Page 1

Operating Instructions

for

Oscillation Flowmeter

Model: DOG-4...

Transducer and Electronic Options A/B…O/P

Page 2

DOG-4

page 2 DOG-4 K08/0818

1. Contents

1. Contents ....................................................................................................... 2

2. Note .............................................................................................................. 4

3. Information on operating the device in potentially explosive environments

(Ex, A0/D0/F0/H0/K0/N0/P0 option) ........................................................... 4

3.1 General requirements .......................................................................... 5

3.2 Startup, installation .............................................................................. 6

3.3 Application ........................................................................................... 6

3.4 Repair, maintenance (for applications in Ex areas) ............................. 7

3.1 Disposal .............................................................................................. 7

4. Instrument Inspection ................................................................................... 8

5. Regulation Use ............................................................................................. 8

6. Operating Principle ....................................................................................... 9

7. Mechanical Connection .............................................................................. 10

8. Identification (Ex version) ........................................................................... 11

9. Electrical connections ................................................................................. 12

9.1 General ............................................................................................. 12

9.2 Measuring cable in Ex areas ............................................................. 12

9.3 Connection to the measuring sensor ................................................. 12

9.4 Terminal assignment of the DOG-4… reader/transducer .................. 13

9.5 Terminal assignment of the electronic option

G0/H0/I0/K0/M0/N0/O0/P0 ................................................................ 15

9.6 Connections of DOG-4 Transmitter with KOBOLD Evaluation

Electronics ZED-X and ZOK-Zx ......................................................... 17

10.Startup ........................................................................................................ 20

11.Setup and operation of the flow controller/flow computer (option

G0/H0/I0/K0/M0/N0/L0/O0/P0) ................................................................ 20

12.Transmitter error message ......................................................................... 21

12.1 Status display not illuminated ............................................................ 21

12.2 OPERATING illuminated green but no output signal ......................... 21

12.3 RANGE illuminated yellow................................................................. 21

12.4 ERROR illuminated red ..................................................................... 21

13.Maintenance ............................................................................................... 22

13.1 Replacing the sensor ......................................................................... 22

13.2 Disassembly and cleaning the Flowmeter ......................................... 22

14.Technical Data ............................................................................................ 24

14.1 Electronic options .............................................................................. 25

15.Order Details .............................................................................................. 29

16.Pressure Loss/Flow .................................................................................... 31

17.Dimensions ................................................................................................. 32

18.EU Declaration of Conformance ................................................................. 34

19.ATEX-Certificate ......................................................................................... 35

20.IECEx-Certificate ........................................................................................ 41

Page 3

DOG-4

DOG-4 K08/0818 page 3

Manufactured and sold by:

Kobold Messring GmbH

Nordring 22-24

D-65719 Hofheim

Tel.: +49(0)6192-2990

Fax: +49(0)6192-23398

E-Mail: info.de@kobold.com

Internet: www.kobold.com

Page 4

DOG-4

page 4 DOG-4 K08/0818

2. Note

Please read these operating instructions before unpacking and putting the unit into

operation. Follow the instructions precisely as described herein.

The devices are only to be used, maintained and serviced by persons familiar with

these operating instructions and in accordance with local regulations applying to

Health & Safety and prevention of accidents.

as per machine-guidelines 2006/42/EC

CE mark acc. ATEX-guideline 2014/34/EU

When used in machines, the DOG-4 should be used only when the machines fulfil

the EC-machine guidelines.

as per PED 2014/68/EU

Model Connection PN

no dangerous gases

(diagr. 7, 2)

dangerous gases

(diagr. 6, 1)

DOG-4

DN 25 10 article 4, § 3 I

DN 40 until DN 50 10 I II

DN 80 until DN 150 10 I II

DN 200 10 I II

Funded by the Federal Ministry of Economics and Technology based on a decision

of the German Bundestag.

3. Information on operating the device in potentially

explosive environments (Ex, A0/D0/F0/H0/K0/N0/P0

option)

The devices can be used in the following way:

1. DOG-4S Flowmeter: In zones 0, 1 and 2 (gas Ex, category 1G, 2G, 3G) in

explosion groups IIA, IIB and IIC

2. DOG-4A Reader/Transducer Reader: Outside the EX area

Here the following ambient temperatures must be adhered to

-20 °C ≤ Ta ≤ 60 °C

The DOG-4 is suitable for use with gases of the explosion group IIC and temperature

class ≥ T4.

Further important details can be found in the EC Type Examination Certificate.

Page 5

DOG-4

DOG-4 K08/0818 page 5

3.1 General requirements

In the event of failure to comply with this information or unauthorized tampering with

the device, the manufacturer's liability will no longer apply. Moreover, the guarantee

for the device and accessory parts will become void.

Comply with the information in these operating instructions and adhere to the

conditions of use and permissible data printed on each device / type plates.

Follow the generally accepted rules of technology when selecting and

operating a device.

Take appropriate measures to prevent unintentional activation or inadmissible

impairments.

The devices may be used only in the correct way and for the intended

purpose in a normal industrial environment. Use for unsuitable purposes, will

render all guarantees and liability of the manufacturer void!

Ensure that only devices with ignition protection suitable for the operating

zones are installed.

All electronic operating resources connected must be suitable for the

respective use.

The operator is obligated to provide lightning protection according to local

regulations.

Page 6

DOG-4

page 6 DOG-4 K08/0818

3.2 Startup, installation

The devices are intended for installation in a higher-level system. The intervals for

cleaning the operating resources (dust deposits) are specified depending on the

degree of IP protection. It is extremely important to ensure that only devices with

suitable ignition protection for the zones/categories are installed! It is essential that

the installation regulations applicable at the national level, e.g. EN 60079-14, are

adhered to during installation. Other important factors:

In the event of adverse environmental conditions, it is necessary to ensure

that the devices are accordingly protected.

Follow the operating instructions for the respective device and adhere to any

special conditions described there.

The device may only be used for the purpose for which it was intended.

It is essential to avoid electrostatic charges.

Any possible metal parts in the device/lines (e.g. shielding) must be

incorporated in the potential equalization PA in compliance with the user’s

country regulations.

Parts that have jammed (e.g. as the result of frost or corrosion) may not be

loosened by force in hazardous atmospheres.

