Page 1

Model No. / N

CH0030SQB

CH0036SQB

CH0042SQB

CH0048SQB

KOBE Brand Range Hood

os

de modèles / Modelo No.

CH-100 SERIES – 18” HEIGHT

INSTALLATION INSTRUCTIONS

AND OPERATION MANUAL

MANUEL D'INSTALLATION

ET MODE D'EMPLOI

INSTRUCCIONES DE INSTALACIÓN

Y MANUAL DE OPERACIÓN

Page 2

[ENGLISH]................................................................................................................................. 1

[FRENCH]................................................................................................................................ 28

[SPANISH]............................................................................................................................... 55

2

Page 3

[ENGLISH]

- READ AND SAVE THESE INSTRUCTIONS -

CONTENTS

IMPORTANT SAFETY INSTRUCTIONS .................................................................................... 2

COMPONENTS OF PACKAGE.................................................................................................. 4

INSTALLATION.......................................................................................................................... 5

OPERATION INSTRUCTIONS................................................................................................. 12

MAINTENANCE....................................................................................................................... 13

SPECIFICATIONS ................................................................................................................... 15

MEASUREMENTS & DIAGRAMS............................................................................................ 16

PARTS LIST............................................................................................................................. 18

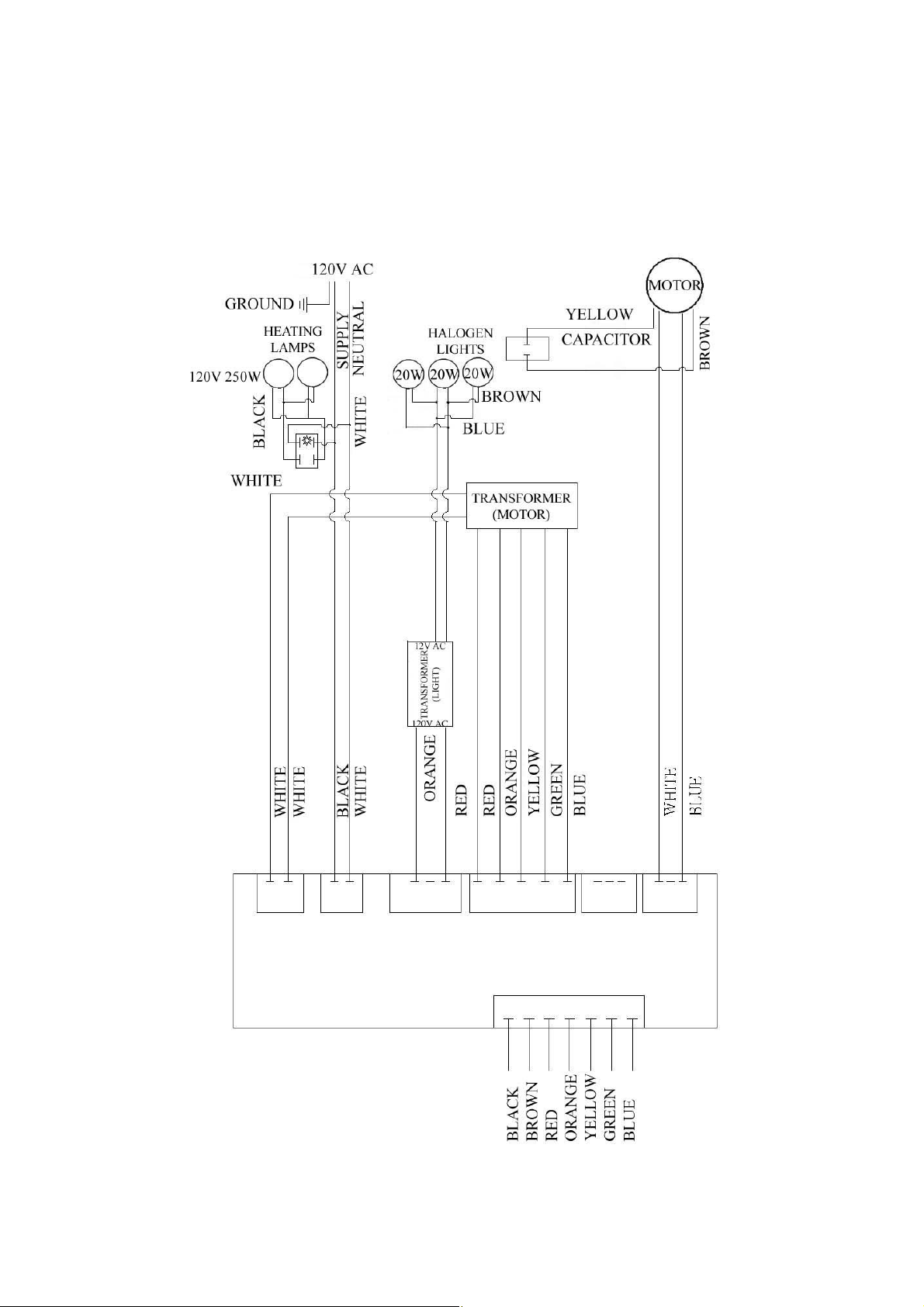

CIRCUIT DIAGRAM.................................................................................................................21

TROUBLE SHOOTING ............................................................................................................ 23

DISCLAIMER ........................................................................................................................... 24

WARRANTY ............................................................................................................................ 25

PRODUCT REGISTRATION.................................................................................................... 27

- READ ALL INSTRUCTIONS CAREFULLY BEFORE STARTING -

ALL WIRING MUST BE DONE BY A PROFESSIONAL AND IN

ACCORDANCE WITH NATIONAL AND LOCAL ELECTRICAL CODES.

1

Page 4

IMPORTANT SAFETY INSTRUCTIONS

- PLEASE READ THIS SECTION CAREFULLY BEFORE INSTALLATION -

WARNING

1) Installation and electrical wiring must be done by qualified professionals and in accordance with all

applicable codes and standards, including fire-rated construction.

2) When cutting or drilling into wall or ceiling, be careful not to damage electrical wiring or other hidden

utilities.

3) Ducted fans must be vented to the outside.

a) Before servicing or cleaning unit, open the light panel and SWITCH POWER OFF AT SERVICE

PANEL.

b) Clean all grease laden surfaces frequently. To reduce the risk of fire and to disperse air

properly, make sure to vent air outside. DO NOT vent exhaust air into wall spaces, attics, crawl

spaces or garages.

NOT E - This warranty is invalid without an authorized agent’s receipt or if unit is

- KOBE RANGE HOODS will not be held responsible for any damages to

:

TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK OR PERSONAL

INJURY, OBSERVE THE FOLLOWING:

damaged due to misuse, poor installation, improper use, mistreatment,

negligence or any other circumstances beyond the control of KOBE

RANGE HOODS authorized agents. Any repair carried out without the

supervision of KOBE RANGE HOODS authorized agents will

automatically void the warranty.

personal property or real estate or any bodily injuries whether caused

directly or indirectly by the range hood.

WARNING

1. Keep all fan, baffle/spacer/filter/oil tunnel/oil container and grease-laden surfaces clean. Grease

should not be allowed to accumulate on fan, baffle/spacer/filter/oil tunnel/oil container.

2. Always turn hood ON when cooking.

3. Use high settings on cooking range ONLY when necessary.

4. Do not leave cooking range unattended when cooking.

5. Always use cookware and utensils appropriate for the type and amount of food prepared.

6. Use this unit only in the manner intended by the manufacturer.

7. Before servicing, switch power off at service panel and lock service panel (if possible) to prevent

power from switching on accidentally.

8. Clean ventilating fan frequently.

: TO REDUCE THE RISK OF PERSONAL INJURY IN THE EVENT OF A RANGE

TOP GREASE FIRE:

2

Page 5

What to Do In The Event Of a Range Top Grease Fire

• SMOTHER FLAMES with a tight fitting lid, cookie sheet, or metal tray, and then turn off the burner.

KEEP FLAMMABLE OR COMBUSTIBLE MATERIAL AWAY FROM FLAMES. If the flames do not

go out immediately, EVACUATE THE AREA AND CALL THE FIRE DEPARTMENT or 911.

• NEVER PICK UP A BURNING PAN – You May Get Burned.

• DO NOT USE WATER, including wet dishcloths or towels – a violent steam blast will result.

• Use an extinguisher ONLY if:

a) You have a Class A, B, C extinguisher and know how to operate it.

b) The fire is small and contained in the area where it started.

c) The fire department has been called.

d) You can fight the fire with your back to an exit.

What to Do If You Smell Gas

-

Extinguish any open flame.

-

Do not try to turn on the lights or any type of appliance.

-

Open all doors and windows to disperse the gas. If you still smell gas, call the Gas Company and

Fire Department right away.

CAUTION

1) For general ventilation use only. Do not use to exhaust hazardous or explosive materials and

vapors.

2) To reduce the risk of fire, use only metal ductwork. Sufficient air is needed for proper combustion

and exhausting of gases through the flue (chimney) to prevent back drafting.

3) Follow the heating equipment manufacturer’s guideline and safety standards such as those

published by the National Fire Protection Association (NFPA), and the American Society for

Heating, Refrigeration and Air Conditioning Engineers (ASHRAE), and code authorities.

4) Activating any switch on may cause ignition or an explosion.

5) Due to the size and weight of this hood, two people installation is recommended.

ELECTRICAL SHOCK HAZARD – Can result in serious injury or death.

Disconnect appliance from electric power before servicing. If equipped, the

fluorescent light bulb contains small amounts of mercury, which must be

recycled or disposed of according to Local, State, and Federal Codes.

3

Page 6

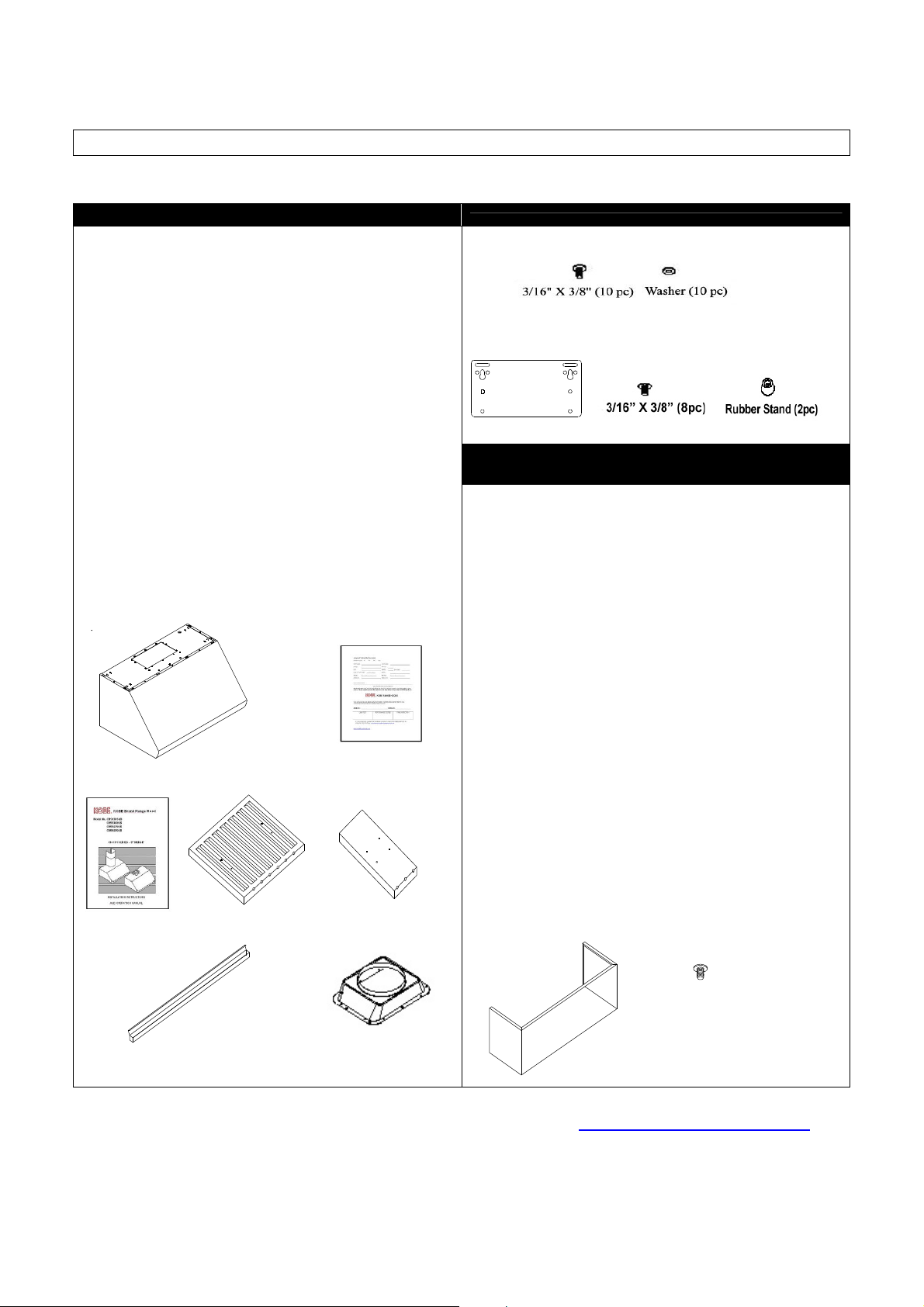

COMPONENTS OF PACKAGE

(Must keep all material for returns or refunds)

RANGE HOOD BOX

KOBE Range Hood – 1

Warranty Registration Card –1

Instructions Manual – 1

Baffle Filter

- 2 (30”, 36”, 42”)

- 3 (48”)

Stainless Steel Spacer

- 1 (30”)

- 3 (36”)

- 3 (42”)

- 2 (48”)

Oil Tunnel – 1

Ducting Transition – 1

Screw Package for Transition – 1

Hood-Mounting Bracket-2

Screw Package for Hood-Mounting Bracket

w/ Rubber Stand –1

ORIGINAL KIT

(Sold Separately)

Option Of:

Model No. CH0030DC-12 for 30'' hood

KOBE Duct Cover – 1

Screw Package for Duct Cover – 1

Hood-Mounting Bracket-2

Model No. CH0036DC-12 for 36'' hood

KOBE Duct Cover – 1

Screw Package for Duct Cover – 1

Hood-Mounting Bracket-2

Model No. CH0042DC-12 for 42'' hood

KOBE Duct Cover – 1

Screw Package for Duct Cover – 1

Hood-Mounting Bracket-2

Model No. CH0048DC-12 for 48'' hood

KOBE Duct Cover – 1

Screw Package for Duct Cover – 1

Hood-Mounting Bracket-2

3/16" X 3/8" (8 pc)

-

FOR MORE INFORMATION, PLEASE VISIT OUR WEBSITE www.KOBERangeHoods.com OR

CONTACT KOBE RANGE HOODS AT (626) 775-8880.

4

Page 7

INSTALLATION

PLEASE READ ENTIRE INSTRUCTIONS BEFORE PROCEEDING

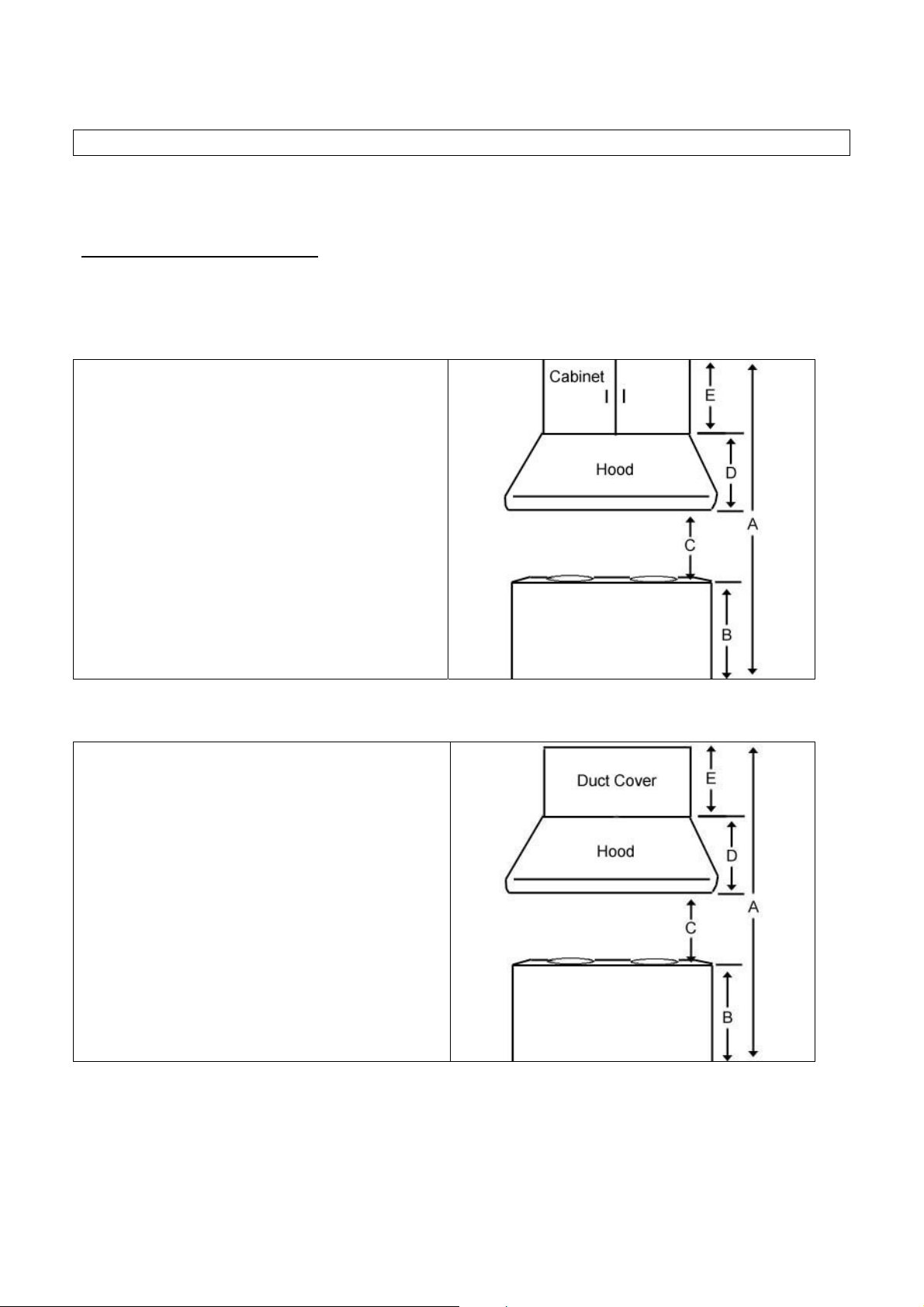

Calculation before Installation

Calculate the length of the installation, before installing the hood. (All calculation is measure in inches.)

