Page 1

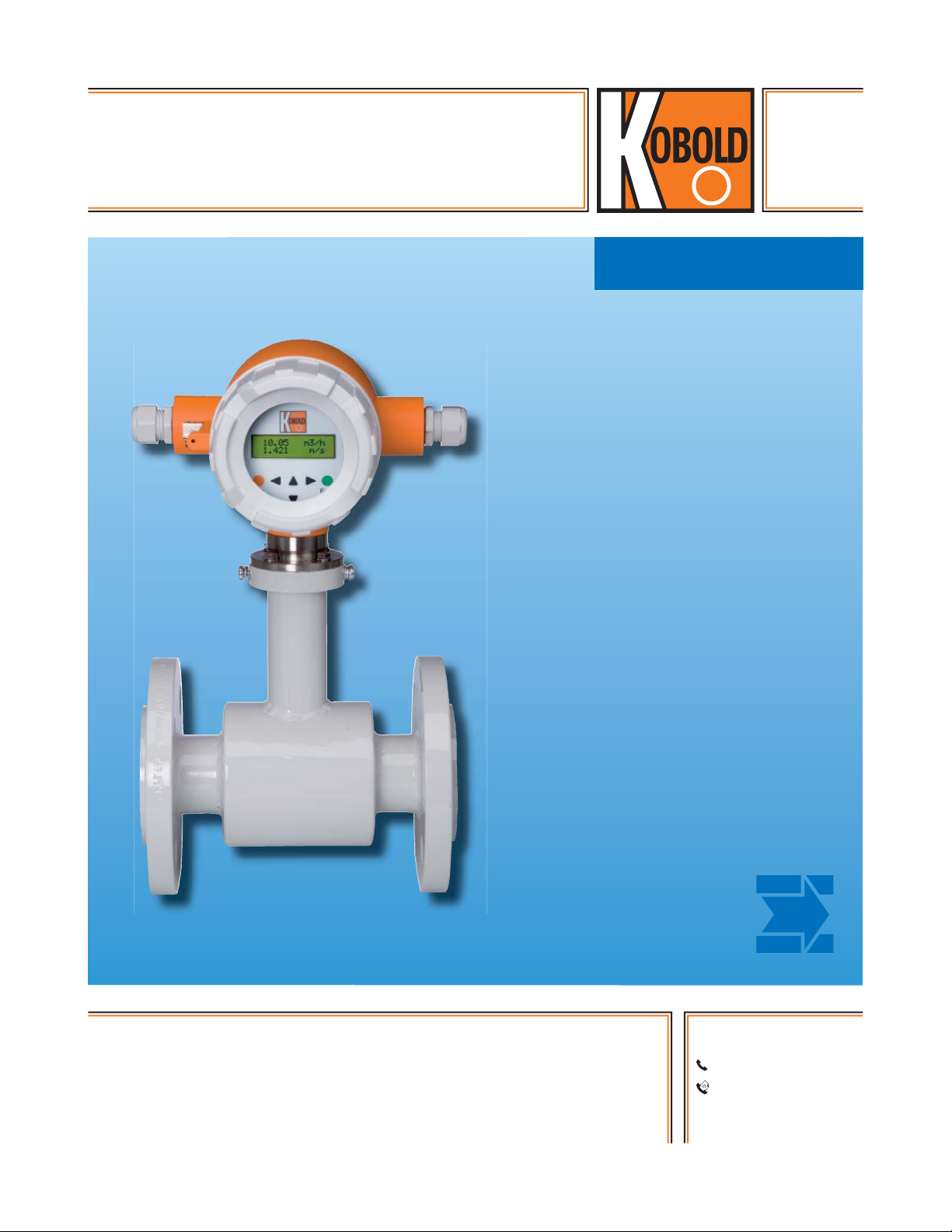

Magnetic Inductive

Flowmeter

for conductive liquids

measuring

•

monitoring

•

analyzing

DMH

Measuring Range: 0.29...26.4 to

431.6…43,333 GPM

Accuracy: ± 0.3% of Reading

± 0.01% x Q

p

: 580 PSI; t

max

Connection: Flange ASME ½" ... 24"

Lining Material: Hard Rubber,

max

Soft Rubber, or PTFE

Output: Analog with HART

Pulse, and Status

KOBOLD companies worldwide:

ARGENTINA, AUSTRIA, BELGIUM, BULGARIA, CANADA, CHILE, CHINA, COLUMBIA, CZECH

REPUBLIC, EGYPT, FRANCE, GERMANY, GREAT BRITAIN, HUNGARY, INDIA, INDONESIA, ITALY,

MALAYSIA, MEXICO, NETHERLANDS, PERU, POLAND, ROMANIA, SINGAPORE, SOUTH KOREA,

SPAIN, SWITZERLAND, TAIWAN, THAILAND, TUNISIA, USA, VIETNAM

: 300 °F

max

KOBOLD Instruments, Inc.