Operate the device only in the completely assembled state and enclosed in

undamaged housing. Operating with a damaged housing is prohibited.

At ambient temperatures of less than -5°C the connecting lines must be

securely laid.

Do not allow the outside of the device to come into contact with strongly

corrosive media.

Do not subject the system to excessive vibrations, bending or torsion.

The devices may not – or only with the manufacturer's permission, and then

only using special measures – be used in systems with electric corrosion

protection. Parasitic currents must not be fed in via the shielding.

Installations in Ex areas may be carried out only in compliance with the local

installation regulations.

Installation and maintenance only in ex-free atmospheres in compliance with

the user’s national regulations.

Additional precautionary measures must be taken if there is a possibility that

hydrogen sulfide, ethylene oxide and/or carbon monoxide could be present. These

compounds have very low ignition power!

Only non-arcing tools may be used for these compounds as well as all compounds

included in explosion group IIC – if explosive atmospheres are still to be expected!

3.3 Application

The devices may be used only in the correct way and for the intended purpose in a

normal industrial environment. Use for unsuitable purposes, will render all

guarantees and liability of the manufacturer void!

See Chapter 4, 5, 7 and 9.

Page 7

DOG-4

DOG-4 K08/0818 page 7

3.4 Repair, maintenance (for applications in Ex areas)

Definition of terms as defined in IEC 60079-17:

Repair and maintenance: A combination of all activities carried out to maintain an

item or restore the object to a state in which it is able to meet the requirements of the

relevant specification and ensure the execution of its required functions.

Inspection: An activity comprising the careful examination of an item carried out

either without demounting or, if necessary, with partial demounting through such

steps as measurement in order to reliably determines the condition of the item.

Visual inspection: An inspection in which visible faults, e.g. missing bolts, are

detected without the use of equipment or tools.

Close inspection An inspection which comprises the aspects of a visual inspection

in addition to identifying defects, e.g. loose bolts, apparent only by access with the

use of equipment, e.g. steps (when necessary) and tools. Close inspections do not

normally require an open enclosure or the de-energizing of the equipment.

Detailed inspection An inspection which encompasses those aspects covered by a

close inspection and, in addition, identifies those defects, e.g. loose connections

which are only be apparent by opening the enclosure and/or using tools and test

equipment where necessary.

Maintenance work may be performed only by qualified personnel with the

equivalent of or qualification according to TRBS 1203 (German Technical

Rules for Industrial Safety).

Only accessory parts which fulfill all European regulations and national laws

may be used in hazardous areas.

The replacement of components may only take place using original spare

parts approved for use in Ex areas as well.

The devices in Ex areas must be cleaned regularly. The intervals must be

specified by the operator according to the environmental load.

After maintenance and/or repair, replace all barriers and notices removed in

the process in their original positions.

Uninstall the device if any faults are detected. The customer may not repair

internal parts. Send the device to the manufacturer for inspection.

Task

Visual inspection

monthly

Check

every 6 months

Detailed inspection

every 12 months

Visual inspection of the device for

integrity, remove dust residues

● ●

Inspection of the entire system Responsibility of the operator

3.1 Disposal

Disposal of the packaging and the used parts must be carried out according to the

regulations of the country in which the device is installed.

Page 8

DOG-4

page 8 DOG-4 K08/0818

4. Instrument Inspection

Instruments are inspected before shipping and sent out in perfect condition.

Should damage to a device be visible, we recommend a thorough inspection of the

delivery packaging. In case of damage, please inform your parcel service /

forwarding agent immediately, since they are responsible for damages during transit.

Scope of delivery:

The standard delivery includes:

DOG-4S Flowmeter including flange housing, measuring head, thermal wire

sensor and connection box.

Measuring cable from the Flowmeter to the measuring converter (optional).

DOG-4A/B…O/P reader/transducer.

Operating instructions.

5. Regulation Use

DOG-4 type devices are used for measuring and monitoring the rate of flow. Only

clean media may be measured, against which the materials used are resistant. Dirt

particles and other impurities can impair the measurement results, in spite of the fact

that the continuous change in direction of the flow ensures a self-cleaning effect. The

measuring sensor may be used only with the corresponding transducer.

Connectioon box

Measuring cable

Reader/

Transducer

Flowmeter

Flange housing

Measuring head

Direction

Page 9

DOG-4

DOG-4 K08/0818 page 9

6. Operating Principle

This device is a oscillating beam device and works without any movable parts. An

orifice plate in the base creates flow resistance, which forces a partial flow to be

directed into the measurement head. The gas in the measuring head begins to

oscillate. The frequency of oscillation is proportional to the flow of volume. As the

ratio between the flow through the measuring head and the flow through the

measuring housing is constant, the frequency of oscillation is directly proportional to

the entire flow of volume through the device. A platinum sensor determines the

oscillation in the measuring head. The measuring converter normalises the

measured oscillation to 0 Hz (without flow) and to 150 Hz for the end of the

measuring range.

View from underneath

Platinum sensor

View from above

Page 10

DOG-4

page 10 DOG-4 K08/0818

7. Mechanical Connection

The measuring sensor should be installed in a horizontal position with the measuring

head facing upwards. A slight inclination in the direction of flow is permitted. The

arrow on the flange housing must point in the direction of flow. The recommended

minimum inlet path is 10 times the diameter of the pipe and the maximum outflow

zone 5 times the diameter of the pipe. To prevent any possible rotational flow, it is

recommended that a flow straightener be fitted upstream of the counter. For damp

media, slightly inclined installation in the direction of flow is recommended in order to

ensure the removal of condensate from the oscillator.

Direction of flow

It is also recommended to install a condensate separator, preferably in a vertical pipe

in front of the flow meter (see figure below). The condensate can thus be removed

before entering the flow meter.

Should the temperature difference between ambient and medium be +20 °C or

greater, the pipeline and the flow meter should be thermally insulated to prevent

condensation.

Page 11

DOG-4

DOG-4 K08/0818 page 11

8. Identification (Ex version)

Flowmeter (DOG-4S) type plate

(flange housing, measurement tube)

There is a warning label on the plastic housing “WARNING – DANGER Of

ELECTROSTATIC DISCHARGE – SEE OPERATING INSTRUCTIONS”

Transducer (DOG-4A) type plate

(see left)

Page 12

DOG-4

page 12 DOG-4 K08/0818

9. Electrical connections

9.1 General

Install the measuring sensor near the transducer (max. 100 m cable length,

depending on the electrical interference zone).

