Page 1

KOBE Brand Range Hood

Model No. / Nos de modèles / Modelo No.

CH7730SQB

CH7736SQB

CH-77 SERIES – 10" HEIGHT

INSTALLATION INSTRUCTIONS

AND OPERATION MANUAL

MANUEL D'INSTALLATION

ET MODE D'EMPLOI

INSTRUCCIONES DE INSTALACIÓN

Y MANUAL DE OPERACIÓN

Page 2

[ENGLISH] ............................................................................................................................. 1

[FRENCH] ............................................................................................................................ 31

[SPANISH] ........................................................................................................................... 62

2

Page 3

IMPORTANT

READ THIS

FIRST

READ BEFORE INSTALLATION

1. Carefully check all contents of packages;

2. Thoroughly inspect the unit for any cosmetic damages or

defects;

3. Test the unit before installation;

4. Have a certified contractor/electrician do the installation.

IF THERE IS ANY PROBLEM:

1. DO NOT INSTALL THE UNIT AND KEEP ALL ORIGINAL

PACKAGING MATERIAL.

2. Have your original proof of purchase and product serial

number ready.

3. Call 1-877-BUY-KOBE (289-5623); or e-mail to

info@koberangehoods.com to report the problem.

NO RETURN, NO REFUND, NO EXCHANGE IF:

1. PRODUCT HAS BEEN INSTALLED

2. KNOCK-OUT HOLES HAVE BEEN PUNCTURED

3. MISSING ORIGINAL PACKAGING MATERIAL AND/OR

PARTS

1

Page 4

[ENGLISH]

- READ AND SAVE THESE INSTRUCTIONS -

CONTENTS

IMPORTANT SAFETY INSTRUCTIONS ................................................................................ 3

COMPONENTS OF PACKAGE .............................................................................................. 5

INSTALLATION ...................................................................................................................... 6

OPERATING INSTRUCTIONS............................................................................................. 19

MAINTENANCE ................................................................................................................... 20

SPECIFICATIONS ................................................................................................................ 21

MEASUREMENTS & DIAGRAMS........................................................................................ 22

PARTS LIST ......................................................................................................................... 24

CIRCUIT DIAGRAM ............................................................................................................. 26

TROUBLE SHOOTING ........................................................................................................ 27

WARRANTY ......................................................................................................................... 28

PRODUCT REGISTRATION ................................................................................................ 30

- READ ALL INSTRUCTIONS CAREFULLY BEFORE STARTING -

ALL W I R I N G MUST B E D O N E B Y A P R O F E S S I ONAL A N D I N

ACCO RD A N C E W IT H N A T I O N A L AND L O C A L E LEC T R I C A L C O DES

2

Page 5

IMPORTANT SAFETY INSTRUCTIONS

- PLEASE READ THIS SECTION CAREFULLY BEFORE INSTALLATION -

WARNING

:

TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK OR PERSONAL

INJURY, OBSERVE THE FOLLOWING:

1) Installation and electrical wiring must be done by qualified professionals and in accordance with all

applicable codes and standards, including fire-rated construction.

2) When cutting or drilling into wall or ceiling, be careful not to damage electrical wiring or other hidden

utilities.

3) Ducted fans must be vented to the outside.

a) Before servicing or cleaning unit, open the light panel and SWITCH POWER OFF AT SERVICE

PANEL.

b) Clean all grease laden surfaces frequently. To reduce the risk of fire and to disperse air

properly, make sure to vent air outside. DO NOT vent exhaust air into wall spaces, attics, crawl

spaces or garages.

NOTE - This warranty is invalid without an authorized agent’s receipt or if unit is

damaged due to misuse, poor installation, improper use, mistreatment,

negligence or any other circumstances beyond the control of KOBE

RANGE HOODS authorized agents. Any repair carried out without the

supervision of KOBE RANGE HOODS authorized agents will

automatically void the warranty.

- KOBE RANGE HOODS will not be held responsible for any damages to

personal property or real estate or any bodily injuries whether caused

directly or indirectly by the range hood.

WARNING

1. Keep all fan, baffle/spacer/filter/oil tunnel/oil container and grease-laden surfaces clean. Grease

should not be allowed to accumulate on fan, baffle/spacer/filter/oil tunnel/oil container.

2. Always turn hood ON when cooking.

3. Use high settings on cooking range ONLY when necessary.

4. Do not leave cooking range unattended when cooking.

5. Always use cookware and utensils appropriate for the type and amount of food prepared.

6. Use this unit only in the manner intended by the manufacturer.

7. Before servicing, switch power off at service panel and lock service panel (if possible) to prevent

power from switching on accidentally.

8.

Clean ventilating fan frequently.

: TO REDUCE THE RISK OF PERSONAL INJURY IN THE EVENT OF A RANGE

TOP GREASE FIRE:

3

Page 6

What to Do In The Event Of a Range Top Grease Fire

• SMOTHER FLAMES with a tight fitting lid, cookie sheet, or metal tray, and then turn off the burner.

KEEP FLAMMABLE OR COMBUSTIBLE MATERIAL AWAY FROM FLAMES. If the flames do not

go out immediately, EVACUATE THE AREA AND CALL THE FIRE DEPARTMENT or 911.

• NEVER PICK UP A BURNING PAN – You May Get Burned.

• DO NOT USE WATER, including wet dishcloths or towels – a violent steam blast will result.

• Use an extinguisher ONLY if:

a) You have a Class A, B, C extinguisher and know how to operate it.

b) The fire is small and contained in the area where it started.

c) The fire department has been called.

d) You can fight the fire with your back to an exit.

What to Do If You Smell Gas

-

Extinguish any open flame.

-

Do not try to turn on lights or any type of appliance.

-

Open all doors and windows to disperse the gas. If you still smell gas, call the Gas Company and

Fire Department right away.

CAUTION

1) For general ventilation use only. Do not use to exhaust hazardous or explosive materials and

vapors.

2) To reduce the risk of fire, use only metal ductwork. Sufficient air is needed for proper combustion

and exhausting of gases through the flue (chimney) to prevent back drafting.

3) Follow the heating equipment manufacturer’s guideline and safety standards such as those

published by the National Fire Protection Association (NFPA), and the American Society for

Heating, Refrigeration and Air Conditioning Engineers (ASHRAE), and code authorities.

4) Activating any switch may cause ignition or an explosion.

5) Due to the size and weight of this hood, two people installation is recommended.

ELECTRICAL SHOCK HAZARD – Can result in serious injury or

death. Disconnect appliance from electric power before servicing.

If equipped, the fluorescent light bulb contains small amounts of

mercury, which must be recycled or disposed of according to Local,

State, and Federal Codes.

4

Page 7

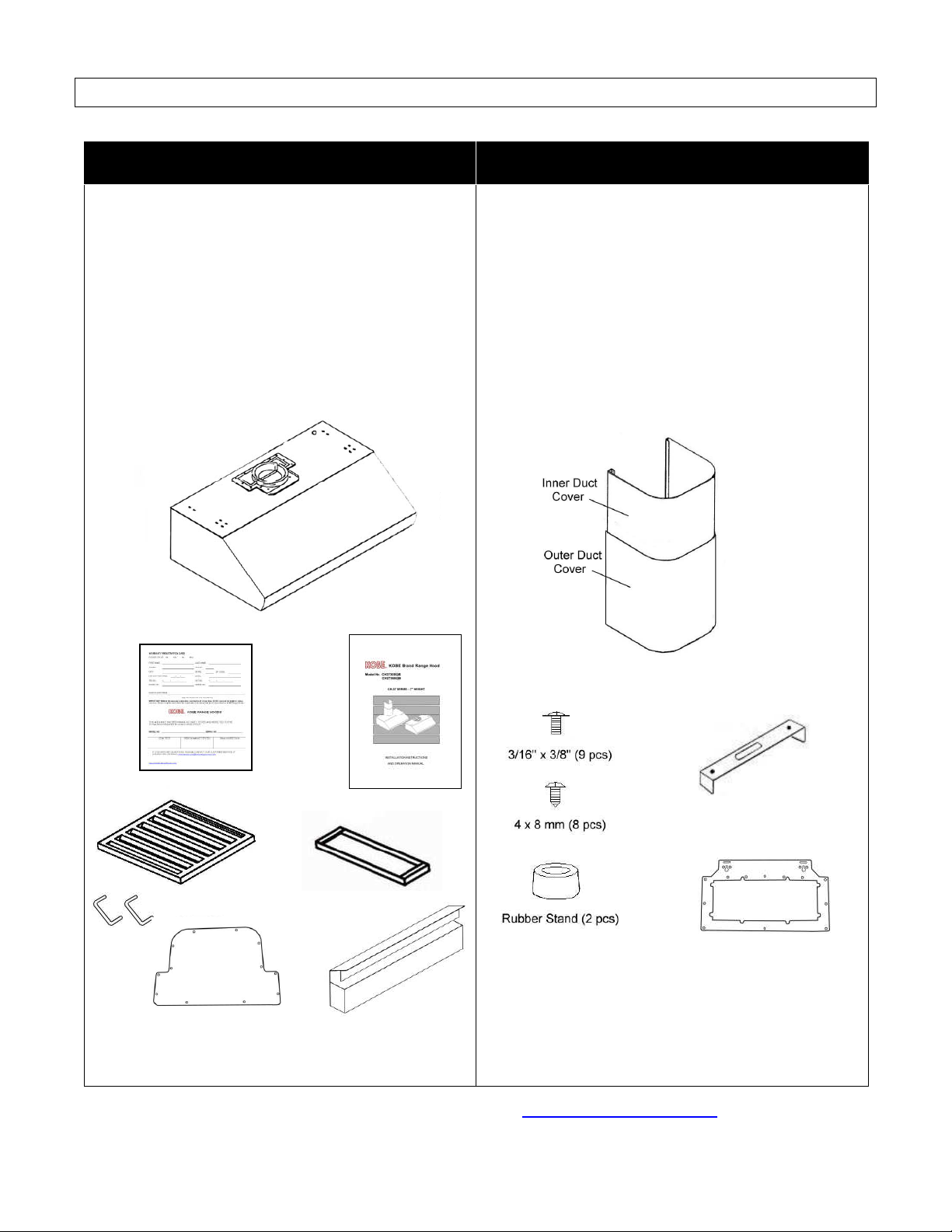

Range Hood Box

Duct Cover Box

– (Sold Separately)

{A} KOBE Range Hood

- 1

{H} KOBE A

djustable Duct Cover

- 1

COMPONENTS OF PACKAGE

(Must keep all material for returns or refunds)

{B} Warranty Registration Card - 1

{C} Instructions Manual - 1

{D} Baffle Filter - 2 (for 30”, 36”)

{E} Spacer - 1 (for 30”)

- 3 (for 36”)

{F} Vent Cover (Top) – 1

{G} Oil Tunnel – 1

{A}

{B} {C}

{D} {E}

{I} Screws Package – 1

{J} Duct Cover-Mounting Bracket – 1

{K} Hood-Mounting Bracket – 1

{H}

{I} {J}

{K}

{F} {G}

FOR MORE INFORMATION, PLEASE VISIT OUR WEBSITE www.KOBERangeHoods.com OR CONTACT KOBE

RANGE HOODS AT (877-289-5623).

5

Page 8

TABLE 1

Bottom (Recommended

TABLE 2

Bottom (Recommended

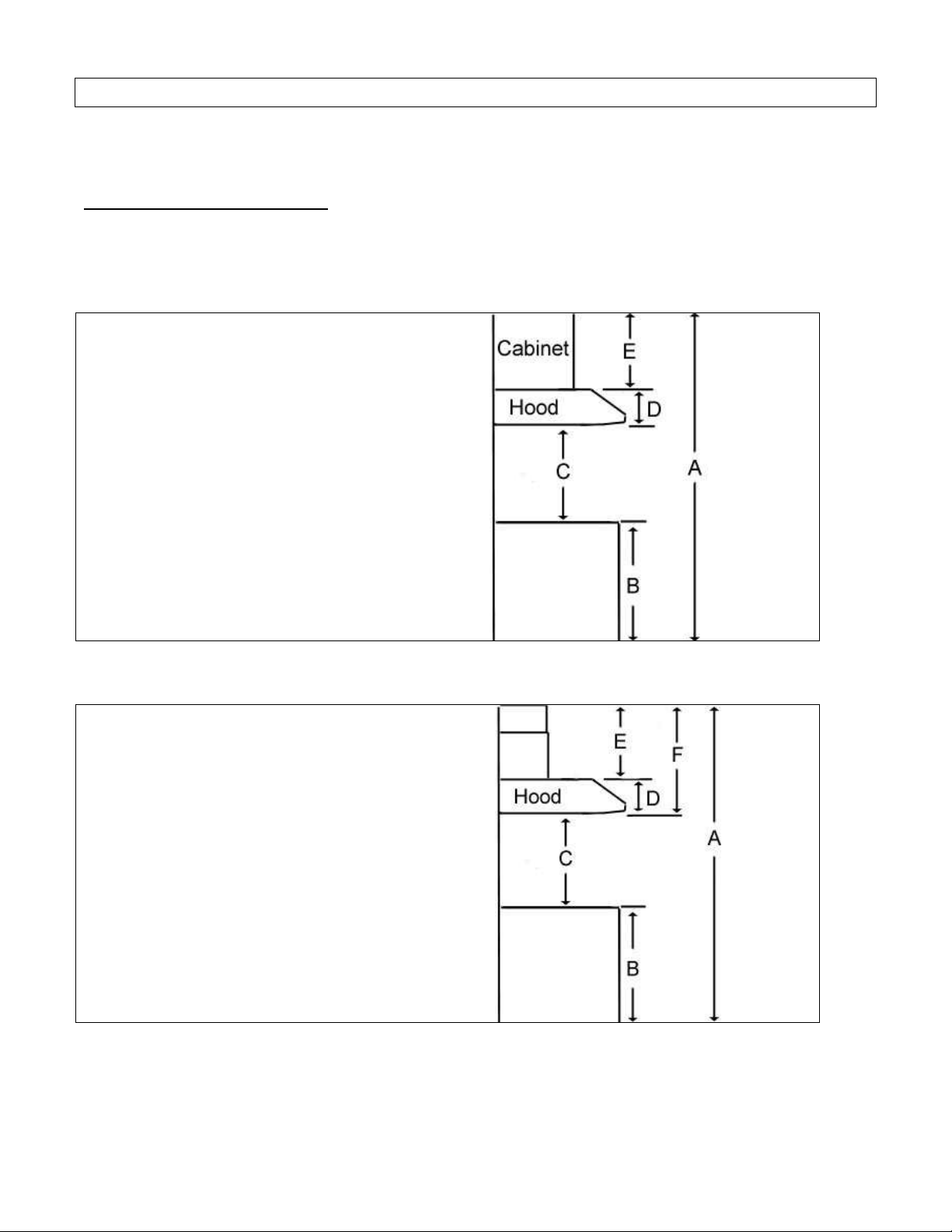

INSTALLATION

PLEASE READ ENTIRE INSTRUCTIONS BEFORE PROCEEDING

Calculation before Installation

To calculate installation, please refer to TABLE 1 or TABLE 2. (All calculation in inches.)

- FOR UNDER THE CABINET -

A = Height of Floor to Ceiling

B = Height of Floor to Counter Top

(Standard: 36")

C = Preferred Height of Counter Top

to Hood

27" to 30")

D = Height of Hood

E = Height of the Cabinet

- FOR WALL MOUNT (WITH OPTIONAL DUCT COVER) -

A = Height of Floor to Ceiling

B = Height of Floor to Counter Top

(Standard: 36")

C = Preferred Height of Counter Top

to Hood

27" to 30")

D = Height of Hood

E = Height of Duct Cover [F – D]

F = Height of the Hood Installation

[A – (B+C)]

6

Page 9

SAFETY WARNING

HOOD MAY HAVE VERY SHARP EDGES; PLEASE WEAR PROTECTIVE GLOVES IF

REMOVING ANY PARTS FOR INSTALLING, CLEANING OR SERVICING.

NOTE: BE CAREFUL WHEN USING ELECTRICAL SCREWDRIVER, DAMAGE TO THE HOOD

MAY OCCUR.

Installation Contents

UNDER THE CABINET

Top Vent…………………………………………………………………………………

Rear Vent………………………………………………………………………………..

WALL MOUNT

Top Vent…………………………………………………………………………………

Rear Vent………………………………………………………………………………..

