Page 1

KOBE Brand Range Hood

Model No. CH7630SQB (30”)

CH7636SQB (36”)

CH7642SQB (42”)

CH7648SQB (48”)

CH-176 SERIES – 10” HEIGHT

INSTALLATION INSTRUCTIONS

AND OPERATION MANUAL

Page 2

CONTENTS

- READ AND SAVE THESE INSTRUCTIONS -

IMPORTANT SAFETY INSTRUCTIONS .........................................................................1

COMPONENTS OF PACKAGE .......................................................................................3

INSTALLATION ................................................................................................................4

UNDER THE CABINET INSTALLATION ............................................................ 6

STAND ALONE INSTALLATION ........................................................................ 9

OPERATION INSTRUCTIONS ......................................................................................13

MAINTENANCE .............................................................................................................15

SPECIFICATIONS..........................................................................................................17

MEASUREMENTS & DIAGRAMS .................................................................................18

PARTS LIST ...................................................................................................................23

CIRCUIT DIAGRAM .......................................................................................................27

DISCLAIMER .................................................................................................................29

WARRANTY ...................................................................................................................30

PRODUCT REGISTRATION ..........................................................................................32

– READ ALL INSTRUCTIONS CAREFULLY BEFORE STARTING –

ALL WIRING MUST BE DONE BY A PROFESSIONAL AND IN

ACCORDANCE WITH NATIONAL AND LOCAL ELECTRICAL CODES.

Page 3

IMPORTANT SAFETY INSTRUCTIONS

- PLEASE READ THIS SECTION CAREFULLY BEFORE INSTALLATION -

WARNING:

TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK OR PERSONAL INJURY,

OBSERVE THE FOLLOWING:

1) Installation and electrical wiring must be done by qualified professionals and in accordance with all

applicable codes and standards, including fire-rated construction.

2) When cutting or drilling into wall or ceiling, be careful not to damage electrical wiring or other hidden

utilities.

3) Ducted fans must be vented to the outside.

a) Before servicing or cleaning unit, open the light panel and SWITCH POWER OFF AT SERVICE

PANEL.

b) Clean grease laden surfaces frequently. To reduce the risk of fire and to disperse air properly,

make sure to vent air outside. DO NOT vent exhaust air into wall spaces, attics, crawl spaces

or garages.

NOTE - This warranty is invalid without an authorized agent’s receipt or if

unit is damaged due to misuse, poor installation, improper use,

mistreatment, negligence or any other circumstances beyond the

control of KOBE RANGE HOODS authorized agents. Any repair

carried out without the supervision of KOBE RANGE HOODS

authorized agents will automatically void the warranty.

- KOBE RANGE HOODS will not be held responsible for any

damages to personal property or real estate or any bodily injuries

whether caused directly or indirectly by the range hood.

WARNING

- Keep all fan, baffle/spacer/filter/oil tunnel/oil container and grease-laden surfaces clean. Grease

should not be allowed to accumulate on fan, baffle/spacer/filter/oil tunnel/oil container.

- Always turn hood ON when cooking at high heat.

- Use high settings on cooking range ONLY when necessary.

- Do not leave cooking range unattended when cooking.

- Always use cookware and utensils appropriate for the type and amount of food prepared.

- Use this unit only in the manner intended by the manufacturer.

- Before servicing, switch power off at service panel and lock service panel (if possible) to prevent

power from switching on accidentally.

- Clean ventilating fan frequently.

: TO REDUCE THE RISK OF PERSONAL INJURY IN THE EVENT OF A RANGE

TOP GREASE FIRE:

1

Page 4

ELECTRICAL SHOCK HAZARD

–

Can result in serious injury or death.

What to Do In The Event Of a Range Top Grease Fire

• SMOTHER FLAMES with a close fitting lid, cookie sheet, or metal tray, and then turn off the burner.

KEEP FLAMMABLE OR COMBUSTIBLE MATERIAL AWAY FROM FLAMES. If the flames do not

go out immediately, EVACUATE THE AREA AND CALL THE FIRE DEPARTMENT or 911.

• NEVER PICK UP A BURNING PAN – You May Get Burned.

• DO NOT USE WATER, including wet dishcloths or towels – a violent steam blast will result.

• Use an extinguisher ONLY if:

a) You have a Class A, B, C extinguisher and know how to operate it.

b) The fire is small and contained in the area where it started.

c) The fire department has been called.

d) You can fight the fire with your back to an exit.

What to Do If You Smell Gas

•

Extinguish any open flame.

•

Do not try to turn on the lights or any type of appliance.

•

Open all doors and windows to disperse the gas. If you still smell gas, call the Gas Company

and Fire Department right away.

CAUTION

1) For general ventilation use only. Do not use to exhaust hazardous or explosive materials and

vapors.

2) To reduce the risk of fire, use only metal ductwork. Sufficient air is needed for proper combustion

and exhausting of gases through the flue (chimney) to prevent back drafting.

3) Follow the heating equipment manufacturer’s guideline and safety standards such as those

published by the National Fire Protection Association (NFPA), and the American Society for

Heating, Refrigeration and Air Conditioning Engineers (ASHRAE), and code authorities.

4) Activating any switch on may cause ignition or an explosion.

5) Due to the size and weight of this hood, two people installation is recommended.

Disconnect appliance from electric power before servicing. If

equipped, the fluorescent light bulb contains small amounts of

mercury, which must be recycled or disposed of according to Local,

State, and Federal Codes.