1801 Parkway View Drive

Pittsburgh, PA 15205

Main Of ce:

1.412.788.2830

1.412.788.4890

info@koboldusa.com

www.koboldusa.com

®

,

03 - 2013

1

Page 2

Magnetic Inductive Flowmeter Model DMH

Description

The KOBOLD DMH fl owmeter is used to measure and

monitor the volume fl ow rate of liquids, pulps, pastes, and

other electrically conductive medias without loss of pressure.

When an electrically conductive media passes through a

directional magnetic fi eld, a voltage is induced in accordance

with Faraday’s Law of Induction.

The measured voltage is proportional to the mean rate of fl ow

and consequently also to the volumetric fl ow rate.

The fl owmeter consists of a sensor that picks up the measuring signal generated from the induced voltage, and a transducer that converts this signal into a standardized output signal

(4-20mA or pulse). The measuring transducer can be connected to the sensor directly or mounted remotely.

Pressure, temperature, density, and viscosity do not affect

the volume measurement. Large solids and gas bubbles

should be avoided.

The signifi cant properties exhibited by DMH include:

great choice of linings

stainless steel, Hastelloy, tantalum, platinum, or titanium

electrodes

wide variety of process connections

can be used in rough ambient conditions

Fields of application

acids, alkalis

pastes

drinking water, waste water

beer, wine, milk, mineral water

spirits, molasses, fruit juice

soft cheese etc.

Technical data

Adjustable measuring

range terminal values: 0.5...10 m /s

Minimum conductivity: ≥5 μS /cm

(for liquids in general)

≥20 μS/cm

(demineralized water)

Accuracy: ±0.3 % of read. ± 0.01 % x Q

Repeatability: ±0.15 % of read. ± 0.005% x Q

max

max

(reference conditions: water,

measured medium

temperature of

72°F ±4K,

ambient temperature 72 °F ±2K,

inlet ≥ 10 x pipe diameter,

outlet ≥ 5 x pipe diameter,

Q

at 10 m/s)

max

Process temperature: 32 ... + 176 °F

(hard rubber, soft rubber)

-4 ... +300 °F (PTFE)

Ambient temperature: -4 ... +140 °F,

depending on process temperature

Rated pressure: ASME 150 lb

½" … 24"

ASME 300 lb

½" … 24"

higher pressures upon request

Sensor materials

Linings: hard rubber, soft rubber, or PTFE

Reference/Grounding

Electrodes: stainless steel, Hastelloy C4,

tantalum, platinum, titanium, and

other materials upon request

Housing: enameled steel

Process connection: enameled steel or enameled 304

stainless steel fl ange ASME B16.5,

other connections upon request

Nominal sizes: ½" to 24"

other nominal sizes upon request

Protection type: IP 67 (IP 68 upon request)

Transmitter UMF2

Display: 2-line, lighted

fl ow, counter (forward + backward)

Operation: 6 buttons

Assembly type: compact or remote

Housing: enameled die-cast aluminum

rotatable in 90° steps

Outputs: galvanically isolated

Analog: 1 x 4-20 mA

load: <600 Ω (>250 Ω for HART

®

)

2

www.koboldusa.com

No responsibility taken for errors;

subject to change without prior notice.

03 - 2013

Page 3

Magnetic Inductive Flowmeter Model DMH

Technical Data (continued):

Pulse output: passive, using optocoupler,

max. 30 V, 60 mA, 1.8 W

Status: passive, using optocoupler

max. 30 V, 60 mA, 1.8 W

Power supply: 115 V

230 V

24 V

50 / 60 Hz, 10 VA

AC

,

, 50 / 60 Hz, 10 VA

AC

±10 %, 10 W / VA

DC

Electrical connection: Cable connection M 20 x 1,5

or ½ NPT

Ambient temperature: -4 … +140°F,

depending on process temperature

for compact version

Protection type: IP 67

Communication: HART

®

Diagnosis functions: empty pipe recognition,

fl ushing fl ow monitoring

error message in plain text

Measuring range

Line

Minimum Measuring Value Maximum Measuring Value

Size

½"

¾"