6

8

10

13

7

Page 10

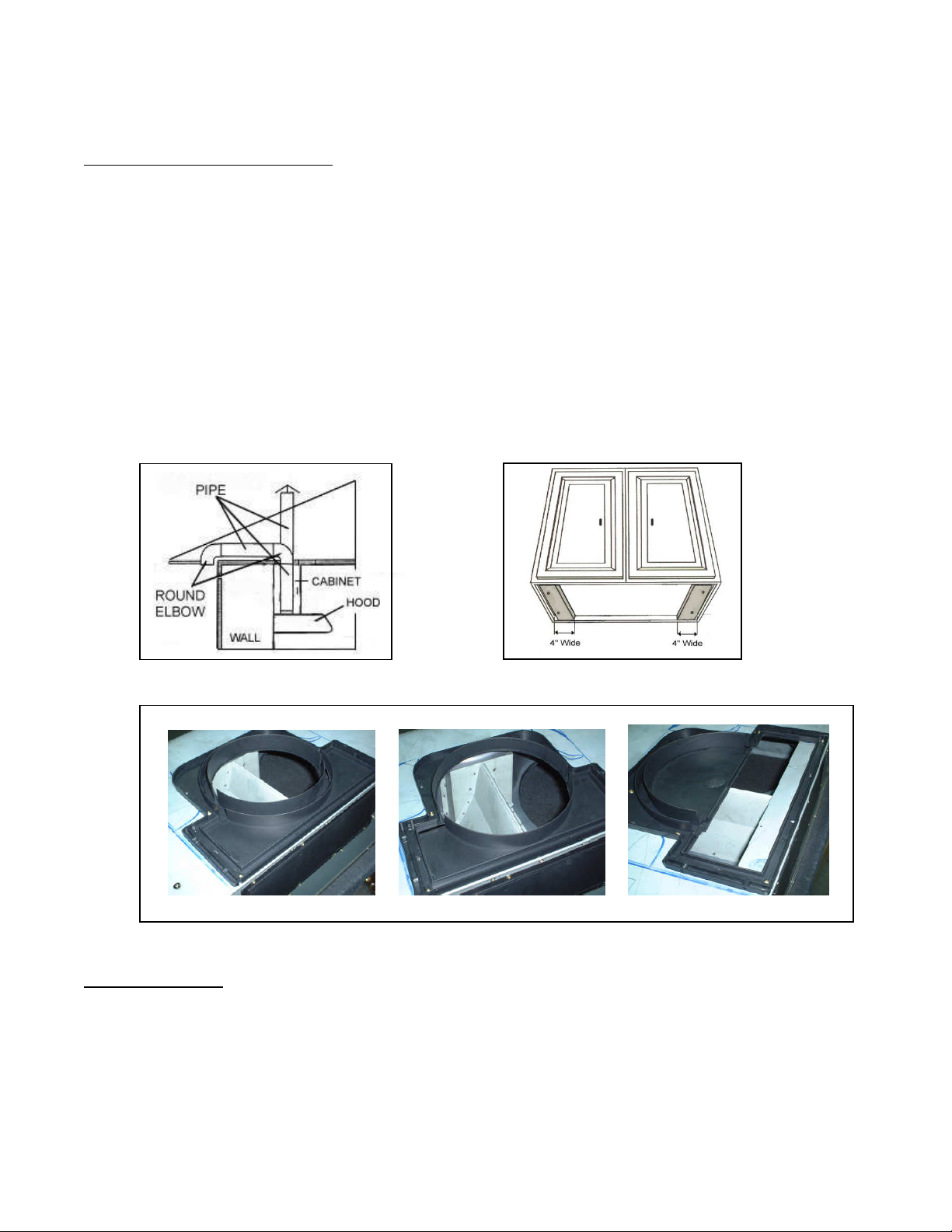

UNDER THE CABINET INSTALLATION – TOP VENT

Preparation before Installation

NOTE: TO AVOID DAMAGE TO YOUR HOOD, PREVENT DEBRIS FROM ENTERING THE

VENT OPENING.

- Decide the location of the venting pipe from the hood to the outside. Refer to Figure 1.

- A straight, short venting run will allow the hood to perform more efficiently.

- Try to avoid as many transitions, elbows, and long run as possible. This may reduce

the performance of the hood.

- Temporarily wire the hood to test for proper operation before installing.

- Peel protective film off the hood (if any).

- For installing under the cabinet with recessed bottom, attach 4-inch wide wood filler

strips (not included) on each side. Refer to Figure 2.

- Measure and create access opening for electrical wires under the cabinet.

- Cut the multi duct exhaust according to the size of the venting pipe. Refer to Figure 3.

Figure 1 Figure 2

6" Round Vent 7" Round Vent 3-1/4" x 10" Vent

Figure 3

Hood Installation

CAUTION: If required to move the cooking range to install the hood, turn off the power on an

electric range at the main electrical box. SHUT OFF THE GAS BEFORE MOVING A GAS

RANGE.

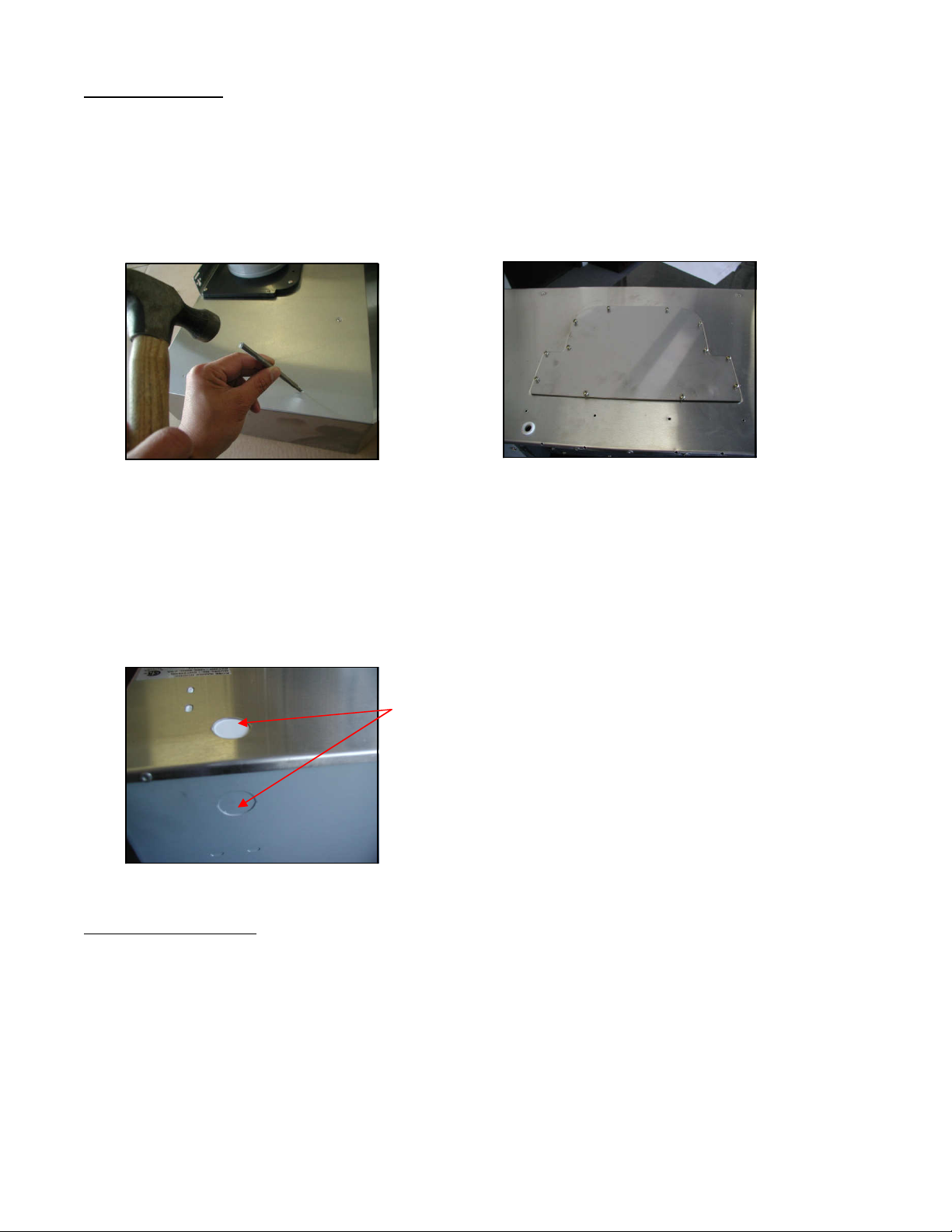

1. Puncture the knockout holes on the hood as shown in Figure 4.

8

Page 11

2. Remove the baffle filters and spacers. If necessary, arrange the electrical wires to run

through the 1” diameter hole on the top or the rear of the hood. Refer to Figure 5.

3. Using references on Table 1 and measurements on page 20 center the hood in place

beneath the cabinet and flush with the front of the cabinet.

Hole

1" Diameter

Figure 4 Figure 5

4. Draw electrical wires through cabinet access opening.

5. Place screw (not provided) into the exact center of each knockout hole. Make sure all

screws are in place before tightening screws. CAUTION: MAKE SURE THE HOOD IS

SECURE BEFORE RELEASING.

Ductwork Installation

6. Use aluminum or steel pipe to connect the plastic exhaust on the hood to the ductwork

above. Use duct tape to make all joints secure and air tight.

7. Continued at “Wiring to Power Supply” on page 16.

9

Page 12

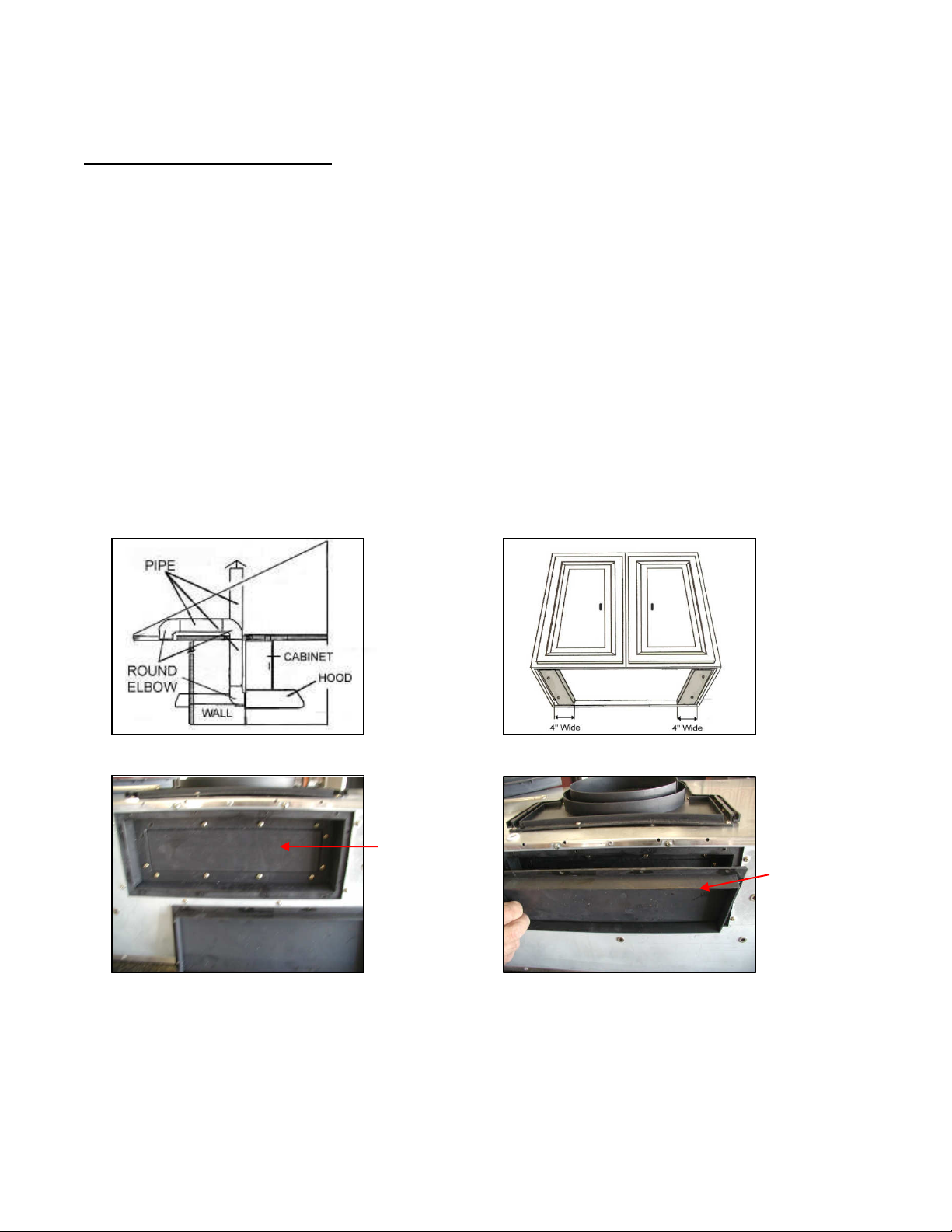

UNDER THE CABINET INSTALLATION – REAR VENT

Preparation before installation

NOTE: TO AVOID DAMAGE TO YOUR HOOD, PREVENT DEBRIS FROM ENTERING THE

VENT OPENING.

- Decide the location of the venting pipe from the hood to the outside. Refer to Figure 6.

- A straight, short venting run will allow the hood to perform more efficiently.

- Try to avoid as many transitions, elbows, and long run as possible. This may reduce

the performance of the hood.

- Temporarily wire the hood to test for proper operation before installing.

- Peel protective film off the hood (if any).

- For installing under the cabinet with recessed bottom, attach 4-inch wide wood filler

strips (not included) on each side. Refer to Figure 7.

- Measure and create access opening for electrical wires under the cabinet or access

opening for the electrical wires at the rear of the hood.

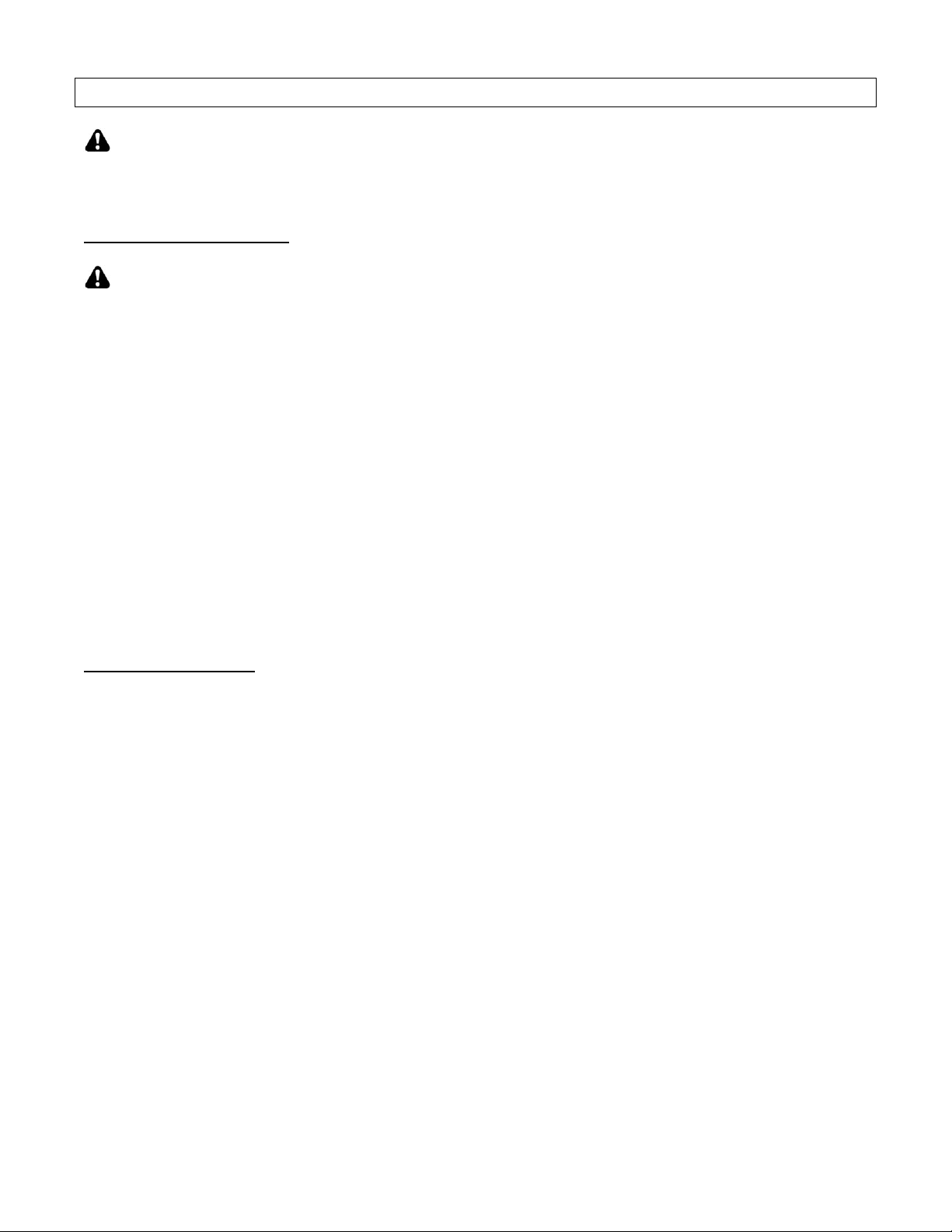

- Remove the screws on the vent cover (rear) and cut along the line of the inner vent

cover (rear) opening. Refer to Figure 8.

- Cut the vent cover (rear) opening and reverse to the other side. Refer to Figure 9.

Reattach the vent cover (rear).

Inner Vent Reversed

Cover (Rear) Vent Cover

(Rear)

Figure 8 Figure 9

Figure 6 Figure 7

10

Page 13

Hood Installation

CAUTION: If required to move the cooking range to install the hood, turn off the power on an

electric range at the main electrical box. SHUT OFF THE GAS BEFORE MOVING A GAS

RANGE.

1. Puncture the knockout holes on the hood as shown in Figure 10.

2. Unscrew and remove the multi duct exhaust. Replace with {F} vent cover (top) on page

3. Refer to Figure 11.

Figure 10 Figure 11

3. Remove the baffle filters and spacers. If necessary, arrange the electrical wires to run

through the 1” diameter hole on the top or the rear of the hood. Refer to Figure 12.

4. Using references on Table 1 and measurements on page 20 center the hood in place

beneath the cabinet and flush with the front of the cabinet.

5. Place screw (not provided) into the exact center of each knockout hole. Make sure all

screws are in place before tightening screws. CAUTION: MAKE SURE THE HOOD IS

SECURE BEFORE RELEASING.

1” Diameter Hole

Figure 12

Ductwork Installation

6. Use aluminum or steel pipe to connect the exhaust opening at the rear of the hood to the

ductwork. Use duct tape to make all joints secure and air tight.