The measuring cable must be laid well away from strong sources of electrical

interference and not parallel to power cables.

The measuring cable of several DOG-4s must not be laid over long distances

next to one another or bundled together.

The DOG-4A transducer must be installed outside of the Ex zone.

Lay the electrical cabling according to the following wiring diagram.

Each transducer is matched specifically to the respective measuring sensor

and must not be swapped over.

The pipelines and the flange housing must be grounded.

9.2 Measuring cable in Ex areas

An Ölflex EP (without shield) or Ölflex EBCY (with shield) may be used as measuring

cable between the sensor and transmitter. Alternatively a cable with comparable

properties may be used.

Ölflex EB Li=0.65 mH/km Cisy=110 nF/km

Ölflex EBCY Li=0.65 mH/km Cisy=135 nF/km Ciasy=185 NF/km

The length of the cable may not exceed 100 m. The maximum permitted cable

inductance is Limax=65 µH and the maximum capacitance Cimax=32 nF.

9.3 Connection to the measuring sensor

To connect the measuring cable, first unscrew the lid of the connection box and

remove the lid. Feed the cable through the cable gland and connect it to the

connecting terminal (independent of polarity). When using a shielded cable, the

shield must be connected to the grounding screw.

Page 13

DOG-4

DOG-4 K08/0818 page 13

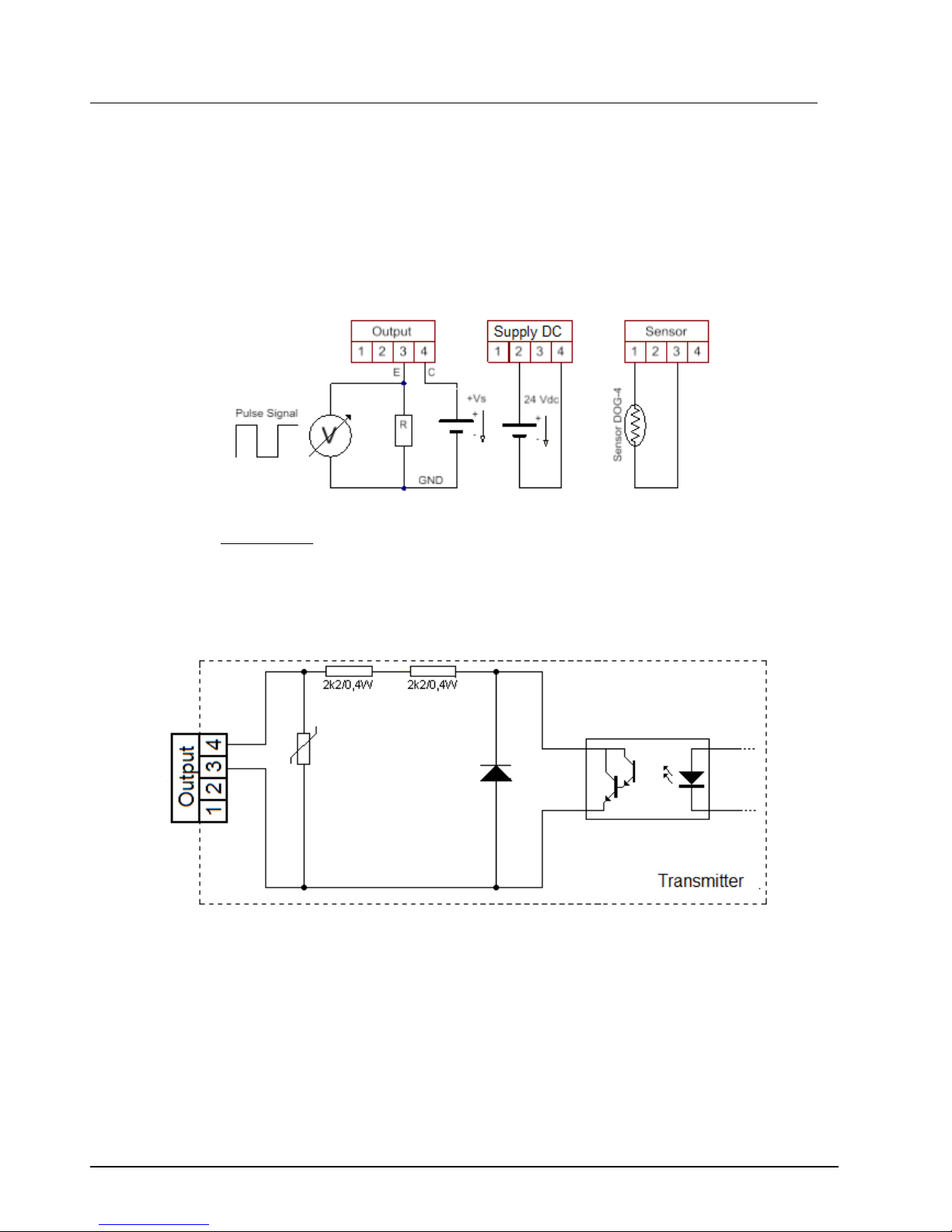

9.4 Terminal assignment of the DOG-4… reader/transducer

230 V

AC

110 VAC

24 VAC

24 V

DC

Output

Sensor

L = 230 V/110 V/24 V outer conductor + = supply DC+

N= 230 V/110 V/24 V neutral conductor - = supply DC-

E = emitter optical coupler

C = collector optical coupler

I-= sensor conductor

I+= sensor conductor

Supply

black

1 2 3 4

L N

+ -

Output

orange

1 2 3 4

E C

Sensor

blue

1 2 3 4

+ -

for AC

for DC

Page 14

DOG-4

page 14 DOG-4 K08/0818

U

HIGH

= ; U

LOW

< 0.5 V

Example: Vs = 24 VDC: U

HIGH

=17 VDC@ R=10 kOhm, U

HIGH

=23 VDC@R=80 kOhm,

R

R+4.4 kΩ

Optical coupler output, external supply max. 30 VDC, I

max

= 50 mA

Page 15

DOG-4

DOG-4 K08/0818 page 15

9.5 Terminal assignment of the electronic option

G0/H0/I0/K0/M0/N0/O0/P0

With the electronic option G0/H0/M0/N0, the reader/transducer is located together

with the flow controller/flow computer prewired in the plastic wall housing. The

connection terminal strip is located underneath the terminal cover. This must be

removed for the electrical connection.

