Page 1

Oval Gear Flowmeter

for Low and High Viscosity Liquids

measuring

•

monitoring

•

analyzing

DON

●● Measuring Range:

0.13 … 9.5 GPH to 40 … 660 GPM

●● Viscosity Range: up to 1000 cP

(Higher upon Request)

●● Accuracy: ± 0.2% …1% of Reading

●● Material: Aluminum or Stainless Steel

●● p

: 1450 PSI; t

max

●● Pulse Output, LCD Display, 4…20 mA,

max

Alarms, Mechanical Totalizer

KOBOLD companies worldwide:

ARGENTINA, AUSTRALIA, AUSTRIA, BELGIUM, BULGARIA, CANADA, CHILE, CHINA, COLOMBIA,

CZECH REPUBLIC, EGYPT, FRANCE, GERMANY, HUNGARY, INDIA, INDONESIA, ITALY, MALAYSIA,

MEXICO, NETHERLANDS, PERU, POLAND, REPUBLIC OF KOREA, ROMANIA, SINGAPORE, SPAIN,

SWITZERLAND, TAIWAN, THAILAND, TUNISIA, TURKEY, UNITED KINGDOM, USA, VIETNAM

05/07-30-2019

: 300 °F

KOBOLD Instruments, Inc.

1801 Parkway View Drive

Pittsburgh, PA 15205

Main Ofce:

