Kobelco KNW Series, KNWA00 Instruction Manual

MODEL#: SERIAL#:

INSTRUCTION MANUAL

KOBELCO is the international trademark found on all products of KOBE STEEL, LTD.

MODEL:

KNWA00

RECORD OF CHANGE H

KIMA00H1 (0204)

SAFETY PRECAUTIONS

Safety notices, marked with this symbol, are used in this

publication to emphasize that a hazardous condition exists that

could cause personal injury and/or damage to the equipment.

1. Read and understand the contents of this manual before installing,

operating or maintaining the compressor.

2. Electricity and compressed air are dangerous. When performing

maintenance or service work, make absolutely sure the electrical supply is

disconnected and locked out. The discharge air lines service valve

(customer furnished) must be closed and the compressor relieved of all

internal pressure. DO NOT rely on the discharge air line check valve.

3. Compressed air from this unit must not be used for breathing or food

processing without adequate filtering and monitoring to meet OSHA 29

CFR 1910 or FDA 21 CFR 178.3570.

4. Do not allow flammable, toxic or corrosive gases to enter the air inlet

system or electrical devices.

5. Never attempt to work on compressor or remove guards, panels,

covers, shields, etc. while the compressor is in operation.

6. Periodically confirm that all safety and shutdown devices are operating

properly.

7. Do not override any safety or shutdown device.

8. Make certain all associated pipe and equipment beyond this

compressor is compatible with maximum pressures and temperatures to

be encountered during normal and adverse operation. Do not use plastic

pipe in the compressed air system.

9. Keep doors closed during normal operation. The noise level inside

cabinet exceeds 90 decibels (dbA) and the operating temperature of some

components is sufficient to burn the skin.

10. Never assume it is safe to work on the compressor because it is not

operating. Many installations have automatic start/stop controls, and the

compressor may start at any time.

KIMA00H1 (0204)

