Kobewel PC 70i, PC 100i Operating Manual

MODEL

• PC 70i

• PC 100i

Operating Manual

(Owner’s Manual)

IMPORTANT: Read these instructions before installing, operating, or servicing this system.

First Edition Manual No. K0901

- 1 -

PC 70i, 100i Operating Manual

CONTENTS

SYMBOL LEGEND---------------------------------------------------------------------------------------------------2

STATEMENT OF WARRANTY------------------------------------------------------------------------------------3

1.0 GENERAL INFORMATION-------------------------------------------------------------------------------4

1.01 Notes, Cautions and Warnings------------------------------------------------------------------------4

1.02 Important Safety Precautions--------------------------------------------------------------------------4

1.03 Transporting methods-----------------------------------------------------------------------------------6

2.0 INSTALLATION RECOMMENDATION----------------------------------------------------------------7

2.01 Electrical Input Connections---------------------------------------------------------------------------8

2.02 Specifications--------------------------------------------------------------------------------------------10

2.03 Duty cycle-------------------------------------------------------------------------------------------------10

3.0 OPERATOR CONTROLS-------------------------------------------------------------------------------11

3.01 PC series controls--------------------------------------------------- -----------------------------------11

3.02 Cut parameter description--------------------------------------------------------------------------13

4.0 SET-UP FOR PCM---------------------------------------- ----------------------------------------------- -14

5.0 POWER SUPPLY CONTROLS INDICATORS AND REATURES-----------------------------15

6.0 MAINTENANCE--------------------------------------------------------------------------------------------16

7.0 BASIC TROUBLESHOOTING-------------------------------------------------------------------------16

7.01 Check the item and excrescent phenomenon exclusion method---------------------------16

7.02 Power source problems-- --------------------------------------------------- --------------------------18

8.0 REMARK-----------------------------------------------------------------------------------------------------19

APPENDIX: INTERCONNECT DIAGRAM

- 2 -

PC 70i, 100i Operating Manual

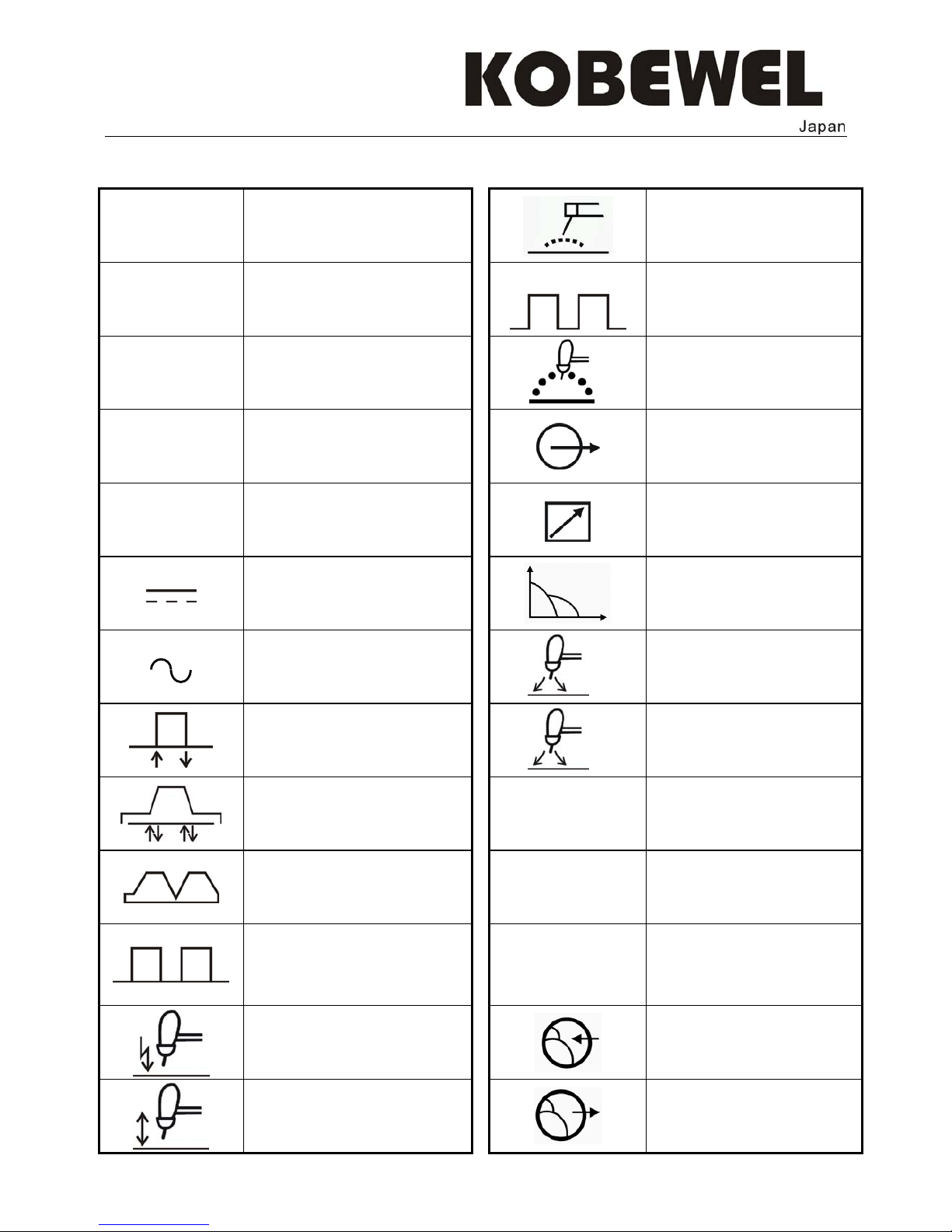

SYMBOL LEGEND

A

Amperage

Stick (SMAW)

V

Voltage

Pulse Current Function

(GTAW)

Hz

Hertz (frequency)

t

Spot Time (GTAW)

SEC

Seconds

Remote outputs control

(Panel/Remote)

%

Percent

Remote Function

DC (Direct Current)

Arc Control (SMAW)

AC (Alternating Current)

t

2

Gas Post-Flow Time

2T (GTAW)

t

1

Gas Pre-Flow Time

4T (GTAW)

VRD

Voltage Reduction

Device Circuit

Repeat Function (GTAW)

—

Negative

Spot Function (GTAW)

+

Positive

High Frequency Starting

(GTAW)

Gas Input

Lift Start (GTAW)

Gas Output

- 3 -

PC 70i, 100i Operating Manual

STATEMENT OF WARRANTY

LIMITED WARRANTY: "KOBEWEL" warrants to customers of its authorized distributors hereafter "KOBEWEL" that its products