1.800.998.1020

1.412.788.4890

info@koboldusa.com

www.koboldusa.com

Page 2

Oval Gear Flowmeter Model DON

Description

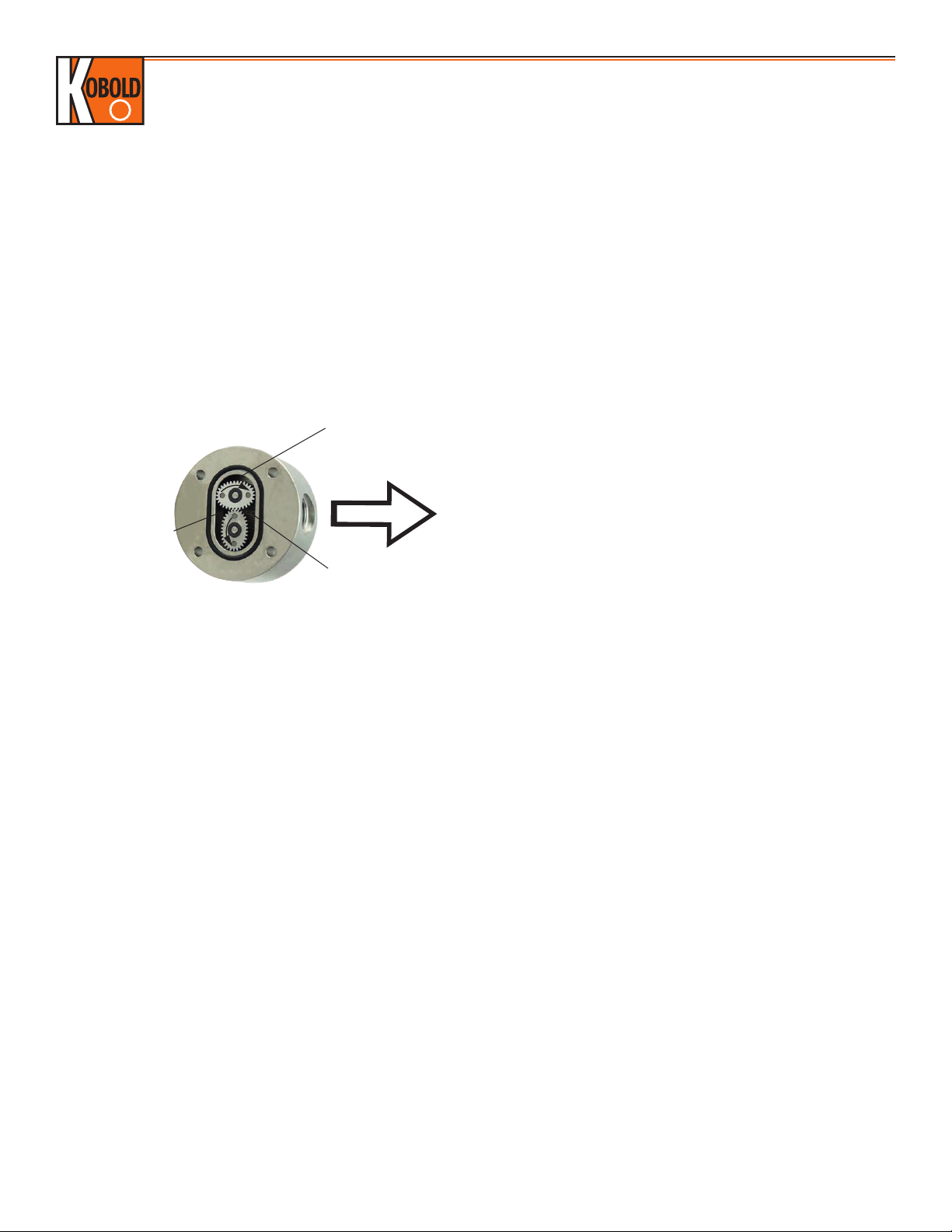

Oval gear flowmeters are categorized as positive displacement

flow technology. When liquid flows through this type of positive

displacement flowmeter, two oval geared rotors measure a constant

volume per rotation within a precisely machined measuring chamber.

With each rotation, a constant volume of liquid is measured. The

rotation of the oval gears is sensed via magnets embedded within

the rotors. These magnets transmit a high resolution pulse output.

The output signal can be processed externally via a remote display

controller or PLC or via a variety of output/display options available

as accessories attached to the flowmeters.

Operation:

Liquid travels around

the crescent shaped

chambers created by

the rotational movement

of the rotors

Liquid in transit

Flow

Liquid entering the

measuring chamber

The positive displacement flow technology allows for precise flow

measurement of most clean liquids regardless of the media's

conductivity. Other liquid properties also have a minimal effect on

the performance of this type of meter. Flow profile conditioning is

not required, as with alternative flow technology options, making

oval gear installations simple to install in tight spaces and at a

economical price.

Areas of Application

Suitable for viscous, non abrasive, clean liquids like:

Petroleum

Grease

Pastes

●

●

Oil

Fuels

●

●

Aluminum body meters are compatible with fuels, fuel oils, & other

lubricating liquids. In addition to lubricating media, stainless steel

flowmeters are suitable for most products and chemicals.

Technical Data

Materials

DON-1

Body: Aluminum

Gears: PPS GF 30 / PTFE

Axles: 316L Stainless Steel

DON-2

Body

DON-x05 ... DON-x15: 316L Stainless Steel

(DON-205 Body Cover is 316LN SS)

DON-x20 ... DON-x60: 316L/301* Stainless Steel

2

Liquid exits

the measuring

chamber

Chemicals

Ink

www.koboldusa.com

Gears

DON-x05 ... DON-x40: 316L Stainless Steel

DON-x45 ... DON-x60: 301* Stainless Steel

Bearing: Carbon Graphite

Axles: 316L Stainless Steel

DON-8

Body

DON-x05 ... DON-x15: 316L Stainless Steel

(DON-805 Body Cover is 316LN SS)

DON-x20 ... DON-x60: 316L/301* Stainless Steel

Gears: PPS GF 30 / PTFE

Axles: 316L Stainless Steel

O-Rings (Media Temperature Limits)

FKM: -4 ... 300 °F

NBR: -4 ... 212 °F

FEP-Clad EPDM: 5... 266 °F

Electrical Cover (for Cable Connection)

Standard: Polyamide PA6 GF35 UL94 HB/VO

Optional: 316L Stainless Steel

Cable Entry: M 20 x 1.5 or ½" NPT Adapter

Screw Material

for Aluminum Housing: Stainless Steel (Standard)

Steel Coated with GEOMET® 321

(for DON-225 and DON-825)

for Stainless Steel

Housing: Stainless Steel (Standard)

Steel Coated with GEOMET®321

(optional) for Higher Pressure Rating

(See Order Details)

Accuracy**

DON-x05...DON-x15: ± 1% of Reading

DON-x20...DON-x60

SS Rotors: ± 0.5% of Reading; ± 0.2% of Reading

with Optional Z3/E3 Electronics with

Linearization Function

PPS Rotors: ± 1% of Reading; ± 0.5% of Reading

with Optional Z3/E3 Electronics with

Linearization Function

Option M4: ± 1% of Reading

Additional Inaccuracy

for Analog Outputs: ± 0.15% of Full Scale

(Better Accuracies for Higher Viscosities Available upon Request)

