainless steel 1.4404 (316L)

Bearing: graphite/PTFE

Seals: FPM (standard): -15…+200°C

EPR (ethylene propylene rubber): -20…+120°C, for

PTFE encapsulated FPM: -20…+200°C

NBR (Nitril): -65…+125°C

Electronics

Output frequency at max. velocity: 220...240 Hz (hall effect and voltage output),

73...80 Hz (reed switch output)

Supply voltage: see electrical output specifications and electronics

Electronic features: see electronics comparison table in the data sheet

Wiring (standard): 5 core, screened cable, length 3 meters

Transmission distance: 1,000 meters maximum, without integrated electronics

Cable entry (terminal box): M20x1.5 (standard), 1/2“ NPT adapter (optional)

Protection Class: IP68 (cable connection),

IP66/67 (all other electrical connections)

Straight piping requirement: Minimum: 10xd (upstream), 5xd (downstream)

Optimal: 25xd (upstream), 10xd (downstream)

Weight: (approx., without electronics):

1.6 kg (DOR-4), 2.5 kg (DOR-5)

DN40 to DN2500 pipes; 0.15...10 m/s when using the

linearisation function of electronic type Z3

runs

temperature table for other options and restrictions

ketones only

comparison table in the data sheet

Page 4

page 4

page 5

2.0 INSTALLATION

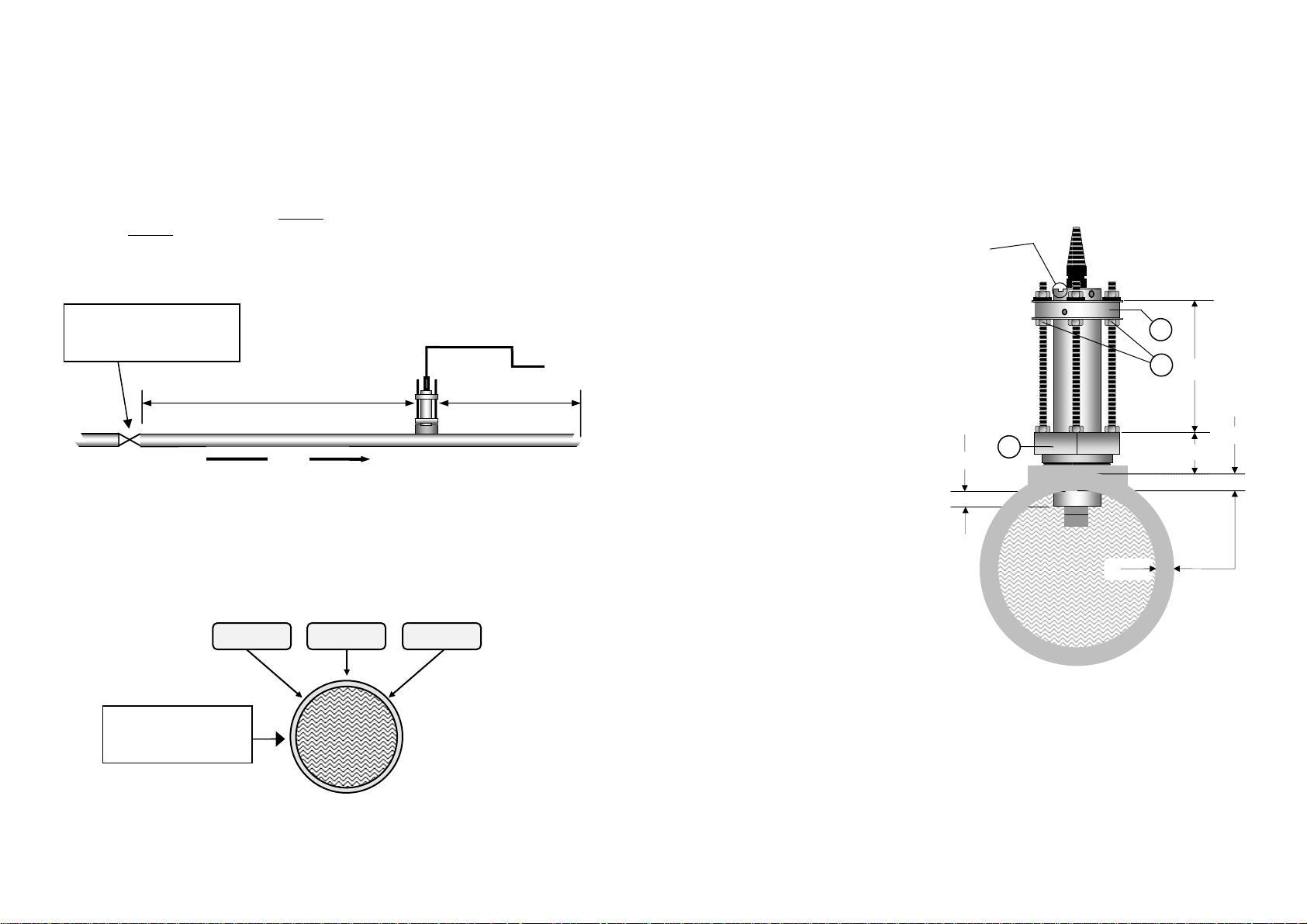

2.1 Meter location

Choose an appropriate section of horizontal or vertical pipe as per the guidelines below.

With vertical pipe installations the media should be pumped up through the pipe past the

flow sensor so that any entrained air will pass freely.

The DOR flow sensor requires a fully developed turbulent flow profile to ensure maximum

measurement accuracy and repeatability. This can be achieved by installing the DOR in a

straight run of pipe. We recommend at least 10 but ideally 25 straight pipe diameters

upstream & at least 5 but ideally 10 pipe diameters downstream of the flowmeter. Major

obstructions such as pumps, valves or strainers will require longer straight runs before and

after the flowmeter.

Major obstructions such as

pumps,valves,reducers or strainers

to be kept well outside the straight

run pipe sections

10 pipe dia. minimum

25 pipe dia. prefered

FLOW

5 pipe dia. min.

10 pipe dia. prefered

2.3 Height adjustment calculation

Calculate the adjustment height A for DOR-42 (or AA for the DOR-52) as follows:

A ( for DOR-42 ) = 175mm ( 6.9") - ( B + C + D )

AA ( for DOR-52 ) = 420mm (16.5") - ( B + C + D )

Where :

B = Distance between the top of the pipe & the top of the hex adaptor.

C = Pipe wall thickness

D = Insertion depth ( pipe ID ÷ 8 )

ALIGNMENT SLOT TO

PARRALLEL PIPE

LOCK

Examples of insertion depth D :

For 40mm pipe ID ( D= 5.0 mm )

For 50mm pipe ID ( D= 6.25 mm )

3

1

A (AA)

For 100mm pipe ID ( D= 12.5 mm )

For 400mm pipe ID ( D= 50.0 mm )

2

D

B

C

2.2 Meter installation & orientation

Cut a 40mm diameter hole (1.6") on either the 2, 10 or 12 o’clock positions of the pipe. If

there is any likelihood of air entrainment in a horizontal pipe do not locate the flow

transducer in the 12 o’clock position.

12 o’clock

2 o’clock

Other positions

around the pipe are

ptable

acce

Install a female threaded weld on fitting (threadolet) or service saddle.

Wrap the threads of the flowmeter with PTFE tape or sealing compound & screw the unit

into the installed fitting.

C

Turn the height adjustment nuts (1) as required so that the distance between the top of the

hex adaptor (2) and the top of the positioning collar (3) equals your calculated distance A

(for DOR-42) or AA for model DOR-52. Retighten the height adjustment nuts (1).

2.4 Flow direction orientation

The unit is bi-directional however the paddle must be aligned with the direction of flow.

Using a 2mm hex key (Allen key), unlock the locking screw located on the positioning collar

(3) then insert the hex key (as a lever) in the body rotating hole located above the collar,

turn the body until the alignment slot is parallel with the direction of pipe. Retighten the

locking screw.

Page 5

page 6

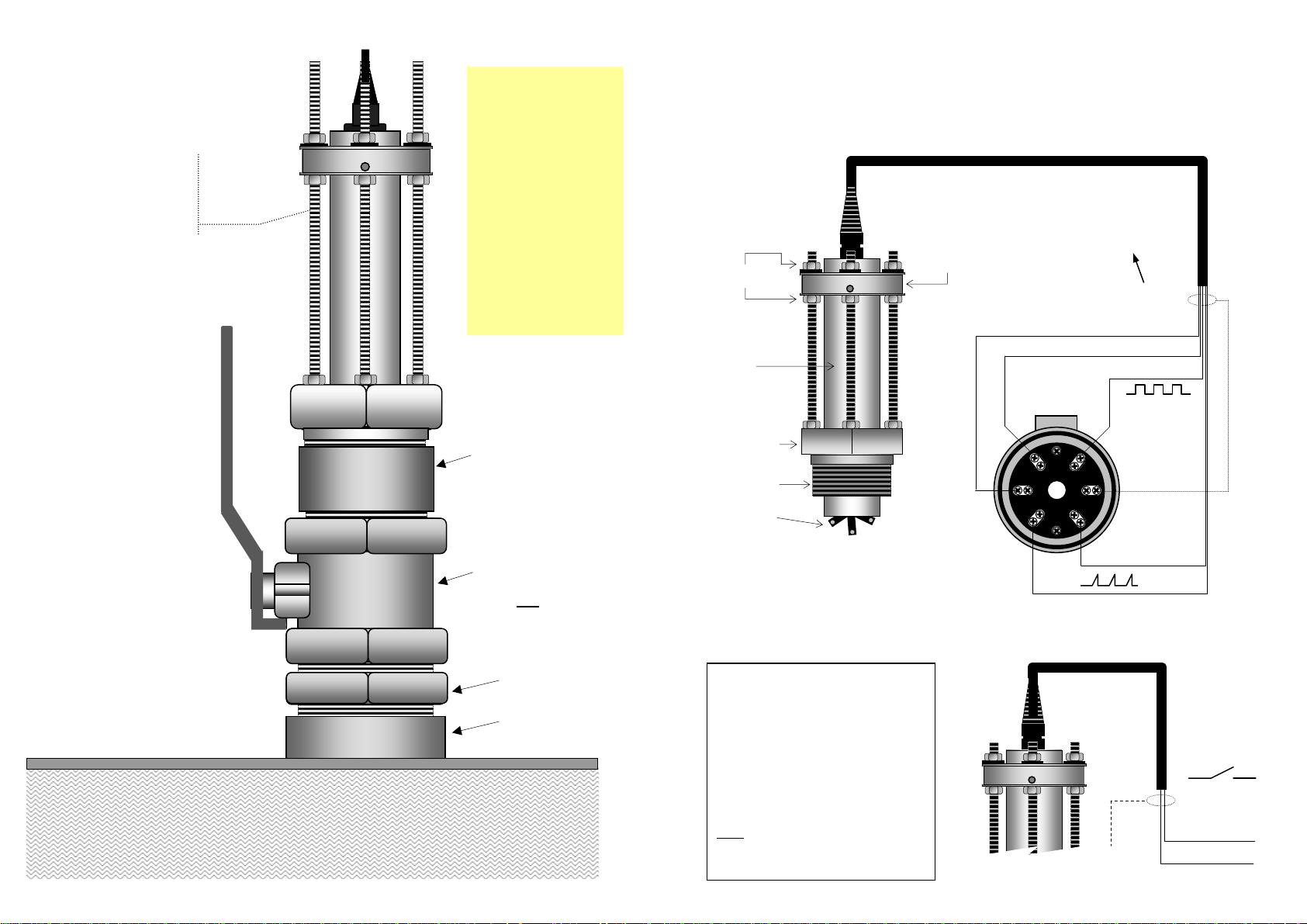

2.5 Hot tap installation

( model DOR-52 )

Clean & lubricate screw

threads before

withdrawing the

transducer body in order

to avoid nut seizure

IMPORTANT

Before removing the

DOR-52 from the

installation first

withdraw the

transducer body to

the maximum

distance allowed by

the three height

adjusting threaded

rods. This will enable

the isolating valve

to be fully closed

without damaging the

paddle.

If necessary extend valve

port using a 2” nipple &

socket combination to

ensure the paddle is clear

of the ball valve.

CAUTION : Hot tap installation

should only be performed by

qualified personal. Installation

procedures should be in accordance

with the safety rules, regulations and

requirements applying to the territory

in which the flow transducer is being

installed.

2" ball or gate

isolation valve.

(Allow min. 40mm I.D. to

clear metering head)

2" Nipple

2" Weld-O-let

( threadolet )

FLOW

Hot tap clearance hole in

pipe wall to be a minimum

of 40mm diameter (1.6").

page 7

3.0 ELECTRICAL CONNECTIONS

( see page 9 for QP outputs )

