Page 1

Variable-Area Flow Meter

for Horizontal and Vertical Installation

Installation and Operating Instructions

BGF

Page 2

Heinri

chs Messtechnik

BGF Installation and Operating Instructions

Contents

1 Introduction ............................................................................................................................................. 4

2 Identification............................................................................................................................................ 4

2.1 Supplier/manufacturer .................................................................................................................................... 4

2.2 Product type .................................................................................................................................................... 4

2.3 Issue date ......................................................................................................................................................... 4

2.4 Version no. ....................................................................................................................................................... 4

3 Applications ............................................................................................................................................. 4

4 Safety instructions ................................................................................................................................... 4

4.1 Intended use .................................................................................................................................................... 4

4.2 Installation, start-up and operating personnel ................................................................................................ 4

5 Packaging / Storage / Transportation ....................................................................................................... 4

6 Operational mode and system design ...................................................................................................... 5

6.1 Measuring principle ......................................................................................................................................... 5

6.2 System design .................................................................................................................................................. 5

7 Input ........................................................................................................................................................ 5

7.1 Measured variable ........................................................................................................................................... 5

7.2 Measuring range (lower-range and upper-range value) ................................................................................. 5

7.3 Measuring range chart .................................................................................................................................... 6

8 Output (electrical equipment, options) .................................................................................................... 6

8.1 Binary output ................................................................................................................................................... 6

8.1.1 KEI 1 or KEI 2 limit switches ............................................................................................................................. 6

8.1.2 KEM 1 or KEM 2 limit transducers (special version) ........................................................................................ 6

8.2 Analog output with the electronic transmitter ES .......................................................................................... 6

8.3 Model ES-PPA and ES-FF .................................................................................................................................. 7

9 Characteristic values ................................................................................................................................ 7

9.1 Measuring Accuracy ........................................................................................................................................ 7

9.1.1 Reference conditions ....................................................................................................................................... 7

9.1.2 Measured error................................................................................................................................................ 7

9.1.3 Repeatability .................................................................................................................................................... 7

9.2 Influence of ambient temperature .................................................................................................................. 7

9.3 Influence of fluid temperature ........................................................................................................................ 7

10 Conditions of use ..................................................................................................................................... 7

10.1 Installation conditions ..................................................................................................................................... 7

10.1.1 Mounting/start-up ........................................................................................................................................... 8

10.1.2 Device settings ................................................................................................................................................. 9

10.1.3 Adjusting the switch point for the inductive limit switch KEI ......................................................................... 9

10.1.4 Adjusting the switch point of the SPDT Micro Switch KEM ............................................................................ 9

10.1.5 Installation in hazardous areas ...................................................................................................................... 10

10.2 Ambient conditions ....................................................................................................................................... 11

10.2.1 Ambient temperature ranges ........................................................................................................................ 11

10.2.2 Storage temperature ..................................................................................................................................... 11

10.2.3 Climatic category ........................................................................................................................................... 11

10.2.4 Degree of protection ..................................................................................................................................... 11

10.2.5 Shock resistance/vibration resistance ........................................................................................................... 11

10.2.6 Electromagnetic compatibility ....................................................................................................................... 11

10.3 Fluid conditions ............................................................................................................................................. 12

10.3.1 Fluid temperature ranges .............................................................................................................................. 12

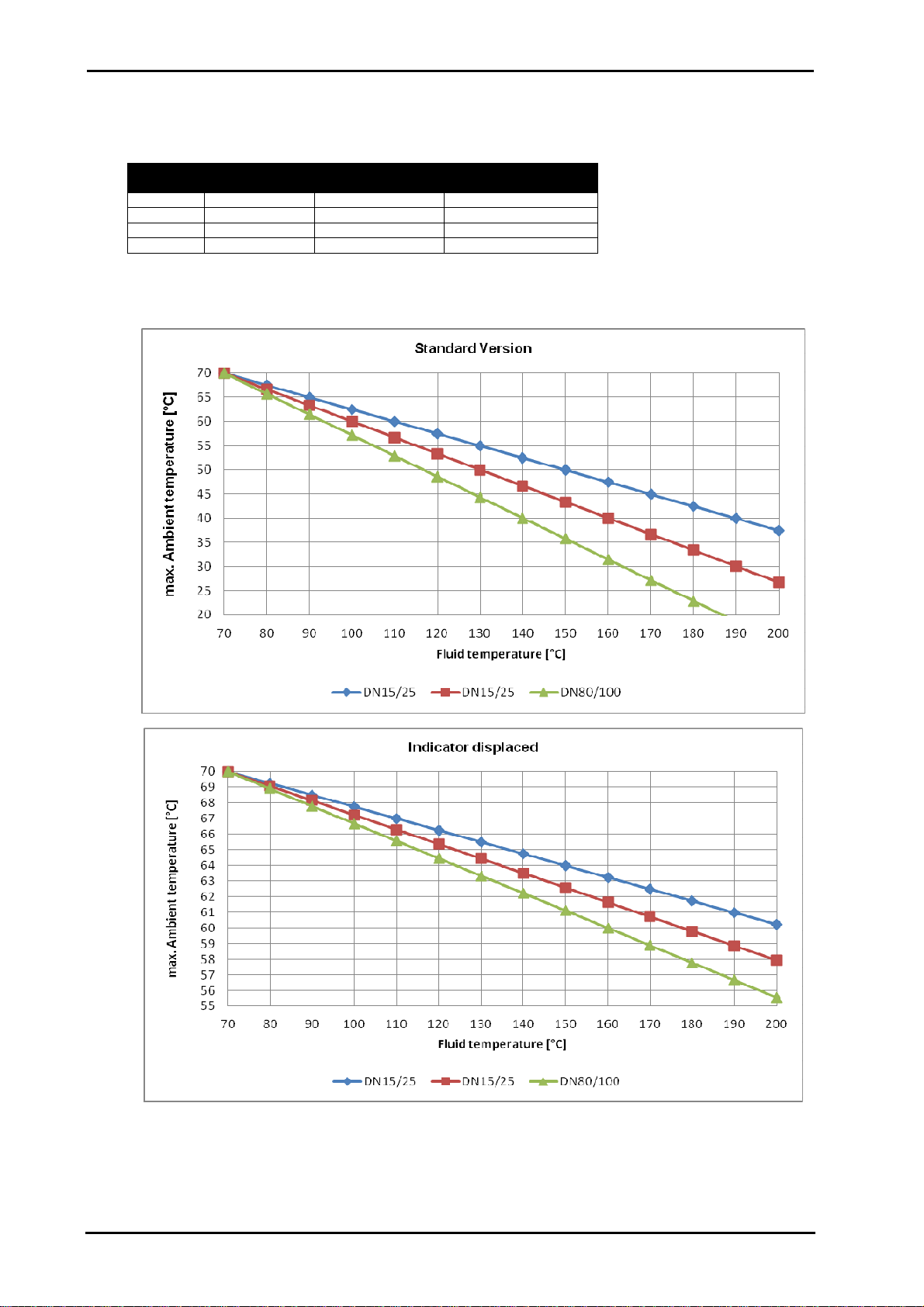

10.3.2 Diagrams: Max. ambient temperature based on the fluid temperature for the ES ...................................... 12

10.3.3 Fluid pressure limit ........................................................................................................................................ 13

10.3.4 Inlet and outlet sections ................................................................................................................................ 13

10.3.5 Physical state ................................................................................................................................................. 13

10.3.6 Density ........................................................................................................................................................... 13

10.3.7 Viscosity ......................................................................................................................................................... 13

10.3.8 Pressure (for gas measurement) ................................................................................................................... 13

10.3.9 Pressure Drop ................................................................................................................................................ 13

11 Construction details ............................................................................................................................... 13

11.1 Type of construction/dimensions .................................................................................................................. 13

Page 2 of 38

Subject to change without notice

Page 3

Heinri

chs Messtechnik

BGF Installation and Operating Instructions

11.1.1 Aluminum indicator housing ......................................................................................................................... 13

11.1.2 Dimensional drawing with heating connection ............................................................................................. 14

11.1.3 Indicator housing made of stainless steel ..................................................................................................... 15

11.2 Weights .......................................................................................................................................................... 16

11.3 Materials ........................................................................................................................................................ 16

11.4 Process connection ........................................................................................................................................ 17

11.5 Magnetic filter ............................................................................................................................................... 17

11.6 Electrical connection ..................................................................................................................................... 18

11.6.1 Wiring diagram for ES transmitter (signal output 4-20 mA with HART) ..................................................... 18

11.6.2 Wiring diagram for ES transmitter with 4-20 mA output and 2 limit switches ............................................. 19

11.6.3 Wiring diagram for ES transmitter with 4- 20 mA output, pulse output and limit switch ............................. 19

11.6.4 Wiring diagram for inductive limit switches KEI ............................................................................................ 20

11.6.5 Wiring diagram for KEM 1 and KEM 2 micro switches .................................................................................. 20

11.6.6 Devices with unconnected cable end ............................................................................................................ 20

12 Indicator unit ......................................................................................................................................... 20

13 Power supply ......................................................................................................................................... 20

14 CE marking ............................................................................................................................................. 21

15 Order information .................................................................................................................................. 21

16 Standards and directives, certificates and approvals .............................................................................. 21

17 Maintenance .......................................................................................................................................... 21

18 Installing and removing the resetting spring and the measuring body ................................................... 21

19 Trouble shooting .................................................................................................................................... 21

20 Returning devices for repair and service ................................................................................................ 22

21 Spare parts ............................................................................................................................................. 22

22 Exploded views ...................................................................................................................................... 23

22.1 Fitting with measuring body .......................................................................................................................... 23

22.1.1 BGF-.... standard version DN 15-25 .............................................................................................................. 23

22.1.2 BGF-.... standard version DN 50-80 .............................................................................................................. 23

22.2 Indicator unit ................................................................................................................................................. 24

22.2.1 Complete indicator unit, local with scale ...................................................................................................... 24

22.2.2 Complete indicator unit with 1 limit switch SJ 3,5 N .................................................................................... 24

22.2.3 Complete indicator unit with 2 limit switches SJ 3,5 N ................................................................................ 25

22.2.4 Complete indicator unit with 1 pc SPDT micro switch ................................................................................... 25

22.2.5 Complete Indicator unit with 2 pcs SPDT micro switches KEM ................................................................... 25

22.2.6 Complete Indicator unit with transmitter ES Ex HART ............................................................................. 25

22.3 Model Code ................................................................................................................................................... 26

23 Decontamination certificate for device cleaning .................................................................................... 29

24 EC Type Examination Certificate ............................................................................................................. 30

25 Declaration of conformity ...................................................................................................................... 36

Page 3 of 38

Subject to change without notice

Page 4

Heinri

chs Messtechnik

BGF Installation and Operating Instructions

1 Introduction

These Installation and Operating Instructions serve as a tool for the correct installation, operation and maintenance of the device.