Repeatability: ± 0.03 % Typical

Protection Class: IP 66/67 (IP 65 for M4)

Media Temperature

Options ..Lx, ..Zx, ..M4: -4...176 °F

DON-1/DON-8 Max: 176 °F (PPS Rotors)

Pulse Out or Option ..Zx

with Cooling Fins: -4...250 °F

Option ..T0: -4...300 °F

Ambient Temperature -4 ... 176 °F,

Option M4: 32...140 °F

Cable Entry: M20 x 1.5 or 1/2" NPT Adapter

* Closest AISI Equivalent to 1.3955 Stainless Steel

** Reference Conditions: DON-x05...x20 (Mineral Oil, 10 cSt, 68 °F, 75 PSIG)

DON-x25...x60 (Mineral Oil, 3 cSt, 68 °F, 14 PSIG)

Accuracy data is valid for given viscosities and higher

No responsibility taken for errors;

subject to change without prior notice.

Page 3

Oval Gear Flowmeter Model DON

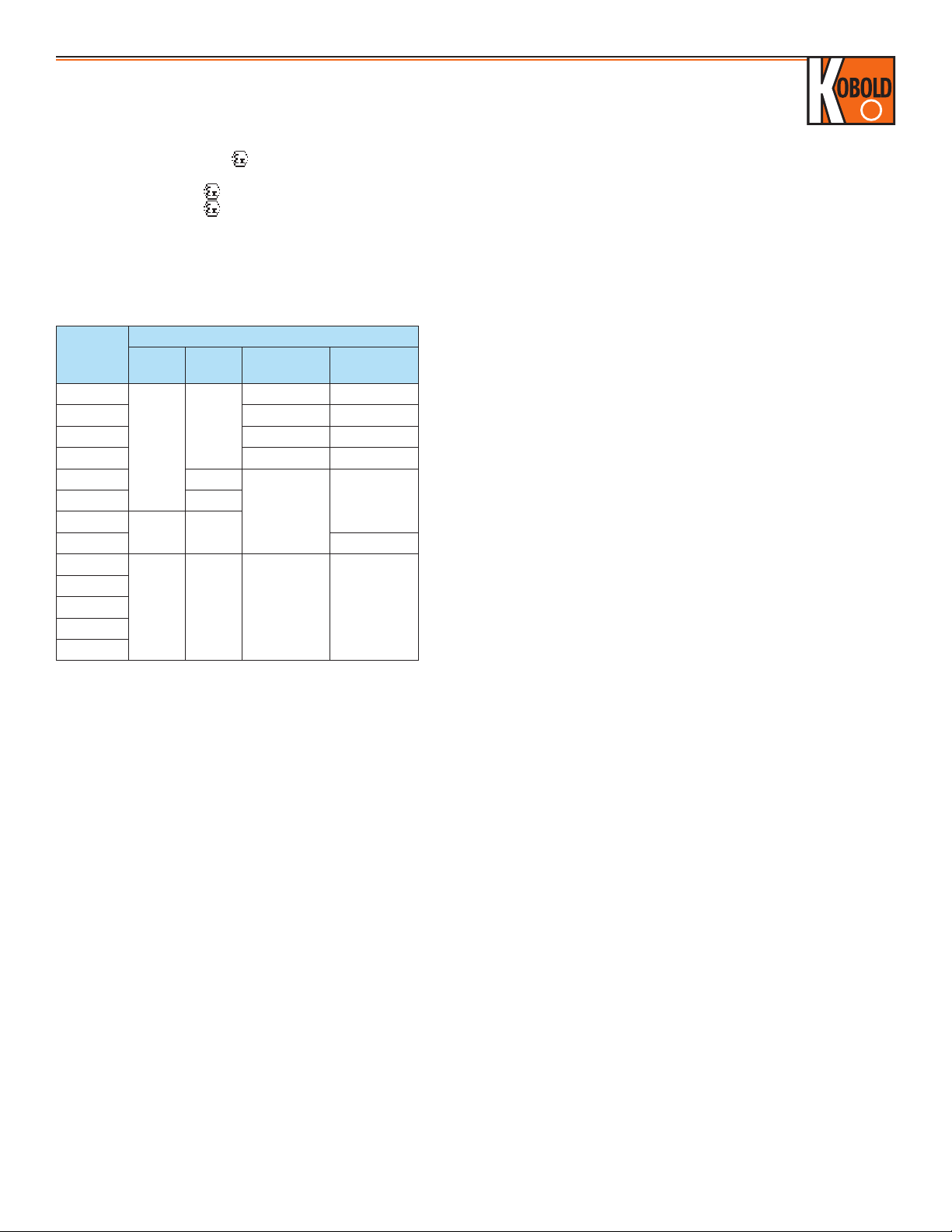

ATEX-Approval

(Options E1/E2/E3/E4/E5): II 2G Ex ia IIC T4 Gb (-20 °C ≤ Ta ≤ +60 °C)

(Options HE, DE, BE,

KE, GE, LE, RE): II 2G Ex db IIC T4/T6 Gb

I M2 Ex db I Mb

IECEx-Approval

(Options E1/E2/E3/E4/E5): Ex ia llC T4 Gb

(Options HE, DE, BE, KE,

GE, LE, RE): Ex db llC, Ex db l Mb

Maximum Pressure (Threaded Models)

Maximum Pressure (PSI)

Model

DON-x05

DON-x06 - -

DON-x10 - -

DON-x15 - -

DON-x20 1000*

DON-x30

DON-x35 435

DON-x40

DON-x45

DON-x50

DON-x55

DON-x60

With flanges: Maximum pressure rating as above or as per flange rating,

whichever is lower.

* Max pressure of 1450 psi possible with steel screws (see order details)

DON-1

925

580 725

230 230 230 230

DON-

2/8

1450

DON-1 (Op-

tion-M4)

- -

580

DON-2/8

(Option–M4)

580DON-x25 870*

Output Types

Reed Switch Pulse Output (.. R0 / RE)

The reed switch output is a two wire, normally open, SPST, voltage

free contact ideal for installations without power or for use in

hazardous area locations where Intrinsically Safe (I.S.) is required.

Note: when using the reed switch output, the liquid temperature must

not change at a rate greater than 18 °F per minute.

Average switching life of reed contact (MTTF):

Max. Load (100 V / 10 mA) 5 x 105 switching cycles

Min. Load (<5 V / 10 mA) 5 x 108 switching cycles