7. Continued at “Wiring to Power Supply” on page 16.

11

Page 14

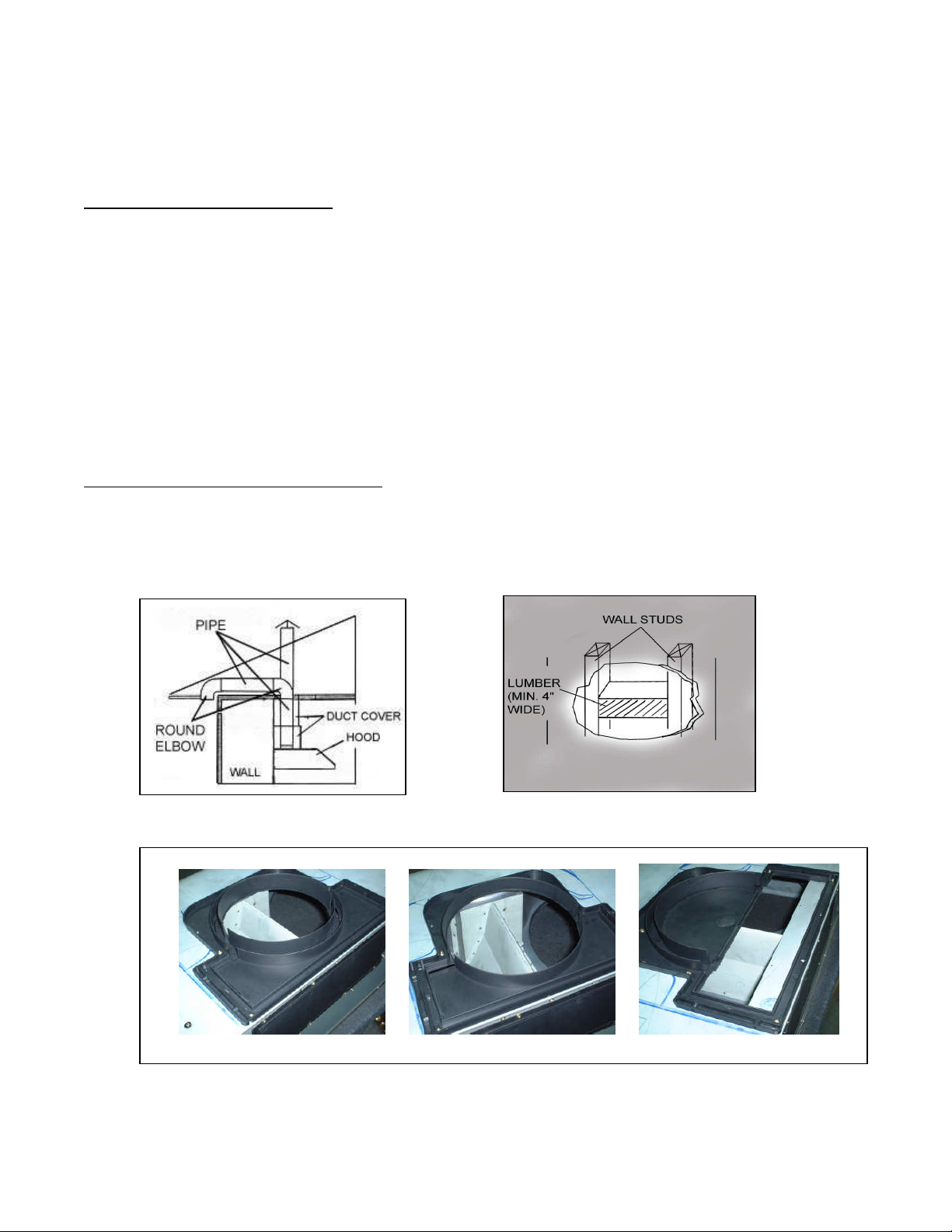

WALL MOUNT INSTALLATION – TOP VENT

***This installation only applied with the purchase of a duct cover (Model No. CH1120DC).

Preparation before Installation

NOTE: TO AVOID DAMAGE TO YOUR HOOD, PREVENT DEBRIS FROM ENTERING THE

VENT OPENING.

- Decide the location of the venting pipe from the hood to the outside. Refer to Figure 13.

- A straight, short venting run will allow the hood to perform more efficiently.

- Try to avoid as many transitions, elbows, and long run as possible. This may reduce

the performance of the hood.

- Use duct tape to seal the joints between pipe sections.

- If necessary, prepare back wall frame with cross framing lumber for secure installation.

- Using references on Table 2 and measurements on page 20-21, decide the level of the

lumber. Refer to Figure 14.

Hood Preparation before Installation

- Temporarily wire the hood to test for proper operation before installing.

- Peel protective film off the hood and the duct cover (if any).

- Cut the multi vent exhaust according to the size of the venting pipe. Refer to Figure 15.

Figure 13 Figure 14

6" Round Vent 7" Round Vent 3-1/4" x 10" Vent

Figure 15

12

Page 15

Mounting

- If necessary, attach two rubber stands (provided) with two (4x8 mm) screws (provided)

to the back of the hood.

- Attach the hood-mounting bracket to the back of the hood with nine (3/16" x 3/8")

screws (provided) as shown in Figure 16.

Hood Installation

CAUTION: If required to move the cooking range to install the hood, turn off the power on an

electric range at the main electrical box. SHUT OFF THE GAS BEFORE MOVING A GAS

RANGE.

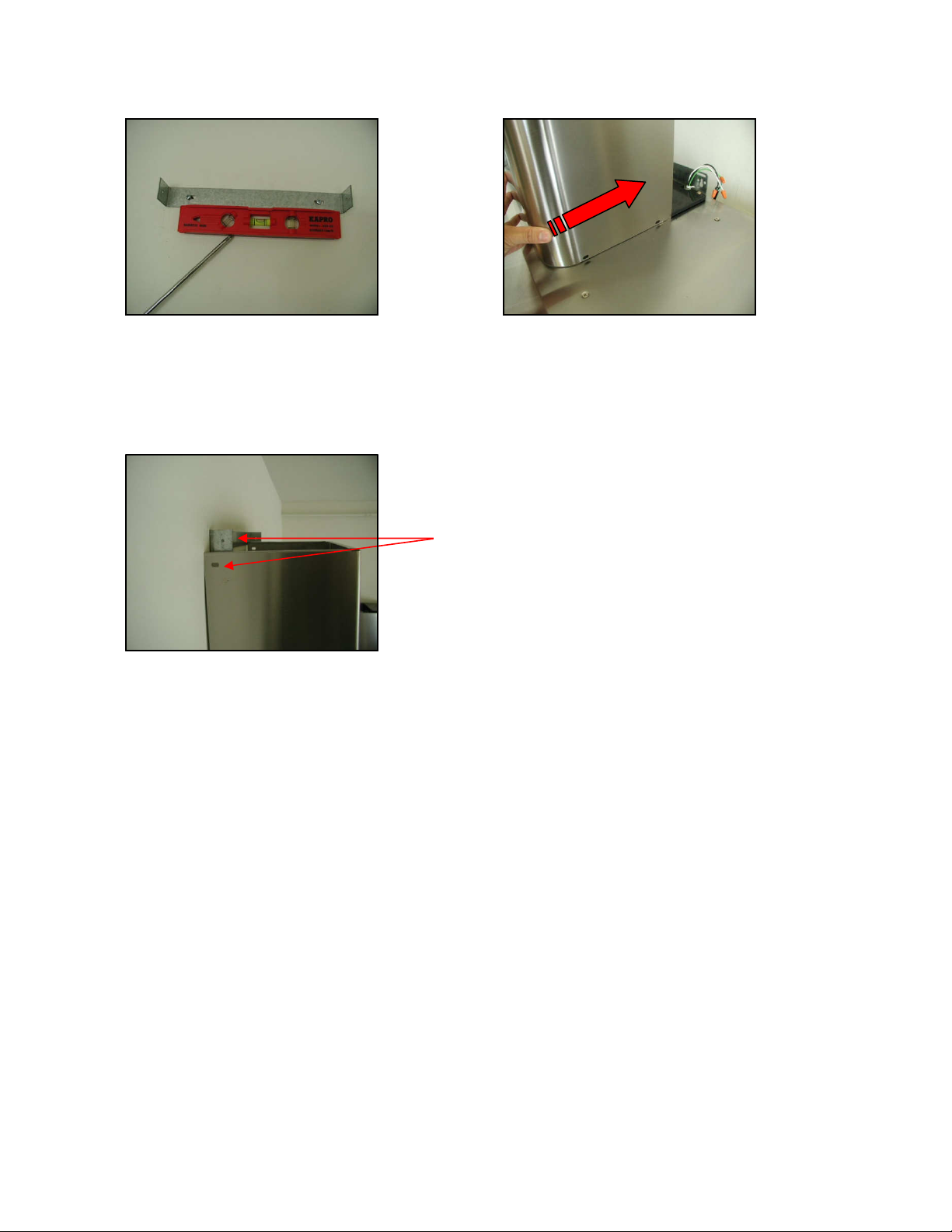

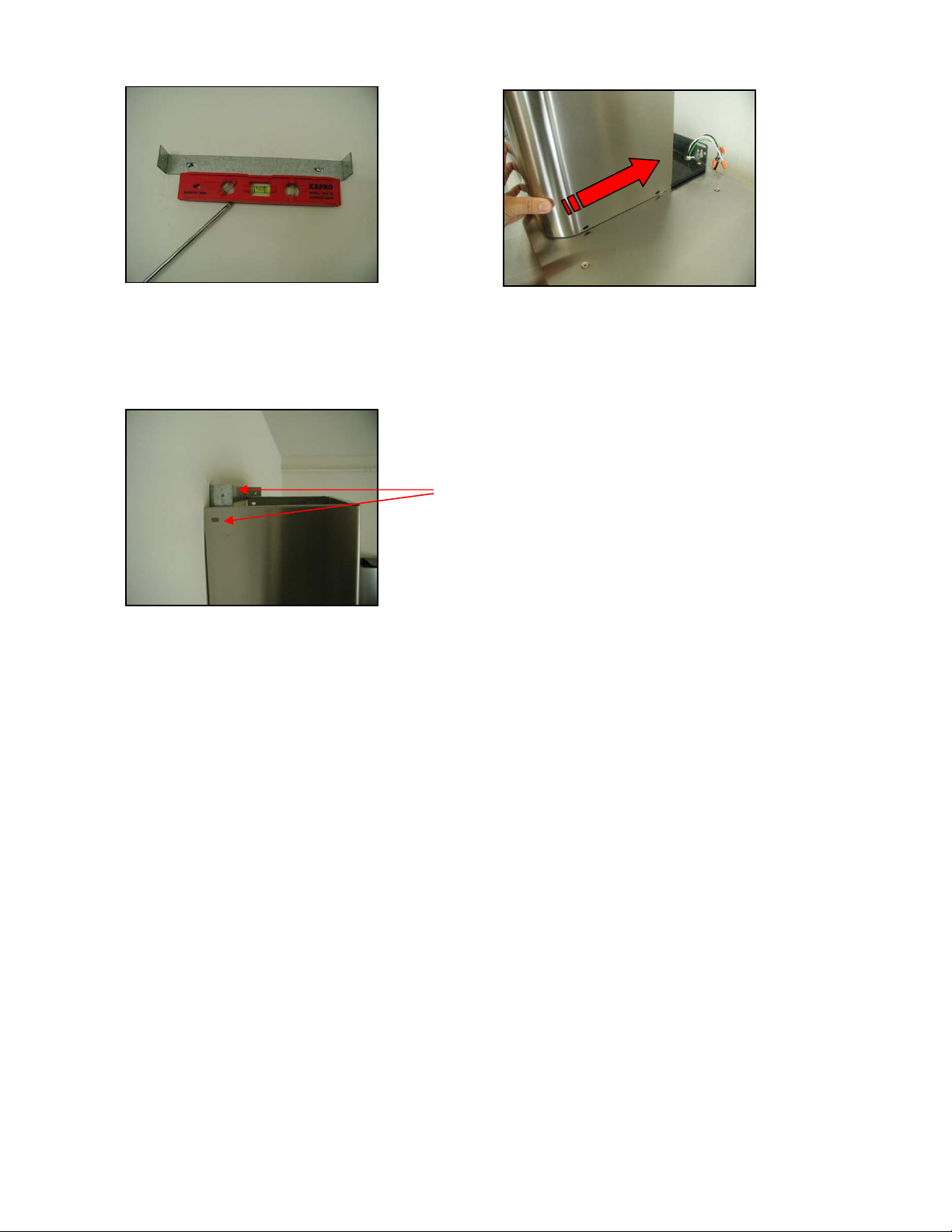

1. Using references on Table 2 and measurements on page 20-21, mark the leveling point

of the hood. Position two mounting screws (not provided) on the wall, leaving 1/8” away

from the wall as shown in Figure 17.

Screws

Figure 16 Figure 17

2. Align hood-mounting bracket to the two screws on the wall and hook hood into place.

Tighten screws to secure hood to the wall. CAUTION: MAKE SURE THE HOOD IS

SECURE BEFORE RELEASING.

Duct Cover Installation

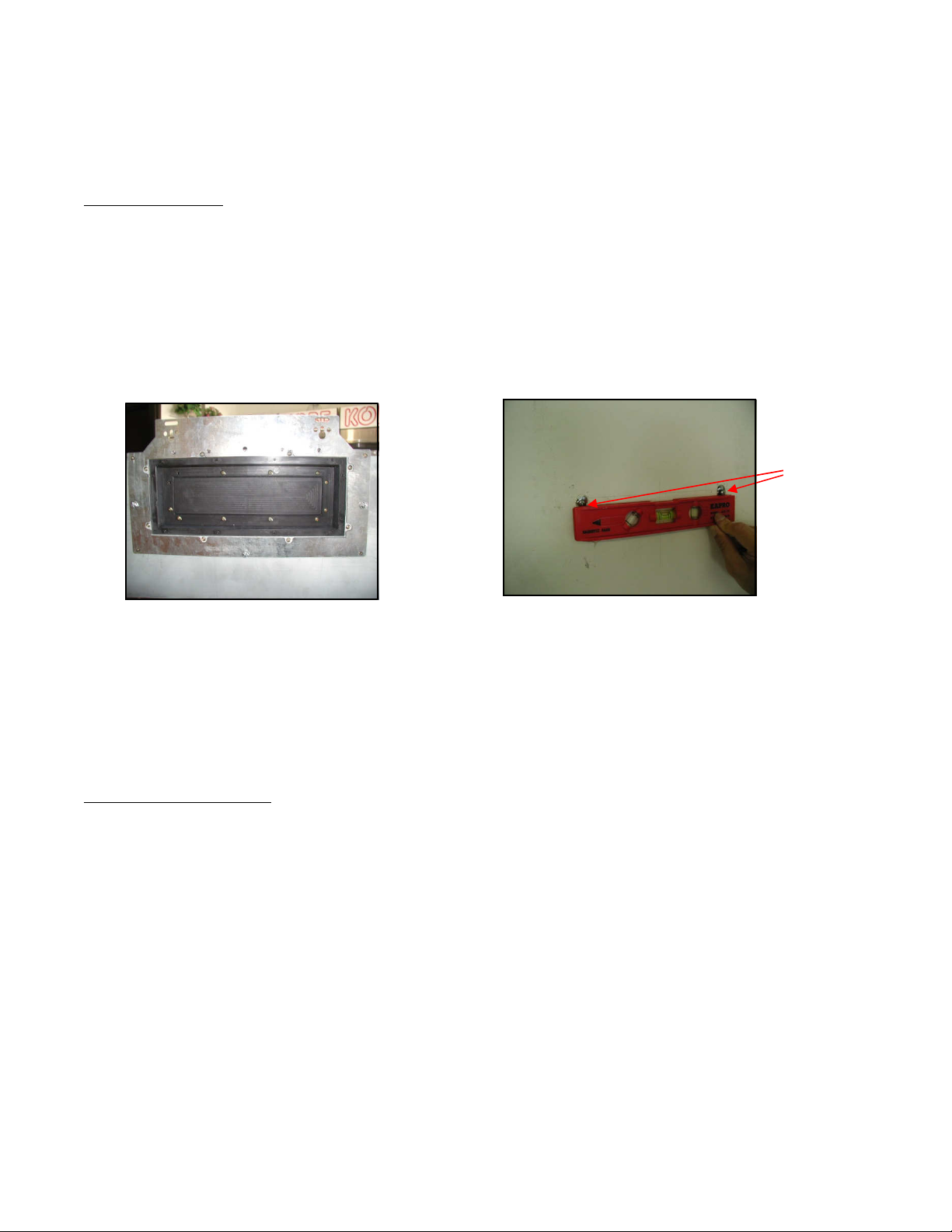

3. Mark the position of the duct cover-mounting bracket. Use reference E from Table 2 and

measurements on page 20-21. Attach and secure duct cover-mounting bracket with two

screws (not provided). Refer to Figure 18. NOTE: Inner duct cover will cover the duct

cover-mounting bracket.

4. Use aluminum or steel pipe to connect the plastic exhaust on the hood to the ductwork

above. Use duct tape to make all joints secure and air tight.