2

Page 5

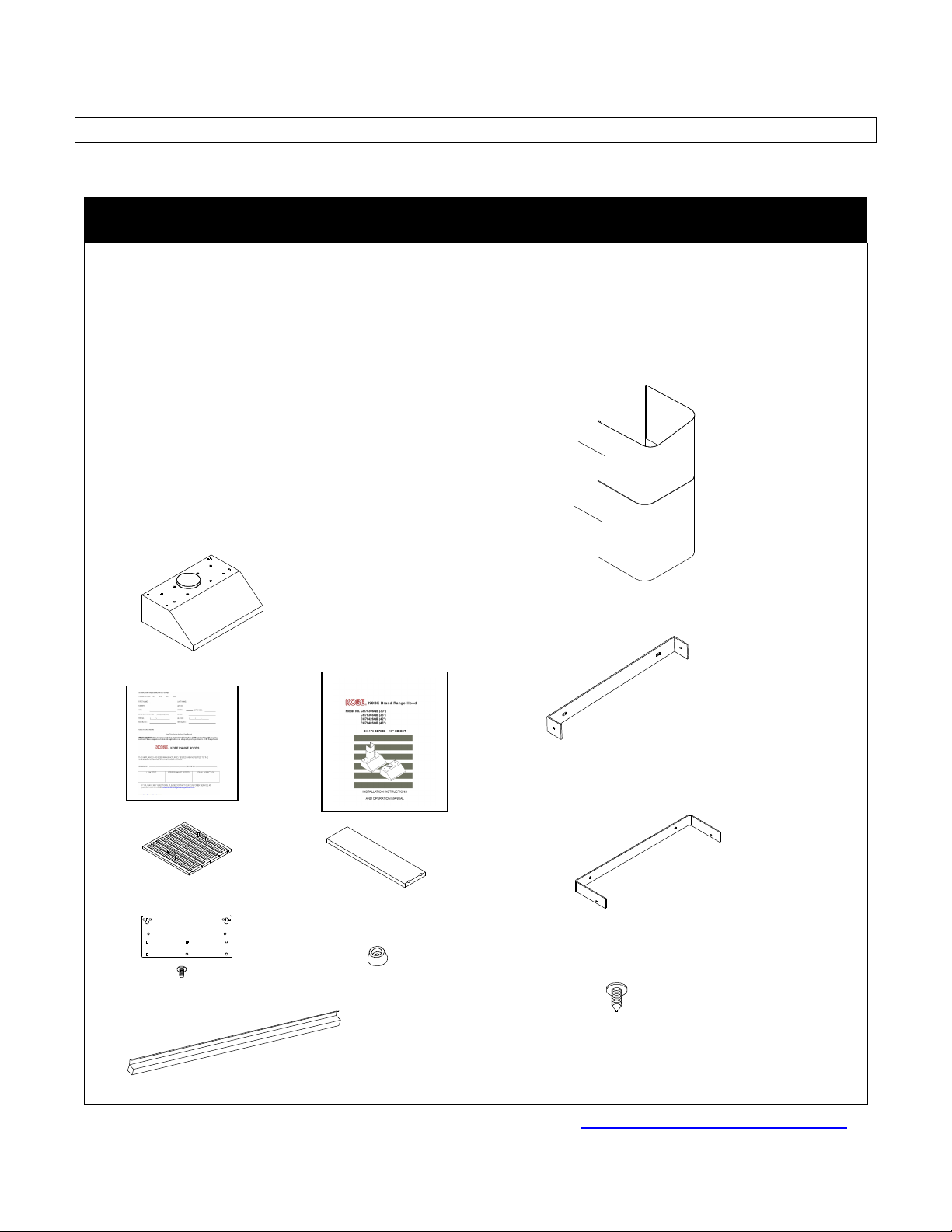

Range Hood Box

Duct

Cover Box (Sold Separately)

{A}

KOBE

Range Hood

{I} KOBE

D

uct Cover

COMPONENTS OF PACKAGE

(Must keep all material for returns or refunds)

{B} Warranty Registration Card

{C} Instruction Manual

{D} Baffle Filter

-- 2 (30”, 36”, 42”)

-- 3 (48”)

{E} Stainless Steel Spacer

-- 0 (30”)

-- 1 (36”)

-- 3 (42”)

-- 2 (48”)

{F} Hood-Mounting Bracket w/ Screws Set

{G} Rubber Stand

{H} Oil Tunnel

{A}

{B} {C}

{D} {E}

{F} {G}

3/16" X 1/2" (8 pcs)

Rubber Stand (2 pcs)

{H}

(Model No. CH1120DC)

{J} Inner Duct Cover-Mounting Bracket

{K} Outer Duct Cover-Mounting Bracket

{L} Screws Package

{I}

Inner Duct

Cover

Outer Duct

Cover

{J}

{K}

{L}

1/8" X 3/8" (4 pcs)

FOR MORE INFORMATION, PLEASE VISIT OUR WEBSITE WWW.KOBERANGEHOODS.COM

OR CONTACT KOBE RANGE HOODS AT (626) 350-1355.

3

Page 6

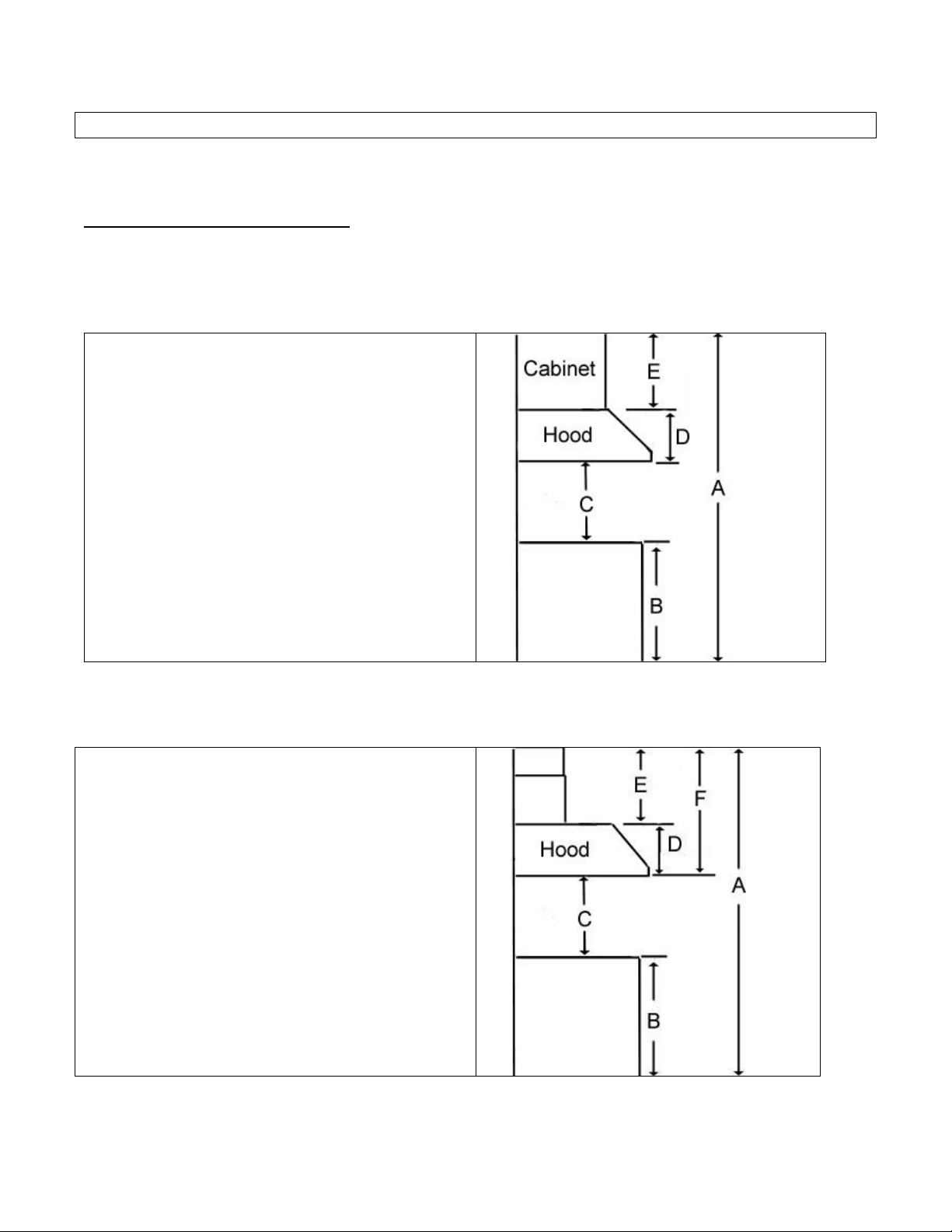

TABLE 1

TABLE 2

INSTALLATION

PLEASE READ ENTIRE INSTRUCTIONS BEFORE PROCEEDING

Calculation before Installation

To calculate installation, please refer to TABLE 1 or TABLE 2. (All calculation in inches.)

- FOR UNDER THE CABINET -

A = Height of Floor to Ceiling

B = Height of Floor to Counter Top

(Standard: 36”)

C = Preferred Height of Counter Top to Hood

Bottom (Recommended 27” to 30”)

D = Height of Hood

E = Height of the Cabinet

- FOR STAND ALONE (WITH OPTIONAL DUCT COVER) -

A = Height of Floor to Ceiling

B = Height of Floor to Counter Top (Standard:

36”)

C = Preferred Height of Counter Top to Hood

Bottom (Recommended 27” to 30”)

D = Height of Hood

E = Height of Duct Cover [F – D]

F = Height of the Hood Installation

[A – (B+C)]

4

Page 7

SAFETY WARNING

HOOD MAY HAVE VERY SHARP EDGES; PLEASE WEAR PROTECTIVE GLOVES IF IT IS

NECESSARY TO REMOVE ANY PARTS FOR INSTALLING, CLEANING OR SERVICING.