Power supply: max. 30 VDC, max. 200 mA

Hall Sensor Pulse Output (.. H0/HE)

In the electronics options H0/HE, a Hall Effect sensor is combined

with an active push-pull output. The signal output is actively switched

either to +Vs or to ground. No additional external circuit is required

(e.g. pull-up resistor). The "high" signal is approximately equal to the

supply voltage +Vs and the "low" signal is approximately 0 V. The

electronic utilizes a 3-wire connection with an external supply voltage

of 8 ... 30 VDC. The electrical load may be optionally connected to

the supply voltage or to GND. Maximum output current (current

source or sink): 100 mA (short circuit protected). In addition to the

Hall sensor, this option is equipped with a Reed switch which works

the same as option R0/RE.

No responsibility taken for errors;

subject to change without prior notice.

www.koboldusa.com

Hall Sensor Pulse Output (.. HU)

Like option H0, except an NPN output in place of the

push-pull output and a supply voltage of 5-30 V

DC.

Hall Sensor Pulse Output, (.. B0/BE)

Like options H0/HE; however with bipolar sensors and

alternating polarized magnets. This option is used for

pulsating flow, but is not equipped with a Reed switch and

has half the k-factor value as compared to H0/HE.

High-Resolution Hall Sensor Pulse Output, (..G0/GE,

..K0/KE)

Like options H0/HE; the models DON-x05 and DON-x10 can

be supplied with four times the pulse count per volume unit

and models DON-x05...x20 with double the amount of pulses

(K0/KE) (see table «Output Pulse Resolution» on the following

pages).

Quadrature Hall Effect Pulse Output (..D0/DE)

The DON with option D0/DE provides two independent Hall

sensors. They are arranged to give separate outputs out of

phase with one another.

The QUAD output is mostly suitable for detecting bidirectional

flows (detection of flow direction) or where a redundant signal

is desirable. Maximum output current per channel (current

source or sink): 100 mA (short circuit protected).

