Kober C38GC25, C38GC35-CH1, C38GC25-P, C38GC35, C38GC29 User Manual

...

18

KÖBER SRL VADURI BRANCH

USER MANUAL

CONDENSING GAS BOILER

C38GC25 C38GC29 C38GC35

C38GC25-P C38GC35-CH1 C38GC35-CH2

Image for presentation only. Product

may look slightly different depending

on the area and the purchase period.

KÖBER Ltd, no. 25 Vaduri, Alexandru cel Bun Commune, Neamt 617511, Romania

Tel.:+40.233.24.17.46, 233.24.19.33, Fax:+40.233.24.19.29

www.motan.ro

2726

P M0 0 2 2 7 3

USER MANUAL CENTRAL HEATING BOILER TYPE C38GC25; C38GC25-P; C38GC29; C38GC35; C38GC35-CH1; C38GC35-CH2

Contents

1 Safety instructions and symbols ................................................................................................................................................... 4

1.1 Valability of instructions ......................................................................................................................................................................... 4

1.2 CE Marking .............................................................................................................................................................................................. 4

1.3 Use according to destination ............................................................................................................................................................... 4

2 Technical and functional characteristics .................................................................................................................................... 5

2.1 Structure ................................................................................................................................................................................................... 5

2.1.1 Structure of boiler type C38GC25 / C38GC29 / C38GC35........................................................................................ 5

2.1.2 Structure of boiler type C38GC25-P .............................................................................................................................. 6

2.1.3 The structure of condensation mural central heating gas boilers C38GC35-CH1 .................................................... 7

2.1.4 The structure of condensation mural central heating gas boilers C38GC35-CH2 .................................................... 8

2.2 Constructive and functional characteristics ...................................................................................................................................... 9

3 Safety instructions ........................................................................................................................................................................ 12

3.1 Instalation and adjustment ................................................................................................................................................................. 12

3.2 Gas smell ................................................................................................................................................................................................ 12

3.3 Changes in the area adiacent to the heating BOILER .................................................................................................................. 12

4 Mounting ...................................................................................................................................................................................... 12

4.1 Mounting set.......................................................................................................................................................................................... 12

4.2 Dimensions and mounting positions .................................................................................................................................................. 13

4.2.1 Installation site .................................................................................................................................................................. 13

4.2.2 Minimum necessary distances/ free spaces for mounting ....................................................................................... 15

4.2.3 Installing the boiler ........................................................................................................................................................... 15

5 Installation .................................................................................................................................................................................... 16

5.1 Conditions for the installation of the central heating BOILER ........................................................................................................ 16

5.1.1 Installation indication ...................................................................................................................................................... 16

5.1.2 Protection of the BOILER in order to keep the warranty ........................................................................................... 16

5.2 Gas connecting pipe .......................................................................................................................................................................... 16

5.3 General directions for the heating installation ................................................................................................................................ 16

5.4 General directions for the hot water circuit ..................................................................................................................................... 17

5.5 Connecting pipe of the condensation output duct ...................................................................................................................... 17

5.6 Connecting pipe of the safety valve ................................................................................................................................................ 18

5.7 Air inlet pipe / burnt gases outlet pipe ............................................................................................................................................. 18

5.8 Electric grid connection ...................................................................................................................................................................... 18

6 Operation instructions ................................................................................................................................................................. 19

6.1 Control Panel LMC1X for boiler types C38GC25, C38GC29, C38GC35 ...................................................................................... 19

6.2 Description of functions and graphic contexts displayed by the control panel LMC1X

6.2.1 Graphical context - Display the E88 error .................................................................................................................... 20

6.2.2 Graphic context

6.2.3 LIGHT function control panel LMC1X ............................................................................................................................ 20

6.2.4 Graphic context - Stand-by control panel LMC1X ..................................................................................................... 20

6.2.5 Graphic context – on hold (ON) control panel LMC1X ............................................................................................. 20

6.2.6 Graphic context – user menu control panel LMC1X ................................................................................................. 21

6.2.7 Graphic context – SERVICE submenu control panel LMC1X .................................................................................... 21

6.2.8 Graphic context – ECONOMIC submenu control panel LMC1X ............................................................................. 21

6.3 Control Panel

Table 5: Control panel keys

6.3.1

6.3.2 Graphical context - Display the E88 error .................................................................................................................... 22

6.3.3

6.3.4

6.3.5

6.3.6

6.3.7

6.3.8

6.3.9

7 COMMISSIONING ........................................................................................................................................................................ 24

7.1 Commissioning work ............................................................................................................................................................................ 24

7.2 Starting the boiler and choosing the operating mode: ................................................................................................................. 24

7.2.1

7.2.2

7.2.3

7.2.4 Domestic hot water operation via an individual boiler connected to the boiler (see chapter 11 '' Operating

modes '') 25

7.2.5 Functioning as heating BOILER (HS) .............................................................................................................................. 25

7.2.6 Preset functions related to BOILER safety .................................................................................................................... 25

7.3 BOILER switch off in safety conditions ............................................................................................................................................... 25

7.4 User training ........................................................................................................................................................................................... 26

7.5 Quality Conditions and Warranty ...................................................................................................................................................... 26

8 INSPECTION AND MAINTENANCE................................................................................................................................................ 26

8.1 Inspection and maintenance intervals ............................................................................................................................................. 26

8.2 Maintenance works ............................................................................................................................................................................. 27

9 Error signals .................................................................................................................................................................................. 27

10 Drawings necessary for mounting and installation ................................................................................................................... 29

LMC1112-15

Description of functions and of graphic contexts diplayed on the control panel LMC1112

LIGHT function control panel LMC1112

Graphic context – station startup control panel LMC1112

Graphic context - Stand-by control panel LMC1112

Graphic context – error state control panel LMC1112

Graphic context – waiting state control panel LMC1112

Graphic context – functioning state control panel LMC1112

Graphic context – adjustment of functioning parameters control panel LMC1112

Starting

Choosing the functioning modes of the central heating BOILER

Functioning

the boiler (control panel LMC1X and control panel LMC1112) ................................................................ 24

– switching the boiler on

for boiler versions C38GC25-P, C38GC35-CH1, C38GC35-CH2 .................................................. 22

........................................................................................................................................................................ 22

as domestic hot water BOILER (DHW) ................................................................................................... 24

control panel LMC1X .......................................................................... 20

..................................................................................................................... 22

.................................................................................. 23

............................................................................................ 23

......................................................................................... 23

.................................................................................... 23

............................................................................. 23

....................................................................... 24

.................................................. 20

...................... 22

.................................... 23

REV. 01.07.2019

2 din 37

USER MANUAL CENTRAL HEATING BOILER TYPE C38GC25; C38GC25-P; C38GC29; C38GC35; C38GC35-CH1; C38GC35-CH2

11.2. Minimum distances recommended for the mounting of the co-axial kit ................................................................................... 29

