Page 1

All-Metal Armored Flowmeter and Counter

for Liquids and Gases

●● 316 Stainless Steel, PTFE-Lined Stainless

Steel, and Hastelloy® C-22 Measuring

Tubes

measuring

•

monitoring

•

analyzing

BGN

●● Line Sizes up to 6"

●● Direct Reading Scales Calibrated

for Media Viscosity, Density, Operating

Pressure and Temperature

●● Analog Output, HART

●● Connection: 1/4"...2" NPT, ANSI

®

, and Profibus®-PA

1/2"...6", Others Available

●● Special Versions Available for Process

Temperatures up to 660 °F

●● Special Materials: Monel

®

, Tantalum,

Others on Request

KOBOLD companies worldwide:

ARGENTINA, AUSTRALIA, AUSTRIA, BELGIUM, BULGARIA, CANADA, CHILE, CHINA, COLOMBIA,

CZECH REPUBLIC, EGYPT, FRANCE, GERMANY, HUNGARY, INDIA, INDONESIA, ITALY, MALAYSIA,

MEXICO, NETHERLANDS, PERU, POLAND, REPUBLIC OF KOREA, ROMANIA, SINGAPORE, SPAIN,

SWITZERLAND, TAIWAN, THAILAND, TUNISIA, TURKEY, UNITED KINGDOM, USA, VIETNAM

01/03-18-2019

KOBOLD Instruments, Inc.

1801 Parkway View Drive

Pittsburgh, PA 15205

Main Ofce:

1.800.998.1020

1.412.788.4890

info@koboldusa.com

www.koboldusa.com

Page 2

All-Metal Armored Flowmeter and Counter Model BGN

Description

The KOBOLD BGN armored variable area flowmeter is ideal for difficult

applications that require high pressure capability, high temperature

operation, or low pressure loss. The BGN's standard design is

available in stainless steel, PTFE-clad stainless steel, or Hastelloy®

C-22. The standard BGN is well suited for water, most viscous

liquids, and compressed gases in line sizes up to 6". The direct

reading scales are calibrated for media viscosity, density, operating

pressure, and temperature. Electronic limit switches and an analog

flow transmitter are available as options and are able to operate via

intrinsically safe methods of protection and may be used in hazardous

areas where intrinsically safe installations are permitted. Custom

designs for high pressure, high temperature, special fittings, and

special materials (such as Monel® and tantalum) are available. Other

options include: self-draining flow bodies, gas or liquid damping, and

a flow counter module.

Technical Details

Sensor

Wetted Materials: 316 L SS / 316-Ti SS,

Hastelloy® C-22/C4, PTFE

Other Materials on Request

Process Connection: ASME B16.5, NPT,

Other Connections on Request

Nominal Pressure: 580 PSIG, ASME Cl150 / 300

(Standard) (BGN-S/H)

230 PSIG, ASME Cl150

(Standard) (BGN-P)

Higher Pressures Upon Request

(Max. 8700 PSIG)

Process Temperature: -40...392 °F

(BGN-S/H without Electr. Output)

-40...300 °F

(BGN-S/H with Electr. Output)

-40...660 °F

(BGN-S/H with Option V / H / W)

-40... 257 °F (BGN-P)

Ambient Temperature: -40...176 °F

Accuracy

Liquid: ± 1.6 % of Full Scale (BGN-S/H)

± 2.0 % of Full Scale (BGN-P)

Gas: ± 1.8 % of Full Scale (BGN-S/H)

± 2.2 % of Full Scale (BGN-P)

Additional Inaccuracy

with Transmitter (ES): ± 0.2 %

Repeatability: ± 0.5 % of Full Scale

Protection: IP 65 (Aluminum Housing)

IP 67 (Stainless Steel Housing)

Certification

Explosion Protection: BVS 03 ATEX H/B 112

CE-Marking: Pressure Equipment Directive

97/23/Eg

2

www.koboldusa.com

Display

Material: Aluminum (Stove-Enameled)

Stainless Steel (as Option)

Electrical Outputs: Inductive Switch,

SJ 3,5-N NAMUR (Standard)*

Inductive Switch,

SJ 3,5-SN NAMUR (Safety

Design)* on Request

Microswitch*

Others on Request

Ambient Temperature: -40...176 °F

(without Limit Switch)

-40...149 °F

(with Limit Switch)

* Using the segments of the slot-type initiators or the eccentric discs of the

microswitches, any switching point between 10 % and 90 % of the flow rate

can be set.