5. Connect electrical wires. Refer to “Wiring to Power Supply” on page 16.

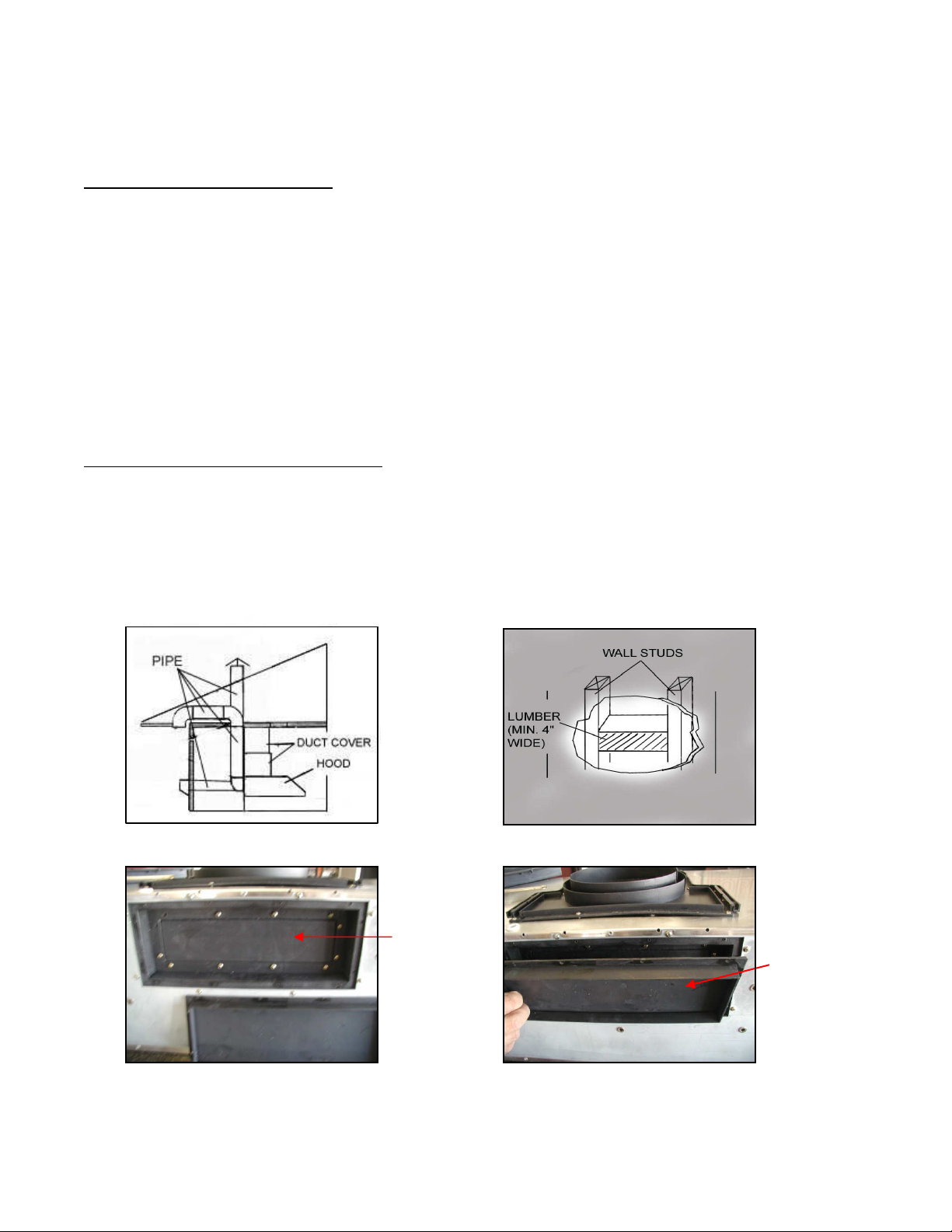

6. Slide the inner duct cover up 2 inches before sliding the entire duct cover onto the hood.

Refer to Figure 19.

13

Page 16

Figure 18 Figure 19

7. Adjust the height of the inner duct cover to the duct cover-mounting bracket. Secure the

inner duct cover with two (4x8 mm) screws (provided) as shown in Figure 20.

Figure 20

8. Fasten outer duct cover to multi vent exhaust on the hood with four (4x8 mm) screws

(provided).

9. Continued at “Install Accessories” on page 16.

Attach Together

14

Page 17

WALL MOUNT INSTALLATION – REAR VENT

***This installation only applied with the purchase of a duct cover (Model No. CH1120DC).

Preparation before Installation

NOTE: TO AVOID DAMAGE TO YOUR HOOD, PREVENT DEBRIS FROM ENTERING THE

VENT OPENING.

- Decide the location of the venting pipe from the hood to the outside. Refer to Figure 21.

- A straight, short venting run will allow the hood to perform more efficiently.

- Try to avoid as many transitions, elbows, and long run as possible. This may reduce

the performance of the hood.

- Use duct tape to seal the joints between pipe sections.

- If necessary, prepare back wall frame with cross framing lumber for secure installation.

Using references on Table 2 and measurements on page 20-21, decide the level of the

lumber. Refer to Figure 22.

Hood Preparation before Installation

- Temporarily wire the hood to test for proper operation before installing.

- Peel protective film off the hood and the duct cover (if any).

- Remove the screws on the vent cover (rear) and cut along the line of the inner vent

cover (rear) opening. Refer to Figure 23.

- Cut the vent cover (rear) opening and reverse to the other side. Refer to Figure 24.

Figure 21 Figure 22

Inner Vent

Cover (Rear) Reversed

Vent Cover

(Rear)

Figure 23 Figure 24

15

Page 18

Mounting

- If necessary, attach two rubber stands (provided) with two (4x8 mm) screws (provided)

to the back of the hood.

- Attach the hood-mounting bracket to the back of the hood with nine (3/16" x 3/8")

screws (provided) as shown in Figure 25.

Hood Installation

CAUTION: If required to move the cooking range to install the hood, turn OFF the power on an

electric range at the main electrical box. SHUT OFF THE GAS BEFORE MOVING A GAS

RANGE.

1. Using references on Table 2 and measurements on page 20-21, mark the leveling point

of the hood. Position two mounting screws (not provided) on the wall, leaving 1/8” away

from the wall as shown in Figure 26.

Screws

Figure 25 Figure 26

2. Use aluminum or steel pipe to connect the exhaust opening at the rear of the hood to the

ductwork. Use duct tape to make all joints secure and air tight.

3. Align hood-mounting bracket to the two screws on the wall and hook hood into place.

Tighten screws to secure hood to the wall. CAUTION: MAKE SURE THE HOOD IS

SECURE BEFORE RELEASING.

Duct Cover Installation

4. Mark the position of the duct cover-mounting bracket. Use calculation E from Table 2 for

references. Attach and secure duct cover-mounting bracket with two screws (not

provided). Refer to Figure 27. NOTE: Inner duct cover will cover the mounting bracket.

5. Connect electrical wires. Refer to “Wiring to Power Supply” on page 16.

6. Slide the inner duct cover up 2 inches before sliding the entire duct cover onto the hood.

Refer to Figure 28.

16

Page 19

Figure 27 Figure 28

7. Adjust the height of the inner duct cover to the duct cover-mounting bracket. Secure the

inner duct cover with two (4x8 mm) screws (provided) as shown in Figure 29.

Figure 29

8. Fasten outer duct cover to multi vent exhaust on the hood with four (4x8 mm) screws

(provided).

9. Continued at “Install Accessories” on page 16.

Attach Together

17

Page 20

Wiring to Power Supply

SAFETY WARNING

RISK OF ELECTRICAL SHOCK. THIS RANGE HOOD MUST BE PROPERLY GROUNDED.

MAKE SURE THIS IS DONE BY SPECIALIZED ELECTRICIAN IN ACCORDANCE WITH ALL

APPLICABLE NATIONAL AND LOCAL ELECTRICAL CODES. BEFORE CONNECTING

WIRES, SWITCH POWER OFF AT SERVICE PANEL AND LOCK SERVICE PANEL TO

PREVENT POWER FROM BEING SWITCHED ON ACCIDENTALLY.

Connect the electrical wires.

- If necessary to hide the electrical wire connections, push wires back into the wiring box.

Before reattaching the bottom casing, make sure wires do not slip between motors,

impellers, or any moving parts to prevent any damage.

- Connect three wires (black, white and green) to house wires and cap with wire

connectors.

- Connect according to color: black to black, white to white, and green to green.

- Test the operation of the hood before moving on to the next step. Make sure power is

supplied to the hood.

Install Accessories

1. Attach oil tunnel. Refer to Figure 30.

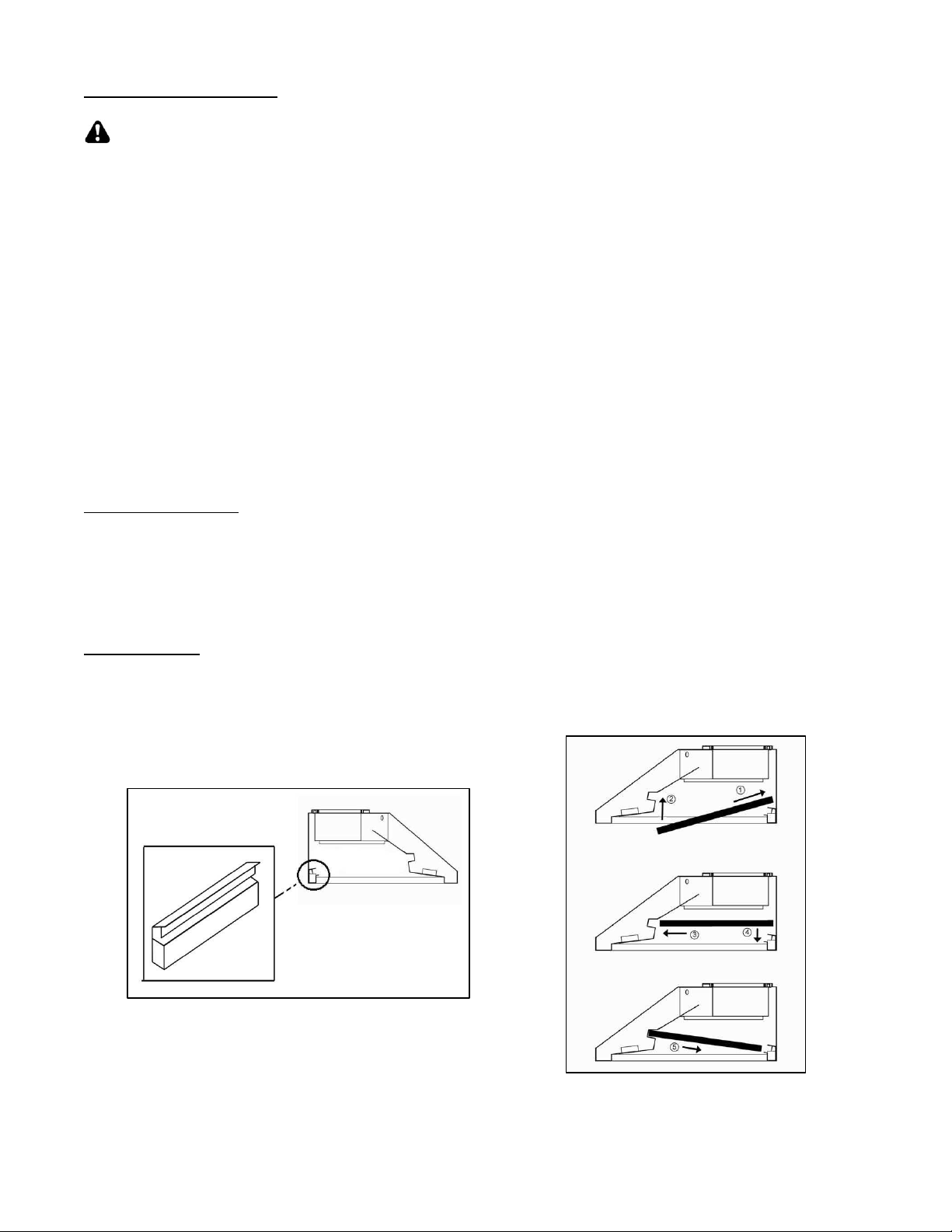

2. Refer to Figure 31. Slide the baffle filter into the hood. Push the baffle filter

upward. Slide forward. Pull downward. Fit into place.

3. For Spacer, repeat above steps.

Final Assembly

4. Turn power ON in control panel. Check all lights and fan operation.

5. Make sure to leave this manual for the homeowner.

Figure 30

Figure 31

18

Page 21

OPERATING INSTRUCTIONS

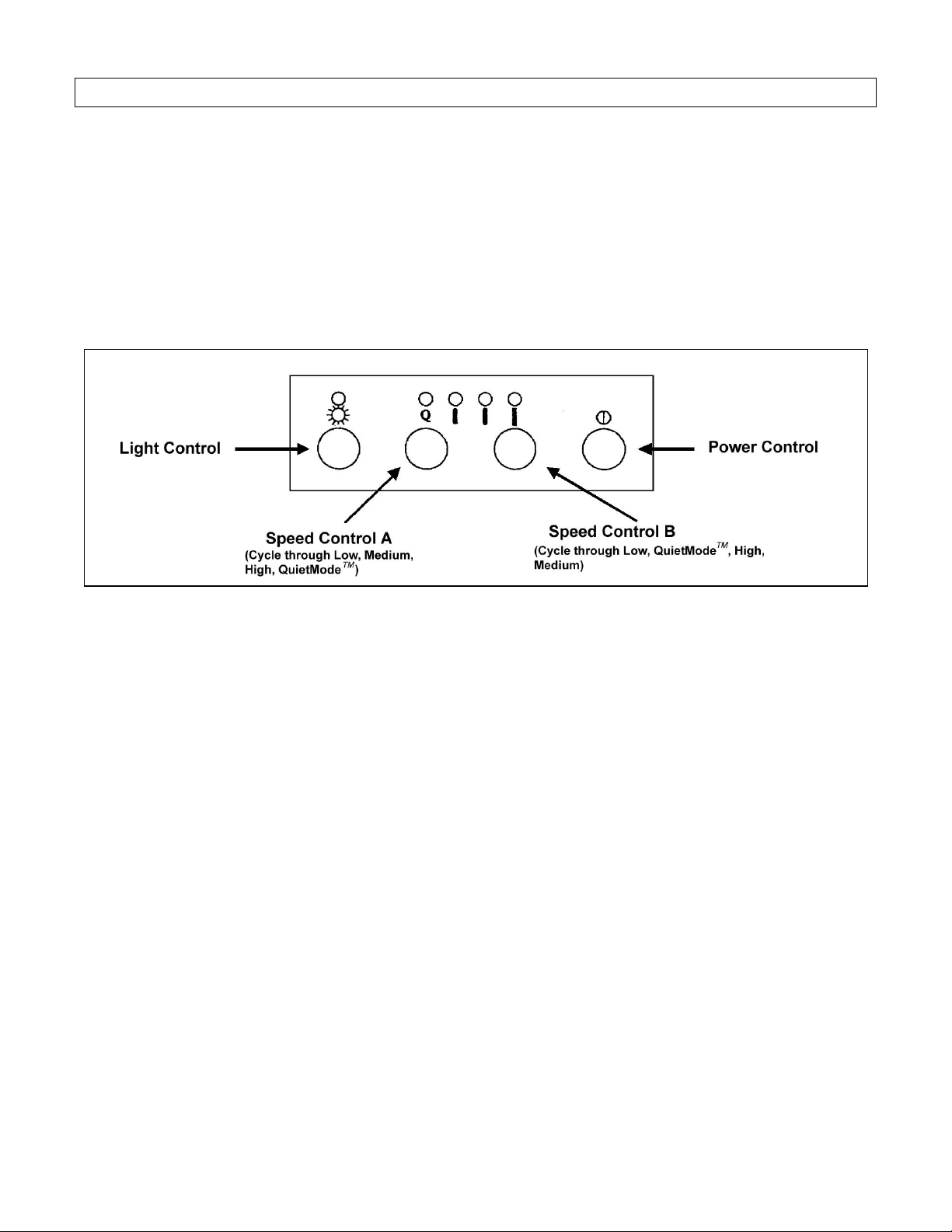

This KOBE hood is equipped with four electronic controls with a 10-second standby startup &

30-second delay shutoff, two powerful centrifugal turbine impellers with safety screens, two

bright LED, and baffle filters.

The four electronic controls are Light Control, Speed Control A (cycles through Low, Medium,

High, QuietMode), Speed Control B (cycles through Low, QuietMode, High, Medium) and

the Power Control (On/Off). Refer to Figure 32.

Turn On:

- Press Power Control (On/Off) button once. (If another Control button is not pressed

- The KOBE hood will start on Low speed. Each press of the Speed Control button

- Press Speed Control A button to cycle from Low, Medium, High, or QuietMode.

- Press Light Control button to turn LED on.

Turn Off:

- Press Power Control (On/Off) button once, panel lights will flash, the power and

- Press Power Control (On/Off) button twice, power and lights will be shut off

- If only the lights are on, pressing Power Control (On/Off) button once will turn lights

Figure 32

within 10 seconds, power will be automatically turned off).

will cycle through the various speeds.

Press Speed Control B button to cycle from Low, QuietMode, High or Medium.

lights will be completely shut off after 30 seconds.

OR

immediately.

off after 30 seconds.

19

Page 22

MAINTENANCE

SAFETY WARNING

NEVER PUT YOUR HAND INTO AREA HOUSING THE FAN WHILE THE FAN IS

OPERATING.

Cleaning Hood Surface

CAUTION

:

NEVER USE ABRASIVE CLEANERS, PADS, OR CLOTHS. DO NOT

USE PAPER TOWEL ON STAINLESS STEEL.

For optimal operation, clean range hood and all baffle/spacer/filter/oil tunnel/oil container regularly.

*** Regular care will help preserve the appearance of the hood.

1. Use only mild soap or detergent solutions. Dry surfaces using soft cloth. DO NOT USE PAPER

TOWELS.

2. If hood looks splotchy (stainless steel hood), use a stainless steel cleaner to clean the surface

of the hood. Avoid getting cleaning solution onto or into the control panel. Follow directions of

the stainless steel cleaner. Caution: Do not leave on too long as this may cause damage to

hood finish. Use soft towel to wipe off the cleaning solution, gently rub off any stubborn spots.

Use dry soft towel to dry the hood.

3. DO NOT allow deposits to accumulate or remain on the hood.

4. DO NOT use ordinary steel wool or steel brushes. Small bits of steel may adhere to the surface

and cause rusting.

