Koblenz-Thorne Electric U-80, U-90 User Manual

INDEX

I.- FINAL TEST FOR PRODUCT SAFETY 3

II.- REPLACEMENT PROCEDURES 3

III.- TROUBLE SHOOTING CHART 5

IV.- WIRING DIAGRAM 6

V.- ELECTRICAL RATING 6

VI.- EXTERNAL PARTS FOR UPRIGHT VACUUM CLEANER PARTS U-80 7

VII.- EXTERNAL PARTS FOR UPRIGHT VACUUM CLEANER PARTS U-90 8

VIII.- EXTERNAL PARTS LIST FOR UPRIGHT VACUUM CLEANER U-80 & U-90 9

IX.- PARTS LIST FOR UPRIGHT VACUUM CLEANER U-80 10

X.- LIST PARTS UPRIGHT VACUUM CLEANER U-80 11

XI.- INTERNAL PARTS FOR UPRIGHT VACUUM CLEANER U-90 12

XII.- PARTS LIST FOR UPRIGHT VACUUM CLEANER U-90 13

2 DECEMBER-10

I.-FINAL TEST FOR PRODUCT SAFETY

At the completion of any repairs the product should be electrically tested for operating and electric

strength as follows.

1.-ELECTRIC TEST

1. Set hi-pot test meter at 1500 Volts

2. Lower product handle to “ON” position

3. Place one probe of tester to one blade of the power cord plug and place the other probe to the

handle tube, there should be no breakdown.

2.-OPERATING TEST

Run the machine with the height adjustment knob on high position and check.

1. There should be no unusual noise or vibration.

2. The carbon brushes spark should be small and uniform.

3. The current should not exceed 7.0 Amps

II. REPLACEMENT PROCEDURES

1.-TO REMOVE BAG

1.1.-Release spring, from handle, slide off coupling unit.

2.-TO REMOVE HANDLE TUBE (2 AND 8) FIG.1 AND FIG.3

2.1.-Pull out the line cord from the cord retainer (5)

2.2-Remove the nut and screw (14,15 AND 7) and pull out the tube.

3.-TO REPLACE BELT (49), FIG.2 AND FIG.4.

3.1.-Turn the upright upwards.

3.2.-Remove the bottom plate (23)and the fan cover by pressing and releasing one side of the retaining

shaft(22)

3.3.-Pull and twist the belt over the pulley to remove it.

3.4.-Pull the brush roll (21) from the ends to take it out of the chassis.

3.5.-First, place the new belt on the brush roll, then place brush roll in the chassis, put the belt on the

pulley verifying that the belt is in the right position,. Finally, assemble the fan cover and bottom plate.

4.-TO REPLACE BRUSH ROLL ( 21 ) OR BEARING SUPPORTS FIG. 2 AND FIG.4.

4.1.-Follow steps 3.1 to 3.4.

4.2.-Remove the supports by pulling them out.

4.3.-Replace the new brush roll as indicated in item number 3.5.

5.-TO REPLACE REAR WHEELS (5), FIG.2 AND FIG.4.

5.1.-Remove the cover(2) as described in procedure number 7.

5.2.-Pull washer cap retainer (6) from rear wheel hub (41) and remove the wheels.

5.3.-Replace the new wheels by placing the washers (9), the wheels as well as the padlocks.

5.4.-Place the cover back in position.

6.-TO REPLACE FRONT WHEELS (11), FIG.2 AND FIG.4.

6.1.-Remove cover (2) as described in procedure number 7.

6.2.-Remove screws (7) from the front axle retainer and the front axle spring (10).

6.3.-Take out front axle with the wheels.

6.4.-Remove the old wheel and place the new wheels..

6.5.-Replace the axle, the retainers and the spring.

6.6.-Place the cover back in position.

3 DECEMBER-10

7.-TO REMOVE THE COVER (2), FIG.2 AND FIG.4.

7.1.-Remove the bag assy as described in procedure number 1.

7.2.-Release and lower the handle(39) to a horizontal position.

7.3.-Unscrew and pull out the height adjustment knob (1).

7.4.-Turn around the upright be careful not to scratch the cover.

7.5.-Use a flat screwdriver to release the snaps of the cover hood in the chassis(18)

8.-TO REPLACE MOTOR (51), FIG.2 AND FIG.4.

8.1.-Uplug the machine.

8.2.-Remove belt follow steps 3.1 to 3.3.

8.3.-Remove cover (step 7).

8.4.-Remove the four screws (4) that hold the motor and disconnect it.

8.5.-Replace the motor (51)

9.-TO REPLACE HEIGHT ADJUSTMENT LEVER (I5), FIG.2 AND FIG.4

9.1.-Release pedal lower the handle(39) and place the handle tube in horizontal position.

9.2.-Remove the screw (14) and the adjustment knob (1)

9.3.-Remove the spring(10) and screw (44), to remove the retain for lever(17).

10.-TO FOOT RELEASE PEDAL (39) FIG.2 AND FIG.4

10.1.-Remove cover (step 7)

10.2.-Remove spring (40) from chassis

10.3.-Pull pedal towards spring side and remove

11.-TO REPLACE YOKE ASSEMBLY (54), FIG.2 AND FIG.4

11.1.-Remove cover (step 7)

11.2.-Remove foot pedal (step 10)

11.3.-Remove the yoke bolt (31), along with the security locks (20)

12.-TO REPLACE THE LINE CORD ASSEMBLY (25), FIG.2 AND FIG.4

12.1.-Remove cover (step 7)

12.2.-Remove strain relief (26) from chassis with strain relief pliers

12.3.-Reassemble with the strain relief pliers making sure to locate the strain relief as it was before.