Transmitter

• ES with HART®-Protocol

• ES with HART®-Protocol and

2 NAMUR-Switches*

• ES with HART®-Protocol and

1 NAMUR-Switch* / 1 Pulse Output

• ES with Profibus® PA

• ES with HART®-Protocol and Counter Module

• ES with Fieldbus® Foundation™

* Contact can be configured using HART

Power Supply: 14 - 30 V

®

DC

Output: Passive, Galvanically Isolated

Current: 4-20 mA

Binary 1 and 2: Ui = 30 V, Ii = 20 mA, Pi = 100 mW

Input Binary: Counter Reset

(only for ES with Counter Module)

Ambient Temperature: -40...158 °F

Certification

Explosion Protection: DMT 00 ATEX E 075

Type of Protection: II 2G EEx ia IIC T6

CE-Marking: Explosion Protection Directive

94/9/EG

No responsibility taken for errors;

subject to change without prior notice.

Page 3

All-Metal Armored Flowmeter and Counter Model BGN

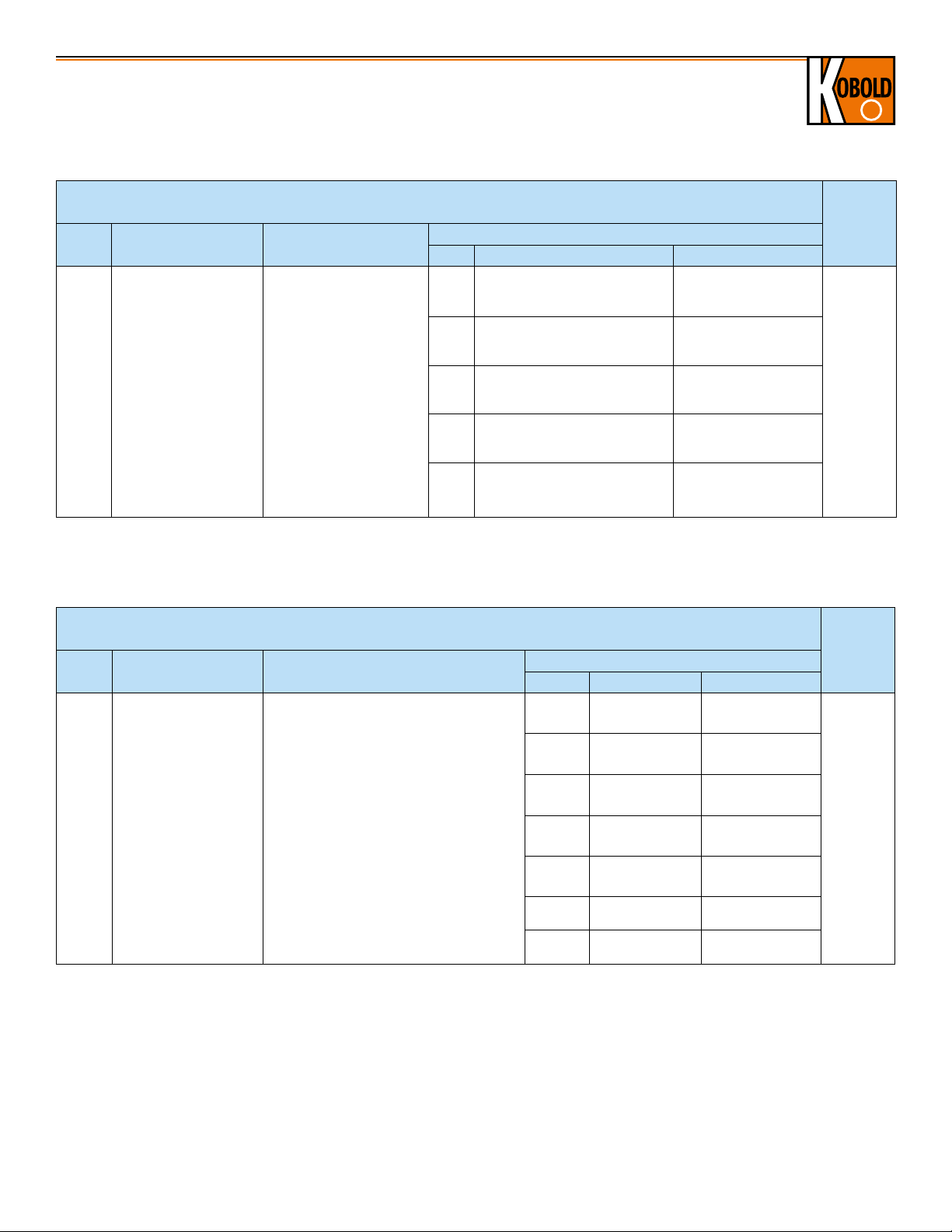

Order Details for Low Flow Models: (Example: BGN-S10 201R A 0000 S 1 0 0K)

Low Flow Models

Measuring Ranges: 0.0022...0.022 GPM to 0.0176...0.176 GPM

Model

BGN-..

Measuring Tube

Material

..S10.. = Stainless Steel,

Process Temp.

≤ 660 °F

Connection

5) 11)

..201R

.. = 1/2" Class 150

RF ASME

5) 11)

..221R

.. = 1/2" Class 300

RF ASME

..202R.. = 3/4" Class 150

RF ASME

..222R1).. = 3/4" Class 300

RF ASME

..203R.. = 1" Class 150

Code Water Air

..A..

..B..

..C..

BGN-S10: 0.0022...0.022 GPM

BGN-P10: 0.0031...0.031 GPM

BGN-S10: 0.0044...0.044 GPM

BGN-P10: 0.0053...0.053 GPM