Note:

Additional pressure and temperature sensors are required for the electronic options

M0/N0/O0/P0 (flow computer). These sensors are not included in the scope of delivery.

Page 16

DOG-4

page 16 DOG-4 K08/0818

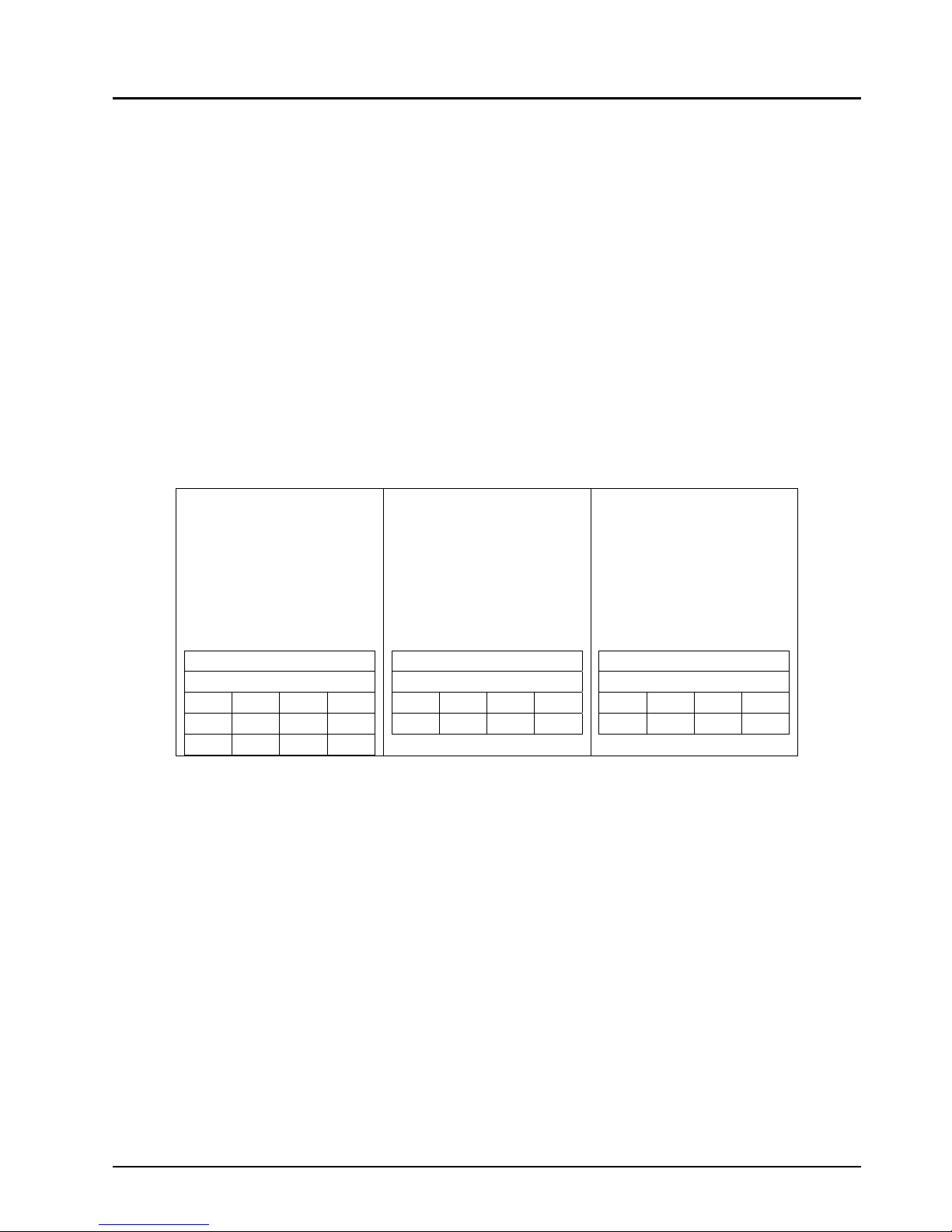

Wiring diagram electronic option DOG-4 G0/H0/I0/K0

Wiring diagram electronic option DOG-4 L0

Wiring diagram electronic option DOG-4 M0/N0/00/P0

Note:

There is installation space for 2 additional Zener barriers in the housing if the

pressure/temperature sensors do not have the required certification. Establishing

contact in Ex areas can take place via terminals 17 to 20. The required cabling is the

responsibility of the installer.

Page 17

DOG-4

DOG-4 K08/0818 page 17

9.6 Connections of DOG-4 Transmitter with KOBOLD Evaluation

Electronics ZED-X and ZOK-Zx

DOG-4 connection with ZED-Zx

1,2 kOhm

Page 18

DOG-4

page 18 DOG-4 K08/0818

DOG-4 connection with ZOK-ZxP

Notes:

* The sensor supply from ZOK-ZxP must be set to 8 VDC.

From the software menu of ZOK-Zx, the ‘Sensor type’ must be set to ‘PNP’

(For details please see the operating manual of ZOK-Zx electronics).

Page 19

DOG-4

DOG-4 K08/0818 page 19

Connection example for DOG-4 with ZOK-ZxK

The sensor type must be set to "PNP" in the ZOK-ZX software menu (see operating

manual ZOK-Zx electronics).

Page 20

DOG-4

page 20 DOG-4 K08/0818

10. Startup

During startup, ensure that the shut-off valves upstream and downstream of the

device are opened slowly. Avoid increasing the flow velocity to prevent the discharge

rate from damaging the sensor.

The output frequency of the DOG-4 is proportional to the measuring range.

In the event of a sensor fault (breakdown or short circuit) the transistor output is

permanently connected. During self-diagnosis, the transistor output is switched to the

high-resistance state.

11. Setup and operation of the flow controller/flow

computer (option G0/H0/I0/K0/M0/N0/L0/O0/P0)

The integrated flow controller/flow computer are preset and calibrated at the factory.

See the separate operating instructions for the DOG-4G0/H0 and the DOG-4M0/N0

for details.