NOTE: BE CAREFUL WHEN USING ELECTRICAL SCREWDRIVER, DAMAGE TO THE HOOD

MAY OCCUR.

Installation Contents

UNDER THE CABINET INSTALLATION ........................................................................6

P

REPARATION BEFORE INSTALLATION

H

OOD INSTALLATION

D

UCTWORK INSTALLATION

W

IRING TO POWER SUPPLY

A

CCESSORIES

F

INAL ASSEMBLY

................................................................................................................ 8

...................................................................................................... 6

.............................................................................................. 7

............................................................................................ 7

............................................................................................................ 8

............................................................................. 6

STAND ALONE INSTALLATION .....................................................................................9

P

REPARATION BEFORE INSTALLATION

H

OOD PREPARATION BEFORE INSTALLATION

H

OOD INSTALLATION

W

IRING TO POWER SUPPLY

D

UCT COVER INSTALLATION

A

CCESSORIES

F

INAL ASSEMBLY

.............................................................................................................. 11

...................................................................................................... 9

.......................................................................................... 10

......................................................................................... 11

.......................................................................................................... 12

............................................................................. 9

................................................................... 9

5

Page 8

Preparation before Installation

Hood Installation

UNDER THE CABINET INSTALLATION

NOTE: TO AVOID DAMAGE TO YOUR HOOD,

PREVENT DEBRIS FROM ENTERING THE

VENT OPENING.

•

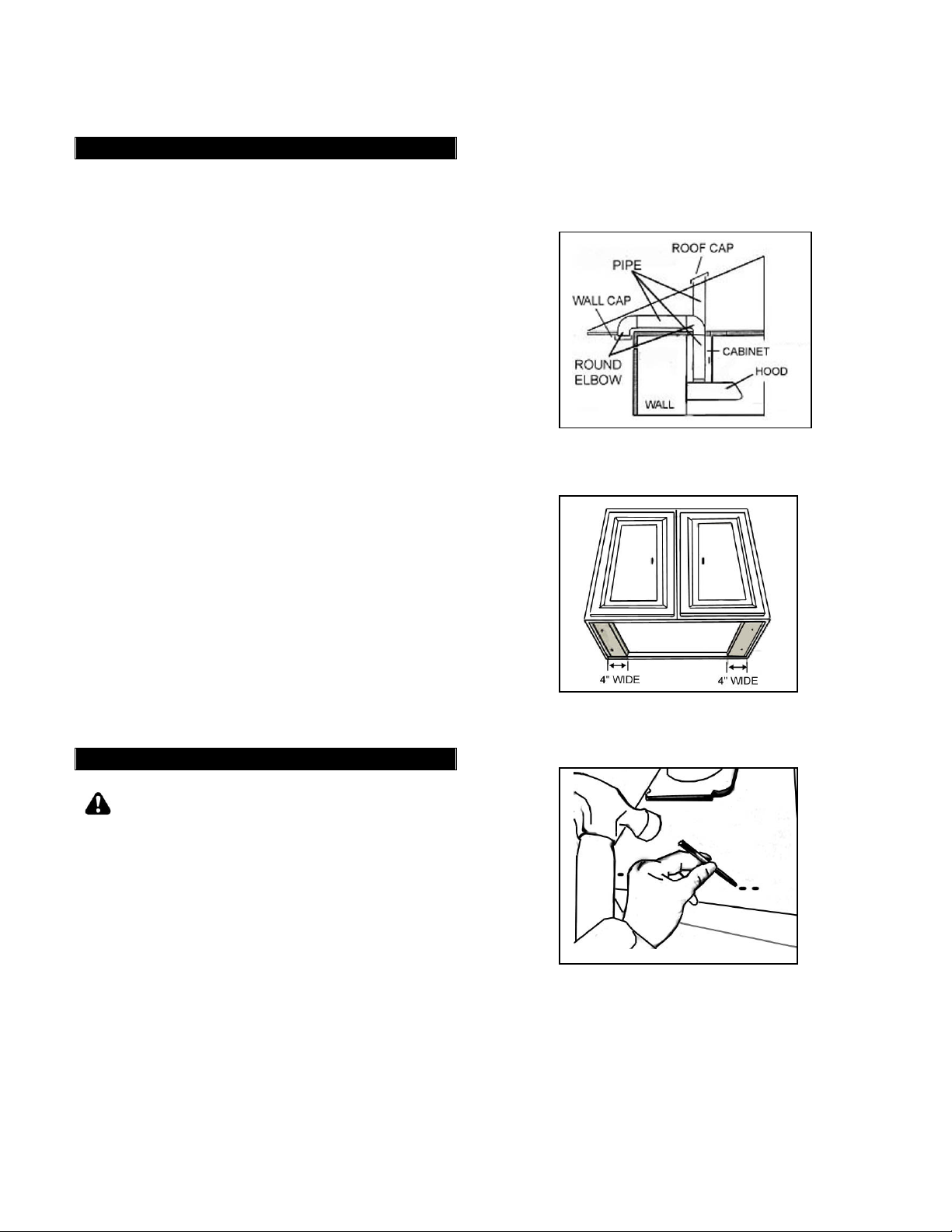

Decide the location of the venting pipe

from the hood to the outside. Refer to

Figure 1.

•

A straight, short vent run will allow the

hood to perform more efficiently.

•

Try to avoid as many transitions,

elbows, and long run as possible. This

may reduce the performance of the

hood.

•

Temporarily wire the hood to test for

proper operation before installing.

•

Important: Peel protective film off the

hood, if any.

•

Use duct tape to seal joints between

pipe sections.

•

For installing under the cabinet with

recessed bottom, attach 4-inch wide

wood filler strips (not provided) on each

side. Refer to Figure 2.

•

Using references in TABLE 1 and

Measurements and Diagrams on page

18, create access opening for electrical

wires and hood exhaust under the

cabinet.

CAUTION

range is necessary to install the hood, turn

off the power on an electric range at the

main electrical box. SHUT OFF THE GAS

BEFORE MOVING A GAS RANGE.