5. DO NOT allow salt solutions, disinfectants, bleaches, or cleaning compounds to remain in

contact with stainless steel for extended periods. Many of these compounds contain chemicals,

which may be harmful. Rinse with water after exposure and wipe dry with a clean lint free cloth.

To Clean Baffle Filter

CAUTION: DRAIN OIL FROM BAFFLE FILTER BEFORE OIL WILL OVERFLOW.

1. Remove all the baffle filters and oil tunnel.

2. Using a sponge, wash with warm soapy water. Dry completely before returning into place.

(Note: Baffle Filters are top rack dishwasher safe.)

20

Page 23

MODEL / SIZE

COLOR

CONSUMPTION / AMPERE

VOLTAGE

NUMBER OF MOTOR

S

DESIGN

FAN TYPE

EXHAUST

CONTROLS

LED

HOOD DIMENSION

OPTIONAL ACCESSORIES

Net Gross

(CH7730SQB)

(CH7736SQB)

SPEED

Low

Medium

High

Air Capacity (cfm)

Sone

*

SPECIFICATIONS

CH7730SQB / 30”

CH7736SQB / 36"

Commercial Grade Stainless Steel

198W / 1.71A

120V 60Hz

2

18-Gauge Seamless / Satin Finish

Twin Turbine Impeller

Top –

6" Round

7" Round

3-1/4" x 10" Rectangular

Rear –

3-1/4" x 10" Rectangular

Electronic Control (4 Buttons) –

10-Second Standby Startup

30-Second Delay Shutoff

12V 3W x 2

(CH7730SQB) 29-3/4” x 22” x 10”

(W x D x H)

(CH7736SQB) 35-3/4” x 22” x 10”

1) Two-Piece Adjustable Duct Cover

(W x D x H)

(CH1120DC) 11-7/8" x 10-1/4" x (20-5/8" ~ 39-3/4")

2) 30" Stainless Steel Back Panel

(SSP30) 30" x 1/10" x 32"

3) 36" Stainless Steel Back Panel

(SSP36) 36" x 1/10" x 32"

WEIGHT (lbs)

QuietMode

300 450 620 760

1.2 3.0 4.5 4.8

*One sone is equivalent to the sound of a refrigerator at 40 decibels.

**Specifications information is subject to change without notice.

48.5 68.5

53.0 75.0

21

Page 24

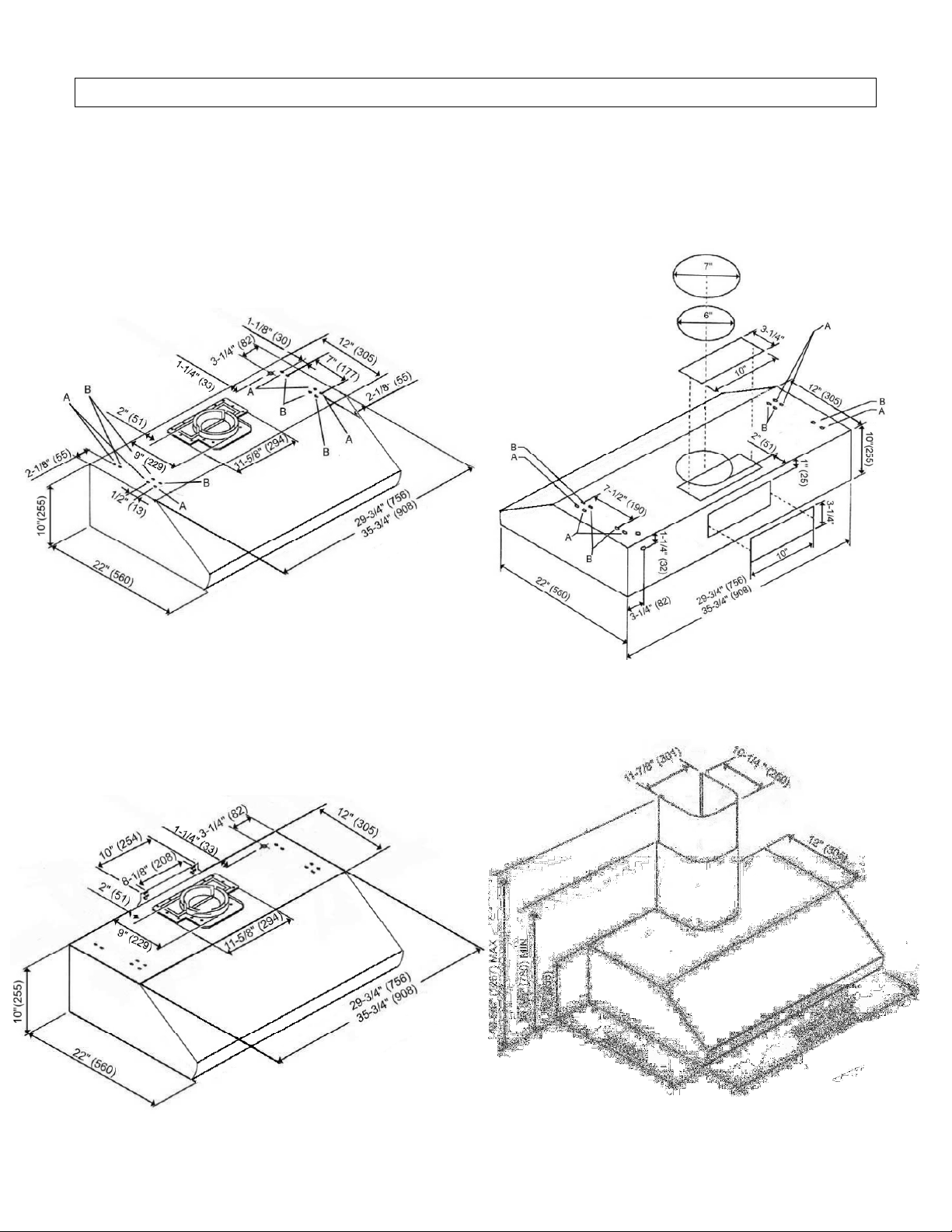

- FOR UNDER THE CABINET

-

MEASUREMENTS & DIAGRAMS

***All inch measurements are converted from millimeters. Inch measurements are estimated.

***All measurements in ( ) are millimeters.

30" = Knockout Holes “A”

36" = Knockout Holes “A” & “B”

- FOR WALL MOUNT (WITH OPTIONAL DUCT COVER) -

22

Page 25

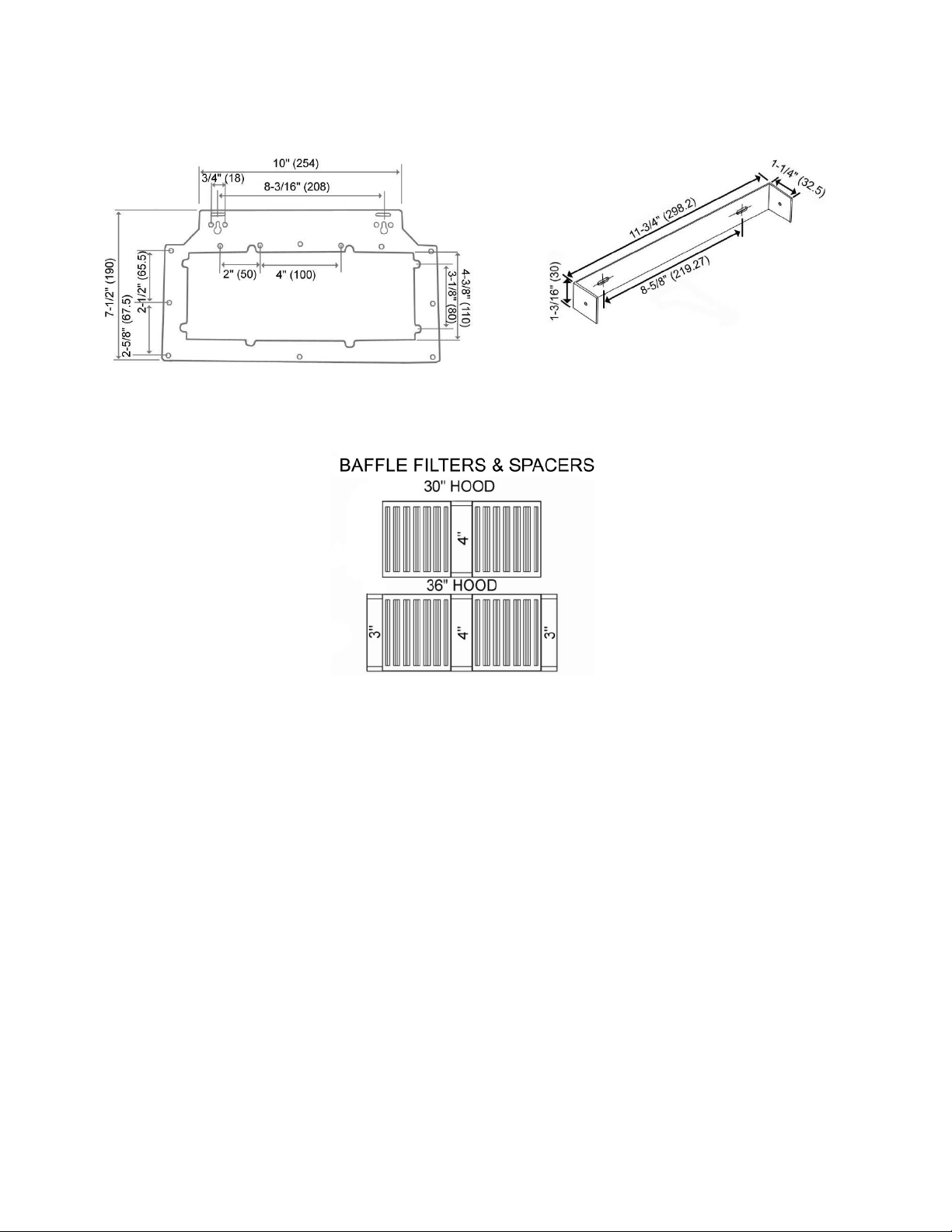

***Hood-Mounting Bracket ***Duct Cover-Mounting Bracket

23

Page 26

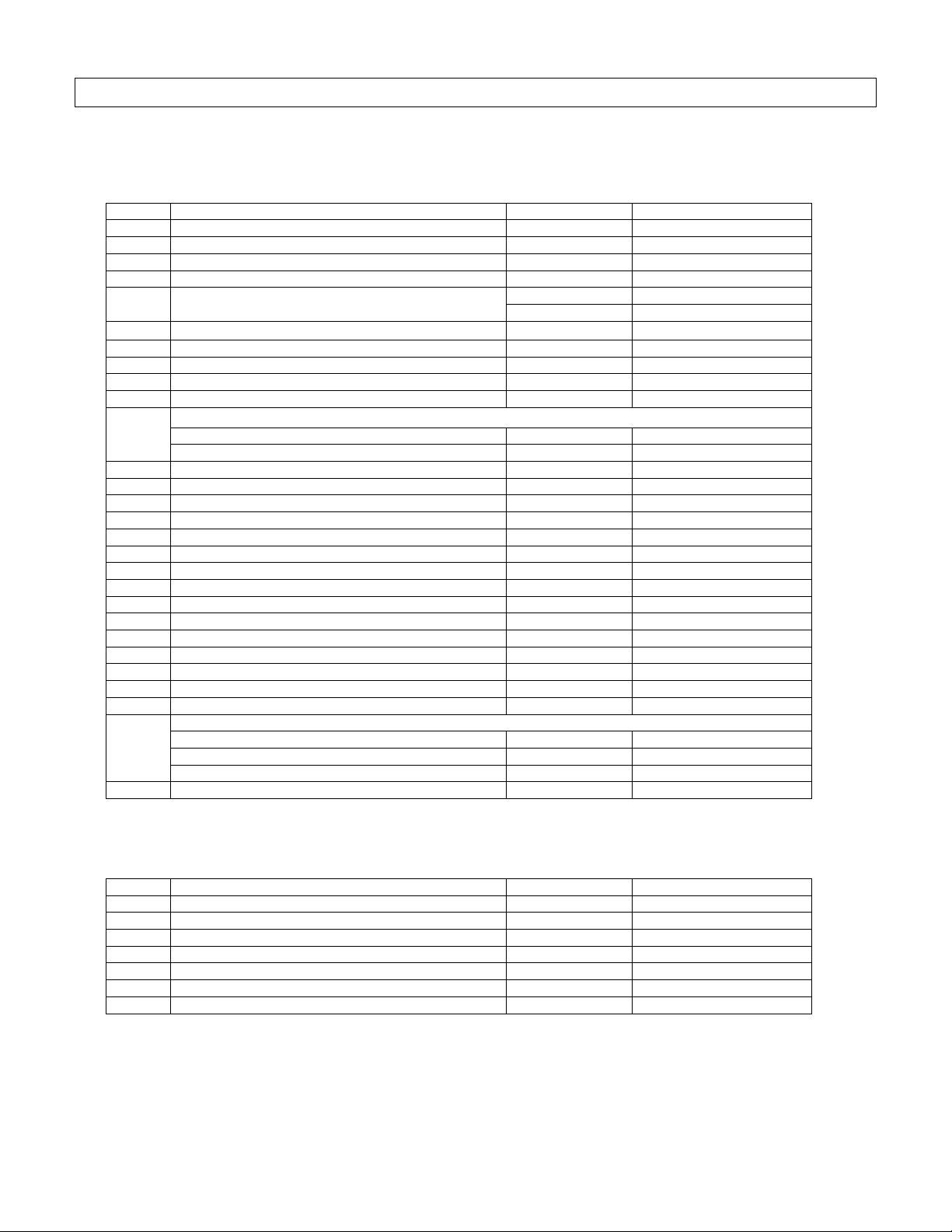

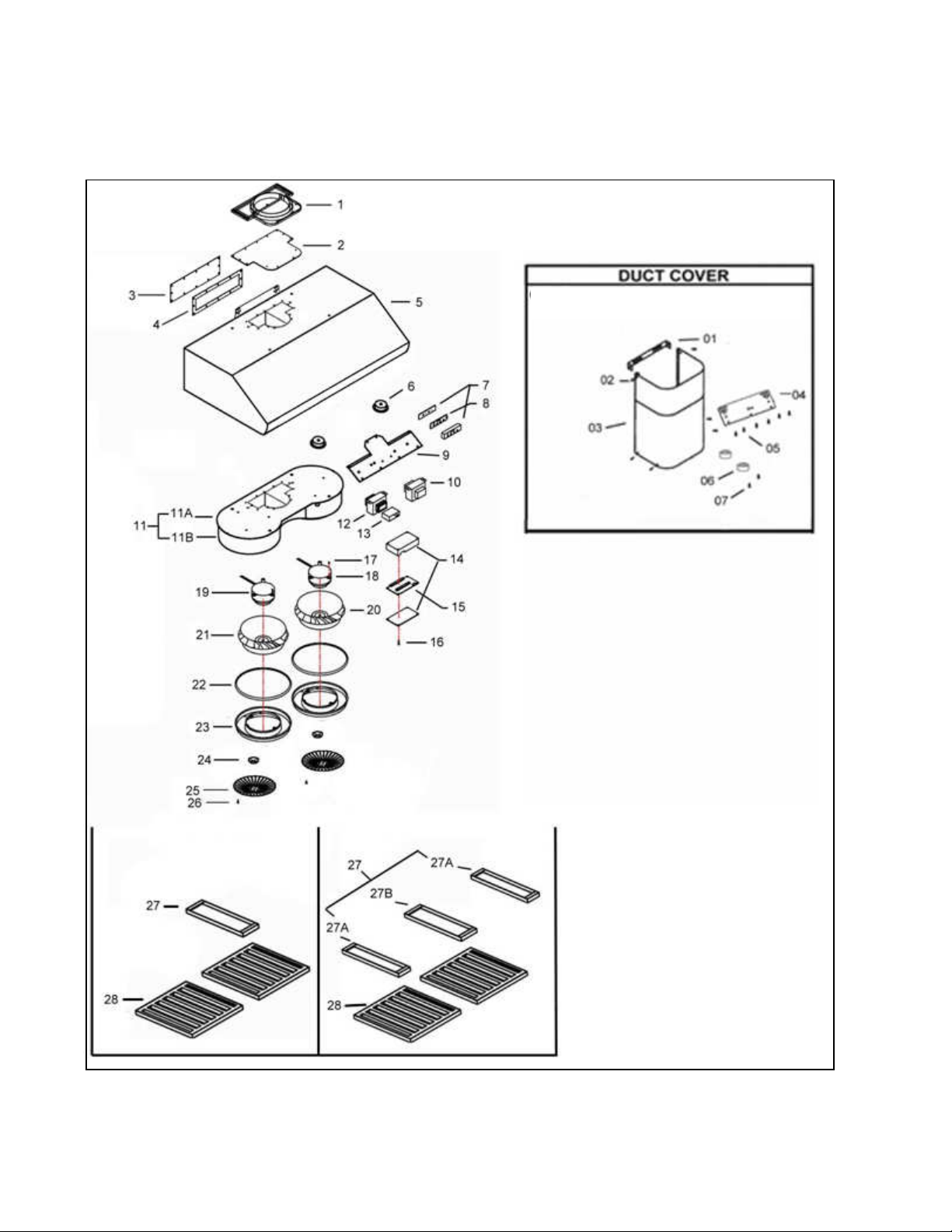

MODEL NO.:

CH7730SQB

NO. DESCRIPTION

MODEL /SIZE

PART NO.

NO. DESCRIPTION

MODEL /SIZE

PART NO.