TABLE OF CONTENTS

1. GENERAL DESCRIPTION................. 1 5.2 Programmable Logic

1.1 Compressor................................ 1 Controller.................................... 27

1.2 Compressed Air Flow................. 3 5.2.1 CPU................................. 27

1.3 Cooling Air Flow......................... 5 5.2.2 PLC Status LED’s............ 29

1.4 Oil Flow....................................... 5 5.2.3 PLC Inputs....................... 29

1.5 Capacity Control System............ 7 5.2.4 PLC Outputs.................... 29

1.5.1 Unloaded, Off...................7 5.2.5 PLC Analog Inputs........... 31

1.5.2 Loaded, Running............. 7 5.2.6 Expansion Module

1.5.3 Unloaded, Running.......... 7 Replacement....................31

1.6 Monitoring and Limiting 5.3 Motor Starter............................... 31

Devices....................................... 7

1.7 Alerts........................................... 9 6. MAINTENANCE.................................. 33

1.8 Shutdowns.................................. 9 6.1 Daily............................................ 33

6.2 Weekly........................................ 33

2. INSTALLATION...................................13 6.3 Monthly........................................33

2.1 Inspection....................................13 6.4 Yearly.......................................... 33

2.2 Handling...................................... 13 6.5 Two Year.....................................35

2.3 Foundation.................................. 13 6.6 Lubrication.................................. 35

2.4 Location...................................... 13 6.7 Filter Maintenance...................... 37

2.5 Cooling Air.................................. 13 6.7.1 Dust Filters.......................37

2.6 Air Discharge Piping................... 15 6.7.2 Inlet Air Filter....................37

2.7 Air Receiver................................ 15 6.7.3 Lube Oil Filter...................37

2.8 Wiring.......................................... 17 6.7.5 Sump Breather.................37

3. START UP............................................ 19 SERVICE PARTS LIST.......................38

3.1 Pre-Start Up Check....................... 19

3.2 Initial Start Up................................19

7. STANDBY and STORED UNITS........ 39

4. OPERATING INSTRUCTIONS............ 21 7.1 Stand-by Compressors............... 39

4.1 Starting the Compressor............... 21 7.2 Short Term Storage.................... 39

4.2 Stopping the Compressor............. 21 7.3 Long Term Storage.................... 39

4.2.1 Manual Stop.......................21

4.2.2 Automatic Stop.................. 23

4.3 Normal Operating Conditions........23 8. PROBLEM SOLVING......................... 40

Problem-Cause & Remedy

5. ELECTRICAL CONTROLS................. 25 Compressor................................ 40

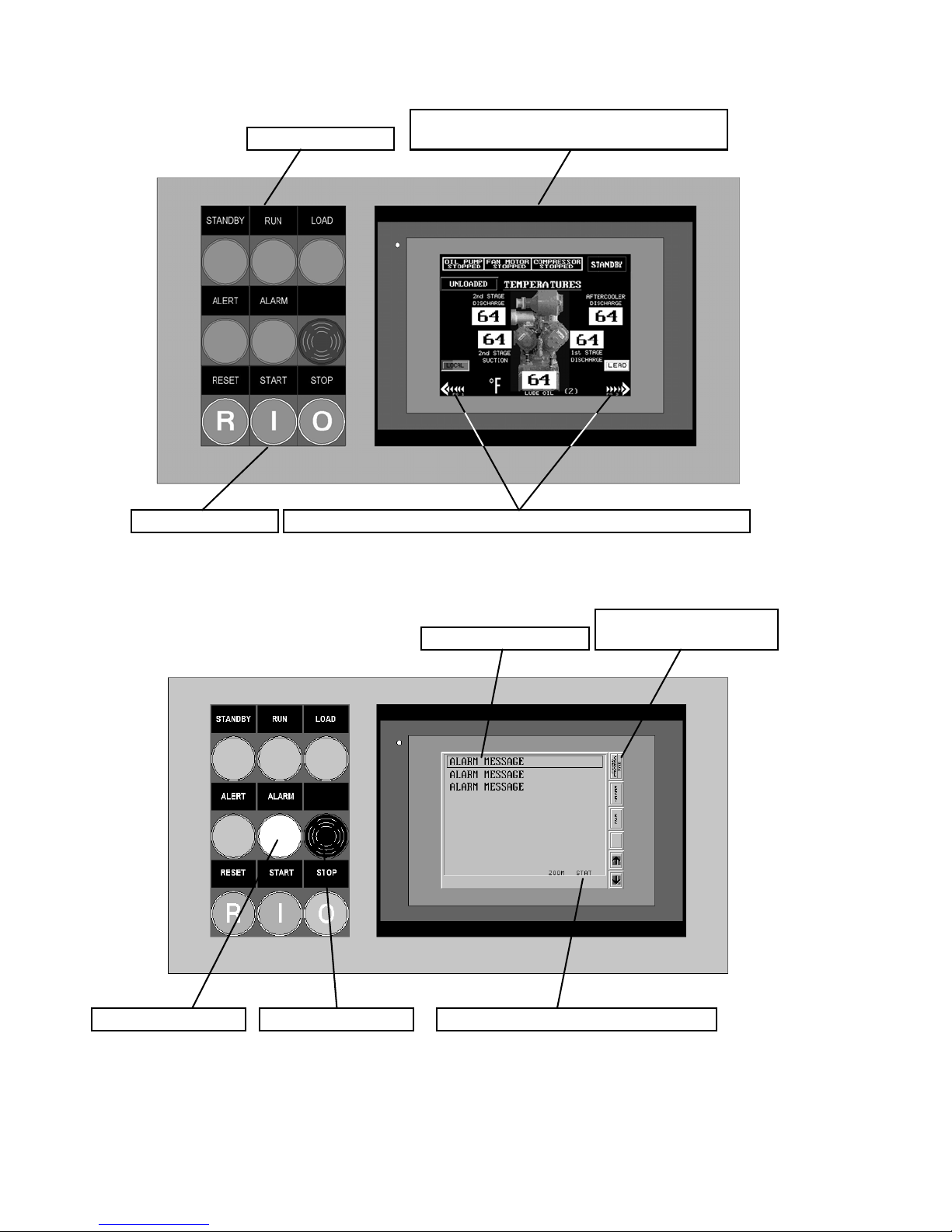

5.1 Compressor Operator Panel PLC ............................................ 42

5.1.1 GT Terminal

Page Selection.................25 APPENDIX

5.1.2 Display Maintenance....... 27 A. Daily Operating Record ..................43

5.1.3 GT Terminal Options....... 27 B. Unit Dimensions .............................45

KIMA00H1 (0204)

