Kobelco SK210LC, SK250-6E User Manual

Kobelco

Dynamic

Acera

Kobelco Construction Machinery America LLC

Machine Familiarization

Dynamic Acera 03/05 Rev. 05

Kobelco Construction

Machinery America LLC

Page 3-1

MACHINE FAMILIARIZATION

DYNAMIC ACERA SERIAL NUMBER RANGE

SK160LC YM02U0101 ~

ED190LC YL02U0101 ~

SK210LC YQ07U0101 ~

SK250LC LL08U0101 ~

SK290LC LB03U0101 ~

SK330LC YC06U0101 ~

SK480LC YS06U0101 ~

MINOR CHANGE SERIAL NUMBER RANGE

SK160LC YM03U0522 ~

ED190LC YL03U0136 ~

SK210LC YQ08U0969 ~

SK250LC LL09U0575 ~

SK290LC LB04U0298 ~

SK330LC YC07U0623 ~

Note: Minor Change information is designated

in much of this manual with either the words

“minor change or abbreviation “M/C”.

Page 3-2

Kobelco Construction

Machinery America LLC

Dynamic Acera 03/05 Rev. 05

_

_

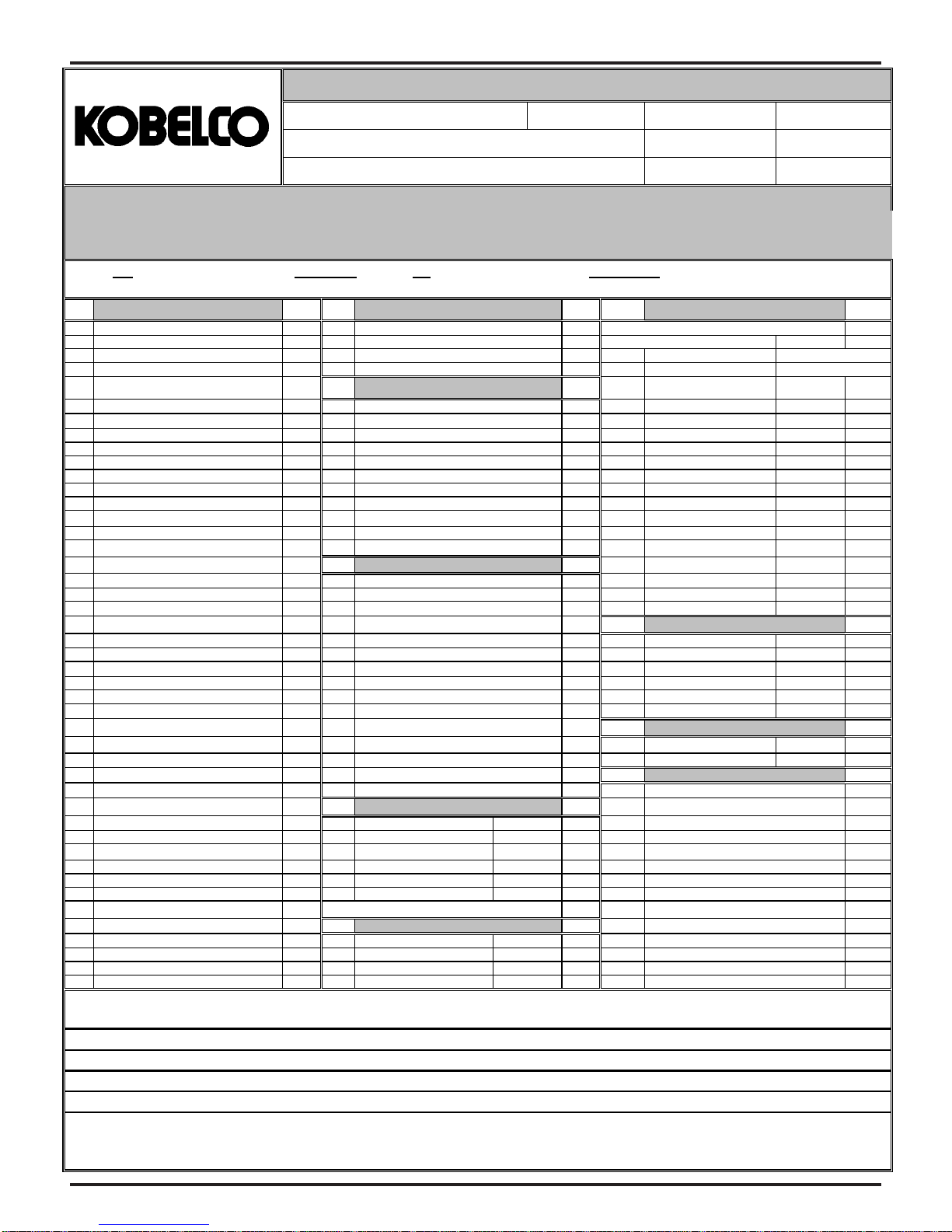

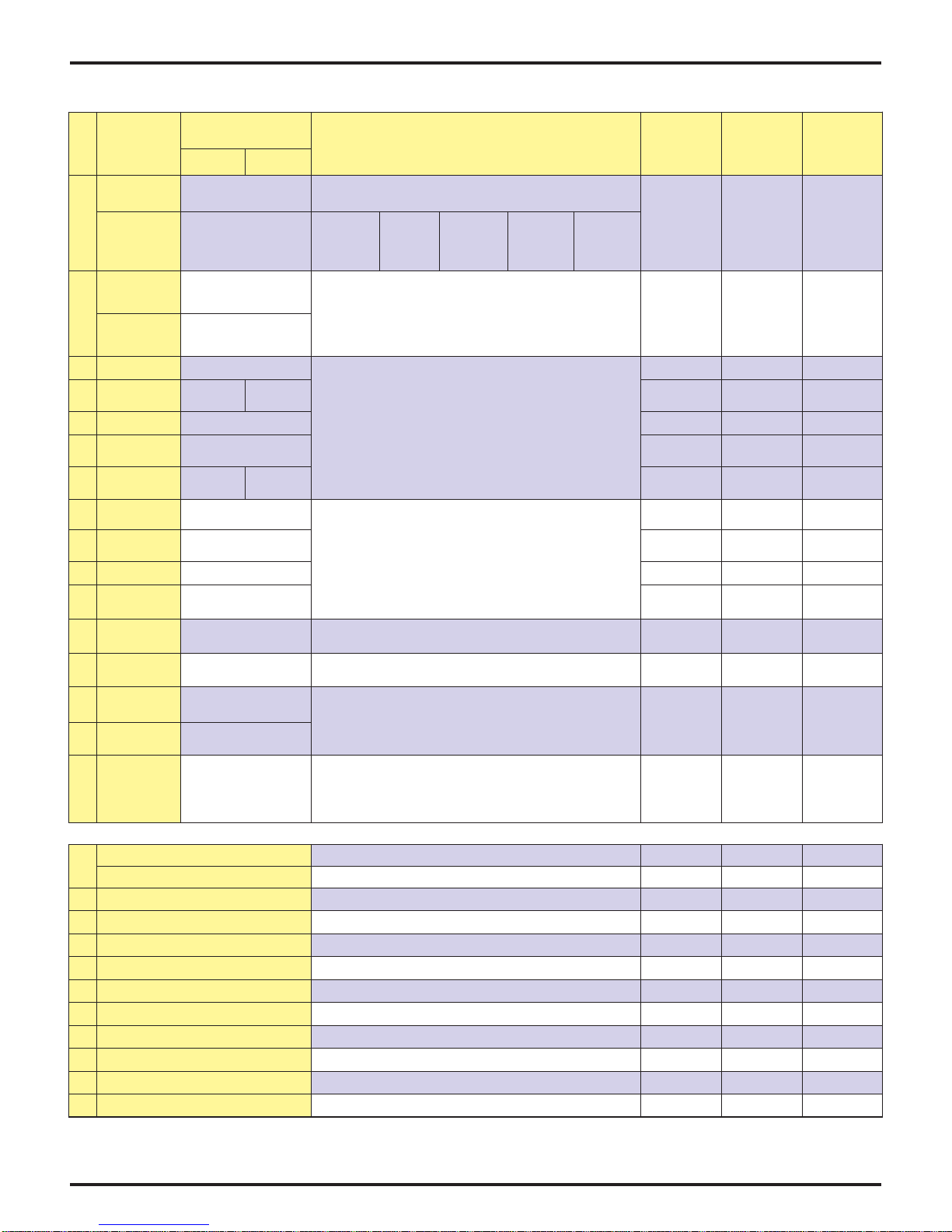

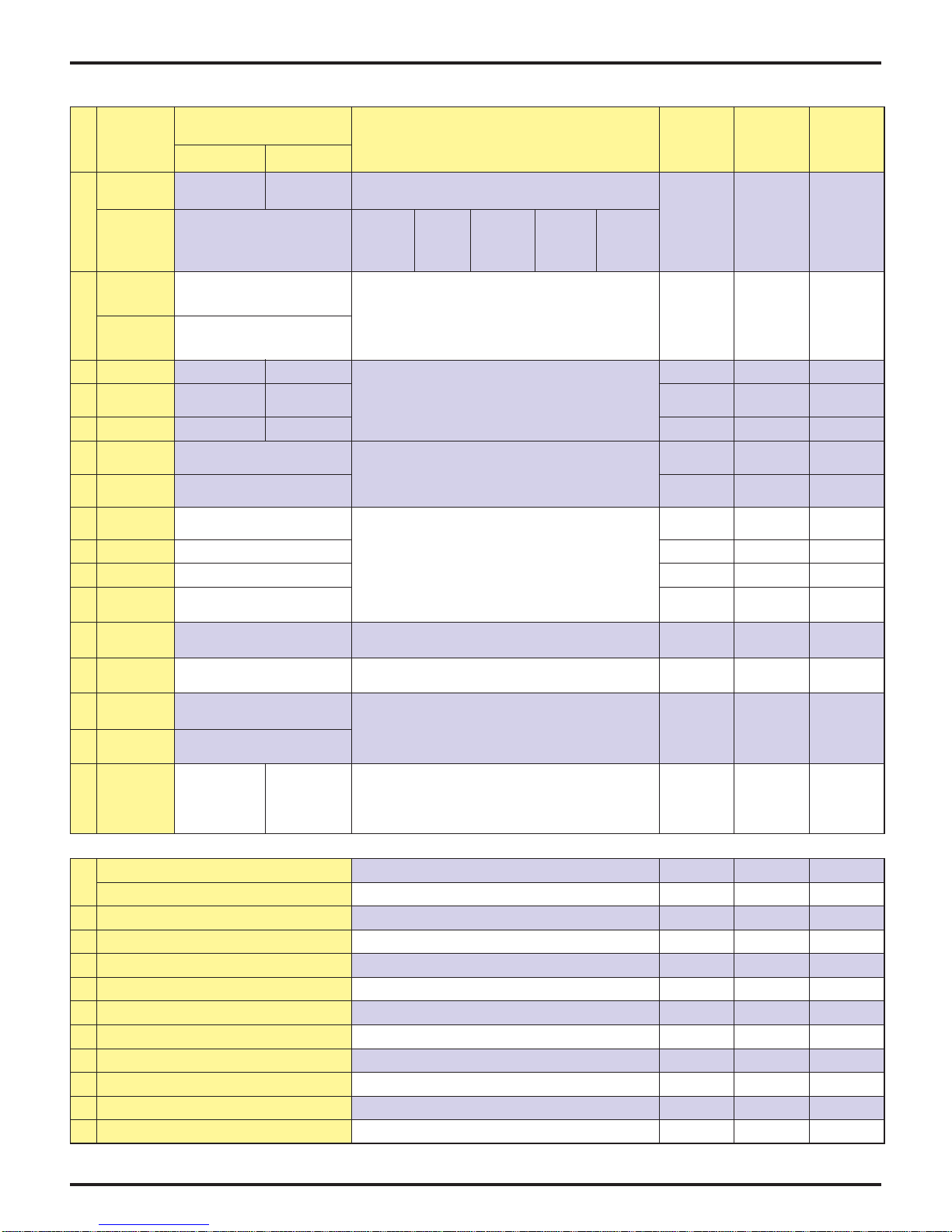

COMPACT, SR, & DYNAMIC ACERA PRE-DELIVERY INSPECTION

_

p

Dealer Name

Address

City State Zip Code:

Dlr. Code Model No.

Serial No.

Hr. Meter

Engine Model _______________________ Engine S/N ___________________________ Bkt. Mfg. _________________________ S/N _________________________

Attachment Type _________________________ Make ______________________ S/N ____________________ Arm Length ___________ Boom Length __________

Arm Cyl. S/N ____________________ Bkt. Cyl. S/N ___________________ Boom Cyl. (L.H.) S/N____________________ Boom Cyl. (R.H.) S/N___________________

Place a "C" in the column if the item is CORRECT. Place a "I" in the column if the item is INCORRECT , and explain by item number under the

comments section. Fill in the blanks provided beside each item.

Visual Checks Miscellaneous

1 Appearance (Overall) 11 40

Good 12 * Display Number

2 Glass * No. 1 Main Cont. P/No.

Dirty Program Version

Broken C/I * No. 2 Eng.Speed Rpm

3 Paint Defects 13 Low Idle (Set Val.)

Cab 14 Engine Coolant Low Idle (Meas. Val)

Upper Frame 15 High Idle (Set Val.)

Lower Frame 16 High Idle (Meas. Val)

Attachments 17 Auto Accel

Counterweight 18 A/S-Mode High Idle

4 Cab 19 B/FC-Mode High Idle

Appearance (Good) 20 * No. 14 C-1 Pump P-1 w/H.L.

Cab Mounting 21 C-1 Pump P-1 w/H.L.

Instrument panels 22 C-1 Pump P-1

Seat assembly 23 C-1 Pump P-1

Cab operation levers C/I C-2 Pump P-2 w/H.L.

Switches / Controls 24 C-2 Pump P-2 w/H.L.

Radio/Speakers C-2 Pump P-2.

Air Cond. / Heating Unit C-2 Pump P-2

Gauge / Warning Lamps 25 C/I

5 Decals 41 Boom Cyl - Out

Misapplied / Damaged 42 Boom Cyl. - In

Wrong/Missing Decal 26 43 Arm Cyl. - Out

6 Hoses,Tubes, Fittings 44 Arm Cyl. - In

Powertrain components 45 Bucket Cyl. - Out

Upper - Loose/Routing 27 46 Bucket Cyl. - In

Lower - Loose/Routing C/I

Attach.- Loose/ Routing 28 47 Swing Speed - LH

7 All Bolts & Fasteners 29 48 Swing Speed - RH

Powertrain components C/I

Upper 49

Lower C/I

Attach. 30 Pilot System Pressure 50

8 Wiring Harness 31 Main Relief w/H.L. *

Routing / Misassembly 32 Main Relief 51

Connections loose 33 Dozer Main Relief *

9 Component Fluid Leakage 34 Swing Port Relief - L

Engine Assembly 35 Swing Port Relief - R

Hyd. Control Valve

Hyd. Main Pump C/I

Hyd. Travel Motor/Red. 36 P1 Main 54

Hyd. Swing Motor/Red. 37 P2 Main

10 Track Adjustment 38 P3 Main

Proper Tension

C/I C/I C/I

Basic Machine Operation Proper

Support Packages

Manual Missing

Parts Missing

Fluid Levels / Lubrication

Engine Oil Level

o

F

Engine Coolant level

Hydraulic Oil Level

Swing Gear Bath

Swing Reduction Unit

Travel Reduction Unit - L.H

Travel Reduction Unit - R.H

Lubricate Attachments

Check Fuel Water Sep.

Check Pilot Filter

Engine Checks

Air Intake/Exhaust Connections

Loose/Misassemble - Connectors

Leaking - Hoses/Tubes/Fittings

Exhaust Connections

Loose/Misassemble - Connectors

Leaking - Hoses/Tubes/Fittings

Fuel System Connections

Loose/Misassemble Connectors

Hoses/Tube/Fitting Leaking

Oil & Fuel Filters

Loose / Leaking

Fan Belt Adjustment

Air Cleaner Elements

Missing

Damaged

Hyd. System.Press. (SK70 ~330)

psi

psi

psi

psi

psi

psi

(

) Note: If applicable for specific machine

*

Hyd. System Press. (Compact Exc.)

psi

psi

psi

39 P4 Main

psi

Service Diagnostic Check

Condition M/H- Mode

Cylinder Cycle Times, M/H-Mode

Swing System Performance

Electrical System

Work & Cab Lights

Inoperable

Swing Flashers

Inoperable

Horn

Inoperable

Pilot Lever Lock Switch

52

Inoperable

53

Travel Alarm

Inoperable

Battery

Electrolyte Level

Charge (Low)

rpm

rpm

rpm

rpm

rpm

rpm

rpm

V

K

V

K

V

K

V

K

Sec

Sec

Sec

Sec

Sec

Sec

Sec

Sec

Comments: (Please enter line item # and Description)

Completed By:_____________________________________ Completed Date:________________

Rev. # 2.0 Form# 00020MIVALL

Dynamic Acera 03/05 Rev. 05

Note:

Please promptly submit this form to the Kobelco

Service Department via mail or the Kobelco Internet

System. For assistance please contact the Kobelco

Service De

t.