PARTS LIST

CH7736SQB

1 Multi Duct Exhaust C1-0507-1530

2 Vent Cover (Top) B101-1530-12

3 Vent Cover (Rear) C1-0508-1530-A

4 Vent Cover Frame C1-0508-1530-B

5 Hood Casing CH7730SQB 10-5030B-51

CH7736SQB 10-5036B-51

6 LED Light C1-0403-0306

7 Control Unit C1-0501-0101

8 Control Board C1-0404-4001-A

9 Transformer Support C1-0201-1530

10 Transformer (Motor) C1-0402-A120-01

11

A

12 Transformer (LED Light) C1-0402-D001

13 Capacitor C1-0401-0120-01

14 Processor Board Box C1-0501-0102

15 Processor Board C1-0404-4110-B

16 Round Head Screw (1/8” x 3/8”) C1-0708-0003

17 Motor Position Screw (TS 1/4 x 7/16 C1-0703-0001

18 Motor (Right) C1-0301-0120-23B

19 Motor (Left) C1-0301-0120-23A

20 Turbine Impeller ( Right) C1-0251-0880-B

21 Turbine Impeller ( Left) C1-0251-0880-A

22 Oil Tunnel Seal C1-0502-0301

23 Oil Tunnel C1-0502-0102

24 Impeller Plastic Cover C1-0251-0001

25 Safety Screen C1-0602-0101

26 Safety Screen Screw C1-0705-0001

27 Bottom Casing

28 Baffle Filter B101-1930-15

01 Hood-Mounting Bracket C1-0221-1530

02 Screws (TS 4 x 8 mm) C1-0708-0006

03 Duct Cover CH1120DC 12-15300-51

04 Duct Cover-Mounting Bracket C1-0221-1530

05 Screw (3/16” x 3/8”) C1-0707-0001

06 Rubber Stand C1-0511-0382

07 Screw ( TS 4 x 8 mm) C1-0708-0006

Air Chamber

Air Chamber (Top) CH7730SQB C1-0101-1530

B

Air Chamber (Side) CH7736SQB C1-0102-1530

A 4” Wide CH7730SQB B101-1930-09

3” Wide CH7736SQB B101-1936-09

B 4” Wide CH7736SQB B101-1930-09

(Optional Duct Cover)

24

Page 27

MODEL NO.:

CH7

730SQB

Sold Separately

CH7736SQB

CH7730SQB

CH7736SQB

25

Page 28

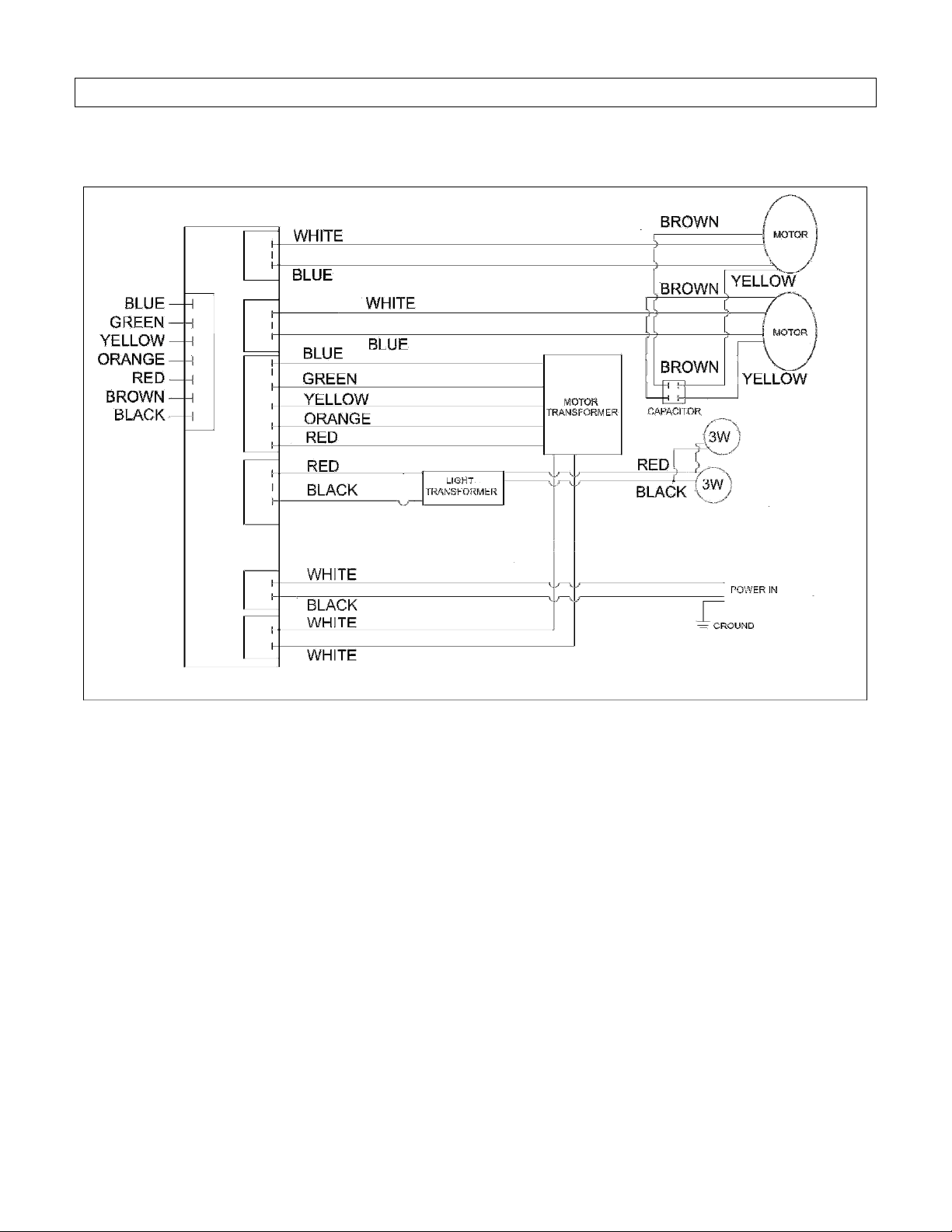

MODEL NO.:

CH7

730SQB

CIRCUIT DIAGRAM

CH7736SQB

26

Page 29

Issue

Possible Cause

Solution

TROUBLE SHOOTING

After Installation,

both motors and

lights are not

working.

Lights are

working, but

motor(s) is not.

The range

hood is

vibrating.

The motor is

working, but

the lights are

not working.

The range

hood is not

venting out

correctly.

Cold air is

coming into the

home.

The power is not on. Make sure the circuit breaker and the unit’s power is

ON. Use a voltage meter to check the power supply.

The wire connection is not secure. Check and tighten wire connection.

The control panel and processor board

wiring are disconnected.

The motor transformer is defective. Check the power input and power output on the

The control panel and processor board is

defective.

The motor(s) is defective.

The capacitor(s) is defective.

The control panel or processor board is

defective.

The blower system is not secure.

The turbine impeller/squirrel cage is

not balanced.

Hood is not secured in place.

Light bulb(s) is defective.

The light wiring(s) is loose.

Light transformer is defective.

The control panel or processor board is

defective.

The range hood is installed outside of

the manufacture recommended

clearance.

There is no make-up air inside the

house.

Obstacle blocking the pipe work.

The pipe size is smaller than the

suggested pipe size.

The pipe connection is not properly

sealed.

The damper is not properly installed or

is missing from the installation.

The damper is not installed.

Check wire continuity from control panel to processor

board.

motor transformer.

If it’s needed, replace the motor transformer.

Replace the control panel or processor board.

Replace the motor.

Replace capacitor(s).

Replace the control panel or processing board.

Tighten the turbine impeller/squirrel cage and air

chamber.

Replace the turbine impeller/squirrel cage.

Check the installation of hood, tighten the

mounting bracket.

Try placing the trouble light bulb(s) to a working

socket, if the bulb(s) still doesn’t work; replace

the halogen light bulb(s).

Check wire continuity from processor board to

light transformer to halogen light housing(s).

Check power input and power output on the light

transformer. If it’s needed, replace the light

transformer.

Replace the control panel or processing board.

Adjust the clearance between the range hoods

and cook top to 27” to 30”. For Island range

hood, the clearance between the range hoods

and cook top is 30” to 36”.

Open the window to enhance the performance

of the range hood by creating a sufficient make-

up air.

Remove all obstacles from the duct work.

Change the ducting according to the

manufacture suggestion.

Check the pipe installation.

Check the damper installation.

By installing the damper, it will help to eliminate

air backflow.

27

Page 30

WARRANTY

WARRANTY CERTIFICATE

KOBE Range Hoods (referred to herein as “we”or “us”) warrants to the original purchaser

(referred to herein as “you” or “your”) all products manufactured or supplied by us to be free

from defect in workmanship and materials as follows:

TWO-YEAR LIMITED WARRANTY FOR PARTS AND LABOR ON KOBE PREMIUM

SERIES:

For two years from the date of your original invoice from a KOBE authorized dealer, we will, at

our sole discretion, choose to repair or replace the product free of charge that failed due to

manufacturing defects.

It is your sole responsibility to ensure the product is readily accessible for the service

technician to perform repairs. The service technician will not, under any circumstance,

remove, alter or modify any fixture built around and/or connected to the product to gain

access to perform repairs.

During the two-year Limited Warranty period, additional charges may apply which include but

are not limited to:

• Service technician travel charges if the requested service location is 30-miles out of

KOBE’s authorized service area

• Parts shipping expenses

• Un-installation of defective product and Installation of replacement product

ONE-YEAR LIMITED WARRANTY FOR PARTS ON KOBE BRILLIA SERIES:

For one year from the date of your original invoice from a KOBE authorized dealer, we will

provide, free of charge, parts to replace those that failed due to manufacturing defects. It is our

sole discretion to choose to repair or replace defective parts. It is your sole responsibility for all

labor costs associated with this warranty.

Warranty Exclusions:

This warranty does not cover, including but not limited to the following:

a. Improper installation.

b. Any repair, alteration, modification not authorized by KOBE.

c. Duct alteration, modification and connection.

d. Incorrect electric current, voltage or wiring.

e. Normal maintenance and service required for the product.

f. Consumable parts such as light bulbs and carbon filters.

g. Improper usage of the product that it is not intended for, such as commercial use,

outdoor use and multi-family use.

h. Normal wear and tear.

i. Chips, scratches or dents by abuse or misuse of the product.

j. Damages caused by accident, fire, flood and other Acts of God.

k. Expenses incurred for service located outside of the designated service area.

l. Purchases from unauthorized dealers.

m. Removal fees of defective product and Installation fees associated with replacement

product.

28

Page 31

If we determine that the warranty exclusions listed above apply or if you fail to provide all

necessary documentation for warranty service, you will be responsible for all expenses

associated with the requested service, including parts, labor, shipping, travelling and any other

expense related to the service request.

To qualify for warranty service, you must:

1. Have the ORIGINAL proof of purchase

2. Be the ORIGINAL purchaser of the product

3. Have the model number

4. Have the serial number

5. Have a description of the nature of any defect in the product or part

TO REQUEST WARRANTY SERVICE, PLEASE CONTACT THE KOBE RANGE HOODS

SERVICE CENTER:

KOBE SERVICE CENTER

Tel: 1-855-800-KOBE (5623)

E-mail: kobe@adcoservice.com

29

Page 32

WARRANTY INFORMATION FORM

Fill in the blanks and keep this paper with the original invoice in a

safe place for future service purpose.

1. Date of purchase :

2. Model No. :

3. Serial No. :

For warranty service or spare parts purchase contact:

KOBE Service Center

Toll Free: 1-855-800-KOBE (5623)

Email: kobe@adcoservice.com

To report a problem, please contact:

Toll Free: 1-877-BUY-KOBE (289-5623)

Email: customer.service@koberangehoods.com

For product information contact:

Toll free: 1-877-BUY-KOBE (289-5623)

Email: info@koberangehoods.com

Your notes:

30

Page 33

[Français]

31

Page 34

IMPORTANT !

LISEZ CECI EN PREMIER

LIEU.

LISEZ CECI AVANT L'INSTALLATION

1. Vérifiez soigneusement tous les contenus des emballages;

2. Inspectez soigneusement l'appareil pour tous dommages ou

défauts cosmétiques;

3. Tester l'appareil avant l'installation;

4. Engagez un entrepreneur/électricien certifié pour procéder à

l'installation.

EN CAS DE PROBLEME:

1. N’INSTALLEZ PAS L'APPAREIL ET CONSERVER LE

CONTENU DE L 'EMBALLAGE D'ORIGINE.

2. Ayez votre preuve d'achat originale et le numéro de série du

produit.

3. Appelez au 1-877-BUY-KOBE (289-5623) ou contactez-nous

par courriel à info@koberangehoods.com pour signaler le

problème.

PAS DE RETOUR, DE REMBOURSEMENT, NI

D’EXCHANGE SI:

1. Le produit a été installé

2. Les trous prédécoupés ont été perforés

3. Contenus et/ou pièces de l'emballage d'origine

manquent

32

Page 35

[FRENCH]

- VEUILLEZ CONSERVER CE MANUEL À TITRE DE RÉFÉRENCE -

TABLE DES MATIÈRES

MESURES DE SÉCURITÉ IMPORTANTES ........................................................................ 34

CONTENU DE L’EMBALLAGE ............................................................................................ 36

INSTALLATION .................................................................................................................... 37

MODE D'EMPLOI ................................................................................................................. 50

ENTRETIEN- NETTOYAGE ................................................................................................. 51

SPÉCIFICATIONS ............................................................................................................... 52

MESURES et DIAGRAMMES .............................................................................................. 53

LISTE DES PIÈCES ............................................................................................................. 55

DIAGRAMME DES CIRCUITS ............................................................................................. 57

TROUBLE SHOOTING ........................................................................................................ 58

GARANTIE ........................................................................................................................... 59

ENREGISTREMENT DU PRODUIT ..................................................................................... 61

- LIRE ATTENTIVEMENT TOUTES LES INSTRUCTIONS AVANT DE

DÉBUTER -

L’INSTALLATION DOIT ÊTRE FAITE PAR UN PROFESSIONNEL ET

CONFORME AUX CODES ÉLECTRIQUES NATIONAUX ET LOCAUX.

33

Page 36

MESURES DE SÉCURITÉ IMPORTANTES

- BIEN LIRE ATTENTIVEMENT CETTE SECTION AVANT DE PROCÉDER À L'INSTALLATION -

AVERTISSEMENT

1. L'installation et le câblage électrique doivent être faits par des professionnels qualifiés et doivent

être conforme aux codes locaux et nationaux applicables, incluant ceux concernant les

constructions pare-feu.

2. En coupant ou perçant dans mur ou plafond, faites preuve de prudence afin de ne pas

endommager de câbles électriques ou d'autres installations et équipements techniques

dissimulées.

3. L’évacuation d’air doit se faire vers l’extérieur :

a) Avant l'entretien ou le nettoyage de l'unité, ÉTEIGNEZ LE PUISSANCE à partir du

PANNEAU D’ALIMENTATION ÉLECTRIQUE.

b) Nettoyer les ventilateurs, les filtres et les surfaces graisseuses fréquemment. Pour réduire le

risque de feu et disperser l'air correctement, assurez-vous d’évacuer l’air vers l'extérieur du

bâtiment. Ne déchargez pas l'air évacuée dans les espaces entres les murs et plafonds, ni

dans les greniers, les galeries rampantes ou les garages.

NOTE - La garantie sur ce produit est invalide sans la facture de ventes ou si l'unité est

endommagée due à un mauvais usage, une installation fautive, un usage incorrect, un

mauvais traitement, de la négligence ou autres circonstances hors du contrôle des agents

autorisés de KOBE.

Toute réparation effectuée sans l’accord des dépositaires ou centres de services autorisés

de KOBE annuleront automatiquement la garantie du produit.

- KOBE ne pourra être tenu responsable de dommages à biens personnels, immobiliers ou

de blessures physiques causés directement ou indirectement par ces hottes.

: POUR RÉDUIRE LE RISQUE D’INCENDIE, D’ÉLECTROCUTION

OU DE BLESSURES VOUS DEVEZ OBSERVER LES

CONSIGNES SUIVANTES :

AVERTISSEMENT

1. Conserver les ventilateurs, les filtres, et toutes les surfaces propres

2. Toujours faire fonctionner le ventilateur lorsque vous cuisinez

3. N’employer les réglages élevés seulement lorsque nécessaires. Chauffer l'huile lentement de la

plus basse puissance à la moyenne.

4. Ne jamais laisser les surfaces de cuisson sans surveillance

5. Utiliser des récipients de taille appropriée au type de nourriture et à la quantité préparée.

6. N’utiliser cette unité que seulement pour l’usage auquel elle a été destinée par le fabricant.

7. Avant l'entretien, éteindre l’alimentation électrique à partir du panneau d’alimentation principal et

bloquer le panneau pour éviter que la puissance ne soit remise en circuit accidentellement

8. Nettoyer les ventilateurs fréquemment. Ne laisser pas la graisse s’accumuler sur les ventilateurs,

les grilles ou dans les contenants de récupération.

: POUR RÉDUIRE LE RISQUE DE BLESSURES EN CAS D'UN

FEU DE GRAISSE/FRITURE

34

Page 37

Que faire en cas de feu de graisse

• ÉTOUFFER LA FLAMME à l’aide d’un couvercle, d’une tôle à biscuit, d’un plateau de métal.

Faites attention aux brûlures. Tenir les matières combustibles inflammables loin du feu. Si

les flammes ne s’éteignent pas quitter la pièce et téléphoner au 911.

• NE PRENEZ JAMAIS UNE CASSEROLE BRÛLANTE – Le métal étant un élément

conducteur, vous pourriez être brûlé.

• N'EMPLOYER PAS D'EAU, incluant des lavettes ou des serviettes humides – cela pourrait

causer un jet de vapeur violent.

• Employer un extincteur SEULEMENT si :

a) Vous avez un extincteur de classe A, B, C et savez comment le faire fonctionner.

b) Le feu est petit et contenu dans le secteur où il a commencé.

c) Les pompiers ont été appelés.

d) Vous pouvez combattre le feu si votre dos fait face à une sortie.