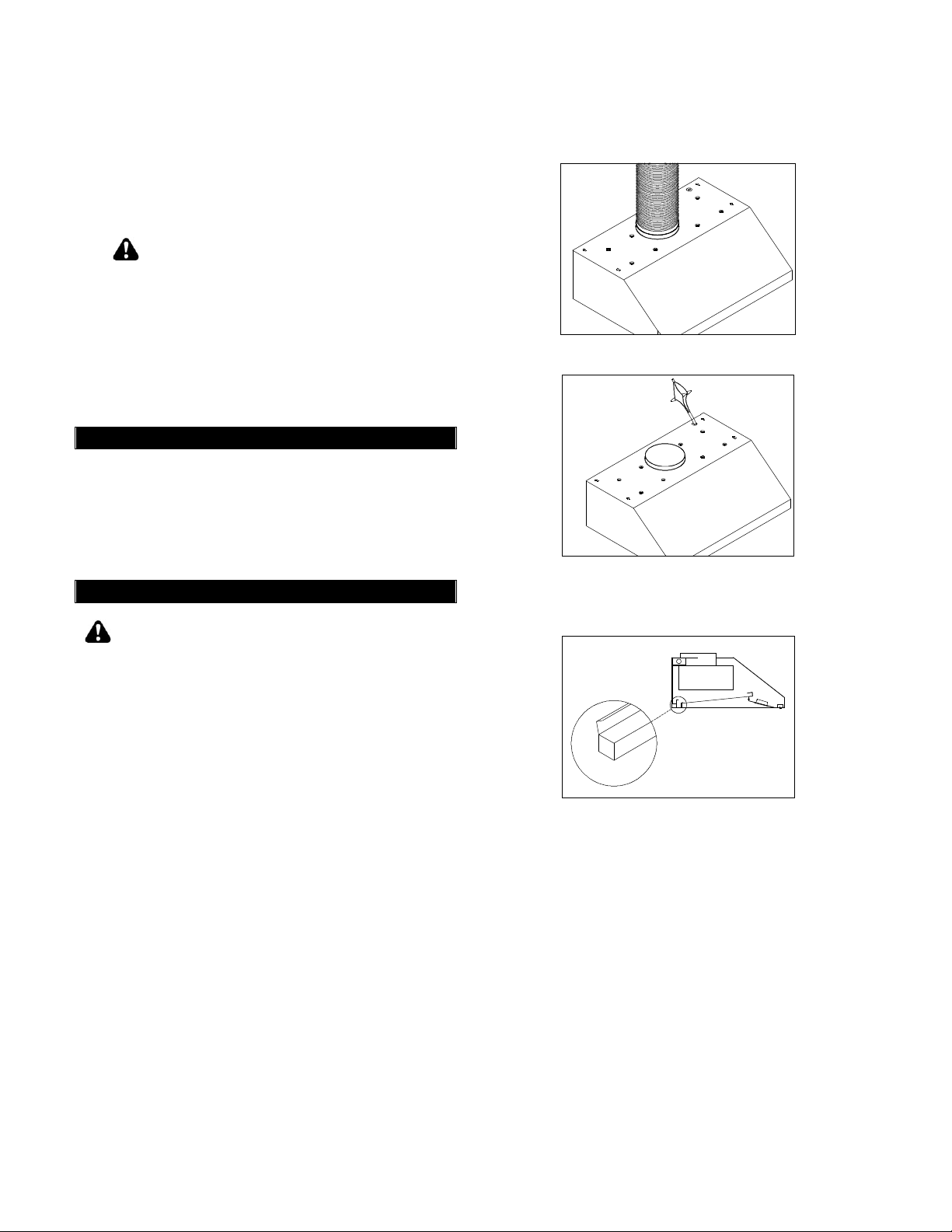

1. Puncture the knockout holes (for mounting

under the cabinet) on the hood as shown in

Figure 3.

2. If necessary, attach two rubber stands

(provided) with 3M adhesive tapes

(provided) to the back corners of the hood.

3. Using references in TABLE 1 and

Measurements and Diagrams on page 18

center the hood beneath the cabinet and

flush with the front of the cabinet.

: If moving the cooking

Figure 1

Figure 2

.

Figure 3

6

Page 9

Ductwork Installation

Wiring to Power Supply

4. Draw electrical wires through cabinet

access opening.

5.

From inside of the hood, place screw (not

provided) into the exact center of each

knockout hole and secure to cabinet bottom.

Once all mounting screws are in place,

finish tightening screws until secure.

CAUTION

HOOD IS SECURE BEFORE RELEASING.

6.

For safety purpose, pre-drilled mounting

holes are provided through the back of the

hood. For a more secure installation, use as

many mounting holes as needed to secure

from the inside of hood (screws not

provided).

: MAKE SURE THE

7. Use 7” round steel pipe (follow building

codes in your area) to connect the exhaust

on the hood to the ductwork above. Use

duct tape to make all joints secure and air

tight. Refer to Figure 4.

SAFETY WARNING

RISK OF ELECTRICAL SHOCK. THIS

RANGE HOOD MUST BE PROPERLY

GROUNDED. MAKE SURE THIS IS DONE BY

QUALIFIED ELECTRICIAN IN ACCORDANCE

WITH ALL APPLICABLE NATIONAL AND

LOCAL ELECTRICAL CODES. BEFORE

CONNECTING WIRES, SWITCH POWER OFF

AT SERVICE PANEL AND LOCK SERVICE

PANEL TO PREVENT POWER FROM BEING

SWITCHED ON ACCIDENTALLY.

8. Connect the electrical wires.

-

Connect three wires (black, white and

green) to house wires and cap with wire

connectors. Connect according to color:

black to black, white to white, and green

to green as shown in Figure 5.

-

Store wires in the wiring box.

Figure 4

Figure 5

Figure 6

7

Page 10

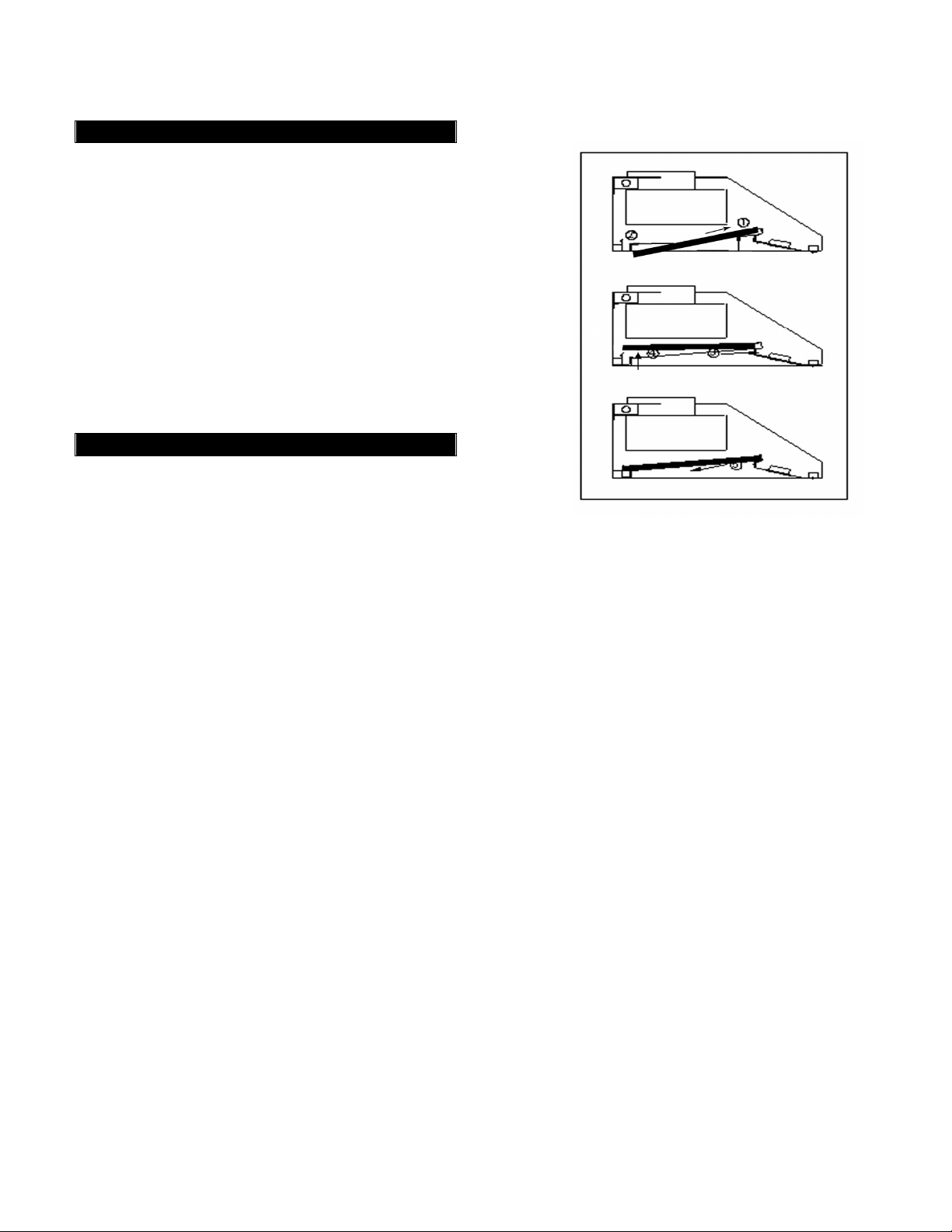

Accessories

Final Assembly

9. Drop oil tunnel into recess support near rear

of hood. Refer to Figure 6.