Page 3-3

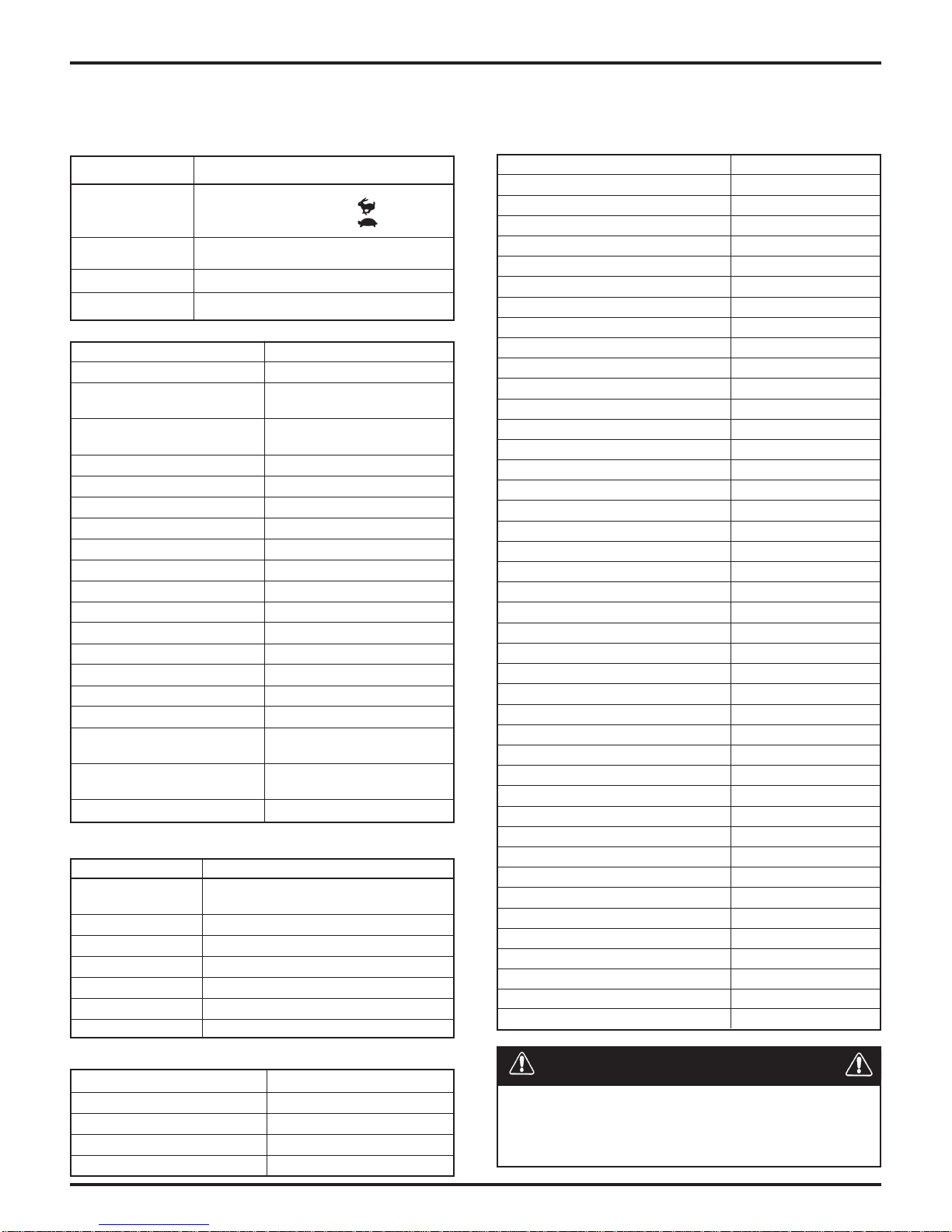

MACHINE FAMILIARIZATION

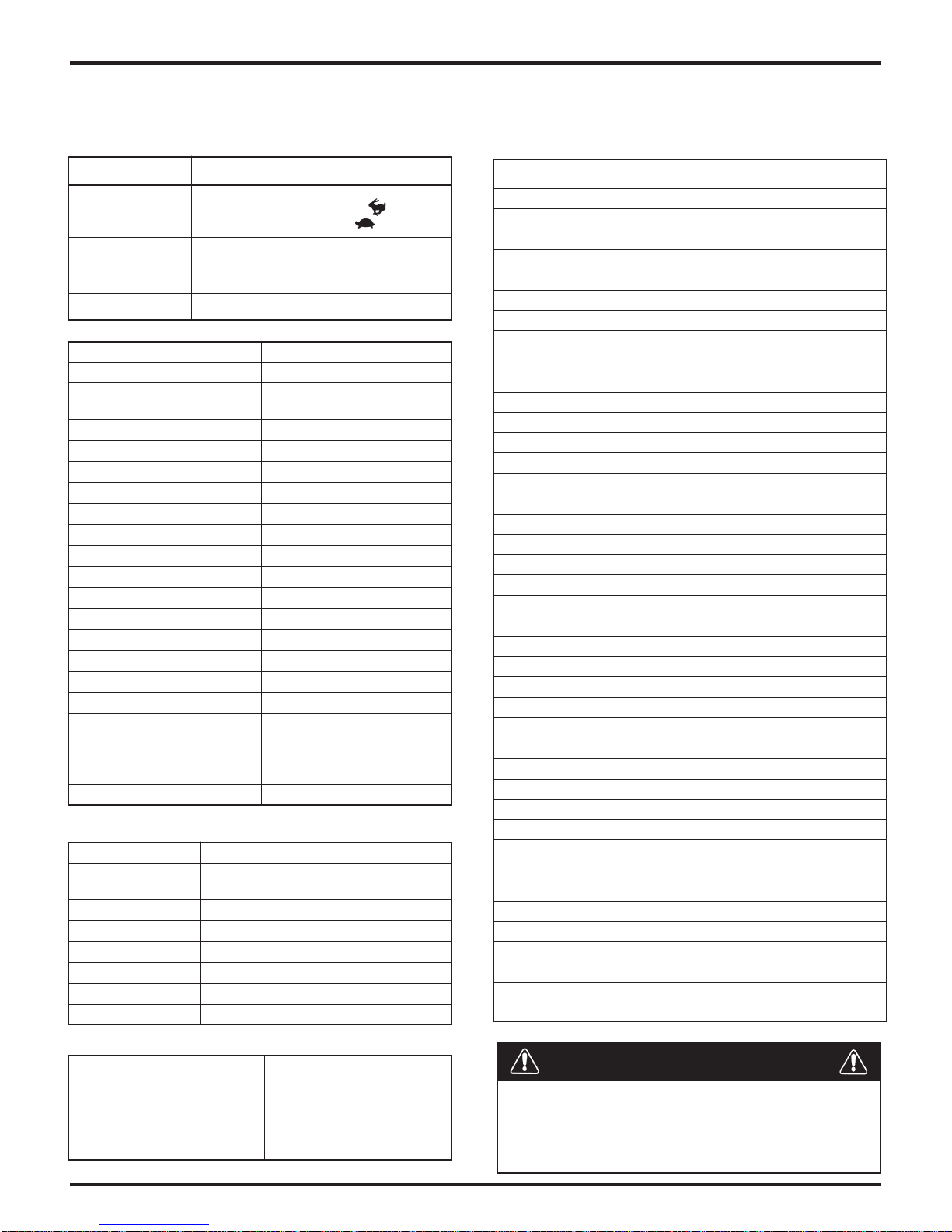

SK160LC-VI -

The following performance specifications are based on the standard machine with standard attachment.

1. Travel Speed, Swing Speed & Gradeability

DESCRIPTION SPECIFICATION

TRAVEL SPEED 6.0 km per hr (3.7 mph) in mode.

SWING SPEED 11 RPM IN M-Mode / “HI” Idle.

GRADEABILITY 70% (35°) {Limited by engine lubrication}

DRAWBAR FORCE 156 KN (35,100 lbs)

2. Engine

Engine Maker Mitsubishi

Model 4D34-TEG

Type

Number of Cylinders– Bore X Stroke

4.53")

Displacement 3.91 liter (238 cu in.)

Compression Ratio 16.5 : 1

Output Rating 82 kW (111 HP) / 2,200 rpm

Maximum Torque 382 N•m (283 lb-ft)/ 1,800 rpm

Ignition Order 1–3–4–2 CCW Viewed from Flywheel

Injection Timing 16° Before Top Dead Point

Intake Valve Clearance Cold 0.4 mm (0.0157")

Exhaust Valve Clearance Cold 0.4 mm (0.0157")

Electrical System D.C. 24 V

Starting Motor 24 V–5.0 kW

Alternator 24 V–35 A

Batteries 2– 12 V- (136 Ah)

Engine Dry Weight* 403 kg (888 lbs)

Thermostat Begin to open at 76.4°C (169°F).

Cooling Fan Drive Method Ø545mm (Ø21.5") Suction Type Belt

Air Cleaner Dry Type with Safety Elements

3. Hydraulic Components

COMPONENT TYPE

HYDRAULIC PUMPS Tandem, Variable Displacement,

2X143 L/min (2x37.9 Gal/min)

SWING MOTOR Axial Piston

TRAVEL MOTOR Axial Piston

CONTROL VALVES 6 Spool Multiple Control

CYLINDERS (ALL) Double Acting

RETURN FILTER Safety Valve containing Filter Type

OIL COOLER Air Cooled

4. Operating Pressures

PILOT SYSTEM 50 (710)

IMPLEMENT 350 (4980)

SWING 285 (4050)

TRAVEL 350 (4980)

POWER BOOST/HEAVY LIFT 385 (5470)

PERFORMANCE SPECIFICA TIONS

4.0 km per hr (2.5 mph) in mode.

4-Cycle, Water Cooled, Direct

Injection with Turbocharger , Diesel

4–104 mm X 115 mm (4.09" X

Full open at 90°C (194°F).

Drive Pulley Ratio : 0.85

*Less flywheel and electrics.

Axial Piston with Pilot Gear Pump.

Kgf/cm2 (psi)

MACHINE & COMPONENT WEIGHTS

The following weight specifications are based on

the standard machine with standard attachment.

Unit: Kg (lb)

COMPONENT SK160LC-VI

COMPLETE MACHINE (STANDARD) 16,700 (36,800)

UPPER FRAME ASSEMBL Y

UPPER FRAME + COV & GUARDS 1,831 (4,037)

COUNTERWEIGH 3,007 (6,629)

CAB + ELECT + PANEL + SEAT + AC 415 (915)

*BOOM CYLINDER + lower pins 165 (322) X 2

*ENGINE + MUFFLER + ACCESS 431 (950)

RADIA TOR & OIL COOLER 75 (165)

PUMP ASSEMBLY + COUPLER 108 (198)

CONTROL V AVE 250 (551)

*FUEL T ANK 99 (218)

*HYDRAULIC TANK 102 (225)

SWING MOTOR & REDUCTION UNIT

HYDRAULIC PIPES & HOSES 316 (697)

LOWER FRAME ASSEMBL Y

FRAME + Guides + Covers + Piping 2,162 (4,766)

SLEWING RING ASSY 218 (481)

TRAVEL MOTOR & REDUCTION UNIT

TRACK TENSION + IDLERS 210 (463) X2

LOWER ROLLER ASSEMBL Y 35 (77) X14

UPPER ROLLER ASSEMBL Y 17 (37) X4

SPROCKET 72 (159) X2

SWIVEL JOINT 30 (66)

TRACK LINK W/ 600mm (23.6") SHOES

ATT ACHMENT (STANDARD) 2,638 (5,816)

BUCKET ASSEMBL Y [0.52m3 (0.68 yd3)]

ARM ASSEMBL Y

ARM [3.10 m (10’-2”)] 564 (1,340)

*BUCKET CYL + 2 PINS 142 (313)

IDLER LINKS 32 (71)

BUCKET LINK 65 (143)

PINS (4- for bucket, & links)

BOOM ASSEMBL Y 1,411 (3,11 1)

BOOM + Cyl. pin + Foot pin 1,176 (2,593)

*ARM CYLINDER + 2 PINS 215 (474)

PIN (Mounting the Arm) 20 (44)

FLUIDS 311 (686)

HYD OIL 139 (306)

ENG OIL 14 (31)

FUEL 139 (306)

WATER 19 (42)

BOLTS & OTHEER 291 (642)

[3.10 m (10’-2”)]

6,852 (15,106)

204 (450)

6,608 (14,568)

217 (478) X2

1,321 (2,912) X2

370 (816)

857 ( 1,889 )

54 (119)

* DRY WEIGHT

WARNING

USE ONLY LIFTING DEVICES AND EQUIPMENT

WITH RA TED CAPACITIES SUFFICIENT T O LIFT THE

SPECIFIC COMPONENT(S) BEING REMOVED OR

INSTALLED.

Page 3-4

Dynamic Acera 03/05 Rev. 05

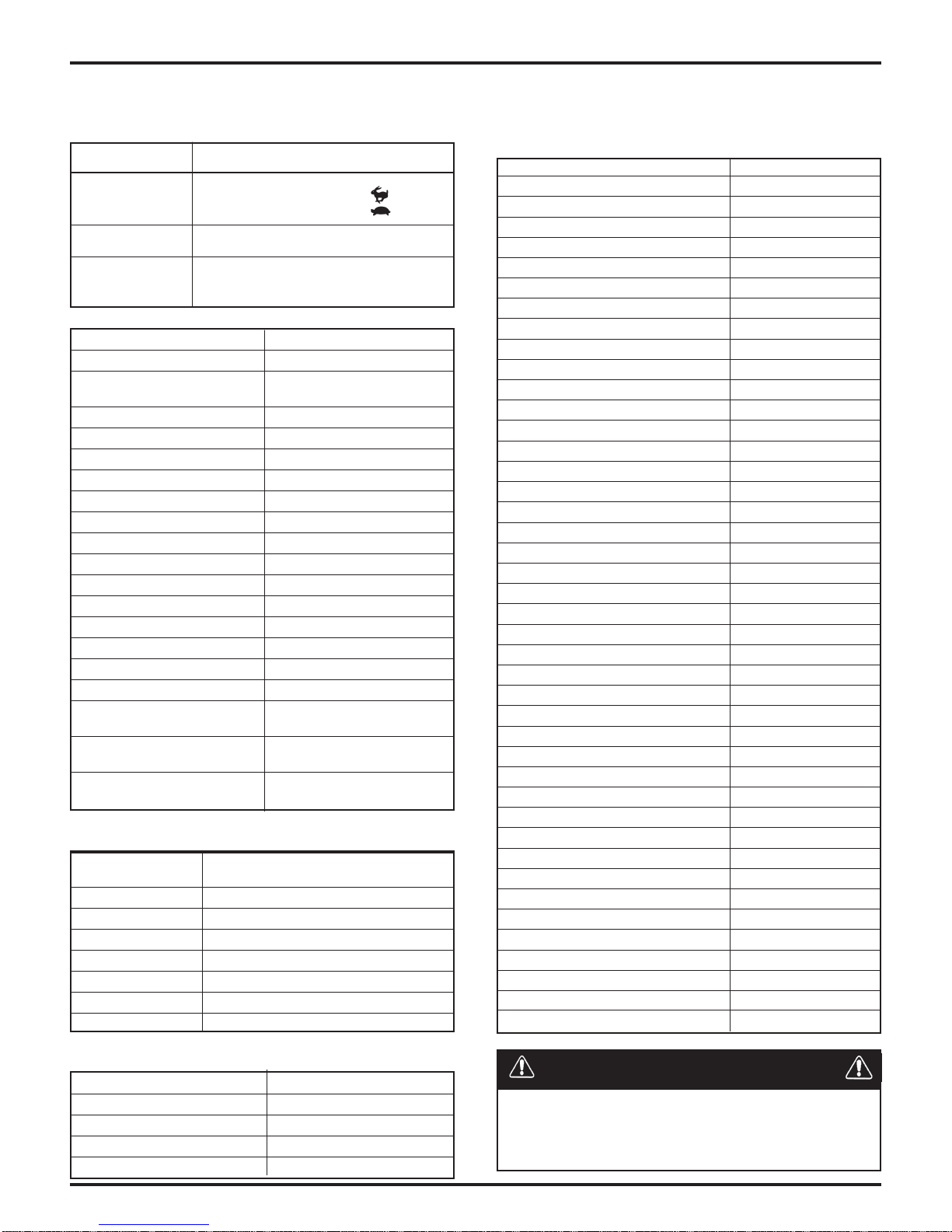

MACHINE FAMILIARIZATION

ED190 -

DESCRIPTION SPECIFICATION

TRAVEL SPEED 6.0 km per hr (3.7 mph) in

SWING SPEED 11 RPM IN M-Mode / “HI” Idle.

GRADEABILITY 70% (35°) Limited by engine lubrication

DRAWBAR FORCE 189 KN (42,556 lbs)

Engine Maker Mitsubishi

Model 4D34-TEG

Type

Number of Cylinders : 4 – Bore X Stroke

Displacement 3.91 liter (238 cu in.)

Compression Ratio 16.5 : 1

Output Rating 82 kW (11 1 HP) / 2,200 rpm

Maximum Torque 382 N•m (283 lb-ft)/ 1,800 rpm

Ignition Order 1–3–4–2 CCW Viewed from Flywheel

Injection Timing 16° Before Top Dead Point

Intake Valve Clearance Cold 0.4 mm (0.0157")

Exhaust Valve Clearance Cold 0.4 mm (0.0157")

Electrical System D.C. 24 V

Starting Motor 24 V–5.0 kW

Alternator 24 V–35 A

Batteries 2– 12 V- (136 Ah)

Engine Dry Weight* 403 kg (888 lbs)

Thermostat Begin to open at 76.4°C (169°F).

Cooling Fan Drive Method Ø545mm (Ø21.5") Suction Type Belt

Air Cleaner Dry Type with Safety Elements

COMPONENT TYPE

HYDRAULIC PUMPS Tandem, Variable Displacement,

2X143 L/min (2x37.9 Gal/min)

DOZER PUMP Gear Pump 61.6 L/Min (16.3/Gal/min

SWING MOTOR Axial Piston

TRAVEL MOTOR Axial Piston

CONTROL VALVES 7 Spool Multiple Control

CYLINDERS (ALL) Double Acting

RETURN FIL TER Safety Valve containing Filter Type

OIL COOLER Air Cooled

4. Operating Pressures

PILOT SYSTEM 50 (710)

IMPLEMENT 350 (4980)

SWING 285 (4050)

TRAVEL 350 (4980)

POWER BOOST/HEAV Y LIFT 385 (5470)

Dynamic Acera 03/05 Rev. 05

PERFORMANCE SPECIFICATIONS

The following performance specifications are based on the

standard machine with standard attachment.

1. Travel Speed, Swing Speed & Gradeability

3.6 km per hr (2.2 mph) in mode.

2. Engine

4-Cycle, Water Cooled, Direct Injection

with Turbocharger, Diesel

104mm X 115mm (4.09" X 4.53")

Full open at 90°C (194°F).

Drive Pulley Ratio : 0.85

*Less flywheel and electrics.

3. Hydraulic Components

Axial Piston with Pilot Gear Pump.

mode.

Kgf/cm2 (psi)

MACHINE & COMPONENT WEIGHTS

The following weight specifications are based on

the standard machine with standard attachment.

Unit: Kg (lb)

COMPONENT ED190-VI

COMPLETE MACHINE (STANDARD) 19,820 (43,704)

UPPER FRAME ASSEMBL Y

UPPER FRAME + COV & GUARDS 1,405 (3.091)

COUNTERWEIGHT 3,007 (6,615)

CAB + ELECT + PANEL + SEAT + AC 415 (915)

*BOOM CYLINDER + lower pins 165 (322) X 2

*ENGINE + MUFFLER + ACCESS. 431 (950)

RADIA TOR & OIL COOLER 75 (165)

PUMP ASSEMBLY + COUPLER 108 (238)

CONTROL VALVE 250 (551)

*FUEL T ANK 99 (218)

*HYDRAULIC TANK 102 (225)

SWING MOTOR & REDUCTION UNIT

HYDRAULIC PIPES & HOSES 316 (697)

LOWER FRAME ASSEMBL Y

FRAME + Guides + Covers + Piping 2,162 (4,766)

SLEWING RING ASSY 218 (481)

TRAVEL MOTOR & REDUCTION UNIT

TRACK TENSION + IDLERS 210 (463) X2

LOWER ROLLER ASSEMBL Y 35 (77) X14

UPPER ROLLER ASSEMBL Y 17 (37) X4

SPROCKET 72 (159) X2

SWIVEL JOINT 30 (66)

TRACK LINK W/ 600mm (23.6") SHOES

ATT ACHMENT (STANDARD) 2,638 (5,816)

BUCKET ASSEMBL Y [0.52m3 (0.68 yd3)]

ARM ASSEMBL Y

ARM [3.10 m (10’-2”)] 564 (1,340)

*BUCKET CYL + 2 PINS 142 (313)

IDLER LINKS 32 (71)

BUCKET LINK 65 (143)

PINS (4- for bucket, & links)

BOOM ASSEMBL Y 1,411 (3,111)

BOOM + Cyl. pin + Foot pin 1,176 (2,593)

*ARM CYLINDER + 2 PINS 215 (474)

PIN (Mounting the Arm) 20 (44)

FLUIDS 311 (686)

HYD OIL 139 (306)

ENG OIL 14 (31)

FUEL 139 (306)

WATER 19 (42)

BOL TS & OTHERS 291 (642)

[3.10 m (10’-2”)]

6,928 (15,242)

204 (450)

9,728 (21,402)

217 (478) X2

1,321 (2,912) X2

370 (816)

857 ( 1,889 )

54 (119)

* DRY WEIGHT

W ARNING

USE ONL Y LIFTING DEVICES AND EQUIPMENT WITH

RA TED CAP ACITIES SUFFICIENT TO LIFT THE SPECIFIC COMPONENT(S) BEING REMOVED OR INST ALLED.

