Page 1

Operating Instructions

for

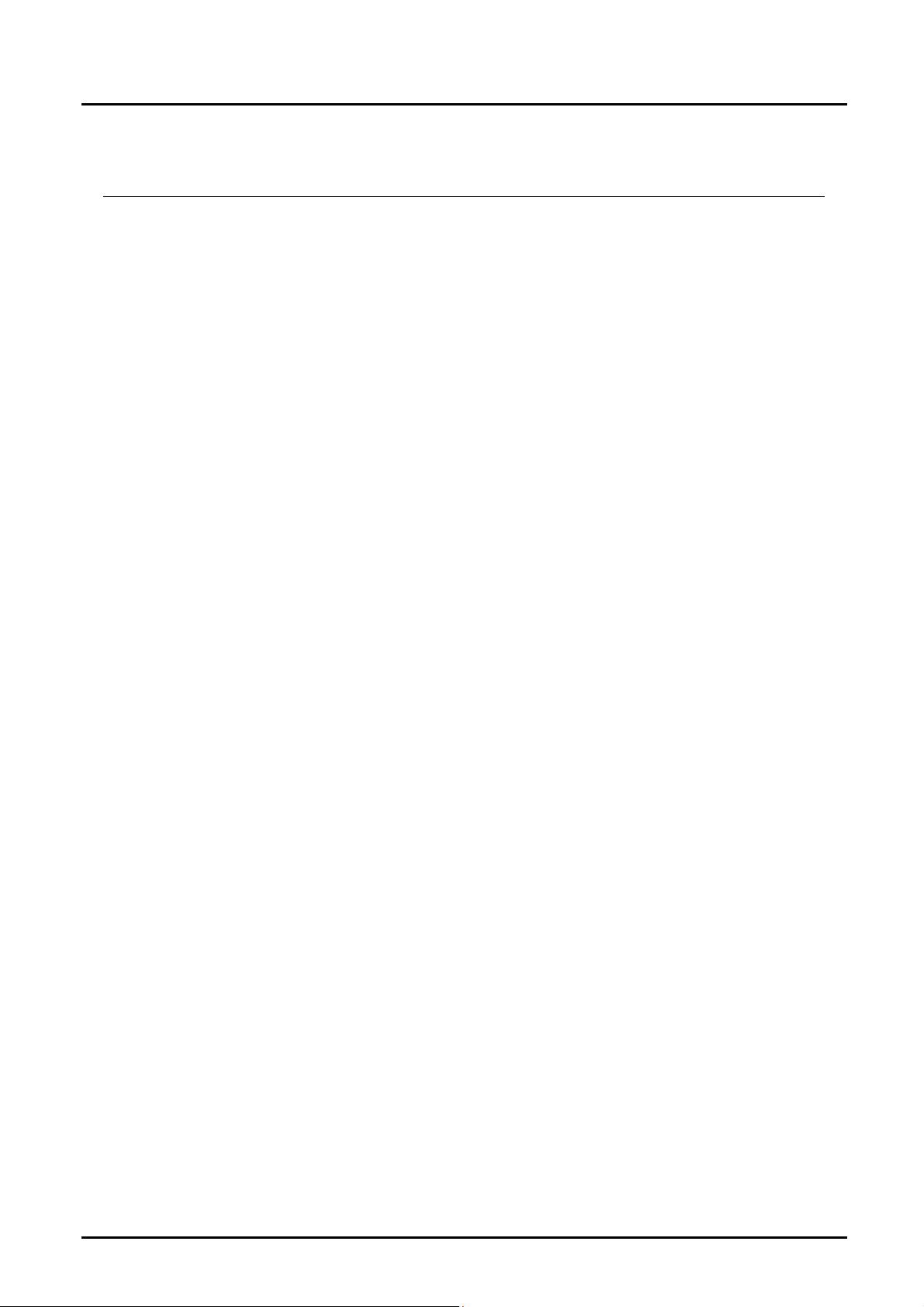

Rotor flow Indicator

Model: DKF

Page 2

DKF

1. Contents

1. Contents ........................................................................................................ 2

2. Note .............................................................................................................. 3

3. Instrument Inspection .................................................................................... 3

4. Regulation Use .............................................................................................. 3

5. Mechanical Connection ................................................................................. 4

5.1 Before installation ................................................................................ 4

6. Technical Information .................................................................................... 4

7. Order Codes ................................................................................................. 5

8. Dimensions ................................................................................................... 5

9. ATEX - Declaration of the Manufacturer ....................................................... 6

9.1 General ................................................................................................ 6

9.2 Areas of use ......................................................................................... 6

9.3 Evaluation ............................................................................................ 6

Manufactured and sold by:

Kobold Messring GmbH

Nordring 22-24

D-65719 Hofheim

Tel.: +49(0)6192-2990

Fax: +49(0)6192-23398

E-Mail: info.de@kobold.com

Internet: www.kobold.com

page 2 DKF K01/1115

Page 3

DKF

2. Note

Please read these operating instructions before unpacking and putting the unit

into operation. Follow the instructions precisely as described herein.

The devices are only to be used, maintained and serviced by persons familiar

with these operating instructions and in accordance with local regulations

applying to Health & Safety and prevention of accidents.