Page 21

DOG-4

DOG-4 K08/0818 page 21

12. Transmitter error message

12.1 Status display not illuminated

Check terminal “230 VAC” of the terminal assignment.

Check supply voltage

12.2 OPERATING illuminated green but no

output signal

Check terminal “Output” of the terminal assignment

12.3 RANGE illuminated yellow

Measuring range overflows or underflows, decrease

or increase flow

12.4 ERROR illuminated red

Short circuit or interruption of the sensor circuit from

the sensor to the transmitter.

Check terminal “Sensor” of the terminal assignment

Defective platinum sensor (target value: 40-60 Ohm)

Page 22

DOG-4

page 22 DOG-4 K08/0818

13. Maintenance

13.1 Replacing the sensor

To replace the sensor, turn off the flow of medium and discharge the pressure in the

lines. For versions with ball valves, it is

sufficient to simply shut these.

Demounting (see diagram) is carried out in

the following order:

1) Open the connection box (4 x screws)

2) Unclamp the sensor from the strip terminal

(2 screws)

3) If necessary (due to lack of space or tight

cable arrangement), also unclamp from the

strip terminal, loosen the cable gland and pull

out the cable

4) Loosen the connection box from the plate

(2 x screws)

5) Slowly release the sensor screws and

carefully pull out the sensor. Take care that

no sensor parts remain in the device and also

that no foreign parts fall into the device (2

screws).

Reassembly is in the reverse order. Replac the O-rings with the new ones supplied

with the sensor. Uniformly tighten the sensor screws crosswise.

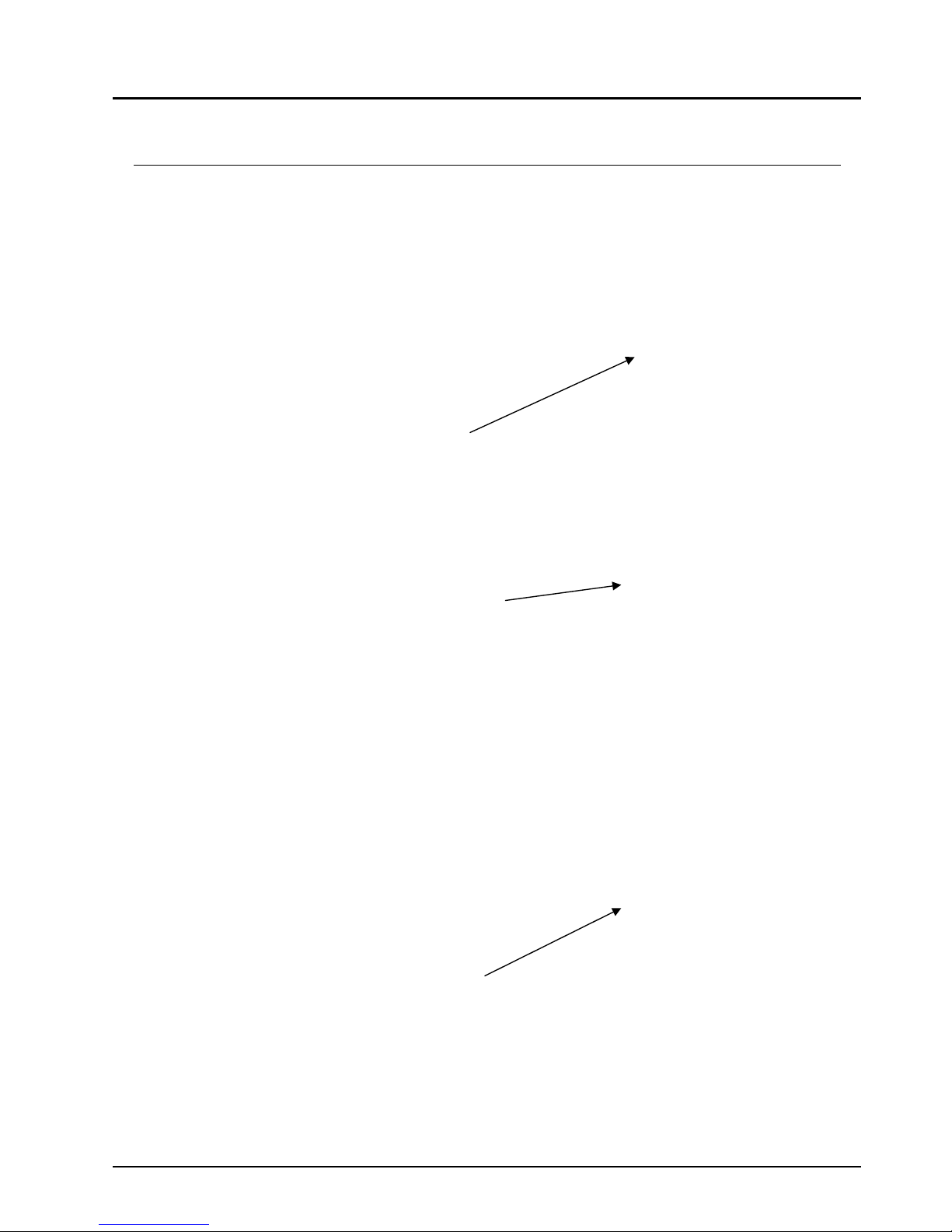

13.2 Disassembly and cleaning the Flowmeter

In the event that the internal section of

the oscillator is dirtied by the medium or

foreign particles fall into this during

replacement of the sensor, the device

must be demounted and cleaned (see

figure at left).

Before the device can be demounted, the

connection box and the sensor must be

unscrewed. For this, see point 13.1.

Then unscrew the screws in the upper

plate, separate the parts and clean the

flow channel of the oscillator on both

sides.

Gasket

above

Gasket

below

2) Order of disassembly

2x Number of screws

NM Requires tightening torque

1) 4x – 1.2-1.5 Nm

2) 4x – 0.3 – 0.5 Nm

5) 4x – 1 – 1.2 Nm

4) 2x – 3 – 4Nm

3) 1x – 4 – 5Nm

Page 23

DOG-4

DOG-4 K08/0818 page 23

Do not use any sharp objects or

aggressive cleaning agents. These

could damage the oscillator, causing

measurement inaccuracies or

breakdown of the device. Check the

inflow and discharge channel and

clean if necessary.

