Page 1

Operating Instruction

for

Humidity/Temperature- Measuring

Instrument

Model: AFH-G

Page 2

AFH-G

Seite 2 AFH-G 07/02

1. Note

Please read and take note of these operating instructions before unpacking and

setting the unit for operation, and follow the instructions precisely as described

herein.

The devices are only to be used, maintained and serviced by persons familiar

with these operating instructions and with the prevailing regulation applying to

procedural safety and the prevention of accidents.

2. Contents

1. Note.................................................................................... 2

2. Contents ............................................................................. 2

3. Specific Application ............................................................ 3

4. Operating Principles ........................................................... 3

5. Instrument Inspection ......................................................... 5

6. Mechanical connection ....................................................... 5

7. Electrical connection........................................................... 7

8. Technical Data.................................................................... 8

9. Order Codes....................................................................... 9

10. Maintence and Instruction for use ...................................... 9

11. Calibration ........................................................................ 10

12. Dimensions....................................................................... 11

13. Declaration of Conformance............................................. 12

Manufactured and sold by:

Kobold Messring GmbH

Nordring 22-24

D-65719 Hofheim

Tel.: +49(0)6192-2990

Fax: +49(0)6192-23398

E-Mail: info.de@kobold.com

Internet: www.kobold.com

Page 3

AFH-G

AFH-G 07/02 Seite 3

3. Specific Application

The AFH-G is to be installed only in the specified applications. Every usage

which exceeds the specifications is considered to be non-specified. Any damages resulting thereform are not the responsibility of the manufacturer. The user

assumes all risk for such usage. The application specifications include the installation, start-up and service requirements specified by the manufacturer.

4. Operating Principles

The type AFH-G measuring instrument serves to measure relative humidity indoors and in air ducts. Auxiliary temperature measurement is available as an option.

The moisture sensing element in the sensor comprises several strips of plastic

fabric each with 90 fibres of 3 µm diameter. These plastic fibres undergo a special process to acquire hygroscopic properties, this means that they absorb and

release moisture. The molecular structure of the fibres changes when they absorb water, giving rise to a measurable change in length. The length of the plastic

fibres is thus a measure of the relative humidity.

The swelling effect, acting primarily in the longitudinal direction, is sensed by an

electronic pick-off system and transferred to an integrated signal preprocessing

system. The output signal of the passive sensors is 100-138.5 ., and

4- 20 mA for the active sensors.

The special treatment of the measuring element ensures that its hygroscopic

properties remain stable, that is sensitivity is maintained until destroyed by external influence. Regeneration found in conventional instruments is not required

here, but is also not damaging.

The measuring element is protected by a perforated tube and is open to the

housing.

Measuring instruments with an integrated temperature sensor provide temperature measurement. The temperatures are also converted to the standardized

signals 0-20 mA, 0-10 V , and 4-20 mA.

4.1. Design of the sensor

The expanding action (predominantly lengthways) of the fibres is picked up by

means of an electronic sensing system and converted by integrated signal preprocessing into standardised signals 0..20mA or 4..20mA or 0...10V.

Page 4

AFH-G

Seite 4 AFH-G 07/02

The fan-shaped measuring element, which faces outward from the housing, is

protected by a perforated sensor tube. The sensors are designed for pressureless systems. The unit should be installed in a location where condensation cannot enter into the housing. A preferred position would be ”sensor vertically down”

or ”sensor horizontal”. In these positions, a cover plate with a 0.8 mm diameter

hole will prevent water from entering.

The AFH-G range of sensors have built-in temperature sensors (mainly Pt100)

for simultaneous measurement of temperature. Temperature readings are converted likewise into standardised signals 0..20mA or 4..20mA or 0..10V.

4.2. Ageing

In order to maintain their long-term stability, it is important that the measuring

elements undergo a special ageing process, details of which cannot be given

here.