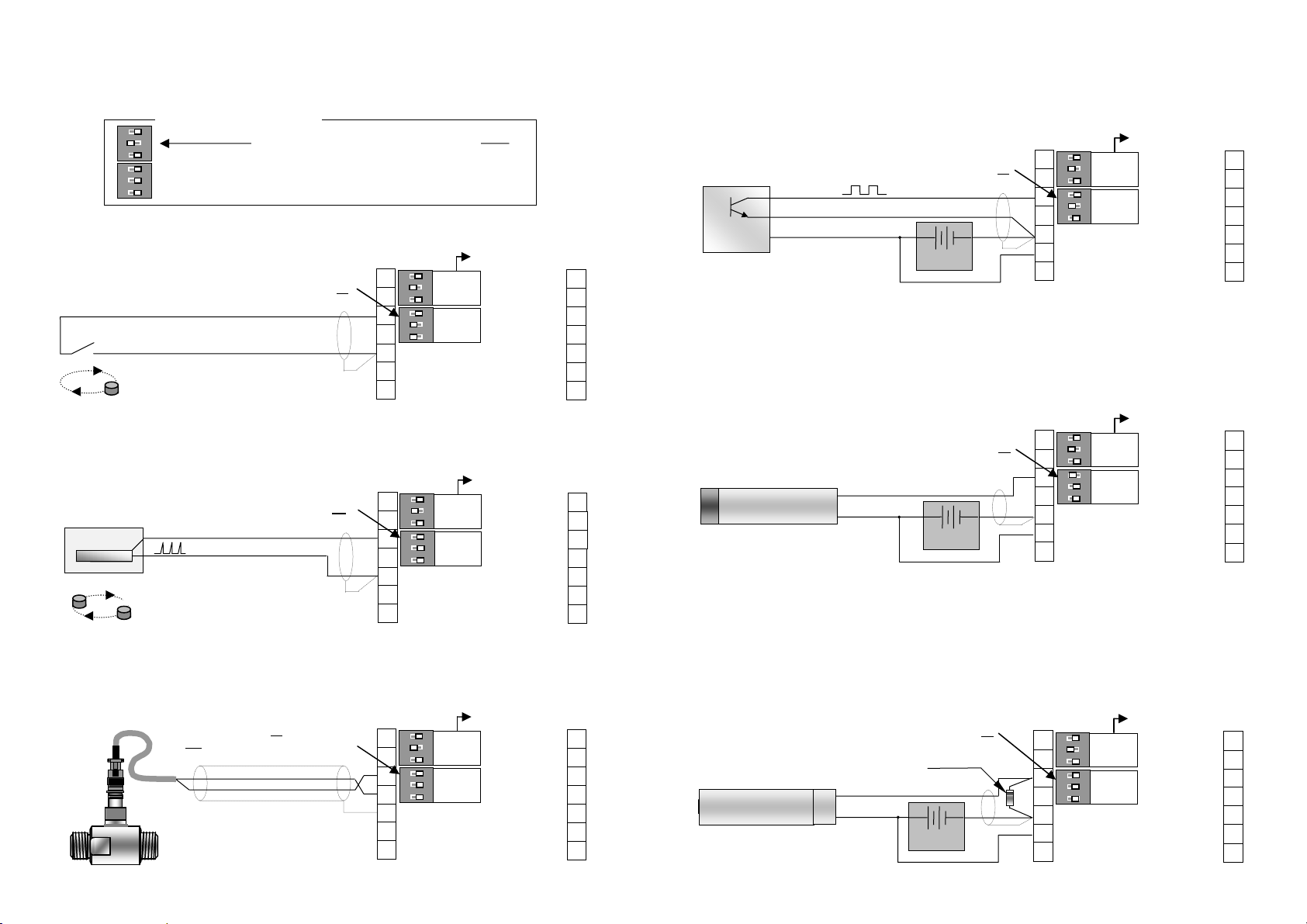

3.1 Standard outpu

ts

Conductor color coding also applies to the Non-magnetic

sensor and high temperature output options

Height

adjustment

Body

KOBOLD

LOCK

Positioning

collar

Pull up resistor

required, they are

generally incorporated

in most receiving

instruments

SQUARE WAVE

PULSE OUTPUT

Black ( -0v ground )

Red ( VDC supply )

White ( + Sig. output )

Hex adaptor

1.5” or 2” BSPT

or NPT

Rotor

Terminal box option

terminal connections

b1

A1

A2

B2 B1

VOLTAGE PULSE

Screen

OUTPUT

Yellow ( + )

Green ( - )

3.2 Optional Reed switch output

The REED SWITCH output is classed as a

“simple apparatus“ as defined in the

CENELEC standard EN50020 &

recognized ATEX directive. It can be

connected to an approved I.S. secondary

instrument with both being located in the

hazardous area.

The Reed Switch may also be connected

through an approved I.S. barrier.

Note: The Reed switch produces 1/3

( eg. 1/3 the standard K-factor )

HAZARDOUS AREAS

the normal pulse output value

KOBOLD

LOCK

rd

Screen

To -0V

REED SWITCH

OUTPUT

Yellow

Green

Page 6

page 8

3.3 Instrument cable installation requirements

Use twisted multi-core low capacitance shielded instrument cable (22 AWG ~ 7x 0.3

stranded) for electrical connection between the flow meter and the remote instrumentation.

The screen should be earthed at the readout instrument end only to protect the transmitted

signal from mutual inductive interference.

The cable should not be run in a common conduit or parallel with power and high inductive

load carrying cables as power surges may induce erroneous noise transients onto the

transmitted pulse signal. Run the cable in separate conduit or with other low energy

instrument cables .

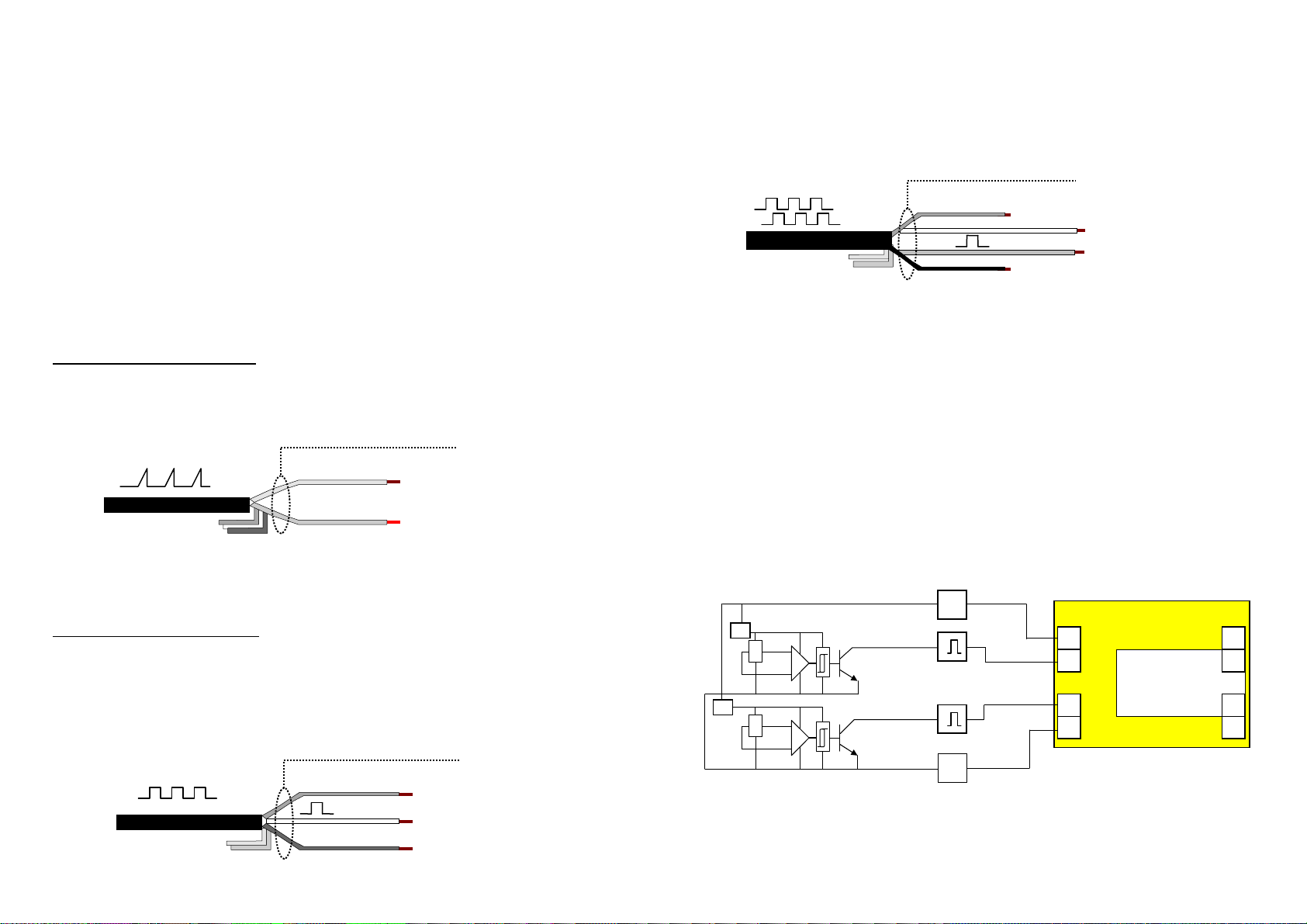

3.4 Pulse output selection ( standard outputs )

The standard flowmeter has two independent pulse output signals that are linearly

proportional to volumetric flow rate. Pulse transmission can be up to 1000 metres (3300 ft ).

An optional I.S. Reed Switch output is available (see page 7).

Voltage pulse (pulse wire) output

A self generating pulse output which produces a strong 1.5 volt voltage spike of

approximately 10 micro/second duration with no dependence on rotor speed.

Screen

Yellow ( + )

Green ( - )

Square Wave Pulse (Hall sensor) ( also applies to non-magnetic & QP Hall outputs )

An NPN open collector transistor pulse output produced by a solid state Hall Effect device.

This three wire device requires 5~24vdc and produces an NPN square wave output (20mA

max. sink), pulse width is 2~75 mSec. The Hall output requires a pull up resistor, these are

generally incorporated in most receiving instruments. For (QP) Quadrature pulse output

refer details page 9.

(5-24vdc supply )

signal output

( -0v ground )

Screen

Red

White

Black

Page 9

3.5 Quadrature outputs

DOR series flow meters supplied with the QP option produce two NPN open collector pulse

outputs from two Hall Effect sensors. The outputs are “ phase offset ” in their timing so that

external electronics are able to differentiate. These outputs may be used to assure output

signal integrity or to measure bi-directional flow.

Red ~ Vdc

Black ~ -0V

Screen

White ~ output 1

Blue ~ output 2

3.6 Bi-directional flow

The DOR flow transducer is capable of accurately measuring flow in both directions without

modification. Meters fitted with the QP output option (quadrature pulse output) may be

interfaced with the Pulse Discriminator Module (PD2). The PD2 accepts the Quadrature

pulse inputs & from these will discriminate between forward & reverse flow. Two individual

& proportional pulse outputs can then be sent to appropriate totalising registers or an Z3

add and subtract flow rate totaliser.

It is important to note that the Quadrature Pulse option has the same pulse resolution

(pulses/unit volume) as a standard flowmeter for both forward & reverse outputs.

Flowmeter with QP outputs

Reg

X

Reg

X

5~24Vdc maximum

Output Signal 1

(forward flow)

Output Signal 2

(reverse flow)

Vdc

+

+

PD2 Pulse Discriminator

10

Sig.1

9

Sig.2

7

6

+Vdc

-0V

+8~24Vdc

Forward flow Sig.

Output signals

Reverse flow Sig.

-0V

5

4

2

1

Ground

-0V

Page 7

page 10

)

)

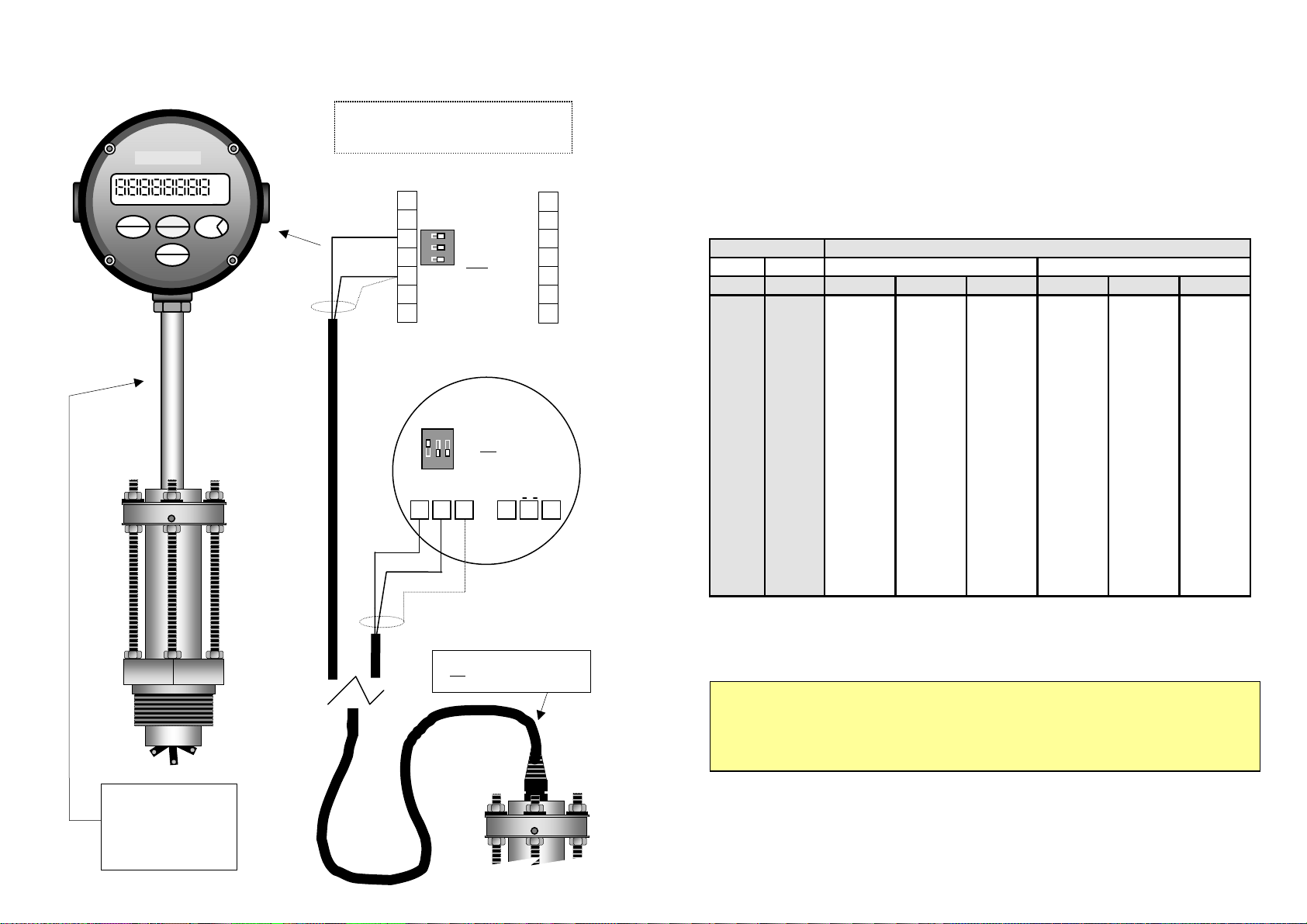

3.7 Voltage Pulse Connection to family instruments

RATE TOTALISER

RUN ACCUM. TOTAL STOP BAT LOW

RESET

PROGRAM

ENTER

>

RATE

TOTAL

ACCUM

TOTAL

gal

^

Note: For other output styles see

receiving instrument manual

Z3 & B1 SERIES

yellow

green

Screen

1

INSTRUMENTS

2

3

3

O

2

N

4

1

-0V (ground)

5

6

7

All flow DIP

switches in the

position

OFF

14

13

12

11

10

9

8

KOBOLD

LOCK

yellow

green

Z1 TOTALISER

ON

1 2 3

1 2 3

-

+

1 2 3

DIP switch 1 in

the ON

position

( 2 Khz max.)

gnd

+Vdc

4 5 6

+∏

-gnd

Screen

The flowmeter cable should

not

be run with other high

energy cables ( clause 3.3 ).

Flow instruments or a

terminal box can be

directly mounted to the

flowmeter using ST4 (for

DOR-42) or ST5 (DOR-

52) mounting stem kits

FLOMEC

LOCK

page 11

4.0 K – FACTORS ( calibration factors for meter )

The K-factor (pulses / litre, gallon etc.) will vary in relation to the bore size of the pipe in

which the flowmeter is installed.