10. Install baffle filters and stainless spacer(s).

Refer to Measurements and Diagrams on

page 22 for baffle filter and stainless spacer

placement. Angle baffle filter toward back of

hood . Push baffle filter up until almost

level . Slide forward into recess behind

the front of hood . Lower baffle filter .

Slide back until it fits into resting position .

Refer to Figure 7.

11. Repeat step 10 to install all baffle filters and

stainless spacer(s).

12. Turn power ON in control panel. Check all

light and fan operation.

13. Make sure to leave this manual for the

homeowner.

Figure 7

8

Page 11

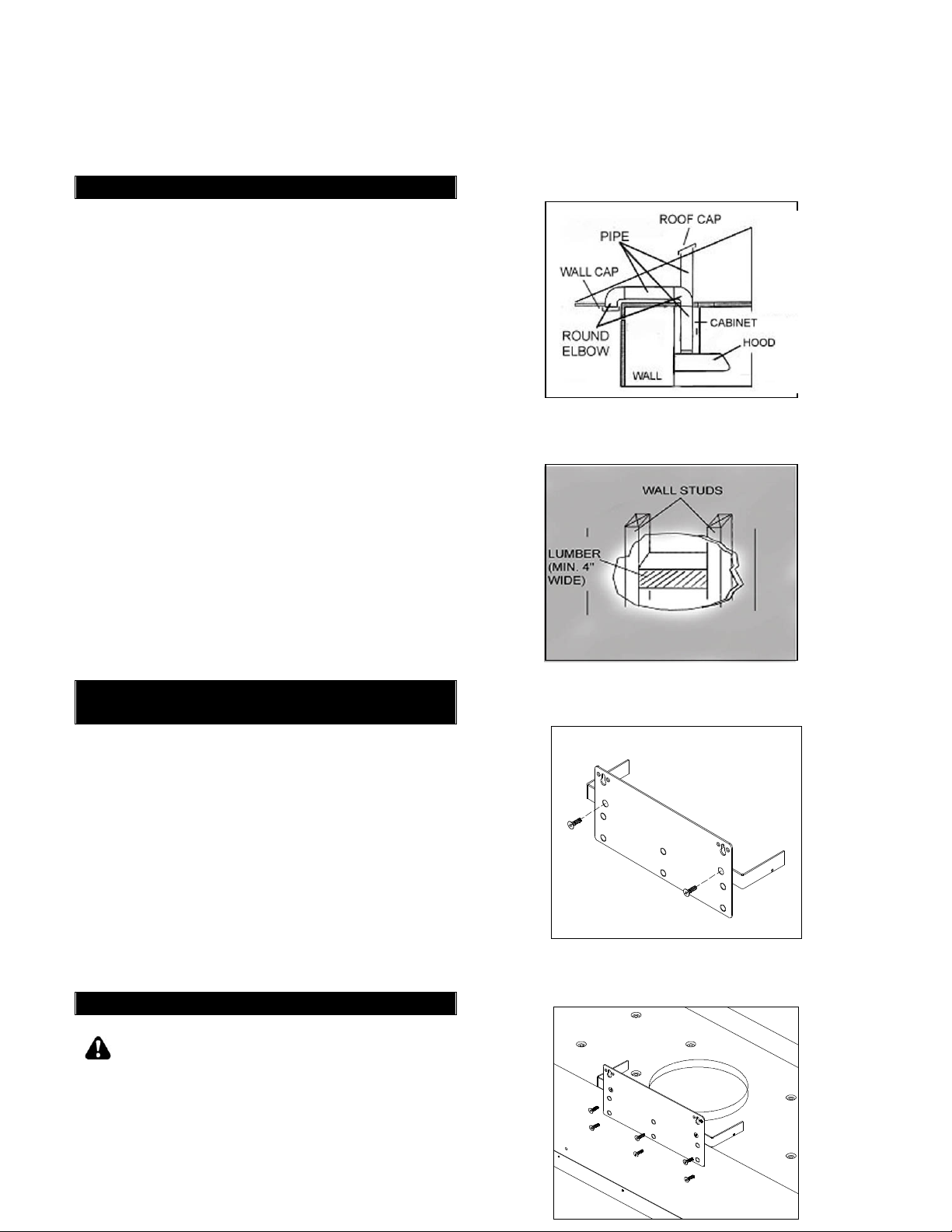

Preparation before Installation

Hood Preparation before

Hood Ins

tallation

STAND ALONE INSTALLATION

*** This installation only applies if installing with

the CH1120DC duct cover.

NOTE: TO AVOID DAMAGE TO YOUR HOOD,

PREVENT DEBRIS FROM ENTERING THE

VENT OPENING.

•

Decide the location of the venting pipe

from the hood to the outside. (Figure 8)

•

A straight, short vent run will allow the

hood to perform more efficiently.

•

Try to avoid as many transitions, elbows,

and long run as possible. This may

reduce the performance of the hood.

•

Temporarily wire the hood to test for

proper operation before installing.

•

Important: Peel protective film off the

hood and duct covers, if any.

•

Use duct tape to seal joints between pipe

sections.

•

If necessary, prepare back wall frame with

cross framing lumber for secure

installation.

•

Using references in TABLE 2 and

measurements on pages 19-21, determine

the level of the lumber. (Figure 9)

Installation

•

If necessary, attach two rubber stands

(provided) with 3M adhesive tapes

(provided) to the back corners of the

hood.

•

Attach the outer duct cover-mounting

bracket {K} (provided) to the hoodmounting bracket {F} (provided) with two

(3/16” x 1/2”) screws (provided) as shown

in Figure 10.

•

Attach the hood-mounting bracket {F} to

the back of the hood with six (3/16” x 1/2”)

screws (provided) as shown In Figure 11.

CAUTION

to install the hood is necessary, turn off the

power on an electric range at the main

electrical box. SHUT OFF THE GAS BEFORE

MOVING A GAS RANGE.

: If moving the cooking range

Figure 8

Figure 9

Figure 10

Figure 11

9

Page 12

Wiring to Power Supply

1. Using references in TABLE 1 and

Measurements and Diagrams on pages 19-21,

mark the leveling point of the hood. Position

two mounting screws (not provided) on the

wall, leaving 1/8” space away from the wall.

2. Puncture the knockout wire access hole at

the back of the hood and draw the electrical

wires through as shown in Figure 12.

3. Align hood-mounting bracket to the screws on

the wall and hook hood into place as shown in

Figure 13. Tighten screws to secure hood to

the wall.