BGN-S10: 0.0071...0.071 GPM

BGN-P10: 0.0088...0.088 GPM

..D5).. 0.011...0.11 GPM 0.044..0.44 SCFM

RF ASME

..223R1).. = 1" Class 300

RF ASME

*Reference Conditions: Water at 68 °F @1 mPas, Air at 68 °F @ 0 PSIG (Range Values for Other Media Upon Request)

..E5).. 0.0176...0.176 GPM 0.077...0.77 SCFM

Measuring Range*

0.008...0.08 SCFM

0.018...0.18 SCFM

0.085...0.282 SCFM

Part

Number

Continued

To

complete

part

number,

please go

directly to

order table

on page 7.

Order Details for DN15 Models: (Example: BGN-S15 201R F 0000 S 1 0 0K)

DN15 Models

Measuring Ranges: 0.022...0.22 GPM to 0.264...2.64 GPM

Model

BGN-..

*Reference Conditions: Water at 68 °F @1 mPas, Air at 68 °F @ 0 PSIG (Range Values for Other Media Upon Request)

1)

Pressure stated for models BGN-S and BGN-H

2)

Damping / spring not available

3)

Only available with forward advanced indicating housing

4)

Not available with heating / cooling

5)

Not for model BGN-P

6)

Not for model BGN-H

7)

Not for model BGN-S

9)

Cannot be converted for other media

10)

IEC 61508-2:2010 conformity confirmed by EXIDA

11)

Reduced rasied face

No responsibility taken for errors;

subject to change without prior notice.

Measuring Tube

Material

..S15.. = Stainless Steel,

Process Temp.

≤ 660 °F

..P15.. = Stainless Steel

Measuring Tube,

PTFE-Lining,

Process Temp.

≤ 257 °F,

Max. Pressure

230 PSIG

..H15.. = Hastelloy® C-22,

Process Temp.