They are a supplement to the BGF Device Description. Read the manual carefully before the device is installed and put into use. It

does not include special versions or applications.

All devices are thoroughly checked for order compliance and operability before delivery. Upon receipt, please conduct a visual

inspection of possible damage that may be identified as having occurred during shipment. If you discover any defect, please

contact our head office in Cologne or the local sales office responsible for your area (see the telephone directory at the end of this

manual or on our Web site). Apart from a description of the error, we will need the equipment type and serial number of the

delivery.

Heinrichs Messtechnik shall not furnish guarantee for any repair work done without prior notice. Unless otherwise agreed on, the

rejected parts must be made available to us in case a claim is made.

2 Identification

2.1 Supplier/manufacturer

Heinrichs Messtechnik GmbH

Robert-Perthel-Str. 9 ⋅ D-50739 Köln

Phone +49 (221) 49708 - 0

Fax +49 (221) 49708 - 178

Internet: http://www.heinrichs.eu

E-mail: mailto:info@heinrichs.eu

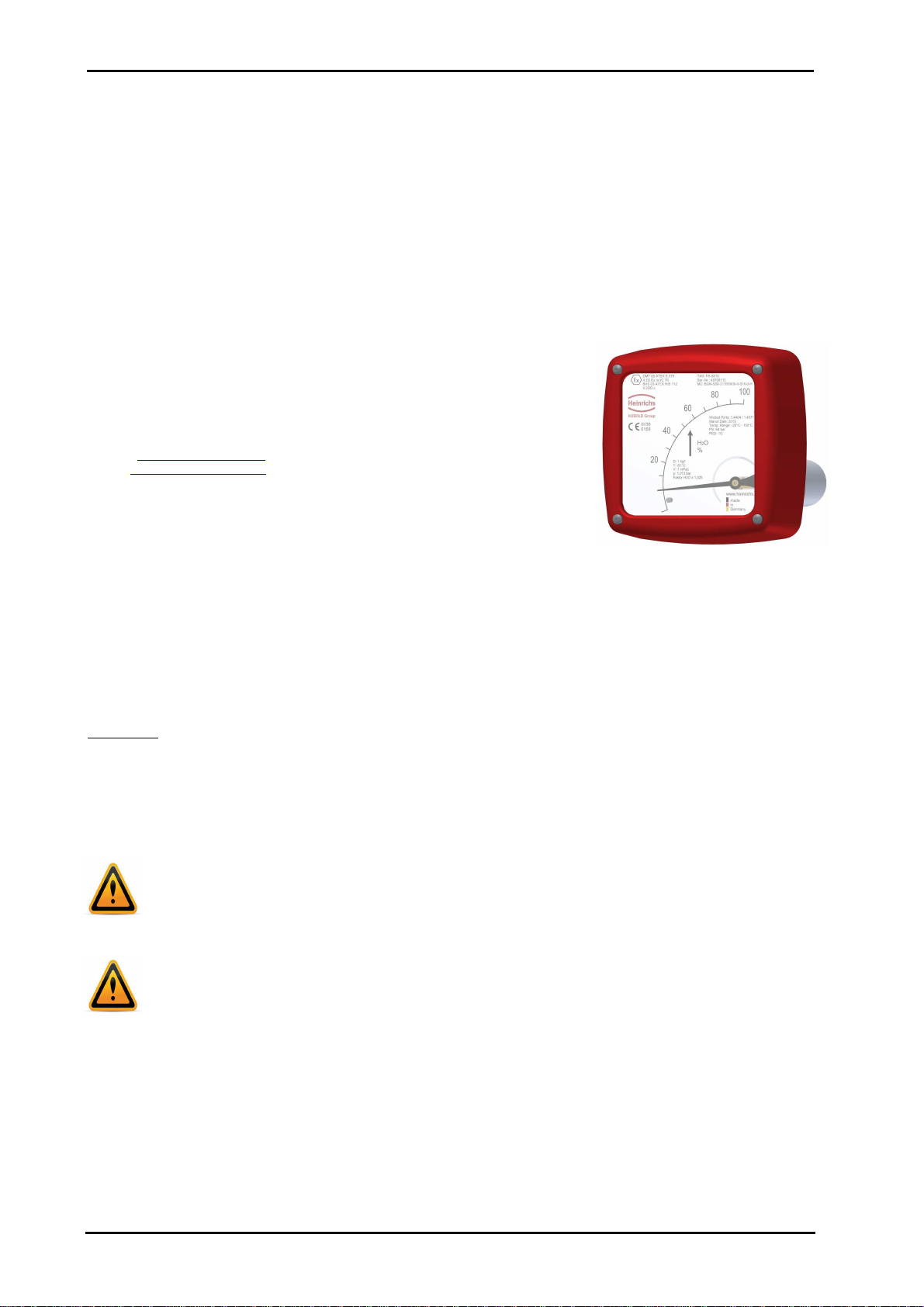

2.2 Product type

Mechanical flow meter in all-metal design

Instruments series BGF will be

delivered without label stickers.

All important informations such as:

-Measuring range

-Manufacturer

-Serial number

-Model code

-CE marking

-Neccessary Ex marking

are printed on instrument scale and

can be read from there.

2.3 Issue date

19.10.2016

2.4 Version no.

File: BGF_BA_16.02_en

3 Applications

The BGF flow meter is suitable for flow measurement of liquid or gaseous products in pipes. The special advantage is that it can

be used for all directions. It shows the current flow rate in volume or mass per unit in time.

Applications: flow measurement, dosing, monitoring, adjusting and control of liquid and gaseous products.

The meter’s design makes it ideal for processes under difficult and adverse operating conditions.

The devices are available with additional electrical equipment for process monitoring and control.

4 Safety instructions

4.1 Intended use

The BGF variable area flow meter may be used only for flow measurements of liquid and gaseous media. The

manufacturer shall not be liable for damages that may result from improper or unintended use.

When dealing with an aggressive medium, clarify the material durability of all wetted parts. When using the device in

hazardous areas, follow the applicable national installation rules.

4.2 Installation, start-up and operating personnel

Only trained specialists authorized from the system operator may carry out the installation, electrical installations,

startup, maintenance and operation. They must read and understand the operating manual and follow its instructions.

Basically, follow the conditions and provisions applicable in your country.

5 Packaging / Storage / Transportation

Carefully unpack the device to avoid damage. The magnet body is secured against damage in transit depending on the device size.

Remove this transport protection from the fitting. By pressing the float from the bottom upwards (using a wooden stick, for

example), check whether the float can easily be moved upwards and slides back downwards. The pointer position of the indicator

unit must follow the direction of movement of the float.

With the help of the delivery note enclosed in the packaging, check whether all technically relevant data correspond with your

requirements.

Storage and installation must be done in a clean and dry room so that contamination – especially of the interior of the fitting – is

avoided. Follow the limit values for ambient temperature. When transporting the device to a remote mounting location, we

recommend that you reuse the factory-issued packaging and the transport protection.

Page 4 of 38

Subject to change without notice

Page 5

Heinri

chs Messtechnik

BGF Installation and Operating Instructions

6 Operational mode and system design

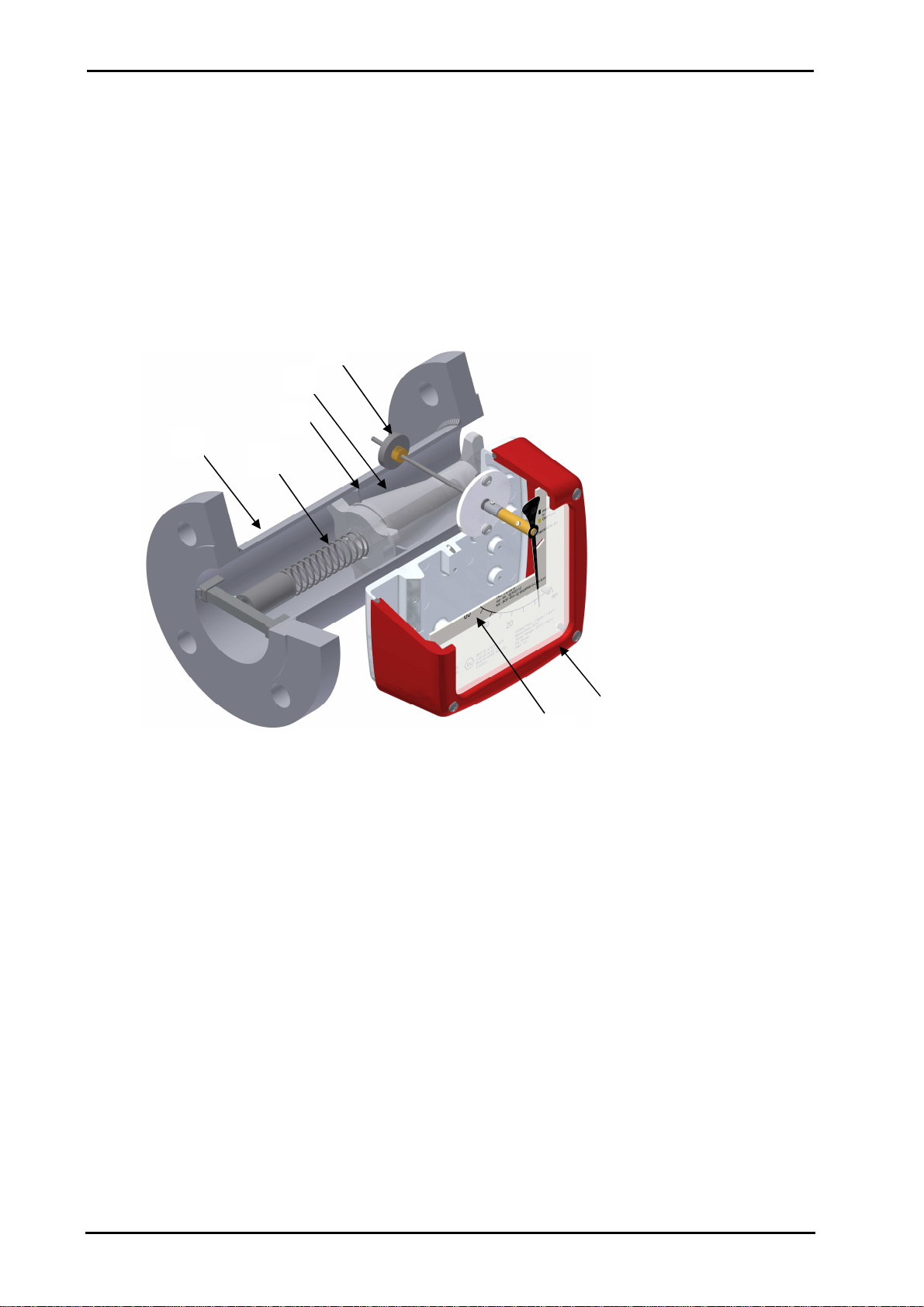

6.1 Measuring principle

The measuring element consists of a sharp-edged measuring ring and a conical measuring body with a compression spring.