1.25" 1.33 5.04 123.2 466.3

1.5" 1.99 7.54 167.3 633.2

2.5" 5.29 20.03 493.1 1866.6

10" 79.26 300.1 8347.8 31600.2

12" 111.0 420.2 11808.4 44700.0

14" 154.1 583.2 14388.6 54466.8

16" 198.2 750.0 18932.2 71666.4

18" 237.8 900.0 23991.2 90816.6

20" 299.5 1133.4 29886.7 113133.6

24" 431.6 1633.2 43333.0 164033.4

[GPM] [LPM] [GPM] [LPM]

0.29 1.10 26.4 100.0

0.53 2.01 35.2 133.2

1" 0.80 3.03 74.8 283.1

2" 3.18 12.04 272.9 1033.2

3" 7.93 30.02 717.6 2716.8

4" 12.33 46.68 1268.0 4800.0

5" 18.94 71.70 2007.7 7600.2

6" 28.62 108.4 2950.0 11166.6

8" 50.64 191.7 5230.6 19800.0

Order Details (Example: DMH-1 L15 H 11 A 1 6)

Model/

Flange

Material

Process Connection

(fl ange acc. to ASME

Form B1)

L15 =

½", 150 lb

L20 = ¾", 150 lb

L25 = 1", 150 lb

L32 = 1.25", 150 lb

L40 = 1.5", 150 lb

L50 = 2", 150 lb

DMH-1=

enameled

steel

DMH-2 =

enameled

stainless

steel 304

L65 = 2.5", 150 lb

L80 = 3", 150 lb

L1H = 4", 150 lb

L1Z = 5", 150 lb

L1F = 6", 150 lb

L2H = 8", 150 lb

L2F = 10", 150 lb

L3H = 12", 150 lb

L3F = 14", 150 lb

L4H = 16", 150 lb

L4F = 18", 150 lb

L5H = 20", 150 lb

L6H = 24", 150 lb

1)

ASME-fl ange class 300 lb: code Mxx, other process connections on request

03 - 2013

No responsibility taken for errors;

subject to change without prior notice.

1)

H = hard

W = soft

T = PTFE

Liner

Material

rubber

rubber

Reference/Grounding

11 = stainless steel

33 = Hastelloy C4

55 = tantalum

66 = titanium

77 = platinum

33 = Hastelloy C4

55 = tantalum

66 = titanium

77 = platinum

Electrode

Material

www.koboldusa.com

Version/

Cable Length

A = compact

B = remote

version/2,5 m

C = remote

version/5 m

D = remote

version/10 m

E = remote

version/15 m

F = remote

version/ 20 m

G = remote

version/ 30 m

H = remote

version/ 50 m

Electronic

Transmitter

1 = UMF2-

electronics

with control

unit, without

HART

2 = UMF2-

electronics

with control

unit, with

HART

®

®

Power Supply/

Electrical

Connection

0 = 230 V

4 = 115 V

3 = 24 V

5 = 230 V

AC

M20x1,5

AC

M20x1,5

DC

M20x1,5

AC

½ NPT

6 = 115 VAC

½ NPT

8 = 24 VDC

½ NPT

3

Page 4

Dimensions

Transmitter UMF2

158

Ø 103

Magnetic Inductive Flowmeter Model DMH

Connection box for sensor, remote version

184

109

75

138

57

M20x1,5

80

Sensor, fl ange connection

A

Line

Size

½"

¾" 150 105 62 170 200 66 7

1" 150 115 72 180 200 96 7

1¼" 150 140 82 199 200 96 9

1½" 150 150 92 209 200 96 9

2" 150 165 107 223 200 96 13.5

2½" 150 185 127 244 200 96 20

3" 150 200 142 260 200 96 32

4" 150 220 162 280 250 96 36

5" 150 250 192 310 250 126 42

6" 150 285 218 340 300 126 25

8" 150 340 274 398 350 211 56

10" 150 395 370 480 450 211 120

12" 150 445 420 535 500 320 170

14" 150 505 480 584 550 320 203

16" 150 565 530 642 600 320 256

18" 150 c/f c/f c/f 600 320 340

20" 150 670 640 752 600 320 370

24" 150 780 760 870 600 320 695

* Weights of the sensors are only approximate values, please also include the weight of the electronic assembly - approx. 5.6 lbs.

D

Flange

ASME

I

L

D

[mm]

DN

[mm]

d

A

[mm]

L

[mm]

I

[mm]

150 95 62 164 200 66 7

Weight*

[lbs]

4

www.koboldusa.com

No responsibility taken for errors;

subject to change without prior notice.

03 - 2013

Loading...

Loading...