≤ 660 °F

Connection

5) 11)

..201R

..221R

.. = 1/2" Class 150 RF ASME

5) 11)

.. = 1/2" Class 300 RF ASME

..202R.. = 3/4" Class 150 RF ASME

..222R1).. = 3/4" Class 300 RF ASME

..203R.. = 1" Class 150 RF ASME

..223R1).. = 1" Class 300 RF ASME

5) 6)

..6010

..6020

..6030

..6040

.. = 1/4" NPT

5) 6)

.. = 3/8" NPT

5) 6)

.. = 1/2" NPT

5) 6)

.. = 3/4" NPT

www.koboldusa.com

Code Water Air

..F.. 0.022...0.22 GPM 0.088..0.88 SCFM

..G.. 0.031...0.31 GPM 0.118...1.24 SCFM

..H.. 0.044..0.44 GPM 0.176...1.76 SCFM

..I.. 0.071...0.71 GPM 0.294...2.71 SCFM

..J.. 0.11...1.1 GPM 0.412...4.12 SCFM

..K.. 0.176...1.76 GPM 0.589...6.47 SCFM

..L.. 0.264...2.64 GPM 1.0...10.0 SCFM

Measuring Range*

Part

Number

Continued

To

complete

part

number,

please go

directly to

order table

on page 7.

3

Page 4

All-Metal Armored Flowmeter and Counter Model BGN

Order Details for DN25 Models: (Example: BGN-S25 202R M 0000 S 1 0 0K)

DN25 Models

Measuring Ranges: 0.44...4.4 GPM to 1.76...17.6 GPM

Model

BGN-..

*Reference Conditions: Water at 68 °F @1 mPas, Air at 68 °F @ 0 PSIG (Range Values for Other Media Upon Request)

Measuring Tube

Material

..S25.. = Stainless Steel,

Process Temp.

≤ 660 °F

..P25.. = Stainless Steel

Measuring Tube,

PTFE-Lining,

Process Temp.

≤ 257 °F,

Max. Pressure

230 PSIG

..H25.. = Hastelloy® C-22,

Process Temp.

≤ 660 °F

Connection

5) 11)

..202R

..222R

.. = 3/4" Class 150 RF ASME

5) 11)

.. = 3/4" Class 300 RF ASME

..203R.. = 1" Class 150 RF ASME

..223R1).. = 1" Class 300 RF ASME

5) 6)

..6010

..6020

..6030

..6040

.. = 1/4" NPT

5) 6)

.. = 3/8" NPT

5) 6)

.. = 1/2" NPT

5) 6)

.. = 3/4" NPT

Code Water Air

..M.. 0.44...4.4 GPM 1.76...17.6 SCFM

..N.. 0.705...7.05 GPM 2.35...27.1 SCFM

..P.. 1.1...11 GPM 4.12...41.2 SCFM

5)9)

..Q

.. 1.76...17.6 GPM 6.47...64.7 SCFM

Measuring Range*

Part

Number

Continued

To

complete

part

number,

please go

directly to

order table

on page 7.

Order Details for DN40 Models: (Example: BGN-S40 205R P 0000 S 1 0 0K)

DN40 Models

Measuring Ranges: 1.1...11 GPM to 2.64...26.4 GPM

Model

BGN-..

*Reference Conditions: Water at 68 °F @1 mPas, Air at 68 °F @ 0 PSIG (Range Values for Other Media Upon Request)

1)

Pressure stated for models BGN-S and BGN-H

2)

Damping / spring not available

3)

Only available with forward advanced indicating housing

4)

Not available with heating / cooling

5)

Not for model BGN-P

6)

Not for model BGN-H

7)

Not for model BGN-S

9)

Cannot be converted for other media

10)

IEC 61508-2:2010 conformity confirmed by EXIDA

11)

Reduced raised face

Measuring Tube

Material

..S40.. = Stainless Steel,

Process Temp.

≤ 660 °F

..P40.. = Stainless Steel

Measuring Tube,

PTFE-Lining,

Process Temp.