Page 3-5

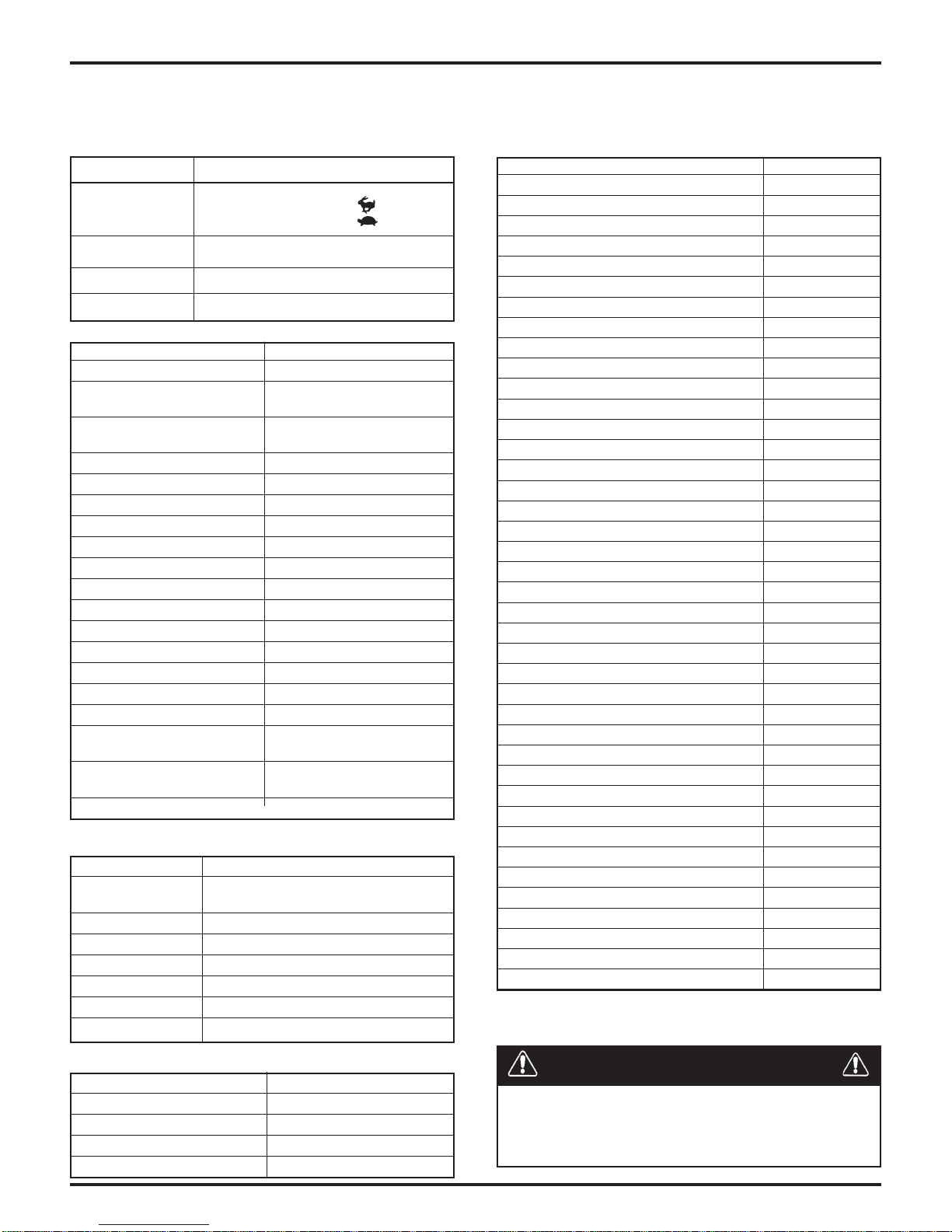

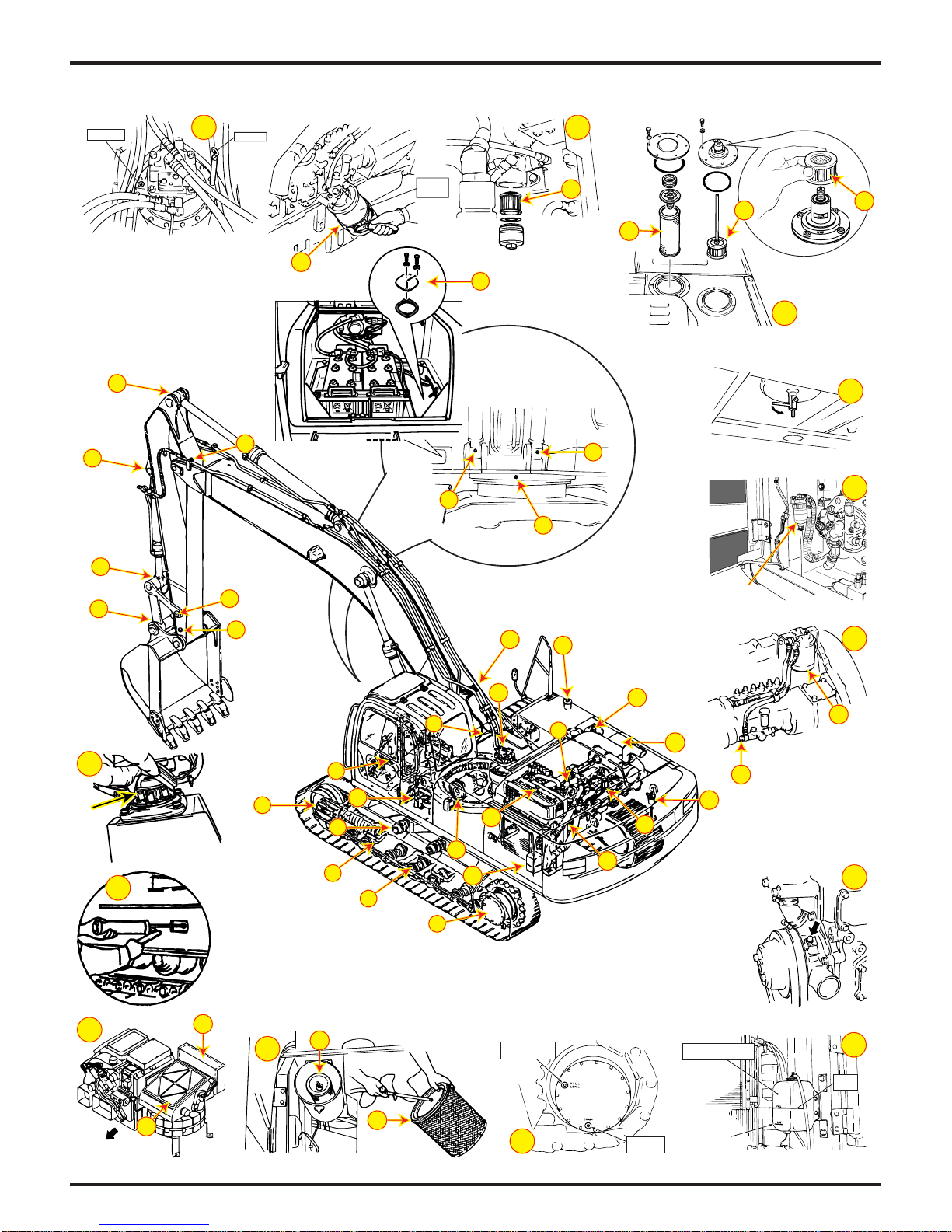

SK160LC/ED190-6E (Minor Change) COMPONENT FAMILIARIZATION

FILL PLUG

6

DIPSTICK

21

C

D

9

E

B

A

9

9

13

1

9

9

9

9

9

9

16

6

2

1

21

16

20

9

22

FRONT

11

8

Drain every 50 hrs

20

and clean every 500 hrs

19

11

22

3

14

17

19

12

18

5

9

4

7

H

10

9

I

9

PROPER

LEVEL

12

18

8

9

9

9

9

J

17

K

F

G

FILL/LEVEL

PLUG

7

9

9

9

RADIATOR EXPANSION

TANK

FULL

DRAIN

PLUG

LOW LEVEL

Page 3-6

Dynamic Acera 03/05 Rev. 05

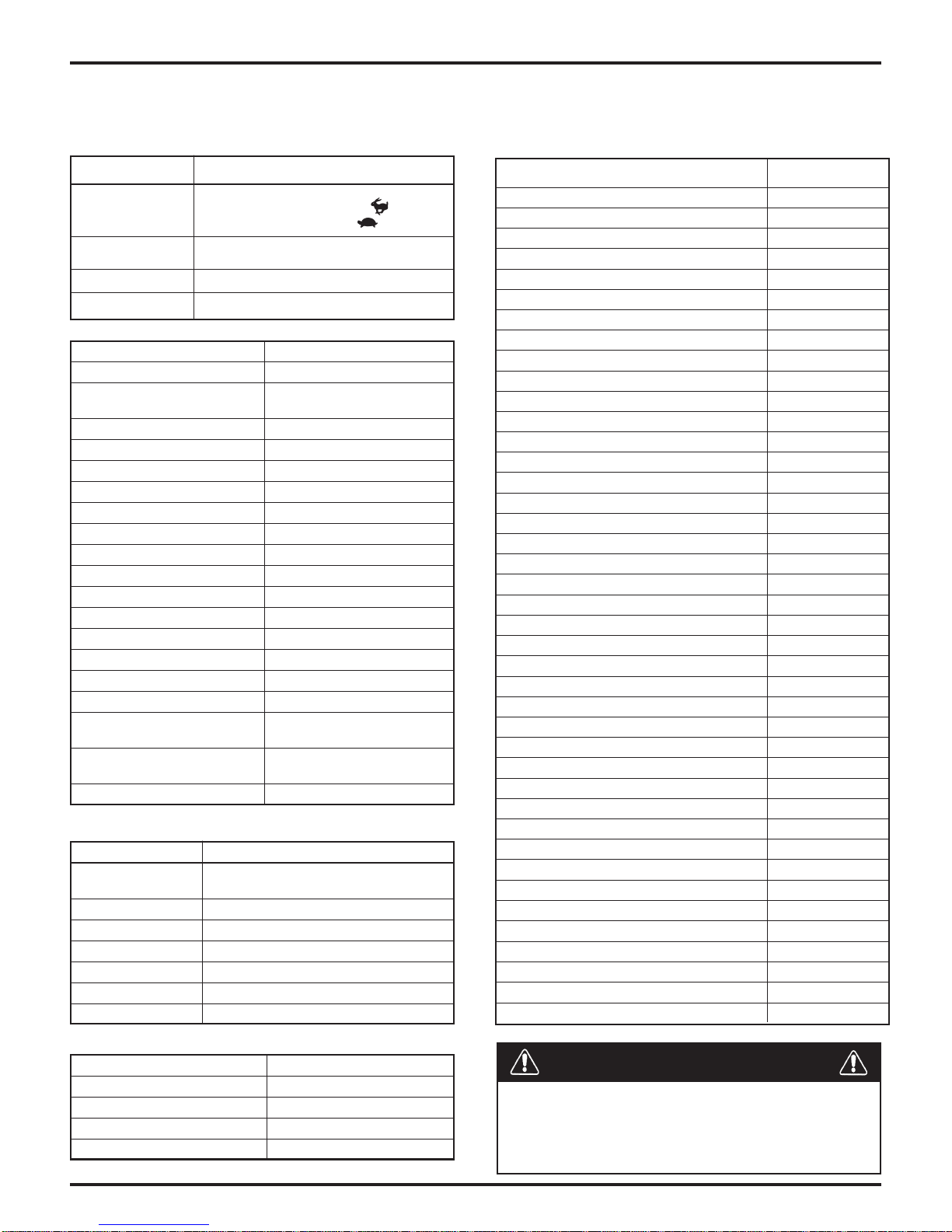

SK160LC/ED190-6E (Minor Change) COMPONENT MAINTENANCE

E6-CL061KS E6-091DE

41Xcc061

41X)zO.lF14.5(

2XL7.4

)2XlaG42.1(

SEITICAPAC

)laG42(L19

L951

)laG0.24(

)laG4(L51

)laG4.3(L31

4X)zOdiulF96.1(cc05

41Xcc022

41X)zO.lF44.7(

2X)zOdiulF67.6(cc002

L5.7

)laG0.2(

2XL9

)2XlaG4.2(

tniojhcaenideriuqersA

secalP61

)rezoD(secalP41

)4Xº09(ecalP1

secalP2

gK7.8

)sbl2.91(

*

DIGIRF

C¡51~C¡03-

)F¡95~F¡22-(

22GVOSI

*

22-()evobadnaF¡68()F¡401~F¡32(

DIGIRF

C¡03~C¡02-

)F¡68~F¡4-(

23GVOSI

C¡03~C¡03-evobadnaC¡03C¡04~C¡5-

)F¡68~F¡

o

N.I.G.L.N

EPYTDIULF

REBMUNTRAP;TNACIRBUL

)gnimaof-nondnatnadixoitna,raew-itnA(LIOCILUARDYH

lio64SULLETLLEHShtiwyrotcafmorfdeppihserasenihcaM

MRAW-DIGIRF

C¡04~C¡52-

S23GVOSI

04W51EAS03W01EAS

*

MRAW

C¡04~C¡5-

)F¡401~F¡31-(

)F¡401~F¡32(

64GVOSI

*

)"DCecivreS"rofnoitacifisalc.I.P.A(LIOENIGNE

lio04W51EAShtiwyrotcafmorfdeppihserasenignellA

TOHYREV

C¡55~C¡5

)F¡131~F¡14(

86GVOSI

TOHYREVMRAWDIGIRF

05W51EAS

NOITCEPSNI

LAVRETNI

TSRIF

ECNANETNIAM

srH8 — srH0002

srH8srH05srH005

— — srH0002

— — srH0002

)"DCecivreS"rofnoitacifisalc.I.P.A(LIOENIGNE

lio04W51EAShtiwyrotcafmorfdeppihserastnenopmocesehT

— — srH0002

srH021 srH005 srH0002

srH021 srH005 srH0002

srH021——

ESAERG2PE

)esaergepytPE2.oNesoprupitlumerusserpemertxE(

srH05——

srH005——

srH05——

2…N.I.G.L.NASARG

)gniraebrofesabmuihtiL(

SOMhtiwesaergesabmuihtil2

2

srH005 — —

srH005— srH0002

.FER

)noitacoL(

knatciluardyH

1

TNENOPMOC

metsysciluardyH

naplioenignE

)level-H(

2

naplioenignE

)level-L(

3

4

5

6

7

8

9

01

11

21

31

srellorreppU

srellorrewoL

sreldI

tinunoitcudergniwS

tinunoitcuderlevarT

tniojrevelgnitarepO

sniptnemhcattA

gniraebgniwS

noisnetkcarT

tnemtsujda

gniraebpmupretaW )tohsnugesaergeno.xorpA(cc1.6

gnirgniwelS

htabesaerg

LAMRON

ECNANETNIAM

LAVRETNI

41

51

61

rotaidaR

metsysgnilooC

emulovlatot

knatleuF

A

B

C

D

E

F

G

H

I

J

K

)laG9.2(L11

L91

)laG5(

L182

)laG2.47(

retlifnrutermetsysciluardyH

)rekaerbhtiwdeppiuqesenihcamroF(retlifnruteR

reniartsnoitcusciluardyH

retlifevlavrehtaerbknatciluardyH

retlifmetsystoliP

retliflioenignE

tnemelerennirenaelcriA

tnemeleretuorenaelcriA

retlifleufenignE

retlifezuagpmupgnimirP

retlifriahserfC/A

retlifriaetalucricerC/A

erutxiM

retniW)¡31-~F¡5-(

o

N579DMTSALESEID

:tnemelE )1(1P40000V05RY :tiK 4F20000T03VY

:tnemelE )1(1P10000V05NY :tiK 4F20000T03VY

tbootsnoitcurtsni

)F…2.92-(C…43-)CLL(EZEERFITNA

.erutximreporpnia

LEUFLESEID

)F…32~F…5(dezi

o

N579DMTSALESEID1

lliwenihcamehterutarepmettsedlocehtnahtrewol)F…9(C…5ottcetorpdluohsoitar

rerutcafunamezeerfitnawolloF.srotcafllihcdniwnoitaredisnocotniekaT.ecneirepxe

TOHYREVMRAWDIGIRF

evobadna)F…32(C…5-C¡51-~C¡1-C¡52-~C¡51-

o

N579DMTSALESEID2

2

srH8 — srH0002

———

— srH05 srH005

—srH05srH005

)6D19Z54:N/PlaessedulcnI()1(100S20000V05NY

)1(010S20000V75NY

)1(500S10010V05NY

)1(200512EMAV*

)1(6S772R6442

)1(5S772R6442

)1()328610EMAV*(A2-421R1542

)1(156717EMAV*

)1(1P60010V05NY

)1(050S40000M02TY

srH8 deriuqersA

srH8deriuqersA

srH05srH005

srH05 srH005

srH0002

srH0002

srH005

srH005

srH052

srH005

srelaedocleboKtaylnoelbaliavA*

Dynamic Acera 03/05 Rev. 05

Page 3-7

MACHINE FAMILIARIZATION

SK210LC-VI -

The following performance specifications are based on the standard machine with standard attachment.

1. Travel Speed, Swing Speed & Gradeability

DESCRIPTION SPECIFICATION

TRAVEL SPEED 6.0 km per hr (3.7 mph) in mode.

SWING SPEED 11 RPM IN M-Mode / “HI” Idle.