11.3. Hydraulic characteristic of pump ...................................................................................................................................................... 30

11.4. Functioning schemes covered by warranty .................................................................................................................................... 31

11.4.1 Radiators heating and instant preparation of hot water ..................................................................................................... 31

11.4.2 Underfloor heating and instant preparation of hot water, .................................................................................................. 31

11.4.3 Radiators heating and accumulated preparation of hot water (accummulation water tank) ................................... 32

11.4.4 Underfloor heating and accumulated preparation of hot water (accummulation water tank) ................................. 32

11.4.5 Radiators heating, C38GC35-CH2 boiler (without V3C valve, only with heating circuit preparation) ........................ 33

11.4.6 Underfloor heating, C38GC35-CH2 boiler (without V3C valve, only with heating circuit preparation) ...................... 33

11.4.7 Raditors and underfloor heating and external boiler for DHW, C38GC35-CH2 boiler .................................................... 34

11.4.8 Raditors heating and external boiler for DHW, C38GC35-CH2 boiler ................................................................................ 34

11.4.9 Underfloor heating and external boiler for DHW, C38GC35-CH1 boiler ............................................................................ 35

11.4.10 Combine radiators and underfloor heating and external boiler for DHW, C38GC35-CH1 boiler ............................... 35

11.4.11 Radiators heating, external boiler for DHW and solar panel, C38GC35-CH1 boiler...................................................... 36

11.4.12 Underfloor heating, external boiler for DHW and solar panel, C38GC35-CH1 boiler .................................................... 36

11.4.13 Combine radiators and underfloor heating, external boiler for DHW and solar panel, C38GC35-CH1 boiler ......... 37

REV. 01.07.2019

3 din 37

USER MANUAL CENTRAL HEATING BOILER TYPE C38GC25; C38GC25-P; C38GC29; C38GC35; C38GC35-CH1; C38GC35-CH2

1

Safety instructions and symbols

When installing the central heating BOILER we ask you to respect the safety instructions contained in this manual!

This manual is the property of KÖBER SRL-Vaduri branch. Copying or reproduction without written consent KÖBER SRL-Vaduri

branch is strictly forbidden.

The following lines explain the symbols used in the text:

Danger!

–

direct danger for corporal integrity and life.

Danger!

Caution!

Note!

–

danger of death by electrocution.

–

pontentially dangerous situation for the product and the environment.

–

useful notes and information. This symbol indicates a necessary activity.

1.1 Valability of instructions

These instructions are valid exclusively for central heating boilers models:

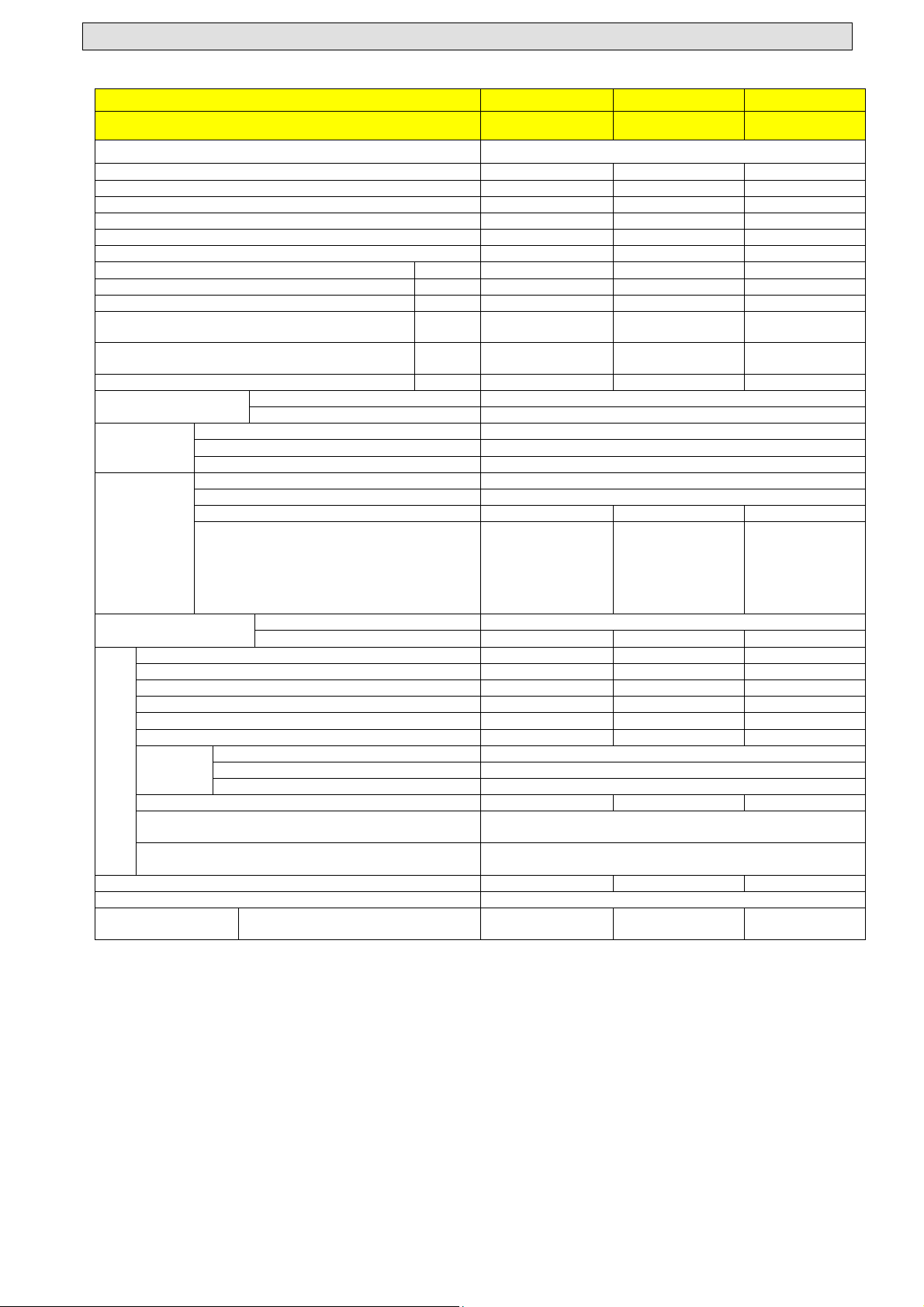

BOILER TYPE NAME POWER FUNCTIONS PARTICULARITY

C38GC25 MKDENS25 25 kW DHW + CENTRAL HEATING BRASS HYDRAULIC GROUP

C38GC29 MKDENS29 29 kW DHW + CENTRAL HEATING

C38GC35 MKDENS35

C38GC25-P MKDENS25-P 25 kW DHW + CENTRAL HEATING PA66GF30 HYDRAULIC GROUP

C38GC35-CH1 MKDENS35 TERMOV

C38GC35-CH2 MKDENS35 TERMO

Where:

C38 – internal name;

G – type of fuel-gas;

C – compensating;

25, 29 and 35 - t

P/CH1/CH2 - constructive versions

The boilers are designed to use gas from classes: I2H

The type of gas for which the device is adjusted is specified on the product label and nameplate.