The K-factors and formula shown are a result of factory testing using smooth bore piping

under ideal conditions. Variations to the given K-factors may occur when using rough bore

piping or inadequate flow conditioning on either side of the flow transducer (refer clause

2.1). In these instances on site calibration may be used to determine the K-factor.

4.1 Flow transducer K- factors for common pipe sizes

Pipe detail

NB ID (#40)

K-factors

Schedule 40 pipe - (#40

inches mm p / litre p / m3 p / USgal p / litre p / m3 p / USgal

1.5" 40.9 18.678 18678 70.695 21.524 21524 81.468

2" 52.6 11.238 11238 42.534 12.818 12818 48.517

2.5" 62.7 7.880 7880 29.824 8.899 8899 33.682

3" 78.0 5.062 5062 19.161 5.676 5676 21.485

3.5" 90.2 3.768 3768 14.263 4.200 4200 15.896

4" 102 2.912 2912 11.021 3.233 3233 12.237

5" 128 1.839 1839 6.959 2.025 2025 7.665

6" 154 1.268 1268 4.798 1.402 1402 5.307

8" 203 0.719 719.0 2.721 0.787 787.2 2.980

10" 255 0.450 450.3 1.705 0.496 495.9 1.877

12" 303 0.316 316.0 1.196 0.347 347.4 1.315

14" 333 0.261 260.5 0.986 0.286 285.7 1.081

16" 381 0.198 198.0 0.750 0.217 217.0 0.821

18" 429 0.156 155.8 0.590 0.171 170.6 0.646

20" 478 0.125 125.4 0.475 0.138 137.8 0.521

24" 575 0.087 86.64 0.328 0.095

For other pipe sizes below 610mm (24") not listed above, use the graphs and apply the

formula on the following pages ( 12 & 13 ).

4.2 K-factors for large pipes 460mm ID (18") and above use:

Pulses per litre = 28647 ÷ pipe ID² (mm)

Pulses per M³ = 28647000 ÷ pipe ID² (mm)

Pulses per US gallon = 168.14 ÷ pipe ID² (inches)

Pulses per Imp. gallon = 201.94 ÷ pipe ID² (inches)

( standard K-factors for voltage & square wave outputs )

Schedule 80 pipe - (#80

95.39 0.361

NOTE : K-factors for Reed Switch output option are 1/3 the standard factors of voltage

pulse output.

Page 8

page 12

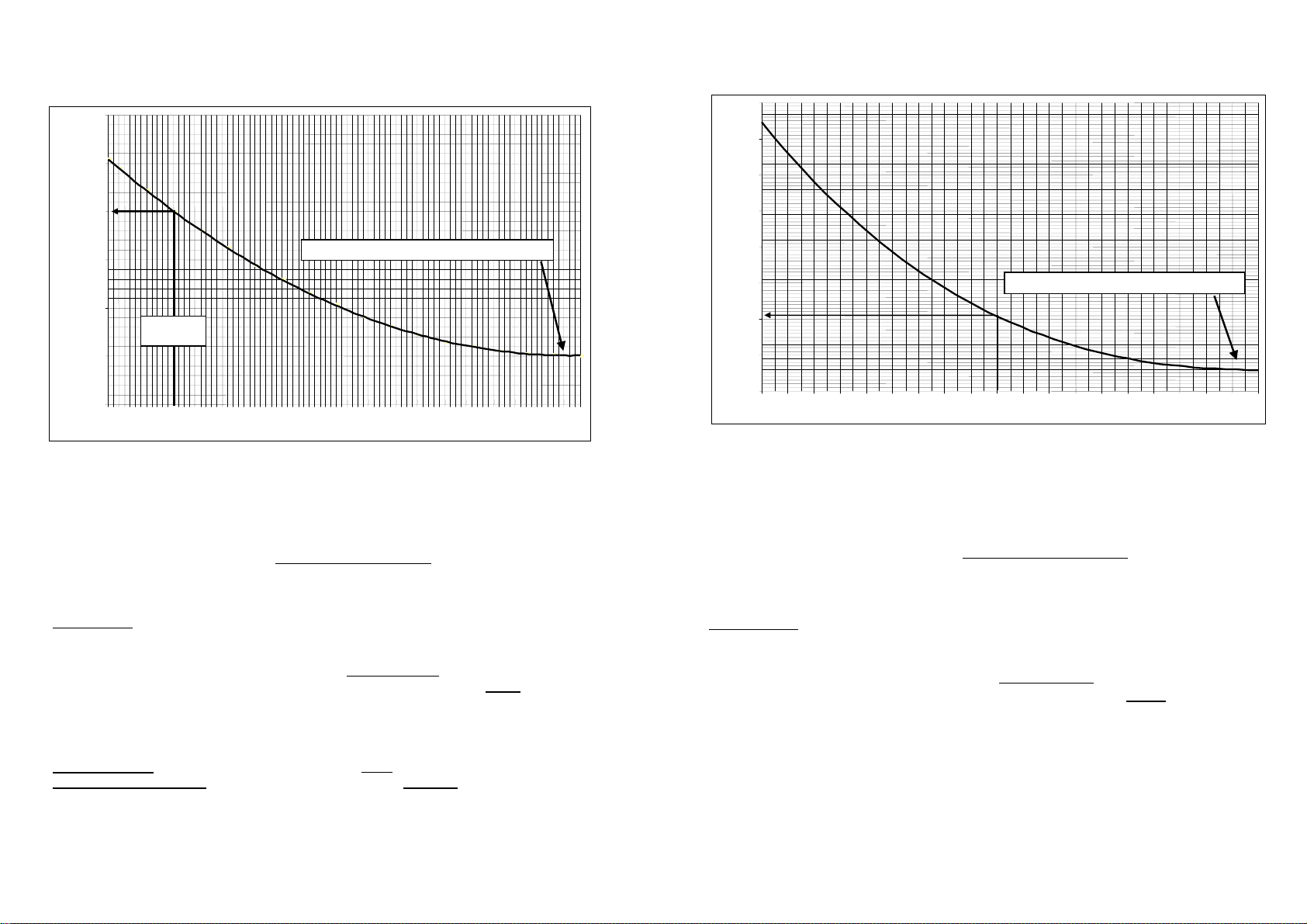

4.3 Calculating K-factors ( litres or m³ )

25

24.5

24

(A)

23.5

Pipe ID 450mm & above (A) = 22.5

23

See

example a

22.5

22

40 60 80 100 120 140 160 180 200 220 240 260 280 300 320 340 360 380 400 420 440 460

pipe ID (mm)

Calculate K-factor ( pulses / litre ) using the above graph and the metric constant of 1273.2

as follows :

Pulses / litre = 1273.2 x (A) from graph

pipe ID² (mm)

Example ‘a’ :

K-factor for 100mm pipe: 1) from graph 100mm ID (A) = 24.0

2) pulses/litre. = 1273.2 x 24.0

10000 = 3.056 p/litre

K-factor for m³ : multiply by 1000 eg. K = 3056 p/m³

K-factor for megalitres : multiply by 1000000 eg. K = 3056000 p/megalitre

NOTE : K-factors for Reed Switch output option are 1/3 the standard factors of voltage

pulse output.

page 13

4.4 Calculating K-factors ( US gallons )

7.6

7.5

7.4

7.3

7.2

(A)

7.1

Pipe ID 19.5 ” & above (A) = 6.86

7.0

6.9

6.8

12345678 91011 12 13 14 15 16 17 18 19 20

pipe ID

(inches)

Calculate K-factor ( pulses / gallon ) using the above graph and the volumetric

constant of 24.51 as follows :

Pulses / US gal. = 24.51 x (A) from graph

pipe ID² (inches)

Example ‘b’ :

K-factor for 10" pipe: 1) from graph 10" ID (A) = 7.01

2) pulses/gal. = 24.51 x 7.01

100 = 1.718 p/gal

NOTE :

K-factors for Reed Switch output option are 1/3 the standard factors of voltage pulse output.

Page 9

page 14

5.0 Declaration of Conformance

We, KOBOLD Messring GmbH, Hofheim-Ts, Germany, declare under our sole responsibility that the product:

Bi-Directional Insertion Flow Transducer Model: DOR

to which this declaration relates is in conformity with the standards noted below:

97/23 EC Pressure Equipment Directive

Pressure Accessory – Insertion Flowmeter – No CE Marking

Article 3, Paragraph 3; Diagram 9, Piping, Group II Liquids

Article 3, Paragraph 3; Diagram 8, Piping, Group I Liquids – with the following restrictions

Connection Nominal Size Maximum Pressure Rating

For Group I Liquids

1.5“ (40 mm)

2” (50 mm)

2002/96/EC Waste Electrical & Electronic Equipment (WEEE)

2002/95/EC Restriction of Hazardous Substances (RoHS)

Also the following EEC guidelines are fulfilled:

2004/108/EC EMC Directive – Electromagnetic Compatibility Directive

When fitted with an optional Reed Switch ONLY pulse outp ut, which is classified as a simple apparatus, and

when installed in accordance with Hazardous Area standards by a competent professional the product also

complies with:

EN 60079-11: 2011 – Section 5.7

Equipment protected by Intrinsic Safety – Simple Apparatus

EN 13463-1: 2009

Non electrical equipment for use in potentially explosive atmospheres

When fitted with an integral EX-ia certified instrument such as the ZOD-Z3 or ZOD-Z1, in combination with a

Reed Switch only output, the product also complies with:

94/9/EC

ATEX Directive

50 bar

40 bar

Certificate about acknowledgement of quality assurance production

Certificate number: BVS 12 ATEX ZQS/E110

Certification body: DEKRA EXAM GmbH, notified body No 0158

SIRA 06 ATEX M348 – Only when equipped with integral ZOD-Z3 or ZOD-Z1 options

Issued by Sira Certification – United Kingdom

EN 13980:2002

Potentially Explosive Atmospheres – Application of Quality Systems

94/9/EC Articles IV and VII

ATEX Directive

Hofheim, 12. Nov. 2013

H. Peters M. Wenzel

General Manager Proxy Holder

page 15

Page 10

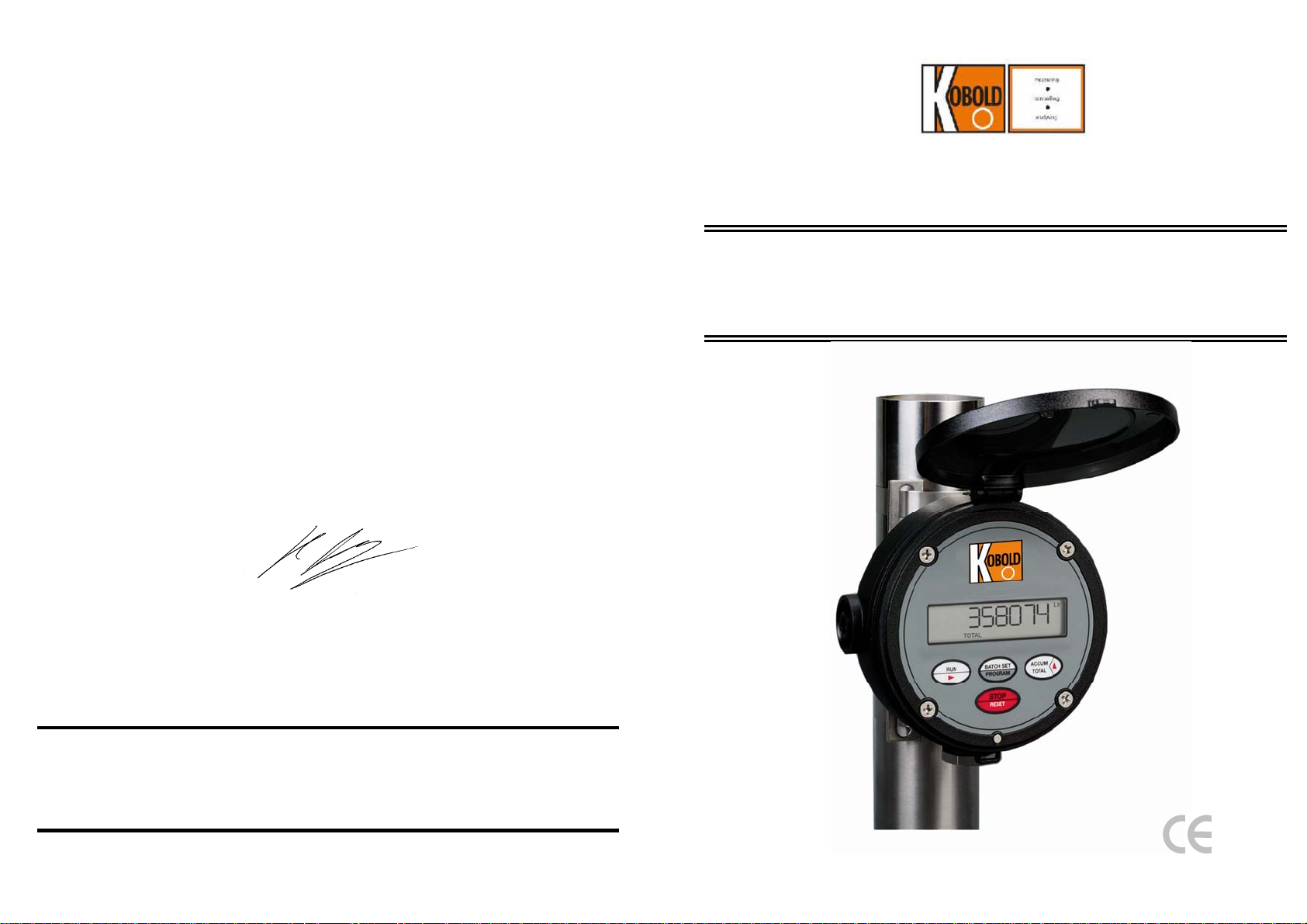

11. Declaration of Conformance

We, KOBOLD Messring GmbH, Hofheim-Ts, Germany, declare under our sole responsibility that

the product:

Batch Controller Model: ZOD-B1K

to which this declaration relates is in conformity with the standards noted below:

EN 60529, DIN VDE 0470-1 1992-11

I.P. Ingress Protection Classifications

EN 61326-1: 2006-10

Electrical equipment for control, instrumentation technology and laboratory use – EMC

requirements (Industrial area)

EN 61010-1: 2002-08

Safety requirements for electrical equipment for measurement, control, and laboratory use

2008/35/EC Waste Electrical & Electronic Equipment (WEEE)

Also the following EWG guidelines are fulfilled:

2004/108EC EMC Directive

2006/95 EC Low Voltage Directive

Universal Mount Series

BATCH CONTROLLER Model ZOD-B1K

I N S T R U C T I O N M A N U A L

Hofheim, 8. Nov. 2010

H. Peters M. Wenzel

General Manager Proxy Holder

Manufactured and sold by:

Kobold Messring GmbH

Nordring 22-24

D-65719 Hofheim

Tel.: +49(0)6192-2990

Fax: +49(0)6192-23398

K01/1110

Page 11

Software versions

01.09.04 V 3.0

11.02.08 V 3.1

Replacement Battery:

Supplied battery

P/No. ERS-ZOD-1312007

3.6V x 2.4Ah AA

Lithium Thionyl Chloride

-

non - rechargeable cell

+

Suitable batteries also available from :

R S Components

Stock No. 596-602

Farnell Components

Order code 206-532

Table of contents 1

1. INTRODUCTION

1.1 Model number designation 2

1.2 Specifications 3

1.3 Overview 4

1.4 LCD displays 4

2. OPERATION

2.1 Batch Set 5

2.2 Batch RUN 5

2.3 Batch STOP 5

2.4 Batch Total 5

2.5 Accumulative total 5

2.6 Total Number of Batches ( TNB ) 5

2.7 Keypad function matrix 5

3. INSTALLATION

3.1 Mounting - integral mount - wall mount 6

- pipe mount – panel mount 7

3.2 Flowmeter connections - unpowered sensors 8

- powered sensors 9

3.3 Wiring connections - external powering 10

- remote switches 10

- wiring requirements 10

- single stage control 10

- two stage control 11

- relay control logic 11

- status & relay connections 16 & 17

4. PROGRAM PARAMETERS

4.1 PIN number protection 12

4.2 Resetting accumulative total 12

4.3 Engineering units 12

4.4 K-factor (scale factor) 12

4.5 Decimal points 12

4.6 Count direction 12

4.7 Start delay & Pre-stop 12

4.8 Automatic overrun compensation ( AOC ) 13

4.9 Missing pulse detection - no flow alarm output 13

4.10 Batch limiting 13

4.11 Controller network ID number 13

5. PROGRAMMING FLOW CHART 14

6. BATCH OPERATING PROCEDURE 15

7. SECONDARY I/O

7.1 Batch status output 16

7.2 No flow alarm output 16

7.3 Run inhibit input 16

7.4 Solid state output logics ( NPN selection ) 17

7.5 Solid state output logics ( PNP selection ) 17

8. BATCH CONTROLLER NETWORKING 18 & 19

9. REFERENCE INFORMATION

9.1 Program detail record 20

9.2 Error messages 20

9.3 Back up PIN number 20

10. ALPHABETICAL INDEX 21

Page 12

2 Introduction

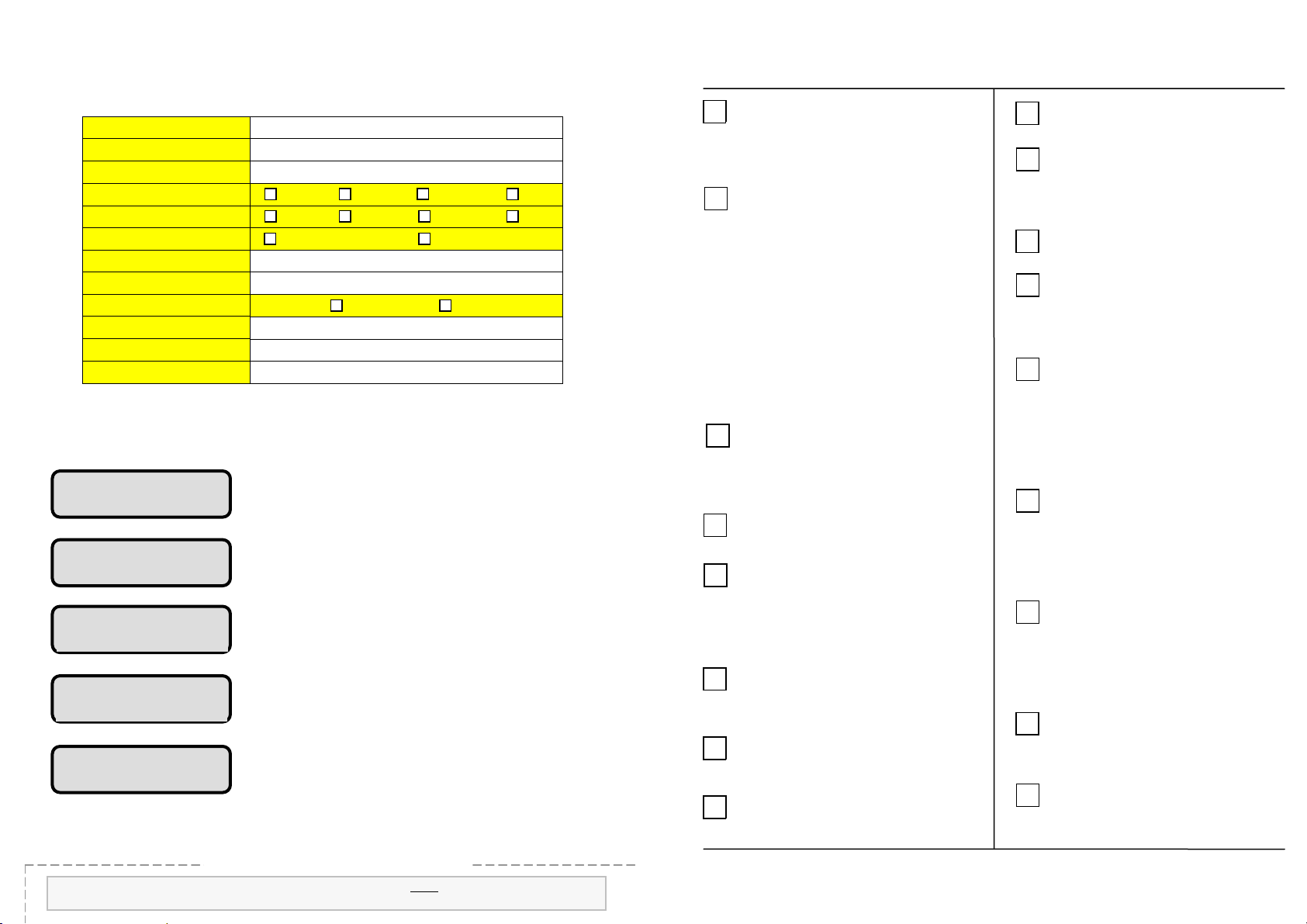

1.1 Model number designation

Order Details (E

Model Housing Type

ZOD-B1 KM¹⁾ = integral mount

xample: ZOD-B1KS1F300)

KS = universal mount

(standard)

PP = panel mount

(IP20)

¹⁾order only when retrofitting a pulse meter

²⁾only possible with ZOD-B1PP...

Electrical

connection/

Cable gland

=

1

3 x cable entry

M20

2 =

3 x cable entry

1/2" NPT

0²⁾ =

screw terminal

Supply Voltage Options

F3 = 8…24 VDC,

Battery

F1²⁾ = 110 VAC,

8…24 VDC 0 = without

R = 2 x

Relay

F0²⁾ = 220 VA

8…24 VDC

C,

(for ZODB1K)

Mechanical

protection

0 =

without

S²⁾ = silicone

bezel boot

1.2 Specifications

Display : 8 digit alpha numeric LCD characters 9mm

Functions : Batch total, Accumulated total & Total number of batches (TNB).

Configuration : Flow chart entry of data with scrolling English text prompts. User

Signal Input : Universal pulse/frequency input compatible with Reed switch,

Power requirement : Regulated 12~24Vdc x 50mA (add switched current).

Battery : 3.6Vdc lithium battery annunciates a power loss & preserves

Control outputs : Two independent NPN open collectors, 1A dc resistive load max.

Introduction 3

( 0.35 ”) high with

second line sub script text. 8 digits totalising, 3 programmable

decimal points, 5 digits for Total number of batches.

selectable 4 digit PIN number set-up protection. Programmable

decimal points and K-factors. All programmed data and batch

status are E

2

PROM protected in the event of a power failure.

Hall effect, Namur proximity detectors, Pulse wire, voltage,

current & Coil (15mV P-P min). Max. input frequency 10Khz.

batch settings & progress at time of power loss.

May be link configured for PNP to drive compatible logic circuits.

Part No.

1522001 stainless steel wall mount kit

1522002 stainless steel 2" pipe mount kit

1522011 DOM series cooling fin kit for flowmeters with integral instruments

1522005 DOR & Turbine stem adaptor - metric ( M16 to M20 )

1522006 DOR & Turbine stem adaptor - USA ( M16 to 1/2" NPT )

1323006 DOR-42 stem ( 100mm effective height, threaded M16 male )

1323011 DOR-52 stem ( 350mm effective height, threaded M16 male )

1412063

ACCESSORIES FOR ABOVE SERIES: Model: ERS-ZOD-...

Relay contol output board with two SPCO relays

Alarm / pulse output : NPN-PNP solid state alarm or non-scaleable pulse output @

terminal 7, ( 5000hz max.), 1A maximum drive capability.

Batch status output : NPN open collector, 0.1A dc resistive load max.

(page 16).

K-factor range : Eg. Pulses/litre, gallon, lb etc. Programmable range is 0.001~

9999999.999 with a floating decimal point during K-factor entry.

Engineering units : Selectable Ltr, gal, m3, kgs, lbs (maximum 8 digits of batch).

Count direction : Count UP or count DOWN selectable at program level.

Automatic overrun : AOC enabled-disabled selection at programming level (

page 13).

compensation

Batch limiting : Batch size limits can be set at programming level

(page 13).

Run inhibit input : Run key can be inhibited from an external source (page 16).

Network I/O : A two wire loop system can link up to 9 individual batch

controllers with one common flowmeter to provide an economical

multi source/dispense interlocked batching system (page 18) .

Physical : A) IP66 / 67 high impact glass reinforced Polyamide enclosure.

B) 3 x M20 or ½” NPT female conduit entries.

C) 125mm diameter (5”) x 61mm deep (2.5”) x 400g (0.9lb).

D) Temperature range from -20ºC to +80ºC ( -4ºF to +176ºF).

Page 13

4 Introduction

A

p

A

1.3 Overview

The ZOD-B1 is a dc powered high speed batch controller specifically designed for liquid

batching using a flowmeter with a pulse or frequency output.

ZOD-B1 is push button programmable with PIN protection and an internal battery is provided

allowing pre-programming without applying power. The large LCD provides batch quantity in

selected engineering units, batch status and has scrolling English prompts to make

programming easy.

Two independent output relays, the second with programmable start delay and pre-stop,

enable pump and valve control or 2 stage flow phasing at the start and end of each batch.

Precise batching is aided by Automatic Overrun Compensation which, when enabled,

automatically manages variations in system time lags which could otherwise lead to

discrepancies in dispensed quantity.

Safety features includes for an alarm output and automatic cessation of batching if no flow

input is detected and programmable batch limiting protects against setting an oversize batch

quantity. Scrolling messages on the LCD annunciate any alarm fault conditions.

Control features include batch count up or down, remote operational switch interface, run

inhibit interlock and batch status output. The ZOD-B1 is capable of networking with up to 9

batch controllers using one common flowmeter.

Operation 5

2. OPERATION

2.1 Batch set : Pressing the Batch set key allows the user to enter a batch value by

using the arrowed keys to select the appropriate digits and change their value. Pressing

Batch set again enters & confirms that the new batch value has been entered.

2.2 Run : Press RESET then RUN to start the batch. If there are no interruptions the

batch controller will automatically stop the batch once the batch value has been reached.

2.3 Stop : Pressing the STOP key at any time during the batch will cause the batcher to

go into a “PAUSED ” state and the output relays will be turned off. At this point the user can

resume batching by pressing the RUN key or abort the batch by pressing the RESET key.

2.4 Batch Total : The batch value is displayed in all normal operational modes.

2.5 Accumulative Total : Accumulative total can be reset in the program mode.

The accumulative total is displayed momentarily by pressing the ACCUM TOTAL key.

2.6 TNB display ( Total number of batches ) : ZOD-B1 will accumulate the total number of

individual completed batches. Reset of TNB is simultaneous with the resetting of the

Accumulative total in program mode. To view the TNB value simultaneously press & hold the

two top right hand keys ( Prog. & Accum Tot).

Environments

The ZOD-B1 is designed to suit harsh indoor and outdoor industrial environments & conforms

to EMC directives. The housing is weatherproof to IP66/67 (Nema 4X) standards, UV

resistant, robust glass re-enforced plastic with stainless steel screws & FKM O-ring seals.

ZOD-B1 can be mounted on a variety of flowmeters or as a stand alone instrument for wall,

surface, pipe or panel mount. Various mounting kits are available.