If a medium flows with sufficient velocity through the measuring ring, the position of the measuring body will be shifted until the flow

force and the measuring body plus the spring tension establish equilibrium.

The position of the measuring body in the measuring ring serves as the measure of the flow and is converted to a rotary motion by

the permanent magnet embedded in the measuring body through a magnetic coupling system. It is then transmitted to the scale

and the additional electrical equipment.

1

2

3

4

5

6

1 Fitting

2 Resetting spring / guide

3 Measuring ring

4 Measuring body

5 Magnet tracking system

6 Scale

7 Indicator unit

7

6.2 System design

The meter consists of a cylindrical fitting pipe with flange connections on both sides, a measuring ring is firmly inserted in it and a

vertically movable, conical measuring body.

The position of the measuring body resulting from the flow rate is converted to a rotary motion on the pointer axis of the analog

indicator unit via the built-in permanent magnet through the magnetic tracking system.

7 Input

7.1 Measured variable

Volume flow

7.2 Measuring range (lower-range and upper-range value)

Lower-range value 10% of full scale value

Upper range value 100% of full scale value

Measuring range span 10-100%

Smallest measuring range 10-100 l/h water

Largest measuring range 6000-60000 l/h water (standard Version 1.4571 / 316 TI)

Page 5 of 38

Subject to change without notice

Page 6

Heinri

chs Messtechnik

BGF Installation and Operating Instructions

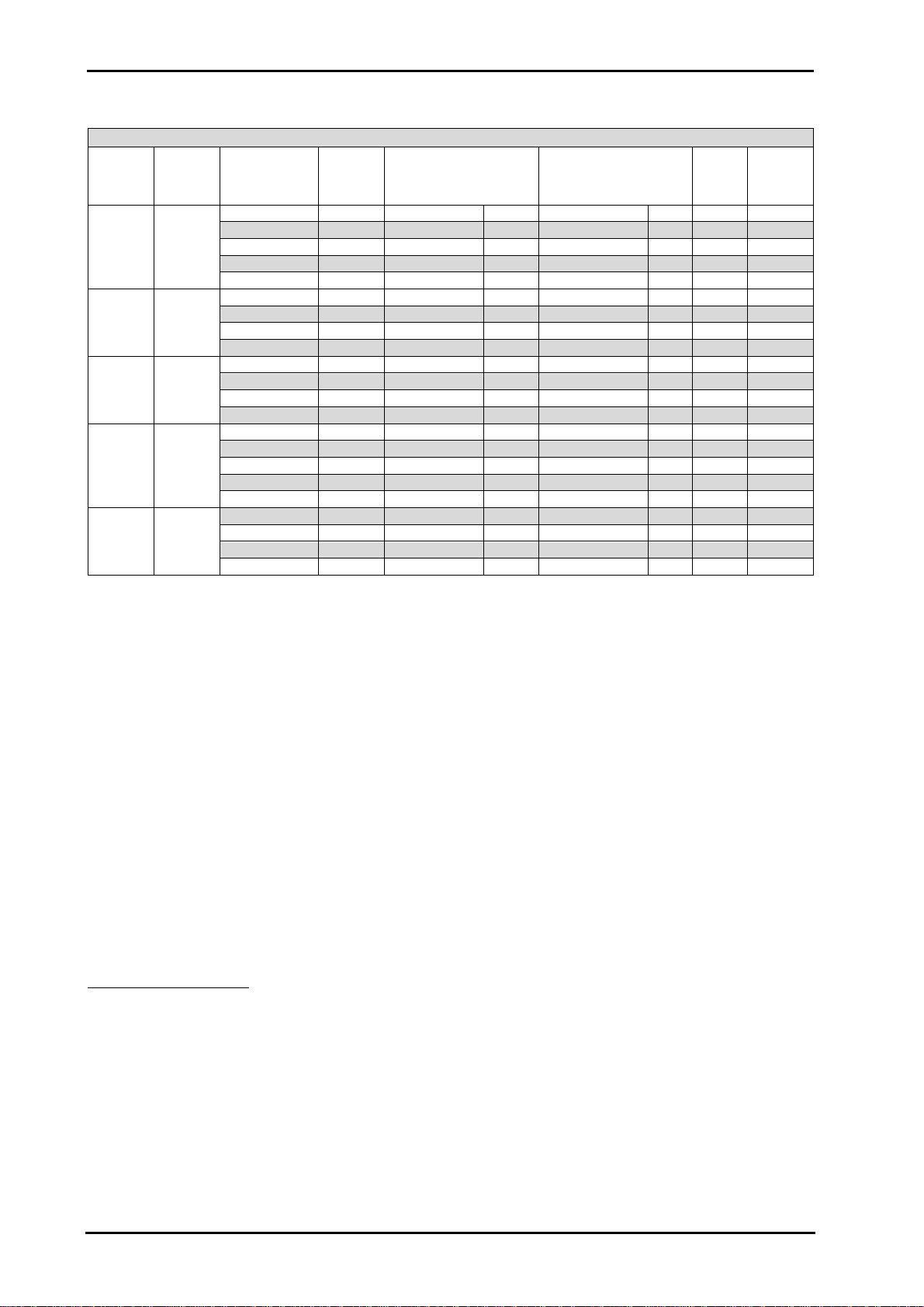

Measuring range chart BGF

4)

Body

Range

Measuring rang water

Measuring range air

Press.

Note

15 1/2”

1)

1)

20 3/4"

1)

25 1”

1)

32 1 ¼”

1)

15 3/4"

1)

20 1”

1)

25 1 ¼”

1)

32 1 ½”

1)

40 1 ½”

1)

1)

1)

1)

50 2”

2)

65

2)

2)

2)

2)

80 3”

2)

2)

2)

2)

1)

7.3 Measuring range chart

4)

DN

EN1092-1

ASME

B16.5-2003

S… st.st.

code

(1000 kg/m3; 1 mPas)

P… PTFE

H… Hastelloy

S15 H 10 - 100 I/h 0,3 - 3 m3/h 110

S15 I 16 - 160 l/h 0,5 - 4,6 m3/h 110

S15 J 25 - 250 I/h 0,7 - 7,0 m3/h 110

S15 K 40 - 400 I/h 1,0 - 11 m3/h 110

S15 L 60 - 600 I/h 1,7 - 17 m3/h 120

S25 M 100 - 1000 I/h 3 - 30 m3/h 90

S25 N 160 - 1600 I/h 4 - 46 m3/h 105

S25 P 250 - 2500 I/h 7 - 70 m3/h 130

S25 Q 400 - 4000 I/h 11 - 110 m3/h 240

S40 P 250 - 2500 I/h 7 - 70 m3/h 75

S40 Q 400 - 4000 I/h 11 - 110 m3/h 110

S40 R 600 - 6000 I/h 17 - 170 m3/h 130

S40 S 1000-10000 l/h 29-290 m3/h ?

S50 Q 400 - 4000 I/h 11 - 110 m3/h 100

S50 R 600 - 6000 I/h 17 - 170 m3/h 110

S50 S 1000 - 10000 I/h 29 - 290 m3/h 120

S50 T 1600 - 16000 I/h 46 - 460 m3/h 130

S50 U 2500 - 25000 I/h 70 - 700 m3/h 200

S80 T 1600 - 16000 I/h 46 - 460 m3/h 110

S80 U 2500 - 25000 l/h 70 - 700 m3/h 130

S80 V 4000 - 40000 I/h 110 - 1100 m3/h 200

S1H W 6000 - 60000 I/h 170 - 1700 m3/h

Measuring body PTFE or stainless steel

2)

Measuring body PP, PTFE or stainless steel

3)

with only atmospheric pressure a measurement is not possible. Indicated values are for orientation. For gas

measurements a factor of 2-3 of the inlet pressure should be considered

4)

Restrictions for instruments with PTFE lining

8 Output (electrical equipment, options)

(1.013 bar abs., 20°C) 3)

loss

(mbar)

8.1 Binary output

Using the segments of the slot-type initiators or the eccentric discs of the micro switches, any switching point between 10% and

90% of the flow rate can be set.

8.1.1 KEI 1 or KEI 2 limit switches

KEI 1 = 1 limit switch

KEI 2 = 2 limit switches

Model: SJ 3,5N, manufacturer Pepper l+ Fuchs (special switch possible, e.g. safety version)

Safety class: PTB Nr. 99 ATEX 2219 X

PTB Nr. 00 ATEX 2048 X

8.1.2 KEM 1 or KEM 2 limit transducers (special version)

SPDT micro switches whose switching point is activated by a cam plate.

KEM 1 = 1 SPDT micro switch

KEM 2 = 2 SPDT micro switches

Maximum switching capacity:

230 VAC 50/60Hz 6 A

24 VDC 0.5 A

110 VDC 0.2 A

8.2 Analog output with the electronic transmitter ES

The electronic transmitter ES is factory-calibrated to the delivered scale values. The signal output can only be supplied in a twowire connection with 4-20 mA. The 4-20 mA signal includes HART protocol - alternatively it can have PROFIBUS PA® or

FIELDBUS FOUNDATION® interface - see point 8.3

Additional options: 2 limit values, alternatively 1 limit value and 1 pulse output

The signal output and the limit values can be configured using a HART modem operating on the following configuration programs:

SensorPort from Bopp & Reuther, PDM from Siemens or AMS from Rosemount. Furthermore, a HART hand-held terminal (with

DD software) can also be used.

Page 6 of 38

Subject to change without notice

Page 7

Heinri

chs Messtechnik

BGF Installation and Operating Instructions

For more information about configuration, please refer to the separate operating Instructions for ES-PPA and ES-FF.