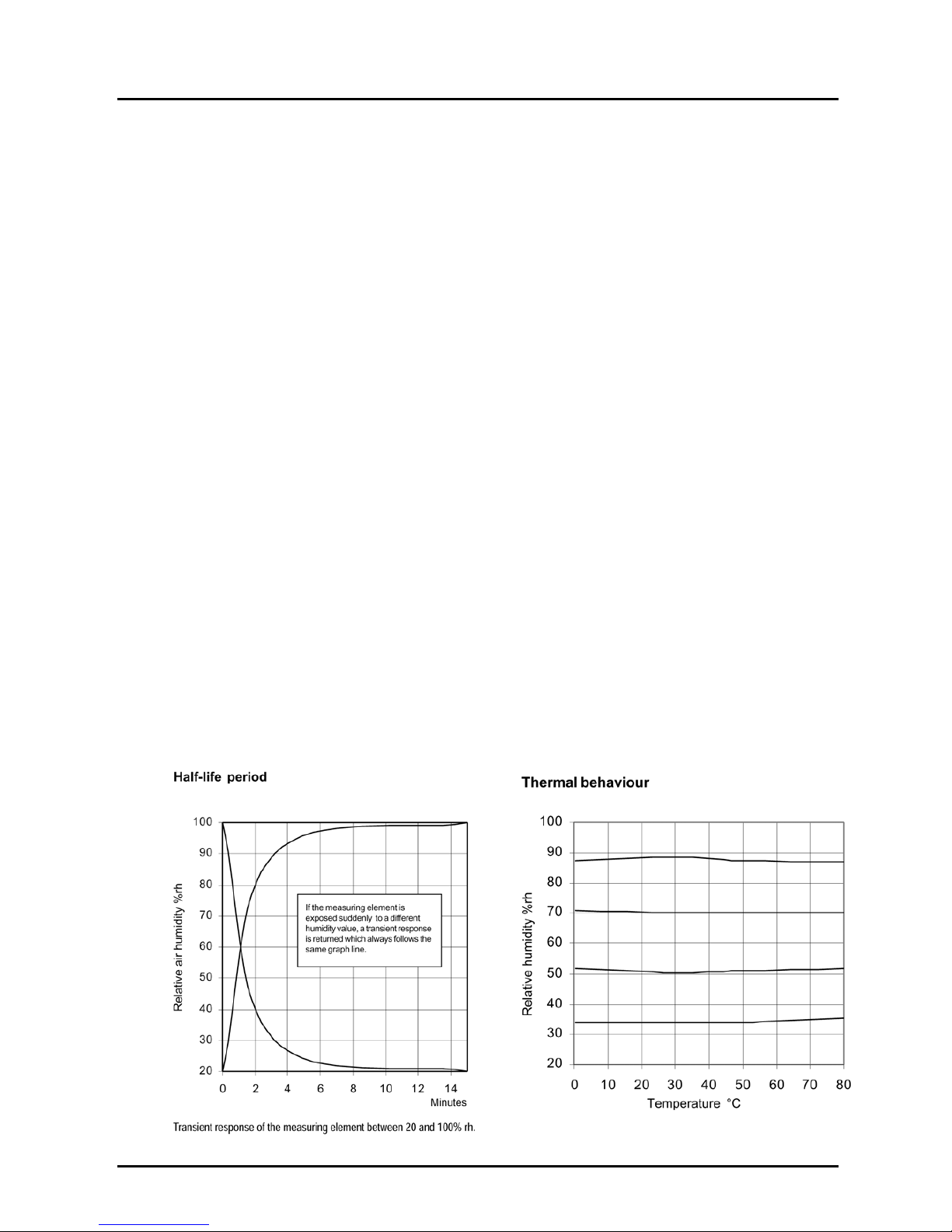

4.3. Reaction of the sensor

Due to the law of diffusion, there is a time delay before the fibres are saturated

during water absorption. This is a decisive factor when determining the reaction

time. Thus, for one individual fibre with a diameter of 3 µm, a short saturation

time (several seconds) can be measured. Empirical investigations show that

bundled or woven fibres, as are used here in the Kobold sensor, give rise to a

longer period prior to saturation. This is because the individual fibres impede

each other during water absorption and/or water loss, and the ensuing humidity

does not register until later. Measurements have shown that, at a wind speed of

2m / sec. the half-life period is 1.2 mins. This represents an effective period of

approx. 30 - 40 mins.

Page 5

AFH-G

AFH-G 07/02 Seite 5

80º C is given as the maximum temperature value. Higher temperatures can only

be tolerated for a short period of time. The eventual result is a change in the

molecular structure which causes a constant error. The maximum temperature of

80º C only applies, however, if no harmful substances (acids, solvents etc.) are

present in the medium.

4.4. Humidity and tolerance diagram

5. Instrument Inspection

These devices are checked before dispatch and sent away in perfect condition.

Should the damage to a device be visible, we recommend a thorough inspection

of the delivery packing. In case of damage, please inform your parcel service/

forwarding agent immediately, since they are responsible for damages during

transit.

Scope of delivery:

· Measuring Unit Model “AFH-G”

· Operating Instructions

6. Mechanical connection

Unavoidable sources of interference should be kept at a good distance

from the control systems.

Data and signalling lines should not be used in parallel with control,

networking and power lines.

Page 6

AFH-G

Seite 6 AFH-G 07/02

For data and signalling lines, shielded cable should be used, and the shielding

must be applied to the earth terminal. Ensure that earth circuits and fault currents

do not arise as a result of a second earth connection.

For equipment with a network connection, it is recommended that a separate

network circuit be used.

During the switch process, electrical power consumers such as switch contactors,

magnetic valves etc. produce induction voltages that can cause interference. In

the trade there is an abundance of protective and suppressor component parts

that are most effective when applied directly to the source of the trouble. A suitable suppressor has the added advantage that components such as relays, microswitches etc. have a longer service life.

Further difficulties during installation can arise if signalling lines are joined together with common lines. It is essential to check whether this is permissible. Interference is particularly likely when installing using equipment of different

makes. Here, too, the trade offers isolating amplifiers that overcome the problem.