GRADEABILITY 70% (35°) {Limited by engine lubrication}

DRAWBAR FORCE 20,190 Kgf (44,512 lbs)

2. Engine

Engine Maker Mitsubishi

Model 6D34-TEB

Type

Number of Cylinders– Bore X Stroke

4.53")

Displacement 5,861 liter (358 cu in.)

Compression Ratio 16.5 : 1

Output Rating 107 kW (144 HP) / 2,000 rpm

Maximum Torque 519 N•m (383 lb-ft)/ 1,600 rpm

Ignition Order 1–5–3–6–2–4 Clockwise Rotation

Injection Timing 15° Before Top Dead Point

Intake Valve Clearance Cold 0.4 mm (0.0157")

Exhaust Valve Clearance Cold 0.4 mm (0.0157")

Electrical System D.C. 24 V

Starting Motor 24 V–5.0 kW

Alternator 24 V–35 A

Batteries 2– 12 V- (136 Ah)

Engine Dry Weight* 470 kg (1,040 lbs)

Thermostat Begin to open at 76.5°C (170°F).

Cooling Fan Drive Method Ø600 (Ø24") Suction Type Belt

Air Cleaner Dry Type with Safety Elements

3. Hydraulic Components

COMPONENT TYPE

HYDRAULIC PUMPS Tandem, Variable Displacement,

2X210 L/min (55.5 Gal/min)

SWING MOTOR Axial Piston

TRAVEL MOTOR Axial Piston

CONTROL VALVES 6 Spool Multiple Control

CYLINDERS (ALL) Double Acting

RETURN FILTER Safety Valve containing Filter Type

OIL COOLER Air Cooled

PERFORMANCE SPECIFICA TIONS

4.0 km per hr (2.5 mph) in mode.

4-Cycle, Water Cooled, Direct

Injection with Turbocharger , Diesel

6–104 mm X 115 mm (4.09" X

Full open at 90°C (194°F).

Drive Pulley Ratio : 1.00

*Less flywheel and electrics.

Axial Piston with Pilot Gear Pump.

1A. MACHINE & COMPONENT WEIGHTS

The following weight specifications are based on

the standard machine with standard attachment.

Unit: Kg (lb)

COMPONENT SK210LC-VI

COMPLETE MACHINE (STANDARD) 20,500 (45,200)

UPPER FRAME ASSEMBL Y

COUNTERWEIGHT 4,500 (9,920)

CAB 260 (570)

BOOM CYLINDER* 168 (370) X 2

ENGINE* 470 (1,040)

RADIA TOR & OIL COOLER 97 (210)

PUMP ASSEMBLY 142 (310)

CONTROL VALVE 280 (620)

FUEL T ANK* 91 (200)

HYDRAULIC TANK* 143 (320)

SWING MOTOR & REDUCTION UNIT

LOWER FRAME ASSEMBL Y

SLEWING RING 245 (540)

TRA VEL MOTOR & REDUCTION UNIT

IDLER ASSEMBL Y 106 (230) X2

LOWER ROLLER ASSEMBL Y 35 (77) X16

UPPER ROLLER ASSEMBL Y 22 (48) X4

TRACK TENSION ASSEMBLY 104 (230) X2

SPROCKET 54 (120) X2

SWIVEL JOINT 30 (66)

TRACK LINK W/ 800mm (31.5") SHOES

TRACK LINK 540 (1,190) X2

ATT ACHMENT (STANDARD) 3,600 (7,930)

BUCKET ASSEMBL Y [0.81m3 (1.06 cu yd)]

ARM ASSEMBLY [2.94 m (9’-8”)] 980 (2,160)

ARM [2.94 m (9’-8”)] 610 (1,340)

BUCKET CYLINDER* 135 (300)

IDLER LINK 21 (46) X2

BUCKET LINK 91 (200)

PIN (2 PCS for mtg bucket cyl & bucket)

BOOM ASSEMBL Y 1,650 (3,640)

BOOM 1,320 (2,910)

ARM CYLINDER* 230 (510)

PIN (Mounting the Arm) 27 (59)

FLUIDS 540 (1,190)

HYD OIL 215 (470)

ENG OIL 20 (44)

FUEL 285 (630)

WATER 20 (44)

9,400 (20,720)

235 (520)

7,500 (16,530)

250 (550) X2

1,720 (3,784) X2

650 (1,430)

65 (140)

* DRY WEIGHT

4. Operating Pressures

PILOT SYSTEM 50 (710)

IMPLEMENT 350 (4980)

SWING 285 (4050)

TRAVEL 350 (4980)

POWER BOOST/HEAVY LIFT 385 (5470)

Page 3-8

Kgf/cm2 (psi)

W ARNING

USE ONL Y LIFTING DEVICES AND EQUIPMENT WITH

RA TED CAP ACITIES SUFFICIENT TO LIFT THE SPECIFIC COMPONENT(S) BEING REMOVED OR INST ALLED.

Dynamic Acera 03/05 Rev. 05

MACHINE F AMILIARIZATION

SK250LC-VI -

The following performance specifications are based on the standard machine with standard attachment.

1. Travel Speed, Swing Speed & Gradeability

DESCRIPTION SPECIFICATION

TRAVEL SPEED 6.0 km per hr (3.7 mph) in mode.

SWING SPEED 11 RPM IN M-Mode / “HI” Idle.

GRADEABILITY 70% (35°) {Limited by engine lubrication}

DRAWBAR FORCE 20,190 Kgf (44,512 lbs)

2. Engine

Engine Maker Mitsubishi

Model 6D34-TLEB

Type

Number of Cylinders– Bore X Stroke

Displacement 5,861 liter (358 cu in.)

Compression Ratio 18.2 : 1

Output Rating 125 kW (168 HP) / 2,100 rpm

Maximum Torque 590 N•m (435 lb-ft)/ 1,600 rpm

Ignition Order 1–5–3–6–2–4 Clockwise Rotation

Injection Timing 17° Before Top Dead Point

Intake Valve Clearance Cold 0.4 mm (0.0157")

Exhaust Valve Clearance Cold 0.4 mm (0.0157")

Electrical System D.C. 24 V

Starting Motor 24 V–5.0 kW

Alternator 24 V–35 A

Batteries 2– 12 V- (136 Ah)

Engine Dry Weight* 470 kg (1,040 lbs)

Thermostat Begin to open at 76.5°C (170°F).

Cooling Fan Drive Method Ø600 (Ø24") Suction Type Belt

Air Cleaner Dry Type with Safety Elements

3. Hydraulic Components

COMPONENT TYPE

HYDRAULIC PUMPS Tandem, Variable Displacement,

2X240 L/min (63.4 Gal/min)

SWING MOTOR Axial Piston

TRAVEL MOTOR Axial Piston

CONTROL VALVES 6 Spool Multiple Control

CYLINDERS (ALL) Double Acting

RETURN FILTER Safety Valve containing Filter Type

OIL COOLER Air Cooled

PERFORMANCE SPECIFICA TIONS

4.0 km per hr (2.5 mph) in mode.

4-Cycle, Water Cooled, Direct

Injection with Turbocharger , Diesel

6–104 mm X 1 15 mm (4.09" X 4.53")

Full open at 90°C (194°F).

Drive Pulley Ratio : 1.00

*Less flywheel and electrics.

Axial Piston with Pilot Gear Pump.

1A. MACHINE & COMPONENT WEIGHTS

The following weight specifications are based on

the standard machine with standard attachment.

Unit: Kg (lb)

COMPONENT SK250LC-VI

COMPLETE MACHINE (STANDARD) 24,100 (53,130)

UPPER FRAME ASSEMBL Y

COUNTERWEIGHT 5,510 (12,150)

CAB 260 (570)

BOOM CYLINDER* 220 (490) X 2

ENGINE* 480 (1,060)

RADIAT OR & OIL COOLER 97 (210)

PUMP ASSEMBLY 142 (310)

CONTROL VALVE 280 (620)

FUEL TANK* 91 (200)

HYDRAULIC TANK* 143 (320)

SWING MOTOR & REDUCTION UNIT

LOWER FRAME ASSEMBL Y

SLEWING RING 364 (800)

TRAVEL MOTOR & REDUCTION UNIT

IDLER ASSEMBL Y 106 (230) X2

LOWER ROLLER ASSEMBL Y 35 (77) X16

UPPER ROLLER ASSEMBL Y 22 (48) X4

TRACK TENSION ASSEMBLY 94 (210) X2

SPROCKET 54 (120) X2

SWIVEL JOINT 30 (66)

TRACK LINK W/ 800mm (31.5") SHOES

TRACK LINK 580 (1,276) X2

ATT ACHMENT (STANDARD) 3,900 (8,600)

BUCKET ASSEMBL Y [0.81m3 (1.06 cu yd)]

ARM ASSEMBLY [2.94 m (9’-8”)] 1,150 (2,540)

ARM [2.94 m (9’-8”)] 710 (1,570)

BUCKET CYLINDER* 177 (390)

IDLER LINK 25 (55) X2

BUCKET LINK 98 (220)

PIN (2 PCS for mtg bucket cyl & bucket)

BOOM ASSEMBL Y 2.140 (4,720)

BOOM 1,670 (3,680)

ARM CYLINDER* 300 (660)

PIN (Mounting the Arm) 28 (62)

FLUIDS 550 (1,210)

HYD OIL 225 (500)

ENG OIL 20 (44)

FUEL 285 (630)

WATER 22 (48)

11,400 (25,130)

290 (640)

8,800 (19,400)

300 (660) X2

1,490 (3,280) X2

780 (1,720)

80 (180)

* DRY WEIGHT

4. Operating Pressures

PILOT SYSTEM 50 (710)

IMPLEMENT 350 (4980)

SWING 285 (4050)

TRAVEL 350 (4980)

POWER BOOST/HEAVY LIFT 385 (5470)

Dynamic Acera 03/05 Rev. 05

Kgf/cm2 (psi)

W ARNING

USE ONL Y LIFTING DEVICES AND EQUIPMENT WITH

RA TED CAP ACITIES SUFFICIENT TO LIFT THE SPECIFIC COMPONENT(S) BEING REMOVED OR INST ALLED.

Page 3-9

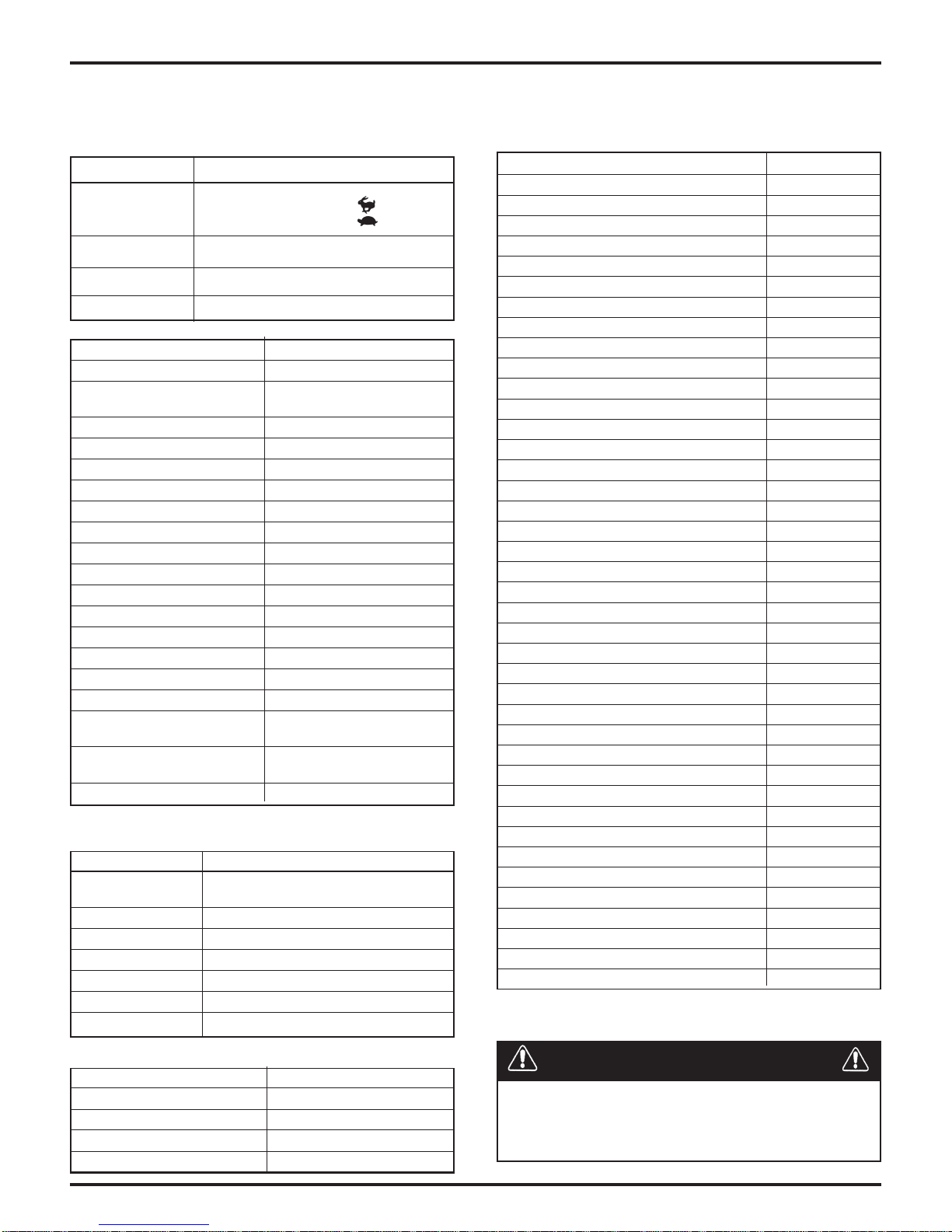

SK210LC/SK250-6E (Minor Change) COMPONENT FAMILIARIZATION

SK210/SK250LC-6E-MC

FILL PLUG

9

9

9

6

DIPSTICK

21

C

D

E

B

A

9

9

13

9

9

1

16

10

9

20

9

9

16

8

22

FRONT

11

6

9

2

8

5

22

3

14

17

11

18

4

12

1

Drain every 50 hrs

and clean every 500 hrs

21

19

20

19

H

I

12

7

J

17

K

F

G

Use low pressure air

for cleaning

FILL/LEVEL

PLUG

7

DRAIN

PLUG

RADIATOR EXPANSION

TANK

FULL

LOW LEVEL

PROPER

LEVEL

18

Page 3-10

Dynamic Acera 03/05 Rev. 05

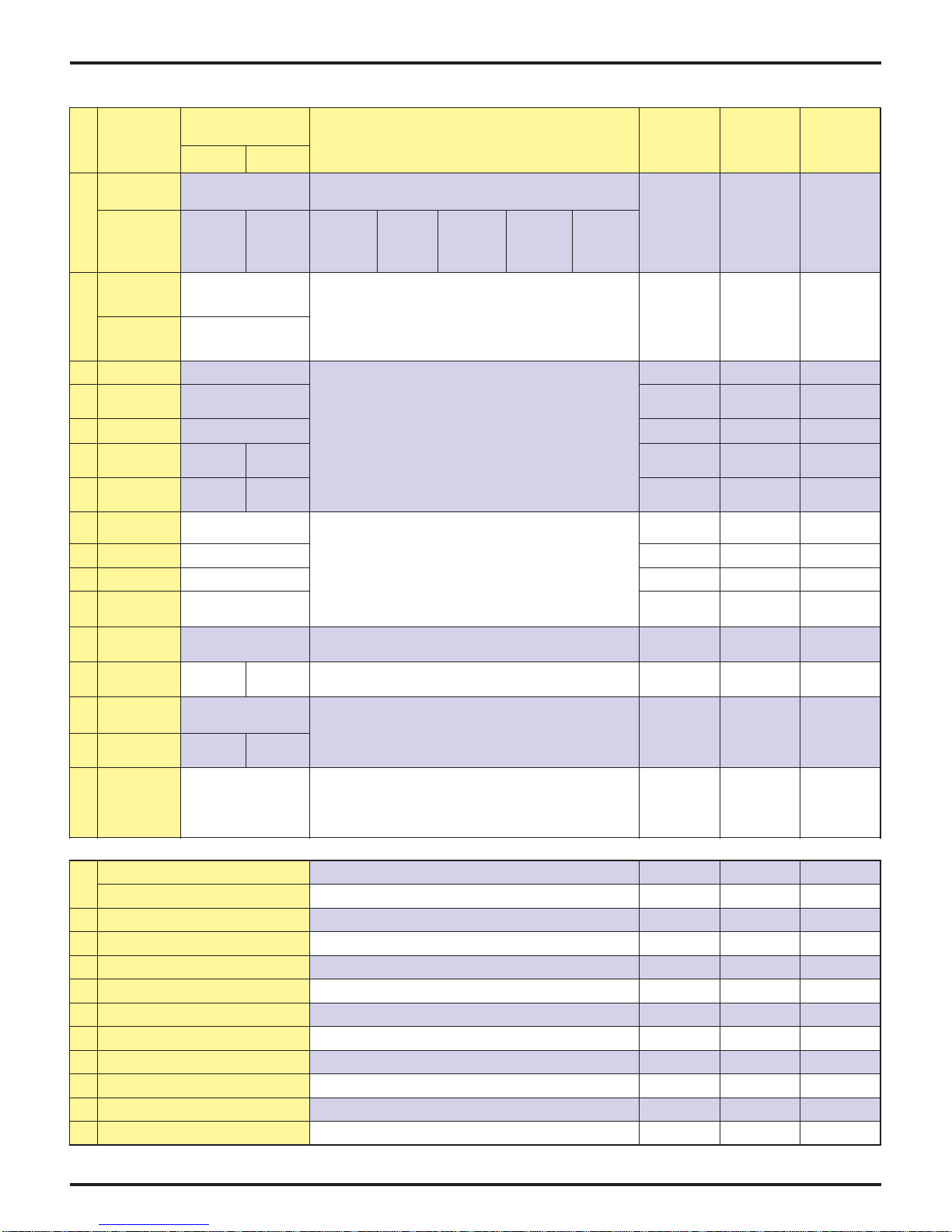

SK210LC/SK250-6E (Minor Change) COMPONENT MAINTENANCE

SK210/SK250LC-6E-MC

gK3.8

)laG56(

)laG0.2(

2XL5.5

)sbl3.81(

E6-CL012KS E6-CL052KS

)2XlaG5.1(

SEITICAPAC

*

L062

)laG96(

)laG8.4(L81

)laG1.4(L5.51

41X).zOdiulF14.5(cc061

CL-61X).zOdiulF14.5(cc061

L3.51

)laG0.4(

2XL7.4

)2XlaG2.1(

DIGIRF

C¡51~C¡03-

22GVOSI

DIGIRF

)F¡95~F¡22-(

C¡03~C¡02-

)F¡68~F¡4-(

23GVOSI

*

C¡03~C¡03-evobadnaC¡03C¡04~C¡5-

)F¡68~F¡

22-()evobadnaF¡68()F¡401~F¡32(

EPYTDIULF

REBMUNTRAP;TNACIRBUL

)gnimaof-nondnatnadixoitna,raew-itnA(LIOCILUARDYH

lio64SULLETLLEHShtiwyrotcafmorfdeppihserasenihcaM

MRAW-DIGIRF

C¡04~C¡52-

)F¡401~F¡31-(

S23GVOSI

04W51EAS03W01EAS

*

MRAW

C¡04~C¡5-

)F¡401~F¡32(

64GVOSI

*

)"DCecivreS"rofnoitacifisalc.I.P.A(LIOENIGNE

lio04W51EAShtiwyrotcafmorfdeppihserasenignellA

)"DCecivreS"rofnoitacifisalc.I.P.A(LIOENIGNE

TOHYREV

C¡55~C¡5

)F¡131~F¡14(

86GVOSI

TOHYREVMRAWDIGIRF

05W51EAS

lio04W51EAShtiwyrotcafmorfdeppihserastnenopmocesehT

NOITCEPSNI

LAVRETNI

TSRIF

ECNANETNIAM

srH8 srH0002

srH8srH05srH005

srH021 srH005 srH0002

srH021 srH005 srH0002

srH021

ESAERG2PE

secalp2

2…N.I.G.L.NASARG

)gniraebrofesabmuihtiL(

gK3.11

)sbl9.42(

o

N.I.G.L.N

)esaergepytPE2.oNesoprupitlumerusserpemertxE(

SOMhtiwesaergesabmuihtil2

2

srH05

srH005

srH05

srH005

srH005srH0002

.FER

)noitacoL(

knatciluardyH )laG14(L651

1

TNENOPMOC

metsysciluardyH

*naplioenignE

)level-H(

L642

2

*naplioenignE

)level-L(

3

4

5

6

7

8

9

01

11

21

31

srellorreppU 4X).zOdiulF96.1(cc05

srellorrewoL

sreldI 2X).zOdiulF67.6(cc002

tinunoitcudergniwS

tinunoitcuderlevarT

tniojrevelgnitarepO tniojhcaenideriuqersA

sniptnemhcattA secalP61

gniraebgniwS )4X…09(ecalP1

noisnetkcarT

tnemtsujda

gniraebpmupretaW )tohsnugesaergeno.xorpA(cc1.6

gnirgniwelS

htabesaerg

L5.7

LAMRON

ECNANETNIAM

LAVRETNI

srH0002

srH0002

srH0002

41

51

61

* )laG3.6(L42:emulovlioenignelatoT;laudiser)laG3.1(L9.4;)laG3.0(L1.1:yticapacretliF