- FOR UNDER THE CABINET -

TABLE 1

A = Height of Floor to Ceiling

B = Height of Floor to Counter Top

(Standard: 36”)

C = Preferred Height of Counter Top to Hood

Bottom (Recommended 27” to 30”)

D = Height of Hood

E = Height of the Cabinet

- FOR STAND ALONE (WITH OPTIONAL DUCT COVER) -

TABLE 2

A = Height of Floor to Ceiling

B = Height of Floor to Counter Top

(Standard: 36”)

C = Preferred Height of Counter Top to Hood

Bottom (Recommended 27” to 30”)

[(A – B] – (D + E)]

D = Height of Hood

E = Height of Duct Cover

5

Page 8

SAFETY WARNING

HOOD MAY HAVE VERY SHARP EDGES; PLEASE WEAR PROTECTIVE GLOVES IF IT IS

NECESSARY TO REMOVE ANY PARTS FOR INSTALLING, CLEANING OR SERVICING.

NOTE: BE CAREFUL WHEN USING ELECTRICAL SCREWDRIVER, DAMAGE TO THE HOOD

MAY OCCUR.

UNDER THE CABINET INSTALLATION ............................................................................................... 7

STAND ALONE INSTALLATION ........................................................................................................... 9

6

Page 9

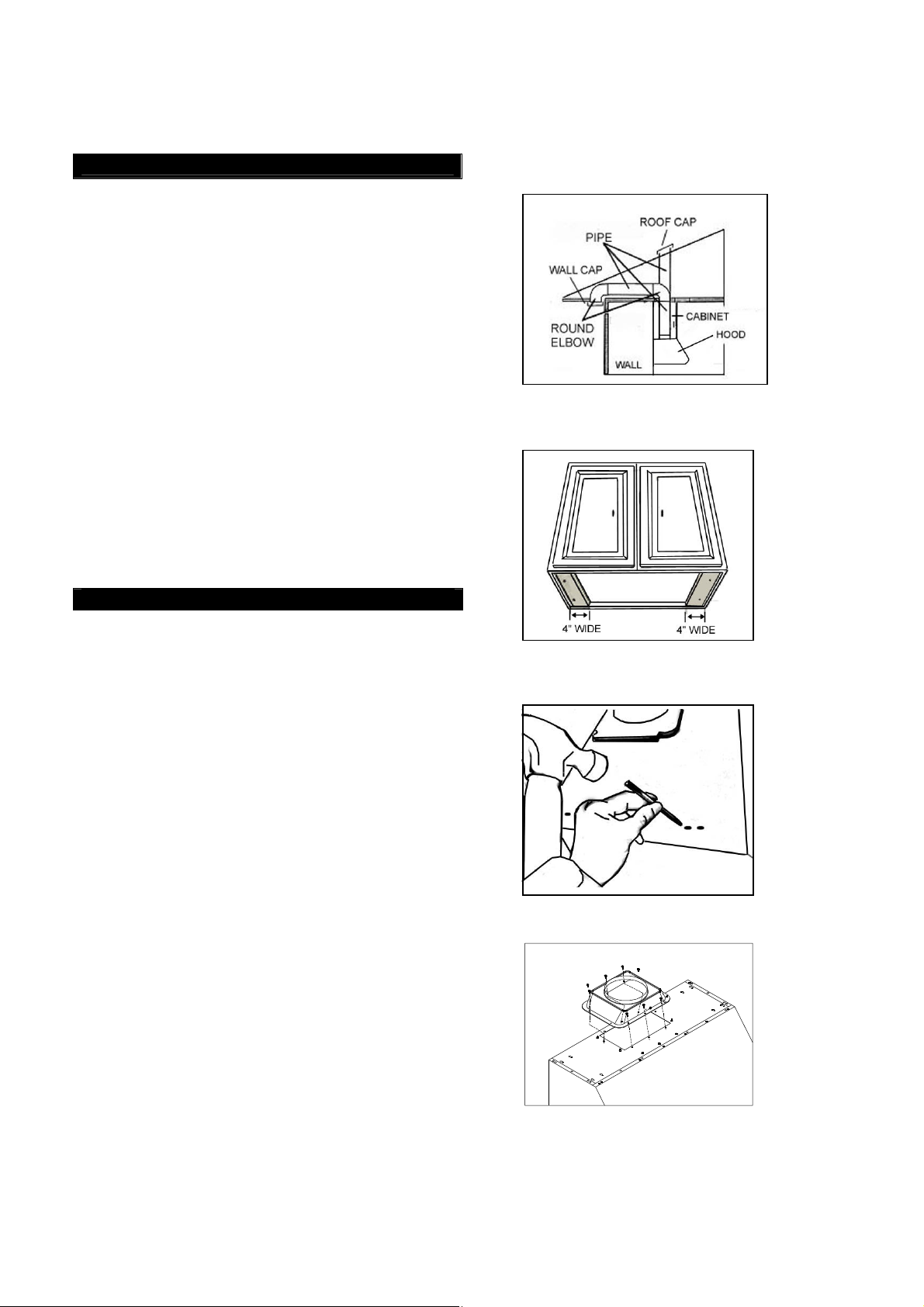

UNDER THE CABINET INSTALLATION

Preparation before Installation

NOTE: TO AVOID DAMAGE TO YOUR HOOD,

PREVENT DEBRIS FROM ENTERING

THE VENT OPENING.

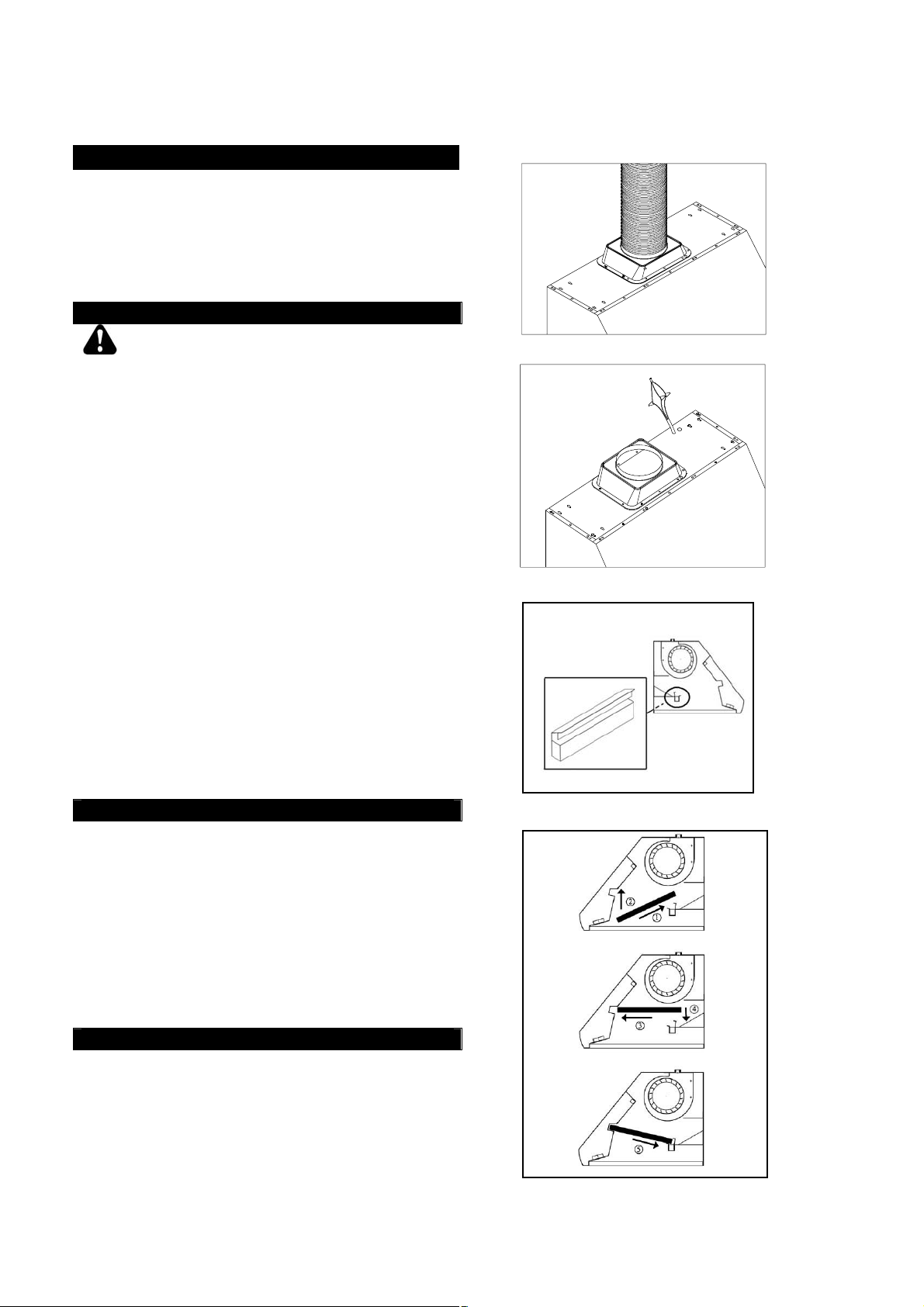

Decide the location of the venting pipe from the

hood to the outside. Refer to Figure 1.

A straight, short venting run will allow the hood

to perform more efficiently.

Try to avoid as many transitions, elbows, and

long run as possible. This may reduce the

performance of the hood.

Temporarily wire the hood to test for proper

operation before installing.

Important: Peel protective film off the hood

(if any).

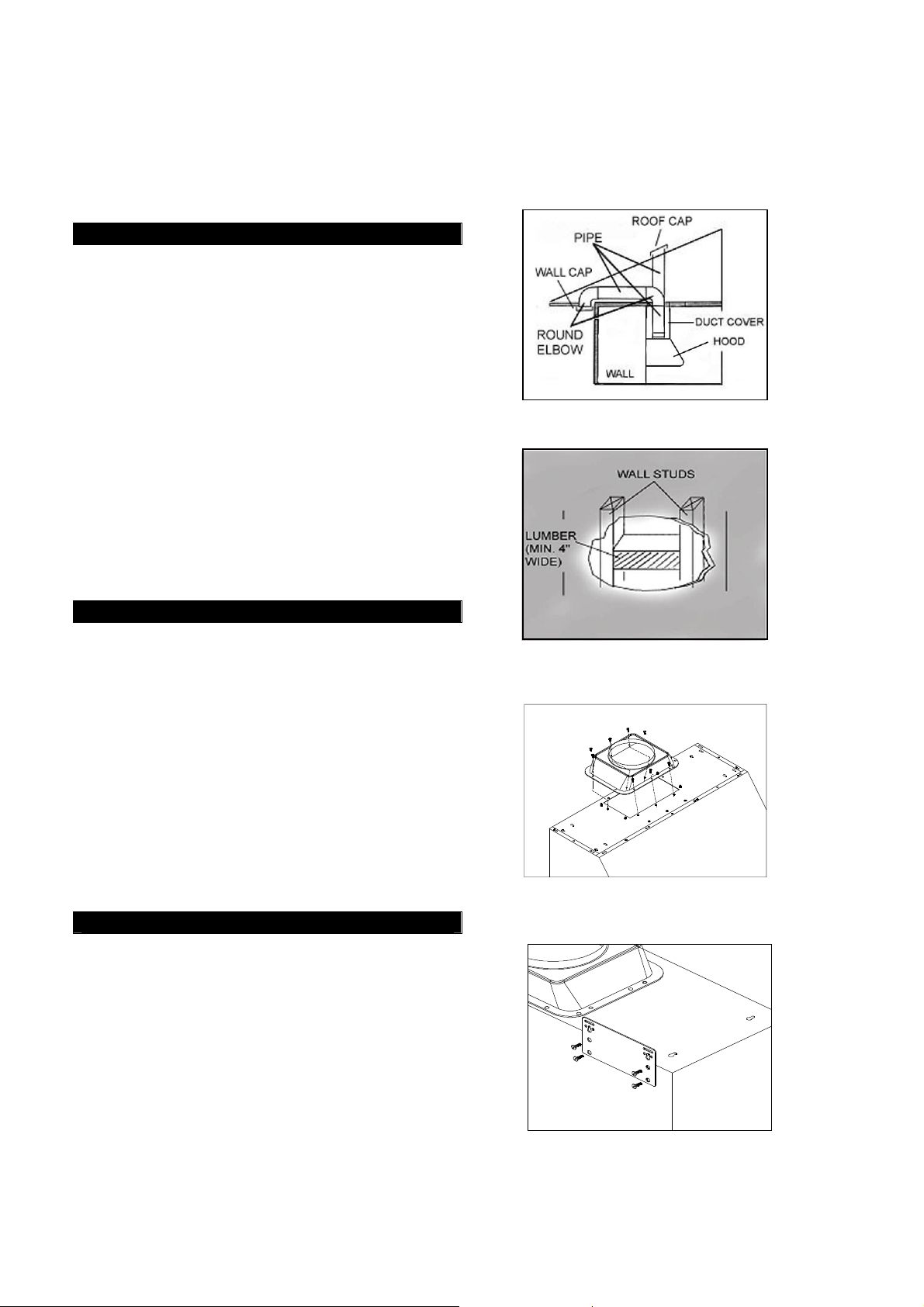

For installing under the cabinet with recessed

bottom, attach 4-inch wide wood filler strips (not

included) on each side. Refer to Figure 2.

Measure and create access opening for

electrical wires under the cabinet.

Figure 1

Figure 2

Hood Installation

CAUTION: If required to move the cooking

range to install the hood, turn off the power on

an electric range at the main electrical box.

SHUT OFF THE GAS BEFORE MOVING A GAS

RANGE.

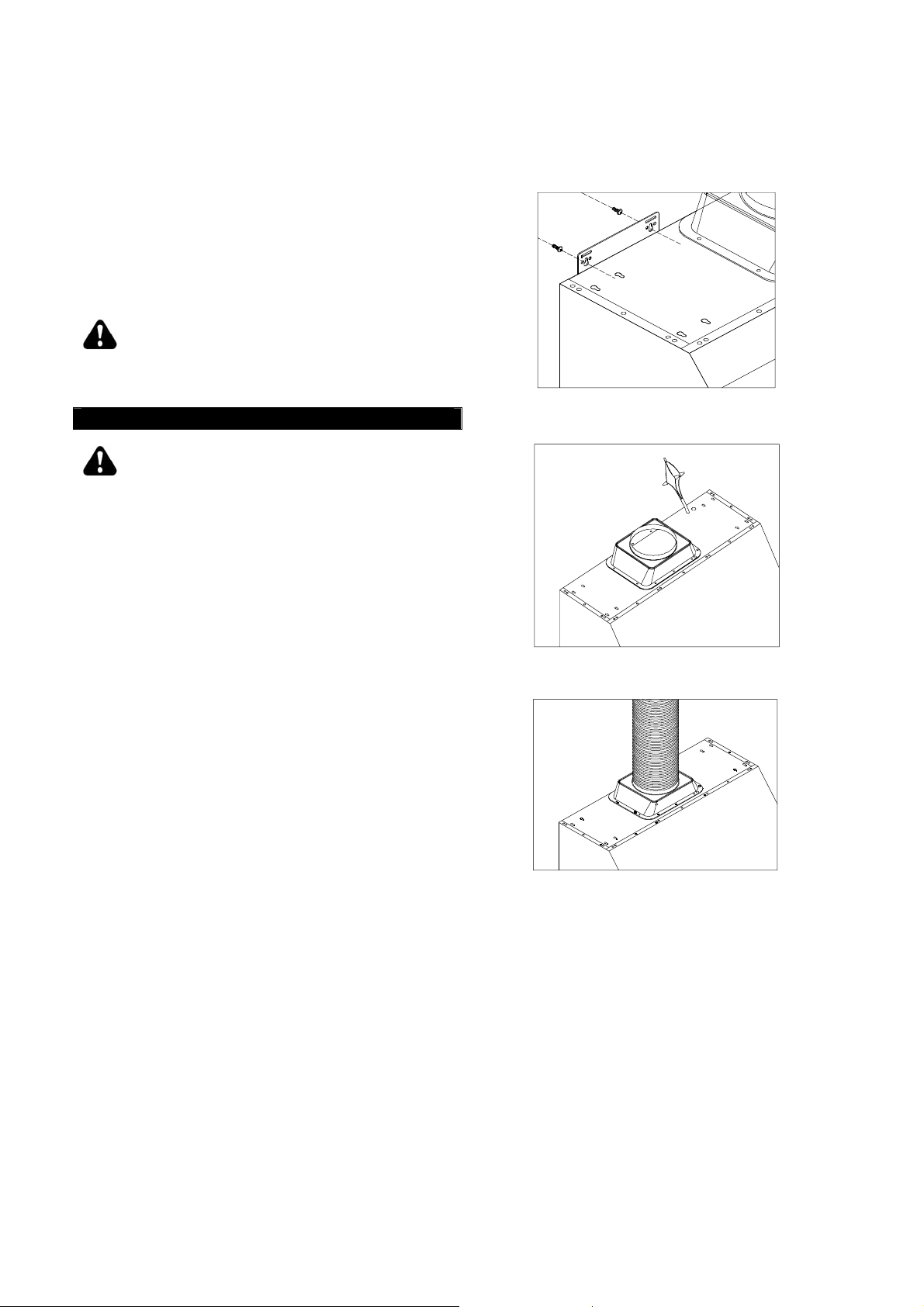

1. Puncture the knockout holes on the hood as

shown in Figure 3.