Safety class: DMT 00 ATEX 075 / II2G Ex ia IIC T6

When installing electrical equipment in hazardous areas, the conditions and provisions specified in the

approval documents must be followed. See also Fehler! Verweisquelle konnte nicht gefunden werden.

8.3 Model ES-PPA and ES-FF

The ES-PPA and ES-FF transmitters are FISCO field devices which are connected via a two-wire field bus circuit according to the

FISCO model.

The devices can also be connected to intrinsically safe field bus circuits which not correspond to the FISCO model. In this case the

electrical maximum values (Ui, Ii, Pi, Li and Ci) must be observed.

Details for the use and operation can be found in separate instruction manual ES-PPA and ES-FF

9 Characteristic values

9.1 Measuring Accuracy

9.1.1 Reference conditions

Water 20°C

9.1.2 Measured error

BGF-S/P ± 2.0 % of actual value acc VDI/VDE 3513-2 (qG=50%) for local display

Additional inaccuracy for: ES transmitter = ± 0.2%

9.1.3 Repeatability

±0.8 % of full scale

9.2 Influence of ambient temperature

1. Without electrical equipment and with limit switches without influence

2. With ES transmitter:: ± 0.5 % / 10 K reference temperature 22°C

9.3 Influence of fluid temperature

Deviations in fluid temperature from the temperature observed during calibration can result in a proportional display fault because of

the corresponding change in density. Changes in viscosity cause a non-linear display fault..

10 Conditions of use

The VDI/VDE guidelines 3513, Sheet 3, must be observed. The meter is suitable for:

1) Liquids with sufficient flow ability which are free of solids, do not bond and do not tend to settle.

2) Gases with linear flow behavior and an adequate inlet pressure.

Viscosity specifications ≥ 1 mPas cannot be considered for calibration.

10.1 Installation conditions

Vertical or horizontal installation, according to the direction of flow specified in the order.

The limit values for temperature and air humidity at the mounting location must be maintained. Avoid corrosive atmospheres. If this

cannot be avoided, ventilation must be installed.

and testing whether the pointer position changes.

Select the mounting location so as to enable a reliable reading of the scale values. Please take note as well of the space

requirement for any possible disassembly of the device.

As a rule, inlet and outlet sections in front of and behind the device are unnecessary if the medium has a linear flow profile. Avoid

mounting accessories converging on one side in front of the device. However, if this is indispensable maintain a minimum device

length of 250 mm as an inlet section.

The nominal size of the pipes to be connected must correspond to that of the meter. Avoid fittings converging on one side directly in

front of the device. As a rule, install valves behind the measuring equipment if there are gases involved.

For horizontal installation, make sure the indicator unit is not pointing upwards. This is to prevent water lodging on

the glass window and entering the device under the protective shroud of the housing.

Please make sure that there is adequate clearance from parts that might cause magnetic interferences such as

solenoid valves and ferromagnetic components like steel brackets/supports. We recommend that the minimum

lateral distance between two adjacently mounted devices be 300 mm. The devices can be mounted close together if

vertically offset by one device length. The minimum lateral clearance for interfering steel parts should be 200 mm. In

case of doubt, check the interference by moving the device back and forth in the selected distance by about 200 mm

Page 7 of 38

Subject to change without notice

Page 8

Heinri

chs Messtechnik

BGF Installation and Operating Instructions

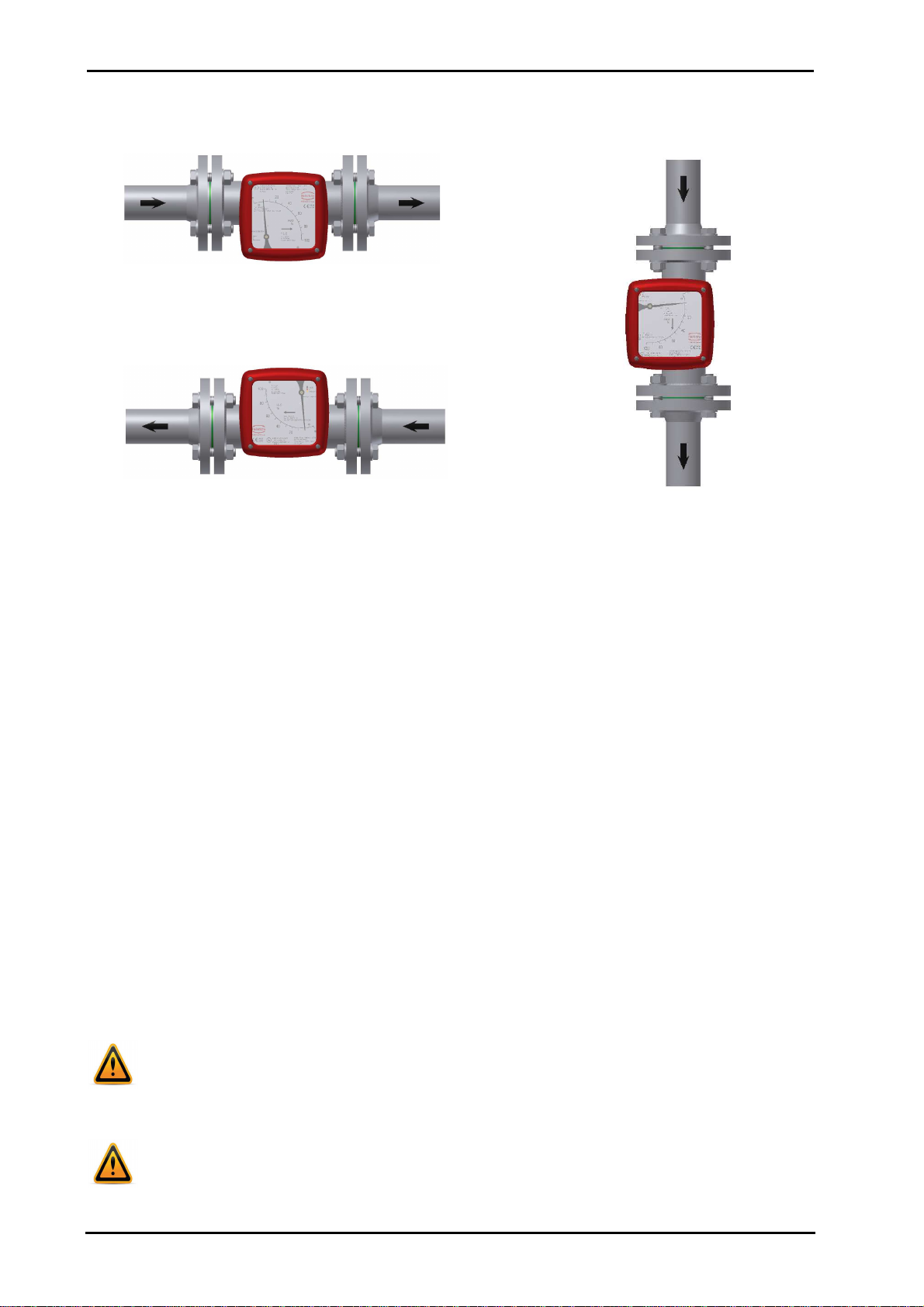

Flow from left to right

Flow from right to left

Flow from top to bottom

10.1.1 Mounting/start-up

Before installation check whether the measuring body is free from containment. The instrument must be mounted vertically or

horizontally according the ordered confirmed flow direction.

The nominal size of the device and the process pipes must be identical. The pressure ratings and, hence, the dimensions of the

flanges must correspond. The surface roughness of the flange sealing surface must be suitable for the prescribed gaskets.

Please check whether possible accessories like spring stops, gas/viscous-type damping sets are still correctly sitting on the flange.

Check whether the mounting clearance between the flanges of the pipes corresponds to the assembly dimension of the device plus

two gaskets. To achieve stress-free mounting, the flanges of the pipes must be aligned parallel to each other.

Use connecting bolts and gaskets in the prescribed dimensions. The gaskets must be suitable for the operating pressure, the

temperature and the measured medium. With PTFE-coated devices, use gaskets whose interior and exterior diameter correspond

to the sealing strip of the device.

Tighten the screws crosswise so that the process connections are tight. See to the tightening torques of screws especially with

PTFE-coated devices.

The maximum torques for PTFE-coated devices are:

DN15/DN25 = 14 Nm/DN50 = 25 Nm/DN80 = 35 Nm/DN100 = 42 Nm (following VDI/VDE Guideline 3513).

Please check whether the pipe is adequately stable mounted so that vibration or swinging of the device can be excluded.

Do not use any mounting parts made of steel directly on the device.

When gas is used as the medium, pay special attention to the position of any adjusting valves (e.g. special option). If the device is

calibrated to more than 1.013 bars absolute pressure, the valve is usually installed behind the flow meter. At 1.013 bars absolute

pressure (free exhaust) install it in front of the device.

If there is risk of dirt or solid matter penetrating the process pipes, flush them beforehand so that these materials do not stick in the

device. Ferromagnetic solid matter such as spatter can lead to the breakdown of the device. If these materials cannot be excluded

during normal operating conditions, mount a magnetic filter (accessory) in front of the device.

10.1.1.1 Liquid Measurement / start up

10.1.1.2 Gas measurement / start up

When using liquids, flush to avoid a surge of gas bubbles. Basically avoid activation of solenoid valves to prevent the

measuring body from rocketing upwards. In general water hammers must be avoided to prevent measuring body from

damages.

When using gases, slowly increase the operating pressure. At the same time, vary the operating pressure through a

setting valve so that the measuring body will not be exposed by any flow hammer - otherwise this would damage the

measuring element.

Page 8 of 38

Subject to change without notice

Page 9

Heinri

chs Messtechnik

BGF Installation and Operating Instructions

10.1.2 Device settings

The measuring equipment is delivered ready for operation according to your order specifications. The limit transducers are set to

the desired values. If you have submitted no requirements, the basic setting for

1 switch: Minimum contact switching point at 10% of descending flow (damped/closed-circuit principle).

2 switches: Minimum contact switching point at 10% of descending flow and maximum contact switching point at

90% of ascending flow.

10.1.3 Adjusting the switch point for the inductive limit switch KEI

The inductive contact can be adjusted via a limit switch indicator (2) located at the front side of the scale

1) unscrew 4 screws of the front cover and lift off the cover

2)

!! do not remove the scale (4) !!