A

B

C

D

E

F

G

H

I

J

K

rotaidaR )laG5.2(L5.9

metsysgnilooC

emulovlatot

knatleuF

erutxiM

L91

)laG5(

retlifmetsystoliP )500S10010V05NY:N/Plaesgnir-OsedulcnI()1(500S10010V05NY

retliflioenignE )1(200512EMAV*

retlifleufenignE )1(452510EMAV*

retlifriahserfC/A )1(1P60010V05NY

L22

)laG8.5(

L043

)laG09(

retlifnrutermetsysciluardyH :tnemelE )1(1P10000V05RY :tiK 1F70000T03NY

)rekaerbhtiwdeppiuqesenihcamroF(retlifnruteR :tnemelE )1(1P90000V05NY :tiK 2F70000T03NY

reniartsnoitcusciluardyH )6D19Z54:N/PlaessedulcnI()1(100S20000V05NY

retlifevlavrehtaerbknatciluardyH )1(010S20000V75NY

tnemelerennirenaelcriA )1(6S552R6442

tnemeleretuorenaelcriA )1(5S552R6442

retlifezuagpmupgnimirP )1(156717EMAV*

retlifriaetalucricerC/A )1(050S40000M02TY

tniW)¡31-~F¡5-(

o

N579DMTSALESEID

tbootsnoitcurtsni

)F…2.92-(C…43-)CLL(EZEERFITNA

.erutximreporpnia

LEUFLESEID

)F…32~F…5(dezire

o

N579DMTSALESEID1

lliwenihcamehterutarepmettsedlocehtnahtrewol)F…9(C…5ottcetorpdluohsoitar

rerutcafunamezeerfitnawolloF.srotcafllihcdniwnoitaredisnocotniekaT.ecneirepxe

TOHYREVMRAWDIGIRF

evobadna)F…32(C…5-C¡51-~C¡1-C¡52-~C¡51-

o

N579DMTSALESEID2

2

srH8 srH0002

srH005

srH05 srH005

srH05srH005

srH0002

srH0002

srH005

srH05srH005

srH8 deriuqersA

srH8deriuqersA

srH05 srH005

srH005

srH052

srH005

srelaedOCLEBOKtaylnoelbaliavA*

Dynamic Acera 03/05 Rev. 05

Page 3-11

MACHINE F AMILIARIZATION

SK290LC-VI -

The following performance specifications are based on the standard machine with standard attachment.

1. Travel Speed, Swing Speed & Gradeability

DESCRIPTION SPECIFICATION

TRAVEL SPEED 5.6 km per hr (3.5 mph) in mode.

SWING SPEED 11 RPM IN M-Mode / “HI” Idle.

GRADEABILITY 70% (35°) {Limited by engine lubrication}

DRAWBAR FORCE 26,218 Kgf (57,800 lbs)

2. Engine

Engine Maker Mitsubishi

Model 6D16-TLEC

Type

Number of Cylinders– Bore X Stroke

Displacement 7,545 liter (460 cu in.)

Compression Ratio 17.5 : 1

Output Rating 138 kW (185 HP) / 2,100 rpm

Maximum Torque 726 N•m (534 lb-ft)/ 1,600 rpm

Ignition Order 1–5–3–6–2–4 Clockwise Rotation

Injection Timing 15° Before Top Dead Point

Intake Valve Clearance Cold 0.4 mm (0.0157")

Exhaust Valve Clearance Cold 0.4 mm (0.0157")

Electrical System D.C. 24 V

Starting Motor 24 V–5.0 kW

Alternator 24 V–35 A

Batteries 2– 12 V- (136 Ah)

Engine Dry Weight* 580 kg (1,280 lbs)

Thermostat Begin to open at 76.5°C (170°F).

Cooling Fan Drive Method Ø620 (Ø24.2") Suction Type Belt

Air Cleaner Dry Type with Safety Elements

3. Hydraulic Components

COMPONENT TYPE

HYDRAULIC PUMPS Tandem, Variable Displacement,

2X210 L/min (55.5 Gal/min)

SWING MOTOR Axial Piston

TRAVEL MOTOR Axial Piston

CONTROL VALVES 6 Spool Multiple Control

CYLINDERS (ALL) Double Acting

RETURN FILTER Safety Valve containing Filter Type

OIL COOLER Air Cooled

4. Operating Pressures

PILOT SYSTEM 50 (710)

IMPLEMENT 350 (4980)

SWING 280 (3980)

TRAVEL 350 (4980)

POWER BOOST/HEAVY LIFT 385 (5470)

PERFORMANCE SPECIFICA TIONS

3.5 km per hr (2.2 mph) in mode.

4-Cycle, Water Cooled, Direct

Injection with Turbo & Inner cooler

6–118 mm X 115 mm (4.65" X 4.53")

Full open at 90°C (194°F).

Drive Pulley Ratio : 0.90

*Less flywheel and electrics.

Axial Piston with Pilot Gear Pump.

Kgf/cm2 (psi)

1A. MACHINE & COMPONENT WEIGHTS

The following weight specifications are based on the

standard machine with standard attachment.

COMPONENT SK290LC-VI

COMPLETE MACHINE (STANDARD) 30,000 (66,100)

UPPER FRAME ASSEMBL Y

COUNTERWEIGHT 6,118 (13,484)

CAB + CONTROLS + A/C + SEAT 836 (1,843)

BOOM CYLINDER* 270 (595) X 2

ENGINE + MUFFLER + MINOR ITEMS 716 (1,578)

RADIAT OR & OIL COOLER 175 (386)

PUMP ASSEMBLY + COUPLING 148 (326)

CONTROL VALVE 441 (972)

FUEL TANK* 170 (375)

HYDRAULIC TANK* 173 (381)

SWING MOTOR & REDUCTION UNIT 511 (1,126)

UPPER FRAME + GUARDS & COVERS 3,109 (6,852)

LOWER FRAME ASSEMBL Y 11,232 (24,755)

CAR BODY 3,618 (7,974)

SLEWING RING 586 (1,292)

TRAVEL MOTOR + RED. UNIT 309 (697) X2

IDLER ASSEMBL Y 170 (370) X2

LOWER ROLLER ASSEMBL Y 45 (77) X18

UPPER ROLLER ASSEMBL Y 26 (57) X4

TRACK TENSION ASSEMBLY 127 (280) X2

SPROCKET + BOLTS 76 (168) X2

SWIVEL JOINT + LOWER LINES 74 (163)

TRACK CHAINS W/800mm (31.5”) SHOES

TRACK GUIDES + GREASE BATH + MOT OR COVERS

ATT ACHMENT (ST ANDARD) 5,136 (1 1,320)

BUCKET ASSEMBL Y [1.20M3 (1.57 CU YD)] 954 (2,100)

ARM ASSEMBLY [3.2 m (10’- 6”) 1,485 (3,273)

ARM 952 (2,098)

BUCKET CYLINDER 220 (485)

IDLER LINK 27 (60) X2

BUCKET LINK 130 (290)

PIN

(6 PCS for mtg bucket cyl, links, bckt &arm cyl rod)

BOOM ASSEMBL Y 2,697 (5,944)

BOOM 2,116 (4,664)

ARM CYLINDER* 370 (816)

PINS

(4 PCS for mtg arm cyl, boom cyl’s & boom)

FLUIDS 554 (1,221)

HYD OIL 171 (377)

FUEL 348 (767)

WATER 35 (77)

Unit: Kg (lb)

12,937 (28,513)

2,338 (5,153) X2

90 (198)

139 (306)

211 (465)

* DRY WEIGHT

WARNING

USE ONLY LIFTING DEVICES AND EQUIPMENT

WITH RATED CAPACITIES SUFFICIENT TO LIFT

THE SPECIFIC COMPONENT(S) BEING REMOVED

OR INST ALLED.

Page 3-12

Dynamic Acera 03/05 Rev. 05

MACHINE F AMILIARIZATION

SK330LC-VI -

The following performance specifications are based on the standard machine with standard attachment.

1. Travel Speed, Swing Speed & Gradeability

DESCRIPTION SPECIFICATION

TRAVEL SPEED 5.8 km per hr (3.6 mph) in mode.

SWING SPEED 11 RPM IN M-Mode / “HI” Idle.

GRADEABILITY 70% (35°) {Limited by engine lubrication}

DRAWBAR FORCE 28,950 Kgf (63,800 lbf)

2. Engine

Engine Maker Mitsubishi

Model 6D16-TLEB

Type

Number of Cylinders– Bore X Stroke

Displacement 7,545 liter (460 cu in.)

Compression Ratio 17.5 : 1

Output Rating 177 kW (238 Hp) / 2,200 rpm

Maximum Torque 824 N•m (608 lb-ft)/ 1,800 rpm

Ignition Order 1–5–3–6–2–4 Clockwise Rotation

Injection Timing 14° Before Top Dead Point

Intake Valve Clearance Cold 0.4 mm (0.0157")

Exhaust Valve Clearance Cold 0.4 mm (0.0157")

Electrical System D.C. 24 V

Starting Motor 24 V–5.0 KW

Alternator 24 V–35 A

Batteries 2– 12 V- (136 Ah)

Engine Dry Weight* 580 kg (1,280 lbs)

Thermostat Begin to open at 76.5°C (170°F).

Cooling Fan Drive Method Ø620 (Ø24.2") Suction Type Belt

Air Cleaner Dry Type with Safety Elements

3. Hydraulic Components

COMPONENT TYPE

HYDRAULIC PUMPS Tandem, Variable Displacement,

2X242 L/min (63.4 Gal/min)

SWING MOTOR Axial Piston

TRAVEL MOTOR Axial Piston

CONTROL VALVES 6 Spool Multiple Control

CYLINDERS (ALL) Double Acting

RETURN FILTER Safety Valve containing Filter Type

OIL COOLER Air Cooled

4. Operating Pressures

PILOT SYSTEM 50 (710)

IMPLEMENT 350 (4980)

SWING 280 (3980)

TRAVEL 350 (4980)

POWER BOOST/HEAVY LIFT 385 (5470)

PERFORMANCE SPECIFICA TIONS

3.4 km per hr (2.1 mph) in mode.

4-Cycle, Water Cooled, Direct

Injection with Turbo & Innercooler

6–118 mm X 115 mm (4.65" X 4.53")

Full open at 90°C (194°F).

Drive Pulley Ratio : 0.90

*Less flywheel and electrics.

Axial Piston with Pilot Gear Pump.

Kgf/cm2 (psi)

1A. MACHINE & COMPONENT WEIGHTS

The following weight specifications are based on the

standard machine with standard attachment.

Unit: Kg (lb)

COMPONENT SK330LC-VI

COMPLETE MACHINE (STANDARD) 35,300 (77,800)

UPPER FRAME ASSEMBL Y

COUNTERWEIGHT 8,420 (18,558)

CAB + CONTROLS + A/C + SEAT 836 (1,843)

BOOM CYLINDER* 270 (595) X 2

ENGINE + MUFFLER + MINOR ITEMS 716 (1,578)

RADIAT OR & OIL COOLER 175 (386)

PUMP ASSEMBLY + COUPLING 148 (326)

CONTROL VALVE 475 (1,047)

FUEL TANK* 204 (450)

HYDRAULIC TANK* 173 (381)

SWING MOTOR & REDUCTION UNIT 511 (1,126)

UPPER FRAME + GUARDS & COVERS 3,800 (8,375)

LOWER FRAME ASSEMBL Y 12,362 (27,167)

CARBODY 3,990 (8,794)

SLEWING RING 586 (1,292)

TRAVEL MOTOR + RED. UNIT 360 (790) X2

IDLER ASSEMBL Y 170 (370) X2

LOWER ROLLER ASSEMBL Y 58 (130) X18

UPPER ROLLER ASSEMBL Y 30 (66) X4

TRACK TENSION ASSEMBLY 190 (420) X2

SPROCKET + BOLTS 88 (190) X2

SWIVEL JOINT + LOWER LINES 85 (187)

TRACK CHAINS W/800mm (31.5”) SHOES

TRACK GUIDES + GREASE NBA TH + MOTOR COVERS

ATT ACHMENT (STANDARD) 6,134 (13,519)

BUCKET ASSEMBL Y [1.20M3 (1.57 CU YD)] 1,040 (2,290)

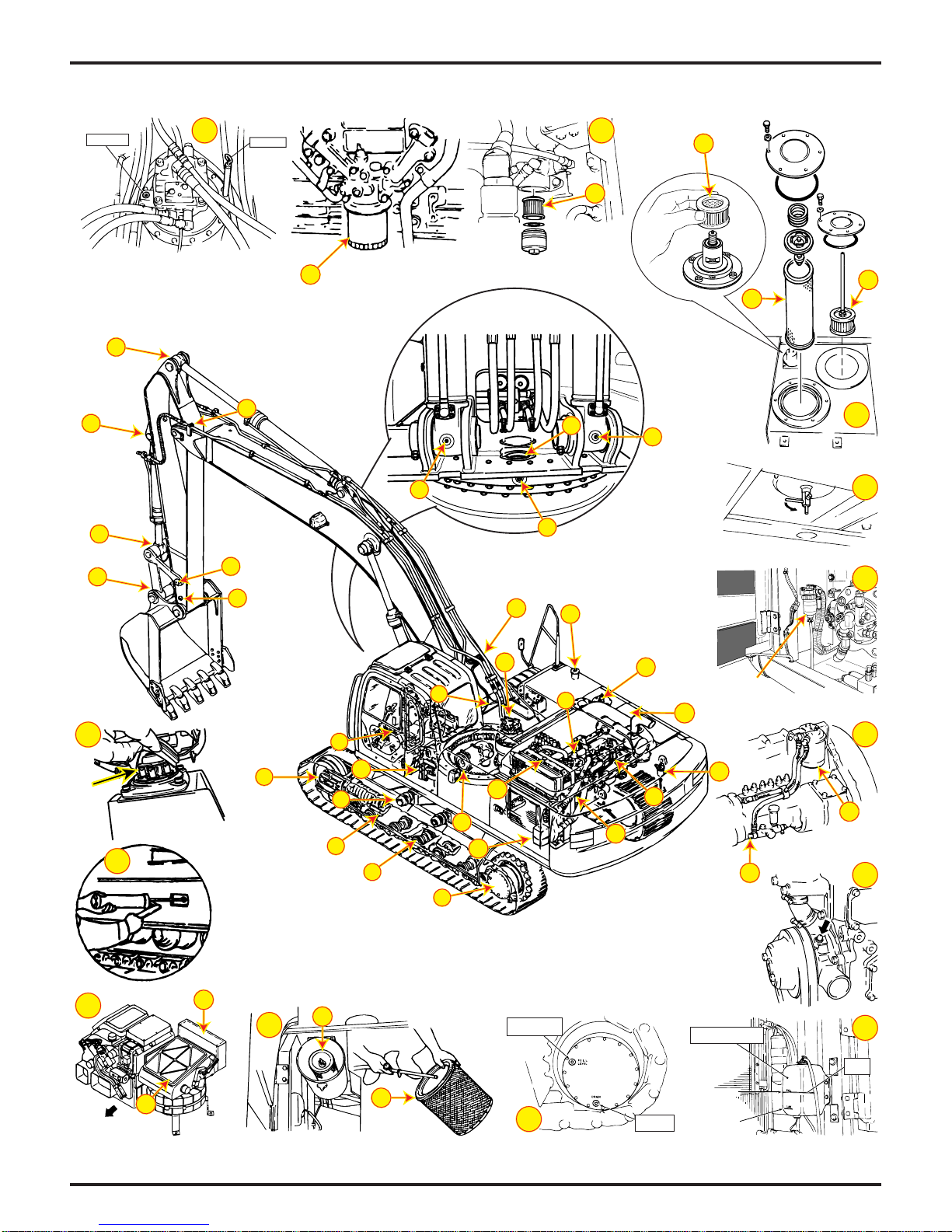

ARM ASSEMBLY [3.2 m (10’- 6”) 1,785 (3,875)

ARM 1,160 (2,560)

BUCKET CYLINDER 260 (570)

IDLER LINK 27 (60) X2

BUCKET LINK 130 (290)

PIN

(6 PCS for mtg bucket cyl, links, bckt &arm cyl rod)

BOOM ASSEMBL Y 3,336 (7,353)

BOOM 2,580 (5,690)

ARM CYLINDER* 500 (1,100)

PINS

(4 PCS for mtg arm cyl, boom cyl’s & boom)

FLUIDS 805 (1,774)

HYD OIL 304 (670)

FUEL 466 (1,030)

WATER 35 (77)

15,998 (35,260)

2,390 (5,286) X2

105 (231)

139 (306)

256 (485)

* DRY WEIGHT

WARNING

USE ONLY LIFTING DEVICES AND EQUIPMENT

WITH RATED CAPACITIES SUFFICIENT TO LIFT

THE SPECIFIC COMPONENT(S) BEING REMOVED

OR INST ALLED.