2. Attach ducting transition to hood exhaust with

ten (3/16” x 3/8”) screws (included). Shown in

Figure 4.

3. Using references on Table 1 and

measurements on page 15-16 center the hood

in place beneath the cabinet and flush with the

front of the cabinet.

4. Draw electrical wires through cabinet access

opening.

5. From the bottom of the hood, place screw (not

provided) into the exact center of each

knockout hole. Make sure all screws are in

place before tightening screws. CAUTION:

MAKE SURE THE HOOD IS SECURE

BEFORE RELEASING.

6. For safety purpose, pre-drilled mounting holes

are provided through the back of the hood. For

a more secure installation, use as many

mounting holes as needed to secure from the

inside of hood (screws not included).

7

Figure 3

Figure 4

Page 10

Ductwork Installation

7. Use 8” round steel pipe (follow building codes

in your area) to connect the ducting transition

on the hood to the ductwork above. Use duct

tape to make all joints secure and air tight.

Refer to Figure 5.

Wiring to Power Supply

Figure 5

SAFETY WARNING

RISK OF ELECTRICAL SHOCK. THIS RANGE

HOOD MUST BE PROPERLY GROUNDED.

MAKE SURE THIS IS DONE BY SPECIALIZED

ELECTRICIAN IN ACCORDANCE WITH ALL

APPLICABLE NATIONAL AND LOCAL

ELECTRICAL CODES. BEFORE CONNECTING

WIRES, SWITCH POWER OFF AT SERVICE

PANEL AND LOCK SERVICE PANEL TO

PREVENT POWER FROM BEING SWITCHED

ON ACCIDENTALLY.

8. Connect the electrical wires.

-

Connect three wires (black, white and

green) to house wires and cap with wire

connectors. Connect according to color:

black to black, white to white, and green to

green as shown on Figure 6.

-

If necessary to hide the electrical wire

connections, push wires back into the

wiring box. Access the wire connections

underneath the hood. Make sure wires do

not slip between motor or any moving parts

to prevent any damage.

Figure 6

Figure 7

Install Accessories

9. Attach Oil Tunnel. Refer to Figure 7.

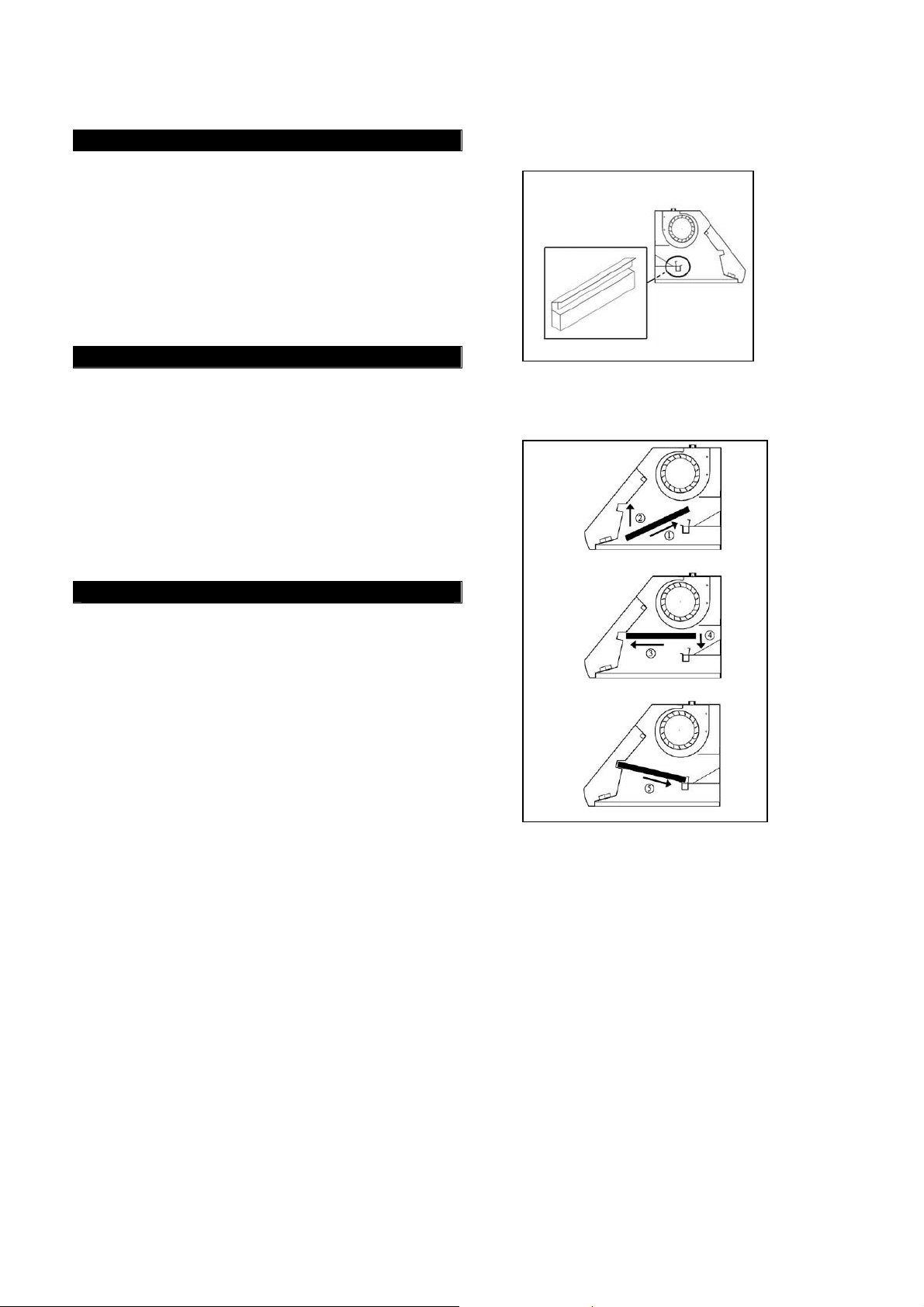

10. Refer to Figure 8. Slide the baffle filter into

the hood. Push the baffle filter upward.

Slide forward. Pull downward. Fit into

place.

11. Repeat for all baffle filters and spacers. Refer

to page 17.

12. Install heating lamps (not included), 120 Volts

175 Watts max. each.

Final Assembly

13. Turn power ON in control panel. Check all

lights and fan operation.

14. Make sure to leave this manual for the

homeowner.

Figure 8

8

Page 11

STAND ALONE INSTALLATION

***This installation only applied with the purchase

of an optional duct cover:

Preparation before Installation

NOTE: TO AVOID DAMAGE TO YOUR HOOD,

PREVENT DEBRIS FROM ENTERING

THE VENT OPENING.

Decide the location of the venting pipe from the

hood to the outside. Refer to Figure 9.

A straight, short venting run will allow the hood

to perform more efficiently.

Try to avoid as many transitions, elbows, and

long run as possible. This may reduce the

performance of the hood.

Use duct tape to seal the joints between pipe

sections.

If necessary, prepare back wall frame with

cross framing lumber for secure installation.

Using references on Table 2 and

measurements on page 16-17, decide the level

of the lumber. Refer to Figure 10.

Hood Preparation before Installation

• Temporarily wire the hood to test for proper

operation before installing.

• Important: Peel protective film off the hood

and the duct cover (if any).

• Attach ducting transition to hood exhaust with

ten (3/16” x 3/8”) screws (included). Refer to

Figure 11.

• If necessary, attach two rubber stands

(included) with adhesive tape (included) to the

back corners of the hood.

• Use eight (3/16” x 3/8”) screws (included) to

attach the two hood-mounting brackets

(included) to the back of the hood. Refer to

Figure 12.

Hood Installation

Figure 9

Figure 10

Figure 11

Figure 12

CAUTION: If required to move the cooking

range to install the hood, turn off the power on

an electric range at the main electrical box.

SHUT OFF THE GAS BEFORE MOVING A GAS

RANGE.

1. Using references in Table 2 on page 4 and

Measurements and Diagrams on pages 16-17,

mark the leveling point of the hood. Position

two mounting screws (not included) on the wall,

leaving 1/8” away from the wall. Refer to Figure

13.

9

Page 12

2. Align hood-mounting bracket to the two screws

on the wall and hook hood into place. Tighten

screws to secure hood to the wall.

3. For safety purpose, pre-drilled mounting holes

are provided through the back of the hood. For

a more secure installation, use as many

mounting holes as needed to secure from the

inside of hood (screws not included).

CAUTION: MAKE SURE HOOD IS SECURE

BEFORE RELEASING.

Figure 13

WALL

Wiring to Power Supply

Figure 14

SAFETY WARNING

RISK OF ELECTRICAL SHOCK. THIS RANGE

HOOD MUST BE PROPERLY GROUNDED.

MAKE SURE THIS IS DONE BY SPECIALIZED

ELECTRICIAN IN ACCORDANCE WITH ALL

APPLICABLE NATIONAL AND LOCAL

ELECTRICAL CODES. BEFORE CONNECTING

WIRES, SWITCH POWER OFF AT SERVICE

PANEL AND LOCK SERVICE PANEL TO

PREVENT

POWER FROM BEING SWITCHED ON

ACCIDENTALLY.

4. Connect the electrical wires.

-

Connect three wires (black, white and

green) to house wires and cap with wire

connectors. Connect according to color:

black to black, white to white, and green to

green as shown on Figure 13.

-

If necessary to hide the electrical wire

connections, push wires back into the

wiring box. Access the wire connections

underneath the hood. Make sure wires do

not slip between motor or any moving parts

to prevent any damage.

Figure 15

10

Page 13

Duct Cover Installation

5. Use 8” round steel pipe (follow building codes

in your area) to connect the ducting transition

on the hood to the ductwork above. Use duct

tape to make all joints secure and air tight.

Refer Figure 15. Slide the duct cover onto the

hood.

6. Use 3/16” x 3/8” screws (included) to attach

duct cover to hood.

Figure 16

Install Accessories

7. Attach oil tunnel. Refer to Figure 16.

8. Refer to Figure 17. Slide the baffle filter into

the hood. Push the baffle filter upward.

Slide forward. Pull downward. Fit into

place.

9. For bottom casing, repeat above steps. Refer

to page 17.

10. Install heating lamps (not included), 120 Volts

175 Watts max. each.

Final Assembly

11. Turn power ON in control panel. Check all

lights and fan operation.

12. Make sure to leave this manual for the

homeowner.

Figure 17

11

Page 14

OPERATION INSTRUCTIONS

This KOBE hood is equipped with four electronic controls with a 10-second standby startup &

30-second delay shutoff, powerful centrifugal squirrel cage with baffle filters, and bright 12-volt

20-watt halogen lights.

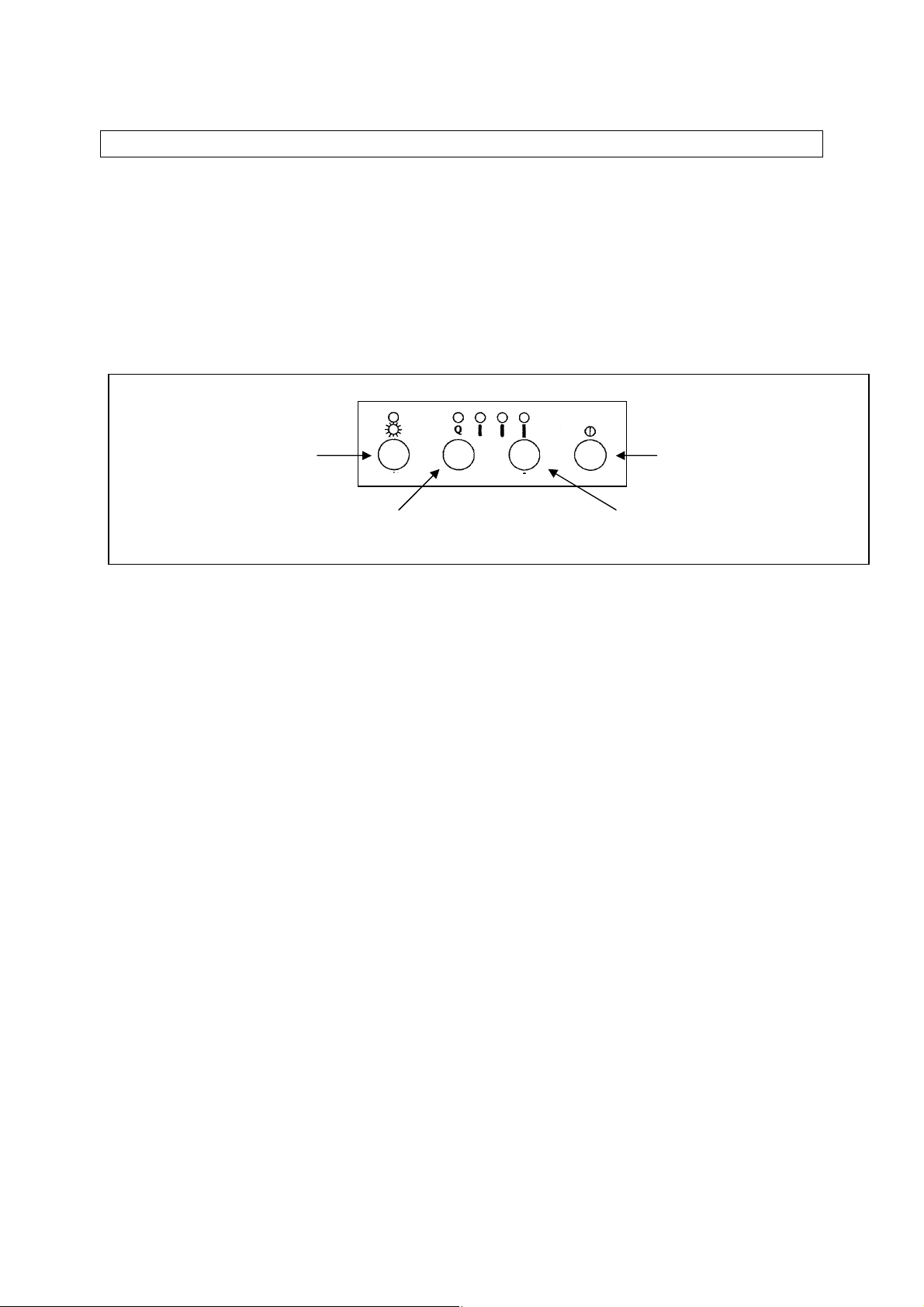

The four electronic controls are Light Control, Speed Control A, Speed Control B and the Power

Control (On/Off). Refer to Figure 18.

Figure 18

Speed Control A

TURN ON:

Light Control

Speed Control B

•

Press Power Control (On/Off) button once.

(Note: If any Control button is not pressed within 10 seconds, power will be

automatically turned off).

Power Control

•

The KOBE hood will start on Low speed. Each press of the Speed Control

button will cycle through the various speeds.

•

Press Speed Control A button to cycle from Low, Medium, High, or

QuietMode™. Press Speed Control B button to cycle from Low, QuietMode™,

High or Medium.

(Note: Speed Control A or B will operate both fans. These two speed buttons will

allow you to change the speed quicker.)

•

Press Light Control button to turn halogen light on.

•

Press the back Red button to turn on heating lamp.

(Note: Heating lamps are sold separately. Heating lamps required 120-volt,

175-watt.)