3) unfasten 2 locking screws (3) of the red limit switch indicator (2)

4) move the red switch indicator to the desired switch point on the scale

and tighten the locking screws (3) again

5) mount the cover and tighten it´s four screws again

1 Pointer

2 Limit switch indicator (fig. MIN)

3 Limit switch indicator locking srews

4 Locking screw switching disc

5 Switching disc KEI

10.1.4 Adjusting the switch point of the SPDT Micro Switch KEM

KEM1 and KEM2 limit switches do not have limit switch indicators.

Switch point(s) are normally factory set.

To adjust the switch points use the following procedure:

1) Ensure that the supply lines are powerless and will not be switched

active during operation.

2) unscrew 4 screws of the front cover and remove the cover

3)

!! do not remove the scale (4) !!

4) Move the pointer (3) carefully in direction of the desired switch point

5) Unfasten the screws (1) of the disc (2) carefully and move the disc

^ towards the lever of the micro switch

6) Depending on the switching function ( N/O or N/C ) the switch must be

activated (for N/C ) or non activated (for N/O )

NOTE

Due to hysteresis of KEM switches they must not be used for ranges below 250 l/h water

1 Locking screws switching disc

2 Switching disc

3 Pointer

4 Scale

5 Switching lever

Page 9 of 38

Subject to change without notice

Page 10

Heinri

chs Messtechnik

BGF Installation and Operating Instructions

°=°−°=−

=

10.1.5 Installation in hazardous areas

10.1.5.1 Without electrical equipment

The basic version of the flow meter is a non-electrical device without its own ignition sources and meets DIN EN 13463-1

requirements. It can be used in hazardous areas that require Category 2 equipment.

Marking:

Since the device does not have its own power sources that would result in a temperature increase, the fluid temperature is decisive

for the maximum surface temperature.

When used in potentially explosive dust atmospheres, the device must be cleaned regularly in order to avoid deposits exceeding

5 mm.

10.1.5.2 With built-in limit switches

When the limit switches are installed, the device becomes an electrical assembly and gets a marking in accordance with

DIN EN 60079 of built-in electrical limit transducers.

The electrical and thermal data and the special conditions of the EC Type Examination Certificate of the built-in limit transducers

must be observed (see also the diagram in Section 10.2.1.

The influence of the fluid temperature on the built-in limit transducers must be observed. The over-temperature of the maximum

fluid temperature based on the maximum ambient temperature must be considered with a factor according to the following table:

Nominal size Factor for standard

DN15 and DN25 / 1/2" and 1" 0.2 0.07

DN40 and DN50 / 1,5" and 2" 0.25 0.085

DN80 / 3" 0.3 0.1

Example for built-in limit switch at DN 15 / (1/2") and DN 25 / (1"):

Max. ambient temperature T

Max. fluid temperature Tm = 120°C

Factor for brought-in heat F = 0.2

Temperature class T4

Tü = Over-temperature

Ta = Ambient temperature of limit switch

In accordance with the tables in the PTB 99 ATEX 2219 X EC Type Examination Certificate, the SJ 3,5-... N... inductive sensor must

be operated in the T5 temperature class with an intrinsically safe circuit that does not exceed the maximum values of the Type 3

circuit.

When using the device in hazardous areas, follow the applicable national installation rules.

Example for calculating the max. fluid temperature based on the max. ambient temperature for the built-in sensor Type ES

for DN 15/25.

Ta = 70°C

T

= 60°C

amb

F = 0.2

TambTa

−

Tm °=°+

= 11060

Tamb

F

II 2GD c

Reg. No.: BVS 03 ATEX H/B 112

Tech. File Ref. 03-02 X

version

= 40°C

amb

CCCTambTmTü

8040120

=+

6070

2,0

CCCTambFTüTa

°=°+°=+=

56402,0*80*

CC

°−°

Factor for instruments with the

indicator on disctance

CC

10.1.5.2.1 Marking for the device with built in SJ 3,5...N... limit switch

PTB 99 ATEX 2219 X

II 2G EEx ia IIC T6

ZELM 03 ATEX 0128 X

II 1D Ex iaD 20 T108°C

10.1.5.2.2 Marking for the device with built in electric transmitter ES

DMT 00 ATEX 075

II2G Ex ia IIC T6

Page 10 of 38

Subject to change without notice

Page 11

Heinri

chs Messtechnik

BGF Installation and Operating Instructions

10.1.5.3 Atmospheric conditions

In accordance with EN 1127, a “potentially explosive atmosphere“ is defined as a mixture of air and combustible gases, vapour, mist

or dust under atmospheric conditions. Such conditions are defined in EN 13463-1, para. 1, with values Tatm = -20 °C to +60 °C and

Patm = 0.8 to 1.1 bar. Outside this range, safety parameters for most ignition sources are not available.

Usually, variable-area flow meters operate under operating conditions outside the atmospheric conditions of 0.8 to 1.1 bar.

Irrespective of the zone classification –safety parameters of explosion protection – are basically not applicable to the inside of the

measuring tube.

10.1.5.4 Earthing of the instrument

In variable-area flow meters, in principal it is possible that through the flow of non-conductive liquids a charge separation occur

inside the measuring tube. A dissipation of such charge carriers from the metal flow tube through permanent ground connection

must be ensured.

If grounding cannot be made via the process connections ( e.g. on plastic process connections or undefined connections), the flow

meter must be connected to the local grounding cable. potential via a separate ground cable .

Therefore operation with combustible products is only allowed if a potentially explosive air mixture is not formed inside

the flow meter. Where this condition are not met, the operator will need to assess the ignition hazard in each individual

case and give due consideration to existing parameters (e.g. pressure, temperature, process product, materials of

construction for the measuring tube).

10.2 Ambient conditions

10.2.1 Ambient temperature ranges

Without electrical accessories:

-40°C to +80°C

With limit switches:

-40 °C to +65°C

With ES signal output:

-40°C to +70°C

For the hazardous area version, take note of the maximum ambient temperatures depending on the temperature class as specified

on the Type Examination Certificate.

10.2.2 Storage temperature

The storage temperatures are identical to the ambient temperature ranges.

10.2.3 Climatic category

Weather-protected and/or unheated locations, class C according to IEC 654 Part 1

10.2.4 Degree of protection

IP 65 (Aluminum indicator unit)

IP 67 (Stainless steel indicator unit)

10.2.5 Shock resistance/vibration resistance

The meter should be protected from extreme shocks and vibrations, which could cause damage.

10.2.6 Electromagnetic compatibility

EN 61000-6-2:2011 Störfestigkeit Industriebereich / immunity industrial environment

EN 61000-6-3:2011 Störaussendung Wohnbereich / emission residential, commercial

EN 55011:2011 Gruppe 1, Klasse B , Funkstörungen / Group 1 Class B , ISM ratio-frequency equipment

EN61326-1:2013 EMV-Anforderungen / EMC requirements

NAMUR recommendation NE 21

Page 11 of 38

Subject to change without notice

Page 12

Heinri

chs Messtechnik

BGF Installation and Operating Instructions

Model

Fitting

Measuring body

Fluid-

10.3 Fluid conditions

10.3.1 Fluid temperature ranges

BGF-S st.st. st.st. -40°C up to 200°C

BGF-S st.st. PTFE -20°C up to 125°C

BGF-S st.st. PPH 0°C up to 80°C

BGF-P st.st./PTFE PTFE -20°C up to 125°C

The effect of the fluid temperature on the indicator unit and its built-in components must be considered. A pulled-forward indicator

unit is necessary if the fluid temperature rises above 200°C.

10.3.2 Diagrams: Max. ambient temperature based on the fluid temperature for the ES

Material

Material

Temperature

Page 12 of 38

Subject to change without notice

Page 13

Heinri

chs Messtechnik

BGF Installation and Operating Instructions

Fitting

DN

/ ASME

PN

/ CL Ø l.W.

A

10.3.3 Fluid pressure limit

Standard version: BGF-S DN 15/25/40/50/80 PN 40

Special version: BGF-S up to PN 400

BGF-P DN 15/25/50/80 PN 16

10.3.4 Inlet and outlet sections

Inlet and outlet sections are not required for a linear flow profile of the fluid. For an extremely non-linear flow profile (e.g. shutoff/control valves are located in front of the meter), we recommend an inlet section with a mounting length of 250 mm (see also

guidelines in accordance with VDI/VDE 3513).

10.3.5 Physical state

Liquid or gaseous

10.3.6 Density

Liquids: up to 2.0 kg/l

Gases: no restrictions

10.3.7 Viscosity

Cannot be considered for the calibration.

10.3.8 Pressure (for gas measurement)

The measured values only apply to the calibrated fluid data stated on the scale. Any change or deviation in pressure causes a

display fault in gases. Viscosity factors cannot be considered by the system.

10.3.9 Pressure Drop

Pressure loss: Depends on the device size and the measuring range (see Measuring range chart).

11 Construction details

11.1 Type of construction / dimensions

11.1.1 Aluminum indicator housing

11.1.1.1 Version with flange connection

Dimensions:

S15 15 / 1/2" 40 / (150/300) 26 77,0

S25 25 / 1" 40 / (150/300) 32 80,1

S40 40 / 11/2" 40 / (150/300) 46 87,9

S50 50 / 2" 40 / (150/300) 70 100,9

S80 80 / 3" 40 / (150/300) 102 117,4

*

=+100 mm for indicator on distance

(mm)

(mm)

Page 13 of 38

Subject to change without notice

Page 14

Heinri

chs Messtechnik

BGF Installation and Operating Instructions

Fitting

NPT(f) / G(f)

PN / CL SW A

DN /

PN / CL B

B

S

X

1)

11.1.1.2 Version with threaded connection

Dimensions:

S15 1/4-3/8-1/2-3/4 40 / 300 36 77,0

S25 1/4-3/8-1/2-3/4 40 / 300 36 80,1

S40 3/4-1-1 1/4 40 / 300 60 87,9

S50 1 1/4-1 1/2-2 40 / 300 80 100,9

*

=+100 mm for indicator on distance

(in)

11.1.2 Dimensional drawing with heating connection

Connections for the heating jacket

Pipe for Ermeto 12 mm

Thread ½“ NPT(f)

Flanges acc.. DIN/EN DN15 or DN251) PN40

Flanges acc. ASME ½“ 150lbs

Flanges DN25 - special version.