Dynamic Acera 03/05 Rev. 05

Page 3-13

SK290LC/SK330-6E (Minor Change) COMPONENT FAMILIARIZATION

FILL PLUG

9

9

9

6

DIPSTICK

OIL

FILTER

21

D

B

C

A

E

13

1

9

9

B101GreaseBathCover

9

9

16

20

10

Drain every 50 hrs

9

9

9

16

and clean every 500 hrs

19

8

22

FRONT

11

6

9

2

8

5

22

3

14

17

11

18

1

H

21

I

20

19

12

12

4

7

J

17

K

F

G

Use low pressure air

FILL/LEVEL

PLUG

7

DRAIN

PLUG

RADIATOR EXPANSION

TANK

FULL

LOW LEVEL

PROPER

LEVEL

18

Page 3-14

Dynamic Acera 03/05 Rev. 05

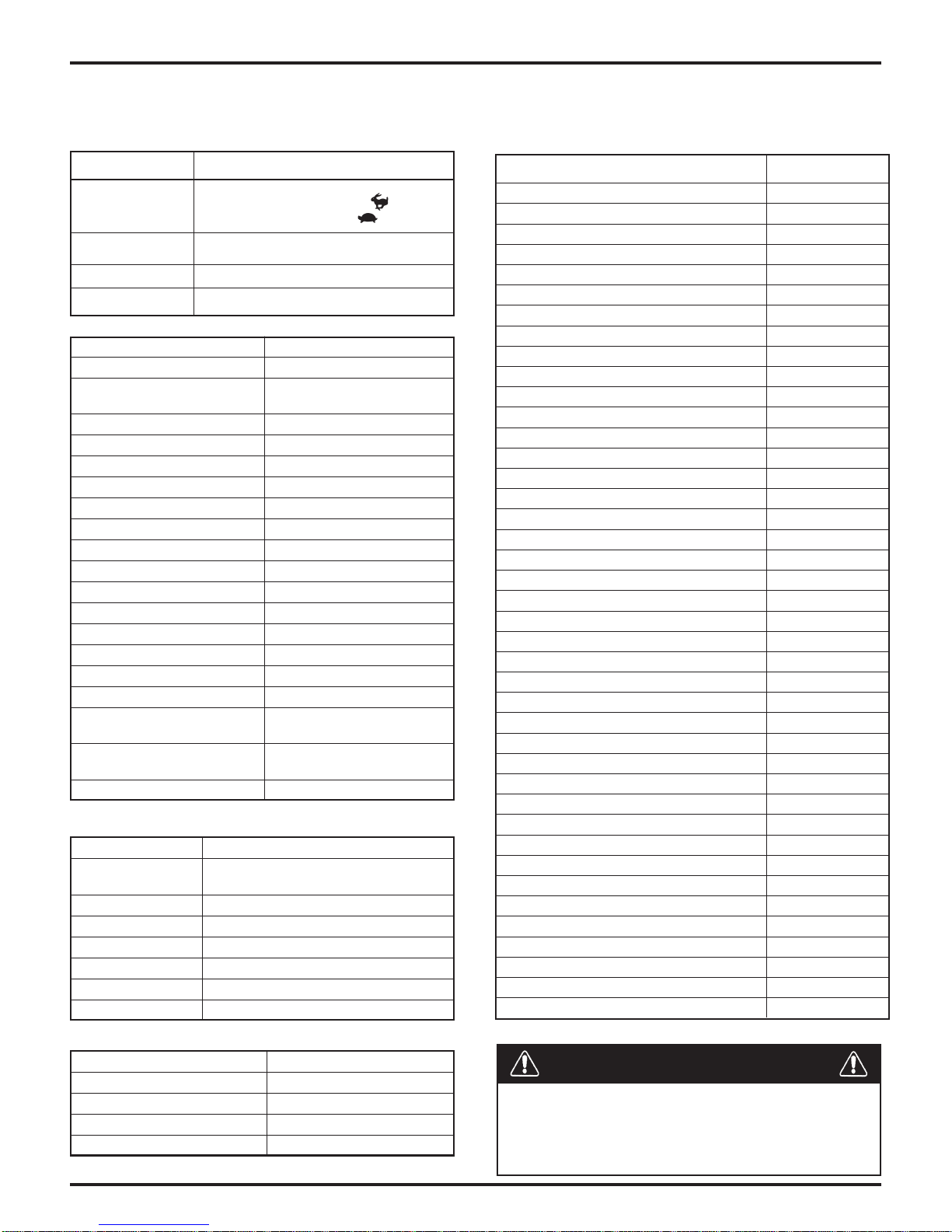

SK290LC/SK330-6E (Minor Change) COMPONENT MAINTENANCE

E6-CL092KS E6-CL033KS

secalp2

gK7.51

)sbl6.43(

SEITICAPAC

*

DIGIRF

C¡51~C¡03-

22GVOSI

)laG4.7(L82*

)laG1.6(L32*

DIGIRF

)F¡95~F¡22-(

C¡03~C¡02-

)F¡68~F¡4-(

23GVOSI

*

C¡03~C¡03-evobadnaC¡03C¡04~C¡5-

22-()evobadnaF¡68()F¡401~F¡32(

)F¡68~F¡

EPYTDIULF

REBMUNTRAP;TNACIRBUL

)gnimaof-nondnatnadixoitna,raew-itnA(LIOCILUARDYH

lio64SULLETLLEHShtiwyrotcafmorfdeppihserasenihcaM

MRAW-DIGIRF

C¡04~C¡52-

S23GVOSI

04W51EAS03W01EAS

*

MRAW

C¡04~C¡5-

)F¡401~F¡31-(

)F¡401~F¡32(

*

64GVOSI

)"DCecivreS"rofnoitacifisalc.I.P.A(LIOENIGNE

lio04W51EAShtiwyrotcafmorfdeppihserasenignellA

)"DCecivreS"rofnoitacifisalc.I.P.A(LIOENIGNE

)noitacifisalc.I.P.Ayb4-LGedarG(LIORAEG

09#lioraegerusserpemertxE

TOHYREV

C¡55~C¡5

)F¡131~F¡14(

86GVOSI

TOHYREVMRAWDIGIRF

05W51EAS

lio04W51EAShtiwyrotcafmorfdeppihserastnenopmocesehT

NOITCEPSNI

LAVRETNI

TSRIF

ECNANETNIAM

srH8 srH0002

srH8srH05srH005

srH021 srH005 srH0002

srH021 srH005 srH0002

srH021

ESAERG2PE

)esaergepytPE2.oNesoprupitlumerusserpemertxE(

srH05

srH005

srH05

2…N.I.G.L.NASARG

)gniraebrofesabmuihtiL(

o

N.I.G.L.N

SOMhtiwesaergesabmuihtil2

2

srH005

srH005srH0002

TNENOPMOC

.FER

)noitacoL(

knatciluardyH )laG5.25(L791 )laG45(L602

1

metsysciluardyH )laG0.39(L153

*naplioenignE

)level-H(

2

*naplioenignE

)level-L(

3

4

5

6

7

8

9

01

11

21

31

srellorreppU 4X)zO.lF96.1(cc05 4X)zO.lF4.3(cc001

srellorrewoL 81X)zO.lF1.01(cc003 61X)zO.lF1.41(cc034

sreldI 2X)zO.lF5.8(cc052 2X)zO.lF1.11(cc053

tinunoitcudergniwS )laG7.5(L5.12

tinunoitcuderlevarT 2X)laG8.2(L5.01

tniojrevelgnitarepO deriuqersA

sniptnemhcattA secalP61

gniraebgniwS )4X…09(ecalP1

noisnetkcarT

tnemtsujda

gniraebpmupretaW )tohsnugesaergeno.xorpA(cc1.6

gnirgniwelS

htabesaerg

LAMRON

ECNANETNIAM

LAVRETNI

srH0002

srH0002

srH0002

41

51

61

*

A

B

C

D

E

F

G

H

I

J

K

rotaidaR )laG4(L51

metsysgnilooC

emulovlatot

knatleuF

L024

)laG211(

)laG5.8(L23:)retlifgnidulcni(emulovlioenignelatoT

erutxiM

)laG9(L43

L065

)laG841(

retlifnrutermetsysciluardyH :tiktnemelE )1(3F40000V05NY

)rekaerbhtiwdeppiuqesenihcamroF(retlifnruteR :tnemelE )1(1P90000V05NY :laeS 00002G11DZ

reniartsnoitcusciluardyH )6D19Z54:N/PlaessedulcnI()1(1F10000V05CL

retlifevlavrehtaerbknatciluardyH )1(010S20000V75NY

retlifmetsystoliP )1(500S10010V05NY

retliflioenignE )1(869031EMAV*

tnemelerennirenaelcriA )1(1P31010P11NY

tnemeleretuorenaelcriA )1(200S10000P11NY

retlifleufenignE )1(076550EMAV*

retlifezuagpmupgnimirP )1(956717EMAV*

retlifriahserfC/A )1(1P60010V05NY

retlifriaetalucricerC/A )1(050S40000M02TY

o

N579DMTSALESEID

tbootsnoitcurtsni

)F…2.92-(C…43-)CLL(EZEERFITNA

.erutximreporpnia

LEUFLESEID

32~F…5(deziretniW)¡31-~F¡5-(

)F…

o

N579DMTSALESEID1

lliwenihcamehterutarepmettsedlocehtnahtrewol)F…9(C…5ottcetorpdluohsoitar

rerutcafunamezeerfitnawolloF.srotcafllihcdniwnoitaredisnocotniekaT.ecneirepxe

TOHYREVMRAWDIGIRF

evobadna)F…32(C…5-C¡51-~C¡1-C¡52-~C¡51-

o

N579DMTSALESEID2

2

srH8 srH0002

srH05 srH005

srH05srH005

srH0002

srH0002

srH005

srH05srH005

srH8 deriuqersA

srH8deriuqerrA

srH05 srH005

srH005

srH052

srH005

srelaedOCLEBOKtaylnoelbaliavA*

Dynamic Acera 03/05 Rev. 05

Page 3-15

MACHINE F AMILIARIZATION

SK480 -

DESCRIPTION SPECIFICATION

TRA VEL SPEED 5.6 km per hr (3.5 mph) in mode.

SWING SPEED 9 RPM IN M-Mode / “HI” Idle.

GRADEABILITY 70% (35°) {Limited by engine lubrication}

DRAWBAR FORCE 26,218 Kgf (57,800 lbs)

Engine Maker Mitsubishi

Model 6D24-TLA2B

Type

Number of Cylinders– Bore X Stroke

Displacement 11.950 Liter (729 cu in.)

Compression Ratio 17.5 : 1

Output Rating 250kW (335 HP) / 2,130 rpm

Maximum Torque 1,275 N•m (940 lb-ft)/ 1,600 rpm

Ignition Order 1–5–3–6–2–4 Clockwise Rotation

Injection Timing 2° Before Top Dead Point

Intake Valve Clearance Cold 0.4 mm (0.0157")

Exhaust Valve Clearance Cold 0.6 mm (0.0236")

Electrical System D.C. 24 V

Starting Motor 24 V–5.0 KW

Alternator 24 V–35 A

Batteries 2– 12 V- (136 Ah)

Engine Dry Weight* 580 kg (1,280 lbs)

Thermostat Begin to open at 76.5°C (170°F).

Cooling Fan Drive Method Ø620 (Ø24.2") Suction Type Belt

Air Cleaner Dry Type with Safety Elements

COMPONENT TYPE

HYDRAULIC PUMPS Tandem, Variable Displacement,

2X210 L/min (55.5 Gal/min)

SWING MOTOR Axial Piston

TRAVEL MOTOR Axial Piston

CONTROL VALVES 6 Spool Multiple Control

CYLINDERS (ALL) Double Acting

RETURN FILTER Safety Valve containing Filter Type

OIL COOLER Air Cooled

PILOT SYSTEM 49.9 / (710) / [4.9 MPa]

IMPLEMENT 320 / (4554) / [31.4 MPa]

SWING 260 / (3698) / [25.5 MPa]

TRAVEL 349 / (4974) / [34.3 MPa]

POWER BOOST/HEAVY LIFT 349 / (4974) / [34.3 MPa]

PERFORMANCE SPECIFICA TIONS

The following performance specifications are based on the standard machine with standard attachment.

1. Travel Speed, Swing Speed & Gradeability

3.5 km per hr (2.2 mph) in mode.

2. Engine

4-Cycle, Water Cooled, Direct

Injection with Turb & Inner cooler

6–130 mm X 150 mm (5.12" X 5.91”)

Full open at 90°C (194°F).

Drive Pulley Ratio : 0.90

*Less flywheel and electrics.

3. Hydraulic Components

Axial Piston with Pilot Gear Pump.

4. Operating Pressures

Kgf/cm2 / (psi) / [ MPa]

1A. MACHINE & COMPONENT WEIGHTS

The following weight specifications are based on the

standard machine with standard attachment.

COMPONENT SK480LC-VI

COMPLETE MACHINE (STANDARD) 49,100 (108,000)

UPPER FRAME ASSEMBL Y

COUNTERWEIGHT 10,027 (22,059)

CAB 260 (570)

BOOM CYLINDER* 422 (928) X 2

ENGINE + MUFFLER + MINOR ITEMS 1,100 (2,420)

RADIA TOR & OIL COOLER 186 (410)

PUMP ASSEMBLY 187 (420)

CONTROL VALVE 380 (840)

FUEL T ANK* 230 (510)

HYDRAULIC TANK* 360 (790)

SWING MOTOR & REDUCTION UNIT 722 (1,590)

LOWER FRAME ASSEMBL Y 19,000 (41,800)

SLEWING RING 700 (1,540)

TRAVEL MOTOR + RED. UNIT 650 (1,430) X2

IDLER ASSEMBL Y 270 (600) X2

LOWER ROLLER ASSEMBL Y 98 (220) X18

UPPER ROLLER ASSEMBL Y 30 (66) X4

TRACK TENSION ASSEMBL Y 325 (720) X2

SPROCKET + BOLTS 100 (220) X2

SWIVEL JOINT 58 (130)

TRACK GUIDE 50 (110) X 4

TRACK CHAINS W/900mm (35.4”) SHOES

TRACK LINK

ATT ACHMENT (STANDARD) 8,100 (17,860)

BUCKET ASSEMBL Y [1.80M3 (2.35 CU YD)] 1,440 (3,170)

ARM ASSEMBLY [3.45m (11’- 4”) 2,380 (5,250)

ARM [3.45 11’ - 4”] 1,450 (3,200)

BUCKET CYLINDER* 360 (790)

IDLER LINK 56 (120) X2

BUCKET LINK 150 (330)

PIN

(2 PCS for mtg bucket cyl, & bucket

BOOM ASSEMBL Y 4,240 (9,350)

BOOM 3,330 (7,280)

ARM CYLINDER* 590 (1,300)

PINS

(mounting for arm)

FLUIDS 1,200 (2,650)

HYD OIL 570 (1,260)

ENG OIL 42 (90)

FUEL 540 (1,190)

WATER 48 (105)

Unit: Kg (lb)

20,800 (45,760)

2,730 (6,006) X2

1,160 (2,560) X2

155 (340)

124 (270)

* DRY WEIGHT

WARNING

USE ONLY LIFTING DEVICES AND EQUIPMENT

WITH RATED CAPACITIES SUFFICIENT TO LIFT

THE SPECIFIC COMPONENT(S) BEING REMOVED

OR INST ALLED.

Page 3-16

Dynamic Acera 03/05 Rev. 05

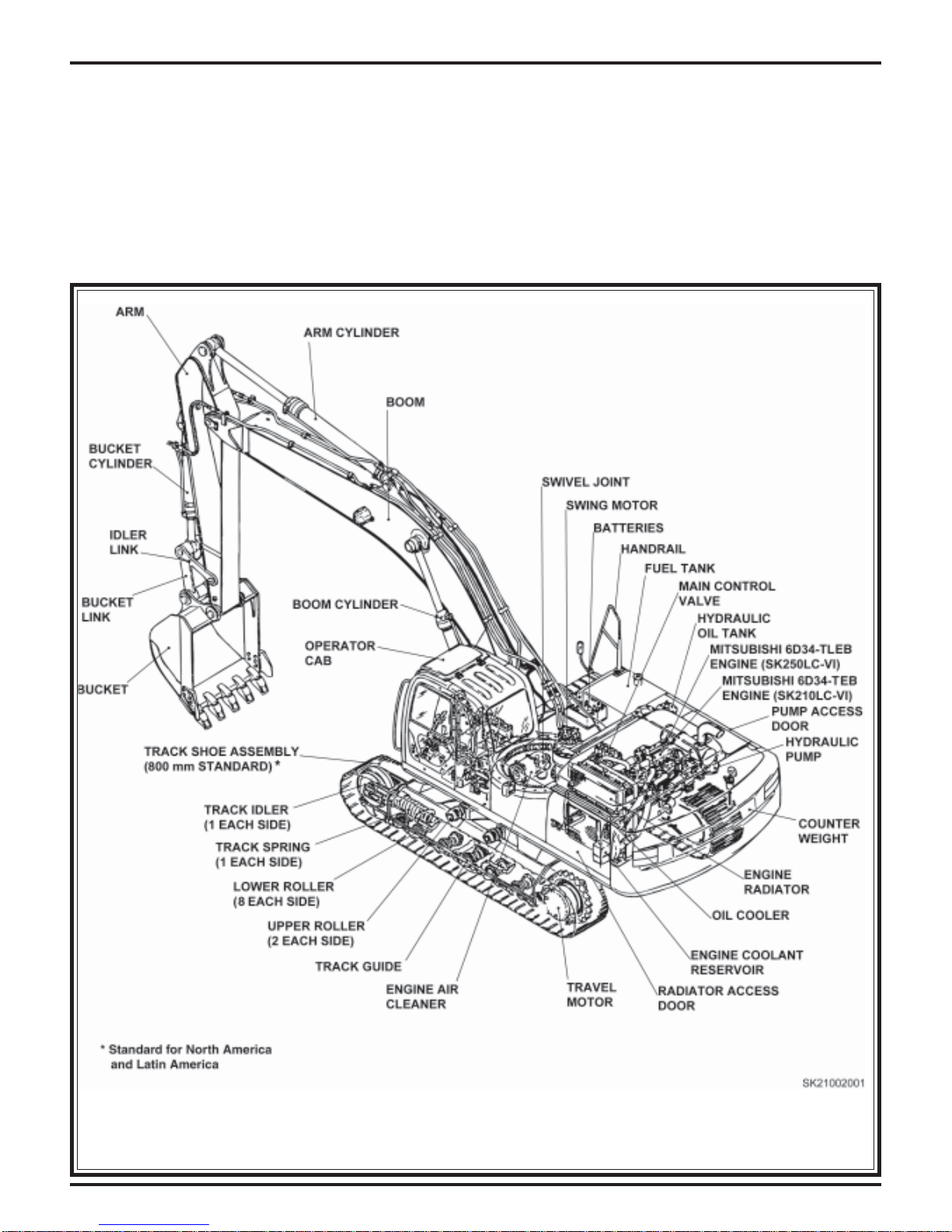

MACHINE FAMILIARIZATION

FAMILIARIZATION

All operators,service mechanics and personnel

responsible for operation,inspection and

maintenance of the machine should become

thoroughly familiar with the controls and components

and their functions before working with or on this

equipment.