TURN OFF:

•

Press Power Control (On/Off) button once, panel lights will flash and power

will be completely shut off after 30 seconds.

•

Press Power Control (On/Off) button twice, all power will be shut off

immediately.

•

If only the lights are on, pressing Power Control (On/Off) button once will turn

power off after 30 seconds.

OR

12

Page 15

MAINTENANCE

For the optimal level of operation, clean the range hood surface and baffles regularly.

To Clean Hood Surface

CAUTION: NEVER USE ABRASIVE CLEANERS, PADS, OR CLOTHS.

*** Regular care will help preserve its fine appearance.

1. Use only mild soap or detergent solutions. Dry surfaces using soft cloth.

2. If hood looks splotchy (stainless steel hood), use an orange base cleaner to clean the

surface of the hood. Avoid cleaner to get on the control switches. Only spread a light

coating over the surface of the hood and leave on for a few minutes (do not leave on too

long or this may cause damage to hood finish). Use soft towel to wipe off the cleaning

solution, gently rubs any stubborn spots. Use a slightly damp towel to get rid of any

cleaning solution. Use dry soft towel to dry the hood.

3. To bring the glow back into a stainless steel finish, use a stainless steel cleaner.

4. DO NOT allow deposits to remain for long periods of time.

5. DO NOT use ordinary steel wool or steel brushes. Small bits of steel may adhere to the

surface causing rust.

6. DO NOT allow salt solutions, disinfectants, bleaches, or cleaning compounds to remain

in contact with stainless steel for extended periods. Many of these compounds contain

chemicals, which may be harmful. Rinse with water after exposure and wipe dry with a

clean cloth.

To Clean Baffle Filters & Oil Tunnel

CAUTION: DRAIN BAFFLE FILTERS AND OIL TUNNEL BEFORE OIL WILL OVERFLOW.

1. Remove the baffle filters and oil tunnel..

2. Using a sponge, wash with warm soapy water. Dry completely before returning into

place.

(Note: Baffle Filters are top rack dishwasher safe.)

13

Page 16

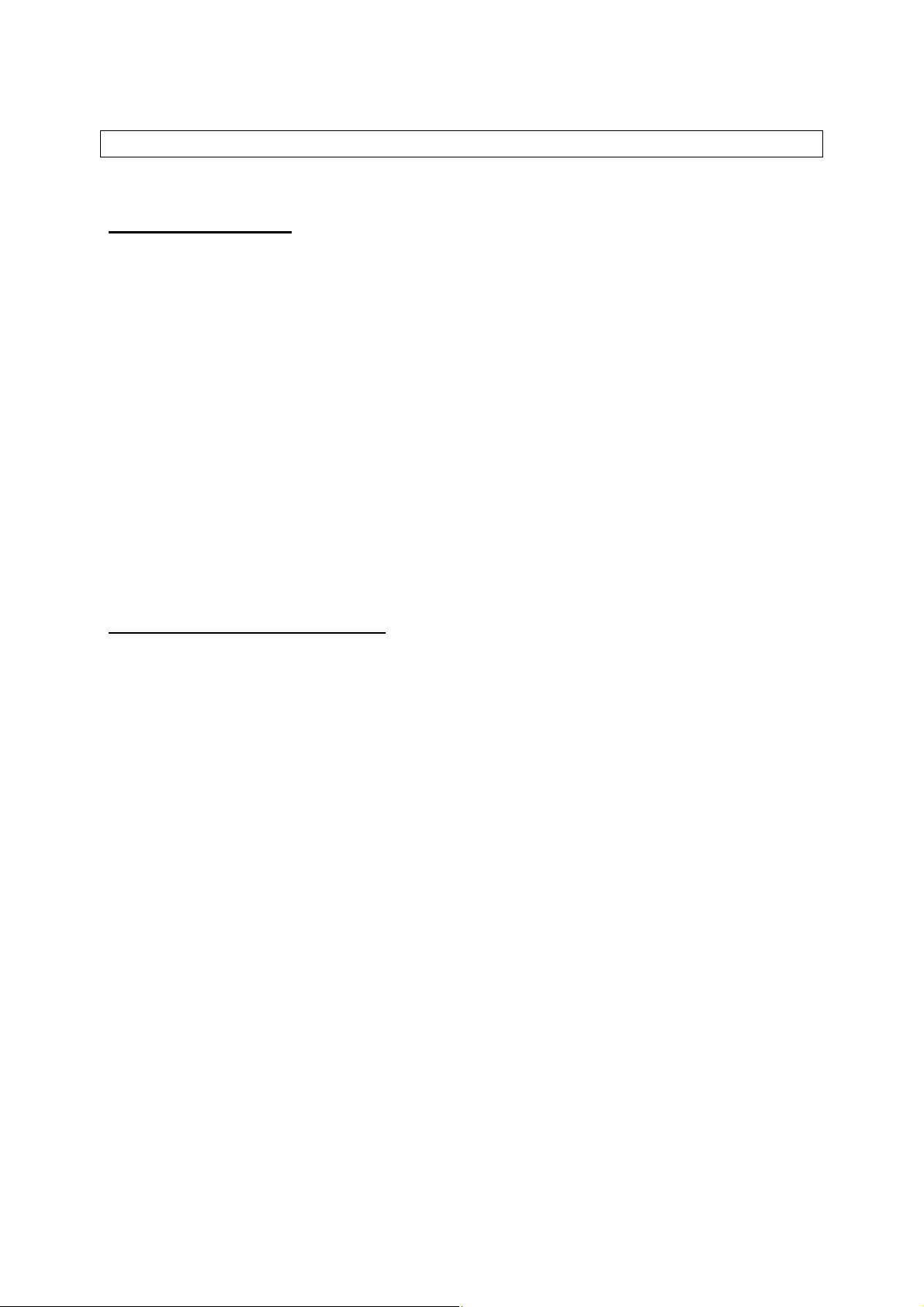

Replacing Light Bulb

CAUTION: HALOGEN LIGHT UNIT MAY BE HOT! WAIT UNTIL UNIT IS COOL.

1. Make sure all controls are off, and range hood is unplugged.

2. Place the flat-headed screwdriver into the groove of the halogen light glass covering and

the housing.

3. Pop out the halogen light glass covering.

4. Gently pull out the defective light bulb and discard. Light bulbs should be 12V 20W

maximum.

5. Using a cloth, hold the new light bulb and push securely into light socket.

6. Return halogen light glass cover to the housing.

7. Turn range hood ON to test for operation.

14

Page 17

SPECIFICATIONS

MODEL / SIZE

COLOR

CONSUMPTION / AMPERE

VOLTAGE

NUMBER OF MOTORS

DESIGN

FAN TYPE: CENTRIFUGAL

EXHAUST

CONTROLS

HALOGEN LIGHTS

HOOD DIMENSION

(W x D x H)

OPTIONAL ACCESSORIES

(W x D x H)

HOOD WEIGHT (lbs)

SPEED

Air Capacity (cfm)

Sone*

CH0030SQB / 30”

CH0036SQB / 36"

CH0042SQB / 42”

CH0048SQB / 48”

Commercial Grade Stainless Steel

CH0030SQB – 300W / 2.68A

CH0036SQB – 300W / 2.68A

CH0042SQB – 320W / 2.86A

CH0048SQB – 320W / 2.86A

120V 60Hz

1

18-Gauge Seamless / Satin Finish

Squirrel Cage

Top Transition Rectangular to 8” Round x 1

Electronic Control (4 Buttons) –

10-Second Standby Startup

30-Second Delay Shutoff

12V 20W x 2 – 30”, 36”

12V 20W x 3 – 42”, 48”

(CH0030SQB) 29-3/4” x 24” x 18”

(CH0036SQB) 35-3/4” x 24” x 18”

(CH0042SQB) 41-3/4” x 24” x 18”

(CH0048SQB) 47-3/4” x 24” x 18”

1) Original Kit - Duct Cover:

Model No. CH0030DC-12 30” x 12” x 12”

Model No. CH0036DC-12 36” x 12” x 12”

Model No. CH0042DC-12 42” x 12” x 12”

Model No. CH0048DC-12 48” x 12” x 12”

2) Model No. SSP30

30” Stainless Steel Back Panel 30” x 1/10” x 32”

3) Model No. SSP36

36” Stainless Steel Back Panel 36” x 1/10” x 32”

Net

(CH0030SQB)

(CH0036SQB)

(CH0042SQB)

(CH0048SQB)

QuietMode™

400 600 800 1000

1.4* 3.5 7.0 8.0

Gross

66.0 84.0

73.0 93.0

84.0 106.0

90.5 115.0

Low Medium High

*One sone is equivalent to the sound of a refrigerator at 40 decibels.

**Specifications subject to change without notice.

15

Page 18

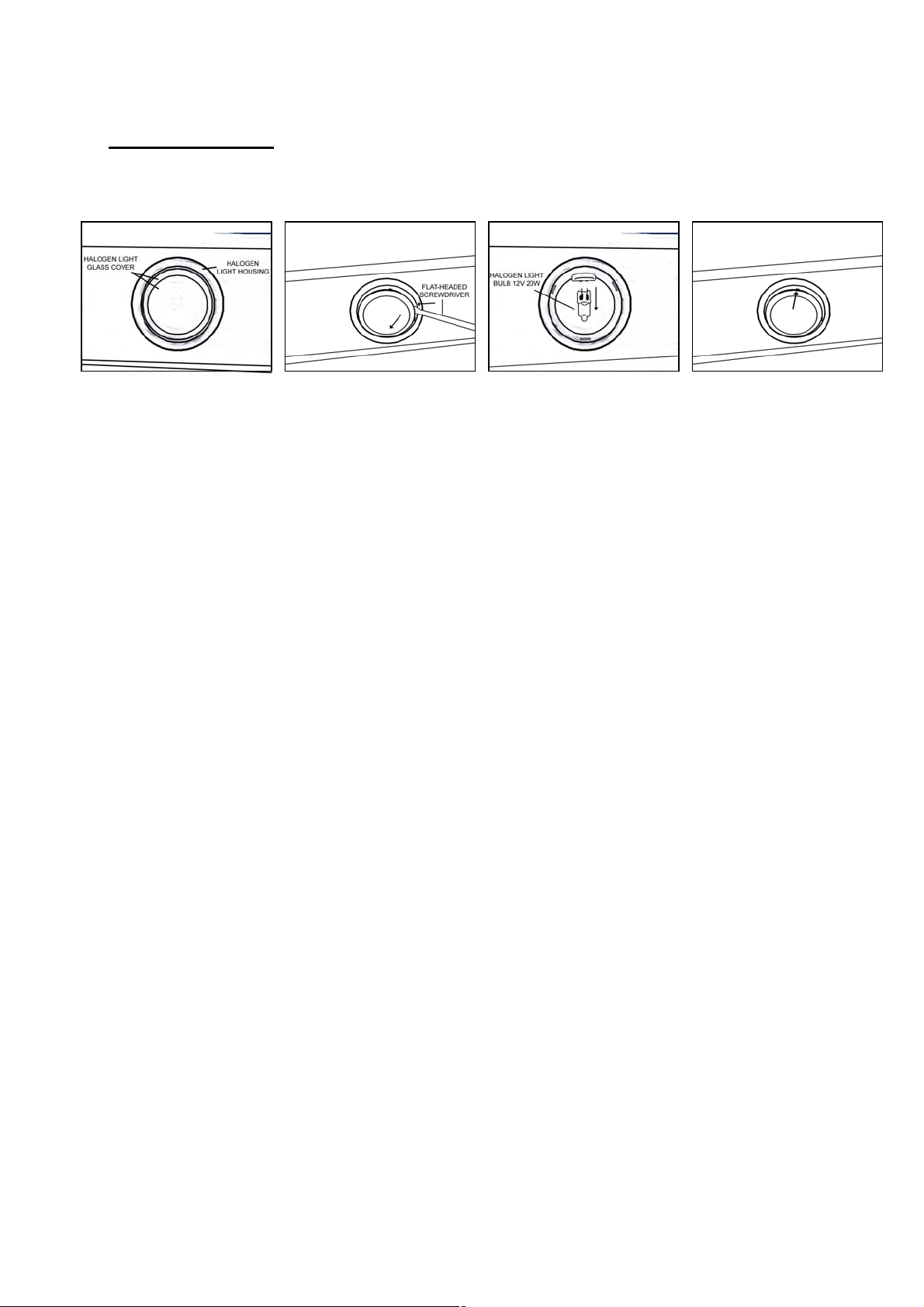

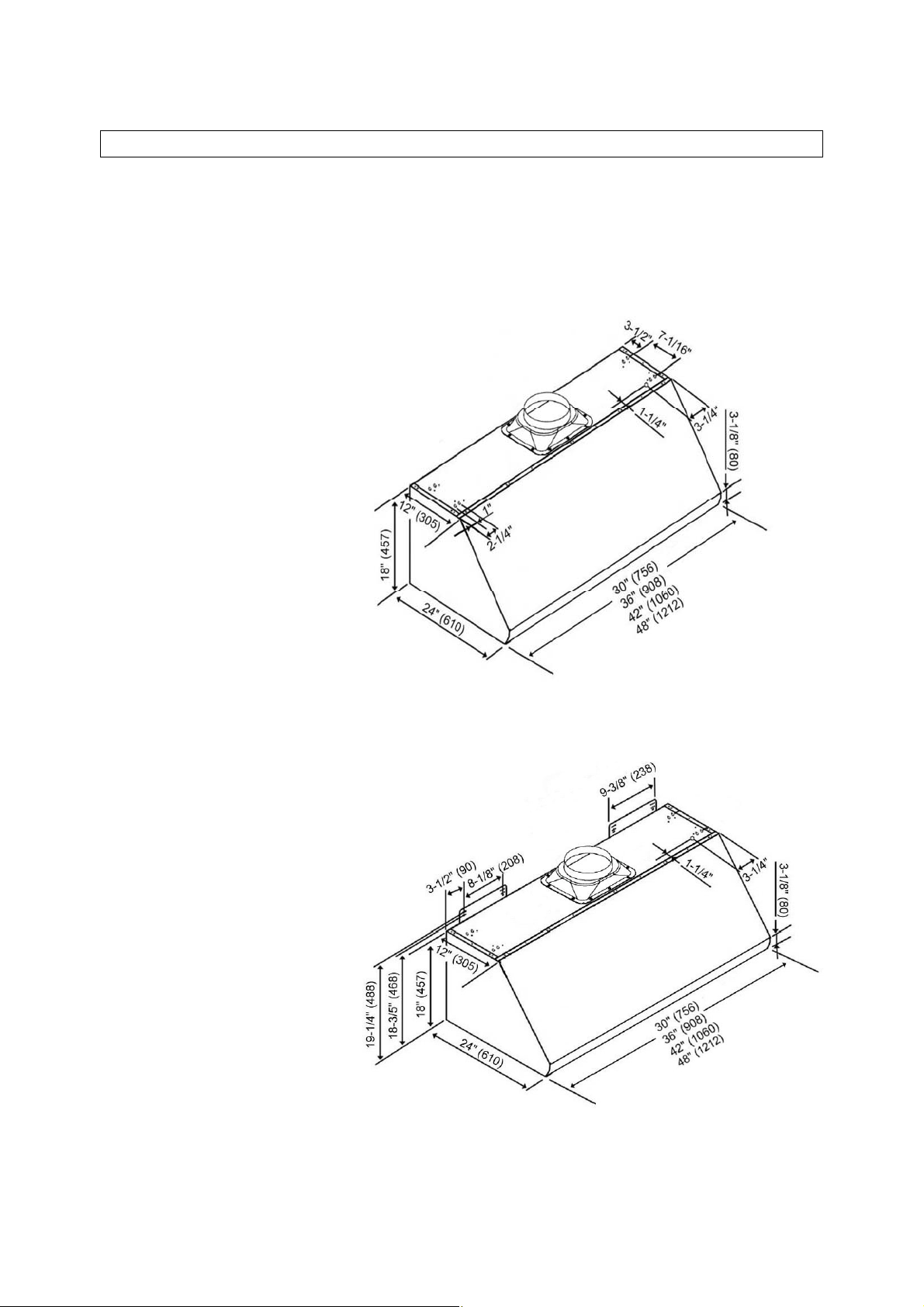

MEASUREMENTS & DIAGRAMS

All measurements in ( ) are millimeters.

All inch measurements are converted from millimeters. Inch

measurements are estimated.