Reassembly takes place in the

reverse order. The two gaskets must

be replaced and are included in the

repair set.

Tighten the screws uniformly with a

torque of 24 to 27 Nm. The figure at

the lower left shows the required

order when tightening. Otherwise the

device may leak or be damaged.

Flow channel top

Flow channel

bottom

Page 24

DOG-4

page 24 DOG-4 K08/0818

14. Technical Data

Measuring accuracy: 1,5% of meas. value (at Qt-100%*)

5% of measured value (at 1%-Qt*)

*The lower limit Qt depends on the density.

Qt = 8% at density 1 kg/m³

Qt = 4% at density 2 kg/m³

Qt = 2% at density 4 kg/m³

Qt = 1% at density 8 kg/m³

Repeatability: 0,1% of measured value

Media temperature: -20 ...+120 °C (non ATEX version)

-20 ...+60 °C (ATEX version)

Ambient temperature: -25 …+80 °C (non ATEX version)

-25…+60 °C (ATEX version)

Operating pressure: DOG-42xxx25…DOG-42xxx50…: PN 40

DOG-42xxx80…DOG-42xxx1F…: PN 16

Span: 1:100

Sensor: platinum sensor

Protection: IP 65

Materials (Transmitter)

Housing: stainless steel 1.4404/316L

Orifice: stainless steel 1.4404/316L

Measuring head: polyphenylene sulfide (PPS)

Sensor: platinum

Gaskets: Klingersil® C-4265, NBR

Ball valves: stainless steel

Page 25

DOG-4

DOG-4 K08/0818 page 25

14.1 Electronic options

Electronics DOG-…A0/B0

(Transducer with/without ATEX certification)

Power supply A/B: 230 V

AC

± 10 %, 50…60 Hz

Power supply C/D: 110 V

AC

± 10 %, 50…60 Hz

Power supply E/F: 24 V

AC

± 20 %, 50…60 Hz

Power supply R: 24 V

DC

± 20 %

Input: Platinum sensor (Allowed distance:

max. 50 m to transmitter)

Output: Opto coupler, frequency linear to flow

V

CE

: 12-24 V (recommended),

max. 30 V

I

C

: max. 50 mA

P

tot

: 100 mW at 25 °C

Derating: 0.91 mW/°C

Ambient temperature: -25…+60 °C

Protection: IP20

Ex-version(A):

ATEX

Transducer: II (1)G [Ex ia Ga] IIC

Sensor: II 1 G Ex ia IIC T4 Ga

IECEx

Transducer: [Ex ia Ga] IIC

Sensor: Ex ia IIC T4 Ga

Mounting: DIN Rail

Dimensions:

Width: 45 mm

Heigth: 105.6 mm

Depth: 113.6 mm

Weight: approx. 200 g

Page 26

DOG-4

page 26 DOG-4 K08/0818

Electronics DOG-…G0/H0

(Transducer without/with ATEX certification and Flow rate/Unit counter, with

current/pulse output)

Display: alphanumeric LCD, UV-resistant, with displayed

functions:

Compensated flow rate

(7 digits, 17 mm high)

Compensated total

(7 digits, 17 mm high)

resettable

Accumulated total

(11 digits, 8 mm high)

not resettable

Units: Flow: m3, cf, scf, Nm

3

Time units: /sec, /min, /hr, /day

Total: m3

Accumulated total: m3

Decimal places: Flow: 0, 1, 2 or 3

Total: 0, 1, 2 or 3

Accumulated total: according to selection for total

Backlightning: yes

Signal input: Flow: DOG-4 sensor

Power supply:

G/H: 230 V

AC

± 10 %, 50…60 Hz

I0/K0: 110 VAC ± 10 %, 50…60 Hz

L0: 24 VDC ± 20 %

Electrical connection: 4 x M16 x 1.5 cable gland

Housing material: ABS with PC cover

Weight: approx. 1800 g

Analogue output: 4…20 mA (active)

10-Bit resolution, 3-wire

Pulse output: PNP, 24 V

DC

active max. 50 mA,

scaled according to linearised accumulated total

(e.g. pulse every 12 liters)

Pulse duration: user defined 0.008 s…2 s

max. frequency: 64 HZ

Protection: IP65

Mounting: Wall mounting

Data protection: EEPROM backup, backup of running totals every

minute, Data retention at least 10 years

Communication: Modbus RTU RS485 2-wire

(optional, other Modbus versions on request)

Page 27

DOG-4

DOG-4 K08/0818 page 27

Electronic Options DOG-…M0/N0/O0/P0

(Transducer without/with ATEX certification and Flow computer)

Display: Alphanumeric LCD, UV-resistant with

Displayed functions:

Compensated Flow rate

(7 digits, 17 mm high)

Compensated total:

(7 digits, 17 mm high)

resettable

Accumulated total

(11 digits, 8 mm high)

not resettable

Actual line temperature (6 digits)

Actual line pressure (6 digits)

Units: Flow: m3, cf, scf, Nm3

Time units: /sec, /min, /hr, /day

Total: m3

Accumulated total: m3

Temperature: °C, °F, or K

Pressure: mbar, bar PSI

Decimals: Flow: 0, 1, 2 or 3

Total: 0, 1, 2 or 3

Accumulated total: according to selection for total

Temperature/Pressure: 1

Backlightning: yes

Signal input: Flow: DOG-4 sensor

Temperature: PT100, 2- or 3-wire

Pressure: 0(4)…20 mA (passive),

14-Bit resolution, 2- or 3-wire

Power supply:

M/N: 230 V

AC

± 10 %, 50…60 Hz

O/P: 110 VAC ± 10 %, 50…60 Hz

Electrical Connection: 5 x M16 x 1.5 cable gland

Housing material: ABS with PC cover

Weight: approx. 1800 g

Analogue output: 4…20 mA (active),

10-Bit resolution, 3-wire

Pulse output: PNP, 24 VDC active max. 50 mA,

scaled according to linearised accumulated total

(e.g. pulse every 12 liters)

Pulse duration: user defined

0.001 s…10 s

max. frequency 500 Hz

Protection: IP65

Mounting: Wall mounting

Data protection: EEPROM backup, backup of running totals every

minute, Data retention at least 10 years

Communication: Modbus RTU RS485 2-wire

(optional, other Modbus versions on request)

Page 28

DOG-4

page 28 DOG-4 K08/0818

Display

Note: Temperature and pressure sensors are not included in scope of delivery.