≤ 257 °F,

Max. Pressure

230 PSIG

..H40.. = Hastelloy® C-22,

Process Temp.

≤ 660 °F

Connection

..205R5).. = 1-1/2" Class 150 RF ASME

1) 5)

..225R

..6040

..6050

..6060

.. = 1-1/2" Class 300 RF ASME

5) 6)

.. = 3/4" NPT

5) 6)

.. = 1" NPT

5) 6)

.. = 1-1/4" NPT

Code Water Air

..P.. 1.1...11 GPM 4.12...41.2 SCFM

..Q.. 1.76...17.6 GPM 6.47...64.7 SCFM

..R.. 2.64...26.4 GPM 10...100 SCFM

Measuring Range*

Part

Number

Continued

To

complete

part

number,

please go

directly to

order table

on page 7.

4

www.koboldusa.com

No responsibility taken for errors;

subject to change without prior notice.

Page 5

All-Metal Armored Flowmeter and Counter Model BGN

Order Details for DN50 Models: (Example: BGN-S50 206R Q 0000 S 1 0 0K)

DN50 Models

Measuring Ranges: 1.76...17.6 GPM to 11...110 GPM

Model

Measuring Tube

Material

..S50.. = Stainless Steel,

Process Temp.

≤ 660 °F

Connection

Measuring Range*

Code Water Air

..Q.. 1.76...17.6 GPM 6.47...64.7 SCFM

Part

Number

Continued

..206R.. = 2" Class 150 RF ASME

..226R1).. = 2" Class 300 RF ASME

5) 6)

..6070

.. = 1-1/2" NPT

..R.. 2.64...26.4 GPM 10...100 SCFM

..S.. 4.4...44 GPM 17.07...170.7 SCFM

BGN-..

..P50.. = Stainless Steel

Measuring Tube,

PTFE-Lining,

Process Temp.

≤ 257 °F,

Max. Pressure

230 PSIG

..6080

5) 6)

.. = 2" NPT

..T.. 7.05...70.5 GPM 27.07...270.7 SCFM

..H50.. = Hastelloy® C-22,

Process Temp.

5)9)

..U

.. 11...110 GPM 41.19...411.9 SCFM

≤ 660 °F

*Reference Conditions: Water at 68 °F @1 mPas, Air at 68 °F @ 0 PSIG (Range Values for Other Media Upon Request)

Order Details for DN80 Models: (Example: BGN-S80 208R T 0000 S 1 0 0K)

DN80 Models

Measuring Ranges: 7.05...70.5 GPM to 17.61...176.1 GPM

Model

BGN-..

Measuring Tube

Material

..S80.. = Stainless Steel,

Process Temp.

≤ 660 °F

..P80.. = Stainless Steel

Measuring Tube,

PTFE-Lining,

Process Temp.

≤ 257 °F,

Max. Pressure

230 PSIG

Connection

..208R.. = 3" Class 150 RF ASME

..228R1).. = 3" Class 300 RF ASME

Code Water Air

..T.. 7.05...70.5 GPM 27.07...270.7 SCFM

..U.. 11...110 GPM 41.19...411.9 SCFM

Measuring Range*

To

complete

part

number,

please go

directly to

order table

on page 7.

Part

Number

Continued

To

complete

part

number,

please go

directly to

order table

on page 7.

..H80.. = Hastelloy® C-22,

..V5).. 17.61...176.1 GPM 64.74...647.4 SCFM

Process Temp.

≤ 660 °F

*Reference Conditions: Water at 68 °F @1 mPas, Air at 68 °F @ 0 PSIG (Range Values for Other Media Upon Request)

1)

Pressure stated for models BGN-S and BGN-H

2)

Damping / spring not available

3)

Only available with forward advanced indicating housing

4)

Not available with heating / cooling

5)

Not for model BGN-P

6)

Not for model BGN-H

7)

Not for model BGN-S

9)

Cannot be converted for other media

10)

IEC 61508-2:2010 conformity confirmed by EXIDA

No responsibility taken for errors;

subject to change without prior notice.

www.koboldusa.com

5

Page 6

All-Metal Armored Flowmeter and Counter Model BGN

Order Details for DN100 Models: (Example: BGN-S1H 210R V 0000 S 1 0 0K)

DN100 Models

Measuring Ranges: 17.61...176.1 GPM to 44.03...440.3 GPM

Model

Measuring Tube

Material

..S1H.. = Stainless Steel,

Process Temp.