Que faire si vous décelez une odeur de gaz

- Éteindre toute les flammes ouvertes.

- Ne pas allumer les lumières d’aucun type d'appareil.

- Ouvrir toutes les portes et fenêtres pour éliminer le gaz. Si vous flairez toujours une odeur de gaz,

téléphoner à la société de gaz et aux pompiers tout de suite.

AVERTISSEMENT

1)

Cet appareil doit être utilisé pour la ventilation de cuisine seulement. Ne pas utiliser pour évacuer

des matériaux dangereux ou explosifs ou encore des vapeurs nocives.

2)

Pour réduire le risque de feu, n’employer seulement que de conduits de métal.

3)

Suivre les directives du fabricant et les standards de sécurité telles que ceux publiés par

l'Association de Protection d'incendie Nationale (NFPA), la Société Américaine de Chauffage,

Réfrigération et des ingénieurs en climatisation (ASHRAE) de même que vos autorités locales.

4)

L'activation d’un commutateur peut provoquer une explosion.

5)

En raison de la taille et du poids de la hotte, il est recommandé que deux personnes

participent à l’installation.

LE RISQUE D’ÉLECTROCUTION – L’Électrocution peut

entraîner la mort ou encore des blessures graves. Débrancher

l'appareil de sa source d’alimentation électrique avant d’en

effectuer l'entretien. L'ampoule fluorescente peut contenir de

petites quantités de mercure, qui doivent être recyclées ou

disposées en concordance avec les réglementations

municipales, provinciales ou fédérales.

35

Page 38

{A} Hotte KOBE

– 1

{H} Couvre

-

conduit réglable KOBE

– 1

CONTENU DE L’EMBALLAGE

(Pour tout retour ou remboursement conserver le matériel ainsi que l’emballage d’origine)

Boîte du couvre conduit

Boîte de la hotte de cuisinière

{B} Fiche d'enregistrement à la garantie – 1

{C} Notice d'installation et mode d'emploi – 1

{D} Filtre déflecteur

2 (pour hottes de 30 et 36 po)

{E} Panneau pare-éclaboussures

1 (pour hotte de 30 po)

3 (pour hottes de 36 po)

{F} Plaque de sortie (verticale) – 1

{G} Récupérateur de graisse – 1

{A}

{B} {C}

{D} {E}

{F} {G}

POUR DE PLUS AMPLES RENSEIGNEMENTS, VEUILLEZ VISITER NOTRE SITE WEB www.KOBERangeHoods.com OU

COMMUNIQUER AVEC KOBE RANGE HOODS AU (877) 289-5623.

(vendue séparément)

{I} Ensemble de vis – 1

{J} Support de fixation du couvre conduit – 1

{K} Support de fixation – hotte – 1

{H}

Couvre-conduit

intérieur

Couvre-conduit

extérieur

{I} {J}

{K}

36

Page 39

TABLE 2

INSTALLATION

Calcul avant Installation

Calculer la longueur de l'installation avant d'installer la hotte. (Toutes les mesures sont données en

pouces).

TABLE 1 (vue de côté)

A = hauteur du plancher au plafond

B = hauteur du plancher jusqu’au comptoir/

à la surface de cuisson (Normalement : 36 po)

C = hauteur recommandée entre le dessus du comptoir

/surface de cuisson jusqu’au dessous de la hotte

(Recommandation : 27po à 30po)

D = hauteur de la hotte

VEUILLEZ LIRE ENTIÈREMENT LES INSTRUCTIONS AVANT DE PROCÉDER

INSTALLATION SOUS LE CABINET

E = hauteur du cabinet d’armoire

MODÈLE ILOT (AVEC COUVRE CONDUIT OPTIONEL)

(vue de côté)

A = hauteur du plancher au plafond

B = hauteur du plancher jusqu’au comptoir/ à la surface

de cuisson (Normalement : 36po)

C = hauteur recommandée entre le dessus du comptoir

/surface de cuisson jusqu’au dessous de la hotte

(Recommandation : 27po à 30po)

D = hauteur de la hotte

E = hauteur du Couvre Conduit : calcul [F - D]

F = hauteur recommandée pour l'installation de la hotte : calcul

[ A - (B+C)]

37

Page 40

AVERTISSEMENT

LES HOTTES COMPORTENT DES REBORDS TRÈS AFFILÉS; NOUS RECOMANDONS

LE PORT DE GANTS PROTECTEURS LORS DE L’INSTALLATION, LE NETTOYAGE ET

L’ENTRETIEN.

MISE EN GARDE : SOYEZ PRUDENT EN EMPLOYANT UN TOURNEVIS ÉLECTRIQUE, CELA

POURRAIT ENDOMMAGER LA HOTTE.

INSTALLATIONS

SOUS LE CABINET

Conduit Supérieur …..

Conduit Arrière

…………………………………………………………………………..

ILOT

Conduit Supérieur ..

Conduit Arrière ….

……………………………………………………………………

………………………………………………………………………

………………………………………………………………………..

36

38

40

43

38

Page 41

INSTALLATION SOUS LE CABINET - CONDUIT SUPÉRIEUR

Préparation avant l’installation

NOTE : AFIN D’ÉVITER QUE VOTRE HOTTE NE SUBISSE DES DOMMAGES,

ASSUREZ-VOUS QUE L’OUVERTURE N’EST PAS BLOQUÉE ET EMPÊCHER QUE DES

DÉBRIS NE PENÈTRE DANS L’OUVERTURE DES CONDUITS.

- Planifier l'emplacement du conduit d’aération qui cheminera de la hotte vers

l'extérieur. (Voir photo 1)

- Un parcours droit, court et dirigé permettra à la hotte de mieux performer.

- Il est toujours préférable de limiter le nombre de transitions, coudes et passages. Les

changements de direction affecteront la performance de votre hotte.

- Connecter temporairement la hotte afin d’en vérifier le fonctionnement avant de

procéder à l’installation finale.

- Retirer la pellicule protectrice de la hotte (s’il y a lieu).

- Lors d’une installation sous un cabinet : ajouter des fixations de bois d’au moins 4

pouces de large (non inclus) sur chaque côté. (Voir photo 2)

- Mesurer et prévoir un accès pour des fils électriques sous le cabinet.

- Couper le conduit d’échappement selon la taille du tuyau de décharge. (Voir photo 3)

Photo 1 Photo 2

39

Photo 3

Page 42

Installation de la hotte :

AVERTISSEMENT :

l’alimentation électrique sur l’appareil ainsi qu’à partir de la boîte principale, ou encore enlevez

l’alimentation en gaz s’il s’agit d’un appareil au gaz.

si vous devez déplacer la cuisinière pour installer la hotte, arrêter

1. Perforer les trous de décochage sur la hotte tel qu’indiqué à la photo 4.

2. Desserrer les six vis de boîtier du bas. Retirer le boîtier (si nécessaire) et placer les fils

électriques pour qu’ils passent au travers de la perforation de 1po de diamètre situé sur

le dessus ou à l'arrière de la hotte. Veuillez vous référer à la photo 5.

3. En utilisant les références de la Table 1 et les mesures à la page 50 centrer la hotte

capuchon en place au-dessous du cabinet et vis à vis le devant du cabinet.

Perforation de 1po

Photo 4 Photo 5

4. Passer les fils électriques au travers de l'ouverture d'accès des cabinets.

5. Insérer les vis en (non fournies) exactement au centre de chaque trou de décochage.

Assurez-vous toutes les vis sont en place avant de les resserrer.

ASSUREZ-VOUS QUE LA HOTTE EST SOLIDEMENT FIXÉE EN PLACE AVANT DE LA

RELACHER

.

AVERTISSEMENT :

Installation des conduits

6. Utiliser des tuyaux d'aluminium ou d'acier pour relier le joint de raccordement en

plastique de la hotte aux conduits dessus. Utiliser du ruban adhésif pour sceller les joints

sûrs et ainsi obtenir une parfaite étanchéité.

7. Continuer à la section «Connexion à l'alimentation d'énergie» de la page 46.

40

Page 43

Photo 8

Photo 9

INSTALLATION SOUS LE CABINET - CONDUIT ARRIÈRE

Préparation avant installation :

NOTE : AFIN D’ÉVITER QUE VOTRE HOTTE NE SUBISSE DES DOMMAGES,

ASSUREZ-VOUS QUE L’OUVERTURE N’EST PAS BLOQUÉE ET EMPÊCHER QUE DES

DÉBRIS NE PENÈTRE DANS L’OUVERTURE DES CONDUITS.

- Planifier l'emplacement du conduit d’aération qui cheminera de la hotte vers

l'extérieur. (Voir photo 6)

- Un parcours droit, court et dirigé permettra à la hotte de mieux performer.

- Il est toujours préférable de limiter le nombre de transitions, coudes et passages. Les

changements de direction affecteront la performance de votre hotte.

- Connecter temporairement la hotte afin d’en vérifier le fonctionnement avant de

procéder à l'installation finale.

- Retirer la pellicule protectrice de la hotte (s’il y a lieu).

- Lors d’une installation sous un cabinet : ajouter des fixations de bois d’au moins 4

pouces de large (non inclus) sur chaque côté. (Voir photo 7)

- Mesurer et prévoir un accès pour les fils électriques sous le cabinet ou raccorder en

passant par l’ouverture pour les fils à l’arrière de la hotte.

- Retirer les vis sur la plaque de sortie arrière et couper le long de la ligne d’ouverture

du conduit intérieur. (Voir photo 8)

- Couper la plaque de sortie arrière et changez-la de côté. Référez-vous à la photo 9.

Rattachez la plaque de sortie arrière.

Photo 6

Couvercle

intérieur (arrière)

Photo 7

Couvercle

inversé

(arrière)

41

Page 44

Photo 12

AVERTISSEMENT :

l’alimentation électrique sur l’appareil ainsi qu’à partir de la boîte principale, ou encore enlevez

l’alimentation en gaz s’il s’agit d’un appareil au gaz.

si vous devez déplacer la cuisinière pour installer la hotte, arrêter

1. Perforer les trous de décochage sur la hotte tel qu’indiqué à la photo 10.

2. Dévisser et retirer l'adaptateur de sortie multi conduits. Remplacez-le par la plaque de

conduit {en forme de « F »} tel qu’indiqué à la photo 11.

Photo 10

Photo 11

3. En utilisant les références de la Table 1 et les mesures à la page 50, centrer la hotte en

place au-dessous du cabinet vis à vis le devant du cabinet.

4. Passer les fils électriques au travers de l'ouverture d'accès des cabinets.

5. Insérer les vis (non fournies) exactement au centre de chaque trou de décochage.

Assurez-vous que toutes les vis sont en place avant de les resserrer.

AVERTISSEMENT : ASSUREZ-VOUS QUE LA HOTTE EST SOLIDEMENT FIXÉE EN PLACE

AVANT DE RELACHER L’APPAREIL.

Trou 1po de

diamètre

Raccordement aux conduits

6. Utiliser des tuyaux d'aluminium ou d'acier pour relier le joint de raccordement en

plastique de la hotte aux conduits dessus. Utiliser du ruban adhésif d’aluminium pour

sceller les joints sûrs et ainsi obtenir une parfaite étanchéité.

7. Continuer à la section «Connexion à l'alimentation d'énergie» de la page 46.

42

Page 45

INSTALLATION MODÈLE ILOT - CONDUIT SUPÉRIEUR

ATTENTION :

CH1120DC.

Ce type d’installation doit être réalisée seulement avec un couvre conduit modèle

Préparation avant Installation

NOTE : AFIN D’ÉVITER QUE VOTRE HOTTE NE SUBISSE DES DOMMAGES,

ASSUREZ-VOUS QUE L’OUVERTURE N’EST PAS BLOQUÉE ET EMPÊCHER QUE DES

DÉBRIS NE PENÈTRE DANS L’OUVERTURE DES CONDUITS.

-

Déterminer l'emplacement du conduit d’aération de la hotte vers l'extérieur. Référez-vous à la

photo 13.

-

Une canalisation droite, courte et dirigée permettra à la hotte de s’exécuter plus efficacement.

-

Lorsque possible, diminuer le nombre de transitions, coudes et longueurs. Les changements de

direction affecteront la performance de votre hotte.

-

Utiliser un ruban adhésif (Duct tape) en toile pour sceller tous les joints, et ainsi assurer une

parfaite étanchéité.

-

Si nécessaire, préparez le mur arrière avec un soutien additionnel pour une installation

sécuritaire.

-

En utilisant les références à la Table 2 et les mesures à la page 50-51, régler la hauteur du

soutien additionnel. Référez-vous à la photo 14.

Préparation de la hotte avant installation

-

Fixer temporairement la hotte afin d’en évaluer le fonctionnement avant de procéder à

l'installation permanente.

-

Retirer le film protecteur de la hotte et du couvre conduit.

-

Découper l’ouverture multi conduit selon la taille des tuyaux d’échappement. Référez-vous à la

photo 15.

Photo 13

Photo 14

43

Photo 15

Page 46

Photo

16

Photo 17

- Si nécessaire, fixer les deux fixations (fournis) en caoutchouc en compagnie des deux

vis (4x8 mm) (fournies) à l’arrière de la hotte.

- Fixer le support de montage au dos de la hotte avec l’aide des neuf (3/16po x 3/8po) vis

(fournies) tel qu’indiqué à la photo 16.

Installation de la hotte

AVERTISSEMENT :

l’alimentation électrique sur l’appareil ainsi qu’à partir de la boîte principale, ou encore enlevez

l’alimentation en gaz s’il s’agit d’un appareil au gaz.

si vous devez déplacer la cuisinière pour installer la hotte, arrêter

1. En utilisant en référence la Table 2 et les mesures à la page 50-51, repérez le point de

nivellement de la hotte. Installer deux vis de fixation (non fournies) sur le mur, laissant

1/8 " d’espace par rapport au mur comme indiqué à la photo 17.

2. Aligner le support de montage avec les deux vis sur le mur et fixer la hotte en la hotte

en place. AVERTISSEMENT : ASSUREZ-VOUS QUE LA HOTTE EST BIEN FIXÉE

AVAN T DE LA RELÂCHER.

Vis de montage

Installation avec couvre- conduits

3. Repérer la position de la fixation pour couvre conduit. Utiliser comme référence

l’indication E de la Table 2 et le mesures à page 50-51. Attacher de façon sécuritaire la

fixation pour couvre conduit à l’aide de deux vis (non fournies). Référez-vous à la photo

18. NOTE : la doublure du couvre conduit masquera la fixation.

4. Utiliser des conduits d’aluminium ou d'acier pour connecter la sortie arrière à la

canalisation. Utiliser un ruban adhésif (Duct tape) en toile pour sceller tous les joints, et

ainsi assurer une parfaite étanchéité.

5. Connecter des fils électriques.

6. Glisser la doublure du couvre conduit environ 2 pouces avant d’introduire le couvre

conduit entier. Voir la photo 19.

44

Page 47

Photo 20

Photo 18

Photo 19

7. Ajuster la hauteur de la doublure intérieure du couvre conduit a la fixation du couvre

conduit. Sécuriser la doublure intérieure du couvre conduit avec deux (4x8 mm) vis

(fournies) tel comme indiqué à la photo 20.

Attacher ensemble

8. Attacher la doublure extérieure du couvre conduit à l’adaptateur d’échappement multi

conduits de la hotte avec les quatre vis 4 x 8 mm fournies.

9. Continuer à la section « Installation des accessoires » de la page 46.

45

Page 48

INSTALLATION ILOT - CONDUIT ARRIÈRE

Attention :

CH1120DC.

Préparation avant Installation

Ce type d’installation doit être réalisée seulement avec un couvre conduit modèle

NOTE : AFIN D’ÉVITER QUE VOTRE HOTTE NE SUBISSE DES DOMMAGES,

ASSUREZ-VOUS QUE L’OUVERTURE N’EST PAS BLOQUÉE ET EMPÊCHER QUE DES

DÉBRIS NE PENÈTRE DANS L’OUVERTURE DES CONDUITS.

-

Déterminer l'emplacement du conduit d’aération de la hotte vers l'extérieur. Référez-vous à la

photo 21.

-

Une canalisation droite, courte et dirigée permettra à la hotte de s’exécuter plus efficacement.

-

Lorsque possible, diminuer le nombre de transitions, coudes et longueurs. Les changements de

direction affecteront la performance de votre hotte.

-

Utiliser un ruban adhésif (Duct tape) en toile pour sceller tous les joints, et ainsi d’assurer une

parfaite étanchéité.

-

Si nécessaire, préparez le mur arrière avec un soutien additionnel pour une installation

sécuritaire.

-

En utilisant les références à la Table 2 et les mesures à la page 50-51, régler la hauteur du

soutien additionnel. Référez-vous à la photo 22.

Préparation de la hotte avant Installation

-

Fixer temporairement la hotte afin d’en évaluer le fonctionnement avant de procéder à

l'installation permanente.

-

Retirer le film protecteur de la hotte et du couvre conduit.

-

Retirer les vis de la plaque de sortie (arrière) et couper le long de la ligne de l'ouverture de la

plaque de sortie intérieure (arrière). Voir Photo 23.

-

Découper l’ouverture multi conduit selon la taille des tuyaux d’échappement. Référez-vous à la

photo 24.

Photo 21

Photo 23

Couvercle

intérieur

(arrière)

46

Photo 22

Adaptateur

rectangulaire

sortie

arrière

Photo 24

Page 49

Photo 25

Photo

26

- Si nécessaire, fixer les deux fixations (fournis) en caoutchouc en compagnie des deux

vis (4x8 mm) (fournies) à l’arrière de la hotte.

- Fixer le support de montage au dos de la hotte avec l’aide des neuf (3/16po x 3/8po) vis

(fournies) tel qu’indiqué à la photo 25.