- FOR UNDER THE CABINET -

MODEL NO.: CH0030SQB

CH0036SQB

CH0042SQB

CH0048SQB

- FOR STAND ALONE -

MODEL NO.: CH0030SQB

CH0036SQB

CH0042SQB

CH0048SQB

16

Page 19

- FOR STAND ALONE (WITH OPTIONAL DUCT COVER) -

***Rear Knockout Holes ***Hood-Mounting Bracket

17

Page 20

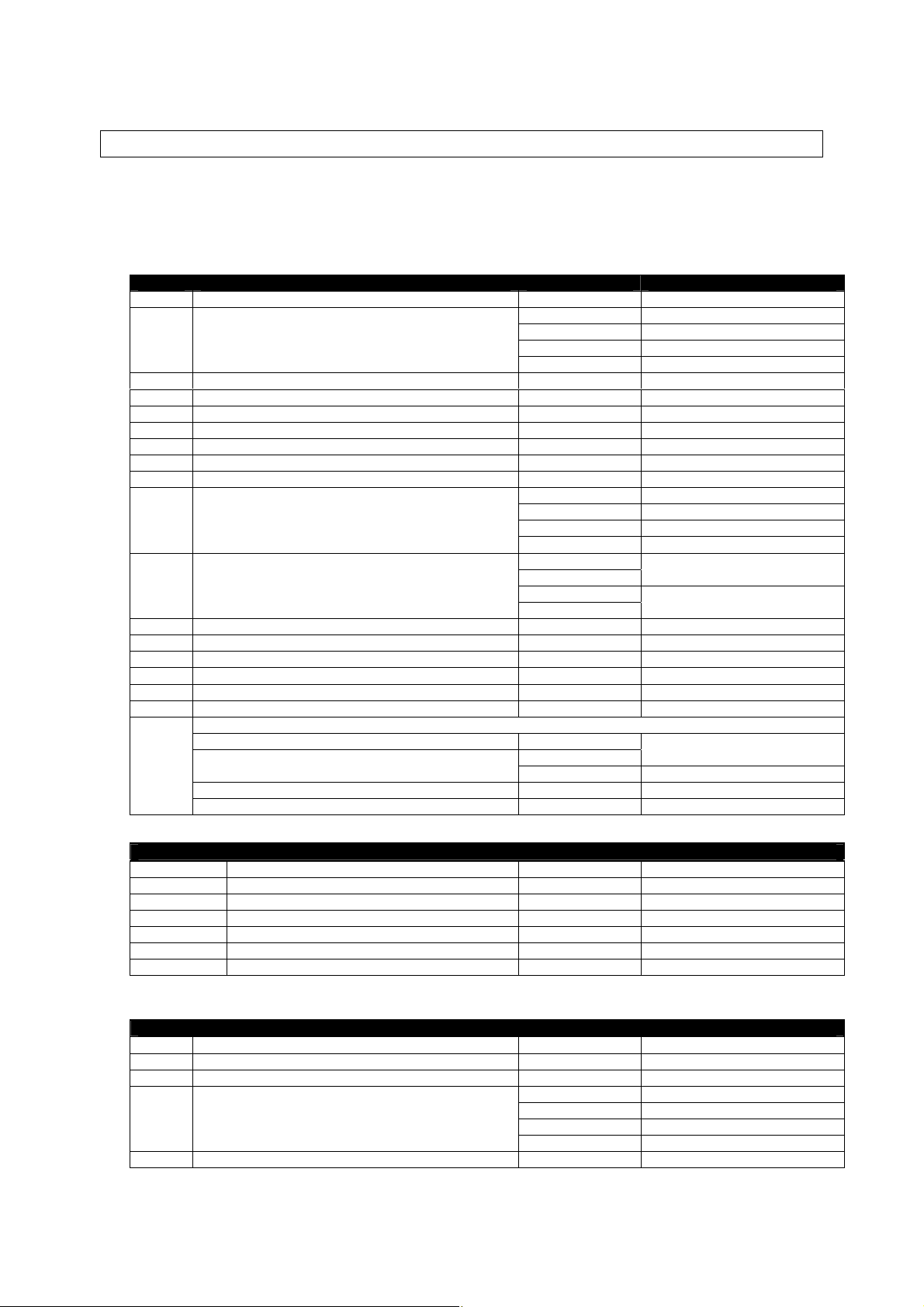

PARTS LIST

MODEL NO.: CH0030SQB

CH0036SQB

CH0042SQB

CH0048SQB

NO. DESCRIPTION MODEL /SIZE PART NO.

1 Ducting Transition B001-2

2 Hood Casing

3 Control Unit C1-0501-0101

4 Control Board C1-0404-0401-A

5 Halogen Light Unit (12V 20W Max.) C1-0403-0101

6 Motor B001-4.5

7 Lamp Socket Cover C1-0204-2130

8 Lamp Socket C1-0414-0120

9 Safety Screen B001-4.2

10 Capacitor Panel

11 Transformer (Light)

12 Capacitor C1-0401-0120-03

13 Transformer (Motor) C1-0402-A-120-01

14 Processor Board Box C1-0501-0102

15 Processor Board C1-0404-0401-B

16 Screw (1/8” x 3/8”) C1-0708-0003

17 Baffle Filter B101-2130-15

18

Bottom Casing

A

4” Wide CH0030SQB

4” Wide

B

3” Wide

C

5-1/4” Wide CH0042SQB B101-2142-09

D

4-1/2” Wide CH0048SQB B101-2148-09

CH0030SQB 10-2130

CH0036SQB 10-2136

CH0042SQB 10-2142

CH0048SQB 10-2148

CH0030SQB C1-0201-2130

CH0036SQB C1-0201-2136

CH0042SQB C1-0201-2142

CH0048SQB C1-0201-2148

CH0030SQB

CH0036SQB

CH0042SQB

CH0048SQB

CH0036SQB

CH0036SQB B101-2136-09

C1-0402-0120-4

C1-0402-0120-60

B101-2130-09

BLOWER ASSEMBLY

NO. DESCRIPTION MODEL /SIZE PART NO.

6-1 Screws (3/16” x 3/8”) B001-4.1

6-2 Left Locknut B001-4.3

6-3 Left Squirrel Cage B001-4.4

6-4 Right Squirrel Cage B001-4.6

6-5 Right Locknut B001-4.7

6-6 Air Chamber B001-4.8

(Optional Duct Cover)

ORIGINAL KIT

NO. DESCRIPTION MODEL /SIZE PART NO.

01 Hood-Mounting Bracket C1-0221-0330

02 Screw (3/16” x 3/8”) C1-0707-0001

03 Duct Cover

02 Screw (3/16” x 3/8”) C1-0707-0001

CH0030DC-12 B102-6012-030

CH0036DC-12 B102-6012-036

CH0042DC-12 B102-6012-042

CH0048DC-12 B102-6012-048

18

Page 21

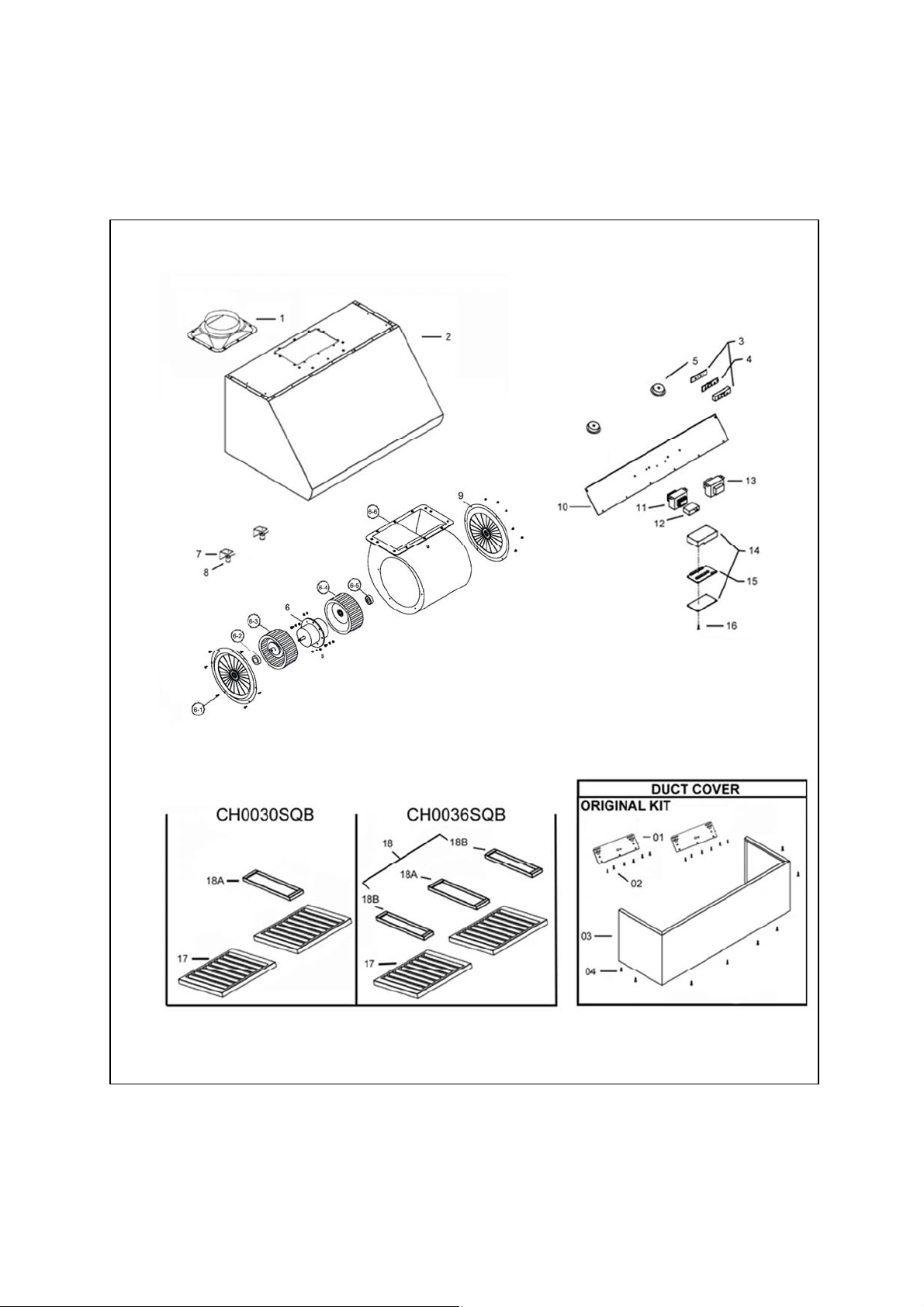

MODEL NO.: CH0030SQB

CH0036SQB

19

Page 22

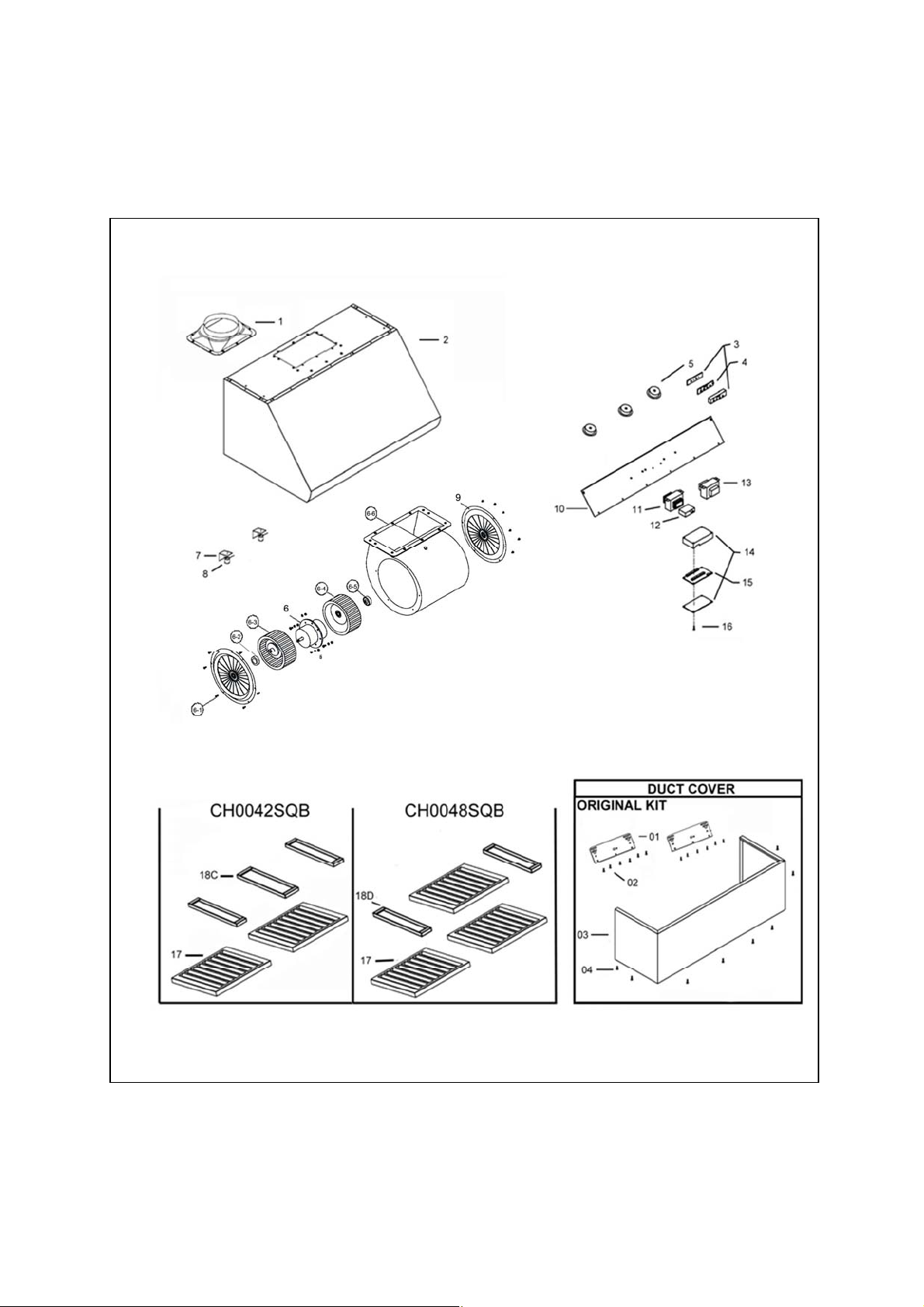

MODEL NO.: CH0042SQB

CH0048SQB

20

Page 23

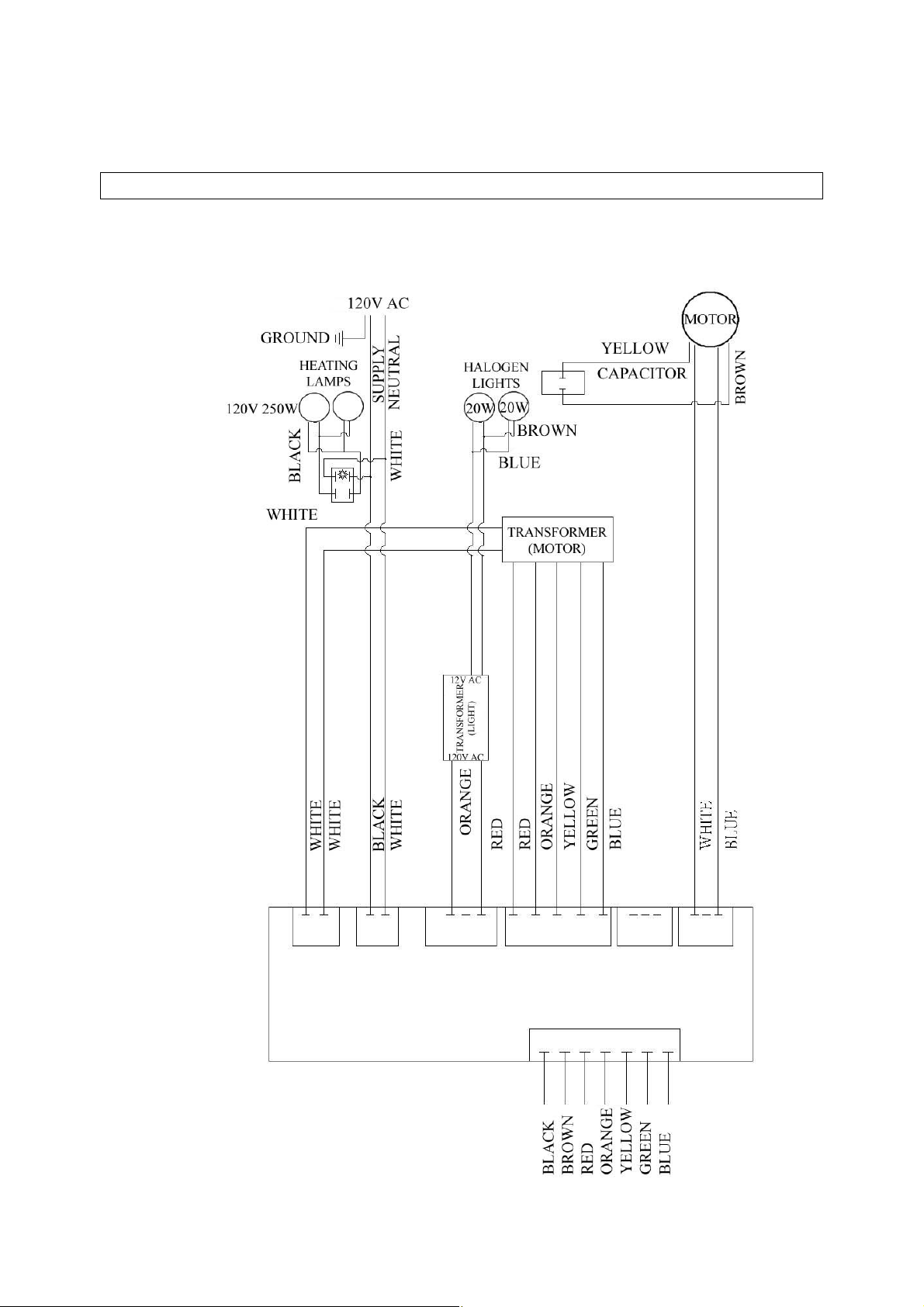

CIRCUIT DIAGRAM

MODEL NO.: CH0030SQB

CH0036SQB

21

Page 24

MODEL NO.: CH0042SQB

CH0048SQB

22

Page 25

TROUBLE SHOOTING

Issue Possible Cause Solution

After Installation,

both motors and

lights are not

working.