≤ 660 °F

Connection

Code Water Air

..V.. 17.61...176.1 64.74...647.4

Measuring Range*

Part

Number

Continued

BGN-..

..P1H.. = Stainless Steel

Measuring Tube,

PTFE-Lining,

Process Temp.

..210R.. = 4" Class 150 RF ASME

..W..

BGN-S/H: 26.42...264.2 GPM

BGN-P: 24.21...242.1 GPM

≤ 257 °F,

Max. Pressure

..230R

1)3)11)

.. = 4" Class 300 RF ASME

..X5).. 35.23...352.3 GPM on Request

230 PSIG

..H1H.. = Hastelloy® C-22,

Process Temp.

2)5)

..2

.. 44.03...440.3 GPM on Request

≤ 660 °F

*Reference Conditions: Water at 68 °F @1 mPas, Air at 68 °F @ 0 PSIG (Range Values for Other Media Upon Request)

Order Details for DN150 Models: (Example: BGN-SH5 212R 2 0000 V 1 0 0K)

DN150 Models

Measuring Ranges: 17.61...176.1 GPM to 44.03...440.3 GPM

Model

BGN-..

Measuring Tube

Material

..SH5.. = Stainless Steel,

Process Temp.

≤ 660 °F

..HH5.. = Hastelloy® C-22,

Process Temp.

≤ 660 °F

..212R

..232R

Connection

11)

.. = 6" Class 150 RF ASME

3)11)

.. = 6" Class 300 RF ASME

Code Water Air

..25).. 44.03...440.3 GPM on Request

..45).. 57.24...572.2 GPM on Request

Measuring Range*

on Request

To

complete

part

number,

please go

directly to

order table

on page 7.

Part

Number

Continued

To

complete

part

number,

please go

directly to

order table

on page 7.

*Reference Conditions: Water at 68 °F @1 mPas, Air at 68 °F @ 0 PSIG (Range Values for Other Media Upon Request)

1)

Pressure stated for models BGN-S and BGN-H

2)

Damping / spring not available

3)

Only available with forward advanced indicating housing

4)

Not available with heating / cooling

5)

Not for model BGN-P

6)

Not for model BGN-H

7)

Not for model BGN-S

9)

Cannot be converted for other media

10)

IEC 61508-2:2010 conformity confirmed by EXIDA

11)

Models from 4" Class 300 and up require selection of display "assembled at distance". Choose display option codes: "V", "H", or "W"

6

www.koboldusa.com

No responsibility taken for errors;

subject to change without prior notice.

Page 7

All-Metal Armored Flowmeter and Counter Model BGN

Order Details** Continued (Example: BGN-S 10 201R A 0000 S 1 0 0K)

Heating5) /

Cooling

..0.. = without

..3.. = with

Heating

ANSIFlange

½"

Class

150

..4.. = with

Heating

1/2"

NPT

Conn.

Damping5) /

Spring Stop

..0.. = without

..R8).. = with Flow

Restrictor

for Gas

Measuring

11)

..F

.. = with

Liquid

Damping

11)

..G

.. = with Gas

Damping

11)

..A

.. = with

Spring

Stop

11)

..S

.. = with Gas

Damping

and

Spring

Stop

Draining

Body

..0.. = without

12)

..L

.. = with Self

Draining

Body

Certificates Display Scale

..0.. = without

Certificate

13)

..S

.. = Aluminum

..V.. = Aluminum,

..1.. = Certificate of

Compliance

with the

Order 2.1

13)