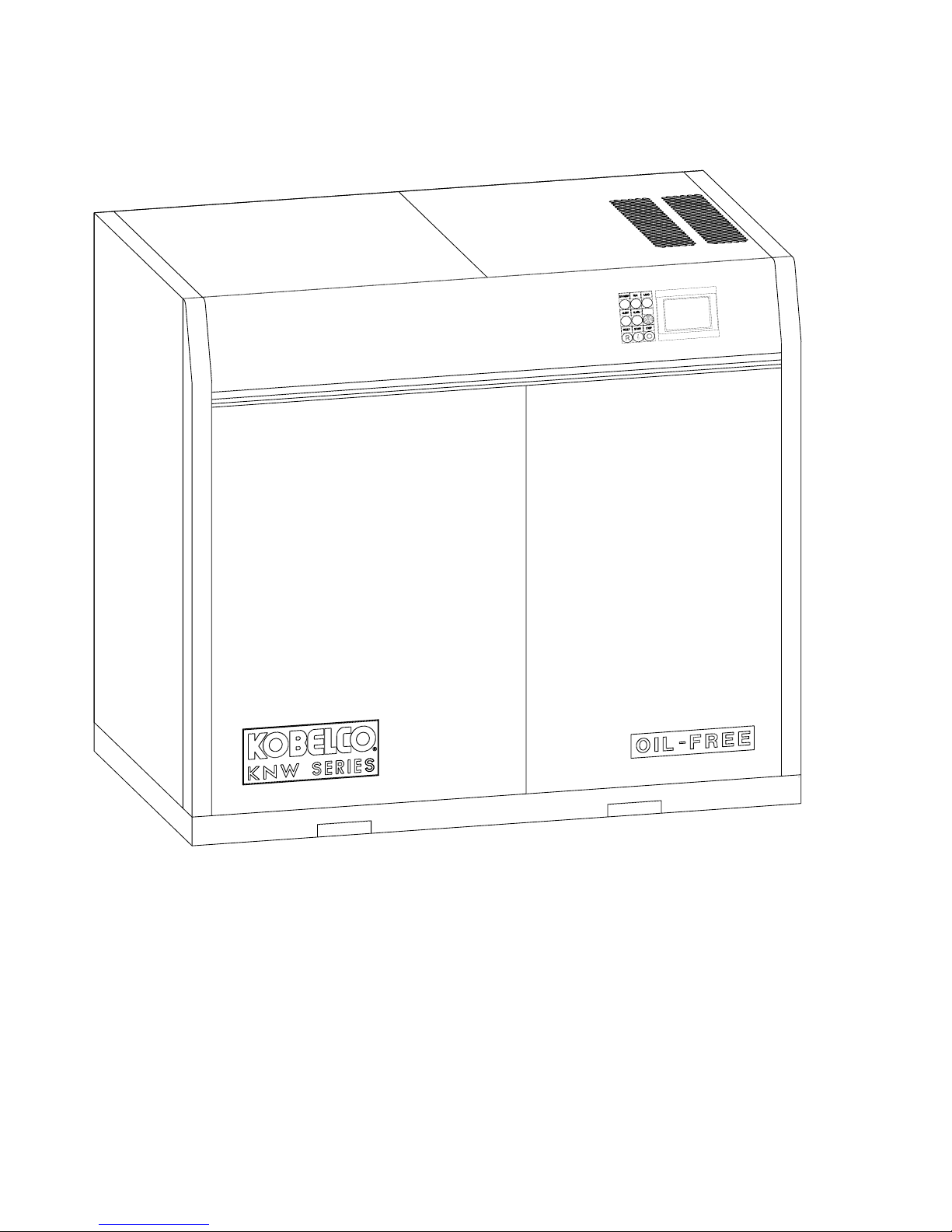

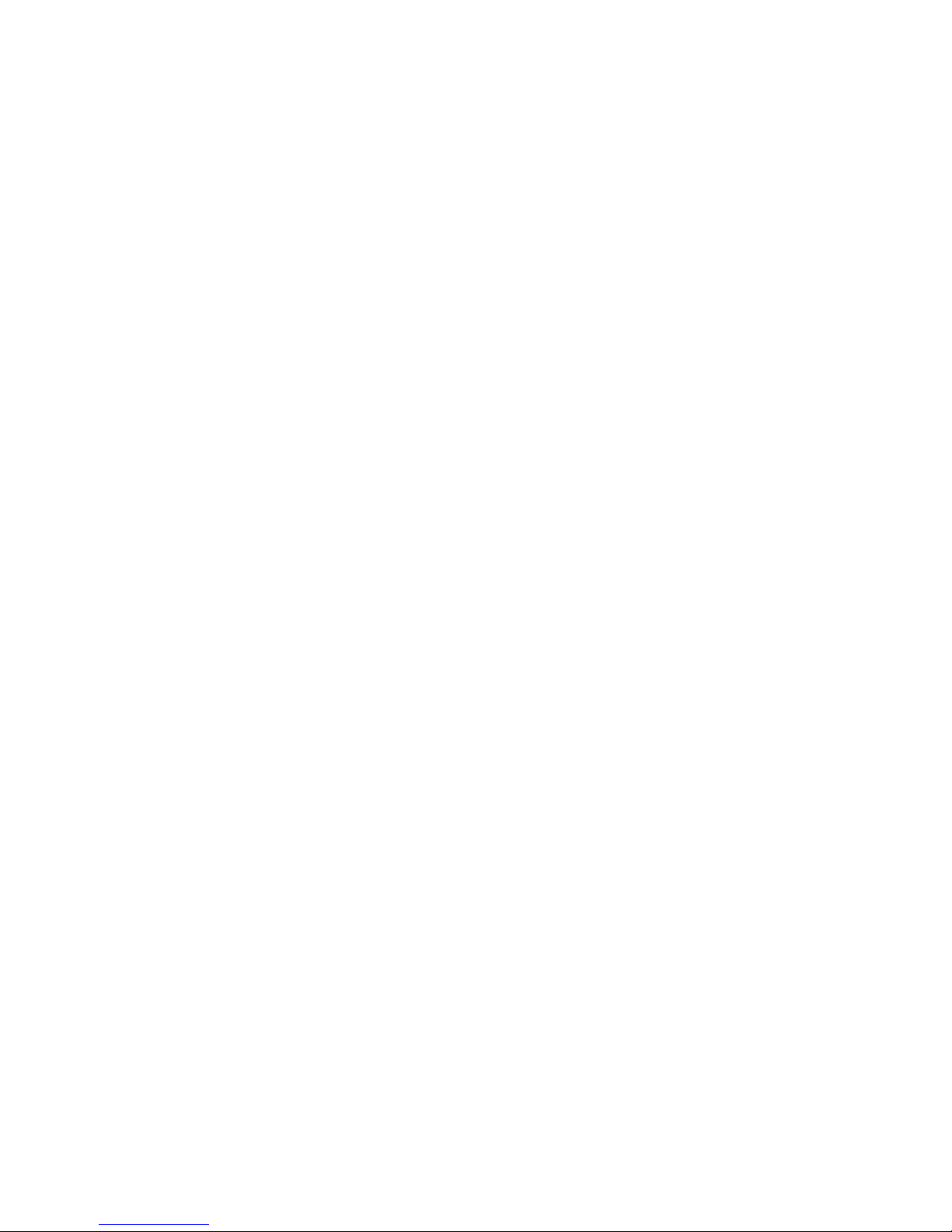

FIGURE 1 - KOBELCO KNW SERIES

MODEL A00 AIR COMPRESSOR

KIMA00H1 (0204)

1. GENERAL DESCRIPTION

1.1

Compressor

The Kobelco KNW Series air compressor is a heavy duty, two-stage,

rotary screw design that provides completely oil-free compressed air.

Oil-Free compressed air is guaranteed by a unique seal arrangement

that separates the bearings and gear chambers from the compression

section of each stage. The dual vent seal design insures that no oil or

its vapor can contaminate air that is being compressed.

The two-stage design provides higher output pressures at a lower

operating temperature than would be available from a single-stage

design. Both compressor stages are mounted on a heavy duty cast

iron gear case for permanent alignment. The stages are driven

through precision machined gears, selected for optimum operating

speed to maximize efficiency and reduce rotor thrust.

Timing gears are used to separate the rotors and to assist in reducing

thrust on the rotors and the rotor bearings, thus extending bearing life.

The Kobelco KNW Series Oil-Free Air Compressor is a complete

operating system. A flange-mounted permanently aligned drive motor,

intercooler, aftercooler, capacity control valve assembly, lube oil

system, compressor controls, and related accessories, are all

mounted inside a sound attenuating steel cabinet. All compressor

mounting points are vibration isolated. Flexible connections between

the compressor assembly and the cabinet insure that no vibration, and

its related noise, are transmitted to the cabinet. The result is a very

stable and quiet running assembly.

The KNW Series compressor features a separately driven oil pump for

drive gear, timing gear, and bearing lubrication. The lube oil pump

starts first, then, after a brief delay, the compressor drive motor starts.

Starting of the drive motor is delayed to allow pressurized lubrication

of the bearings and gears during acceleration of the compressor. The

pump is also timed to stop after the compressor. Oil pressure is

maintained while the compressor coasts to a stop. Maximum

component life is assured by thorough lubrication of moving

components.

Another feature of the KNW Series is the direct operating capacity

control valve and bleed-off system. This unique valve design provides

for extended service intervals and eliminates the need for a bleed-off

cooler.