The power is not on. Make sure the circuit breaker and the unit’s power is

ON. Use a voltage meter to check the power supply.

The wire connection is not secure. Check and tighten wire connection.

The control panel and processor board

wiring are disconnected.

The motor transformer is defective. Check the power input and power output on the

Check wire continuity from control panel to processor

board.

motor transformer.

If it’s needed, replace the motor transformer.

Lights are

working, but

motor(s) is not.

The range

hood is

vibrating.

The motor is

working, but

the lights are

not working.

The range

hood is not

venting out

correctly.

The control panel and processor board is

defective.

Replace the control panel or processor board.

The motor(s) is defective. Replace the motor.

The capacitor(s) is defective. Replace capacitor(s).

The control panel or processor board is

Replace the control panel or processing board.

defective.

The blower system is not secure. Tighten the turbine impeller/squirrel cage and air

chamber.

The turbine impeller/squirrel cage is

Replace the turbine impeller/squirrel cage.

not balanced.

Hood is not secured in place. Check the installation of hood, tighten the

mounting bracket.

Halogen Light bulb(s) is defective. Try placing the trouble light bulb(s) to a working

socket, if the bulb(s) still doesn’t work; replace

the halogen light bulb(s).

The light wiring(s) is loose. Check wire continuity from processor board to

light transformer to halogen light housing(s).

Light transformer is defective. Check power input and power output on the light

transformer. If it’s needed, replace the light

transformer.

The control panel or processor board is

Replace the control panel or processing board.

defective.

The range hood is installed outside of

the manufacture recommended

clearance.

Adjust the clearance between the range hoods

and cook top to 27” to 30”. For Island range

hood, the clearance between the range hoods

and cook top is 30” to 36”.

There is no make-up air inside the

house.

Open the window to enhance the performance

of the range hood by creating a sufficient make-

up air.

Obstacle blocking the pipe work. Remove all obstacles from the duct work.

Cold air is

coming into the

home.

The pipe size is smaller than the

suggested pipe size.

The pipe connection is not properly

Change the ducting according to the

manufacture suggestion.

Check the pipe installation.

sealed.

The damper is not properly installed or

Check the damper installation.

is missing from the installation.

The damper is not installed. By installing the damper, it will help to eliminate

air backflow.

23

Page 26

DISCLAIMER

1. CAREFULLY INSPECT ALL ITEMS FOR DAMAGES BEFORE ACCEPTING DELIVERY.

NOTE ANY DAMAGES ON THE FREIGHT BILL OR EXPRESS RECEIPT. REQUEST

NAME AND SIGNATURE OF THE CARRIER’S AGENT AND KEEP COPY TO SUPPORT

YOUR CLAIM.

Upon acceptance of items, owner assumes responsibility for its safe arrival. Report

damages to the carrier and file a claim immediately. Failure to do so may result in the denial

of your claim. The carrier will furnish you with necessary forms for filing a claim.

DAMAGES CAUSED DURING TRANSIT ARE NOT COVERED UNDER OUR

WARRANTY.

2. PLEASE INSPECT CONTENTS OF PACKAGE(S) CAREFULLY UPON RECEIVING!

We must be notified in writing of any damages and/or missing parts within the allocated days

upon your receipt of package(s). Contact your local KOBE dealer or distributor or call KOBE

for the time limit.

CLAIMS WILL NOT BE ACCEPTED AFTER THE ALLOCATED DAYS.

NOTE: ITEMS WERE THOROUGHLY TESTED AND CAREFULLY PACKED IN OUR

FACTORY BEFORE SHIPPING.

3. Products must be returned in good working condition with ALL original parts and

documentation packed in ALL original cartons, fillers and shipping cartons. A restocking fee

of 25% will be charged for all approved return(s).

EXCHANGES OR RETURNS MAY NOT BE ACCEPTED IF ANY PACKAGING IS

MISSING.

4. MAKE SURE TO INSPECT THE HOOD FOR DAMAGES AND DEFECTS BEFORE

INSTALLATION. Appearance flaws of the hood found after installation and not affecting

hood performance is not covered under our warranty for returns or exchanges. Service

visits not covered under warranty will carry a service charge.

A)

B)

Before Installation: Return for exchange or refund (please see above for

acceptable returns).

After Installation: NO exchange or refund.

24

Page 27

WARRANTY

WARRANTY CERTIFICATE

KOBE Range Hoods, Inc. warrants all products manufactured or supplied by it to be free from

defects in workmanship and materials. Its obligations pursuant to this warranty are limited to a

period of two years from the date of purchase and to the repair or replacement at its option and

subject to the terms and conditions stated below, of any component part, which its examination

shall disclose to be so defective.

TWO-YEAR WARRANTY SERVICE PERIOD

Any covered failure occurring within two years of original purchase arising from defective

workmanship or material in manufacture will be repaired (or at our discretion, replaced) free of

charge by an authorized KOBE Range Hoods Agent or KOBE Range Hoods as applicable.

Keep proof of purchase (or original invoice) handy for inspection.

If the range hood is sold by the original purchaser during the warranty period the new owner is

protected until expiration of the original purchaser’s warranty.

CONDITIONS

The following conditions apply only in relation to the warranty expressly given in this certificate.

1) This warranty applies only:

a)

within U.S.A. and Canada.

b)

to range hoods used for PRIVATE SINGLE FAMILY USE (if used for COMMERCIAL or

MULTIPLE FAMILY USE or other purposes, warranty will be voided).

2) Repair of any fault to be provided under this warranty shall not be provided:

a)

if the identification number attached to the range hood has been altered, rendered

illegible or removed;

b)

if notice of the defect has not been given within the period applicable;

c)

for failure of light bulbs or heat lamps;

d)

for physical damage;

e)

for surfaces damaged by use of improper chemical cleaning agents;

f)

if the appliance has been:

i) subject to misuse, abuse, negligence, accident, incorrect installation or failure to

follow the operating instructions;

ii) connected to improper, inadequate or faulty electricity service or exhaust ducts, flues

or duct cover, or operated using incorrect or contaminated lubricants;

iii) installed, maintained or operated otherwise than in accordance with the instructions

furnished by KOBE Range Hoods including the improper use of detergents,

bleaches, or cleaners.

g)

for damage to range hood during transit, delivery, installation or removal;

h)

for damage by or resulting from attempted repairs conducted by anyone other than our

Authorized Service Agent.

i)

noise or vibration caused by improper installation of range hood and/or damper.

25

Page 28

3) The purchaser shall be responsible for any expenses involved in making the range hood

readily accessible for servicing and where the range hood is installed outside the main sales

territory of the retailer or service territory of the nearest approved KOBE Range Hoods Agent

as applicable, for any traveling expenses and any costs of transporting the range hood or

parts thereof to and from the dealer or Service Agent

4) The purchaser must produce proof of purchase together with this warranty certificate when

making the claim.

5) Damages caused during shipment are not covered under our warranty.

CONSEQUENTIAL DAMAGE

The warrantor is not responsible for any consequential damage. SOME STATES DO NOT

ALLOW THE EXCLUSION OF CONSEQUENTIAL DAMAGE SO THE ABOVE EXCLUSION

MAY NOT APPLY TO YOU.

IMPLIED WARRANTIES/STATE LAW

Any implied warranties, including the implied warranty of merchantability and fitness for

purpose, imposed on the sale by the laws of the state of sale are limited to two year from the

date of original purchase. Some states do not allow limitations on the duration of implied

warranties. This warranty gives you specific legal rights, and may also have rights, which vary

from state to state.

SERVICE

For service contact:

KOBE Range Hoods

11775 Clark Street

Arcadia, CA 91006

U.S.A.

Tel: 1-877-BUY-KOBE (1-877-289-5623)

Email: customer.service@KOBERangeHoods.com

Website: www.KOBERangeHoods.com

26

Page 29

PRODUCT REGISTRATION

Register Your Product!

Any covered failure occurring within two years of original purchase arising from defective

workmanship or material in manufacture will be repaired or at our option the unit will be

replaced free of charge by an authorized KOBE Range Hoods Agent or KOBE Range

Hoods as applicable. Keep proof of purchase (original invoice) handy for inspection.

If the range hood is sold by the original purchaser during the warranty period the new owner

is protected until expiration of the original purchaser’s warranty. See warranty section for

complete warranty coverage information.

This appliance has been manufactured, tested, and inspected to the standards required by

KOBE Range Hoods.

PLEASE MAIL IN YOUR WARRANTY REGISTRATION CARD AND PROOF OF

PURCHASE TO:

KOBE Range Hoods

11775 Clark Street

Arcadia, CA 91006

U.S.A.

RECORD THE FOLLOWING INFORMATION FOR YOUR RECORD:

Model No. ________________________

Serial No. ________________________

Purchased Date _____/_____/_____

Purchased From:

______________________________

______________________________

______________________________

IMPORTANT: PLEASE KEEP A COPY OF YOUR SALE RECEIPT OR INVOICE HANDY

WHEN REQUESTING FOR SERVICE.

27

Page 30

[FRENCH]

- LIRE ET CONSERVER CES INSTRUCTIONS -

CONTENTS

CONSIGNES DE SÉCURITÉ IMPORTANTES ........................................................................ 29

CONTENU DE L’EMBALLAGE ................................................................................................ 31

INSTALLATION ....................................................................................................................... 32

MODE D'EMPLOI .................................................................................................................... 39

ENTRETIEN PRÉVENTIF........................................................................................................ 40

SPÉCIFICATIONS................................................................................................................... 42

MESURES ET SCHÉMAS ....................................................................................................... 43

LISTE DES PIÈCES................................................................................................................. 45

SCHÉMA DE CÂBLAGE.......................................................................................................... 48

TROUBLE SHOOTING ............................................................................................................ 50

AVIS DE NON-RESPONSABILITÉ.......................................................................................... 51

GARANTIE .............................................................................................................................. 52

ENREGISTREMENT DU PRODUIT......................................................................................... 54

LIRE ATTENTIVEMENT TOUTES LES CONSIGNES AVANT DE

COMMENCER

TOUT LE CÂBLAGE ÉLECTRIQUE DOIT ÊTRE EFFECTUÉ

PAR UN PROFESSIONNEL EN CONFORMITÉ AVEC LES CODES D'ÉLECTRICITÉ LOCAUX ET

NATIONAUX

28

Page 31

CONSIGNES DE SÉCURITÉ IMPORTANTES

SVP LIRE CETTE SECTION ATTENTIVEMENT AVANT L'INSTALLATION

AVERTISSEMENT – AFIN DE RÉDUIRE LES RISQUES D'INCENDIE, DE CHOC

ÉLECTRIQUE ET DE BLESSURES, RESPECTER LES CONSIGNES SUIVANTES :

1) L'installation et le câblage électrique doivent être effectués par des techniciens qualifiés et en

conformité avec tous les codes et toutes les normes qui s'appliquent même pour les constructions

ignifugées.

2) Lorsque vous découpez ou percez un mur ou un plafond, prendre soin de ne pas endommager le

filage électrique ou autres conduits cachés.

3) Les hottes à évacuation doivent être évacuées à l'extérieur.

a) Avant une réparation, un entretien préventif ou un nettoyage, ouvrir le panneau de la lumière

et COUPER LE COURANT ÉLECTRIQUE SUR LE TABLEAU DE DISTRIBUTION.

b) Nettoyer le ventilateur, le filtre optionnel et les surfaces chargées de graisse fréquemment.

Afin de réduire les risques d'incendie et afin de disperser l'air adéquatement, évacuer l'air à

l'extérieur. NE PAS ventiler l'air d'évacuation dans les murs, les greniers, les vides sanitaires

ou les garages.

NOTE: La garantie de cet appareil sera nulle sans le reçu d'un distributeur autorisé de KOBE

l'appareil est endommagé par une utilisation inadéquate, une installation déficiente, un usage

inapproprié, un mauvais traitement, de la négligence ou par toute autre circonstance

échappant au contrôle des distributeurs autorisés de KOBE

la supervision d'un agent autorisé de KOBE

KOBE

®

annulera automatiquement la garantie.

®

se dégage de toute responsabilité face à des dommages à la propriété personnelle ou

®

. Toute réparation effectuée sans

aux biens immeubles ou encore à des blessures corporelles causées directement ou

indirectement par la hotte de cuisinière.

AVERTISSEMENT– AFIN DE RÉDUIRE LES RISQUES DE BLESSURES CORPORELLES

DANS L'ÉVENTUALITÉ D'UN INCENDIE DE GRAISSE SE DÉCLARANT SOUS LA HOTTE

DE CUISINIÈRE :

-

Tenir toujours propres le ventilateur, les filtres déflecteurs, s'il y en a, et les surfaces chargées de

graisse.

-

Toujours faire fonctionner la hotte lors d'une cuisson à température élevée.

-

Utiliser les vitesses élevées de la hotte UNIQUEMENT lorsque nécessaire. Chauffer l'huile

lentement aux réglages de basses ou de moyennes vitesses.

-

Ne pas laisser la cuisinière sans surveillance lors de la cuisson.

-

Toujours utiliser les articles de cuisson et les ustensiles appropriés au type et à la quantité

d'aliments préparés.

-

Utiliser l'appareil seulement pour l'usage auquel le fabricant l'a destiné.

-

Avant l'entretien courant, couper l'alimentation électrique au tableau de distribution principal et

verrouiller ce dernier (si possible) pour éviter une mise en marche accidentelle.

-

Nettoyer les ventilateurs fréquemment. La graisse ne doit pas s'accumuler sur les ventilateurs et les

déflecteurs.

®

ou si

29

Page 32

Que faire en cas d'un incendie de graisse sur la cuisinière

• ÉTOUFFER LES FLAMMES à l'aide d'un couvercle hermétique, une plaque à biscuits ou un

plateau métallique, puis fermer le rond ou le brûleur. GARDER LES MATÉRIAUX

INFLAMMABLES OU COMBUSTIBLES LOIN DES FLAMMES. Si les flammes ne s'éteignent pas

immédiatement, ÉVACUER LA ZONE ET APPELER LE SERVICE D'INCENDIE ou le 911.

• NE JAMAIS SOULEVER UNE CASSEROLE EN FEU - Il y a risque de brûlure.

• NE PAS UTILISER D'EAU incluant serviettes ou linges à vaisselle mouillés - cela provoquerait un

violent jet de vapeur.

• Utiliser un extincteur SEULEMENT si:

a) vous possédez un extincteur de classe A, B ou C et si vous savez vous en servir ;

b) le feu est petit et est contenu dans la zone de départ ;

c) vous avez appelé le service d’incendie ;

d) vous pouvez combattre le feu le dos près d'une sortie.

Que faire si une odeur de gaz se dégage

• Éteindre toute flamme nue.

• Ne pas essayer d'allumer des lumières ou tout type d'appareil électroménager.

• Ouvrir toutes les portes et fenêtres afin de chasser le gaz. Si une odeur de gaz est toujours

perceptible, appeler votre fournisseur de gaz ainsi que le service d'incendie immédiatement.

ATTENTION !

1) Cette hotte doit être utilisée UNIQUEMENT pour une ventilation normale. Ne pas s'en servir pour

évacuer des substances et vapeurs dangereuses ou explosives.

2) Afin de réduire les risques d'incendie, employer seulement des gaines ou conduits de métal.

3) Suivre les directives et les consignes de sécurité des fabricants d'équipement de chauffage

comme celles publiées par le National Fire Protection Association (NFPA) et l'American Society

for Heating, Refrigeration and Air Conditioning Engineers (ASHRAE) de même que les codes

nationaux et locaux. L'activation de tout interrupteur peut provoquer une mise à feu ou une

explosion.