Installation:

The installation position should be chosen so as to prevent condensed water

from entering the housing. The preferred installation position is "sensor vertically

pointing downwards" or "sensor horizontal".

A grommet in the probe prevents penetration of water in the installation positions

described above.

Wall mounting set

Page 7

AFH-G

AFH-G 07/02 Seite 7

7. Electrical connection

7.1. Passive sensors

7.2. Active sensors

Page 8

AFH-G

Seite 8 AFH-G 07/02

8. Technical Data

8.1. Humidity

Measuring range: 0-100% RH

Measuring accuracy: > 40% RH: ±2.5% RH

< 40% RH: ±3.5% RH

Recommended

operating range: 30-100% RH

8.2. Temperature

Measuring range: passive sensors: +5 to +80°C

active sensors: -30 to +60°C

Measuring accuracy: ±0.5°C

Measured medium: air, pressureless, non-aggressive

Allowed ambient

temperature: at housing: -20 to +60°C

at sensor: -40 to +80°C

Average temperature

coefficient: -0.1% RH/K

(at 20°C and 50% RH)

Allowed air speed: 8 m/s

with gauze protection

(optional) 15 m/s

Half-life at V=2 m/s: 1.2 min

Sensor length: 220 mm

Sensor material: stainless steel

Mounting: holes in housing base

for duct mounting

Bracket for surface

mounting (optional)

Installation position: sensor vertical pointing down,

or horizontal

Connection terminals: for conductor cross-sections

0.5 mm

Cable connection: Cable gland PG 13.5

Electromagnetic

compatibility:

Noise immunity: EN 50 082-2

emitted interference: EN 50 081-2

Housing: ABS

Protection: IP 64

Weight: approximately 0.4 kg

Page 9

AFH-G

AFH-G 07/02 Seite 9

9. Order Codes

10. Maintence and Instruction for use

The measuring element is maintenance free when the surrounding air is clean.

Agents that are corrosive and contain solvents, depending upon the type and

concentration of the agent, can result in faulty measurements and cause the

measuring element to break down. Direct sunlight should be avoided. Substances deposited on the sensor are damaging as they eventually form a waterrepellent film (this applies to all humidity sensors with hygroscopic measuring

elements). Such substances are resin aerosols, lacquer aerosols, smoke deposits etc. The water-resistant property of the Kobold sensors allows for cleaning

using water. Solvents cannot be used for this purpose. A light-duty detergent is

recommended. Any detergent residue should, however, always be thoroughly

washed out. A special process ensures that Kobold sensors have good long-term

stability. Regeneration is not necessary, but is also not harmful.

The temperature coefficient as well as the self-heating may vary according to the

location and the application (especially with sensors where electronic and measuring system are integrated in one housing).

The guarantee is no longer valid if the interior of the measuring element

has been accessed.

Page 10

AFH-G

Seite 10 AFH-G 07/02

11. Calibration

Kobold sensors are adjusted correctly at a room temperature of 23ºC and 50%rh

at a mean air pressure corresponding to 430m NN. If, however, a further adjustment is necessary, the following procedure should be adhered to :

· Ensure that the ambient humidity as well as the ambient temperature are

constant.

· If possible, use a psychrometer for testing, (do not use testing equipment with

capacitive sensors).

· Leave the equipment to be tested for a minimum of 1 hour under constant

test conditions.

· All Kobold sensors are equipped with an adjustment facility. In most cases

this involves an adjuster screw fixed with screw securing lacquer. When the

lacquer is removed the screw can be adjusted. After calibration, the adjuster

screw should again be secured.

Important: The air’s capacity to absorb water is influenced among other factors

by the temperature. This is a physical law (identified in the hx diagram of Mollier).

The higher the air temperature, the larger the amount of steam that can be absorbed up to saturation point (100%rh). If a sensor is calibrated under varying air

temperature conditions, the result is an irregular, unhomogenous measuring medium which automatically gives calibration errors. The table below shows the influence of the air temperature on air humidity. If, for example, calibration occurs

at an air temperature of 20ºC and 50%rh and a varying temperature range of only

+/-1 ºK, this results in a variation in humidity of the measuring medium (air) of +/-

3.2%rh.

Page 11

AFH-G

AFH-G 07/02 Seite 11

12. Dimensions

Page 12

AFH-G

Seite 12 AFH-G 07/02

13. Declaration of Conformance

We, KOBOLD-Messring GmbH, Hofheim-Ts, Germany, declare under our sole

responsibility that the product:

Humidity/Temperature- Measuring Instrument Model: AFH-G

to which this declaration relates is in conformity with the standards noted below:

DIN EN 60730-2-1 1993

VDE 0631 2 1989

IEC 730-2-1

Also the following EWG guidlines are fulfilled:

73/23/EWG

89/336/EWG

Unterschrift: Datum: 22.06.01

Loading...

Loading...