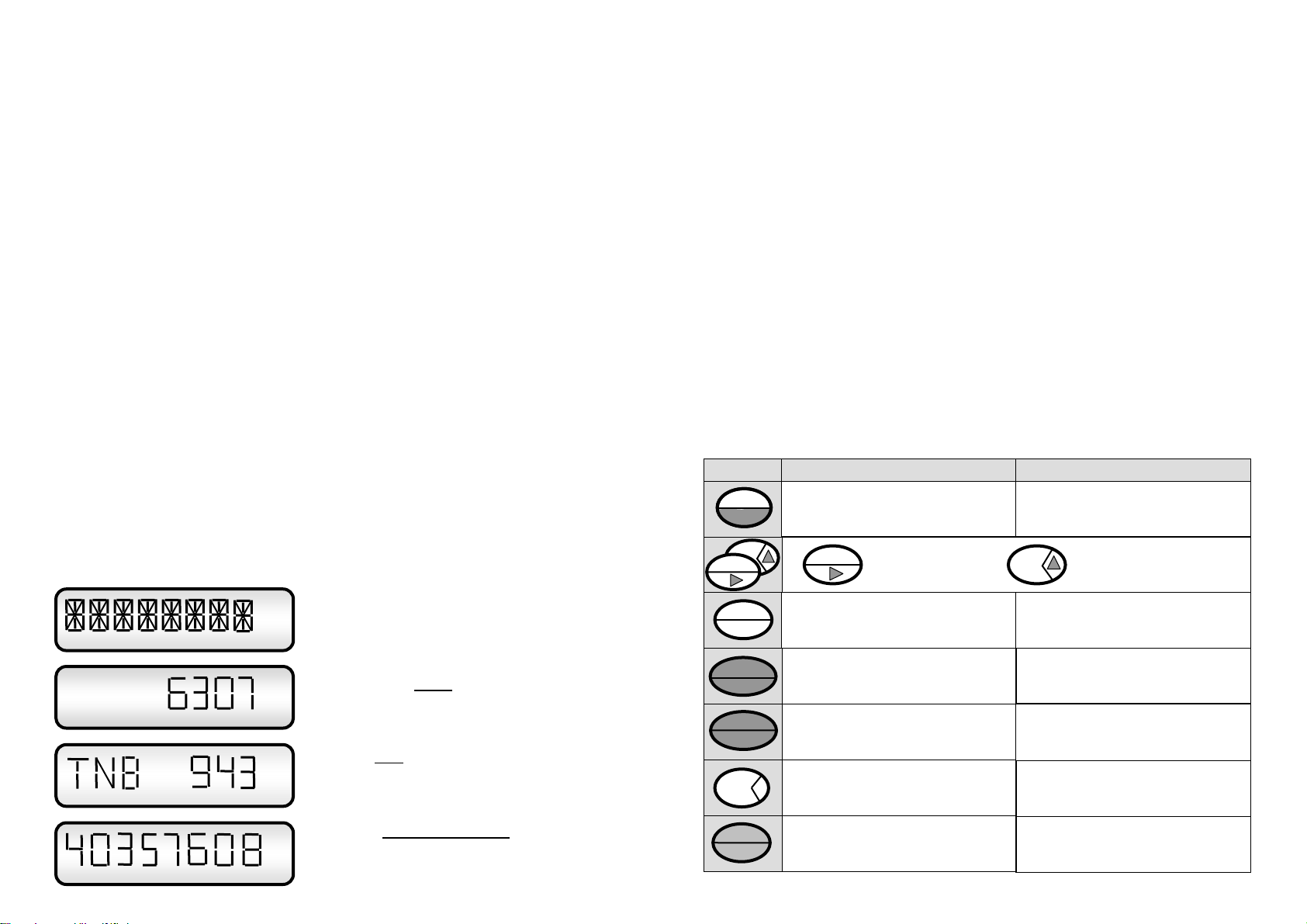

1.4 LCD displays

RUN ACCUM. TOTAL STOP BAT LOW HIGH RATE

Ltr

gal

m3

lbs

kgs

Ltr

Full LCD display test feature illuminates all

display segments and script text displays for 5

seconds when entering the program mode.

Up to 8 digits of Batch quantity programmable

for up to 3 decimal places. English prompts

RUN LOW HIGH

clearly show the status of the batch.

n 5 digit TNB display shows the Total

number of batches dispensed since last reset

TOTAL

gal

ACCUM. TOTAL

( reset of TNB and Accumulative Total is only

ossible whilst in the program mode ).

The 8 digit

ccumulative Total display can be

programmed for up to 3 decimal places. Reset

is only possible when in the program mode

which can be PIN protected for security.

2.7 Keypad functions :

KEY FUNCTION IN OPERATING MODE FUNCTION IN PROGRAM MODE

BATCH SET

RUN

RESET

ACCUM

TOTAL

PROGRAM

1) Enters & Exits the batch set mode.

2) May be pressed during batching to show

batch pre-set value, this action will not

interfere with the batch process.

Selects the digit to be Increments the selected digit

Indexed ( digit will flash ) ( selected digit will be flashing )

1) Starts a batch

2) Resumes a batch if paused

Pauses a batch during batching

1. Resets the batch to the last pre-set value.

2. Resets individual digits to zero when

in the BATCH SET

mode

.

1) Displays Unit ID number followed by the

Accumulative Total as the key is held.

2) Displays total number of batches ( press

Accum. Total & Prog. keys at the same time)

Pressing PROGRAM & ACCUM TOTAL keys

displays the Total Number of Batches ( TNB )

No function

No function

Pressing PROG & STOP keys for 5 sec.

gives entry to the program mode

No function

No function

1) Pressing PROGRAM & STOP keys for 5

seconds gives entry to the program mode.

2) Steps you through the program ladder.

3) Holding for 3 secs. fast tracks to end prog.

Page 14

6 Installation

3.1 Mounting

RATE TOTALISER

RUN ACCUM. TOTAL STOP BAT LOW HIGH

RESET

RUN ACCUM. TOTAL STOP BAT LOW HIGH

RUN

BATCH

ACCUM

TOTAL

PROG

STOP

RESET

gal

PROGRAM

ACCUM

TOTAL

ENTER

RATE

TOTAL

Wall mount using optional

bracket set

gal

Integral meter

mounts

Surface mount footprint

(use 4 screws supplied )

( P/No. AWM )

RUN ACCUM. TOTAL STOP BAT LOW HIGH

RUN

BATCH

ACCUM

TOTAL

PROG

STOP

RESET

96 mm ( 3.8 ” )

gal

42.6 mm

( 1.67 ” )

18 mm

( 0.7 ” )

Installation 7

3.1 Mounting

RUN ACCUM. TOTAL STOP BAT LOW HIGH

RUN

BATCH

PROG

STOP

RESET

ACCUM

TOTAL

gal

* Vertical pipe mount

* order Pipe mount kit P/No. APM

comprising two brackets,

screws and worm drive clamps.

Panel mount

* Horizontal

pipe mount

Conduit entries have an integral

moulded seal, to remove break

seal out using suitable lever

( eg. screwdriver or rod )

Cut a 106.5mm (4.2 ”)

diameter hole in panel

Page 15

8 Installation

t

t

t

_

_

t

t

_

t

3.2 Flowmeter connections ( un powered sensors )

Flow input switch functions

3

O

2

N

1

3

Flow

O

2

Input

N

1

Switch 1 : ON engages 0.01µf capacitor to suppress reed switch bounce

Switch 2 : ON engages 1 meg Ω pull up resister

Switch 3 : ON engages 820Ω pull down resister

Factory set network default settings, do not change

1. Reed switch ( 200hz max.)

Flow DIP switches 1 & 2 are on

Ground screen at -0V (5)

3

1

O

2

N

2

1

3

3

O

2

N

4

1

-0V (ground)

5

+8~24Vdc in

6

Pulse output

7

Factory set, do not change

Network

loop

Flow

Input A

Relay 2 (high)

Relay 1 (low)

Batch status

Not used

Not used

Inhibit inpu

-0V (ground)

14

13

12

11

10

9

8

2. Voltage Pulse ( & pulse wires )

1.1 ~ 30 Vdc

+

_

N

S

All flow DIP swithes off

Ground screen at -0V (5)

3

1

O

2

N

2

1

3

3

O

2

N

4

1

-0V (ground)

5

+8~24Vdc in

6

Pulse output

7

Factory set, do not change

Network

loop

Flow

Input A

Relay 2 (high)

Relay 1 (low)

Batch status

Not used

Not used

Inhibit inpu

-0V (ground)

14

13

12

11

10

9

8

3. Coil ( Turbine & paddle style flowmeters )

All flow DIP switches off (position switch 1

if unit is effected by line noise)

ON

use twisted pairs

3

1

O

2

N

2

1

3

3

O

2

N

4

1

5

-0V (ground)

+8~24Vdc in

6

Pulse output

7

Factory set, do not change

Network

loop

Flow

Input A

Relay 2 (high)

Relay 1 (low)

Batch status

Not used

Not used

Inhibit inpu

-0V (ground)

14

13

12

11

10

9

8

Installation 9

3.2 Flowmeter connections ( powered sensors )

4. Hall Effect ( open collector )

Hall effect

+ Signal out

- 0V ground

Vdc supply

Flow input DIP SW2 is on

+

Reg. Vdc

3

1

O

2

N

2

1

3

3

O

2

N

4

1

-0V (ground)

5

+8~24Vdc in

6

Pulse output

7

Factory set, do not change

Network

loop

Flow

Input A

Relay 2 (high)

Relay 1 (low)

Batch status

Inhibit inpu

-0V (ground)

5. Namur ( inductive proximity switch )

intrinsically safe NAMUR proximities

NAMUR

Inductive Proximity

NOTE : Limit supply to 8.5Vdc

through an approved barrier for

-

+

Flow input DIP SW3 is on

+

Reg. Vdc

3

1

O

2

N

2

1

3

3

O

2

N

4

1

-0V (ground)

5

+8~24Vdc in

6

Pulse output

7

Factory set, do not change

Network

loop

Flow

Input A

Relay 2 (high)

Relay 1 (low)

Batch status

Inhibit inpu

-0V (ground)

6. Current modulated pulse

( 4mA to 20mA pulse amplitude )

Coil with pre-amp

current modulated

NOTE : Position a 100Ω, ¼W

Resistor across terminals 3 & 5

Flow input DIP switches off

-

B

A

+

+

Reg.Vdc

3

1

O

2

N

2

1

3

3

O

2

N

4

1

-0V (ground)

5

+8~24Vdc in

6

Pulse output

7

Factory set, do not change

Network

loop

Flow

Input A

Relay 2 (high)

Relay 1 (low)

-0V (ground)

Batch status

Inhibit inpu

Not used

Not used

Not used

Not used

Not used

Not used

14

13

12

11

10

9

8

14

13

12

11

10

9

8

14

13

12

11

10

9

8

Page 16

10 Installation

_

w

_

w

_

_

_

V

w

3.3 Wiring connections

Powering & Remote switches

+

Reg.Vdc

1

2

3

4

-0V (ground)

5

+8~24Vdc in

6

No flow alarm

7

( remote keys )

Network loop

Flow

Input

Relay 2 high

Relay 1 lo

Batch status

not used

not used

Run inhibit

-0V (ground)

Remote keys

15 16 17 18 19

use momentary contact

14

13

12

11

10

9

8

remote switches only

STOP

TOTAL

SET

RUN

15 16 17 18 19

Wiring requirements : Use multi-core screened twisted pair instrument cable (0.25~0.5mm

electrical connection between the ZOD-B1 and any flowmeter or remote switch input. The screen needs to be

grounded at -0V (terminal 8), this is to protect the transmitted signal from mutual inductive interference.

Instrument cabling should not be run in a common conduit or parallel with power or high inductive load cables.

Power surges & power line frequencies may induce erroneous noise transients onto the signal. Run instrument

cables in a separate conduit or with other instrument cables.

2

) for

Single Stage Control

( use relay 1 or 2, relay 2 has pre-stop programming capability )

+

Reg.Vdc

Network

1

2

3

4

5

6

7

Flow

Input

-0V (ground)

+8~24Vdc in

No flow alarm

Relay 2 high

Relay 1 lo

Batch status

not used

not used

Run inhibit

-0V (ground)

14

13

12

11

10

9

8

IMPORTANT

Fix 1N4004 electrical surge

suppression diode supplied

across solenoid valve coil

( band to + side )

Flow

meter

Flow

+

1N4004

Installation 11

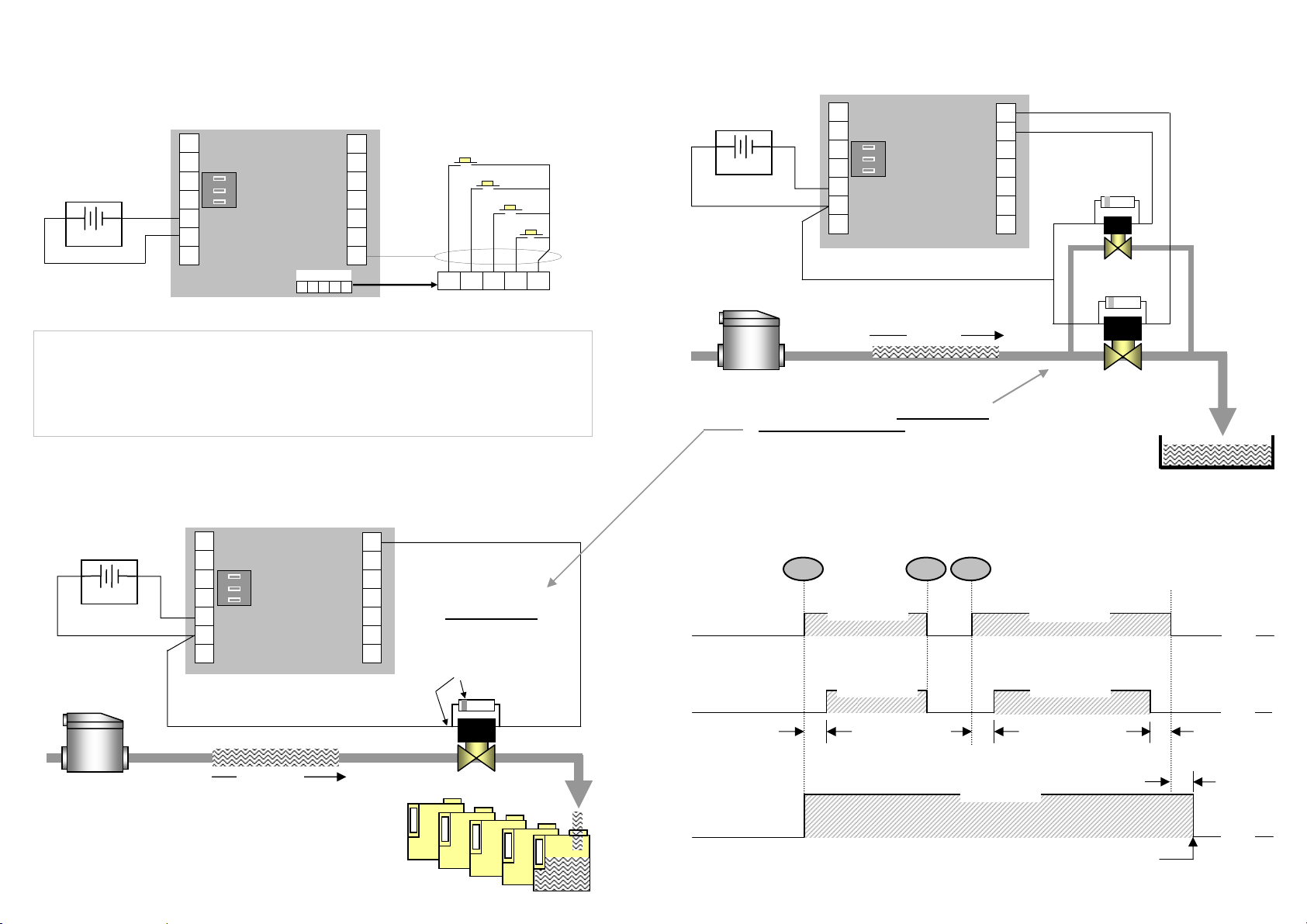

Two Stage Control

( using relays 1 & 2 )

+

Reg.Vdc

Network

1

2

3

4

-0V (ground)

5

+8~24Vdc in

6

No flow alarm

7

Flow

Input

Relay 2 high

Relay 1 lo

Batch status

not used

not used

Run inhibit

-0V (ground)

14

13

12

11

10

9

8

+

1N4004

1

_

1N4004

V2

Flow

meter

Flow

+

See notation on 1N4004 diode. When the solenoid valve coil is de-energized

it generates its own voltage sending a “surge spike” through the circuit.