4. For safety purpose, pre-drilled mounting holes

are provided through the back of the hood.

For a more secure installation, use as many

mounting holes as needed to secure from the

inside of hood (screws not provided).

CAUTION

SECURE BEFORE RELEASING.

: MAKE SURE HOOD IS

SAFETY WARNING

RISK OF ELECTRICAL SHOCK. THIS RANGE

HOOD MUST BE PROPERLY GROUNDED.

MAKE SURE THIS IS DONE BY QUALIFIED

ELECTRICIAN IN ACCORDANCE WITH ALL

APPLICABLE NATIONAL AND LOCAL

ELECTRICAL CODES. BEFORE

CONNECTING WIRES, SWITCH POWER OFF

AT SERVICE PANEL AND LOCK SERVICE

PANEL TO PREVENT POWER FROM BEING

SWITCHED ON ACCIDENTALLY.

5. Connect the electrical wires.

-

Connect three wires (black, white and

green) to house wires and cap with wire

connectors. Connect according to color:

black to black, white to white, and green

to green as shown on Figure 14.

-

Store wires in the wiring box.

Figure 12

Figure 13

Figure 14

WALL

10

Page 13

Duct Cover Installation

Accessories

6. Mark the position of the inner duct covermounting bracket {J} (provided). Use

reference E from TABLE 2 and

Measurements and Diagrams on page 20-21.

Attach and secure inner duct cover-mounting

bracket {J} with two screws (not provided) to

the wall. Refer to Figure 15. NOTE: Inner

duct cover will be attached to the mounting

bracket.

7. Use 7” round steel pipe (follow building codes

in your area) to connect the round exhaust on

the hood to the ductwork above. Use duct

tape to make all joints secure and air tight.

8. Slide the inner duct cover up 2 inches

before sliding the entire duct cover onto the

hood. Refer to Figure 16.

9. Adjust the height of the inner duct cover to the

inner duct cover-mounting bracket {J}.

Secure the inner duct cover with two (1/8” x

3/8”) screws (provided).

10. Fasten outer duct cover to outer duct covermounting bracket {K} with two (1/8” x 3/8”)

screws (provided) as shown in Figure 17.

11. Drop oil tunnel into recess support near rear

of hood. Refer to Figure 18.

12. Install baffle filters and stainless spacer(s).

Refer to Measurements and Diagrams on

page 22 for baffle filter and stainless spacer

placement. Angle baffle filter toward back of

hood . Push baffle filter up until almost level

. Slide forward into recess behind the front

of hood . Lower baffle filter . Slide back

until it fits into resting position . Refer to

Figure 19.

13. Repeat step 12 to install all baffle filters and

stainless spacer(s).

Figure 15

Figure 16

Figure 17

Figure 18

11

Page 14

Final Assembly

14. Turn power ON in control panel. Check all

light and fan operation.

15. Make sure to leave this manual for the

homeowner.

Figure 19

12

Page 15

OPERATION INSTRUCTIONS

This KOBE hood is equipped with six electronic controls, two powerful centrifugal squirrel

cages with stainless steel oil tunnel, stainless steel baffle filters and spacer(s), and bright 12volt 20-watt halogen lights (2 for 30” & 36” and 3 for 42” & 48”).

The six electronic buttons control the Light, Speed (QuietMode™, Low, Medium & High) and

Power (On/Off). The Power Control offers a 10-second delay startup, 3-minute delay shutoff or

immediate shutoff. The Light Control operates independently from the Power Control and is

not affected by the delay startup or shutoff. (Fig. 20)

Figure 20

Q

Light control

Speed control

Power control

Turning Fan ON:

Always turn fans on before cooking to establish air flow and allow fans to run for a few minutes

after cooking for cleaner air in the kitchen. The Power Control (On/Off) button must be

pressed before a Speed Control button can be activated.

- Press the Power Control (On/Off) button once. The four LED lights above the Speed

Controls will flash, if a Speed Control button is not pressed within 10 seconds, power

will be automatically released. Note: The light setting will not be affected by the Power

Control (On/Off) button.

- Press a Speed Control button to activate the desired speed (the LED light above the

button will light up).

- To change the fan speed, press the button for the desired speed. The LED light above

the speed button will indicate fan speed.

13

Page 16

Figure 21

Turning Fan OFF:

The 3-Minute Delay function will only turn off fans. The light settings will not be affected by the

delay function.

3-Minute Delay

- Press Power Control (On/Off) button once, the LED light for the active speed will flash

and fans will shut off after 3 minutes.

- During this 3-minute delay, changing speeds will not affect the 3 minute countdown.

Immediate Shutoff

- Press Power Control (On/Off) button twice, the fans will be shut off immediately.

Light Control:

Light Control operates independently from the Power Control (On/Off) and 3-Minute Delay.

Pressing the Power Control button or activating the delay function will not turn halogen lights

on or off. The light has three settings: High, Low and Off.

- Press the Light Control button to turn halogen lights On.

- Pressing the Light Control button again will change the setting to Low.

- Each press of the Light Control button will cycle the light intensity through High, Low,

and Off.

14

Page 17

MAINTENANCE

SAFETY WARNING

NEVER PUT YOUR HAND INTO AREA HOUSING THE FAN WHILE THE FAN IS

OPERATING.

For optimal operation, clean range hood and all baffle/spacer/filter/oil tunnel/oil container regularly.

To Clean Hood Surface

CAUTION

*** Regular care will help preserve the appearance of the hood.

1. Use only mild soap or detergent solutions. Dry surfaces using soft cloth.

2. If hood looks splotchy (stainless steel hood), use a stainless steel cleaner to clean the surface

of the hood. Avoid getting cleaning solution onto or into the control panel. Follow directions of

the stainless steel cleaner. Caution: Do not leave on too long as this may cause damage to

hood finish. Use soft towel to wipe off the cleaning solution, gently rub off any stubborn spots.

Use dry soft towel to dry the hood.

3. DO NOT allow deposits to accumulate or remain on the hood.

4. DO NOT use ordinary steel wool or steel brushes. Small bits of steel may adhere to the surface

and cause rusting.

5. DO NOT allow salt solutions, disinfectants, bleaches, or cleaning compounds to remain in

contact with stainless steel for extended periods. Many of these compounds contain chemicals,

which may be harmful. Rinse with water after exposure and wipe dry with a clean cloth.

To Clean Baffle, Spacer, Filter, Oil Tunnel and Oil Container

CAUTION

1. Remove all baffles, spacer(s), filters, oil tunnel(s), and oil containers. Follow directions for

installation in reverse.

2. Discard oil and residue.

3. Wash with warm soapy water. Dry thoroughly before replacing.

(Note: Stainless Steel Baffles, Spacer(s) & Oil Tunnel are top rack dishwasher safe.)

: NEVER USE ABRASIVE CLEANERS, PADS, OR CLOTHS.

: DRAIN OIL FROM BAFFLES, SPACER(S), FILTERS, OIL TUNNEL(S) AND OIL

CONTAINERS BEFORE OIL AND RESIDUE CAN OVERFLOW.

15

Page 18

To Replace Light Bulb

CAUTION

1. Make sure all controls are off, and range hood is unplugged.

2. Place a flat-head screwdriver between light cover and housing to remove cover .

3. Gently pull defective bulb straight out and discard. Light bulbs should be 12V 20W

maximum.

4. Wear a cotton glove or use a cloth to handle the replacement bulb (do not handle with bare

fingers as this may shorten the life of the bulb). Push gently but securely into light socket.