1.2 CE Marking

in the applicable European legislation:

- Directive regarding gas equipment 2009/142/CE (ex. 90/396/CEE)

- EcoDesign Directive 2009/125/EC

- Directive regarding energy efficiency 92/42/EEC and European Regulations no.811-814/2013

- Directive regarding electromagnetic compatibility 2004/108/EC (ex. 89/366/CEE)

- Directive for low frequency 2006/95/EC (ex. 73/23/EEC).

1.3 Use according to destination

-

Central heating boilers C38GC25, C38GC29, C38GC35 are designed following current technical standards and observing

recognized safety norms

- In case of misuse or inappropriate use, the health or life of users or third parties can be put in danger, as well as the central

heating BOILER and other goods;

- This equipment must not be used by people with limited psychological and sensitive capacities (including children), or by

people with no experience or/ and no knowledge;

- The BOILER provides both heating in closed circuit central heating installations, as well as hot water. Use for other purposes or for

additional purposes other than stipulated is considered inappropriate use. The manufacturer is not responsible for possible

damage resulting from inappropriate use.

- Compliance with the use and installation instructions, the additional documentation, as well as with the inspection and

maintenance stipulations is part of what is understood by use according to destination.

he maximum rated power which the boiler can supply

CE marking applied on this product guarantees that the equipment complies with the esential conditions stipulated

;

35 KW

35 KW

35 KW

The user is the only one responsible;

DHW + CENTRAL HEATING

CENTRAL HEATING V3C INCLUDED

CENTRAL HEATING WITHOUT V3C

, in kW

BRASS HYDRAULIC GROUP

BRASS HYDRAULIC GROUP

REV. 01.07.2019

4 din 37

USER MANUAL CENTRAL HEATING BOILER TYPE C38GC25; C38GC25-P; C38GC29; C38GC35; C38GC35-CH1; C38GC35-CH2

Figure

2

Technical and functional characteristics

2.1 Structure

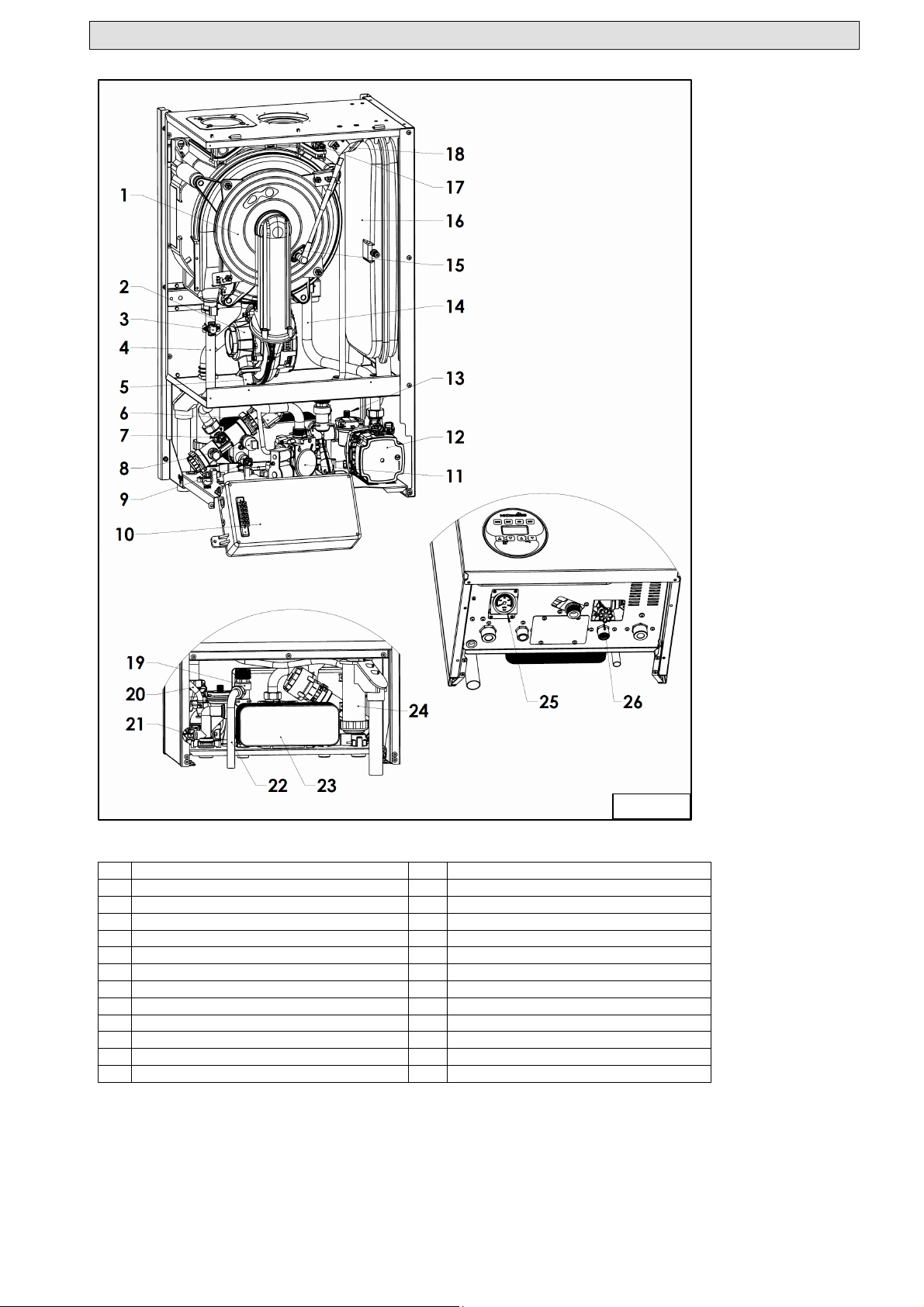

2.1.1 Structure of boiler type C38GC25 / C38GC29 / C38GC35

(*) The boiler in the

standard configuration

is not delivered

equipped with

landmarks from pos. 14.

Equipping the boiler

with those landmarks

can be done by the

producer only by

request.