Depending on the coil size and the number of amp turns it contains, this

generated voltage can be very high. Installing the diode will suppress this

“spike” and protect sensitive components of the electronic instrument.

IMPORTANT

Relay Control Logic

Batch

complete

Relay 1 LOW FLOW

ENERGISED

Relay 2 HIGH FLOW

Start delay

Start delay

Batch & network

status ( NPN ) output

ENERGISED

Batch & network status (end of batch)

(occurs 1~4 seconds after relay 1 is off)

ENERGISED

ENERGISED ENERGISED

OFF

OFF

Pre-stop

1~4 sec.

OFF

Page 17

12 Programming

4. PROGRAM PARAMETERS

4.1 PIN No. Program Protection

Any user defined PIN number other than 0000 will engage the program protection feature,

failure to input the correct PIN number will deny the ability to change any of the program

parameters but will allow the user to step through and view the existing program parameters.

Only one PIN number may be set but this can be changed at any time after gaining access

through PIN entry. A second back up PIN number is installed at the factory should the

programmed PIN be lost or forgotten. ( refer bottom of page 19 for the back up PIN No. )

4.2 Resetting Accumulated Total & Total Number of Batches ( TNB )

Resetting the Accumulated Total & Total Number of Batches (TNB) is done at “RESET

ACCUMULATIVE TOTALS ” in the program mode. Both Accumulated Total & TNB are reset

if you select YES

at this program level.

4.3 Engineering Units ( refer clause 1.4 )

Select from available Engineering units to right of the display. No engineering units denote

NIL set allowing the user to set up the instrument with other units of measure which are not

available on the ZOD-B1 LCD display.

4.4 K-factor ( scale factor )

Enter K-factor starting with the most significant number, up to 7 prime numbers & 3 decimal

numbers can be entered. Trailing decimal numbers move into view as digits to the right are

progressively selected, any significant digits which may move from view remain functional.

4.5 Decimal Points

Up to three decimals points can be selected for Batch Total or Accumulative Total.

4.6 Count Direction

B1 can be programmed to count DOWN from a preset quantity or UP from zero.

Overruns in the count down mode will show with a minus sign in front of the overrun value.

4.7 Start Delay & Pre-Stop

Relay 2 can be programmed to turn on a time period after the run signal is given then turn off

again a preset number of litres, gallons etc. before the end of the batch. These operational

features provide greater control over the dynamics of the batching process through soft start

and/or soft stop or phasing of the control valves and/or pump control.

The Start Delay can be set from 0 seconds ( no delay ) to 999 seconds. The pre-stop range

is 0 (no pre-stop) to 999 units of measure ( litres or gallons etc.).

Programming 13

4.8 Automatic Overrun Compensation ( AOC )

Most batching applications will have an inherent end of batch overrun due mainly to the

response time of the process valve. Overrun can be compensated by closing the valve

slightly before the batch value is reached so that the exact batch value is achieved by the

time that the system comes to rest.

ZOD-B1 has an Automatic Overrun Compensation feature which when enabled will assess

the degree of overrun on previous batches and automatically alters the close timing of the

process valve so that the exact batch value is reached. This feature should not be enabled

on batch processes which are subject to erratic or inconsistent flow conditions.

4.9 Missing Pulse Detection

When a value other than 00 seconds is set at Time Out ( T / OUT ) in the program mode,

ZOD-B1 will monitor for loss of flowmeter input signal at all times when either of the control

relays 1 & 2 are energised. If no pulses are received within the time out period ( 0~99 sec. )

the controller will de-energise both control relays and scroll a “NO INPUT” message across

the LCD display, at the same time it will turn on the “no flow alarm” output at terminal 7, (see

page 17 for flow alarm connection detail).

At “NO INPUT ” the user must acknowledge the alarm condition by pressing the STOP key

once, the operator then has the option of continuing the batch by pressing the RUN key or

aborting the batch by pressing the RESET key which will return the controller to the original

batch set value.

4.10 Batch Limit

To avoid entering excessive batch quantities, a maximum batch limit can be set at the

program level. ZOD-B1 will not accept a batch value which exceeds the batch limit, on

rejecting an excessive batch value the controller will scroll the message “BATCH VALUE

EXCEEDS BATCH LIMIT” and default to the batch limit on entry (batch set).

4.11 Controller networking ID number

Each controller can be given a networking ID number in the range of 1~9. Allocating an ID

number other than 0 is only necessary when a number of controllers are to be networked

together for interlocking purposes

( see page 18 for Controller Networking ). Setting the ID

number to zero inhibits this function.

Note : The instrument defaults out of the program mode if no program entries are made

after 4 minutes.

Page 18

14 Programming

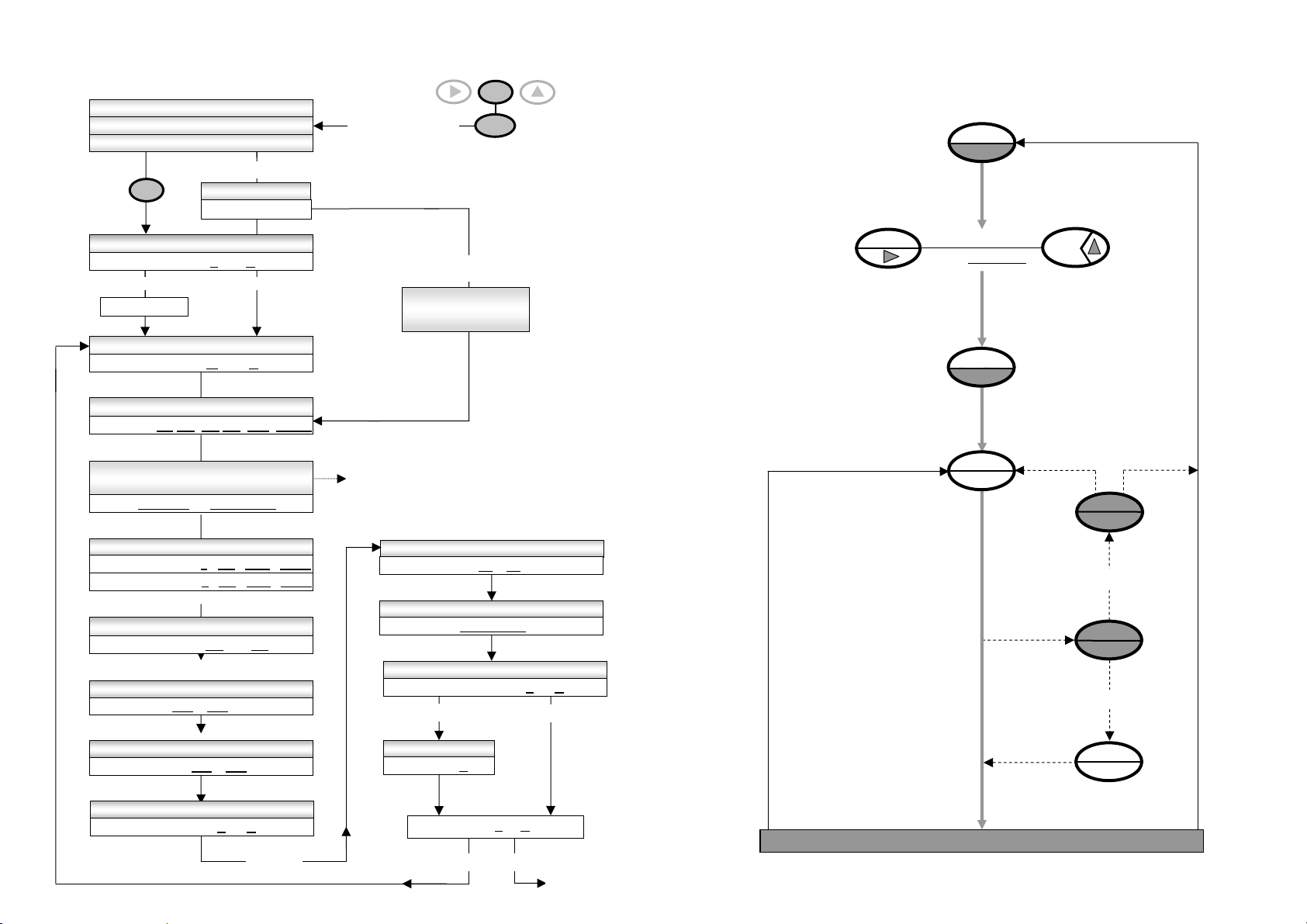

5. PROGRAMMING FLOW CHART

press Prog. key

to step through

program levels

ENG UNIT Ltr gal m3 Ibs kgs (none)

DPt TOTAL 0 0.0 0.00 0.000

DPt ACCUM TOTAL 0 0.0 0.00 0.000

V3.1 HOLD 3 2 1

TESTING DISPLAY 88888888

PROGRAM MODE ENTERED

if PIN protected

PROG

CHANGE PIN No. Y / N

NU PIN Y ~ N

YES NO

PIN _ _ _ _

RESET ACCUM TOTALS Y / N

RESET Y ~ N

SET ENGINEERING UNITS

ENTER NUMBER PULSES PER

Ltr m3 kg gal Ib (unit)

K 0000.001 ~ 999999.999

SET DECIMAL POINTS

SET COUNT DIRECTION

COUNT DN ~ UP

START DELAY - RELAY 2

DELAY 000 ~ 999 seconds

PRE STOP VALUE - RELAY 2

PRE 000 ~ 999

AUTOMATIC OVERRUN COMPENSATION

A/COMP Y ~ N

ENTER PIN

PIN _ _ _ _

continued

PROG

hold Program & Stop

keys for 5 secs to

enter the program

PIN No. is entered

INVALID PIN VIEW

EXISTING PROGRAM

DETAILS ONLY

K-factor (scale factor) is the number of

pulses per unit volume or unit mass

eg: 20.465 pulses / litre, gallon, kg etc.

SET MISSING PULSE TIME OUT

T / OUT 00 ~ 99 seconds

SET BATCH LIMIT

NETWORK OPERATION

N / WORK Y ~ N

YES

SET UNIT ID No.

ID No. X

STOP

if incorrect

XXXXXXXX

See page 13.

END Y ~ N

NO

YES

NO

Exit program

mode

Operating 15

6. BATCH OPERATING PROCEDURE

TO REPEAT

BATCH

B A T C H E N D

BATCH SET

ENTER BATCH

QTY. XXXXXXXX

BATCH SET

RUN

TO

PAUSE

TO CHANGE

TO ABORT

TO RESUME

BATCH

RESET

STOP

RUN

Page 19

16 Secondary I/O

0

0

(

)

(

)

0

7. SECONDARY I/O

7.1 Batch Status Output

A solid state NPN output signal is switched on at terminal 12 when a batch is started, the

signal remains on until the batch cycle is completely finished or the batch is stopped and

aborted using the STOP & RESET keys.

The output is used to notify other control equipment when ZOD-B1 is in operation or is

paused (by pressing STOP) or inhibited through an input at terminal 9 (RUN inhibit), the

signal remains on under all three conditions. The signal can also be used to inhibit (lock out)

other equipment whilst the controller is in use.

1

No flow alarm

(refer 7.4 & 7.5)

Network

2

3

Flow

input

4

5

-0V (ground)

+8~24Vdc in

6

7

Alarm output

High flow-relay 2

Low flow-relay 1

Batch status

Run Inhibit

-0V (ground)

14

13

12

11

10

Remote keys

15 16 17 18 19

Batch status

(refer 7.4)

9

8

Run inhibit

input

( closed = inhibit RUN )

7.2 Alarm Output

An NPN/PNP selectable solid state output signal (terminal 7) is activated when the missing

pulse detection feature detects a no flow condition (refer 4.9). NPN/PNP selection is to be in

accordance with the connection options on the following page (17).

7.3 Run Inhibit Input

The RUN inhibit feature enables ZOD-B1 to interlock with other devices within the system or

process when ZOD-B1 is in use.

When a contact is made across the Run inhibit input at terminal 9, a batch cannot be started

and at the same time an “ENGAGED “ prompt will show on the LCD display. If the inhibit

contact is made whilst a batch is running the batch will be paused. When the run function is

inhibited it is still possible to enter a new batch quantity or review the accumulated totals but

it will not allow the operator to RUN or re-start the batch until the inhibit input is released.

An example of this feature in practice is where a batch should not be allowed to RUN whilst a

valve at another location is open.

Solid state output logics 17

7.4 Current Sinking outputs ( NPN )

Current sinking derives its name from the fact that it “sinks current from a load”. When activated the

current flows from the load into the appropriate output ( terminals 7, 12, 13 & 14 ). NPN is the factory

default configuration for the outputs. Refer to pages 10 & 11 for wiring control outputs.

Driving a logic input The output voltage pulse is typically the internal voltage of the load.

The load would normally have an internal pull up resistor on its input as shown.

Driving a coil - - - - - - - The NPN style of output is to be used when driving a coil. The coil load is

obtained by dividing the coil voltage by coil impediance ( Ω ), is expressed in amps & is not to exceed

100mA at terminals 7 & 12 or 1A at terminals 13 & 14. The coil voltage is connected across & must

match the ZOD-B1 supply voltage & the appropriate output ( terminals 7, 12, 13 & 14 ).

- +

SPO (no flow alarm)

REP repeater pulse

7A

1

2

3

4

-0V (ground)

5

+8~24Vdc in

6

Alarm output

7

7B

0 0 0

PNPNPN

High flow relay 2

Low flow relay 1

Set jumper

7.5 Current Sourcing outputs ( PNP )

Current sourcing gets its name from the fact that it “sources current to a load”. When activated the

current flows from the output (7,13 & 14) into the load. When wired as below the output voltage pulse

is the supply voltage of the load. The load would normally have an internal pull down resistor on its

input as shown.

0

0

13

Batch status

NPN

-0V (ground)

to NPN

0

0

14

13

0

PNP

0

14

14

13

12

11

10

9

8

0

PNP

0

NPN

Set jumper(s)

NPN

to NPN

coil

For solenoid valve coils fix a 1N4004 electrical surge

suppression diode across the coil (refer page 10)

Set jumper(s)

to PNP

IMPORTANT

OR

logic

+

input

load

_

- +

1

2

3

4

5

-0V (ground)

+8~24Vdc in

6

Alarm output

7

0 0 07B

PNP

NPN

High flow relay 2

Low flow relay 1

PNP

-0V (ground)

Set jumper

to PNP

14

13

12

11

10

+

logic

input

_

load

9

8

Do not tie 0 volts of the

logic input to 0 volts of

the ZOD-B1 when wired

in PNP configuration

Page 20

18 Networking

V1V

8. CONTROLLER NETWORKING

ZOD-B1 has a unique networking feature which allows up to 9 individual batch controllers to

be networked together with each being connected to one common flowmeter (see opposite).