NOTE: DO NOT PUSH TOO HARD AS BULB “LEGS” MAY BREAK OFF.

5. Replace light cover .

6. Turn range hood ON to test for operation.

: HALOGEN LIGHT UNIT MAY BE HOT! WAIT UNTIL UNIT IS COOL.

16

Page 19

MODEL / SIZE

COLOR

CONSU

MPTION / AMPERE

VOLTAGE

NUMBER OF MOTORS

DESIGN

MOTOR

TYPE

EXHAUST

CONTROLS

HALOGEN LIGHTS

HOOD DIMENSION

Net Gross

(CH76

30SQB)

(CH76

36SQB)

(CH76

42SQB)

(CH76

48SQB)

SPEED

Low

Medium

High

Air Capacity (cfm)*

Sone

(dB)

SPECIFICATIONS

CH7630SQB / 30”

CH7636SQB / 36"

CH7642SQB / 42”

CH7648SQB / 48”

#304 Commercial Grade Stainless Steel

CH7630SQB – 300W / 3A

CH7636SQB – 300W / 3A

CH7642SQB – 300W / 3A

CH7648SQB – 300W / 3A

120V 60Hz

2

Seamless / Satin Finish

Vertical Squirrel Cage

Top 7” Round

Six Electronic Buttons

CH7630SQB - 12V 20W x 2

CH7636SQB - 12V 20W x 2

CH7642SQB - 12V 20W x 3

CH7648SQB - 12V 20W x 3

(CH7630SQB) 29-3/4” x 22” x 10”

(W x D x H)

(CH7636SQB) 35-3/4” x 22” x 10”

(CH7642SQB) 41-3/4” x 22” x 10”

(CH7648SQB) 47-3/4” x 22” x 10”

WEIGHT (lbs)

QuietMode

385 460 560 700

1.2(42) 3.0(56) 4.0(60) 5.0(64)

*In House Test Static Pressure “0”. HVI Standard.

**Specifications information is subject to change without notice.

49 58

53 64

62 75

69 84

17

Page 20

MEASUREMENTS & DIAGRAMS

All ( ) are in millimeter.

All inch measurements are converted from millimeters. Inch measurements are estimated.

- FOR UNDER THE CABINET -

MODEL NO: CH7630SQB

CH7636SQB

CH7642SQB

CH7648SQB

18

Page 21

All ( ) are in millimeter.

All inch measurements are converted from millimeters. Inch measurements are estimated.

- FOR STAND ALONE (WITH OPTIONAL DUCT COVER) -

MODEL NO: CH7630SQB

CH7636SQB

CH7642SQB

CH7648SQB

19

Page 22

Rear Knockout Holes

4

"

2" (51)

(

1

0

2

)

3

"

(

7

5

)

3

"

(

7

5

)

1

2

"

(

1

3

8

0

"

4

2

(

)

4

4

"

(

3

6

0

"

(

7

6

0

)

f

5

o

6

r

)

3

f

0

8

)

f

o

f

o

r

4

8

0

o

"

r

3

6

"

r

4

2

"

"

3

"

(

7

5

)

3

"

(

7

5

)

20

Page 23

Hood-Mounting Bracket

9" (228)

11/16" (18)

1/2" (13)

8-5/8" (220)

4-3/4" (120)

1-3/8" (35)

9" (228)

10-5/8" (270)

1-3/8" (36)

DUCT COVER-MOUNTING BRACKET

Inner Duct Cover-Mounting Bracket Outer Duct Cover-Mounting Bracket

1

-

1

/

4

"

(

3

2

.

5

)

)

8

9

2

(

"

4

/

3

-

1

)

0

3

(

"

6

1

/

3

-

1

1

)

9

1

2

(

"

8

/

5

-

8

2

-

1

/

3

4

-

"

1

(

/

5

8

7

"

)

(

8

0

)

/

3

-

1

1

-

8

1/8" (4.5)

)

8

9

2

(

"

4

/

5

)

0

2

2

(

"

8

7/8" (22)

1/8" ( 3.4)

21

Page 24

BAFFLE FILTER & STAINLESS STEEL SPACERS

30″H00D

42″H00D

36″H00D

48″H00D

22

Page 25

MODEL NO.:

CH7630SQB

PARTS LIST

CH7636SQB

CH7642SQB

CH7648SQB

Body Components

NO. DESCRIPTION MODEL/SIZE PART NO.

1 Screws (3/16” x 3/8”) CH176-1

2 Hood Casing CH176-2

3 Hood-Mounting Bracket CH176-3

4 Screws (3/16” x 3/8”) CH176-1

5 Stainless Steel Oil Tunnel CH176-4

6 Blower Assembly CH176-5

7 Halogen Light Panel CH176-6

8 Gasket CH176-7

9 Screws (3/16” x 3/8”) CH176-1

10 Halogen Light CH176-9

11 Gasket CH176-8

12 Stainless Steel Spacer

A

B

C

13 Baffle Filter CH176-13

14 Baffle Handle CH176-14

15 Electrical Assembly CH176-15

16 Screws (3/16” x 3/8”) CH176-1

17 Wiring Box CH176-16

18 Screws (3/16” x 3/8”) CH176-1

19 Switch Assembly CH176-17

20 Screws (3/16” x 3/8”) CH176-1

21 Board CH176-18

22 Screws (3/16” x 3/8”) CH176-1

CH7636SQB CH176-11

CH7642SQB CH176-12

CH7648SQB CH176-18

23

Page 26

1

2

3

4

16

15

14

13

19

21

18

10

17

22

11

12A

12B

12C

12

5

6

20

7

8

9

24

Page 27

Blower Assembly

NO. DESCRIPTION MODEL/SIZE PART NO.

1 Air Chamber CH176-6.1

2 Screw Cap CH176-6.2

3 Left Squirrel Cage CH176-6.3

4 Left Locknut CH176-6.4

5 Air Flow Grill CH176-6.5

6 Screws (3/16” x 3/8”) CH176-6.6

7 Right Locknut CH176-6.7

8 Right Squirrel Cage CH176-6.8

9 Gasket CH176-6.9

10 Screws (3/16” x 3/8”) CH176-6.10

11 Left Motor CH176-6.11

12 Right Motor CH176-6.12

13 Safety Screen CH176-6.13

12

10

8

11

7

9

6

1

2

13

3

4

5

25

Page 28

Electrical Assembly

NO. DESCRIPTION MODEL/SIZE PART NO.

1 Processor Board CH176-15.1

2 Transformer CH176-15.2

3 Electrical Box CH176-15.3

4 Electrical Box Cover CH176-15.4

5 Capacitor CH176-15.5

6 Setup Board CH176-15.6

6

5

1

2

3

26

Page 29

MODEL NO.:

CH7630SQB

CIRCUIT DIAGRAM

CH7636SQB

RED

PROCESSOR BOARD

RED

RED

GREEN

RED

BLACK

BLACK

BLACK

WHITE

120V 60Hz

MOTOR MOTOR

CAPACITOR

10uF/450V

GREEN

WHITE

WHITE

CAPACITOR

10uF/450V

CONTROL BOARD

BROWN

BROWN

GREEN

YELLOW

TRANSFORMER

RED

BLACK

HALOGEN LIGHT

WHITE

27

Page 30

MODEL NO.:

CH7642SQB

CH7648SQB

CONTROL BOARD

PROCESSOR BOARD

RED

BLACK

BLACK

BLACK

WHITE

RED

GREEN

WHITE

GREEN

WHITE

RED

BLACK

HALOGEN LIGHT

RED

RED

BROWN

BROWN

GREEN

WHITE

YELLOW

120V 60Hz

MOTORMOTOR

TRANSFORMER

CAPACITOR

10uF/450V

CAPACITOR

10uF/450V

28

Page 31

DISCLAIMER

1. CAREFULLY INSPECT ALL ITEMS FOR DAMAGES BEFORE ACCEPTING DELIVERY. NOTE

ANY DAMAGES ON THE FREIGHT BILL OR EXPRESS RECEIPT. REQUEST NAME AND

SIGNATURE OF THE CARRIER’S AGENT AND KEEP COPY TO SUPPORT YOUR CLAIM.