will be free of defects in workmanship or material. Should any failure to conform to this warranty appear within the time period

applicable to the KOBEWEL products as stated below, KOBEWEL shall, upon notification thereof and substantiation that the

product has been stored, installed, operated, and maintained in accordance with KOBEWEL’s specifications, instructions,

recommendations and recognized standard industry practice, and not subject to misuse, repair, neglect, alteration, or accident,

correct such defects by suitable repair or replacement, at KOBEWEL ‘s sole option, of any components or parts of the product

determined by KOBEWEL to be defective.

The KOBEWEL COMPANY MAKES NO OTHER WARRANTY, EXPRESS OR IMPLIED. THIS WARRANTY IS EXCLUSIVE

AND IN LIEU OF ALL OTHERS, INCLUDING, BUT NOT LIMITED TO ANY WARRANTY OF MERCHANTABILITY OR

FITNESS FOR ANY PARTICULAR PURPOSE.

LIMITATION OF LIABILITY: KOBEWEL shall not under any circumstances be liable for special, indirect or consequential

damages, such as, but not limited to, lost profits and business interruption. The remedies of the Purchaser set forth herein ar e

exclusive and the liability of KOBEWEL with respect to any contract, or anything done in connection therewith such as the

performance or breach thereof, or from the manufacture, sale, delivery, resale, or use of any goods covered by or furnished b y

KOBEWEL whether arising out of contract, negligence, strict tort, or under any warranty, or otherwise, shall not, except as

expressly provided herein, exceed the price of the goods upon which such liability is based. No employee, agent, or

representative of KOBEWEL is authorized to change this warranty in any way or grant any other warranty.

PURCHASER'S RIGHTS UNDER THIS WARRANTY ARE VOID IF REPLACEMENT PARTS OR ACCESSORIES ARE USED

WHICH IN KOBEWEL’S SOLE JUDGEMENT MAY IMPAIR THE SAFETY OR PERFORMANCE OF ANY KOBEWEL

PRODUCT.

PURCHASER'S RIGHTS UNDER THIS WARRANTY ARE VOID IF THE PRODUCT IS SOLD TO PURCHASER BY

NON-AUTHORIZED PERSONS.

The warranty is effective for the time stated below beginning on the date that the authorized distributor delivers the products to

the Purchaser. Not with standing the foregoing, in no event shall the warranty period extend more than the time stated plus one

year from the date KOBEWEL delivered the product to the authorized distributor.

POWER SUPPLIES

POWER SUPPLIES & WIRE FEEDERS

MAIN POWER MAGNETICS (STATIC& ROTATING) 1YEAR

ORIGINAL MAIN POWER RECTIFIER 1YEAR

POWER SWITCHING SEMI-CONDUCTORS & CONTROL PC BOARD 1YEAR

ALL OTHER CIRCUITS AND COMPONENTS INCLUDING 1YEAR

BUT NOT LIMIT ED TO, CONTACTORS, RELAYS,

SOLENOIDS, PUMPS, SWITCHES, MOTORS

Warranty repairs or replacement claims under this limited warranty must be submitted to KOBEWEL by an authorized

KOBEWEL repair facility within thirty (30) days of purchaser’s notice of any Warranty Claim. No transportation costs of any kind

will be paid under this warranty. Transportation charges t o send products to an authorize d warranty repair facility shall be the

responsibility of the Purchaser. All returned goods shall be at the Purchaser’s risk and expense. This warranty super sedes all

previous KOBEWEL warranties.