When used in machines, the measuring unit should be used only when the

machines fulfil the EC-machine guidelines.

as per PED 2014/68/EU

In acc. with Article 4 Paragraph (3), "Sound Engineering Practice", of the

PED 2014/68/EU no CE mark.

Diagram 8, Pipe, Group 1 dangerous fluids

3. Instrument Inspection

Instruments are inspected before shipping and sent out in perfect condition.

Should damage to a device be visible, we recommend a thorough inspection of

the delivery packaging. In case of damage, please inform your parcel service /

forwarding agent immediately, since they are responsible for damages during

transit.

Scope of delivery:

The standard delivery includes:

Rotor Flow Indicator: Model: DKF

Operating Instructions

4. Regulation Use

Any use of the Rotor Flow Indicator, model: DKF, which exceeds the

manufacturer’s specifications, may invalidate its warranty. Therefore, any

resulting damage is not the responsibility of the manufacturer. The user assumes

all risk for such usage.

DKF K01/1115 page 3

Page 4

DKF

5. Mechanical Connection

5.1 Before installation

Remove all packing materials and transport restraints and ensure that no such

materials remain in the device.

Make sure that the maximum operating pressure and temperature of the device

are not exceeded. (see section 6.Technical Information..)

Install the flow indicator in the piping system, ensuring that the piping is rigidly

supported at the inlet and outlet of the unit with pipe clamps

Ensure that the piping is aligned with the inlet and outlet fittings and the no

piping induced stresses are exerted in the indicator. This stress can result in

damage to the device during system operation

Protect the device from external damage.

Avoid pressure surges within the indicator chamber, such as those arising from

fast start up/shut off of flow or pulsating flow.

If possible, after completing the mechanical installation, check the threaded

connection between the device and the piping for leakage immediately.

6. Technical Information

Maximum Temperature: 120 °C

Maximumg Pressure: 6 bar

page 4 DKF K01/1115

Page 5

DKF

7. Order Codes

Order data (Example: DKF-1101H R06)

Indication range Model Connection

l/min

water

0.14 - 2 1

0.25 - 7 1

0.45 - 18 1

0.6 - 28 1

1 - 61 1

1.8 - 83 1

* max. flow

8. Dimensions

∆ P

(bar)*

DKF-11.. DKF-21.. G-thread NPT-thread

DKF-1101H.. DKF-2101H.. R06 N06

DKF-1102H.. DKF-2102H.. R08 N08

DKF-1103H.. DKF-2103H.. R10 N10

DKF-1104H.. DKF-2104H.. R15 N15

DKF-1105H.. DKF-2105H.. R20 N20

DKF-1106H.. DKF-2106H.. R25 N25

Model p

DKF-..01H

DKF-..02H

DKF-..03H

DKF-..04H

DKF-..05H

DKF-..06H

t

max

6 bar 120 °C G 1/8 1/8“ 8 56 41 50 0.3

6 bar 120 °C G 1/4 1/4“ 10 56 41 50 0.28

6 bar 120 °C G 3/8 3/8“ 14 73 53 67 0.57

6 bar 120 °C G 1/2 1/2“ 14 73 53 67 0.54

6 bar 120 °C G 3/4 3/4“ 16 109 72 94 1.41

6 bar 120 °C G 1 1“ 18 109 72 94 1.30

G NPT L1 L A B

max

Weight

kg

DKF K01/1115 page 5

Page 6

DKF

9. ATEX - Declaration of the Manufacturer

9.1 General

Risk analysis report pursuant to EN 13463 (positive list) for use in category

2 Explosion Risk Area was done.

When used properly, and being a piece of mechanical equipment, the rotor flow

indicator Type DKF-x1****** does not have its own potential source of ignition; it

is not assigned an ID in the sense of the ATEX Directive.

9.2 Areas of use

The units can be used as follows:

In the Zone 2 (Gas-Ex, Cat. 3G) into explosion group of IIA, IIB and IIC

In the Zone 22 (Dust-Ex, Category 3D) at non-conductive dusts with a

minimum igniting energy of > 3 mJ

In the Zone 1 (Gas-Ex, Cat. 2G) into explosion group of IIA, IIB and IIC

In the Zone 21 (Dust-Ex, Category 2D) at non-conductive dusts with a

minimum igniting energy of > 3 mJ

In normal use, the rotor flow indicators are completely filled with medium.

Zone 2 – or Zone 1 – conditions may prevail for a short time.

9.3 Evaluation

Adherence to EN 13463, Parts 1 to 8 (Mechanical Explosion Prevention)

When used properly, the rotor flow indicator does not have its own potential

source of ignition as per the conditions of Categories 2 and 3. It does however

fulfil the following requirements:

The manufacturer has subjected all exposed parts of the device to the impact

and environmental strain tests pursuant to EN 13463-1.

When installed, the device must be protected against external

energy impact – or measures should be taken to take into account

any possible zone violations in the system.

The outer casing of the device is made of brass or stainless steel and

borosilicate glass; there are no light metal parts.

Hofheim, 12. Nov. 2015

H. Peters M. Wenzel

General Manager Proxy Holder

page 6 DKF K01/1115

Loading...

Loading...