Analog Output (..L0/LE)

The options L0 and LE (Ex) are available with a loop-powered

4-20 mA output. The loop must be powered with an external,

16...32 VDC power supply. The maximum resistance of the

series loads (PLC analog input / display electronics) depends

on the magnitude of the supply voltage and can be calculated

as follows:

Max. load [Ohm] = (+Vs – 9 VDC) / 0.02 A [Ω]

Example: +Vs = 32 VDC = > max. load = 1150 Ω

+Vs = 16 VDC => max. load = 350 Ω

The load can be inserted at any point in the current loop,

observing correct polarity.

Mechanical Totalizer (..M4)

The DON-x20 .. through DON-x60 .. are available with a 4-digit

resettable totalizer and indication of accumulated total value.

The motion of the rotors is transmitted to the mechanical

register totalizer via an interfacing reduction gear train and

dynamic seal assembly. Option M4 is also optionally available

in liters.

Body Material: Enameled Die-cast Aluminum,

Powder-coated

Protection: IP 65

Ambient Temp: 32...140 °F

Media Temp: -4...176 °F

Recommended Filtration Requirements:

DON-x05 ... DON-x15 < 75 μm (200 mesh)

DON-x20 ... DON-x35 < 150 μm (100 mesh)

DON-x40 ... DON-x60 < 350 μm (45 mesh)

3

Page 4

Electronic with LCD Display

Model ..Z1 ..Z2 ..Z3 ..ZE ..ZB ..E1 ..E2 ..E3 ..E4 ..E5

Oval Gear Flowmeter Model DON

Function

Dual

Totalizer

Batching

Unit

Rate/Totalizer

Dual

Totalizer

Batching Unit Rate /Totalizer Rate /Totalizer Rate /Totalizer

Power Supply

External

(also for Backlighting)

Battery-Operation

(Outputs Inactive)

Battery Included

in Shipment

2)

3)

5 - 28 VDC12 - 28 VDC5 - 28 VDC9 - 28 V

DC

-

yes no yes yes yes yes no yes no no

yes

-

yes no yes yes

-

Ui = 28 V

Ii = 100 mA

Pi = 0.7 W

yes

- -

LCD Display

Selectable Units yes yes yes yes yes yes yes yes yes yes

Decimal Point yes yes yes yes yes yes yes yes yes yes

Accumulative Total yes yes yes yes yes yes yes yes yes yes

Resettable Total yes yes yes yes yes yes yes yes yes yes

Linearization yes no yes yes yes yes no yes yes yes

Rate Display yes yes yes yes yes yes yes yes yes yes

Backlighting yes yes yes yes no no no no no no

Input

Sensors Hall Sensor/Reed Switch Reed Switch

Outputs

4-20 mA no no yes no no no no yes yes (HART®) yes

Flow Rate

Alarm Min./Max.

no

no

NPN/PNP/

Push-Pull

no no no no no no

optocoupler

Batch End & Control no yes no no no no yes no no no

Pulse Output no no Push-Pull Push-Pull no no no no no

2 x SPDT Relays

1)

no yes option no no no

with

optocoupler

no no

optocoupler

Installation

IP 65 yes yes yes IP 66/67 IP 66/67 yes yes yes yes yes

with

with

Cable Entries M20x1.5 or ½" NPT

Media Temperature

Range

(Cooling Fin Option: max.

250 °F)

Ambient Temperature

Range

-4... 176 °F 32 ... 140 °F

-4...176 °F

Housing Material PA6 GF35 UL94 HB/VO / PC UL94 V-2

ATEX Approval no yes

1)

Replaces solid state outputs, for details see ZOK Datasheet

2)

Battery operation only acceptable with reed switch sensor "Rx"

3)

Options Z6, Z7, Z8, and Z9 are shipped without batteries

4

www.koboldusa.com

No responsibility taken for errors;

subject to change without prior notice.

Page 5

DON Pressure Drop Versus Viscosity Curves

Oval Gear Flowmeter Model DON

1 Standard Rotors 100 % of Full Scale

2 Standard Rotors 50 % of Full Scale

Special Cut Rotors 100 % of Full Scale

3 Standard Rotors 25 % of Full Scale

Special Cut Rotors 50 % of Full Scale

4 Special Rotors 25 % of Full Scale

5 Special Rotors 10 % of Full Scale

2 Standard Rotors 50 % of Full Scale

Special Cut Rotors 100 % of Full Scale

3 Standard Rotors 25 % of Full Scale

Special Cut Rotors 50 % of Full Scale

4 Special Cut Rotors 25 % of Full Scale

5 Special Cut Rotors 10 % of Full Scale

6 Special Cut Rotors 5 % of Full Scale

Pressure Drop Limit Versus Flowrate

The curves above represent the pressure drop for standard cut oval rotors. Special cut rotors, option "Y" have alternate tooth relief

which effectively reduces the pressure drop by 50%. When sizing a meter, be sure your selection falls below the 1 bar (14.5 PSI)

maximum allowable pressure drop line on the graph.