..E

.. = Stainless Steel

..2.. = Test Report

2.2

..B.. = Inspection

Certificate

..H.. = Stainless Steel,

13)

..T

.. = Aluminum

with Material

Certificate

3.1

..W.. = Aluminum

..C.. = Inspection

Certificate

with Material

Certificate

3.2

Assembled at

Distance, up to

660 °F

Assembled at

Distance, up to

660 °F

with Pressure

Compensation

with Pressure

Compensation,

Assembled at

Distance, up to

660 °F

Water

..1.. = %-Scale

..2.. = Measuring

Range

Media

..4.. = %-Scale

..5.. = Measuring

Range

..F.. = Dual Scale

**Please specify

media data in

plain text (see

below)

Electrical

Output

..0.. = without

..1.. = 1 Inductive

Limit Switch,

10)

SIL-1

..2.. = 2 Inductive

Limit Switches,

10)

SIL-1

..C.. = 1 Micro

Switch

..D.. = 2 Micro

Switches

..6.. = Transmitter ES

with HART®,

EEx ia, 4-20

mA, SIL-19)

..7.. = Transmitter ES

with HART®,

EEx ia, 4-20

mA and 2

NAMURSwitches,

10)

SIL-1

..8.. = Transmitter ES

with HART®,

EEx ia, 4-20

mA,

1 NAMURSwitch and 1

Pulse Output,

10)

SIL-1

..9.. = Electrical

Transmitter ES

with Profibus®

PA, EEx ia

..I.. = 4-20 mA with

HART® and

Counter Module

..K.. = Electrical

Transmitter ES

with Fieldbus®

Foundation™

Accessories

..0K = Without

..XK = Special

(Please

Specify)

1)

Pressure stated for models BGN-S and BGN-H

2)

Damping / spring not available

3)

Only available with forward advanced indicating housing

4)

Not available with heating / cooling

5)

Not for model BGN-P

6)

Not for model BGN-H

7)

Not for model BGN-S

8)

Only available up to range code "E" (0.077...0.77 SCFM)

9)

Cannot be converted for other media

10)

IEC 61508-2:2010 conformity confirmed by EXIDA

11)

Not for "Low Flow" or DN150 (6") models

12)

Not for "Low Flow" models

13)

Not for DN100 4" with 300lb ANSI, all DN100 5" ANSI, or all DN150 6" models

No responsibility taken for errors;

subject to change without prior notice.

*Additional Information Required for Order:

To ensure proper operation, this product requires a completed

application guide form to be submitted with any order.

Please refer to the ‘documentation’ tab on the bottom of

the product page for this product on our website in order to

obtain the correct form. You can also contact your KOBOLD

representative for this form.

7

www.koboldusa.com

Page 8

A

A

155

1

5

5

2

5

0

A

A

1

9

6

2

5

0

Ø

Dimensions

Aluminum Display

0

5

2

9.84"

All-Metal Armored Flowmeter and Counter Model BGN

3

5

1

6.02"

0

5

2

9.84"

6.10"

155

5

5

1

6.10"

Øl.W.

*5.71"

145*

2.76"

70

,4

7

4

1.87"

Stainless Steel Display

6

0

5

2

9.84"

9

1

Ø

Ø 7.72"

DN PN I. W. (Inner Width)

15 40 1.02" 2.91" 3.94"

25 40 1.26" 3.03" 4.06"

40 40 1.81" 3.35" 4.33"

50 40 2.76" 3.86" 4.84"

80 40 4.02" 4.62" 5.51"

100 16 4.92" 5.00" 6.02"

125 16 5.91" 5.59" 6.54"

150 16 6.26" 5.83" 6.73"

Dimensional Deviations:

* + 3.94" with forward advanced display and generally at DN 150

8

0

5

2

9.84"

www.koboldusa.com

*6.22"

158*

3.19"

81

3

5

1

6.02"

8

6

2.68"

Øl.W.

A

Aluminum Display Stainless Steel Display

No responsibility taken for errors;

subject to change without prior notice.

Loading...

Loading...