Page 29

DOG-4

DOG-4 K08/0818 page 29

15. Order Details

Order details for DOG-4 (Example: DOG-4200 S 50 0 A0 0)

Measuring

range air

[m

3

/h]

Model

Material

st.steel

Pressure

rating

[PN]

Connection

flange

[size/type]

Ball valve

Electronics

Options

0,12...12

DOG-42S0S25..

10…40 bar

DN25

0 = without

ball valve

1 = with ball

valve

B0 = Frequency output,

230 V

AC

A0 = as ‘B’, with ATEX/IECEx

G0 = Unit counter, pulse

output, analogue output,

230 V

AC

H0 = as ‚G‘, with ATEX/IECEx

M0 = Flow computer, pulse

output, analogue output,

230 V

AC

N0 = as ‚M‘, with ATEX/IECEx

C0 = as ‘B0’, 110 V

AC

D0 = as ‘A0’, 110 VAC

E0 = as ‘B0’, 24 V

AC

F0 = as ‘A0’, 24 V

AC

R0 = as ‘B0’, 24 VD

C

I0 = as ‘G0’, 110 V

AC

K0 = as ‘I0’, 110 V

AC

L0 = as ‘G0’, 24 VD

C

O0 = as ‘M0’, 110 V

AC

P0 = as ‘N0’, 110 V

AC

Y0 = Special (specify in clear

text)

0 = without

Y = Special option

(specify in

clear text)

DOG-42S0S40..

DN40

DOG-42S0S50..

DN50

DOG-42S0B25..

Klasse 300

ANSI 1“

DOG-42S0B40..

ANSI 1½“

DOG-42S0B50..

ANSI 2“

0.2…20

DOG-4200S25..

10…40 bar DN25

DOG-4200S40..

DN40

DOG-4200S50..

DN50

DOG-4200B25..

Class 300 ANSI 1“

DOG-4200B40..

ANSI 1½“

DOG-4200B50..

ANSI 2“

0.35…35

DOG-4250S25..

10…40 bar DN25

DOG-4250B25..

Class 300 ANSI 1“

0.7…70

DOG-42A0S25..

10…40 bar DN25

DOG-42A5B25..

Class 300 ANSI 1“

0.9…90

DOG-42A5S40..

10…40 bar DN40

DOG-42A5B40..

Class 300 ANSI 1½“

1.1…110

DOG-42B0S50..

10…40 bar DN50

DOG-42B0B50..

Class 300 ANSI 2“

1.4…140

DOG-42B5F80..

16 bar DN80

DOG-42B5S80..

40 bar DN80

DOG-42B5A80..

Class 150 ANSI 3“

DOG-42BFB80..

Class 300 ANSI 3“

2…200

DOG-42C0S40..

10…40 bar DN40

DOG-42C0B40..

Class 300 ANSI 1½“

2.5…250

DOG-42C5S50..

10…40 bar DN50

DOG-42C5B50..

Class 300 ANSI 2“

2.7…270

DOG-42D0F1H..

16 bar DN100

DOG-42D0S1H..

40 bar DN100

DOG-42D0A1H..

Class 150 ANSI 4“

DOG-42D0B1H..

Class 300 ANSI 4“

4.5…450

DOG-42D5F80..

16 bar DN80

DOG-42D5S80..

40 bar DN80

DOG-42D5A80..

Class 150 ANSI 3“

DOG-42D5B80..

Class 300 ANSI 3“

6.0…600

DOG-42E0F1F..

16 bar DN150

DOG-42E0S1F..

40 bar DN150

DOG-42E0A1F..

Class 150 ANSI 6“

DOG-42E0B1F..

Class 300 ANSI 6“

6.5…650

DOG-42E5F1H..

16 bar DN100

DOG-42E5S1H..

40 bar DN100

DOG-42E5A1H..

Class 150 ANSI 4“

DOG-42E5B1H..

Class 300 ANSI 4“

Page 30

DOG-4

page 30 DOG-4 K08/0818

Order details for DOG-4 (Example: DOG-4200 S 50 0 A0 0) (continuation)

Measuring

range air

[m

3

/h]

Model

Material

st. steel

Pressure

rating

[PN]

Connection

flange

[size/type]

Ball valve

Electronics

Options

8.0…800

DOG-42F0F80..

16 bar DN80

0 = without

ball valve

1 = with ball

valve

B0 = Frequency output,

230 V

AC

A0 = as ‘B’, with ATEX/IECEx

G0 = Unit counter, pulse

output, analogue output,

230 V

AC

H0 = as ‚G‘, with ATEX/IECEx

M0 = Flow computer, pulse

output, analogue output,

230 V

AC

N0 = as ‚M‘, with ATEX/IECEx

C0 = as ‘B0’, 110 V

AC

D0 = as ‘A0’, 110 VAC

E0 = as ‘B0’, 24 V

AC

F0 = as ‘A0’, 24 V

AC

R0 = as ‘B0’, 24 VD

C

I0 = as ‘G0’, 110 V

AC

K0 = as ‘I0’, 110 V

AC

L0 = as ‘G0’, 24 VD

C

O0 = as ‘M0’, 110 V

AC

P0 = as ‘N0’, 110 V

AC

Y0 = Special (specify in clear

text)

0 = without

Y = Special

option

(specify in

clear text)

DOG-42F0S80..

40 bar DN80

DOG-42F0A80..

Class 150 ANSI 3”

DOG-42F0B80..

Class 300 ANSI 3”

10…1000

DOG-42F5F1H..

16 bar DN 100

DOG-42F5S1H..

40 bar DN 100

DOG-42F5A1H..

Class 150 ANSI 4“

DOG-42F5B1H..

Class 300 ANSI 4“

12…1200

DOG-42G0F1F..

16 bar DN 150

DOG-42G0S1F..

40 bar DN 150

DOG-42G0A1F..

Class 150 ANSI 6“

DOG-42G0B1F..

Class 300 ANSI 6“

DOG-42G0E2H..

10 bar DN 200

DOG-42G0F2H..

16 bar DN 200

DOG-42G0S2H..

40 bar DN 200

DOG-42G0A2H..

Class 150 ANSI 8“

DOG-42G0B2H..

