Page 1

Operating Instructions

for

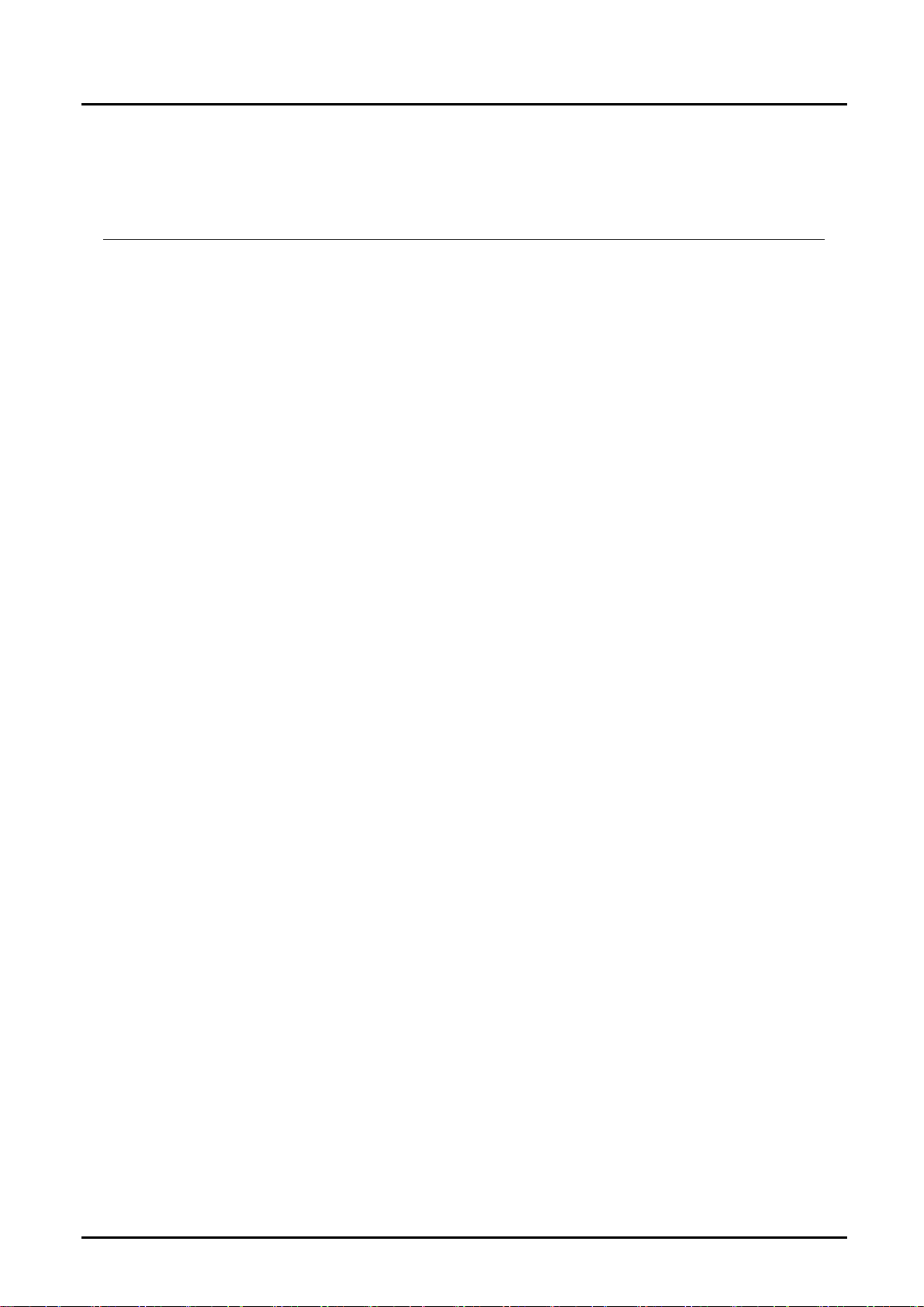

Flow Indicator

Model: DAA

Page 2

DAA

1. Contents

Contents ........................................................................................................ 2

1.