ASME

15 / 1/2" 40 / (150/300) 110 53 150 3,0

25 / 1" 40 / (150/300) 110 58,5 150 4,9

40 / 11/2" 40 / (150/300) 130 63 150 2,65

50 / 2" 16 / (150/300) 140 77,5 150 3,5

80 / 3" 16 / (150/300) 160 93,5 150 4,5

*

=+100 mm for indicator on distance

(mm)

(Flange)

(mm)

(Ermeto

)

(mm)

(mm)

(mm)

Page 14 of 38

Subject to change without notice

Page 15

Heinri

chs Messtechnik

BGF Installation and Operating Instructions

Fitting

DN

/ ASME

PN

/ CL Ø l.W.

A

Fitting

NPT(f) / G(f)

PN / CL SW A

11.1.3 Indicator housing made of stainless steel

11.1.3.1 Version with flange connection

Dimensions

11.1.3.2 Version with threaded connection

Dimensions:

S15 15 / 1/2" 40 / (150/300) 26 99,5

S25 25 / 1" 40 / (150/300) 32 102,6

S40 40 / 11/2" 40 / (150/300) 46 110,4

S50 50 / 2" 40 / (150/300) 70 123,4

S80 80 / 3" 40 / (150/300) 102 139,7

*

=+100 mm for indicator on distance

S15 1/4-3/8-1/2-3/4 40 / 300 36 99,5

S25 1/4-3/8-1/2-3/4 40 / 300 36 102,6

S40 3/4-1-1 1/4 40 / 300 60 110,4

S50 1 1/4-1 1/2-2 40 / 300 80 123,4

*

=+100 mm for indicator on distance

(in)

(mm)

(mm)

(mm)

Page 15 of 38

Subject to change without notice

Page 16

Heinri

chs Messtechnik

BGF Installation and Operating Instructions

Fitting

Fitting Size

Weight (kg)

Weight (kg)

Fitting

Fitting Size

Weight (kg)

Weight (kg)

Fitting

Fitting Size

Weight (kg)

Weight (kg)

Fitting

Thread

Weight (kg)

Weight (kg)

Model

Spring

Meas

uring

Meas.pipe

-

Flange

Flange lining

Measuring body

Model

Base plate

Cover

11.2 Weights

DIN EN

S15 DN 15 4,0 4,7

S25 DN 25 5,0 5,7

S40 DN 40 6,9 7,6

S50 DN 50 9,3 10,0

S80 DN 80 12,8 13,5

ASME CL 150

S15 ¾“, 150 lbs, ASME B16.5 3,0 3,7

S25 1“, 150 lbs, ASME B16.5 4,2 4,9

S40 1 ½“, 150 lbs, ASME B16.5 6,0 6,7

S50 2“, 150 lbs, ASME B16.5 7,5 8,2

S80 3“, 150 lbs, ASME B16.5 13,0 13,7

c/w

Alum.Indicator

c/w

Alum.Indicator

St.st. indicator

st.st. indicator

ASME CL 300

S15 ¾“, 300 lbs, ASME B16.5 3,4 4,2

S25 1“, 300 lbs, ASME B16.5 4,7 5,4

S40 1 ½“, 300 lbs, ASME B16.5 6,8 7,5

S50 2“, 300 lbs, ASME B16.5 8,5 9,2

S80 3“, 300 lbs, ASME B16.5 14,5 15,2

c/w

Alum.Indicator

st.st. indicator

c/w

c/w

c/w

NPT(f) / G(f)

(in)

S15 1/4-3/8-1/2-3/4 3,0 3,7

S25 1/4-3/8-1/2-3/4 3,2 3,9

S40 3/4-1-1 1/4 4,2 4,9

S50 1 1/4-1 1/2-2 6,1 6,8

Note:

All weights for st.st. fitting with PTFE measuring body.

c/w

Alum.Indicator

c/w

st.st. indicator

11.3 Materials

Fitting

BGF – S DN15-DN40 st.st. st.st. non st.st. non PTFE / st.st.

pipe

BGF – S DN50-80 st.st. st.st. non st.st. non PP / PTFE / st.st.

BGF – P DN15-DN40 Hastelloy st.st. PTFE st.st. PTFE PTFE / st.st.

Indicator

BGF – S/P aluminum aluminum, window safety glass

Optional st.st. st.st., window safety glass

Special flanges can be supplied on request.

lining

Page 16 of 38

Subject to change without notice

Page 17

Heinri

chs Messtechnik

BGF Installation and Operating Instructions

Fitting

BGF-S BGF-P

Fitting

BGF-S BGF-P

DN

Ø

11.4 Process connection

DN 15 PN 40 PN 16

DN 25 PN 40 PN 16

DN 40 PN 40 PN 16

DN 50 PN 40 PN 16

DN 80 PN 40 PN 16

ASME ¾“ B16.5 150 lbs 300 lbs 1) 150 lbs 2) 300 lbs 2)

ASME 1“ B16.5 150 lbs 300 lbs 1) 150 lbs 2) 300 lbs 2)

ASME 1 ½“ B16.5 150 lbs 300 lbs 1) 150 lbs 2) 300 lbs 2)

ASME 2“ B16.5 150 lbs 300 lbs 1) 150 lbs 2) 300 lbs 2)

ASME 3“ B16.5 150 lbs 300 lbs 1) 150 lbs 2) 300 lbs 2)

1)

Entire unit PN40

2)

Entire unit PN16

Optional available:

Special flanges (e.g. JIS), Food connections (e.g. TriClamp), Weld ends etc.

Special versions also for higher pressure ratings available.

11.5 Magnetic filter

When dealing with flow media with magnetic particles, the installation of a magnetic filter can relief.

The mounting must be carried out at the inlet of the flow meter.

To protect both magnetic filter types, MF-S (stainless steel) and MF-P/S (PTFE/stainless steel), from corrosion, encapsulated

permanent magnets are laid out in spiral form. The spiral mounting produces optimum effect at small pressure loss.

The filter can be supplied with groove and/ or ring joint*), projection or return*), other standards or special connections according to

customer wishes.

*

only st.st. version

Dimensions:

15 45

25 68

40 88

50 102

65 122

80 138

g (mm)

Page 17 of 38

Subject to change without notice

Page 18

Heinri

chs Messtechnik

BGF Installation and Operating Instructions

11.6 Electrical connection

Wiring

To connect the power supply, remove the indicator cover, insert the connector cable into the cable gland and attach it to the

terminals according to the terminal diagram. Tighten the cable gland securely, remount the indicator cover and close it tightly.

• Cable glands are not part of the delivery

• Customer used cable glands must fit to the specified cable gland thread

• The cable gland must fit to the diameter of the cable

• The cable must form a pig tale in front of the gland to avoid

water ingress - see sketch on the right

• Cable gland must not point upward

• The delivered cable gland connection sealing screw - delivered with

instruments with no electrical output signals - must not be removed

• The sealing of the cable glands must correspond with the instructions

of the original cable gland manufacturer. Wrongly or incorrect tightened

cable glands will cause water ingress into the indicator housing

11.6.1 Wiring diagram for ES transmitter (signal output 4-20 mA with HART)

Please observe the following wiring instruction carefully.( Improper wiring will cause loss of guarantee)

Page 18 of 38

Subject to change without notice

Page 19

Heinri

chs Messtechnik

BGF Installation and Operating Instructions

11.6.2 Wiring diagram for ES transmitter with 4-20 mA output and 2 limit switches

11.6.3 Wiring diagram for ES transmitter with 4- 20 mA output, pulse output and limit switch

Page 19 of 38

Subject to change without notice

Page 20

Heinri

chs Messtechnik

BGF Installation and Operating Instructions

11.6.4 Wiring diagram for inductive limit switches KEI

11.6.5 Wiring diagram for KEM 1 and KEM 2 micro switches

11.6.6 Devices with unconnected cable end

For simple electrical connection, especially at the units with stainless steel display housing, the device can be supplied with a cable

end (silicon cable). The standard cable length is 2.5 m. The cable has 7 wires, yellow / green for earth and 6 black wires with white

numbers 1-6. The function of the wires (1-6) corresponds to the terminal numbers.

If the connection is made in a hazardous area, the cable must be connected in a housing that meets the requirements according to

IEC EN 60079-14.

12 Indicator unit

- Analog indicator approx. 90° with pointer

- Customized product scale

double scale possible ( please tell process data )

- ES transmitter with freely programmable user interface

- Parameters may be changed based on the ES Operating Instructions.

13 Power supply

see Electrical connection

Page 20 of 38

Subject to change without notice

Page 21

Heinri

chs Messtechnik

BGF Installation and Operating Instructions

Diagnosis

Possible reason

Corrective action

Indicator window

Indicator cover

not tight

Indicator window icy

Instrument shows wrong

-

No reaction on pointer

14 CE marking

The measuring system meets the statutory requirements of the following EU directives: Directive 94/9/EC (Equipment and

Protective Systems for Use in Potentially Explosive Atmospheres), the Electromagnetic Compatibility (EMC) Directive 89/336/EEC

and the Pressure Equipment Directive 97/23/EC.

Heinrichs Messtechnik confirms compliance with the directives by attaching the CE mark.

15 Order information

Please include the following information in your order: Product data, specific weight, temperature, pressure, viscosity, material

design, connection size, measuring range, desired accessories, required approvals and material certificates. See Device selection

by model code.

16 Standards and directives, certificates and approvals

See EU Declaration of Conformity Point 25

17 Maintenance

The device requires no maintenance if used according to its intended purpose. However, if cleaning is necessary to remove dirt

from the measuring ring or the float, take note of the following aspects:

- Please take note that, with devices with built-in electrical equipment, removing the indicator cover restricts the EMC protection.

- Before removing a device, make sure that the pipeline is free from the product, is pressureless and has cooled down.

- Fittings with the insides coated may be carefully cleaned after removal with a brush and the appropriate cleansing agent.

Carefully clean the float from possible coating.

-

- The switch points of the limit switches are adjustable. To do this, remove the indicator cover, unfasten the contact point

indicator located on the scale and readjust it. After the adjustment, reattach the bolts of the contact point indicator. Reinstall

and tighten the indicator cover.

- The parameterization of the ES is possible and is done via HART. Please refer to the separate Operating Instructions for the

ES.

- The gas and viscous damping cylinders can be checked for dirt (see Installing/removing the damping sets).

- Attention: do not treat the measuring ring/cone and measuring body with hard objects

(see Removing/installing the measuring body / spring).

18 Installing and removing the resetting spring and the measuring

body

The interior structure of the devices differ according to nominal size.