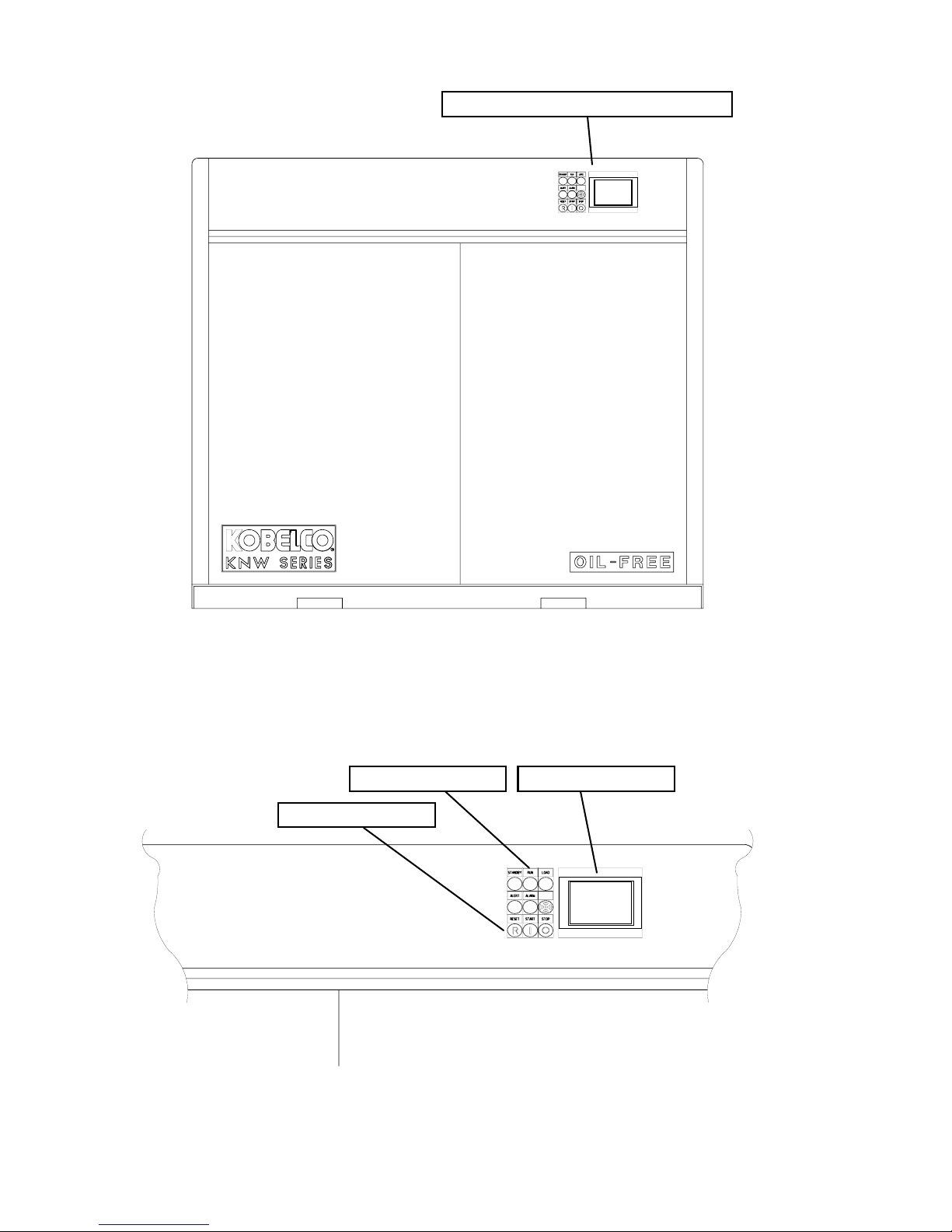

The KNW Series Compressor Operator Panel is a state-of-the-art

control system combining robust industrial controls with leading edge

operator interface and programmable logic controller technology.

Exclusive to KNW Series compressors is the GT Terminal, a versatile

graphic touchscreen display with clear graphics and user-friendly

operation, showing all necessary compressor information in an easy to

understand format.

KIMA00H1 (0204)

1

COOLING

AIR OUTLET

AFTERCOOLER

AIR INLET

COOLING

AIR INLET

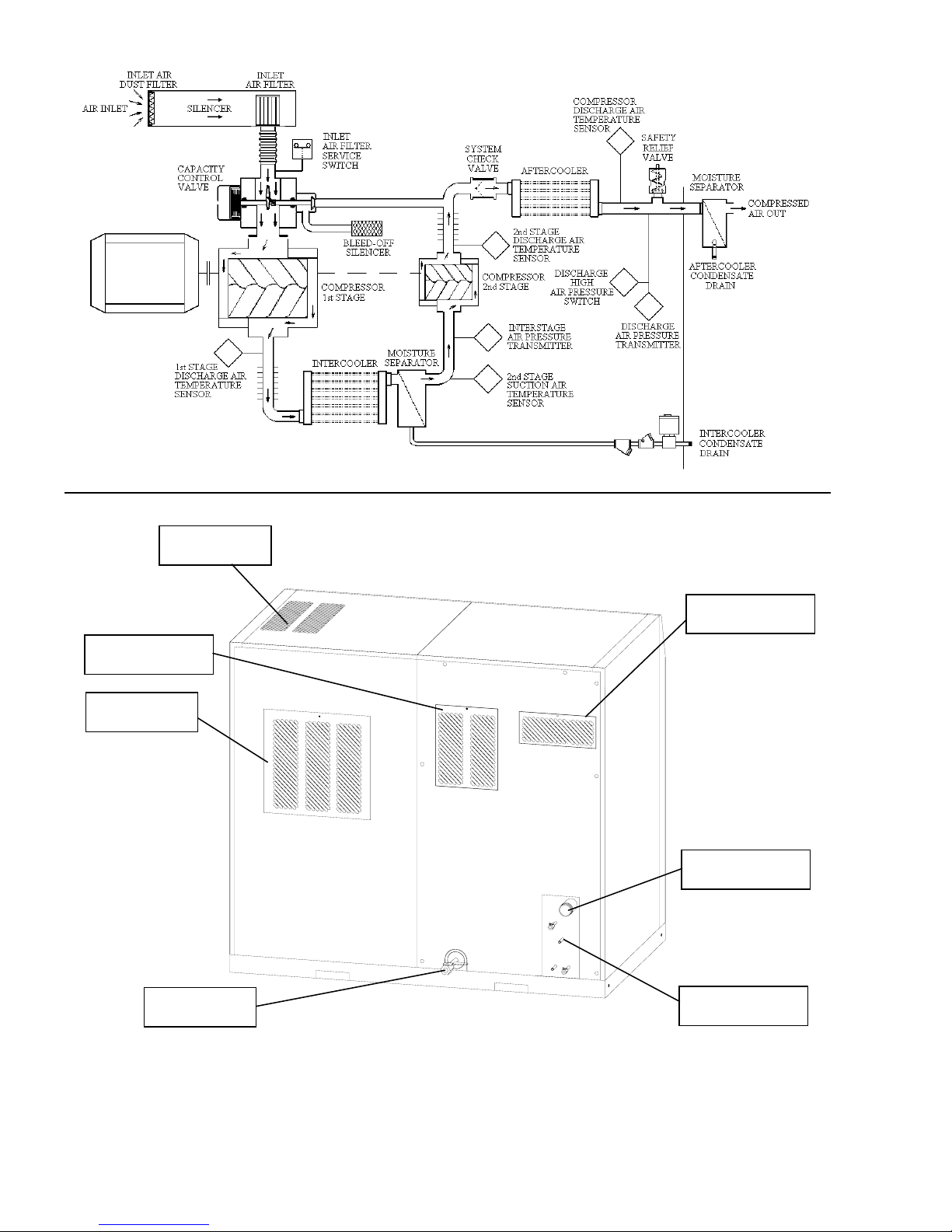

FIGURE 2 - COMPRESSED AIR FLOW DIAGRAM

COMPRESSOR

AIR INLET

COMPRESSED

AIR DISCHARGE

SUMP

OIL DRAIN

FIGURE 3 - BACK OF COMPRESSOR

2

CONDENSATE

DRAIN

KIMA00H1 (0204)

1.2

Compressed

Air Flow

(Figure 2)

Air to be compressed undergoes two stages of filtration before being

compressed. The air enters the cabinet through an opening that is

equipped with a dust filter. The air then passes through the air inlet

silencer, a duct that is lined with a sound absorbing material. Then

the air is drawn through a high efficiency air filter. Filtered air flows

through a flex connector, into the capacity control valve, and then into

the inlet of the compressor first stage.