Study the information in this section to become

familiar With the controls and components of this

machine.

GENERAL MACHINE NOMENCLATURE

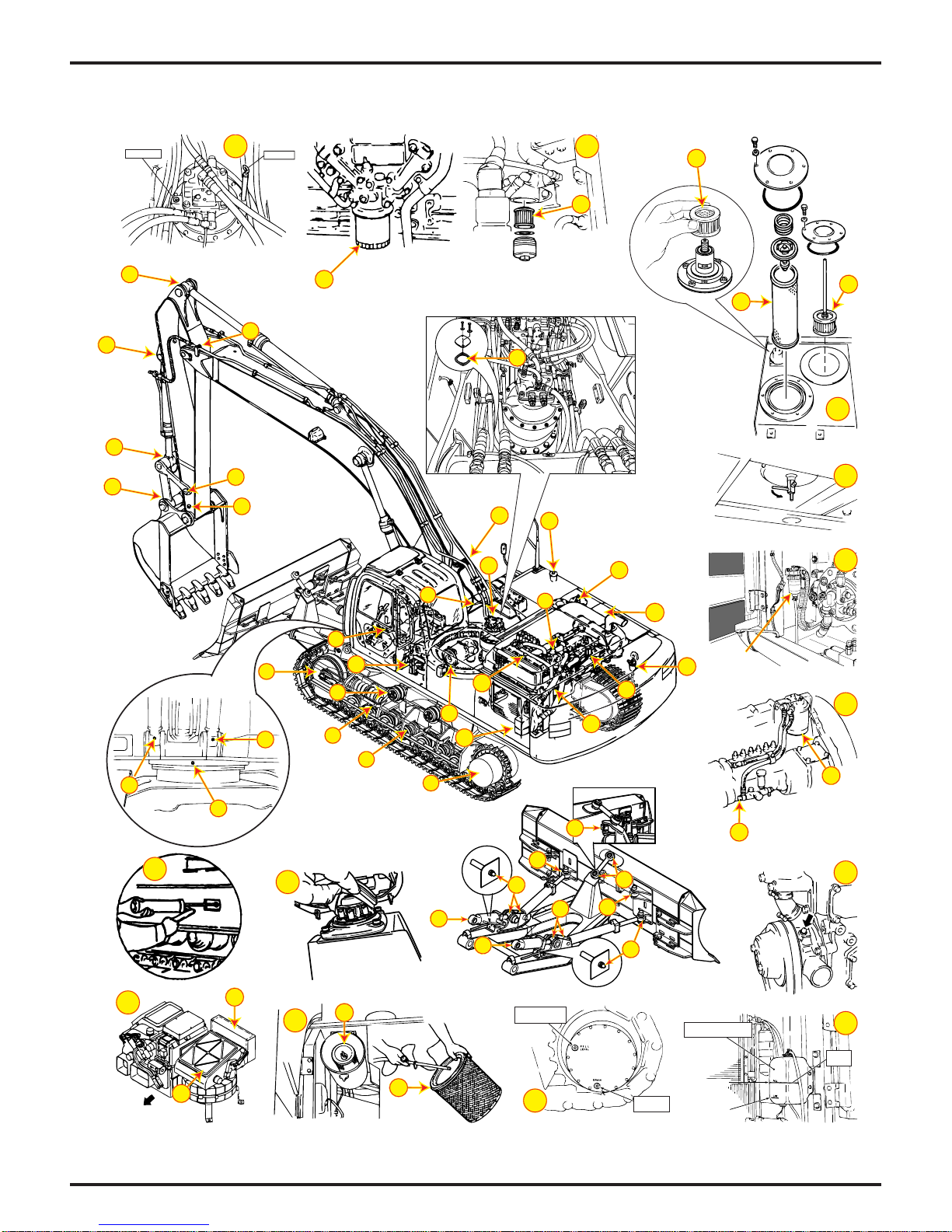

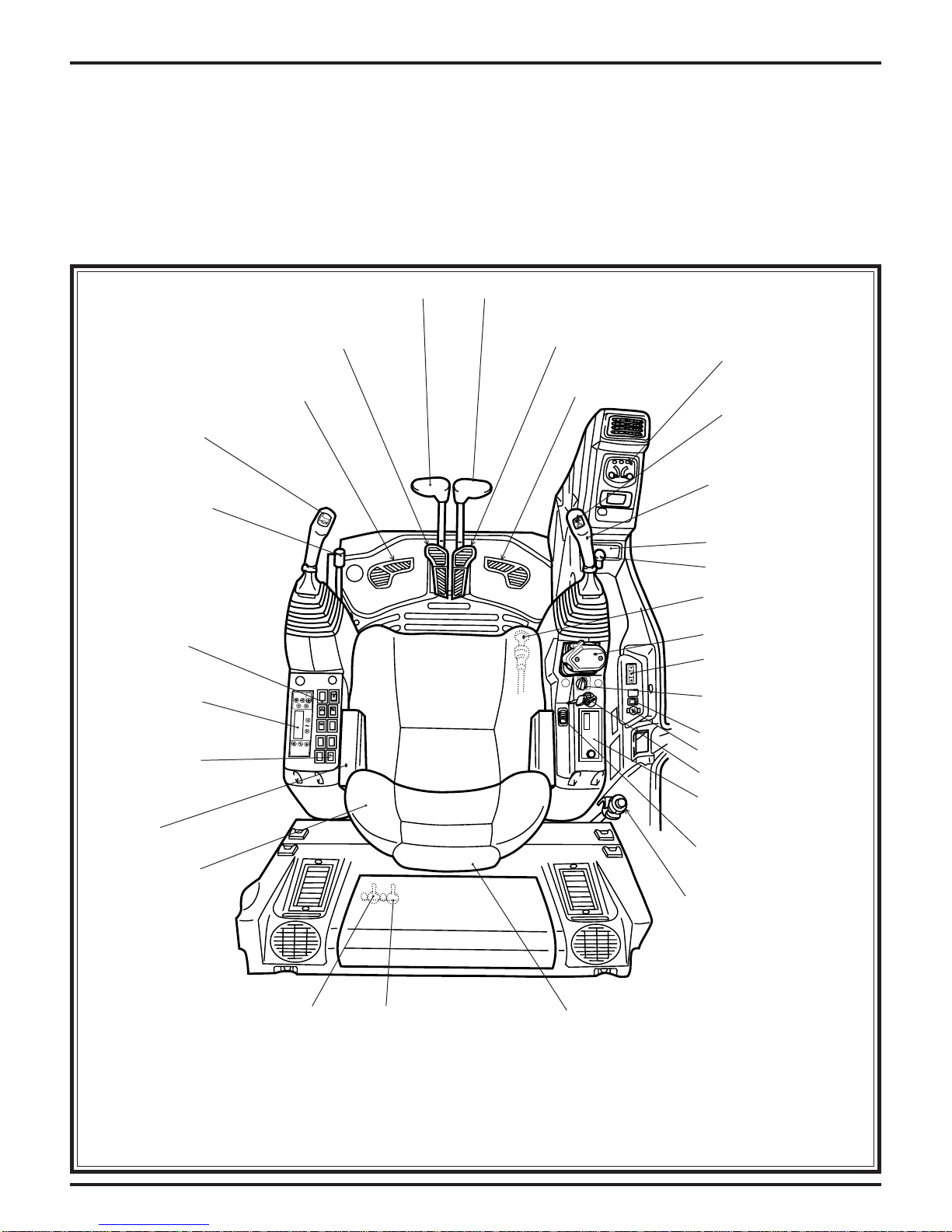

The Nomenclature drawing below (FIGURE

3.12),points out locations of major components of

the KOBELCO SK210(LC)-VI Hydraulic Excavator.

Study these areas and locate these component s on

the machine.Specific information regarding these

components are explained on the following pages of

this section.

Dynamic Acera 03/05 Rev. 05

Figure 3.12 SK210 VI

Page 3-17

MACHINE FAMILIARIZATION

OPERATOR CAB NOMENCLATURE

The operator cab nomenclature (FIGURE 3.13),

points out the locations of operator controls of the

KOBELCO ED190-VI Hydraulic Excavator operator

cab.

LEFT TRAVEL LEVER

LEFT

TRAVEL

PEDAL

LEFT

LEFT HAND OPERATOR

CONTROL LEVER

(HORN SWITCH)

SAFETY LOCK

LEVER

(FOR HYDRAULICS)

FOOT REST

Study these areas and locate these component s on

the machine.Specific information regarding these

components are explained on the following pages of

this section.

RIGHT TRAVEL LEVER

RIGHT

TRAVEL

PEDAL

RIGHT

FOOT REST

GAUGE CLUSTER

POWER BOOST

RIGHT HAND

OPERATOR CONTROL

LEVER

LEFT SIDE

SWITCH PANEL

AIR-CONDITIONER

PANEL

BLADE CONTROL

SWITCH

ARM REST

OPERATORS SEAT

(3 WAY ADJUSTABLE)

ASH-TRAY

24V CIGARETTE

LIGHTER

ENGINE EMERGENCY

STOP CONTROL

DOZER BLADE CONTROL

SWITCH PANEL

(WIPER, WORKING LIGHT)

FAN

TEMP

E

F

F

/

D

E

R

O

D

M

THROTTLE

POTENTIOMETER

SWING FLASHER SWITCH

12V POWER SUPPLY

KEY SWITCH

RADIO (FM & AM)

Locally-procured parts

in European machines

SWITCH PANEL

(KPSS MODE, BUZZER STOP)

ENGINE MANUAL

CONTROL CABLE

KPSS RELEASE

SWITCH

Page 3-18

SWING PARKING BRAKE

RELEASE SWITCH

Figure 3.13 ED190 VI

HEAD REST

(ADJUSTABLE)

ED190opControlpanel

Dynamic Acera 03/05 Rev. 05

MACHINE FAMILIARIZATION

COMPONENT & CONTROLS NOMENCLA TURE

The following information provides a brief description and function of the components and

controls of the KOBELCO SK210(LC)-VI Hydraulic Excavator.

All personnel associated with this machine should

read and understand this information BEFORE

beginning any work with or on this equipment.

RIGHT HAND OPERATOR CONSOLE

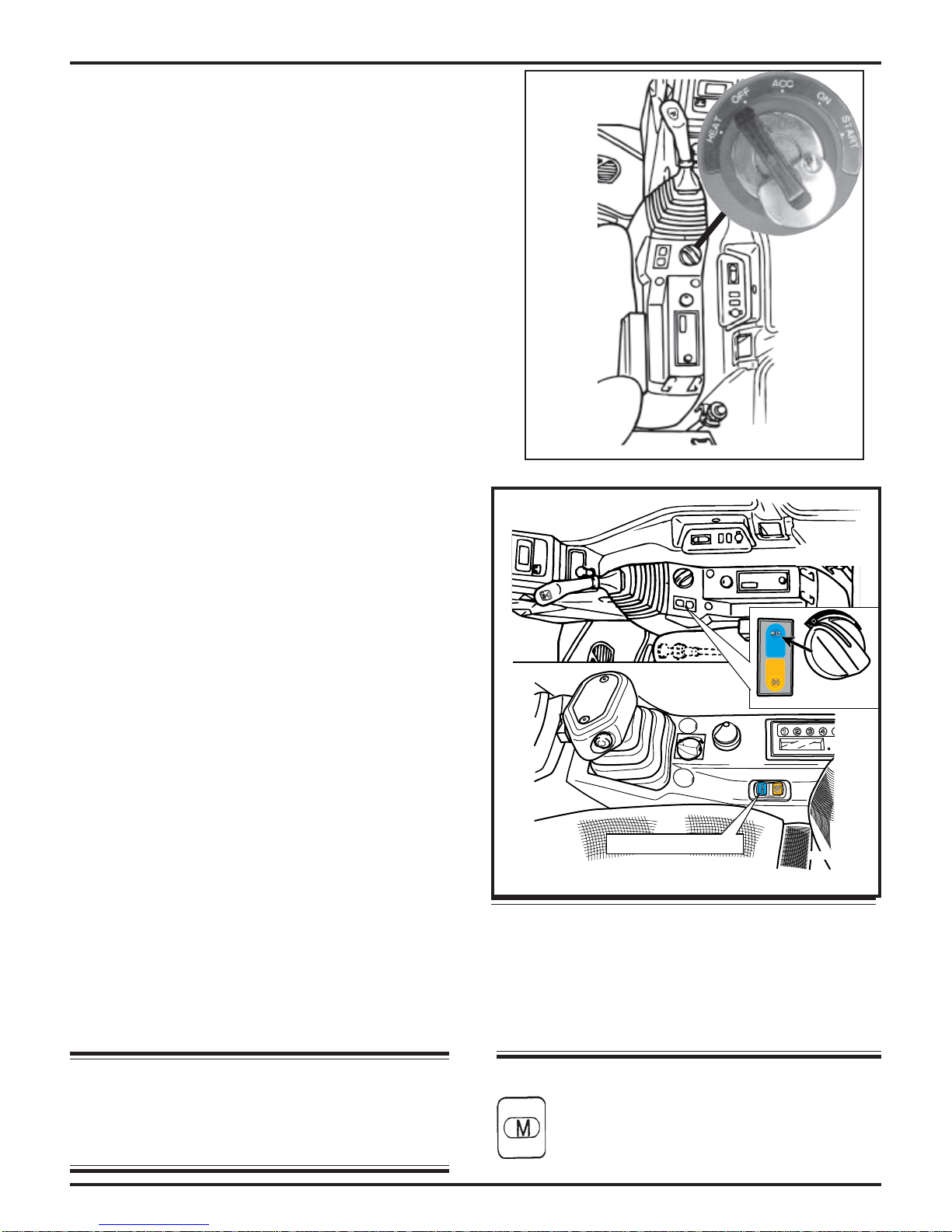

1. Key Switch – FIGURE 3.14.a

The Key Switch is located on the right hand

operator console and has 5 operating functions.

a. “HEAT ”–This position is used for start-

ing the engine in cold climates.

b. “OFF ”–When Key is turned to this posi-

tion, the engine stops and electrical

power to the machine’s electrical systems is stopped after approximately 4

seconds.

c. “ACC ”–With key in the “ACC ”position

only the cigarette lighter, tuner and horn

will have power.

d. “ON”– When Key is in the ON position,

electrical power is supplied to all the

machine ’s electrical systems.

e. “ST ART ”–When key is turned to this po-

sition electrical power is supplied to the

starter solenoid causing the starter to

startthe engine. After engine starts key

should be released to go back to the

“ON ” position.

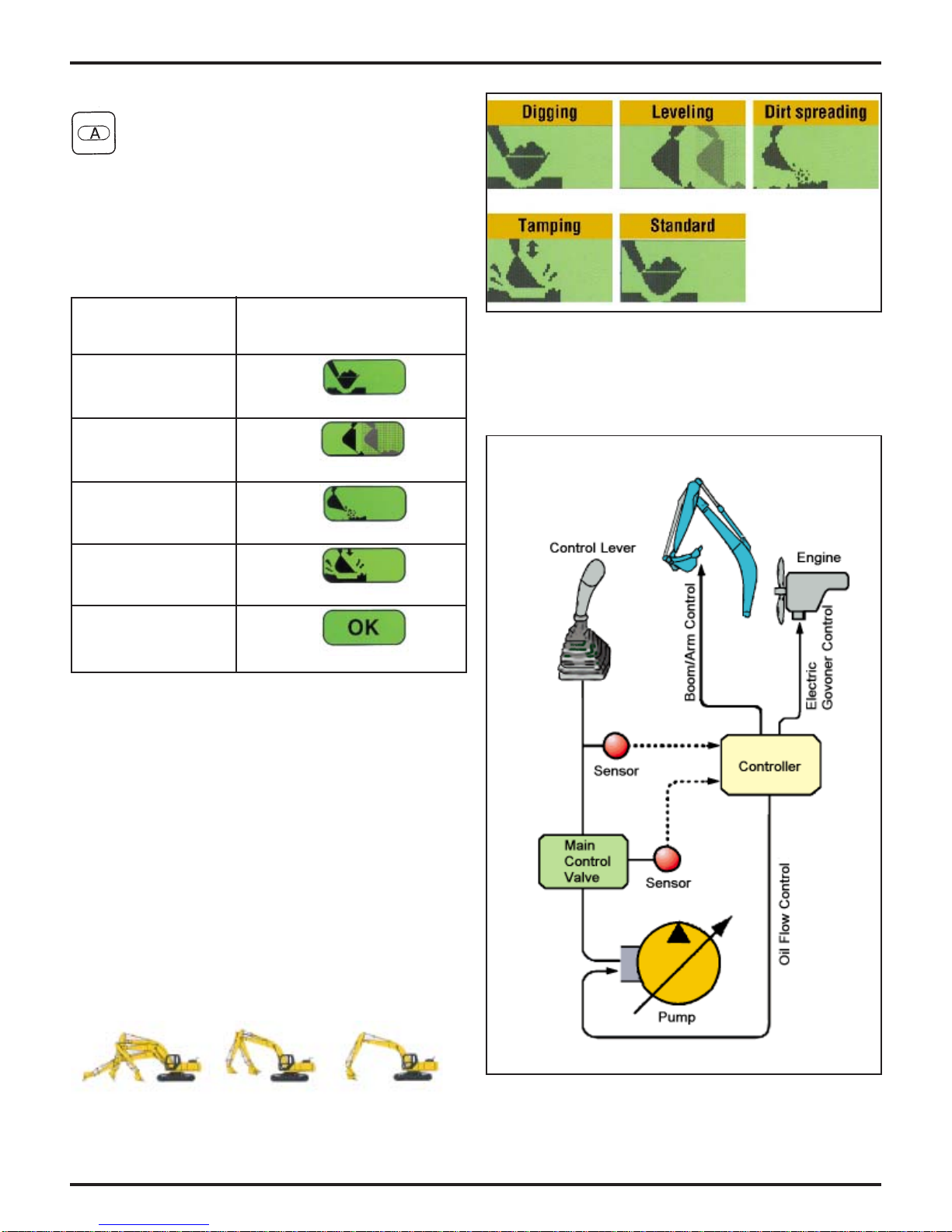

2. KPSS Mode Switch – FIGURE 3.14.b

The KPSS Mode Switch SK160~SK480 is located on the right hand operator console and has

3 operating functions. After starting the engine, the

mode switch defaults to the M for maximum power.