DN 15 (1/2") and DN 25 (1"): To remove the resetting spring, secure the measuring body from turning by using a suitable tool from

above. Unscrew the lock nuts from below and remove the spring. The measuring body can be pulled out upwards after removing

the bottom guide.

DN 40/DN 50 (1,5"/2") and DN 80 (3"): To remove the return spring, press the cross-bar downwards from both lateral locking

brackets. Since the locking brackets are compressed together beneath the bar, some force must be applied. After the bar is

removed, the spring can now be taken out from above. To disassemble the measuring body, secure it from turning by using a

suitable tool, remove the nuts and guide brackets from below and then pull the measuring body upwards.

Proceed in reverse order when reinstalling these parts.

19 Trouble shooting

steamed

measuring values

despite flow

Indicator cover damaged

Indicator sealing damaged

Cable gland not tightened

high temperature differences

aggressive ambient atmosphere

indicator sealing damaged - change indicator cover

ambient temperature too low - install N23 rinsing connection

calibration does not meet process

conditions

pointer de-adjusted

pointer is behind the stopper ( RP)

magnet body is sticked

(pollution)

- change indicator cover

- tighten cable gland

- indicator with pressure relief

- install rinsing connection for N2 gas

- fasten indicator cover screws

- change to high tem. distance housing

- review operating conditions, on deviations new

calibrations from manufacturer is recommended

- re-adjust pointer (RP on meas. scale)

- remove cover, re-adjust pointer

- remove instrument from process and clean magnet

body and all inner parts carefully

- if sticking parts in the process use of magnet filter

recommended

Page 21 of 38

Subject to change without notice

Page 22

Heinri

chs Messtechnik

BGF Installation and Operating Instructions

Magnet body is sticked

Pointer indication is

Electrical equipment e.g.

Un-known

Group

Description

Info

Indicator

Flow tube

Mounting

pulsating

transducer, limit swithes

without function

pollution / residues in the process

Measuring pipe damaged

Resetting spring broken

Inlet pressure too low - increase inlet pressure, instrument for recalibration

wrong wiring / power supply

defective el. parts

- remove instrument from the process and clean

carefully

- resend the instrument to the manufacturer for

evaluation / repair

back to manufacturer (gases) or

- use of instrument with low pressure loss

- re-equip with double turbulent flow damping

- locate valves, gate valves etc. after the instrument

- check wiring diagram acc. instruction manual

- change el. parts ( e.g. limit switches ) or sent the

instrument back to manufacturer

Sent the instrument back to the manufacturer and

include a detailed failure description

20 Returning devices for repair and service

Note: In accordance with the applicable German waste disposal legislation, the owner/client is responsible for the disposal of

special waste and hazardous materials. Consequently, all devices sent to us for repair must be free of any hazardous materials.

This also applies to possible hollow spaces and fissures in the devices. If repair is necessary, confirm the above-mentioned item in

writing (please use the form in the Appendix).

If hazardous materials remain in or on the device after it has been returned, Heinrichs Messtechnik shall be authorized to remove

them at the client’s expense without further inquiry.

21 Spare parts

The following parts can be ordered as replacement parts:

Indicator cover aluminum c/w window/gasket/screws

Scale, blank

Scale incl. customer operating values

Indicator unit(B)-aluminum, c/w. blank-scale

Indicator unit(B)-aluminum, c/w. limit switches KEI1 (SJ3,5-N)

Indicator unit(B)-aluminum, c/w. limit switches KEI2 (SJ3,5-N)

Switching disc for KEI

Electrical. transducer ES, 4-20mA, Hart®

Indicator unit(B)-aluminum, c/w. el. transmitter ES

Bearing unit c/w (B)-standard c/w .axle, bearings and magnets

Bearing unit (B) for indicator on distance

Pointer unit complete. (standard)

Pointer unit complete for el. transducer ES

Base plate(B)-aluminum, c/w cover screw for cable entry(standard)

Base plate(B)-aluminum, c/w cover screw for cable entry(standard)

for indicator on distance

Cable gland M20x1,5, grey, Polyamide

Cable gland M20x1,5, blue, Polyamide

Float st.st. c/w guiding star on request

Float st.st. c/w guiding star, and liquid or gas damping system on request

Retrofit set for KEI1 (SJ3,5-N)

sets

Retrofit set for KEI2 (SJ3,5-N)

NOTE:

When ordering spare parts please always mention the serial number of the instrument.

If the float is being removed we recommend a new calibration of the instrument always. Without new calibration additional

measuring errors must be considered.

For further instruction on spare parts please contact the Heinrichs Messtechnik GmbH service department

Page 22 of 38

Subject to change without notice

Page 23

Heinri

chs Messtechnik

BGF Installation and Operating Instructions

22 Exploded views

22.1 Fitting with measuring body

Name Part no.

Fitting 1

Measuring body 2

Resetting spring 3

22.1.1 BGF-.... standard version DN 15-25

22.1.2 BGF-.... standard version DN 50-80

Page 23 of 38

Subject to change without notice

Page 24

Heinri

chs Messtechnik

BGF Installation and Operating Instructions

Name

Part no.

22.2 Indicator unit

Indicator base plate 1 x M 20 x 1.5 10

Inner earthing connection 15

Bearing assembly 20

Fixing screws for bearing unit 30

Dummy plug M 20 x 1.5 c/w o.ring 40

Cable gland blue (intrinsically safe ) c/w o-ring M20 x 1,5 41

Cable gland grey (ATEX) c/w o-ring M20 x 1,5 42

Scale, blank 50

Fixing screw for the scale 60

Zero-point screw with nut 70

Indicator cover with glass window, gasket, screws 80

Scale pointer 90

Scale pointer c/w 1 switching disc KEI 91

Scale pointer c/w 2 switching discs KEI 92

Scale pointer c/w 1 switching disc KEM 93

Scale pointer c/w 2 switching discs KEM 94

Scale pointer c/w ES position magnet 95

1. SJ 3,5 N limit switch c/w limit value indicator incl. c/w mounting parts 110

1 SPDT micro switch KEM 1 c/w mounting parts 114

2. SJ 3,5 N limit transducer with limit value indicator 120

2 SPDT micro switches KEM 2 c/w mounting parts 124

Distortion lock c/w screw 130

Installation assembly for 1 micro switch KEM 1 131

Installation assembly for 2 micro switches KEM 2 132

ES HART® transmitter c/w fixing screws

140

22.2.1 Complete indicator unit, local with

scale

22.2.2 Complete indicator unit with 1

limit switch SJ 3,5 N

Page 24 of 38

Subject to change without notice

Page 25

Heinri

chs Messtechnik

BGF Installation and Operating Instructions

22.2.3 Complete indicator unit with 2

limit switches SJ 3,5 N

22.2.4 Complete indicator unit with

1 pc SPDT micro switch

22.2.5 Complete Indicator unit with

2 pcs SPDT micro switches KEM

22.2.6 Complete Indicator unit with

transmitter ES Ex HART

Page 25 of 38

Subject to change without notice

Page 26

Heinri

chs Messtechnik

BGF Installation and Operating Instructions

Material

S Stainless Steel, process temperature

≤ 350°C

P Stainless Steel, Wetted Parts PTFE, process temperature

≤ 125°C, process pressure max. 16 bar (not for size "H5" available)

Nominal Fittin

g-Size Measuring Range

-

Code

15 1/2" Measuring ranges see table

H-L

25 1" Measuring ranges see table

M-Q

40 11/2" Measuring ranges see table

P-S

50 2" Measuring ranges see table

Q-U

80 3" Measuring ranges see table

T-W

Flang

e connections

305B DN15 PN40 Form B1 DIN EN 1092

-1

203R 1" Class 150 RF ASME B16.5

-

2003

3A5B DN20 PN40 Form B1 DIN EN 1092

-1

223R 1" Class 300 RF ASME B16.5

-

2003

309B DN25 PN40 Form B1 DIN EN 1092

-1

204R 1¼" Class 150 RF ASME B16.5

-

2003

309D DN25 P

N40 Form D DIN EN 1092

-1

224R 1¼" Class 300 RF ASME B16.5

-

2003

313B DN32 PN40 Form B1 DIN EN 1092

-1

406R 15A 10K RF JIS B2220

313D DN32 PN40 Form D DIN EN 1092

-1

407R 15A 16K RF JIS B2220

201R ½" Class 150 RF ASME B16.5

-

2003 (verringerte Dichtleiste)

406F 15A 10K FF JIS B2220

221R ½" Class 300 RF ASME B16.5

-

2003 (verringerte Dichtleiste)

407F 15A 16K FF JIS B2220

202R ¾" Class 150 RF ASME B16.5

-

2003

222R ¾" Class 300 RF ASME B16.5

-

2003

Thread connections (installation length: 300

mm, float not removable)

4000 G1/4" female thread

6030 1/2" NPT(f)

4010 G3/8" female thread

6040 3/4" NPT(f)

4020 G1/2" female thread

6832 DN25 TriClamp ISO 2852

4030 G3/4" female thread

6830 DN25 TriClamp DIN 32676

6010 1/4" NPT(f)

6630 RD52

x1/6" DIN11851

6020 3/8" NPT(f)

Flange connections

305B DN15 PN40 Form B1 DIN EN 1092

-

1 (verringerte Dichtleiste)

204R 1¼" Class 150 RF ASME B16.5

-

2003

3A5B DN20 PN40 Form B1 DIN EN 1092

-

1 (verringerte Dichtleiste)

224R 1¼" Class 300 RF

ASME B16.5

-

2003

309B DN25 PN40 Form B1 DIN EN 1092

-1

205R 1½" Class 150 RF ASME B16.5

-

2003

309D DN25 PN40 Form D DIN EN 1092

-1

225R 1½" Class 300 RF ASME B16.5

-

2003

313B DN32 PN40 Form B1 DIN EN 1092

-1

416R 25A 10K RF JIS B2220

313D DN32 PN40 Form

D DIN EN 1092

-1

417R 25A 16K RF JIS B2220

202R ¾" Class 150 RF ASME B16.5

-

2003 (verringerte Dichtleiste)

416F 25A 10K FF JIS B2220

222R ¾" Class 300 RF ASME B16.5

-

2003 (verringerte Dichtleiste)

417F 25A 16K FF JIS B2220

203R 1" Class 150 RF ASME B16

.5-2003

223R 1" Class 300 RF ASME B16.5

-

2003

Thread connections (installation length: 300mm, float not removable)

4000 G1/4" female thread

6030 1/2" NPT(f)

4010 G3/8" female thread

6040 3/4" NPT(f)