No responsibility taken for errors;

subject to change without prior notice.

www.koboldusa.com

5

Page 6

Oval Gear Flowmeter Model DON

Maximum Flowrate Multiplier (for Higher Viscosities)

Viscosity

(cPs)

≤ 1,000 1 1

≤ 2,000 0.5 1

≤ 4,000 0.42 0.84

≤ 6,000 0.33 0.66

≤ 8,000 0.25 0.5

≤ 30,000 0.15 0.3

≤ 60,000 0.12 0.25

≤ 150,000 0.1 0.2

≤ 250,000 0.05 0.1

≤ 1,000,000 0.025 0.05

Standard

Rotor

Special Cut

Rotor

Special Cut Rotors for Higher Viscosities

For viscosities > 1000 cP, special cut rotors (option: "Y") are

normally required to keep the maximum pressure drop from

exceeding acceptable levels. This option applies to DON-x15

and larger sizes. For higher viscosities, the flowmeter max.

flowrate is derated according to the table above.

Example:

DON-x25G measuring viscous oil at 8000 cP:

max. flow of 40 GPM x 0.5 = 20.0 GPM new max. flow rate.

Noise Level (in dB) at Full Scale

Size PPS Gears SS Gears

x25 83 91

x30 84 93.1

x35 83.5 95

x40 85.4 96

x45 87.5 98

x50 86.1 99.4

x55 86.1 98.1

x60 85 99

Information Required for Order:

To ensure proper operation, this product requires a

completed application guide form to be submitted with

any order. Please refer to the ‘documentation’ tab on

the bottom of the product page for this product on our

website in order to obtain the correct form. You can

also contact your KOBOLD representative for this form.

Nominal Output Pulse Resolution*

Model

DON-x05 0.13...9.5 GPH 10107 10107

DON-x06 0.5...9.5 GPH 10107 10107

DON-x10 0.5...27 GPH 4020 4020

DON-x15 4...145 GPH 1329 2657

DON-x20 0.26...10.6 310 617

DON-x25 2.6...40 98 394

DON-x30 4.0...66 51 208

DON-x35 8.0...120 24.2 96.5

DON-x40 13...150 18.5 74.2

DON-x45 10...200 9.7 39.0

DON-x50 13...260 5.7 22.3

DON-x55 20...400 3.97 15.9

DON-x60 40...660 2.12 8.71

Flow Range

(GPM)

Reed Switch

Rx

Hall Sensor

Hx

Pulse per Gallon

Hall Sensor

Bx

---

---

---

1329

310

98

51

24.2

18.5

9.7

5.7

3.97

2.12

QuadratureHall Sensor

Dx

10107 42851 20214

- - -

4020 16080 8040

2657 --- 5315

617 --- ---

197 --- ---

102 --- ---

51.1 --- ---

37.1 --- ---

19.5 --- ---

11.4 --- ---

7.95 --- ---

4.35 --- ---

Hall Sensor,

High-Resolution

Gx

*The output resolution values listed in the above table are only approximate values. The exact output resolution value is

noted within the calibration certificate delivered with each flowmeter.

Hall Sensor,

High-Resolution

Kx

6

www.koboldusa.com

No responsibility taken for errors;

subject to change without prior notice.

Page 7

Oval Gear Flowmeter Model DON

Order Details (Example: DON-105G N1 1 L0 N 0)

Housing / Rotor Material

Measuring

Range

0.13...9.5

GPH

0.5...9.5

GPH

0.5...27

GPH

4...145

GPH

0.26...10.6

GPM

2.6...40

GPM

4.0...66

GPM

8.0...120

GPM

13...150

GPM

10...200

GPM

13...260

GPM

20...400

GPM

40...660

GPM

1)

Only for DON-x35; 2) Only for DON-x05 and DON-x10; 3) Without Backlighting; 4) Replace 'G' with 'H' to Order LPM (LPH); 5) With Steel Screws, Only for DON-2... and

DON-8...;

Ordering, (Possible Flow Directions: Bottom to Top, Left to Right, or Right to Left);

9)

Only for DON-x05, -x10, -x15 Without Reed Switch;

Aluminum

with PPS

Rotor

Stainless

Steel

DON-105G.. - -

- DON-206G.. DON-806G..