The operator can select an effective work mode

complyingwith the working conditions and working target from 3 modes. Each time the work mode

switch is pressed, the work mode indicator lamp

is switched from M, to A, then to B in that order.

FIGURE 3.14.a

SK160LC

KPSS MODE

SWITCH

ED190

Blade Runner

KPSS MODE SWITCH

KPSS Mode

FIGURE 3.14.b

NOTE

T o clear fault codes on the ED190 press the travel

speed change switch and the buzzer stop switch

at the same time. The new rocker switch for the

Mode/Buzzer Stop switch makes it impossible to

press both switches at the same time.

NOTE

SK480 A Assist mode reduces engine and

pump yield to approximately 90% of maximum

output.

Dynamic Acera 03/05 Rev. 05

a. M (Manual) mode

This mode senses the movement of control lever and is suitable for the heavy

load digging work giving priority to the

work load at high speed.

Page 3-19

MACHINE FAMILIARIZATION

b. A (Assist) mode SK160~SK330

Pressing the work mode selector switch

once changes to “A” or assist mode, located on the left of the three indicator lamps.

The mechatro controller analyzes the operator’s

pattern of joystick lever movement, and uses

“fuzzy logic” to set one of five machine operating parameters FIGURE 3.15.a

Control Mode

Results

Simple digging,

ditch digging, trench

box digging

Leveling,

slope finishing

( Contents on multidisplay

DIGGING

LEVELING

FIGURE 3.15.b

Spreading

SPREADING

Tamping

T AMPING

Traveling,

waiting time

STANDBY

FIGURE 3.15.a

Once the mechatro has analyzed the operators

joystick pattern, a moving graphic FIGURE

3.1 1.b (icon) flashes on the message display of

the monitor screen to show the operator which

assist mode is selected. Control is made easier

as the machine uses this pattern to “ASSIST” in

setting adequate pump and engine operation.

Operating efficiency increases FIGURE 3.15.c

without the operator even noticing.

LEVELING COMP ACTINGSCATTERING

Page 3-20

FIGURE 3.15.c

Dynamic Acera 03/05 Rev. 05

MACHINE FAMILIARIZATION

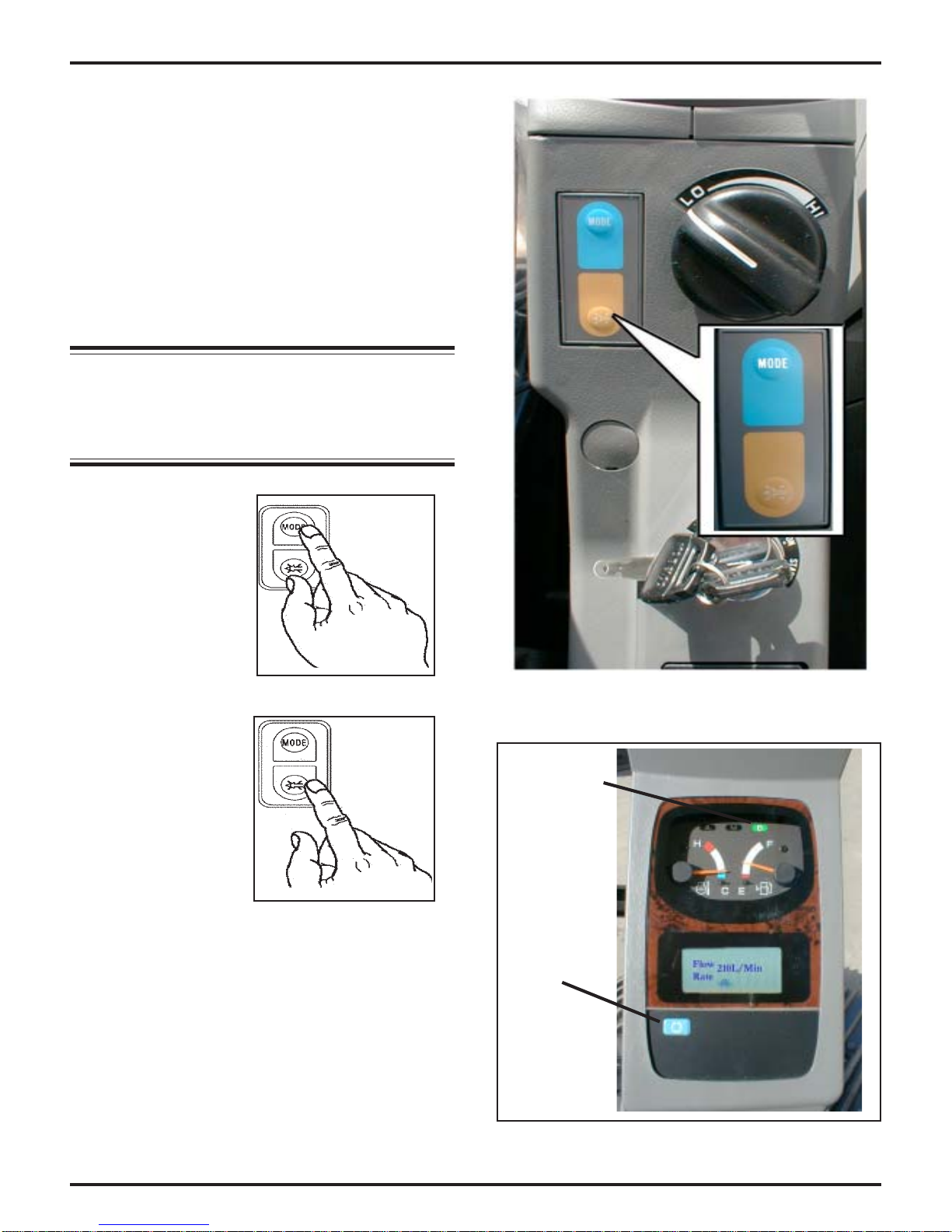

c. Breaker mode

Pressing the work mode selector twice

from “M” mode, changes the machine to

“B” or breaker mode. Located on the

right of M mode. See FIGURE 3.16.a. The purpose of this mode is to allow the operator to

quickly adjust the pump flow rates for various

attachments while sitting in the cab. When the

breaker or attachment is in operation the flow

volume is switched automatically to the operators preset pump flow. The flow returns to normal setting when the breaker or attachment is

not being used.

NOTE

The breaker flow is not set at the factory to deliver

maximum pump flow. T o change the flow rate to a

higher or lower setting see the following

information. “Gauge cluster will display pump flow

in metric units only .”

KPSS WORK MODE LAMP

SCREEN

CHANGE

SWITCH

FIGURE 3.16.a

W ARNING

Do not operate this machine unless you have

read and understand the instructions in the

OPERATORS MANUAL. Improper machine

operation is dangerous and could result in

injury or death.

1. With Safety Lock in the up or lock position,

place keyswitch to on position, do not start

engine. See FIGURE 3.16.b

2. Press the mode switch two times, the LCD

screen will display the set flow rate of the

breaker circuit. See FIGURE 3.17.c.

3. To change the pump flow (both pumps are

changed SK160 and up) move machine to

safe work area and turn keyswitch to off. Wait

ten seconds then procede.

Minimum / Max flow rate

1. Preparation

a. Keyswitch must be in off position for ten

seconds.

b. Turn keyswitch to on position do not start

engine, place safety lock in up position.

c. Press mode switch twice to select (B)

Breaker mode.

adjusting

procedure

FIGURE 3.16.b

NOTE

It is impossible to adjust flow rate after starting of

engine.

Step A-Max./Min. flow rate adjusting procedure

d. Press the screen change switch for 5 ~ 10

seconds and release. See FIGURE 3.16.a

the LCD screen displays the flow rate

stored in memory .

e. Press the mode switch once, see FIGURE

3.17.b flow rate value will increase in 10L/

min. increments. If mode switch is held

down for more than five seconds, flow rate

will increase rapidly . Release mode switch

when you have reached your desired

value.

Continued on next page -

Dynamic Acera 03/05 Rev. 05

Page 3-21

MACHINE FAMILIARIZATION

Min/Max flow rate adjustment - Cont.

f. Press the buzzer stop switch once, see

FIGURE 3.17.c. flow rate value will

decrease in 10L/min. increments. If buzzer

stop switch is held down for more than five

seconds, flow rate will decrease rapidly .

Release buzzer stop switch when you

have reached your desired value.

g. Press the screen change switch to store

the new flow rate value.

NOTE

If keyswitch is turned off before pressing the

screen change button and returning LCD screen

to OK new values will not be saved.

Press mode switch

in breaker flow rate

adjustment will

increase flow.

Press buzzer switch

in breaker flow rate

adjustment will

decrease flow.

FIGURE 3.17.a

FIGURE 3.17.b

FIGURE 3.17.c

KPSS work

mode lamp

Screen

change

switch

Page 3-22

FIGURE 3.17.d

Dynamic Acera 03/05 Rev. 05

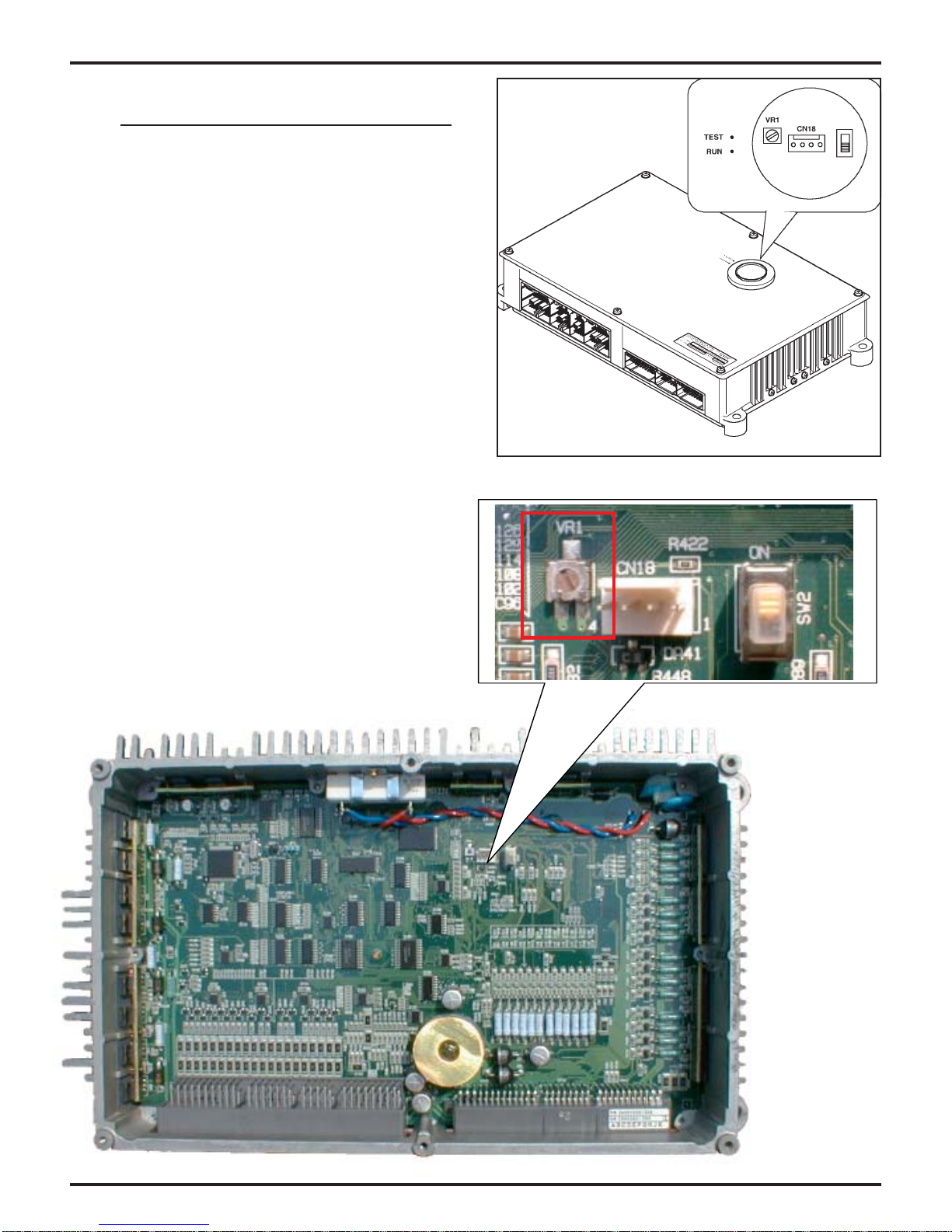

Auxiliary Flow Control Adjustment Potentiometer - (VR1 Trimmer)

Maximum / Minimum VR1 overide Protection - Pre minor change SK160~SK480 only

Located inside the mechantro controller on the

main circuit board is a trimmer dial VR1 which

will override the screen preset flow setting procedures. Not only will this feature provide protection

for equipment in “A” or “M” modes, it can also be

used to dial in flows less than which is stored in

memory of “B” mode.

This Flow control protection can be used to protect “auxiliary hydraulic circuit” but will not limit main

excavator boom,arm,bucket swing or travel

speed.Only the auxiliary attachment flow is controlled through the setting. See FIGURE 3.13.d.

Proper Adjustment thru the VR1 trimmer is

achieved by installing a proper flow meter in Series with the auxiliary attachment and after the

proper axillary attachment pressure has been

adjusted thru that circuit’s relief cartridge then insert a small flat blade screwdriver into the VR1

trimmer and adjust either clockwise or counter

clockwise for increased or decreased pump flow.

FIGURE 3.13.d

Note: Machine is shipped from the factory with

the VR1 trimmer set between 30%~ 95% of flow.

Dynamic Acera 03/05 Rev. 05

Page 3-23

MACHINE FAMILIARIZATION

3. Buzzer Stop Switch – FIGURE 3.18.a

When the engine coolant temperature

is too high, or various sensors of

mechatro controller (self-diagnosis)

fail, the alarm sounds intermittently . T o

stop thesound, press the buzzer stop button.

NOTE

• Buzzer sounding due to engine cooling water

temperature rise can not be stopped.

• The buzzer sounding, because the preheat

complete and E/G oil pressure are displayed,

stops by turning the key switch OFF.

SK160LC

KPSS MODE

SWITCH

ED190

Blade Runner

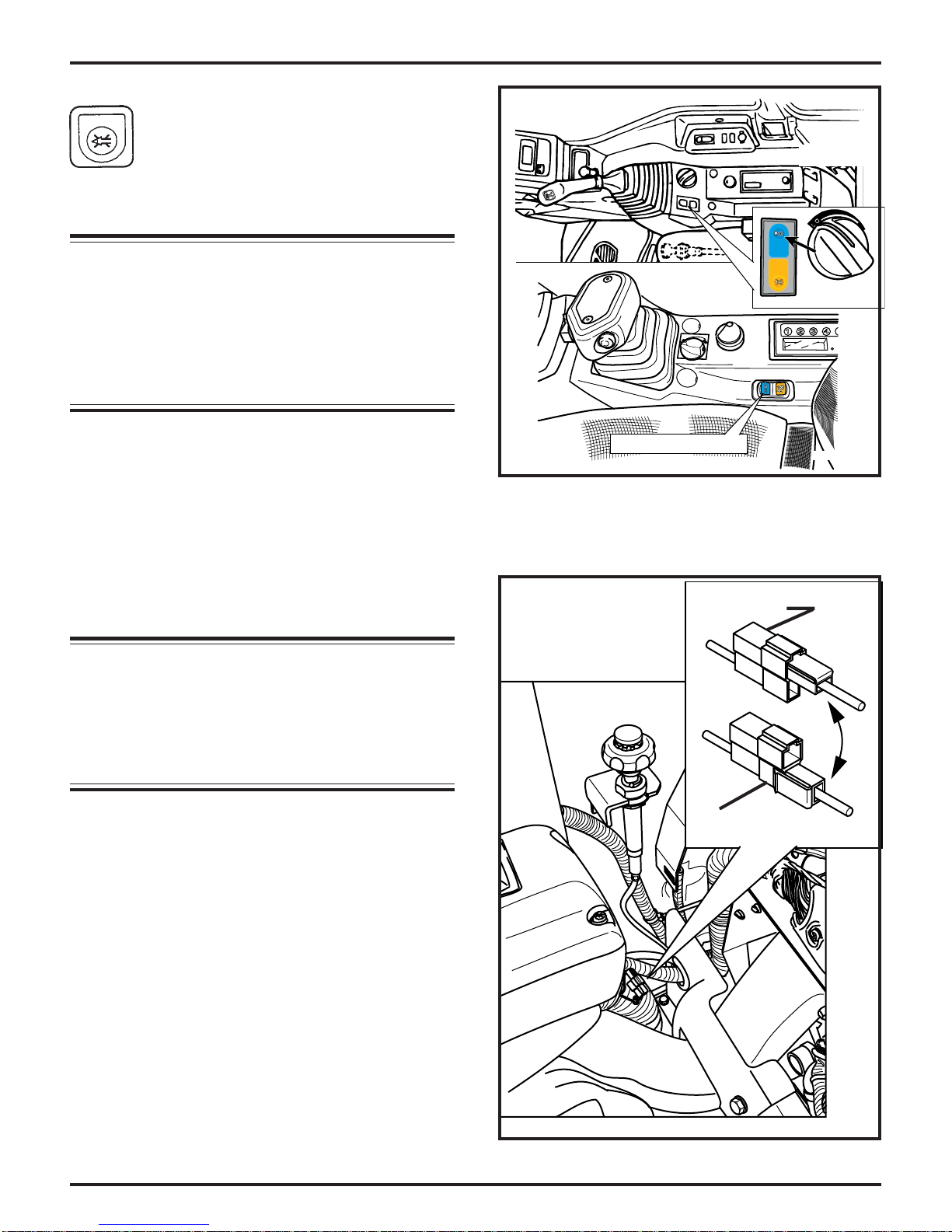

4. Throttle Potentiometer – FIGURE 3.18.A

The throttle potentiometer’s located on the

right hand operator console and controls

engine RPM. When the throttle potentiometer is rotated to right or left position it increases or decreases engine rpm and maintains engine at the programed RPM for that

particular position on the dial.

NOTE

In operation, when all pilot controls are in the

nuetral position for more than three seconds,

and the engine RPM is above 1050, the auto

excel reduces the engine speed to 1050.

Manual Auto Accel Over ride Procedure:

Auto accel release condition

1. Place the safety lever in the up and lock position.

KPSS MODE SWITCH

FIGURE 3.18.a

Normal position

Auto-acel. ON

Maintenance position.

Auto-acel disconnected

KPSS Mode

2. Located the one pin connector for the auto

acceleration function behind the operators

right hand console see FIGURE 3.18.b.

3. Change the position of the connector as in

indicated in FIGURE 3.18.b.

Page 3-24

Autoaccelconnector

FIGURE 3.18.b

Dynamic Acera 03/05 Rev. 05

Loading...

Loading...