Class 300 ANSI 8“

25…2500

DOG-42G5E2H..

10 bar DN 200

DOG-42G5F2H..

16 bar DN 200

DOG-42G5S2H..

40 bar DN 200

DOG-42G5A2H..

Class 150 ANSI 8“

DOG-42G5B2H..

Class 300 ANSI 8“

30…3000

DOG-42H0F1F..

16 bar DN 150

DOG-42H0S1F..

40 bar DN 150

DOG-42H0A1F..

Class 150 ANSI 6“

DOG-42H0B1F..

Class 300 ANSI 6“

60…60001)

DOG-42H5E2H..

10 bar DN200

DOG-42H5F2H..

16 bar DN 200

DOG-42H5S2H..

40 bar DN 200

DOG-42H5A2H..

Class 150 ANSI 8“

DOG-42H5B2H..

Class 300 ANSI 8“

Special

DOG-42YYYYY.. Sonder Sonder

1)

Calibrated up to 4000 m3/h. Higher flow rate calibration on request.

Page 31

DOG-4

DOG-4 K08/0818 page 31

16. Pressure Loss/Flow

The diagram applies for gases with a density of air at NPT (0 °C and 1013.25 mbar).

The pressure loss is always proportional to the density of the gas. For example, the

pressure loss doubles at 100% higher operating pressure.

Calculating the Actual Density

The actual density can be calculated with the following formula:

D0 = density at 1 bar abs. and 0 °C (= 273 K) T = temperature in K

(= °C + 273 for example 20 °C = 273 + 20 = 293 K) T0 = 273 K

P = operating pressure in bar (absolute pressure)

Calculating the Norm Flow

QN = norm flow at 1.013 bar abs. and 0 °C

Q = operating flow

P = operating pressure in bar (absolute pressure)

T = operating temperature in K

Pressure drop [mbar]

Page 32

DOG-4

page 32 DOG-4 K08/0818

17. Dimensions

Dimensions and Weights DOG-4 (without ball valve)

Dimensions and Weights DOG-4 (with ball valve)

Dimensional details without ball valve

DN

[mm] L (Length)

[mm]

H

(Height)

[mm]

øD

(outer ø)

[mm]

øK

(pitch circle)

[mm]

øL

(hole ø)

[mm]

Ød1

(sealing surface)

[mm]

No. of

screws

Screw size Weight

[kg]

25 300 150 115 85 14 68 4 M12 8,1

40 300 158 150 110 18 88 4 M16 10

50 300 164 165 125 18 102 4 M16 11,6

80 300 178 200 160 18 138 8 M16 14,4

100 320 191 220 180 18 58 8 M16 16,6

150 320 218 285 240 22 212 8 M20 24,8

200 320 243 340 295 22 268 8 M20 35,8

Page 33

DOG-4

DOG-4 K08/0818 page 33

Dimensions Electronics DOG-…A/B

Dimensions Electronics DOG-…G/H/M/N

Accessories (optional)

Replacement sensor

Sealing for oscillator

Recalibration set for transmitter

Dimensional details with ball valve

DN

[mm] L (Length)

[mm]

H

(Height

)

[mm]

øD

(outer ø)

[mm]

øK

(pitch circle)

[mm]

øL

(hole ø)

[mm]

Ød1

(sealing surface)

[mm]

No. of

screws

Screw size Weight

[kg]

25 300 166 115 85 14 68 4 M12 8,5

40 300 174 150 110 18 88 4 M16 10,4

50 300 180 165 125 18 102 4 M16 12

80 300 194 200 160 18 138 8 M16 14,8

100 320 207 220 180 18 58 8 M16 16,9

150 320 234 285 240 22 212 8 M20 25,3

200 320 259 340 295 22 268 8 M20 36,3

Page 34

DOG-4

page 34 DOG-4 K08/0818

18. EU Declaration of Conformance

We, KOBOLD Messring GmbH, Hofheim-Ts, Germany, declare under our sole

responsibility that the product:

Oscillation Flowmeter Model: DOG-4

to which this declaration relates is in conformity with the standards noted below:

EN 61326:2013-07 Electrical equipment for measurement, control and laboratory

use - EMC requirements - Part 1: General requirements

EN 13480-1:2013-11 Metallic industrial piping - Part 1: General

EN 50581:2012 Technical documentation for the assessment of electrical and

electronic products with respect to the restriction of hazardous

substances

zusätzlich DOG-4…A/H/N/D/F/P:

EN 60079-0:2014-06 Explosive atmospheres - Part 0: Equipment –

General requirements

EN 60079-11:2012 Explosive atmospheres - Part 11: Equipment protection by

intrinsic safety "i"

EN 60079-26:2007 Explosive atmospheres - Part 26: Equipment with equipment

protection level (EPL) Ga

Also the following EU guidelines are fulfilled:

2014/30/EU EMC Directive

2014/35/EU Low Voltage Directive

2011/65/EU RoHS (category 9)

2014/68/EU PED

Category III (IV) Diagram 1, vessel, group 1 dangerous fluids

Module D, marking CE0575

Notified body: DNV GL

Certificate No. PEDD000000R

additional DOG-4…A/H/N/D/F/P:

2014/34/EU Equipment and protective systems intended for use in

potentially explosive atmospheres (ATEX 100a)

Production quality assurance

Certification no.: BVS 15 ATEX ZQS / E 110

Notified body: DEKRA EXAM

Identification no.: 0158

Hofheim, 31. July 2018

H. Peters M. Wenzel

General Manager Proxy Holder

Page 35

DOG-4

DOG-4 K08/0818 page 35

19. ATEX-Certificate

Page 36

DOG-4

page 36 DOG-4 K08/0818

Page 37

DOG-4

DOG-4 K08/0818 page 37

Page 38

DOG-4

page 38 DOG-4 K08/0818

Page 39

DOG-4

DOG-4 K08/0818 page 39

Page 40

DOG-4

page 40 DOG-4 K08/0818

Page 41

DOG-4

DOG-4 K08/0818 page 41

20. IECEx-Certificate

Page 42

DOG-4

page 42 DOG-4 K08/0818

Page 43

DOG-4

DOG-4 K08/0818 page 43

Page 44

DOG-4

page 44 DOG-4 K08/0818

Loading...

Loading...