DON-110G.. DON-210G.. DON-810G..

DON-115G.. DON-215G.. DON-815G..

DON-120G.. DON-220G.. DON-820G..

DON-125G.. DON-225G.. DON-825G..

DON-130G.. DON-230G.. DON-830G..

DON-135G.. DON-235G.. DON-835G..

DON-140G.. DON-240G.. DON-840G..

DON-145G.. DON-245G.. DON-845G..

DON-150G.. DON-250G.. DON-850G..

DON-155G.. DON-255G.. DON-855G..

DON-160G.. DON-260G.. DON-860G..

10)

6)

Only for DON-x20...DON-x60; see M4 Option Description for Details on Minimum Incremental Volume Unit per Model Number; Please Specify Flow Direction when

Option(s) to Add. Special Cut Rotors for Higher Viscosities: Not for DON-x05...DON-x10, Check Valve: From DON-x30..., and any other Non-Standard Request

No responsibility taken for errors;

subject to change without prior notice.

4)

Stainless

Steel with

Connection

O-ring

Material

PPS Rotor

..N1.. = ⅛

" NPT

..R1.. = G ⅛

..N1.. = ⅛

" NPT

..R1.. = G ⅛

N2.. =

..

..R2.. =

..N3.. = ⅜

¼" NPT

G ¼

" NPT

..R3.. = G ⅜

N4.. =

..

..R4.. =

P45).. =

..

..H45).. =

N6.. =

..

..R6.. =

A6.. =

..

½" NPT

G ½

½" NPT (1450 psi)

G ½ (1450 psi)

1" NPT

G 1

1" 150 lb

ANSI Flange

B6.. =

..

1" 300 lb

ANSI Flange

F6.. =

..

DN25 PN40

DIN Flange

P65).. =

..

..H65).. =

N8.. =

..

..R8.. =

A8.. =

..

ANSI Flange

B8.. =

..

ANSI Flange

F8.. =

..

1" NPT (1450 psi)

G 1 (1450 psi)

1½" NPT

G 1½

1½" 150 lb

1½" 300 lb

DN40 PN40

..1.. = FKM

..3.. = FEP

Coated

EPDM

..4.. = NBR

DIN Flange

N9.. =

..

..R9.. =

A9.. =

..

2" NPT

G 2

2" 150 lb

ANSI Flange

B91).. =

..

2" 300 lb

ANSI Flange

F9.. =

..

DN50 PN16

DIN Flange

..C9.. = DN50 PN40

DIN Flange

NB.. =

..

..RB.. =

AB.. =

..

3" NPT

G 3

3" 150 lb

ANSI Flange

FB.. =

..

DN80 PN16

DIN Flange

NC.. =

..

..RC.. =

AC.. =

..

4" NPT

G 4

4" 150 lb

ANSI Flange

FC.. =

..

DN100 PN16

DIN Flange

7)

10)

Calibrated up to 500 GPM. Higher Flow Rate Calibration on Request;

Only for Electronic Options -Zx/-Ex, not for DON-1.. and DON-8..; 8) Only for DON-2;

www.koboldusa.com

Electronic/ Display Cable Entry Option

..R0..

= Reed Switch Pulse

Output

..RE..

= Reed Switch Pulse

Output ATEX (Exd)

.H0.. = Hall Sensor (Push-Pull) /

Reed Switch Pulse

Output

..HE..

= as H0 + ATEX

..HU..

= NPN Pulse Output

(Hall / Reed),5-30 V

DC

..B03).. = For Pulsating Flow

..BE3).. = B0 + ATEX (Exd)

..K09).. = High Resolution Hall

Sensor (x2)(Push-Pull)

..KE9).. = as K0 + ATEX (Exd)

..G02).. = High Resolution Hall

Sensor (x4)(Push-Pull)

..GE2).. = as G0 + ATEX (Exd)

11)

..D0

.. = Quad. Hall Sensor

..M.. = M20

2 Phased Outputs

(Push-Pull)

11)..