Tab. 2.1 Components of the condensing boiler

1 Main heat exchanger 15 Ignition electrode

2 Built-in fan nozzle 16 Expansion vessel

3 Over-temperature thermostat 17 Flue gas temperature sensor

4 Heating tour connection 18 Ignition transformer

5 Gas supply connection 19 Pressure relief valve 3 bar

6 3-way valve actuator 20

7 Heating temperature sensor 21

8 Domestic hot water temperature sensor 22

9 Electronic box 23

10 Gas valve 24

11 Pump 25

12 Pump automatic air vent 26 Pressure gauge

13 Heating return connection 27 Filling tap

14* Flow switch

Expansion vessel connection

Return heating temperature sensor

Water pressure sensor

Pressure valve connection

Secondary heat exchanger

Drain trap for condense

REV. 01.07.2019

5 din 37

USER MANUAL CENTRAL HEATING BOILER TYPE C38GC25; C38GC25-P; C38GC29; C38GC35; C38GC35-CH1; C38GC35-CH2

Figura 2.1

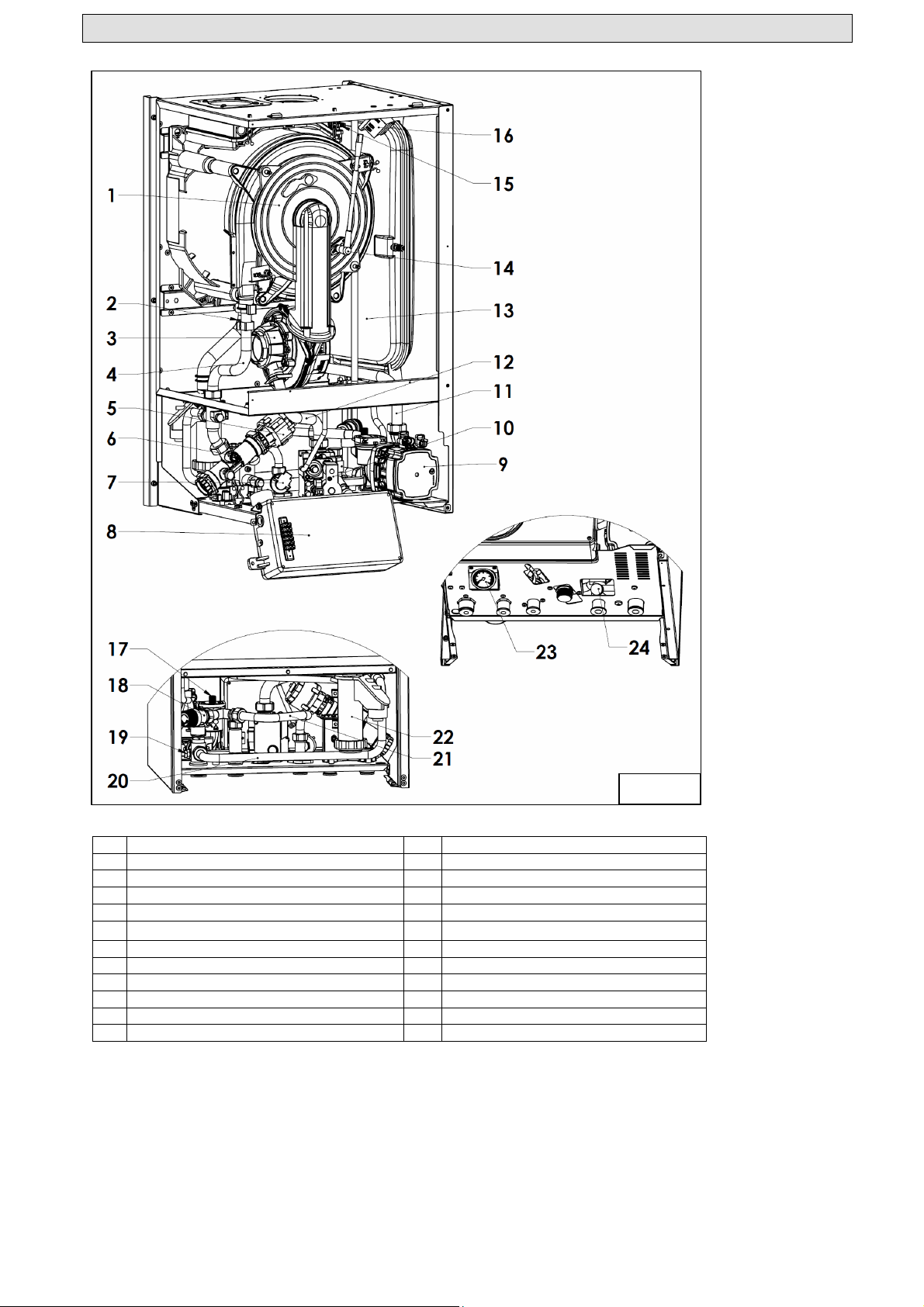

2.1.2 Structure of boiler type C38GC25-P

Tab. 2.1 Components of the condensing boiler

1 Main heat exchanger 14 Heating return connection

2 Built-in fan nozzle 15 Ignition electrode

3 Over-temperature thermostat 16 Expansion vessel

4 Heating tour connection 17 Flue gas temperature sensor

5 Gas supply connection 18 Ignition transformer

6 3-way valve actuator 19 Pressure relief valve 3 bar

7 Heating temperature sensor 20 Expansion vessel connection

8 Water pressure sensor 21

9 Domestic hot water temperature sensor 22

10 Electronic box 23

11 Gas valve 24

12 Pump 25

13 Pump automatic air vent 26 Filling tap

REV. 01.07.2019

Return heating temperature sensor

Pressure valve connection

Secondary heat exchanger

Drain trap for condense

Pressure gauge

6 din 37

USER MANUAL CENTRAL HEATING BOILER TYPE C38GC25; C38GC25-P; C38GC29; C38GC35; C38GC35-CH1; C38GC35-CH2

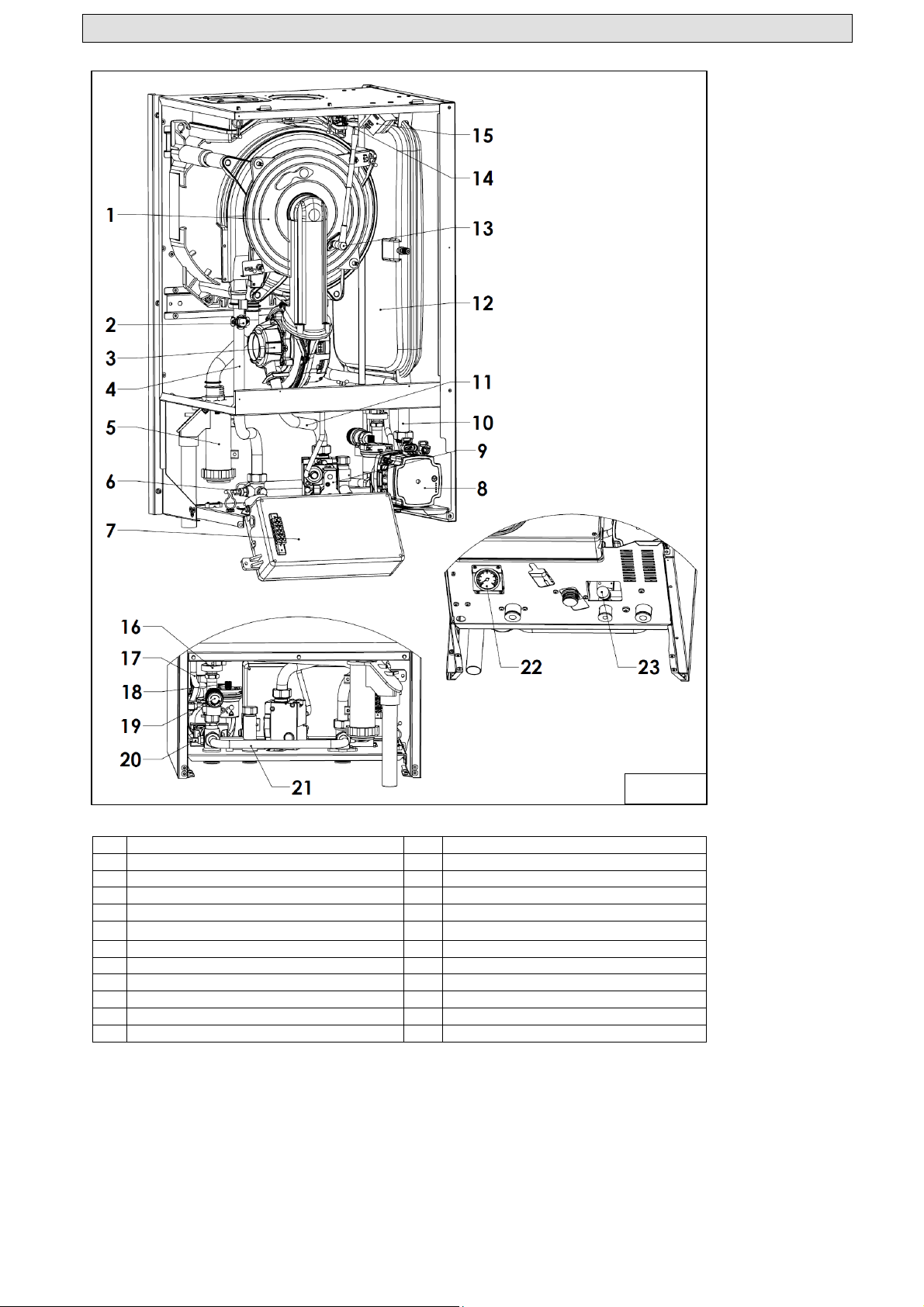

2.1.3 The structure of condensation mural central heating gas boilers C38GC35-CH1

Fig. 2.1

Tab.2.1 Components of the condensation mural central heating gas boiler

1 Main heat-exchanger 13 Expansion vessel

2 Primary circuit over-temperature thermostat 14 Ignition electrode

3 Fan with built-in nozzle 15 Flue gas temperature sensor

4 Heating tour connection 16 Ignition transformer

5 3-way valve actuator 17 Automated air vent

6 Heating temperature sensor 18 Pressure relief valve 3 bar

7 Water pressure sensor 19 Return heating temperature sensor

8 Electronic box 20 By-pass connection

9 Circulation pump 21 Return heating boiler