The compressor first stage compresses the filtered air to

approximately 37 PSIG. The compressed air is discharged into the aircooled intercooler where it is cooled to approximately 115°F (46°C).

The cooled, compressed air then passes through the moisture

separator to remove any condensed moisture from the air stream

before entering the compressor second stage.

The compressor second stage compresses interstage air to the

system operating pressure as controlled by the pressure setting. The

hot compressed air then passes through the system check valve and

air-cooled aftercooler where it is cooled to within approximately 15°F

(8°C) of the ambient air temperature. An ASME safety valve is

downstream of the check valve. The compressed air exits the unit

into a moisture separator, where condensed moisture is removed

before the air enters the plant air system.

The compressed air circuit is monitored with the following discrete

devices:

a. Inlet air filter service switch

b. Discharge high air pressure switch

c. Discharge air safety relief valve

The Programmable Logic Controller, PLC, (ref. Section 5.2) monitors

the compressed air circuit for the following:

a. First stage discharge air temperature

b. Interstage air pressure

c. Second stage suction air temperature

d. Second stage discharge air temperature

e. Compressor discharge air pressure

f. Compressor discharge air temperature

The air temperatures are displayed on the GT Terminal. The PLC

continuously monitors for excessive heat, providing a warning if

temperatures approach the recommended maximum and a shutdown

if they reach the limit. The interstage pressure is monitored to provide

load/unload indication and to confirm capacity control valve operation.

The pressure at the compressor discharge is monitored to provide

load and unload pressure control and a high pressure alarm.

KIMA00H1 (0204)

3

AFTERCOOLER EXHAUST

AFTERCOOLER

AIR DUCT

AIR INLET

(REAR)

AIR DUCT

AIR

OUTLET

COOLING

FAN

OIL

COOLER

FIGURE 4 - COOLING AIR FLOW

INTERCOOLER

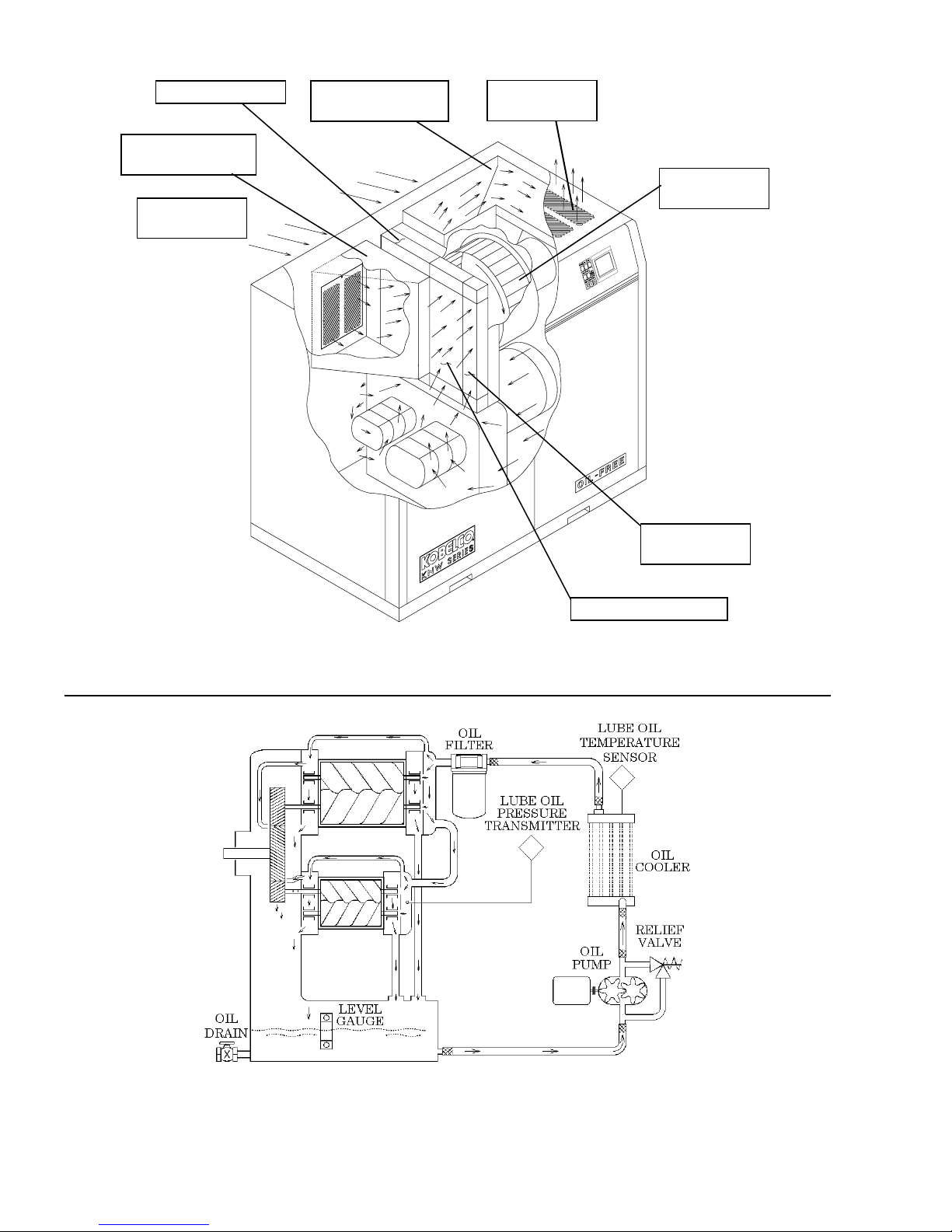

FIGURE 5 - LUBRICATION OIL FLOW DIAGRAM

4

KIMA00H1 (0204)

1.3

Cooling

Air Flow

(Figure 4)

A separate electric motor driven fan draws ambient air into the cabinet

through screens in the back panel. The screens are equipped with

dust filters. The air takes one of two flow paths. The first passes

directly through to the aftercooler and exhausts through the top of the

enclosure. In the second path, air enters near the motor, cools the

compressor motor and passes into the compressor section of the

cabinet. The air then goes through both the intercooler and oil cooler

which are mounted side by side. The fan draws all the air through the

exhaust chamber and out the top of the enclosure.

When the compressor unloads, hot air is discharged through the

bleed-off silencer, pulled through the fan and exhausted. A

temperature switch shuts down the compressor if the air temperature

inside the cabinet exceeds 150°F (65°C).

1.4

Lubrication

Oil Flow

(Figure 5)

Oil for bearing and gear lubrication is stored in a sump, in the lower

section of the main gear case/compressor housing. A sight glass,

located on the side of the oil sump, is used to monitor the oil level.

Lube oil is drawn from the sump by a separate motor driven oil pump.