..DE

= as D0 + ATEX (Exd)

..N.. = ½" NPT

..L0.. = 4 ... 20 mA Loop

Powered Analog Output

..LE.. = as L0 + ATEX (Exd)

..T08).. = Hall Sensor (Push-Pull) /

High-Temp 300 °F Max.

..S7).. = M20

with

Cooling

Fin

..Z1.. = Dual LCD Totalizer

(ZOK-Z1)

..Z2.. = Batching Unit LCD

(ZOK-Z2)

..Z3.. = LCD Totalizer, Rate,

Outputs: 4-20 mA, Alarm,

Pulse (ZOK-Z3) (Impulses

..T7).. = ½" NPT

with

Cooling

Fin

not for Battery Supply)

..Z6.. = Z1 + B0

..Z7.. = Z3 + B0

..Z8.. = Z1 + D0

..Z9.. = Z3 + D0

..ZE.. = LCD Rate / Total

(ZOE with External

Supply / with Battery)

..ZB3).. = LCD Rate / Total (ZOE

Without External Supply /

with Battery)

..E13).. = as Z1 + ATEX/IECEx (Exi)

..E23).. = as Z2 + ATEX/IECEx (Exi)

..E33).. = as Z3 + ATEX/IECEx (Exi)

(Without Switching or

Pulse Outputs)

..E43).. = E3 + HART

®

..E53).. = E3 + Pulse or Switching

Outputs with 4-20 mA

..M46).. = Mechanical Totalizer,

4-Digit

11)

Not for DON-x06;

..0.. = Without

12)

Specify in Writing which

..0 = Without

12)

..Y

= Special

Request

7

Page 8

42,4

13

115

6,5

21,6

61

42,4

13

115

6,5

42,4

13

6,5

Dimensions DON-1(2/8)...

DON-x05...DON-x15

Mounting Surface

Oval Gear Flowmeter Model DON

DON-x45...DON-x60

Pulse Output

Zx/Ex

Zx/Ex with

Cooling Fin

Mech. Totalizer M4

2.0"

Pulse Output

Zx/Ex

DON-x20...DON-x40

Zx/Ex with

Pulse Output

Zx/Ex

Cooling Fin

Zx/Ex with

Cooling Fin

Mech. Totalizer

M4

B

Electronic with LCD Display Zx / Ex

0.9"

21,6

2.4"

0.9"

61

2.4"

52

2.1"

0.9"

with optional Cooling Fins

32

Dimensions* DON-1(2/8)… (± 0.08")

1.3"

2.6"

66

131

5.2"

134

5.3"

A B C

Model

Thread

Connection

Flange

Connection

Pulse Output Zx/Ex

Mechanical

Totalizer M4

Pulse

Output/Lx

Zx/Ex

DON-x05 2.67" - 3.62" 5.16" - 2.83" 5.28" -

DON-x06 (2.67") - (3.62") (5.16") - (2.83") (5.28") -

DON-x10 2.67" - 3.62" 5.16" - 2.83" 5.28" -

DON-x15 2.67" - 3.89" 5.43" - 2.83" 5.28" -

DON-x20 4.33" - 4.13" (3.98") 5.28" (5.12") 7.17" (7.01") 4.41" 5.28" 6.50"

DON-x25 6.93" 9.33" 5.36" 6.50" 7.64" 4.72" 5.28" 6.69"

DON-x30 7.40" 9.92" 6.54" 7.68" 8.78" 6.42" 6.42" 7.88"

DON-x35 8.34" 10.90" 6.77" 7.92" 9.61" 7.09" 7.09" 7.88"

DON-x40 8.34" 10.90" 9.69" 10.83" 11.77" 7.09" 7.09" 7.88"

DON-x45 10.50" 13.90" 9.13" 10.28" 11.18" 9.37" 9.37" 9.41"

DON-x50 11.60" 15.00" 9.02" 10.16" 11.89" 11.41" 11.41" 11.41"

DON-x55 11.60" 15.30" 10.80" 11.93" 13.66" 11.41" 11.41" 11.41"

DON-x60 12.60" 16.30" 13.80" 14.96" 16.70" 13.03" 13.03" 13.03"

*

Dimensions for DON-2/8... are specified in ( ) only when they are different from DON-1...

8

www.koboldusa.com

Mechanical

Totalizer M4

No responsibility taken for errors;

subject to change without prior notice.

Loading...

Loading...