Typical applications are where one liquid is being dispensed to a number of individual outlets

or a number of different liquids are to be batched via one common flowmeter. In either

application each batch controller is wired to the same flowmeter but controls its own process

control valve.

Networking takes place when any one controller is started, at this point the flowmeter input

(count) is restricted to the controller in use, all other controllers will not count and their start

function will be inhibited and an “ENGAGED” will scroll across the LCD display showing the

ID number of the controller in use.

Batch entries can be made whilst individual batch controllers are inhibited (locked out) but

they cannot be started until the controller in operation has completed its batch cycle.

For the network feature to work the network DIP switches must be set as shown & each

batch controller MUST be programmed with an individual ID number other than 0 (zero).

Network loop wiring

1

O

N

2

3

4

-0V (ground)

5

+8~24Vdc in

6

Alarm output

7

ZOD-B1 1

3

Network

2

DIP switch

settings

1

Flow

input DIP

switches

High relay 2

Low relay 1

Batch status

Run inhibit

-0V (ground)

14

13

12

11

10

9

8

1

O

N

2

3

4

-0V (ground)

5

+8~24Vdc in

6

Alarm output

7

ZOD-B1 3

3

Network

2

DIP switch

settings

1

Flow

input DIP

switches

High relay 2

Low relay 1

Batch status

Run inhibit

-0V (ground)

14

13

12

11

10

9

8

1

O

N

2

3

4

-0V (ground)

5

+8~24Vdc in

6

Alarm output

7

ZOD-B1 2

3

Network

2

DIP switch

settings

1

Flow

input DIP

switches

High relay 2

Low relay 1

Batch status

Run inhibit

-0V (ground)

14

13

12

11

10

9

3

Network

1

O

2

DIP switch

N

2

3

4

-0V (ground)

5

6

Alarm output

7

settings

1

Flow

input DIP

switches

+8~24Vdc in

ZOD-B1 4

High relay 2

Low relay 1

Batch status

Run inhibit

-0V (ground)

14

13

12

11

10

9

88

Flowmeter

ZOD-B1 1

Networking (continued) 19

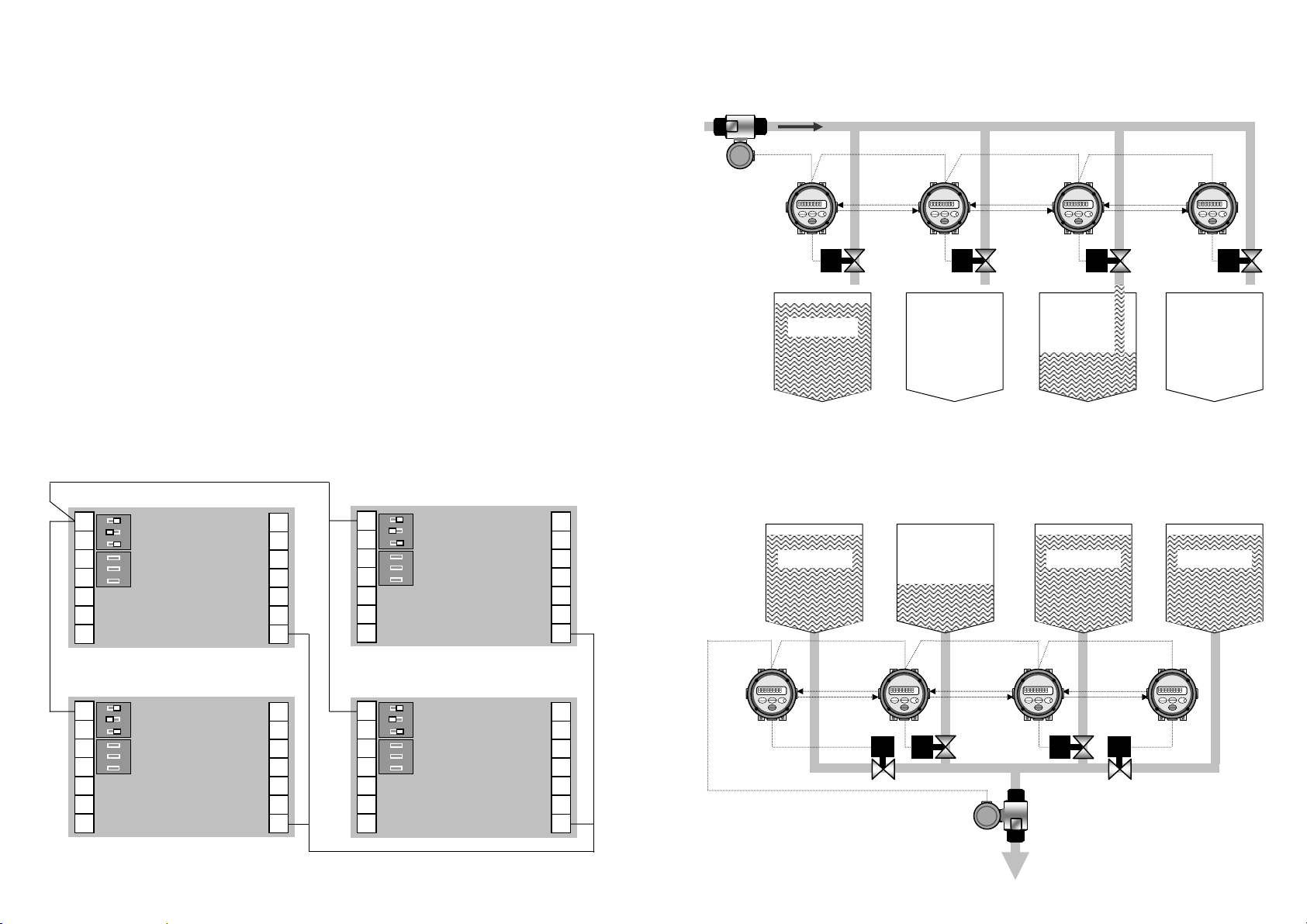

Multi point batching

ZOD-B1 1

V1

Mix tank 1

ZOD-B1 2 ZOD-B1 3

network

loop

Valve

V2 V3 V4

Mix tank 2 Mix tank 3 Mix tank 4

Multi product batching

Product 2

V2 V3

Valves

Flowmeter

Product 3 Product 4

Product 1

ZOD-B1 2 ZOD-B1 3

network

loop

ZOD-B1 4

ZOD-B1 4

4

Page 21

Reference information 20

9. REFERENCE INFORMATION

9.1 Program detail

User selected PIN No.

K-factor (scale factor)

Decimal for batch total

Decimal for Accum. total

Count direction

Start delay on relay 2

Pre-stop value on relay 2

Automatic overrun comp.

Missing pulse time-out

Batch limit

Unit ID number ( 1~9 )

9.2 Error messages: ZOD-B1 has a series of error messages which are scrolled

across the LCD display when ever an error condition exists.

NO POWER

No power indicates that the instrument is on battery power

only and needs to be supplied with an external power source

in order to operate.

NO INPUT

No input (missing pulse detection) indicates that no pulses

were received at the controller input within the time out period

at any stage of the batch cycle. ( see clause 4.9 )

BATCH VALUE EXCEEDS

BATCH LIMIT

The new batch value will not be accepted because it

exceeds the maximum batch limit value. ( see clause 4.10 )

PRE-STOP EXCEEDS

BATCH VALUE

The new batch value will not be accepted as it is less than

the pre-stop value ( clause 4.7)

WAIT

This message will show if the RUN button is pressed whilst

the controller is in the process of assessing the degree of

overrun from the previous batch when AOC is enabled.

9.3.1 Back up PIN number ( see clause 4.1 )

Cut from manual for increased security

Your back up 4 digit PIN number is 0502

Pencil your program details here

Engineering units

K =

000. 00.0 0.00 .000

000. 00.0 0.00 .000

count DOWN count UP

seconds

AOC yes no

seconds

( 0 = inhibit network function)

10. ALPHABETICAL INDEX

Accumulative total

A

Alarm output

Automatic Overrun Comp. 13

B

Batch RUN

Batch SET

Batch STOP

Batch total

Batch limit

Batch operating procedure

Batch status

Back up PIN number

Battery

C

Controller ID number

Controller networking 18,

Count direction

Decimal points 12

D

Engineering units 3,

E

End of batch

Error messages

External DC powering

F

Flow alarm output

Flowmeter connections 8,

ID numbering

I

Inhibit input

Keypad functions

K

K-factor (scale factor) 12,

(batch status)

11, 16 & 17

16

5

5

5

13

15

16

20

4

12

20

18

13

16

14

5

13

19

12

10

Index 21

5

LCD display 4

L

Model number designation 2

M

Missing pulse detection

Mounting options 6,

Networking 18,

N

Operation 5

O

13

7

19

Overrun compensation 13

Overview

PIN number protection

P

Pre-stop

4

12

12

Programming 12, 13

Program detail record 20

Programming flow chart

14

Relay control logic

R

Remote operating keys

Resetting totals

Run inhibit input

Scale factor (K-factor) 12,

S

Single stage control

Specifications

Start delay

11

10

12

16

14

10

12

3

9

Total Number of Batches

T

Two stage control

Wiring connections 10,

5

W

Wiring requirements

5

11

11

10

Page 22

K01/1010

Manufactured and sold by:

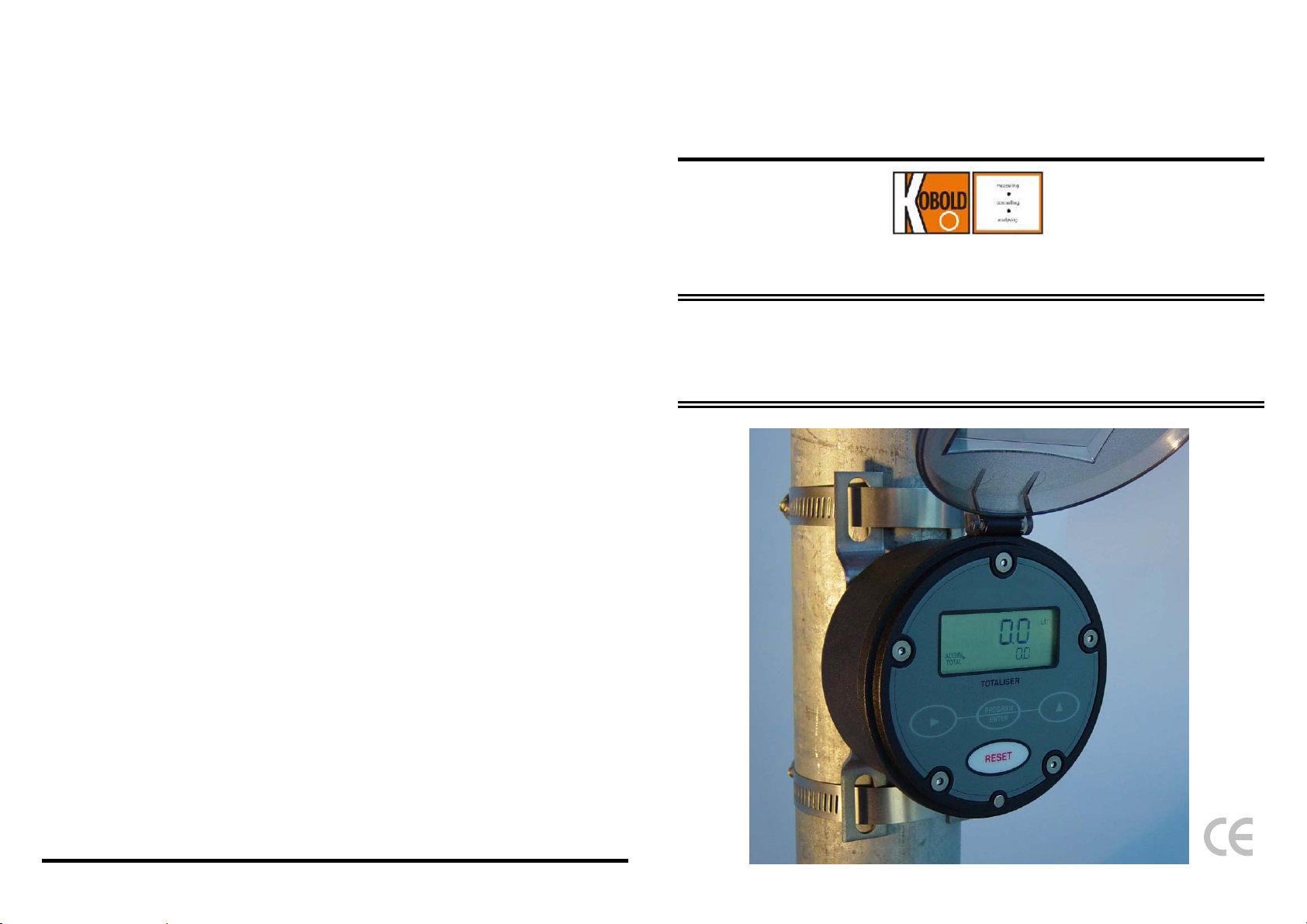

ZOD-Z1 BATTERY TOTALISER

I N S T R U C T I O N M A N U A L

Kobold Messring GmbH

Nordring 22-24

D-65719 Hofheim

Tel.: +49(0)6192-2990

Fax: +49(0)6192-23398

Universal Mount Series

Page 23

prog

y

To review software version No’s press &

hold

ram ke

Replacement Batteries:

Factory supplied batteries :

Non I.S. battery

P/No. 1312007

3.6V x 2.4Ah AA

Lithium Thionyl Chloride

-

non - rechargeable cell

+

Suitable non I.S. batteries also available from :

R S Components

Stock No. 596-602

Farnell Components

Order code 206-532

TABLE OF CONTENTS

1. INTRODUCTION

1.1 Model number designation 2

1.2 Specifications 3

1.3 Overview 4

1.4 LCD displays 4

2. OPERATION

2.1 Resettable total 5

2.2 Accumulative total 5

2.3 Keypad function matrix 5

2.4 Battery replacement 5

2.5 Processor reset button 5

3. INSTALLATION

3.1 Mounting - integral meter mounting 6

- panel mounting 6

- wall / surface mounting 7

- pipe mounting 7

3.2 Flowmeter connections - un-powered sensors 8

- powered sensors 9

3.3 Wiring connections - Terminal designation 10

- Interface board layout 10

- Wiring practice 10

- PNP pulse output 11

4. PROGRAM PARAMETERS

4.1 PIN number protection 12

4.2 Resetting accumulative total 12

4.3 Engineering units 12

4.4 K-factor (scale factor) 12

4.5 Pulse output 12

5. PROGRAMMING FLOW CHART 13

5.1 Program detail record 14

6. TROUBLESHOOTING 14

7. Declaration of Conformance 16

8. ALPHABETICAL INDEX 17

- NPN pulse output 11

Page 1

Page 24

2 Introduction

Introduction 3

1.2 Specifications

1. INTRODUCTION

Model Housing Type Electrical connection/

ZOD-Z1...