2. Note .............................................................................................................. 3

3. Instrument Inspection .................................................................................... 3

4. Regulation Use .............................................................................................. 3

5. Operating Principle ........................................................................................ 4

6. Mechanical Connection ................................................................................. 4

7. Maintenance ................................................................................................. 6

8. Technical Information .................................................................................... 7

9. Order Codes ................................................................................................. 7

10.Dimensions ................................................................................................... 8

11.EU Declaration of Conformance .................................................................... 9

Manufactured and sold by:

Kobold Messring GmbH

Nordring 22-24

D-65719 Hofheim

Tel.: +49(0)6192-2990

Fax: +49(0)6192-23398

E-Mail: info.de@kobold.com

Internet: www.kobold.com

page 2 DAA K03/0218

Page 3

DAA

2. Note

Please read these operating instructions before unpacking and putting the unit

into operation. Follow the instructions precisely as described herein.

The devices are only to be used, maintained and serviced by persons familiar

with these operating instructions and in accordance with local regulations

applying to Health & Safety and prevention of accidents.

When used in machines, the measuring unit should be used only when the

machines fulfil the EC-machine guidelines.

as per PED 2014/68/EU

In acc. with Article 4 Paragraph (3), "Sound Engineering Practice", of the

PED 2014/68/EU no CE mark.

Diagram 8, Pipe, Group 1 dangerous fluids

3. Instrument Inspection

Instruments are inspected before shipping and sent out in perfect condition.

Should damage to a device be visible, we recommend a thorough inspection of

the delivery packaging. In case of damage, please inform your parcel service /

forwarding agent immediately, since they are responsible for damages during

transit.

Scope of delivery:

The standard delivery includes:

Flow Indicator model: DAA

Operating Instructions

4. Regulation Use

The DAA Flow Indicators are designed for liquid flows in pipework.

Only such fluids may be sued that are resistant to the materials used in the Flow

Indicator (see 8. Technical Information).

DAA K03/0218 page 3

Page 4

DAA

5. Operating Principle

The fluid flow is indicated by a plastic rotor installed inside a hard glass body

(borosilicate glass).

With a twist of 180° of the sight glass, integral wipers clean the viewing area do

allow unobstructed observation of the rotor. The offending contaminants are then

simply washed away by the medium flow. The device is kept tight and rotatable

by hand by the use of low friction O-rings.

6. Mechanical Connection

6.1 Before installation

Be sure the maximum allowable working pressures or temperatures specified

for the instrument are not exceeded.

(see 9. Order Codes)

Nominal

Model

DAA-..01H 8 ¼ 12 1/4 9

diameter

DN

[mm]

Female thread

G

Threaded

length

[mm]

Female thread

NPT

Threaded

length

[mm]

DAA-..02H 10 3/8 12 3/8 9

DAA-..03H 15 ½ 12 1/2 12

DAA-..04H 20 ¾ 12 3/4 12

DAA-..05H 25 1 14 1 16

DAA-..06H 32 1 ¼ 18 1 ¼ 21

DAA-..07H 40 1 ½ 20 1 ½ 21

page 4 DAA K03/0218

Page 5

DAA

6.2 Installation

Install this Flow Indicator in the direction of flow (as per the stamped arrow).

Attention: Suddenly opening the inflow may cause pressure peaks

exceeding the working pressure of the instrument; this may result

in water hammer, causing the measuring glass to break.

Attention: Remove any coarse foreign matter before installing the

instrument in the pipe.

To install the indicator, always apply the open-ended spanner to the hexagon

flats onto which the connecting pipe is to be screwed.

Attention: Applying the spanner on the opposite hexagon may

cause the internal support bars to be sheared off, or the connection

nut to be twisted.

During installation, protect the inspection glass against external damage

(Attention: hard glass) !

Attention: Be sure to avoid deforming the indicator by improper

fastening during installation.

DAA K03/0218 page 5

Page 6

DAA

7. Maintenance

7.1 General

Clean the inspection glass if it gets soiled during operation. To this end, merely

rotate the glass while fluid is flowing, if possible, so that any dirt particles will be

carried off by the fluid.

Attention: A maximum temperature of 40 °C should not be

exceeded for cleaning; failing this, be sure to wear protective

gloves. For the DAA model with a rotor, periodic cleaning of the

flow space may be necessary depending on the quality of the fluid

to maintain smooth rotor operation.