Upon acceptance of items, owner assumes responsibility for its safe arrival. Report damages to the

carrier and file a claim immediately. Failure to do so may result in the denial of your claim. The

carrier will furnish you with necessary forms for filing a claim.

DAMAGES CAUSED DURING TRANSIT ARE NOT COVERED UNDER OUR WARRANTY.

2. PLEASE INSPECT CONTENTS OF PACKAGE(S) CAREFULLY UPON RECEIVING!

We must be notified in writing of any damages and/or missing parts within the allocated days upon

your receipt of package(s). Contact your local KOBE dealer or distributor or call KOBE for the time

limit.

CLAIMS WILL NOT BE ACCEPTED AFTER THE ALLOCATED DAYS.

NOTE: ITEMS WERE THOROUGHLY TESTED AND CAREFULLY PACKED IN OUR FACTORY

BEFORE SHIPPING.

3. Products must be returned in good working condition with ALL original parts and documentation

packed in ALL original cartons, fillers and shipping cartons. A restocking fee of 25% will be charged

for all approved return(s).

EXCHANGES OR RETURNS MAY NOT BE ACCEPTED IF ANY PACKAGING IS MISSING.

4. MAKE SURE TO INSPECT THE HOOD FOR DAMAGES AND DEFECTS BEFORE

INSTALLATION. Appearance flaws of the hood found after installation and not affecting hood

performance is not covered under our warranty for returns or exchanges. Service visits not covered

under warranty will carry a service charge.

A)

B)

Before Installation: Return for exchange or refund (please see above for acceptable

returns).

After Installation: NO exchange or refund.

29

Page 32

WARRANTY

WARRANTY CERTIFICATE

KOBE Range Hoods, Inc. warrants all products manufactured or supplied by it to be free from defects in

workmanship and materials. Its obligations pursuant to this warranty are limited to a period of two

years from the date of purchase and to the repair or replacement at its option and subject to the terms

and conditions stated below, of any component part, which its examination shall disclose to be so

defective.

TWO-YEAR WARRANTY SERVICE PERIOD

Any covered failure occurring within two years of original purchase arising from defective workmanship

or material in manufacture will be repaired (or at our discretion, replaced) free of charge by an

authorized KOBE Range Hoods Agent or KOBE Range Hoods as applicable. Keep proof of purchase

(or original invoice) handy for inspection.

If the range hood is sold by the original purchaser during the warranty period the new owner is

protected until expiration of the original purchaser’s warranty.

CONDITIONS

The following conditions apply only in relation to the warranty expressly given in this certificate.

1) This warranty applies only:

a)

within U.S.A. and Canada.

b)

to range hoods used for PRIVATE SINGLE FAMILY USE (if used for COMMERCIAL or

MULTIPLE FAMILY USE or other purposes, warranty will be voided).

2) Repair of any fault to be provided under this warranty shall not be provided:

a)

if the identification number attached to the range hood has been altered, rendered illegible or

removed;

b)

if notice of the defect has not been given within the period applicable;

c)

for failure of light bulbs or heat lamps;

d)

for physical damage;

e)

for surfaces damaged by use of improper chemical cleaning agents;

f)

if the appliance has been:

i) subject to misuse, abuse, negligence, accident, incorrect installation or failure to follow the

operating instructions;

ii) connected to improper, inadequate or faulty electricity service or exhaust ducts, flues or duct

cover, or operated using incorrect or contaminated lubricants;

iii) installed, maintained or operated otherwise than in accordance with the instructions

furnished by KOBE Range Hoods including the improper use of detergents, bleaches, or

cleaners.

g)

for damage to range hood during transit, delivery, installation or removal;

h)

for damage by or resulting from attempted repairs conducted by anyone other than our

Authorized Service Agent.

30

Page 33

3) The purchaser shall be responsible for any expenses involved in making the range hood readily

accessible for servicing and where the range hood is installed outside the main sales territory of the

retailer or service territory of the nearest approved KOBE Range Hoods Agent as applicable, for any

traveling expenses and any costs of transporting the range hood or parts thereof to and from the

dealer or Service Agent

4) The purchaser must produce proof of purchase together with this warranty certificate when making

the claim.

5) Damages caused during shipment are not covered under our warranty.

CONSEQUENTIAL DAMAGE

The warrantor is not responsible for any consequential damage. SOME STATES DO NOT ALLOW

THE EXCLUSION OF CONSEQUENTIAL DAMAGE SO THE ABOVE EXCLUSION MAY NOT APPLY

TO YOU.

IMPLIED WARRANTIES/STATE LAW

Any implied warranties, including the implied warranty of merchantability and fitness for purpose,

imposed on the sale by the laws of the state of sale are limited to two year from the date of original

purchase. Some states do not allow limitations on the duration of implied warranties. This warranty

gives you specific legal rights, and may also have rights, which vary from state to state.

SERVICE

For service contact:

KOBE Range Hoods

10505 Valley Blvd, Suite 302

EI Monte, CA 91731

U.S.A

Tel: (626) 350-1355 Fax: (626) 350-1976

Email: customer.service@KOBERangeHoods.com

Website: www.KOBERangeHoods.com

31

Page 34

PRODUCT REGISTRATION

Register Your Product!

Any covered failure occurring within two years of original purchase arising from defective

workmanship or material in manufacture will be repaired or at our option the unit will be replaced

free of charge by an authorized KOBE Range Hoods Agent or KOBE Range Hoods as applicable.

Keep proof of purchase (original invoice) handy for inspection.

If the range hood is sold by the original purchaser during the warranty period the new owner is

protected until expiration of the original purchaser’s warranty. See warranty section for complete

warranty coverage information.

This appliance has been manufactured, tested, and inspected to the standards required by KOBE

Range Hoods.

PLEASE MAIL IN YOUR WARRANTY REGISTRATION CARD AND PROOF OF PURCHASE

TO:

KOBE Range Hoods

10505 Valley Blvd Suite # 302

El Monte, CA 91731 USA

RECORD THE FOLLOWING INFORMATION FOR YOUR RECORD:

Model No. ________________________

Serial No. ________________________

Purchased Date _____/_____/_____

Purchased From:

______________________________

______________________________

______________________________

IMPORTANT: PLEASE KEEP A COPY OF YOUR SALE RECEIPT OR INVOICE HANDY WHEN

REQUESTING SERVICE.

32

Page 35

for use in the USA and CANADA only. We do

be

Using a KOBE

KOBE Range Hoods

10505 Valley Blvd Suite # 302

El Monte, CA 91731 USA

http://www.KOBERangeHoods.com

This KOBE hood is manufactured

not recommend using this hood overseas as the power supply may not

compatible and may violate the electrical code of that country.

hood overseas is at your own risk and will void your warranty.

VER.070214

Loading...

Loading...