RISQUE DE CHOC ÉLECTRIQUE - Pouvant entraîner la mort ou

des blessures graves. Couper l'alimentation électrique à

l'appareil avant tout entretien ou toute réparation. Si la hotte

est munie d'une ampoule fluorescente, cette dernière contient

une petite quantité de mercure et, en conséquence, elle doit

être recyclée ou éliminée conformément aux codes locaux,

provinciaux et fédéraux qui s'appliquent

30

Page 33

CONTENU DE L’EMBALLAGE

(Pour tout retour ou remboursement conserver le matériel ainsi que l’emballage

d’origine)

Boîte de la hotte de cuisinière

Hotte de cuisinière KOBE – 1

Fiche d'enregistrement à la garantie –1

Notice d'installation et mode d'emploi – 1

Filtre déflecteur

- 2 (pour hotte de 30, 36 et 42 po)

- 3 (pour hotte de 48 po)

Panneau pare-éclaboussures

- 1 (pour hotte de 30 po)

- 3 (pour hotte de 36 po et 42 po)

- 2 (pour hotte de 48 po)

Récupérateur de graisse – 1

Ducting Transition – 1

Ensemble de vis – 1

Support de fixation - hotte -2

Ensemble de vis –1

Trousse initiale

(vendu séparément)

En option:

o

N

de modèle CH0030DC-12

pour hotte de 30 po

Couvre-conduit KOBE – 1

Ensemble de vis – 1

Support de fixation - hotte -2

o

de modèle CH0036DC-12

N

pour hotte de 36 po

Couvre-conduit KOBE – 1

Ensemble de vis – 1

Support de fixation - hotte -2

o

de modèle CH0042DC-12

N

pour hotte de 42 po

Couvre-conduit KOBE – 1Ensemble de vis – 1

Ensemble de vis – 1

Support de fixation - hotte -2

o

N

de modèle CH0048DC-12

pour hotte de 48 po

Couvre-conduit KOBE – 1

Ensemble de vis – 1

Support de fixation - hotte -2

• POUR DE PLUS AMPLES RENSEIGNEMENTS, VEUILLEZ VISITER NOTRE SITE WEB

www.KOBERangeHoods.com

OU COMMUNIQUER AVEC KOBE RANGE HOODS AU (626) 775-8880.

3/16" X 3/8" (8 pc)

31

Page 34

INSTALLATION

SVP LIRE AU COMPLET AVANT L'INSTALLATION

Mesures à prendre avant l'installation

Calculer la longueur de l'installation avant d'installer la hotte. (Toutes les mesures sont données en

pouces).

HOTTE INSTALLÉE SOUS UNE ARMOIRE

TABLEAU 1

A = Hauteur entre le plancher et le plafond

B = Hauteur entre le plancher et le plan de travail

(hauteur standard : 36 po)

C = Hauteur désirée entre le plan de travail

et le dessous de la hotte

(Dégagement recommandé : de 27 à 30 po)

D = Hauteur de la hotte

E = Hauteur de l'armoire

HOTTE INSTALLÉE AU-DESSUS D'UN ÎLOT

(AVEC COUVRE-CONDUIT EN OPTION)

TABLEAU 2

A = Hauteur entre le plancher et le plafond

B = Hauteur entre le plancher et le plan de travail

(hauteur standard: 36 po)

C = Hauteur désirée entre le plan de travail

et le dessous de la hotte

(dégagement recommandé : de 27 à 30 po)

[(A - B) - (D + E)]

D = Hauteur de la hotte

E = Hauteur du couvre-conduit

32

Page 35

CONSIGNES DE SÉCURITÉ

LES HOTTES PEUVENT AVOIR DES BORDS TRÈS TRANCHANTS ; PORTER DES GANTS DE

PROTECTION SI NÉCESSAIRE POUR RETIRER DES PIÈCES LORS DE L'INSTALLATION, DU

NETTOYAGE, DE L'ENTRETIEN ET DES RÉPARATIONS.

NOTE : FAIRE PREUVE DE PRÉCAUTION EN UTILISANT UN TOURNEVIS ÉLECTRIQUE

PUISQUE CE DERNIER RISQUE D'ENDOMMAGER LA HOTTE.

Description des divers types d'installation

INSTALLATION SOUS UNE ARMOIRE .............................................................................................. 34

INSTALLATION SOUS UN ÎLOT ......................................................................................................... 36

33

Page 36

INSTALLATION SOUS UNE ARMOIRE

Préparation avant l'installation

NOTE : AFIN DE PRÉVENIR TOUT DOMMAGE À LA HOTTE, IL

FAUT EMPÊCHER LES DÉBRIS DE PÉNÉTRER DANS

L'OUVERTURE DE VENTILATION.

Choisir l'emplacement du conduit de ventilation de la hotte

vers l'extérieur. Voir Photo 1.

Un conduit court et droit permet de maximiser le

rendement de la hotte.

Essayer d'éviter autant que possible les raccords, les

coudes et les longues sections de conduit puisque ceux-ci

peuvent réduire le rendement de la hotte.

Avant de l'installer, brancher la hotte temporairement pour

vérifier si son fonctionnement est adéquat.

Important : enlever la pellicule protectrice de la hotte

(s'il y a lieu).

Si le fond de l'armoire est en retrait, fixer un morceau de

bois de 4 po de largeur (non inclus) de chaque côté. Voir

photo 2.

Mesurer et découper un orifice permettant l'accès du

filage électrique sous l'armoire.

Photo 1

Installation de la hotte

AVERTISSEMENT : S'il faut déplacer une cuisinière

électrique pour installer la hotte, couper d'abord

l'alimentation électrique à cette cuisinière par le tableau

de distribution principal. COUPER LE GAZ AVANT DE

DÉPLACER UNE CUISINIÈRE À GAZ.

1. Perforer les trous défonçables de la hotte comme illustré à

la photo 3.

2. Utiliser un tuyau d'aluminium ou d'acier pour raccorder

l'évent de sortie en plastique de la hotte au réseau de

conduits au-dessus. Utiliser du ruban adhésif entoilé

d'aluminium pour rendre les raccords sécuritaires et

hermétiques. Voir Figure 4.

3. À l'aide des références du Tableau 1 et des mesures aux

pages 43, centrer la hotte en place en-dessous de

l'armoire et à égalité avec le devant de l'armoire.

4. Tirer les fils électriques à travers l'ouverture dans

l'armoire.

5. Par le fond de la hotte, placer une vis (non fournie)

exactement au centre de chacun des trous défonçables.

S'assurer que toutes les vis sont bien en place avant de

les visser solidement. AVERTISSEMENT : S'ASSURER

QUE LA HOTTE EST FIXÉE SOLIDEMENT AVANT DE

LA LÂCHER.

6. Par mesure de précaution, des trous défonçables

supplémentaires sont fournis à l'endos de la hotte. Pour

une installation plus solide, défoncer le nombre de trous

nécessaires et visser de l'intérieur de la hotte les vis

requises.

Photo 2

Photo 3

Photo 4

34

Page 37

R

ACCORDEMENT AU RÉSEAU DE CONDUITS

7. Utiliser un tuyau d'aluminium ou d'acier de 8 po (respecter

les codes du bâtiment de votre région) pour réunir le

conduit de transition de la hotte au réseau de conduits audessus. Utiliser du ruban adhésif entoilé d'aluminium pour

rendre les raccords sécuritaires et hermétiques. Voir

Photo 5.

B

RANCHEMENT À L'ALIMENTATION ÉLECTRIQUE

CONSIGNE DE SÉCURITÉ

RISQUE DE CHOC ÉLECTRIQUE. CETTE HOTTE DE

CUISINIÈRE DOIT ÊTRE MISE À LA TERRE

ADÉQUATEMENT. CE TRAVAIL DOIT ÊTRE EXÉCUTÉ

PAR UN ÉLECTRICIEN PROFESSIONNEL EN

CONFORMITÉ AVEC TOUS LES CODES D'ÉLECTRICITÉ

LOCAUX ET NATIONAUX QUI S'APPLIQUENT. AVANT DE

BRANCHER DES FILS, COUPER LE COURANT

ÉLECTRIQUE AU TABLEAU DE DISTRIBUTION

PRINCIPAL ET VERROUILLER CE DERNIER POUR

ÉVITER QUE LE COURANT SOIT REMIS

ACCIDENTELLEMENT.

8. Branchement des fils électriques.

- Raccorder les trois fils (noir, blanc et vert) aux fils de

la maison et couvrez-les avec des capuchons de

connexion. Raccorder les fils selon la couleur: noir

avec noir, blanc avec blanc et vert avec vert. Voir

Photo 6.

- S'assurer que les fils ne glissent pas entre le moteur

et toute autre pièce en mouvement en les enfonçant

adéquatement dans la boîte électrique.

I

NSTALLATION DES ACCESSOIRES

Photo 5

Photo 6

Photo 7

9. Fixer le récupérateur à graisse. Voir photo 7.

10. Voir photo 8. 1) Faire glisser le filtre déflecteur dans la

hotte. 2) Pousser le filtre déflecteur vers le haut. 3) Le

glisser vers l'avant. 4) Le tirer vers le bas. 5) Bien

l'insérer en place.

11. Pour le panneau pare-éclaboussures (inférieur), répéter

les étapes précédentes. Voir en page 44.

12. Installer les lampes chauffantes (non fournies) 120 V,

250 W maximum pour chacune.

A

SSEMBLAGE FINAL

13. Démarrer la hotte par la commande marche/arrêt. Vérifier

le fonctionnement de toutes les lampes et du ventilateur.

14. Remettre ce manuel au propriétaire pour consultation

future.

35

Photo 8

Page 38

INSTALLATION SOUS UN ÎLOT

*** Cette installation est possible uniquement avec l'achat

d'un couvre-conduit optionnel.

P

RÉPARATION AVANT L'INSTALLATION

NOTE: AFIN DE PRÉVENIR TOUT DOMMAGE À LA

HOTTE, IL FAUT EMPÊCHER LES DÉBRIS DE PÉNÉTRER

DANS L'OUVERTURE DE VENTILATION.

Choisir l'emplacement du conduit de ventilation de la hotte

à l'extérieur. Voir Photo 9.

Un conduit court et droit permet de maximiser le

rendement de la hotte.

Essayer d'éviter autant que possible les raccords, les

coudes et les longues sections de conduit puisque ceux-ci

peuvent réduire le rendement de la hotte.

Utiliser du ruban adhésif entoilé d'aluminium pour sceller

les raccords entre les sections de tuyau.

Si nécessaire, renforcer le mur arrière en y ajoutant du

bois de charpente pour une installation sécuritaire.

À l'aide des références du Tableau 2 et des mesures et

schémas aux pages 43-44, déterminer la hauteur du

soutien de bois supplémentaire. Voir Photo 10.

P

RÉPARATION DE LA HOTTE AVANT L'INSTALLATION

Photo 9

• Avant de l'installer, brancher la hotte temporairement

pour vérifier si son fonctionnement est adéquat.

• Important : enlever la pellicule protectrice de la hotte et du

couvre-conduit (s'il y a lieu).

• Fixer le conduit de transition à l'évent de sortie de la

hotte à l'aide des dix vis (3/16 po x 3/8 po) fournies. Voir

photo 11.

• Si requis, fixer deux cales de caoutchouc (fournies) à

l'aide de deux vis 4 x 8 mm (fournies) à l'endos de la

hotte.

• Fixer les deux supports de fixation de la hotte à l'arrière

de la hotte à l'aide des huit vis 3/16 po x 3/8 po (fournies)

comme illustré à la photo 12.

I

NSTALLATION DE LA HOTTE

AVERTISSEMENT : S'il faut déplacer une cuisinière

électrique pour installer la hotte, couper d'abord l'alimentation

électrique à cette cuisinière par le tableau de distribution

principal. COUPER LE GAZ AVANT DE DÉPLACER UNE

CUISINIÈRE À GAZ.

1. À l'aide des références du Tableau 2 et des mesures et

schémas aux pages 43-44, marquer les repères de mise à

niveau de la hotte. Fixer deux vis (non fournies) au mur en

laissant un jeu de 1/8 po du mur comme illustré à la Photo

13.

Photo 10

Photo 11

Photo 12

36

Page 39

2. Aligner le support de fixation de la hotte aux deux vis au

mur et accrocher la hotte en place. Serrer les vis pour

bien fixer la hotte au mur.

3. Par mesure de précaution, des trous défonçables

supplémentaires sont fournis à l'endos de la hotte. Pour

une installation plus solide, défoncer le nombre de trous

nécessaires et visser de l'intérieur de la hotte les vis

requises.

AVERTISSEMENT : S'ASSURER QUE LA HOTTE

EST BIEN FIXÉE AVANT DE LA LÂCHER.

WALL

Photo 13

B

RANCHEMENT À L'ALIMENTATION ÉLECTRIQUE

CONSIGNE DE SÉCURITÉ

RISQUE DE CHOC ÉLECTRIQUE. CETTE HOTTE DE

CUISINIÈRE DOIT ÊTRE MISE À LA TERRE

ADÉQUATEMENT. CE TRAVAIL DOIT ÊTRE EXÉCUTÉ

PAR UN ÉLECTRICIEN PROFESSIONNEL EN

CONFORMITÉ AVEC TOUS LES CODES D'ÉLECTRICITÉ

LOCAUX ET NATIONAUX QUI S'APPLIQUENT. AVANT DE

BRANCHER DES FILS, COUPER LE COURANT

ÉLECTRIQUE AU TABLEAU DE DISTRIBUTION

PRINCIPAL ET VERROUILLER CE DERNIER POUR

ÉVITER QUE LE COURANT SOIT REMIS

ACCIDENTELLEMENT.

4. Branchement des fils électriques.

-

Raccorder les trois fils (noir, blanc et vert) aux fils de

la maison et couvrez-les avec des capuchons de

connexion. Raccorder les fils selon la couleur: noir

avec noir, blanc avec blanc et vert avec vert. Voir

Photo 6.

-

S'assurer que les fils ne glissent pas entre le moteur

et toute autre pièce en mouvement en les enfonçant

adéquatement dans la boîte électrique.

Photo 14

Photo 15

37

Page 40

R

ACCORDEMENT AU RÉSEAU DE CONDUITS

5. Utiliser un tuyau d'aluminium ou d'acier de 8 po (respecter

les codes du bâtiment de votre région) pour raccorder le

conduit de transition de la hotte au réseau de conduits audessus. Utiliser du ruban adhésif entoilé d'aluminium pour

rendre les raccords sécuritaires et hermétiques. Voir

Photo 15. Glisser le couvre-conduit sur la hotte.

6. Utiliser des vis 3/16 po x 3/8 po (fournies) pour fixer le

couvre-conduit à la hotte.

I

NSTALLATION DES ACCESSOIRES

7. Fixer le récupérateur à graisse. Voir photo 16.

8. Voir photo 17. 1) Faire glisser le filtre déflecteur dans la

hotte. 2) Pousser le filtre déflecteur vers le haut. 3) Le

glisser vers l'avant. 4) Le tirer vers le bas. 5) Bien l'insérer

en place.

9. Pour le panneau pare-éclaboussures (inférieur), répéter

les étapes précédentes. Voir en page 44.

10. Installer les lampes chauffantes (non fournies) 120 V,

175 W maximum pour chacune.

Photo 16

A

SSEMBLAGE FINAL

11. Démarrer la hotte par la commande marche/arrêt. Vérifier

le fonctionnement de toutes les lampes et du ventilateur.

12. Remettre ce manuel au propriétaire pour consultation

future.

Photo 17

38

Page 41

MODE D'EMPLOI

Cette hotte de cuisinière KOBE

retardement de 3 minutes, un puissant ventilateur centrifuge à pales (cage d'écureuil) avec

filtres déflecteurs, des lampes halogènes 12 volts, 20 watts et l'ajout possible de lampes

chauffantes (non fournies).

L'écran tactile comporte quatre commandes électroniques: la commande des lampes

chauffantes « Heat Lamp», la commande des lampes halogènes « Light Control », la

commande des vitesses« Speed Control » ( cycles bas, moyen, élevé et QuietMode

commande marche/arrêt « Power Control » . Voir Photo 18.

(Commande des lampes)

(Commande de vitesses A) (Commande de vitesse B)

MISE EN MARCHE

®

possède un écran tactile muni d'un dispositif d’arrêt à

TM

) et la

(Commande marche /arrêt)

Photo 18

ARRÊT

•

Presser une fois sur le bouton marche/arrêt.

(Note : Si aucun des autres boutons n'est enfoncé en-dedans de 10 secondes, la

hotte se fermera automatiquement.)

•

La hotte KOBE® démarre à basse vitesse. Chaque fois que la commande de

vitesses est enfoncée, le cycle passe à la vitesse suivante.

•

Presser sur le bouton de commande de vitesses A pour enclencher le cycle

bas, moyen, élevé ou QuietMode ™.

•

Presser sur le bouton de commande de vitesses B pour enclencher le cycle

bas, QuietMode™, élevé ou moyen.

(Note : Les commandes de vitesses A ou B mettront en marche les deux

ventilateurs. Ces deux boutons de vitesses vous permettront cependant de changer

de vitesse plus rapidement.)

•

Presser sur le bouton de commande des lampes pour allumer les lampes

halogènes.

•

Press the back Red button to turn on heating lamp.

(Note: Heating lamps are sold separately. Heating lamps required 120-volt,

175-watt.)

•

Presser une fois sur le bouton marche/arrêt, les lampes vont clignoter et le

courant sera coupé entièrement après 30 secondes.

OU

•

Presser deux fois sur le bouton marche/arrêt, le courant se coupera

immédiatement.

•

Si seules les lampes sont allumées, en pressant une fois sur le bouton

marche/arrêt, le courant se fermera après 30 secondes.

39

Page 42

ENTRETIEN PRÉVENTIF

Pour favoriser un rendement optimal, nettoyer régulièrement les surfaces de la hotte et les

filtres déflecteurs.

N

ETTOYAGE DES SURFACES DE LA HOTTE

AVERTISSEMENT : NE JAMAIS EMPLOYER DE NETTOYANTS OU LINGES ABRASIFS,

OU ENCORE DE LAINES À RÉCURER.

*** Un entretien fréquent aidera à conserver une belle apparence à la hotte.

1. Utiliser seulement du savon doux ou du détergent. Sécher les surfaces avec un chiffon

doux.