The inspection glass is difficult to rotate while it is dry, and the wipers may be

damaged by entrained particles.

7.2 Replacing the measuring glass

Attention! The upper and lower sections of the DAA Flow Indicator

are attached with screw sealing lacquer. Be sure to remove the

upper section from the lower section while warm only.

Fix the lower hexagon of the Flow Indicator ("PN16" marking).

Heat the upper section with a hot-air dryer (specifically in the area of the

connecting bars) until the upper section can be removed using an appropriate

open-jawed spanner without applying much force.

Remove the broken glass and clean the connecting threads of the upper and

lower sections using a wire brush.

Replace the O-rings and the wiper rubbers, and slip the new, moistened

measuring glass onto the lower section.

Apply some releasable screw sealing lacquer (such as Weicon no. 302-42)

onto the connecting threads, and carefully screw the upper section onto the

lower section.

Having tightened the said components, align the spanner surfaces in parallel.

page 6 DAA K03/0218

Page 7

DAA

8. Technical Information

Materials

Housing: nickel plated brass (DAA-11..)

stainless steel 1.4305 (DAA-12..)

Inlet: nickel-plated brass (DAA-11..)

stainless steel 1.4305 (DAA-12..)

Inspection glass: borosilicate glass

O-rings: NBR (DAA-11..)

FPM (DAA-12..)

Orifice: nickel-plated brass (DAA-11..)

stainless steel 1.4301 (DAA-12..)

Rotor: POM (DAA-11..)

PTFE (DAA-12..)

Rotor spindle: stainless steel 1.4305

Support bars: nickel-plated brass (DAA-11..)

stainless steel 1.4305 (DAA-12..)

Wiper carrier: stainless steel 1.4310

Wiper: Polyolefin (DAA-11..)

FPM (DAA-12..)

9. Order Codes

Example: DAA-1101HR08

Indicating

range

l/min

water

0.4 to 4 0.25 16 100 0.3

0.6 to 8 0.25 16 100 0.28

1 to 12 0.25 16 100 0.6

1 to 25 0.25 16 100 0.65

1.6 to 40 0.25 16 100 0.7

8 to 80 0.25 16 100 1.5

8 to 100 0.25 16 100 1.6

p

pmax tmax Weight Model

at

Q

max

bar PN °C Kg

Nickel-plated

brass

with rotor/

wiper

DAA-1101H.. DAA-1201H..

DAA-1102H.. DAA-1202H..

DAA-1103H.. DAA-1203H..

DAA-1104H.. DAA-1204H..

DAA-1105H.. DAA-1205H..

DAA-1106H.. DAA-1206H..

DAA-1107H.. DAA-1207H..

Stainless

steel

with rotor/

wiper

Connection

thread

G NPT

1/4

R08 N08

3/8

R10 N10

1/2

R15 N15

3/4

R20 N20

1

R25 N25

1 ¼

R32 N32

1½

R40 N40

DAA K03/0218 page 7

Page 8

DAA

10. Dimensions

Nominal

Model

DAA-...01H 8 1/4 1/4 71 36 23

DAA-...02H 10 3/8 3/8 71 36 23

DAA-...03H 15 1/2 1/2 86 46 29.5

DAA-...04H 20 1/4 1/4 94 46 29.5

DAA-...05H 25 1 1 104 46 29.5

DAA-...06H 32 1¼ 1¼ 120 65 37.6

DAA-...07H 40 1½ 1½ 130 65 37.6

size

DN

[mm]

Female

thread

G

Female

thread

NPT

Total length

L [mm]

Width across

flats AF [mm]

Rotor-

diameter D

[mm]

page 8 DAA K03/0218

Page 9

DAA

11. EU Declaration of Conformance

We, KOBOLD Messring GmbH, Hofheim-Ts, Germany, declare under our sole

responsibility that the product:

Flow Indicator Model: DAA-...

to which this declaration relates is in conformity with the standards noted below:

EN 50581:2012 Technical documentation for the assessment of electrical

and electronic products with respect to the restriction of hazardous substances

Also the following EC guidelines are fulfilled:

2011/65/EU RoHS (category 9)

Hofheim, 13. Feb 2018

H. Peters M. Wenzel

General Manager Proxy Holder

DAA K03/0218 page 9

Loading...

Loading...