10 Gas valve 22 Drain trap for condense

11 Heating return connection 23 Pressure gauge

12 Gas supply connection 24 Filing tap

REV. 01.07.2019

7 din 37

USER MANUAL CENTRAL HEATING BOILER TYPE C38GC25; C38GC25-P; C38GC29; C38GC35; C38GC35-CH1; C38GC35-CH2

Fig.

2.1.4 The structure of condensation mural central heating gas boilers C38GC35-CH2

Tab.2.1 Components of the condensation mural central heating gas boiler

1 Main heat-exchanger 13 Ignition electrode

2 Primary circuit over-temperature thermostat 14 Flue gas temperature sensor

3 Fan with built-in nozzle 15 Ignition transformer

4 Heating tour connection 16 Water pressure senzor

5 Drain trap for condense

6 Heating temperature sensor 18 Automated air

7 Electronic box 19 Pressure relief valve 3 bar

8 Circulation pump 20 Return heating temperature sensor

9 Gas valve 21 By-pass connection

10 Heating return connection 22 Pressure gauge

11 Gas supply connection 23 Filing tap

12 Expansion vessel

17 Expansion vessel connection vent

REV. 01.07.2019

8 din 37

USER MANUAL CENTRAL HEATING BOILER TYPE C38GC25; C38GC25-P; C38GC29; C38GC35; C38GC35-CH1; C38GC35-CH2

2H (GN

-

G20)

with flow

Nominal power

2.2 Constructive and functional characteristics

Tab.1 Technical characteristics C38GC25, C38GC29, C38GC35

Commercial name MKDENS25 MKDENS35 MKDENS35

Type

Gas category to be used

Flue type Forced Forced Forced

Burning room Condensing Condensing Condensing

Efficiency stars (dir. 92/42/CEE) **** **** ****

Nox class 5 5 5

Heating energy efficiency class A A A

DHW energy efficiency class A A A

Min/Max CH power (kW) kW 2,8/26,7 3,0/30.6 3,5/33,9

Max power 80/60 (kW) kW 25,6 28,3 32,8

Max power 50/30 (kW) kW

Output performance at nominal heat input at

80/60 °C (PCI) (%)

Output performance at nominal heat input at

50/30 °C (PCI) (%)

Consum nominal maxim de combustibil mc/h 2,82 3,24 3,59

Gas pressure

Heating

circuit

DHW circuit

Electrical

characteristics

Height

Width

Depth

Height with installed elbow 850 mm

Pimary heat exchanger capacity ~35 kg

Height

Connec

tors

Expansion vessel with membrane

Evacuation type

Caracteristici constructive

Dimensions flue type

Flue temp. (50/30 °C) ~59 °C

Protection class Class IP40

Informative values:

(*)-The standard gas boiler is delivered flow restrictor of 12l/min

(**)-The standard gas boiler is delivered with dual coaxial kit as accessory; dual kit is delivered as accessory on demand