*order only when retrofitting a pulse meter

KS = universal mount

(standard)

KM* = integral mount

Cable gland

0 = cable gland supplied

(suits 3...6 mm Ø cables)

Supply Voltage Options Mechanical

F3= 8...24 VDC, battery 0= without 0= without

protection

Display : 5 digit resettable LCD totaliser 7.5mm ( 0.3”) high with second

line 8 digit accumulative total display & text 3.6mm ( 0.15”) high.

3 programmable decimal points with both display lines.

Signal Inputs : Universal pulse-frequency input compatible with Reed switch,

Hall effect, Coil-sine (20mV P-P min.), Voltage or current pulse &

Namur proximity detectors. Maximum input frequency is 5Khz for

coils, 2.5Khz for Hall effect & current pulse inputs, 2Khz for voltage

pulse devices & 500Hz for a Namur proximity sensor.

Powering : 3.6Vdc Ultra Lithium battery or I.S. battery pack supplied, life

expectancy can be up to 7~10 years. Battery life reduces when

connected with a coil input from turbine flowmeters. The ZOD-Z1

may also be externally powered from a regulated 8~24Vdc supply

(see page 14 for special instructions regarding ghosting).

Pulse output : Scaleable or non-scaleable NPN-PNP selectable field effect output

Transistor. Non scaleable pulse is particularly suitable for preamplifying pick-off coil inputs from turbine meters ( 5Khz. Max.).

The scaleable pulse output has a fixed pulse width of 60ms and

therefore has a frequency limit of 8hz . Both pulse outputs have a

50mA maximum drive capability.

Physical : A)

IP66/67 high impact, glass reinforced Polyamide enclosure.

B) Self drill cable gland entry at base & rear of the enclosure.

C) Overall 85mm diameter x 45mm deep x 175g (0.4lb).

D) Operating temperature -20ºC ~ +80ºC ( -4ºF ~ +176ºF).

Configuration

Functions : Accumulated & Resettable totals, pre-amplifier pulse output & a

scaleable pulse output. Low battery indication.

Configuration : Flow chart entry of data with English text prompts.

User selectable 4 digit PIN number program protection.

Programmable engineering units, decimal points and K-factors.

All programmed data protected with the battery.

K-factor range : Entered as pulses / litre, gallon, lb etc. Programmable range is

0.001~9,999,999.999 with a floating decimal point during K-factor

(scale factor) entry.

Pulse output range : Entered as engineering units/pulse. Range is 0.1~9999.9

units/pulse.

Engineering units : Selectable Ltr, Gal, m3, kgs, lbs, MLtr & Mgal or no units of display.

Page 25

4 Introduction

1.3 Overview

The ZOD-Z1 series i

nstruments are specifically designed for computing & displaying totals

from flowmeters with pulse or frequency outputs. They are battery powered or can be

powered by an external 8~24Vdc regulated or I.S. certified supply.

The instrument will display Resettable Total and an Accumulated Total in engineering units as

programmed by the user. Simple PIN protected flow chart programming with English prompts

guide you through the programming routine greatly reducing the need to refer to the manual.

Special Features

Standard

: PIN Protection. Amplified non-scaled repeater or scaleable pulse output.

: NPN/PNP selectable pulse output.

Optional : Display backlighting (needs external dc power for this option to illuminate).

: Intrinsic Safety Certification to IECex scheme and ATEX directive.

Environments

The ZOD-Z1 series is designed to suit harsh indoor and outdoor industrial and marine

environments. The robust housing is weatherproof to IP676 / IP67 standards, UV resistant,

glass reinforced Polyamide with stainless steel screws & FKM O-ring seals.

Installation

Specifically engineered to be directly mounted on a variety of flowmeters, wall, surface or pipe

mounted in the field or control room. Various mounting kits are available. The instrument is

self powered using one 3.6Vdc lithium battery or I.S. battery pack, the pulse output option

requires 8~24Vdc.

Operation 5

2. OPERATION

2.1 Resettable Total

Pressing the RESET key will cause the large 5 digit total to reset to zero. The reset function is

possible at any time during counting.

2.2 Accumulative Total

There are 8 digits in the accumulative total display, these can only be reset in the program

mode or can be protected by enabling the PIN protection feature at the front end of program

mode.

2.3 Keypad functions

KEY FUNCTION IN OPERATING MODE FUNCTION IN PROGRAM MODE

Resets the 8 digit accumulative

total display to zero. Resets internal K-factor

1. Each press steps you through each level of

2. Holding for 3 seconds fast tracks to the END

Selects the digit to

will be “flashing ” indicating that it can be

(scale factor) to zero

the program chart.

of the program from any program level.

be set, the selected digit

incremented.

Increments the selected

that it is pressed.

digit each time

PROGRAM

ENTER

Resets the 5 digit resettable

total display to zero.

1. Pressing the Program & Reset keys for 5

seconds enters you into the program mode

2. Displays model & software revision No.

No function

No function

.

1.4 LCD display

The 8 digit Accumulative Total display

can be programmed for up to 3 decimal

places. Reset is only possible when in

the program mode which can be PIN

protected for security.

Full LCD display test feature illuminates all

characters and script text displays for 5

seconds when entering the program mode.

The 5 digit Total display is front panel

resettable and can be programmed for

up to 3 decimal places.

Engineering units are selected during

the initial programming routine.

Battery condition indicator shows only

when battery is low, battery life can last

up to 7~10 years.

2.4 Battery replacement

The instrument draws very little power and will run for many years* without the need to

replace the battery. A battery condition indicator on the LCD display will appear when the

battery is low, if the low battery is not replaced the programmed detail & totals will be lost.

When changing the battery a small capacitor within the instrument will maintain the

programmed detail & totals in memory for up to 10 seconds providing sufficient time for the

battery change to take place. Changing the battery whilst flow is taking place could cause loss

of the programmed detail. It is advisable to record program details prior to battery change.

* The battery can last 7~10 years depending on application & environment.

2.5 Processor reset button

Should the instrument be corrupted by an electrical hit the processor can be reset by pressing

the black re-boot button located above the red DIP switch block on the input interface board

(refer page 10). This procedure does not effect totals or programmed data.

Page 26

6

3. INSTALLATION

3.1 Mounting

Integral meter mounting

Panel mounting

Cut a 75mm ( 3”) dia. hole in

panel. Existing O-ring seals

against panel face

If using the cable gland supplied

carefully

bottom or rear of housing as shown

on housing footprint detail on page 7

drill a 12.5mm (½”) hole at

Installation 7

Surface mount footprint

42.6mm

( 1.67 ” )

If using the cable gland

supplied carefully

12.5mm (½”) hole at

the underside or from

the inside rear of

housing

Use only the 4

special length

self tapping

screws supplied

drill a

Cable diameter range

is 2.9~6.4mm (⅛~¼”)

80 mm ( 3.15 ” )

Wall - surface mount using optional bracket kit ( P/No. AWM )

18 mm

( 0.7 ” )

42.6 mm

( 1.7 ” )

Pipe mounting ( P/No. APM )

APM adaptor pipe

mount kit is suitable

for vertical or

horizontal pipes

Page 27

8 Installation

p

A

3.2 Flowmeter connections ( un-powered sensors )

Reed switch input

DIP switches

ON

1 & 3 (de-bounce)

in the ON

1 2 3

+

gnd

-

( 40 hz max.)

1 2 3

position

+Vdc

4 5 6

+∏

-gnd

Note: DIP switch 3 is to be

OFF

for reed switch input

frequencies greater than 40 hz.

Ground screen at 3

Coil input from

turbines or paddle

ON

DIP switch 1 in

the ON

( 5 Khz max.)

1 2 3

position

+∏

gnd

-

+

1 2 3

+Vdc

-gnd

4 5 6

twisted pair

Voltage pulse

input (pulse

ON

1 2 3

gnd

-

+

1 2 3

Ground screen

wire)

DIP switch 1 in

the ON

position

( 2 Khz max.)

+∏

+Vdc

4 5 6

at 3

-gnd

Screen grounded at

amphenol shroud or

terminal box and

terminal 3 at ZOD-Z1

yellow

green

N

S

Installation 9

3.2 Flowmeter connections ( powered sensors )

NOTE : Voltage not to exceed 13.4 Vdc

through an approved barrier if when using

an intrinsically safe NAMUR proximity in a

hazardous area ( EEx Ia 11C ). Typically

these proximity’s are limited to 8.2 Vdc

NAMUR

Inductive Proximity

-

+

Ground screen at 3

Namur proximity

ON

DIP switch 2 in

the ON

( 250 hz max.)

1 2 3

gnd

-

+

input

position

+Vdc

4 5 6 1 2 3

+

+∏

-gnd

8~24Vdc

external

-

power

NOTE: For an input

>800hz position a ¼

Hall

effect

watt resistor across

terminals 1 & 4,

12Vdc: 1Meg

24Vdc: 2Meg Ω

Ω

+ ∏

-0V gnd

+Vdc

Ground screen at 3

Hall effect input

( NPN open collector )

ON

DIP switch 1 in

the ON

1 2 3

gnd

-

+

+Vdc

position

+∏

4 5 61 2 3

+

-gnd

8~24Vdc

-

external

power

NOTE: Position a 100 ohm,

¼ watt resistor across

terminals 1 & 3 as shown

Modulated current

pulse input (4~20mA)

ON

1 2 3

+

1 2 3

ll DIP switches

to be in the OFF

position

gnd

-

+Vdc

4 5 6

+∏

-gnd

Coil with pre-amp

current modulated

-

B

A

+

Ground screen at 3

+

8~24Vdc

-

external

ower

Page 28

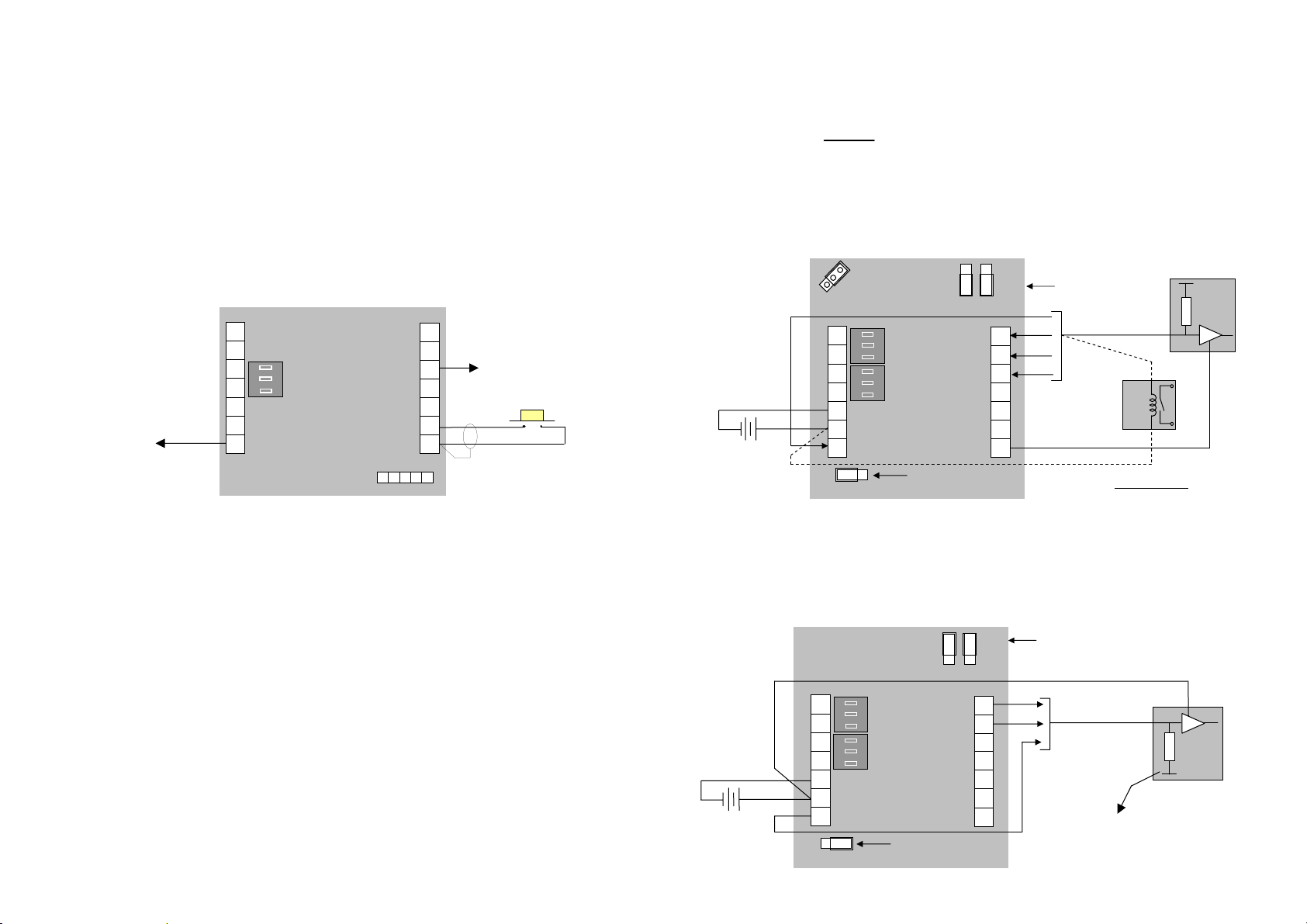

10 Installation

r

(

)

p

r

(

)

( 50

)

(

)

3.3 Wiring connections

Terminal designation

1 + I/P Flow input pulse signal

2 - Vref. Flow input ( coils & voltage type inputs )

3 gnd GND Flow input ( pulse type inputs )

4 +Vdc +Vdc External power , +8~24Vdc (see P14)

5 + ∏ O/P Output pulse ( J1 & J3 selectable )

6 -gnd GND External power

Interface board layout

Processor

reset button

Input DIP

switches

1 = 1MΩ pull up resistor

2 = 820Ω pull down resistor

3 = 0.01µf de-bounce & noise capacitor

( limits max. input freq. to 40hz)

SW5

ON

1 2 3

SW6

+

gnd

-

NPN

PNP

+Vdc

J1

0

0

0

+∏

4 5 61 2 3

I/P Vref O/P

J3