An oil pump discharge relief valve is provided to maintain a constant

pressure for component lubrication by relieving excessive pressure

back to the suction of the pump.

Oil leaving the pump is cooled to approximately 28°F (15°C) above

ambient air temperature in the oil cooler and is then filtered before

entering an oil gallery on the rear of the compressor first stage. A

portion of the lube oil passes through a tube to an oil gallery on the

rear of the compressor second stage. Lube oil flows from the oil

galleries to the front of each stage to lubricate and cool the front

bearings and drive gears. Lube oil passes through internal passages

from the galleries to lubricate the rear bearings and the timing gears.

All lube oil drains back into the sump.

The lube oil circuit is monitored with the following discrete devices:

a. Sump oil level indicator.

b. Lube oil filter differential switch.

The Programmable Logic Controller, PLC, (ref. Section 5.2) monitors

the lubrication circuit for the following:

a. Lube oil pressure

b. Lube oil temperature

The oil temperature is displayed on the GT Terminal. The PLC

monitors the lube oil temperature. A warning is provided as the

temperature approaches the recommended maximum operating

temperature, and a shutdown if it reaches the limit. The lube oil

pressure is monitored for alarm shutdown if the oil pressure is too low

while the compressor is operating.

KIMA00H1 (0204)

5

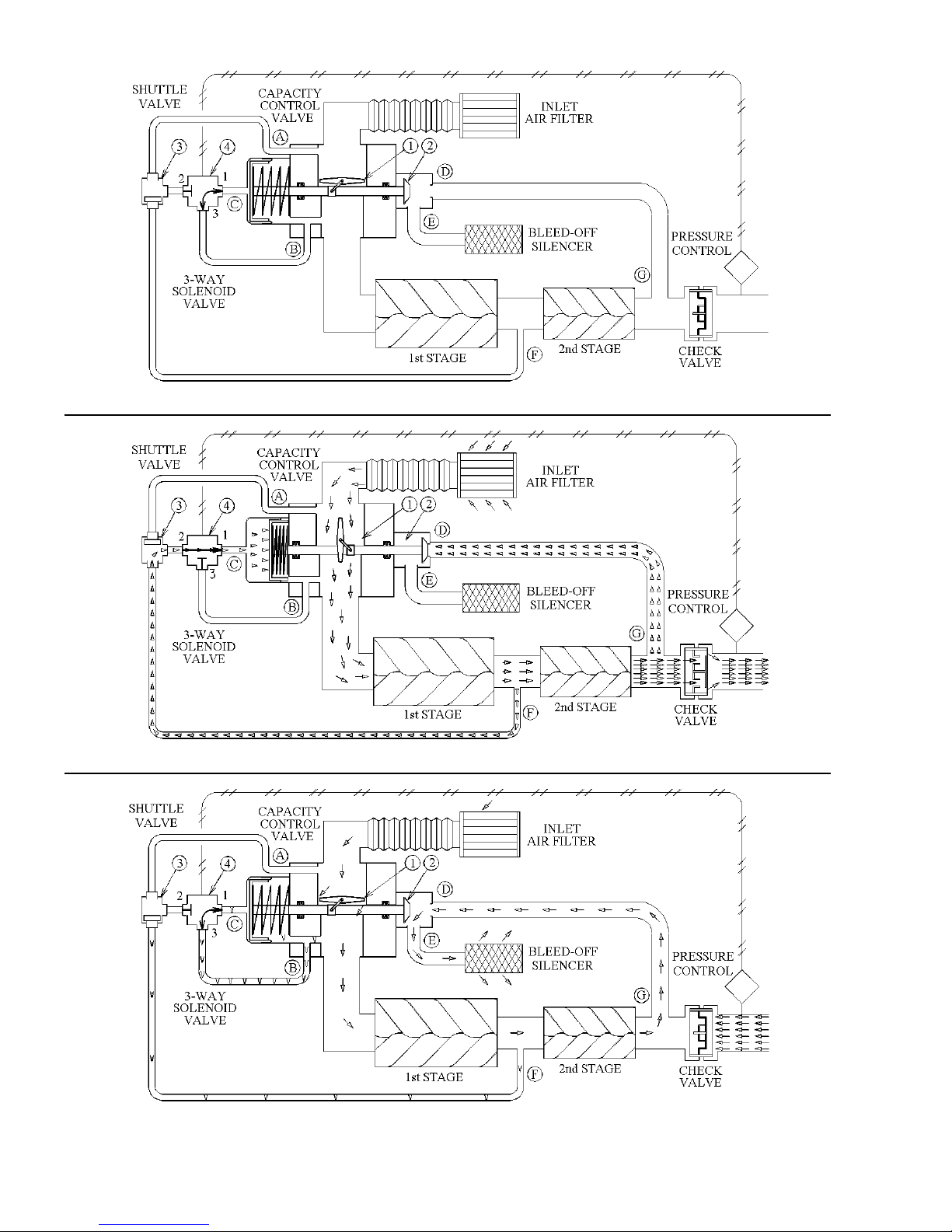

FIGURE 6 - UNLOADED, COMPRESSOR OFF

FIGURE 7 - LOADED, COMPRESSOR RUNNING

FIGURE 8 - UNLOADED, COMPRESSOR RUNNING

6

KIMA00H1 (0204)

1.5

Capacity

Control

System

The capacity control system consists of an inlet capacity control valve

with an integral bleed-off valve, a 3-way solenoid valve, and a shuttle

valve. Opening (loaded) and closing (unloaded) of the inlet valve is

controlled by the solenoid valve which is controlled by the PLC (ref.

Section 5.2). The PLC monitors compressor operating conditions and

system air pressure to determine when loaded or unloaded operation

is required.

1.5.1

Unloaded,

Off

(Figure 6)

1.5.2

Loaded,

Running

(Figure 7)

When the compressor is off, the spring in the capacity control valve

holds the inlet valve (1) closed and the bleed-off valve (2) open. The

solenoid valve (4) is deenergized. When the compressor is started

pressures at the 1st stage inlet (B) and interstage (F) are both

negative, keeping the capacity control valve in the unloaded position.

The compressor remains unloaded until the main drive motor reaches

full speed, and lube oil pressure reaches 10 psig. After the

compressor reaches full speed and oil pressure is established, the

solenoid valve (4) is energized, the capacity control valve operating

chamber (C) is disconnected from 1st stage inlet vacuum and is

vented to atmosphere (A) through the shuttle valve (3). Vacuum on

the spring side of the operating chamber piston helps pull the inlet

valve (1) open and closes the bleed-off valve (2). The inlet valve (1) is

a butterfly valve which rotates and is operated by a slider on the

capacity control valve shaft.