REV. 01.07.2019

Maximum pressure on the hot water circuit minim 0,8 bar - maxim 3 bar

Temperature adjustment interval radiators 30÷80 °C

Temperature adjustment interval underfloor 15÷45 °C

Temperature adjustment interval 30÷60 °C

Temperature adjustment interval-boiler mode 70 °C

DHW Confort EN 13203 ***

Hot water flow at ∆ t = 30 °K

* flow restrictor 12l/min

GN (on the regulator) 20 mbar (max. 25 mbar, min. 17 mbar)

GN max 35 mbar

Power ~230VAC/50 Hz

Thermal input, output 3/4‘’

Cold water input, hot water output 1/2'’

Gas input 3/4'’

Maximum water capacity in central

heating installation

%

% 106 106 106

C38GC25 C38GC35 C38GC35

I

28,2 32,4 35,8

97 97 97

12 l/min with flow

restrictor *

13,5 l/min without

flow restrictor *

81 W

713 mm

415 mm

330 mm

~1,4 l

7 l

B23; B33; C13; C13x; C23; C23x; C33; C33x; C43; C43x; C53;

C53x; C63; C63x; C73; C73x; C83; C83x; C93; C93x

Lenght for coaxial flue D60/D100: min. 1m - max. 20m**

Lenght for dual flue D80/D80: min. 1m - max. 20m

*** ***

12 l/min with flow

restrictor *

15,7 l/min without

flow restrictor *

81W

713 mm

415 mm

390 mm

860 mm

~36 kg

~1,6 l

7 l

~49 °C ~69 °C

200 l 200 l 200 l

12 l/min

restrictor *

17 l/min without

flow restrictor *

81 W

713 mm

415 mm

390 mm

860 mm

~36 kg

~1,8 l

7 l

9 din 37

USER MANUAL CENTRAL HEATING BOILER TYPE C38GC25; C38GC25-P; C38GC29; C38GC35; C38GC35-CH1; C38GC35-CH2

2H (GN

-

G20)

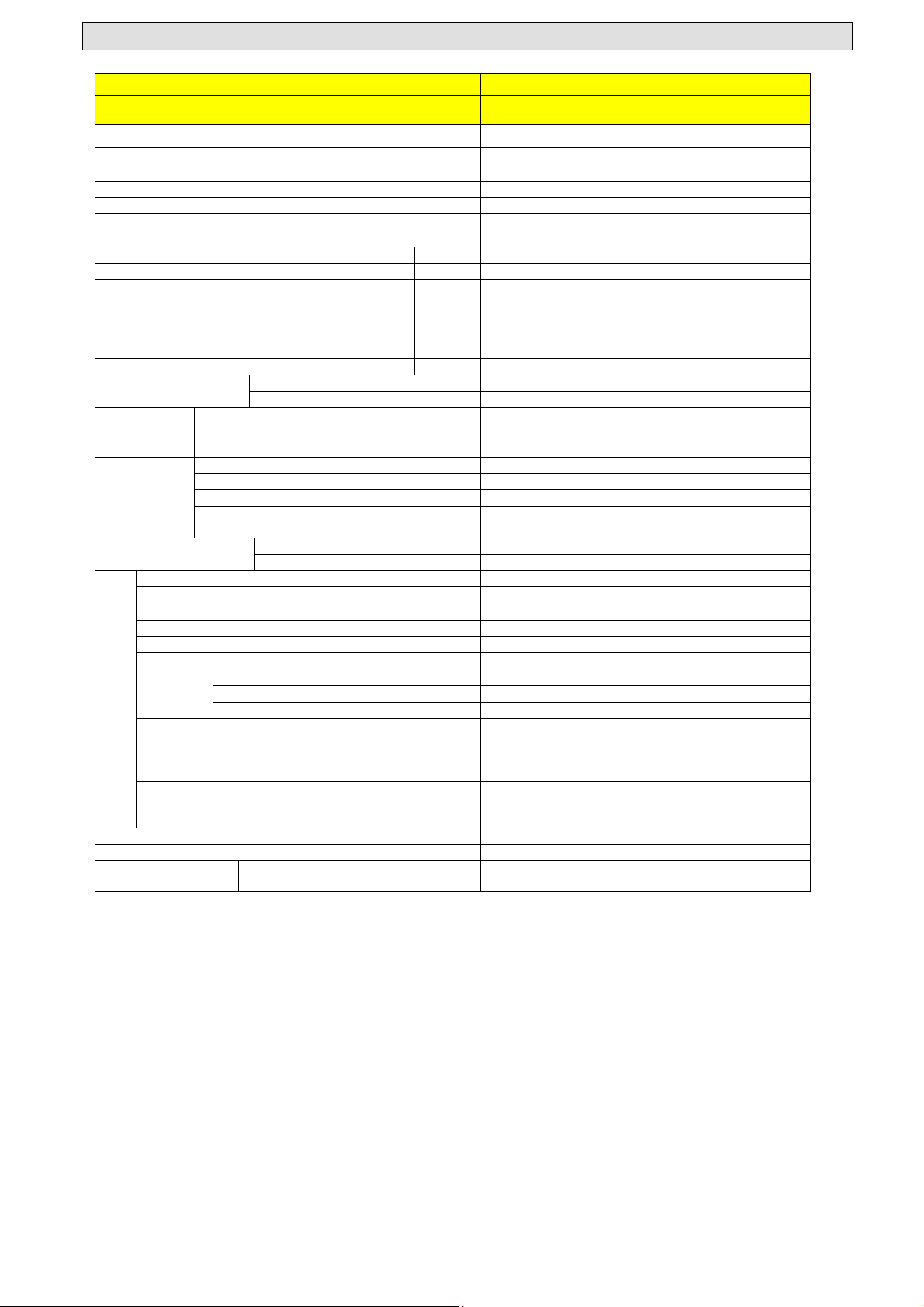

Tab.1 Technical characteristics C38GC25-P

Commercial name MKDENS25

Type

Gas category to be used

Flue type Forced

Burning room Condensing

Efficiency stars (dir. 92/42/CEE) ****

Nox class 5

Heating energy efficiency class A

DHW energy efficiency class A

Min/Max CH power (kW) kW

Max power 80/60 (kW) kW 25,6

Max power 50/30 (kW) kW 28,2

Output performance at nominal heat input at

80/60 °C (PCI) (%)

Output performance at nominal heat input at

50/30 °C (PCI) (%)

Consum nominal maxim de combustibil mc/h 2,82

Gas pressure

Heating

circuit

DHW circuit

Electrical

characteristics

Height

Width

Depth

Height with installed elbow 860 mm

Pimary heat exchanger capacity ~35 kg

Height

Connec

tors

Expansion vessel with membrane

Evacuation type

Dimensions flue type

Caracteristici constructive

Flue temp. (50/30 °C) ~59 °C

Protection class Class IP40

Informative values:

(*)-The standard gas boiler is delivered flow restrictor of 12l/min

(**)-The standard gas boiler is delivered with dual coaxial kit as accessory; dual kit is delivered as accessory on demand

Maximum pressure on the hot water circuit minim 0,8 bar - maxim 3 bar

Temperature adjustment interval radiators 30÷80 °C

Temperature adjustment interval underfloor 15÷45 °C

Temperature adjustment interval 30÷60 °C

Temperature adjustment interval-boiler mode 70 °C

DHW Confort EN 13203 ***

Hot water flow at ∆ t = 30 °K

GN (on the regulator) 20 mbar (max. 25 mbar, min. 17 mbar)

GN max 35 mbar

Power ~230VAC/50 Hz

Nominal power

Thermal input, output 3/4‘’

Cold water input, hot water output 1/2'’

Gas input 3/4'’

Maximum water capacity in central

heating installation

C38GC25-P

I

2,8/26,7

% 97

% 106

12 l/min with flow restrictor *

13,5 l/min without flow restrictor *

81 W

722 mm

415 mm

330 mm

~1,4 l

7 l

B23; B33; C13; C13x; C23; C23x; C33; C33x; C43;

C43x; C53; C53x; C63; C63x; C73; C73x; C83; C83x;

C93; C93x

Lenght for coaxial flue D60/D100: min. 1m - max.

20m**

Lenght for dual flue D80/D80: min. 1m - max. 20m

200 l

REV. 01.07.2019

10 din 37

USER MANUAL CENTRAL HEATING BOILER TYPE C38GC25; C38GC25-P; C38GC29; C38GC35; C38GC35-CH1; C38GC35-CH2

2H (GN

-

G20)

Nominal power

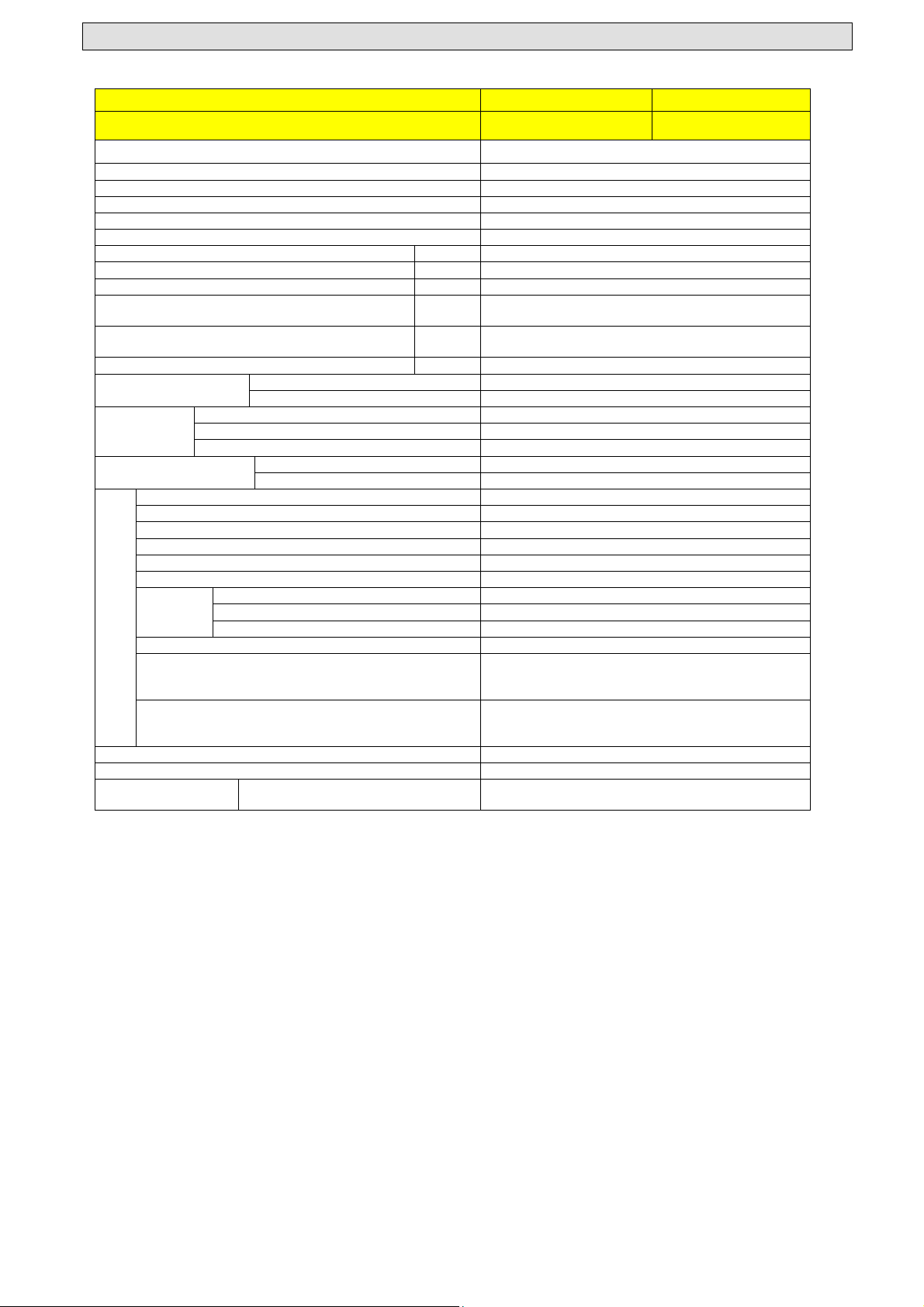

Tab.1 Technical characteristics C38GC25-CH1, C38GC35-CH2

Commercial name C38GC25-CH1 C38GC25-CH2

Type MKDENS35 TERMOV MKDENS35 TERMO

Gas category to be used

Flue type Forced

Burning room Condensing

Efficiency stars (dir. 92/42/CEE) ****

Nox class 5

Heating energy efficiency class A

Min/Max CH power (kW) kW

Max power 80/60 (kW) kW 32,8

Max power 50/30 (kW) kW 35,8

Output performance at nominal heat input at

80/60 °C (PCI) (%)

Output performance at nominal heat input at

50/30 °C (PCI) (%)

Consum nominal maxim de combustibil mc/h 3,59

Gas pressure

Heating

circuit

Electrical

characteristics

Height

Width

Depth

Height with installed elbow 860 mm

Pimary heat exchanger capacity ~36 kg

Height

Connec

tors

Expansion vessel with membrane

Evacuation type

Dimensions flue type

Caracteristici constructive

Flue temp. (50/30 °C) ~59 °C

Protection class Class IP40

Informative values:

(**)-The standard gas boiler is delivered with dual coaxial kit as accessory; dual kit is delivered as accessory on demand

Maximum pressure on the hot water circuit minim 0,8 bar - maxim 3 bar

Temperature adjustment interval radiators 30÷80 °C

Temperature adjustment interval underfloor 15÷45 °C

GN (on the regulator) 20 mbar (max. 25 mbar, min. 17 mbar)

GN max 35 mbar

Power ~230VAC/50 Hz

Thermal input, output 3/4‘’

Cold water input 1/2'’

Gas input 3/4'’

Maximum water capacity in central

heating installation

I

3,5/33,9

% 97

% 106

81 W

722 mm

415 mm

386 mm

~1,8 l

7 l

B23; B33; C13; C13x; C23; C23x; C33; C33x; C43;

C43x; C53; C53x; C63; C63x; C73; C73x; C83; C83x;

C93; C93x

Lenght for coaxial flue D60/D100: min. 1m - max.