13.-TO REPLACE THE ON - OFF SWITCH (48), FIG.2 AND FIG.4.

13.1.-Remove cover (step 7)

13.2.-Disconnect the electrical terminal from the switch.

13.3.-Press the side tabs on the switch and pull it out.

13.4.-Place and push the new switch into the opening until the tabs snap in and reconnect the terminal.

WHEN ORDERING, DO NOT FORGET TO SPECIFY:

PART NUMBER

DESCRIPTION

MODEL NUMBER

NOTE: Drawing numbers are for identification purposes only.

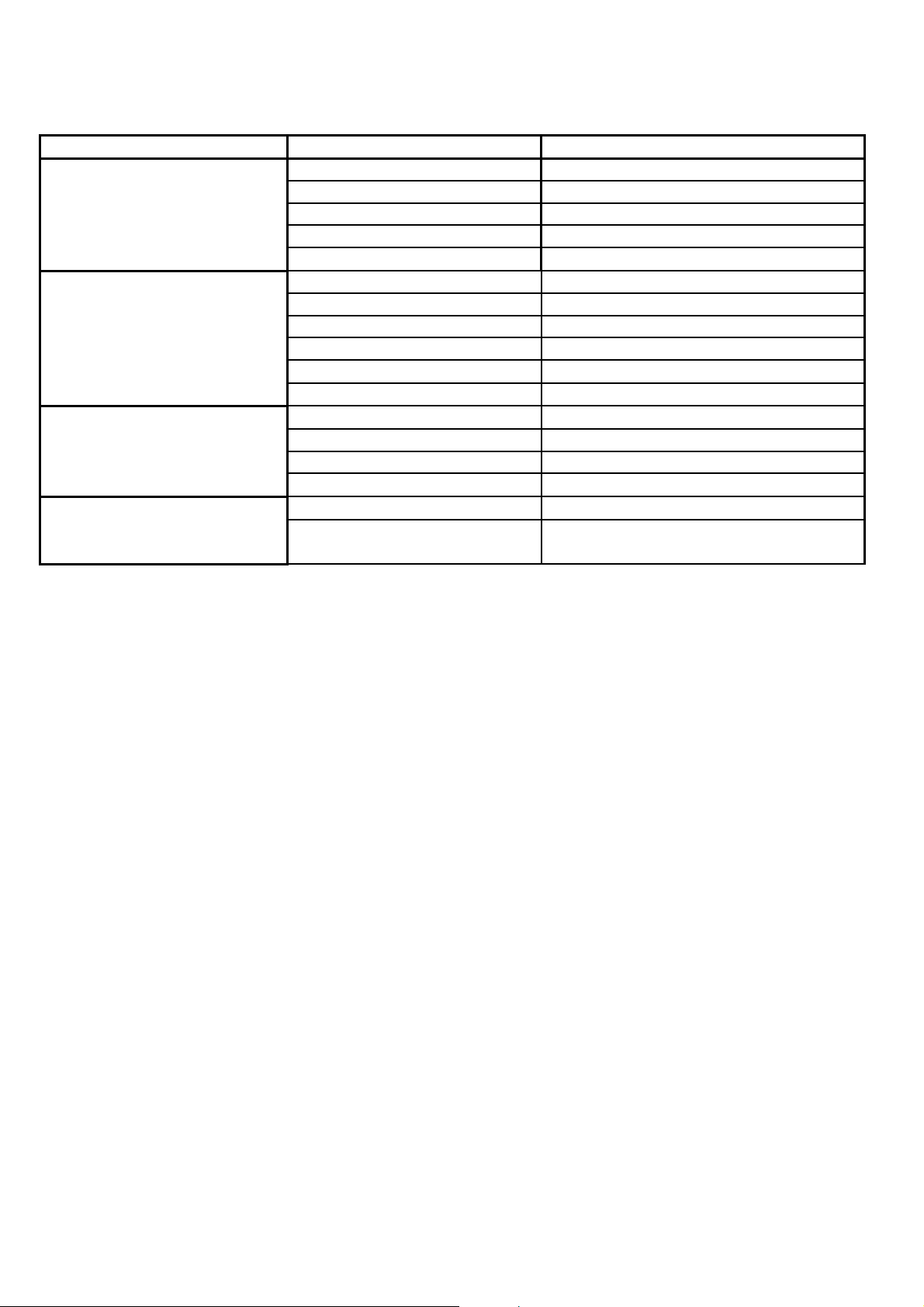

III.-TROUBLE SHOOTING CHART.

4 DECEMBER-10

PROBLEM POSSIBLE CAUSE SOLUTION

A) Motor does not work

B) Motor works but cleaner

does not pick up/has suction

C) Motor works incorrectly

D) Brush roll vibrates.

1.- Not firmly plugged in. 1.- Check attachment plug.

2.- Bad ON-OFF switch. 2.- Replace switch.

3.- Line cord open 3.- Replace cord.

4.- Motor open 4.- Check motor and wiring.

5.- Fan blockage by material 5.- Remove obstruction

1.- Belt broken. 1.- Replace belt.

2.- Blockage air system. 2.- Remove obstruction.

3.- Fan broken. 3.- Replace fan.

4.- Worn brush roller. 4.- Replace brush roller.

5.- Motor slow. 5.- Check carbon brushes.

6.- Bag full. 6.- Empty bag (or change paper bag).

1.- Worn carbon brushes. 1.- Replace brushes.

2.- Detective armature. 2.- Check spark, replace

3.- Bad electrical connection. 3.- Check wiring.

4.- Detective On-Off switch. 4.- Replace switch.

1.- Ball bearing worn out.. 1.- Replace

2.- Ball bearing holder

damaged 2.- Replace ball bearing holder.

5 DECEMBER-10

Loading...

Loading...