4020 G1/2" female thread

6842 DN25 TriClamp ISO 2852

4030 G3/4" female thread

6840 DN25 TriClamp DIN 32676

6010 1/4" NPT(f)

6640 RD52x1/6" DIN11851

6020 3/8" NPT(f)

Flange connections

317B DN40 PN 40 Form B1 DIN EN 1092

-1

426R 40A 10K RF JIS B2220

317D DN40 PN 40 Form D DIN EN 1092

-1

427R 40A 16K RF JIS B2220

205R 1½" 150 lbs RF ASME B16.5

-

2003 426F 40A 10K FF JIS B2220

225R 1½" 300 lbs RF ASME B16.5

-

2003 427F 40A 16K FF JIS B2220

Thread connections (installation length: 300mm, float not removable)

4030 G3/4" female thread

6060 1-1/4" NPT(f)

4040 G1" female thread

6862 DN50 TriClamp ISO 2852

4050 G1-1/4" female thread

6860 DN50 TriClamp DIN 32676

6040 3/4" NPT(f)

6660 RD78x1/6" DIN 11851

6050 1" NPT(f)

Flange connections

321B

DN50 PN40 Form B1 DIN EN 1092

-1

207R 2½" Class 150 RF ASME B16.5

-

2003

321D DN50 PN40 Form D DIN EN 1092

-1

227R 2½" Class 300 RF ASME B16.5

-

2003

325B DN65 PN16 Form B1 DIN EN 1092

-1

431R 50A 10K RF JIS B2220

325D DN65 PN16 Form D DIN EN 1092

-1

432R 50A 16K RF JIS B2220

326B DN65 PN40 Form B1 DIN EN 1092

-1

431F 50A 10K FF JIS B2220

326D DN65 PN40 Form D DIN EN 1092

-1

432F 50A 16K FF JIS B2220

22.3 Model Code

BGF

-

(15)

(25)

(40)

(50)

Page 26 of 38

Subject to change without notice

Page 27

Heinri

chs Messtechnik

BGF Installation and Operating Instructions

206R 2" Class 150 RF ASME B16.5

-

2003

226R 2" Class 300 RF ASME B16.5

-

2003

Thread conne

ctions (installation length: 300mm, float not removable)

4050 G1-1/4" female thread

6060 1-1/4" NPT(f)

4060 G1-1/2" female thread

6070 1-1/2" NPT(f)

4070 G2" female thread

6080 2" NPT(f)

Flange connections

330B DN80 PN16 Form B1

DIN EN 1092

-1

209R 3½" Class 150 RF ASME B16.5

-

2003

330D DN80 PN16 Form D DIN EN 1092

-1

229R 3½" Class 300 RF ASME B16.5

-

2003

331B DN80 PN40 Form B1 DIN EN 1092

-1

441R 50A 16K FF JIS B2220

331D DN80 PN40 Form D DIN EN 1092

-1

442R 50A 16K FF JIS B2220

208R 3" Class 150 RF ASME B16.5

-

2003 441F 50A 16K FF JIS B2220

228R 3" Class 300 RF ASME B16.5

-

2003 442F 50A 16K FF JIS B2220

Measuring ranges (Water 20°C, 1 mPas)

H 10 -

100 l/h

I 16 -

160 l/h

J 25 -

250 l/h

K 40 -

400 l/h

L 60 -

600 l/h

M 100 -

1000 l/h

N 160 -

1600 l/h

P 250 -

2500 l/h

Q 400 -

4000 l/h

R 600 -

6000 l/h

S 1000 -

10000 l/h

T 1600 -

16000l /h

U 2500 -

25000l /h

V 4000 -

40000 l/h

W 6000 -

60000 l/h

Magnet bearer

K Standard PP bis 80 °C

P 81 -

125 °C PTFE

S stainless steel

Flow direction

O Top to bottom

L Left to right

R Right t

o left

U Bottom to top

Heating / cooling

0 without heating / Cooling

1 Heating / cooling, connection EO12 mm

(stainless steel)

2 Heating / cooling, connection DN15, PN 40

(stainless steel)

3 Heating / cool

ing, connection ½" Class 150 ANSI

(stainless steel)

4 Heating / cooling, connection ½" NPT (F)

(stainless steel)

- Certificates

0 without

1 Certificate of compliance with the order 2.1

2 Test report 2.2

B I

nspection certificate 3.1 with material certificate (DIN EN 10204:2004)

C Inspection certificate 3.2 with material certificate (DIN EN 10204:2004)

N Material certificate NACE

- Display

Standard display housing,

V Standard display housing forward advanced, process temperature

≤ 350°C

E Stainless steel display housing IP67, working temperature

≤ 150°C

H Stain

less steel display housing IP67 forward advanced, process temperature

≤ 350°C

Standard display housing with pressure compensation,

W Standar

d display housing with pressure compensation forward advanced, process temperature

≤ 350°C

Scale

1 %-Scale (Water)

2 Measuring range

-

Scale (Water)

F Double

-

scale (acc. customer preference)

4 %-Scale (Media)

5 Measuring range

-

Scale (Media)

Switches / electrical output

0 ohne

(80)

S

Process temperature ≤ 150°C for electrical output,

Process temperature ≤ 200°C for local indication

T

Process temperature ≤ 150°C for electrical output,

Process temperature ≤ 200°C for local indication

Page 27 of 38

Subject to change without notice

Page 28

Heinri

chs Messtechnik

BGF Installation and Operating Instructions

1 1 x inductive switch, Type SJ 3,5 N

2 2 x inductive switch, Type SJ 3,5 N

3 1 x inductive switch, Type SJ 3,5 SN (safety design)

4 2 x inductive switch, Type SJ 3,5 SN (safety design)

6 Transmitter ES with HART

-

protocol, 4

-

20 mA, EEx ia

7 Transmitter ES with HART

-

protocol, 4

-

20 mA, EEx ia / 2x NAMUR

-

switch

8 Transmitter ES with HART

-

protocol, 4

-

20 mA, EEx ia

/ 1x NAMUR

-

switch, 1x pulse output

9 Transmitter ES with Profibus PA, EEx ia

C 1 x microswitch

D 2 x microswitch

E 1 x inductive switch, Type SB 3,5

-

E2, three wire

F 2 x inductive switch, Type SB 3,5

-

E2, three wire

G 1 x induktiver Grenzkontakt NCB2

-

12GM40

-Z0

I Transmitter ES with HART

-

protocol and counter module

K Transmitter ES with Foundation Fieldbus

- Accessories

0 without

X special (separate specification nece

ssary)

- Dessign

H Heinrichs

K Kobold

Page 28 of 38

Subject to change without notice

Page 29

Heinri

chs Messtechnik

BGF Installation and Operating Instructions

23 Decontamination certificate for device cleaning

Company: ............................................ Name: ..........................................

Street: ............................................. Tel.-Nr.: .......................................

PLZ / postal code............................. / Town: ............................................................

The enclosed Flow Meter Model ……………..………..…..

Comm.-Nr. / Ser.Nr.:

has been used with media :.......................................................................................

As the used media is :

harmless

toxic

harmful

caustic

radioactive

explosive

oxidizing

biological harmful

other ……………………………………………………………………..….

we have doen the following things:

all cavities have been tested to be free the used process media

all cavities are rinsed and neutralized

all sealing surfaces and wetted parts have been cleaned

instrument housing and surfaces have been completely cleaned

We herewith confirm that due to the re-delivery of the above mentioned

instrument there is no danger for human and environment which may be

caused by residues of the process media.

Date: .................................. Signature: ....................................

Stamp

Page 29 of 38

Subject to change without notice

Page 30

Heinri

chs Messtechnik

BGF Installation and Operating Instructions

24 EC Type Examination Certificate

Page 30 of 38

Subject to change without notice

Page 31

Heinri

chs Messtechnik

BGF Installation and Operating Instructions

Page 31 of 38

Subject to change without notice

Page 32

Heinri

chs Messtechnik

BGF Installation and Operating Instructions

Page 32 of 38

Subject to change without notice

Page 33

Heinri

chs Messtechnik

BGF Installation and Operating Instructions

Page 33 of 38

Subject to change without notice

Page 34

Heinri

chs Messtechnik

BGF Installation and Operating Instructions

Page 34 of 38

Subject to change without notice

Page 35

Heinri

chs Messtechnik

BGF Installation and Operating Instructions

Page 35 of 38

Subject to change without notice

Page 36

Heinri

chs Messtechnik

BGF Installation and Operating Instructions

Schwebekörper

-

Durchflussmessgerät vom Typ BG*

2014/30/EU

(EMC)

2014/34/EU (ATEX)

2014/35/EU

(LVD)

über die Bereitstellung elektrischer Betriebsmittel zur Verwendung innerhalb

2014/68/EU (PED)

Kontakt

:

25 Declaration of conformity

Konformitätserklärung

Declaration of Conformity

Hersteller:

Manufacturer:

Produktbeschreibung:

Product description:

Hiermit erklären wir, in alleiniger Verantwortung, dass das oben genannte Messsystem den Anforderungen der folgenden EURichtlinien, einschließlich allen bis heute veröffentlichten Änderungen bzw. Nachträgen entspricht:

We declare herewith, in sole responsibility, that the product described above is conform with the provisions of the following EUdirectives, including all published changes and amendments as of today:

Anhang N und X sind ein integraler Bestandteil dieser Erklärung

Annex N and X are an integral part of this declaration

Köln, den 02.09.2016

No. 16.4111.02

Heinrichs Messtechnik GmbH

Robert-Perthel-Strasse 9

50739 Köln

Variable Area Flowmeter Model BG*

EU-Richtlinie über die Elektromagnetische Verträglichkeit

EU-Richtlinie über Geräte zur Bestimmungsgemäße Verwendung in explosionsgefährdeten

EU-Richtlinie zur Harmonisierung der Rechtsvorschriften der Mitgliedstaaten über die

EU-Directive relating to electromagnetic compatibility

Bereichen.

EU-Directive relating to electrical equipment intended for use in potentially explosive

atmospheres

EU-Richtlinie

bestimmter Spannungsgrenzen auf dem Markt

EU-Directive relating to the making available on the market of electrical equipment designed for

use within certain voltage limits

Bereitstellung von Druckgeräten auf dem Markt

EU-Directive on the harmonisation of the laws of the Member States relating to the making

available on the market of pressure equipment

Contact: Email: info@heinrichs.eu

Web: www.heinrichs.eu

Tel: +49 (221) 49708-0

Frank Schramm