Installation de la hotte

AVERTISSEMENT :

l’alimentation électrique sur l’appareil ainsi qu’à partir de la boîte principale, ou encore enlevez

l’alimentation en gaz s’il s’agit d’un appareil au gaz.

si vous devez déplacer la cuisinière pour installer la hotte, arrêter

1. En utilisant en référence la Table 2 et les mesures à la page 50-51, repérez le point de

nivellement de la hotte. Installer deux vis de fixation (non fournies) sur le mur, laissant

1/8 " d’espace par rapport au mur comme indiqué à la photo 26.

Vis de montage

2. Utiliser un ruban adhésif (Duct tape) en toile pour sceller tous les joints, et ainsi assurer

une parfaite étanchéité.

3. Aligner le support de montage avec les deux vis sur le mur et fixer la hotte en la hotte

en place. AVERTISSEMENT : ASSUREZ-VOUS QUE LA HOTTE EST BIEN FIXÉE

AVAN T DE LA RELÂCHER.

Installation avec couvre- conduit

4. Repérer la position de la fixation pour couvre conduit. Utiliser comme référence

l’indication E de la Table deux (2) et le mesures à page 50-51. Attacher de façon

sécuritaire la fixation pour couvre conduit à l’aide de deux vis (non fournies). Référezvous à la photo 27. NOTE : la doublure du couvre conduit masquera la fixation.

5. Connecter des fils électriques.

6. Glisser la doublure du couvre conduit environ 2 pouces avant d’introduire le couvre

conduit entier. Voir la photo 28.

47

Page 50

Photo 27

Photo 28

Photo 2

9

7. Ajuster la hauteur de la doublure intérieure du couvre conduit a la fixation du couvre

conduit. Sécuriser la doublure intérieure du couvre conduit avec deux (4x8 mm) vis

(fournies) tel comme indiqué à la photo 29.

Attacher ensemble

8. Attacher la doublure extérieure du couvre conduit à l’adaptateur d’échappement multi

conduits de la hotte avec les quatre vis 4x8 mm fournies.

9. Continuer à la section « Installation des accessoires » de la page 46.

48

Page 51

Connexion à l'alimentation d'énergie

AVERTISSEMENT DE SÉCURITÉ

POUR RÉDUIRE LE RISQUE D’INCENDIE OU D’ÉLECTROCUTION L’APPAREIL DOIT ÊTRE

CORRECTEMENT MIS A LA TERRE. LES TRAVAUX D’INSTALLATION ET DE CÂBLAGE

ÉLECTRIQUE DOIVENT ÊTRE FAITS PAR UN ÉLECTRICIEN QUALIFIÉ CONFORMÉMENT AUX

CODES NATIONAUX ET LOCAUX ÉLECTRIQUES APPLICABLES. AVANT DE CONNECTER

CET APPAREIL : ÉTEIGNEZ L’ALIMENTATION À PARTIR DU PANNEAU ÉLECTRIQUE

PRINCIPAL ET BLOQUER LE DISPOSITIF DE DÉCONNEXION POUR EMPÊCHEZ QUE LE

POUVOIR NE SOIT ACCIDENTELLEMENT RALLUMÉ.

Connecter les fils électriques.

-

Si nécessaire, pour cacher les connections électriques, poussez les fils derrière dans la boîte

de câblage. Pour accéder aux connections électriques (situées sous la hotte) simplement

retirer les vis retenant le panneau pare éclaboussure (dessous du boîtier de la hotte). Avant

de rassembler le panneau pare éclaboussure, assurez-vous que les fils ne se glissent pas

entre les moteurs, les turbines, ou n'importe quelles composantes pouvant causer des

dommages à l’appareil .

-

Connecter les trois fils (noir, blanc et vert) aux fils de la maison et couvrez-les avec des

capuchons de connexion.

-

Unir les fils selon la couleur : noir à noir (sous tension), blanc à blanc (neutre), et vert à vert

(mise à la terre)

-

Tester la fonctionnalité de la hotte avant de poursuivre. Assurez-vous que l’alimentation

Installation des accessoires

1. Fixer le récupérateur à graisse. Voir photo 30.

2. Voir photo 31. 1) Faire glisser le filtre déflecteur dans la hotte. 2) Pousser le filtre déflecteur vers

3. Pour les panneaux de finition, répéter les étapes précédentes.

Assemblage final

4. Allumer la hotte avec la commande « ON » sur le panneau de commandes. Vérifiez les lumières

5. Assurez-vous de laisser ce manuel au propriétaire.

électrique circule jusqu’à la hotte.

le haut. 3) Le glisser vers l'avant. 4) Le tirer vers le bas. 5) Bien l'insérer en place.

et les commandes de vitesses.

Photo 30

49

Photo 31

Page 52

MODE D'EMPLOI

Cette hotte KOBE® est pourvue de quatre commandes électroniques, un démarrage avec

mise en garde de 10 secondes, un dispositif d’arrêt à retardement, deux (2) puissants

ventilateurs centrifuges avec grilles de sécurité, deux LED de 3 Watt, ainsi que 4 contenant

récupérateurs de graisses.

Les quatre commandes électroniques sont « Light control » : le Contrôle de Vitesse A

(cycles Bas, Moyen, Haut et « QuietMode™ »), le contrôle de Vitesse B (cycles

bas,« QuietMode™ », Haut et Moyen) et le contrôle de"Marche/Arrêt". Voir photo 32.

Mise en marche :

-

Mettre les ventilateurs en marche en utilisant les boutons de contrôles Marche/Arrêt (Power

Control) une fois. Si un des boutons de contrôle de vitesse n’est pas allumé en 10 secondes

l’appareil s’éteindra.

-

La hotte KOBE® débutera à la basse vitesse. Chaque touche du bouton de contrôle de

vitesse changera le niveau de vitesses.

-

Appuyer sur le contrôle de Vitesse A pour cheminer aux cycles Bas, Moyen, Haut, ou

« QuietMode™».

Appuyer sur le contrôle de Vitesse B pour cheminer aux cycles Bas, « QuietMode™» Haut

ou Moyen.

-

Appuyer sur la commande « light control » pour allumer les LED.

Arrêt:

-

Appuyer sur le bouton de contrôle Marche/Arrêt (Power Control) une fois, les lumières du

panneau clignoteront et l’appareil s’éteindra après 30 secondes.

OU

-

Appuyer sur le bouton de contrôle Marche/Arrêt (Power Control) deux (2) fois, et l’appareil

s’éteindra instantanément.

-

Si seulement les lampes halogènes sont allumées, appuyer une fois sur le Contrôle de

puissance «Marche/Arrêt" et l’appareil s’éteindra après 30 secondes.

Photo 32

50

Page 53

ENTRETIEN- NETTOYAGE

AVERTISSEMENT

:

NE VOUS APPROCHER JAMAIS DES LAMES DE

VENTILATEURS LORSQUE L’APPAREIL EST EN

OPÉRATION.

Pour le niveau optimal d'opération, nettoyez la surface, les grilles de sécurité et les

récipients à graisses régulièrement.

POUR NETTOYER LES SURFACES DE LA HOTTE

AVERTISSEMENT

:

N'EMPLOYEZ JAMAIS DE NETTOYEURS OU

TAMPONS ABRASIFS, de plus un entretien régulier

aidera à préserver sa bonne apparence.

*** Un entretien fréquent aidera à conserver une belle apparence à la hotte.

1. Utiliser seulement du savon doux ou du détergent. Sécher les surfaces avec un

chiffon doux.

2. Si la hotte est tachée (hotte en acier inoxydable), utiliser un nettoyant à base

d'agrume pour nettoyer les surfaces. Éviter de mettre du nettoyant sur les boutons de

commande. Étendre une petite quantité sur les surfaces et laisser reposer quelques

minutes (ne pas laisser trop longtemps car cela pourrait endommager le fini de la

hotte). À l'aide d'un chiffon doux, enlever la solution nettoyante et frotter doucement

les taches rebelles. Utiliser un chiffon légèrement humide pour enlever tout résidu de

solution nettoyante. Sécher la hotte avec un chiffon doux. Pour redonner du brillant

au fini en acier inoxydable, utiliser un nettoyant pour acier inoxydable.

3. NE PAS laisser les dépôts s'accumuler durant de longues périodes de temps.

4. NE PAS utiliser de laines ou de brosses à récurer ordinaires. Des particules d'acier

peuvent adhérer à la surface et la faire rouiller.

5. NE PAS permettre à des solutions salines, des désinfectants, des javellisants ou des

agents nettoyants de rester en contact avec l'acier inoxydable durant de longues

périodes. Plusieurs de ces nettoyants contiennent des produits chimiques pouvant

endommager l'acier inoxydable. Après tout contact de ce type, rincer à l'eau et

essuyer avec un chiffon doux.

N

ETTOYAGE DES FILTRES DÉFLECTEURS ET DU RÉCUPÉRATEUR À GRAISSE

AVERTISSEMENT : VIDER LES FILTRES DÉFLECTEURS ET LE RÉCUPÉRATEUR À GRAISSE

AVANT QU'IL N'Y AIT TROP D'ACCUMULATION.

1. Retirer les filtres déflecteurs et le récupérateur à graisse.

2. À l'aide d'une éponge, laver dans une eau chaude savonneuse. Sécher entièrement avant

de remettre en place.

(Note : les filtres peuvent être nettoyés en toute sécurité dans le haut du lave-vaisselle)

51

Page 54

Sone

*

SPÉCIFICATIONS

MODÈLE / FORMAT CH7730SQB - 30 po

CH7736SQB - 36 po

COULEUR Acier inoxydable de qualité commerciale

CONSOMMATION 198 W / 1,71 A

VOLTAGE 120 V - 60 Hz

NOMBRE DE MOTEURS 2

DESIGN Fini satiné sans joints de calibre 18

TYPE DE VENTILATEUR Pale de turbine double

ÉCHAPPEMENT Sur le dessus

6po rond

7po rond

3-1/4po x 10po Rectangulaire

A l’arrière

3-1/4po x 10po Rectangulaire

COMMANDES Commandes électroniques (4 boutons) –

Démarrage avec garde de 10 secondes

Dispositif d'arrêt à retardement de 30 secondes

LAMPES LED 12 V, 3 W x 2

DIMENSIONS DE LA HOTTE CH7730SQB - 29 3/4 x 22 x 10 po

(LARGEUR X PROFONDEUR X HAUTEUR)

ACCESSOIRES EN OPTION 1) Trousse initiale - No de modèle CH1120DC

(LARGEUR X PROFONDEUR X HAUTEUR)

11-7/8 po x 10-1/4 po x (20 5/8 po ~ 39 3/4 po)

2) No de modèle SSP30

Panneau arrière en acier inoxydable 30 po

30 po x 1/10 po x 32 po

3) No de modèle SSP36

Panneau arrière en acier inoxydable 36 po

36 po x 1/10 po x 32 po

NET BRUT

POIDS DE LA HOTTE (lb) CH7730SQ 48,5 68,5

CH7736SQ 53,0 75,0

VITESSE QuietMode

CH7736SQB - 35 3/4 x 22 x 10 po

Couvre-conduit réglable

TM

Basse Moyenne Élevée

Capacité d'air (cfm)

300 450 620 760

1.2 3.0 4.5 4.8

* Un sone est équivalent au son d'un réfrigérateur à 40 décibels.

** Spécifications sujettes à changement sans préavis.

52

Page 55

MESURES et DIAGRAMMES

*** Toutes les mesures de pouce sont converties à partir de millimètres. Les mesures en

pouces sont estimées.

*** Toutes les mesures entre parenthèses ( ) sont des millimètres.

- SOUS LE CABINET-

30po= Trous de montage perçage " A "

36po= Trous de montage "A et B "

-POUR MODÈLE ILOT (AVEC COUVERTURE DE CONDUIT FACULTATIVE)-

53

Page 56

*** Support de fixation – hotte *** Support de fixation – couvre-conduit

FILTRES À CHICANE/PANNEAUX DE FINITION

HOTTE 30 po

HOTTE 36 po

54

Page 57

Nos

de modèles:

CH7730SQB

No

DESCRIPTION

MODÈLE/FORMAT

NO

DE PIÈCE

No

DESCRIPTION

MODÈLE/FORMAT

NO

DE PIÈCE

LISTE DES PIÈCES

CH7736SQB

1 Adaptateur de sortie multi conduit C1-0507-1530

2 Plaque de sortie verticale B101-1530-12

3 Vis de plaque pour sortie verticale C1-0508-1530-A

4 Adaptateur rectangulaire sortie arrière C1-0508-1530-B

5 Caisson supérieur de la hotte

6 LED C1-0403-0306

7 Bloc de contrôle C1-0501-0101

8 Tableau de commandes (contrôle) C1-0404-4001-A

9 Support de transformateur C1-0201-1530

10 Transformateur (moteur) C1-0402-A120-01

7

A

B

12 Transformateur (lumière) C1-0402-D001

13 Condensateur C1-0401-0120-01

14 Boîtier du processeur C1-0501-0102

15 Processeur C1-0404-4110-B

16 Vis à tête ronde (1/8" x 3/8") C1-0708-0003

17 Vis de fixation du moteur (TS ¼ x 7/16) C1-0703-0001

18 Moteur(droit) C1-0301-0120-23B

19 Moteur (gauche) C1-0301-0120-23A

20

21

22 Couvercles de récupérateur de graisse C1-0502-0301

23 Récupérateur de graisse C1-0502-0102

24 Capuchon en plastique de pale de turbine C1-0251-0001

25 Grilles de sûreté C1-0602-0101

26 Vis de grille de protection C1-0705-0001

27 Panneaux de finition

A

B

28

Boîtier de moteur

Boîtier de moteur (supérieur) CH7730SQB C1-0101-1530

Boîtier de moteur (latéral) CH7736SQB C1-0102-1530

Pale de turbine (droite)

Pale de turbine (gauche)

4 po de largeur

3 po de largeur

4 po de largeur

Filtres à chicane

CH7730SQB 10-5030B-51

CH7736SQB 10-5036B-51

C1-0251-0880-B

C1-0251-0880-A

B101-1930-15

B101-1930-09

B101-1936-09

B101-1930-09

01 Support de fixation de la hotte C1-0221-1530

02 Vis ( TS 4 x 8mm) C1-0708-0006

03 Couvre conduit CH1120DC 12-15300-51

04 Support de fixation pour couvre conduit C1-0221-1530

05 Vis ( 3/16 po x 3/8 po) C1-0707-0001

06 Socle de caoutchouc C1-0511-0382

07 Vis (TS 4 x 8 mm) C1-0708-0006

Couvre conduit Optionne

55

Page 58

Nos

de modèles:

CH7730SQB

(Vendue séparément

CH7736SQB

)

CH7730SQB

CH7736SQB

56

Page 59

Nos

de modèles:

CH7730SQB

DIAGRAMME DES CIRCUITS

CH7736SQB

57

Page 60

Problème

Cause probable

Solution

TROUBLE SHOOTING

Après

l’installation,

les deux

moteurs et

les lumières ne

fonctionnent

pas.

Les lumières

fonctionnent,

mais pas le(s)

moteur(s).

La hotte de

cuisine vibre.

Le moteur

fonctionne,

mais pas les

lumières.

La hotte de

cuisine

ne ventile pas

correctement.

De l’air froid

entre dans la

maison.

Pas d’alimentation électrique. Assurez-vous

que le disjoncteur et que l’alimentation

électrique soient en marche.

Le câblage n’est pas bien installé. Vérifiez et serrez les connexions de fils.

Le câblage du panneau de commande et de

la carte processeur est débranché.

Le transformateur du moteur est défectueux Vérifiez l’entrée de courant et la sortie de courant

Le panneau de commande ou la carte

processeur est défectueux.

Le(s) moteur(s) est (sont) défectueux. Remplacez le(s) moteur(s).

Le(s) condensateur(s) est (sont) défectueux. Remplacez le(s) condensateur(s).

Le panneau de commande ou la carte

processeur est défectueux.

Le système de ventilation n’est pas bien

installé.

La pale turbine/cage écureuil n’est pas bien

balancée.

La hotte n’est pas assez bien serrée. Vérifiez l’installation de la hotte, serrez

L’ampoule de la lampe est défectueuse.

Le câblage de la lampe n’est pas assez serré.

Le transformateur de la lumière est

défectueux.

Le panneau de commande ou la carte

processeur est défectueux.

La hotte de cuisine est installée hors des

limites recommandées par le fabricant.

Il n’y a pas d’air d’appoint à l’intérieur de la

maison.

Un obstacle bloque la canalisation.

La canalisation est plus petite que la

canalisation suggérée.

La connexion du conduit n’est pas scellée

correctement.

Le clapet n’est pas bien installé ou manque à

l’installation.

Le clapet n’est pas installé.

Utilisez un voltmètre pour vérifier l’alimentation en

électricité.

Vérifiez le câblage au complet à partir du panneau

de commande jusqu’à la carte processeur.

du transformateur du moteur. Si nécessaire,

remplacez le transformateur du moteur.

Remplacez le panneau de commande ou la carte

processeur.

Remplacez le panneau de commande ou la carte

processeur.

Serrez la pale turbine/cage d’écureuil et le

réservoir d’air.

Remplacez la pale turbine/cage d’écureuil.

le support de fixation.

Essayez l’ampoule de lampe défectueuse sur

une douille qui fonctionne. Si l’ampoule ne

fonctionne toujours pas, remplacez-la.

Vérifiez le câblage au complet à partir de la carte

processeur jusqu’au transformateur puis jusqu’au

boîtier.

Vérifiez l’entrée de courant et la sortie de courant

du transformateur de lampe. Si nécessaire,

remplacez le transformateur de

lampe.

Remplacez le panneau de commande ou la carte

processeur.

Ajustez le dégagement entre la hotte de cuisine

et la table de cuisson pour qu’il soit de 27” à 30”.