Air is now drawn into the compressor stages through the inlet air filter,

compressed, and discharged through the check valve to the air piping

system. As air is compressed interstage pressure (F) increases,

transferring the shuttle valve (3) and pressurizing the operating

chamber (C), keeping the capacity control valve open.

1.5.3

Unloaded,

Running

(Figure 8)

1.6

Monitoring

and Limiting

Devices

(Figures 9-11)

System pressure is monitored by a pressure sensor on the discharge

air piping. When the discharge pressure reaches the upper limit of the

desired operating range, the solenoid valve is de-energized, depressurizing the operating chamber (C). The spring closes the inlet

valve (1) and opens the bleed-off valve (2).

When unloaded a very slight amount of air is drawn through the inlet

valve (1) to cool the compressor during unloaded operation. 2nd stage

discharge air (G) is vented (D) to atmosphere (E) out of the bleed-off

silencer. The check valve prevents system air pressure from

pressurizing the compressor.

The compressor assembly is equipped with the following monitoring

devices:

a. Interstage air pressure transmitter. Monitors air pressure at the

intercooler outlet. The pressure is shown on the GT Terminal

(figure 10). Indicates condition of the intercooler and the

compressor stages.

b. Outlet air pressure transmitter. Monitors air pressure at the

aftercooler outlet connection to plant air system. Pressure is

shown on the GT Terminal (figure 10). Indicates condition of the

aftercooler and the compressor stages.

KIMA00H1 (0204)

7

COMPRESSOR OPERATOR PANEL

FIGURE 9 - COMPRESSOR FRONT VIEW

PILOT LIGHTS

PUSHBUTTONS

GT TERMINAL

FIGURE 10 - COMPRESSOR OPERATOR PANEL

8

KIMA00H1 (0204)

(cont.)

1.6

Monitoring

and Limiting

Devices

c. Lube oil pressure transmitter. Monitors lube oil pressure at the

last bearing oil nozzle. Pressure is shown on the GT Terminal

(figure 10). Indicates condition of the lube oil system, filter, and

the setting of the relief valve.

d. First stage discharge air temperature sensor. Temperature is

shown on GT Terminal (figure 10). Indicates condition of the

compressor first stage.

e. Second stage inlet air temperature sensor. Temperature is

shown on the GT Terminal (figure 10). Indicates condition of the

intercooler.

f. Second stage discharge air temperature sensor. Temperature is

shown on the GT Terminal (figure 10). Indicates condition of the

compressor second stage.

g. Lube oil temperature sensor. Temperature is shown on the GT

Terminal (figure 10). Indicates condition of the oil cooler.

h. Aftercooler discharge air temperature sensor. This is the

temperature of the air delivered to the air out service connection,

and is shown on the GT Terminal (figure 10). Indicates condition

of the aftercooler.

i. Total running time is shown on the GT Terminal (figure 10).

j. Total loaded time is shown on the GT Terminal (figure 10). An

accumulated count of loaded hours assists in tracking air usage

and available excess capacity.

k. Normal condition indication lights, on the Compressor Operator

Panel:

1. Standby

2. Run

3. Loaded

A lamp test is available using the GT Terminal, which tests all

indicating lights on the control panel, and the alarm beeper, if power is

on. This test does not affect normal compressor operation.

1.7

Alerts

KIMA00H1 (0204)

A blue ALERT light, and an appropriate message on the GT Terminal,

indicates that service is required or that a temperature prealarm exists

(temperature is approaching the shutdown point). In addition, an

audible alarm sounds when an alert occurs. The alarm may be

silenced without resetting the indication.

The GT Terminal indicates the following conditions as an ALERT:

a. Service inlet air filter. Indicates that the inlet air filter or the dust

filters are dirty, filter pressure drop exceeds 25 “H2O

b. Service oil filter. Indicates that the lube oil filter is dirty, filter

pressure drop exceeds 15 PSID.

c. Compressor service required. Indicates that 2 years have

elapsed since start-up, or the capacity control valve has cycled

1,000,000 times. Service must be scheduled.

d. Temperature prealarm (applies to all temperatures monitored).

Indicates that a temperature is approaching the shutdown point.

Refer to the appropriate paragraph of section 1.8 for details of

each monitored temperature. See page 22 for setpoint table.

9

PILOT LIGHTS

GT-TERMINAL

GRAPHIC TERMINAL W/ TOUCHSCREEN

PUSHBUTTONS

FIGURE 11 - COMPRESSOR OPERATOR PANEL

PRESS ARROWS TO CHANGE DISPLAY SCREENS

PRESS “ACK” TO

ALARM MESSAGE

SILENCE BEEPER

ALARM LIGHT

ALARM BEEPER

FIGURE 12 - ALARM DISPLAY

10

PRESS “STAT” FOR ALARM DETAILS

KIMA00H1 (0204)

1.8

Shutdowns

Shutdown conditions are indicated by a red ALARM light on the

control panel, and an appropriate message on the graphic display. In

addition, an audible alarm sounds when an alarm occurs. The alarm

beeper may be silenced by pressing ACK/Bell Cancel on the alarm

page. The Bell Cancel does not reset the alarm. A "DRY" relay

contact is provided as a combined signal for remote indication if any

alarm occurs. A table of setpoints is located on page 22.

The GT Terminal indicates the following shutdown conditions:

a. High 1st Discharge Air Temperature (Shutdown)

Warning: HOT 1st Discharge (Prealarm)

Indicates a problem with the first compressor stage.

b. Warning: HOT 2nd Suction (Prealarm)

High 2nd Suction Air Temperature (Shutdown)

Indicates a problem with the intercooler or cooling air flow.

c. Warning: HOT 2nd Discharge (Prealarm)

High 2nd Discharge Air Temperature (Shutdown)

Indicates a problem with the second compressor stage or a

problem with the intercooler.

d. Warning: HOT Air Discharge (Prealarm)

High Discharge Air Temperature (Shutdown)

Indicates a problem with the aftercooler or cooling air flow.

e. Warning: HOT Lube OIL (Prealarm)

High Lube Oil Temperature (Shutdown)

Indicates a problem with the lube oil cooling system.

f. Low Lube Oil Pressure

Indicates low lube oil level in sump, lube oil pump failure, fouled

cooler or piping, clogged oil filter, or improper setting of the relief

valve.

g. Lube Oil Pump Motor Overload

Indicates continued over-current operation of the oil pump motor,

problem with lube oil pump or motor, or high oil pressure.

h. Cooling Fan Motor Overload

Indicates continued over-current operation of the cabinet cooling

fan motor, problem with fan or motor. Also check for obstructed

air flow into or out of the cabinet.

i. Compressor Drive Motor Overload

Indicates continued over-current operation of the drive motor for

the compressor, excessive discharge pressure or a problem with

either compressor stage.

j. High Cabinet Temperature

Indicates an obstruction of the cooling air flow.

k. High Discharge Air Pressure

Indicates a problem with the capacity control system.

l. Main Starter Failure

Indicates a problem with the main starter or controls.