20m**

Lenght for dual flue D80/D80: min. 1m - max. 20m

200 l

REV. 01.07.2019

11 din 37

USER MANUAL CENTRAL HEATING BOILER TYPE C38GC25; C38GC25-P; C38GC29; C38GC35; C38GC35-CH1; C38GC35-CH2

3

Safety instructions

3.1 Instalation and adjustment

Installation and commissioning can be done only by a company authorized and agreed by KÖBER SRL-Vaduri Branch!

This company will assume responsibility for the correct installation and commissioning.

Adjustment work, as well as maintenance and repair are allowed to be performed only by a company authorized and agreed

by KÖBER SRL-Vaduri Branch!

3.2 Gas smell

When gas smell appears, take the following into account:

- Do not activate electric switches in the dangerous zone;

- Do not smoke in the dangerous zone;

- Do not use mobile phones in the dangerous zone;

- Turn off the gas tap;

- Air the dangerous zone;

- Notify the gas distribution company.

3.3 Changes in the area adiacent to the heating BOILER

Modifications of the following installations are not allowed:

- The central heating BOILER;

- The gas or water pipes or electric cables;

- Air/ gas incoming/ outgoing pipes.

Danger!

Danger of death by poisoning and explosion because of breeches in the gas pipes and connections in case of

incorrect installation!

Danger of deterioration when inappropriate tools are used. For tightening or unscrewing connection screws use

appropriate wrenches (no box wrenches, extensions etc).

4

Mounting

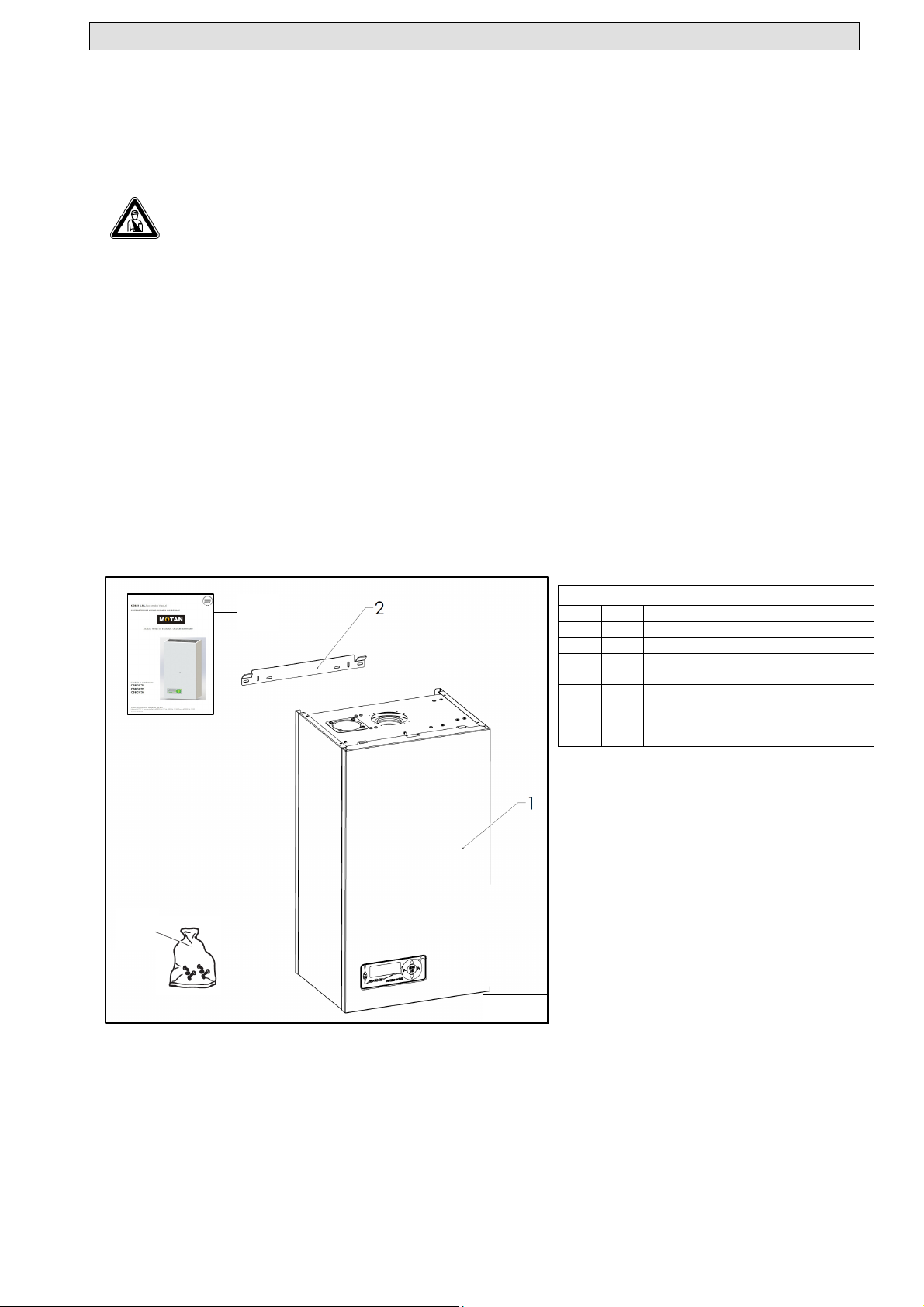

4.1 Mounting set

Check whether the mounting set is complete and undamaged – see table 2.

4

3

Fig. 1.1

Tab. 2 Mounting set

Pcs.

Pos.

1 1 BOILER

2 1 BOILER support

3 1

4 1

Description

Bag of small elements - it contains:

- mounting screws 8x80 - 2 items.

Printed packet – it contains:

- user manual - 1 item

- CE conformity declaration - 1 item

- warranty certificate – 1item

REV. 01.07.2019

12 din 37

Loading...

Loading...