- 4 -

PC 70i, 100i Operating Manual

1.0 GENERAL INFORMATION

1.01 Notes, Cautions and Warnings

Throughout this manual, notes, cautions, and warnings are used to highlight important information. These

highlights are categorized as follows:

NOTE

An operation, procedure, or background information which requires additional emphasis or is helpful in

efficient operation of the system.

CAUTION

A procedure which, if not properly followed, may cause damage to the equipment.

WARNING

A procedure which, if not properly followed, may cause injury to the operator or others in the operating area.

1.02 Important Safety Precautions

WARNING

OPERATION AND MAINTENANCE OF CUTTING EQUIPMENT CAN BE DANGEROUS AND HAZARDOUS

TO YOUR HEAL TH.

To prevent possible injury, read, understand and follow all warnings, safety precautions and instructions

before using the equipment. Call your local distributor if you have any questions.

GASES AND FUMES

Gases and fumes produced during the Arc welding or cutting process can be dangerous and hazardous to

your health.

z Keep all fumes and gases from the breathing area. Keep your head out of the welding fume plume.

z Use an air-supplied respirator if ventilation is not adequate to remove all fumes and gases.

z The kinds of fumes and gases from the arc welding/cutting depend on the kind of metal being used,

coatings on the metal, and the different processes. You must be very careful when cutting or welding

any metals which may contain one or more of the following:

Antimony Arsenic Barium Beryllium Cadmium Chromium Cobalt Copper Lead

Manganese Mercury Nickel Selenium Silver Vanadium

z Always read the Material Safety Data Sheets (MSDS) that should be supplied with the material you

are using. These MSDSs will give you the information regarding the kind and amount of fumes and

gases that may be dangerous to your health.

z Use special equipment, such as water or down draft welding/cutting tables, to capture fumes and

gases.

z Do not use the cutting torch in an area where combustible or explosive gases or materials are

located.

z Phosgene, a toxic gas, is generated from the vapors of chlorinated solvents and cleansers. Remove

all sources of these vapors.

- 5 -

PC 70i, 100i Operating Manual

ELECTRIC SHOCK

Electric Shock can injure or kill. The cutting process uses and produces high voltage electrical energy. This

electric energy can cause severe or fatal shock to the operator or others in the workplace.

z Never touch any parts that are electrically “live” or “hot.”

z Wear dry gloves and clothing. Insulate yourself from the work piece or other parts of the cutting

circuit.

z Repair or replace all worn or damaged parts.

z Extra care must be taken when the workplace is moist or damp.

z Install and maintain equipment according to NEC code, refer to relative standards.

z Disconnect power source before performing any service or repairs.

z Read and follow all the instructions in the Operating Manual.

FIRE AND EXPLOSION

Fire and explosion can be caused by hot slag, sparks, or the arc weld.

z Be sure there is no combustible or flammable material in the workplace. Any material that cannot be

removed must be protected.

z Ventilate all flammable or explosive vapors from the workplace.

z Do not cut or weld on containers that may have held combustibles.

z Provide a fire watch when working in an area where fire hazards may exist.

z Hydrogen gas may be formed and trapped under aluminum workpieces when they are cut

underwater, or while using a water table. Do not cut aluminum alloys underwater or on a water table

unless the hydrogen gas can be eliminated or dissipated. Trapped hydrogen gas that is ignited will

cause an explosion.

NOISE

Noise can cause permanent hearing loss. Arc welding/cutting processes can cause noise levels to exceed

safe limits. You must protect your ears from loud noise to prevent permanent loss of hearing.

z To protect your hearing from loud noise, wear protective ear plugs and/ or ear muffs. Protect others

in the workplace.

z Noise levels should be measured to be sure the decibels (sound) do not exceed safe levels.

ARC WELDING RAYS

Arc Welding/ Cutting Rays can injure your eyes and burn your skin. The arc welding/cutting process produces

very bright ultra violet and infra red light. These arc rays will damage your eyes and burn your skin if you are

not properly protected.

z To protect your eyes, always wear a welding helmet or shield. Also always wear safety glasses with

side shields, goggles or other protective eye wear.

z Wear welding gloves and suitable clothing to protect your skin from the arc rays and sparks.

z Keep helmet and safety glasses in good condition. Replace lenses when cracked, chipped or dirty.

z Protect others in the work area from the arc rays. Use protective booths, screens or shields.

- 6 -

PC 70i, 100i Operating Manual

1.03 Transporting methods

These units are equipped with a handle for carrying purposes.

WARNING: ELECTRIC SHOCK can kill.

DO NOT TOUCH live electrical parts. Disconnect input power conductors from de-energized supply

line before moving the cutting power source.

WARNING: FALLING EQUIPMENT can cause serious personal injury and

equipment damage.

z Lift unit with handle on top of case.

z Use handcart or similar device of adequate capacity.

z If using a fork lift vehicle, place and secure unit on a proper skid before transporting.

Loading...

Loading...