KIMA00H1 (0204)

11

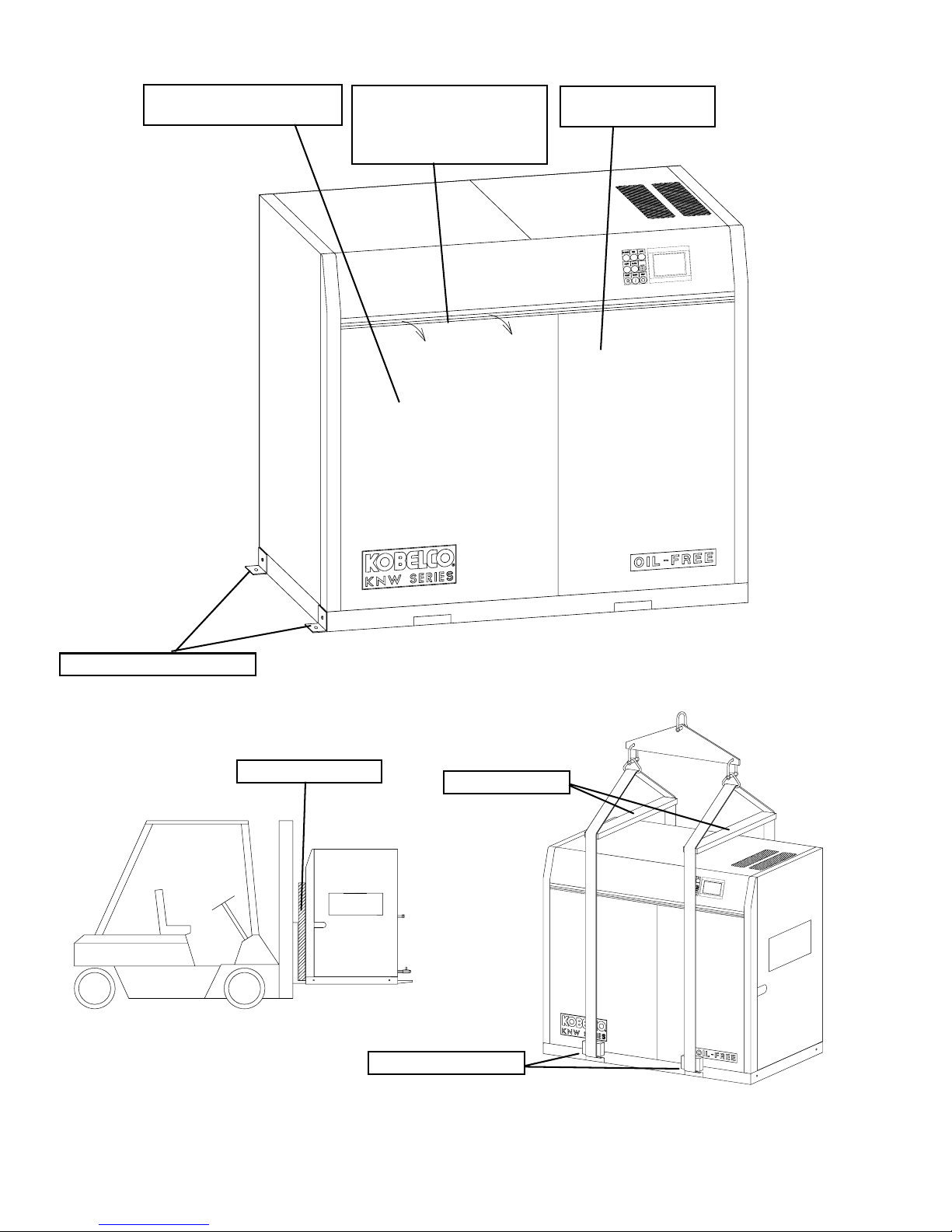

COMPRESSOR SECTION

ACCESS PANEL

TO OPEN PANELS

FOR INSPECTION,

PULL OUT TOP EDGE

THEN LIFT PANEL UP

STARTER SECTION

ACCESS PANEL

MOUNTING BRACKETS

FIGURE 14

SPACER BLOCKS

FIGURE 13

SPREADERS

SPACER BLOCKS

FIGURE 15

12

KIMA00H1 (0204)

2. INSTALLATION

2.1

Inspection

(Figure 13)

2.2

Handling

(Figures

14 & 15)

2.3

Foundation

2.4

Location

The unit should be inspected for damage immediately upon receipt

from the carrier and any claims should be made to the delivery carrier

immediately.

The compressor unit is equipped with forklift slots for ease in handling.

Spacer blocks should be placed between the compressor and forklift

mast to insure the cabinet will not be damaged during handling.

When handling the unit with an overhead crane, the lifting straps or

chains should pass through the forklift slots. Spacers and spreader

bars should be utilized to avoid damage to the enclosure.

The compressor and motor assembly are vibration isolated from the

housing and base plate, additional isolation is not required. The

assembly should be mounted on a level, horizontal floor. Holes are

provided on each end of the compressor for installing bolt down

brackets.

The unit should be installed indoors in a clean, well ventilated area,

free from excessive dust or dripping liquids. Do not install in an area

where chlorine gas, hydrogen sulfide gas, sulfur dioxide gas, highly

concentrated ozone, or any other toxic, corrosive or flammable gasses

are present.

2.5

Cooling

Air

(Figure 17)

WARNING:

The compressor shall not be located where potentially

explosive atmospheres may occur. The compressor and controls are

not rated for installation in hazardous (classified) locations.

Any contaminates in the atmosphere will be compressed along with

the air, therefore, it is important to provide a source of clean intake air.

An external source of clean inlet air to the compressor may need to be

provided.

The machine must be protected against freezing and excessive

ambient temperatures.

For ease of panel removal and maintenance provide ample clearance

around the compressor. A minimum of four feet is required in front of

the compressor. At least three feet is recommended for each end and

for the back.

The compressor should be located where sufficient ventilation is

available to cool the compressor. The cooling air inlet and discharge

must not be blocked. The warm air exiting the cooling air outlet must

be prevented from being drawn into the cooling air inlet. Ventilation

may need to be provided if the room in which the compressor is

installed exceeds 104°F (40°C) during compressor operation.

Air ducts may be connected to air inlets or outlets if desired. However

ducts must be sized to permit no more than 1” H2O restriction at full

flow.

KIMA00H1 (0204)

13

Loading...

Loading...