2. Si la hotte est tachée (hotte en acier inoxydable), utiliser un nettoyant à base d'agrume

pour nettoyer les surfaces. Éviter de mettre du nettoyant sur les boutons de

commande. Étendre une petite quantité sur les surfaces et laisser reposer quelques

minutes (ne pas laisser trop longtemps car cela pourrait endommager le fini de la

hotte). À l'aide d'un chiffon doux, enlever la solution nettoyante et frotter doucement

les taches rebelles. Utiliser un chiffon légèrement humide pour enlever tout résidu de

solution nettoyante. Sécher la hotte avec un chiffon doux.

3. Pour redonner du brillant au fini en acier inoxydable, utiliser un nettoyant pour acier

inoxydable.

4. NE PAS laisser les dépôts s'accumuler durant de longues périodes de temps.

5. NE PAS utiliser de laines ou de brosses à récurer ordinaires. Des particules d'acier

peuvent adhérer à la surface et la faire rouiller.

6. NE PAS permettre à des solutions salines, des désinfectants, des javellisants ou des

agents nettoyants de rester en contact avec l'acier inoxydable durant de longues

périodes. Plusieurs de ces nettoyants contiennent des produits chimiques pouvant

endommager l'acier inoxydable. Après tout contact de ce type, rincer à l'eau et

essuyer avec un chiffon doux.

ETTOYAGE DES FILTRES DÉFLECTEURS ET DU RÉCUPÉRATEUR À GRAISSE

N

AVERTISSEMENT : VIDER LES FILTRES DÉFLECTEURS ET LE RÉCUPÉRATEUR À

GRAISSE AVANT QU'IL N'Y AIT TROP D'ACCUMULATION.

1. Retirer les filtres déflecteurs et le récupérateur à graisse.

2. À l'aide d'une éponge, laver dans une eau chaude savonneuse. Sécher entièrement

avant de remettre en place.

(Note : les filtres peuvent être nettoyés en toute sécurité dans le haut du lave-vaisselle)

40

Page 43

EMPLACEMENT D'UNE AMPOULE

R

AVERTISSEMENT : LA LAMPE HALOGÈNE PEUT ÊTRE BRÛLANTE ! ATTENDRE

QU'ELLE SE REFROIDISSE AVANT DE PROCÉDER.

1. S'assurer que toutes les commandes sont en mode ARRÊT et que la hotte de cuisinière

est débranchée.

2. Glisser le tournevis à tête plate dans l'espace entre la plaque de verre et le boîtier de la

lampe.

3. Retirer la plaque de verre.

4. En douceur, tirer sur l'ampoule défaillante pour l'enlever et la jeter. Les ampoules à

utiliser doivent être de 12 V et de 20 W au maximum.

5. À l'aide d'un linge, tenir la nouvelle ampoule et la pousser fermement dans la douille.

6. Remettre la plaque de verre par-dessus le boîtier.

7. Brancher la hotte de cuisinière pour en vérifier le fonctionnement.

41

Page 44

SPÉCIFICATIONS

MODÈLE / FORMAT

COULEUR

CONSOMMATION

VOLTAGE

NOMBRE DE MOTEURS

DESIGN

TYPE DE VENTILATEUR

ÉVACUATION

COMMANDES

LAMPES HALOGÈNES

DIMENSIONS DE LA HOTTE

(LARGEUR X PROFONDEUR X HAUTEUR)

ACCESSOIRES EN OPTION

(LARGEUR X PROFONDEUR X HAUTEUR)

CH0030SQB / 30”

CH0036SQB / 36"

CH0042SQB / 42”

CH0048SQB / 48”

Acier inoxydable de qualité commerciale

CH0030SQB – 300W / 2.68A

CH0036SQB – 300W / 2.68A

CH0042SQB – 320W / 2.86A

CH0048SQB – 320W / 2.86A

120V 60Hz

1

Fini satiné sans joints de calibre 18

Squirrel Cage

1 conduit de transition rectangulaire supérieure à un évent

rond de 8 po

Commandes électroniques (4 boutons) –

Démarrage avec garde de 10 secondes

Dispositif d'arrêt à retardement de 30 secondes

12V 20W x 2 – 30”, 36”

12V 20W x 3 – 42”, 48”

(CH0030SQB) 29-3/4” x 24” x 18”

(CH0036SQB) 35-3/4” x 24” x 18”

(CH0042SQB) 41-3/4” x 24” x 18”

(CH0048SQB) 47-3/4” x 24” x 18”

1) Original Kit - Duct Cover:

o

N

de modèle CH0030DC-12 - 30 po x 12 po x 12 po

o

de modèle CH0036DC-12 - 36 po x 12 po x 12 po

N

o

de modèle CH0042DC-12 - 42 po x 12 po x 12 po

N

o

de modèle CH0048DC-12 - 48 po x 12 po x 12 po

N

o

de modèle SSP30

2) N

Panneau arrière en acier inoxydable 30 po

30 po x 1/10 po x 32 po

o

de modèle SSP36

3) N

Panneau arrière en acier inoxydable 36 po

36 po x 1/10 po x 32 po

Net

(CH0030SQB)

POIDS DE LA HOTTE (lb)

(CH0036SQB)

(CH0042SQB)

(CH0048SQB)

VITESSE

Capacité d'air (cfm)

Sone*

* Un sone équivaut au son d'un réfrigérateur à 40 décibels.

** Les spécifications sont sujettes à changement sans préavis.

QuietMode™

400 600 800 1000

1.4* 3.5 7.0 8.0

42

Gross

66.0 84.0

73.0 93.0

84.0 106.0

90.5 115.0

Basse Moyenne High

Page 45

MESURES ET SCHÉMAS

Toutes les mesures entre parenthèses sont en millimètres.

Toutes les mesures en pouces sont converties à partir de millimètres. Les

mesures en pouces sont estimées.

INSTALLATION SOUS UNE ARMOIRE

o

N

DE MODÈLE CH0030SQB

CH0036SQB

CH0042SQB

CH0048SQB

INSTALLATION AU-DESSUS D'UN ÎLOT

o

N

DE MODÈLE CH0030SQB

CH0036SQB

CH0042SQB

CH0048SQB

43

Page 46

INSTALLATION AU-DESSUS D'UN ÎLOT

(AVEC COUVRE-CONDUIT EN OPTION)

*** T

ROUS DÉFONÇABLES À L'ARRIÈRE

*** Support de fixation de la hotte

FILTRES DÉFLECTEURS ET

INTERCALAIRES EN ACIER

INOXYDABLE

44

Page 47

LISTE DES PIÈCES

Nos de modèles: CH0030SQB, CH0036SQB, CH0042SQB, CH0048SQB

o

N

DESCRIPTION MODÈLE/FORMAT NO DE PIÈCE

1 Conduits de transition B001-2

Caisson de la hotte

2

3

Bloc de contrôle

Tableau de commandes

4

Lampe halogène (12 V, 20 W max.)

5

Moteur

6

7 Douille couverture C1-0204-2130

8 Douille C1-0414-0120

Grille de protection

9

Condensateur

10

Transformateur (lampe)

11

12

Condensateur

13

Transformateur ( Moteur

Boîtier du processeur

14

Process eur

15

16

Vis

(1/8” x 3/8”) C1-0708-0003

Filtres à chicane

17

18

Panneaux de finition

A

4”

po de largeur

4”

B

C

D

po de largeur

3”

po de largeur

5-1/4”

4-1/2”

po de largeur

po de largeur

) C1-0402-A-120-01

CH0042SQB B101-2142-09

CH0048SQB B101-2148-09

CH0030SQB 10-2130

CH0036SQB 10-2136

CH0042SQB 10-2142

CH0048SQB 10-2148

C1-0501-0101

C1-0404-0401-A

C1-0403-0101

B001-4.5

B001-4.2

CH0030SQB C1-0201-2130

CH0036SQB C1-0201-2136

CH0042SQB C1-0201-2142

CH0048SQB C1-0201-2148

CH0030SQB

C1-0402-0120-4

CH0036SQB

CH0042SQB

C1-0402-0120-60

CH0048SQB

C1-0401-0120-03

C1-0501-0102

C1-0404-0401-B

B101-2130-15

CH0030SQB

B101-2130-09

CH0036SQB

CH0036SQB B101-2136-09

VENTILATEUR ASSEMBLÉE

No DESCRIPTION MODÈLE/FORMAT NO DE PIÈCE .

6-1

Vis

(3/16” x 3/8”) B001-4.1

6-2 Contre-écrou gauche B001-4.3

6-3 Aube inclinée gauche B001-4.4

6-4 Aube inclinée droite B001-4.6

6-5 Contre-écrou droite B001-4.7

6-6

Boîtier de moteur

B001-4.8

(Facultatif Couvre-conduit)

ORIGINAL KIT

No DESCRIPTION MODÈLE/FORMAT NO DE PIÈCE

01 Support de fixation de la hotte C1-0221-0330

02

03

Vis

(3/16” x 3/8”) C1-0707-0001

Couvre-conduit

CH0030DC-12 B102-6012-030

CH0036DC-12 B102-6012-036

CH0042DC-12 B102-6012-042

CH0048DC-12 B102-6012-048

02

Vis

(3/16” x 3/8”) C1-0707-0001

45

Page 48

os

de modèles CH0030SQB

N

CH0036SQB

46

Page 49

os

de modèles CH0042SQB

N

CH0048SQB

47

Page 50

SCHÉMA DE CÂBLAGE

Nos de modèles CH0030SQB

CH0036SQB

48

Page 51

Nos de modèles CH0042SQB

CH0048SQB

49

Page 52

TROUBLE SHOOTING

Problème Cause probable Solution

Après

l’installation,

les deux

moteurs et

les lumières ne

fonctionnent

pas.

Les lumières

fonctionnent,

mais pas le(s)

moteur(s).

La hotte de

cuisine vibre.

Le moteur

fonctionne,

mais pas les

lumières.

La hotte de

cuisine

ne ventile pas

correctement.

De l’air froid

entre dans la

maison.

Pas d’alimentation électrique. Assurezvous que le disjoncteur et que

l’alimentation électrique

soient en marche.

Le câblage n’est pas bien installé. Vérifiez et serrez les connexions de fils.

Le câblage du panneau de commande et

de la carte processeur est débranché.

Le transformateur du moteur est

défectueux

Le panneau de commande ou la carte

processeur est défectueux.

Le(s) moteur(s) est (sont) défectueux. Remplacez le(s) moteur(s).

Le(s) condensateur(s) est (sont)

défectueux.

Le panneau de commande ou la carte

processeur est défectueux.

Le système de ventilation n’est pas bien

installé.

La pale turbine/cage écureuil n’est pas

bien balancée.

La hotte n’est pas assez bien serrée. Vérifiez l’installation de la hotte, serrez

L’ampoule de la lampe halogène est

défectueuse.

Le câblage de la lampe n’est pas assez

serré.

Le transformateur de la lumière est

défectueux.

Le panneau de commande ou la carte

processeur est défectueux.

La hotte de cuisine est installée hors des

limites recommandées par le fabricant.

Il n’y a pas d’air d’appoint à l’intérieur de la

maison.

Un obstacle bloque la canalisation. Enlevez tous les obstacles de la canalisation.

La canalisation est plus petite que la

canalisation suggérée.

La connexion du conduit n’est pas scellée

correctement.

Le clapet n’est pas bien installé ou

manque à l’installation.

Le clapet n’est pas installé. En installant le clapet, vous aiderez à éliminer le

Utilisez un voltmètre pour vérifier l’alimentation en

électricité.

Vérifiez le câblage au complet à partir du panneau

de commande jusqu’à la carte processeur.

Vérifiez l’entrée de courant et la sortie de courant du

transformateur du moteur. Si nécessaire, remplacez

le transformateur du moteur.

Remplacez le panneau de commande ou la carte

processeur.

Remplacez le(s) condensateur(s).

Remplacez le panneau de commande ou la carte

processeur.

Serrez la pale turbine/cage d’écureuil et le réservoir

d’air.

Remplacez la pale turbine/cage d’écureuil.

le support de fixation.

Essayez l’ampoule de lampe défectueuse sur

une douille qui fonctionne. Si l’ampoule ne fonctionne

toujours pas, remplacez-la.

Vérifiez le câblage au complet à partir de la carte

processeur jusqu’au transformateur puis jusqu’au

boîtier.

Vérifiez l’entrée de courant et la sortie de courant du

transformateur de lampe. Si nécessaire, remplacez

le transformateur de

lampe.

Remplacez le panneau de commande ou la carte

processeur.

Ajustez le dégagement entre la hotte de cuisine

et la table de cuisson pour qu’il soit de 27” à 30”.

Pour une hotte de cuisinière sur îlot, le dégagement

entre la hotte de cuisine et la table de cuisson est de

30” à 36”.

Ouvrez la fenêtre pour améliorer la performance

de la hotte en créant suffisamment d’air d’appoint.

Changez la canalisation en accord avec les

suggestions du fabricant.

Vérifiez l’installation du conduit.

Vérifiez l’installation du clapet.

retour d’air.

50

Page 53

AVIS DE NON-RESPONSABILITÉ

1. INSPECTER ATTENTIVEMENT TOUS LES ARTICLES POUR DÉCELER TOUT

DOMMAGE, S'IL Y A LIEU, AVANT D'ACCEPTER LA LIVRAISON. NOTER TOUT

DOMMAGE SUR LA FACTURE DE TRANSPORT OU LE CONNAISSEMENT. EXIGER

LE NOM ET LA SIGNATURE DE L'EMPLOYÉ DU TRANSPORTEUR ET CONSERVER

UNE COPIE COMME PIÈCE JUSTIFICATIVE DE LA RÉCLAMATION.

Sur acceptation des articles, le propriétaire assume la responsabilité de l'état dans lequel

se trouvent les articles à la livraison. Les dommages doivent être déclarés au transporteur

et une réclamation doit être déposée à défaut de quoi le transporteur pourrait refuser

d'honorer la réclamation. Le transporteur fournira les formulaires nécessaires pour

effectuer une réclamation.

LES DOMMAGES CAUSÉS DURANT LE TRANSPORT NE SONT PAS COUVERTS

PAR NOTRE GARANTIE.

2. PRIÈRE DE BIEN VÉRIFIER LE CONTENU DE L'EMBALLAGE (DES EMBALLAGES)

À LA RÉCEPTION! Vous devez nous aviser par écrit de tout dommage ou de toute pièce

manquante à l'intérieur du délai alloué à partir de la réception de la marchandise.

Communiquer avec votre représentant ou distributeur local de KOBE ou appeler chez

KOBE pour connaître le délai alloué.

LES RÉCLAMATIONS QUI NOUS PARVIENDRONT APRÈS LE DÉLAI ALLOUÉ

SERONT REFUSÉES.

NOTE : TOUS LES ARTICLES ONT ÉTÉ MIS À L'ESSAI MINUTIEUSEMENT ET

EMBALLÉS AVEC SOIN À NOTRE USINE.

3. Les produits doivent être retournés en bonne condition de fonctionnement avec TOUTES

les pièces d'origine et la documentation et dans TOUS les emballages d'origine (boîtes de

carton et matériel de remplissage). Des frais de reconstitution de stocks de 25 % seront

facturés pour tous les retours autorisés.

LES ÉCHANGES OU LES RETOURS PEUVENT ÊTRE REFUSÉS SI UNE PARTIE DE

L'EMBALLAGE EST MANQUANTE.

4. INSPECTER AVEC SOIN LA HOTTE POUR DÉCELER TOUT DOMMAGE OU DÉFAUT

AVANT L'INSTALLATION. Les défauts dans l'apparence de la hotte décelés après

l'installation et n’ayant aucune incidence sur son rendement ne sont pas couverts par

notre garantie et ne peuvent constituer une raison valable pour un retour ou un échange.

Des frais seront facturés pour les appels de service non couverts par notre garantie.

A) Avant l'installation : retour pour échange ou remboursement (veuillez voir plus haut les

raisons valables pour un retour).

B) Après l'installation : AUCUN échange ou remboursement.

51

Page 54

GARANTIE

CERTIFICAT DE GARANTIE

Tous les produits fabriqués ou fournis par KOBE Range Hoods, Inc. sont garantis contre tout

défaut de fabrication et de matière première. Les obligations du fabricant dans le cadre de la

présente garantie sont limitées à une période de deux (2) ans à partir de la date d'achat et à la

réparation ou au remplacement, à sa discrétion, conformément aux modalités et conditions

énoncées plus bas, de tout composant qu'il jugera défectueux après examen.

PÉRIODE DE GARANTIE DE DEUX (2) ANS

Toute défaillance couverte par la garantie se produisant dans les deux (2) ans à compter de la

date d'achat d'origine et découlant d'une fabrication ou d'une matière première défectueuse

sera réparée (ou, à notre discrétion, l'appareil pourra être remplacé), sans frais, par un agent

autorisé de KOBE Range Hoods, Inc. ou par KOBE Range Hoods, Inc. selon le cas. Conservez

votre preuve d'achat (ou facture d'origine) pour inspection.

Si la hotte de cuisinière est vendue par l'acheteur d'origine au cours de la période de garantie,

le nouveau propriétaire sera protégé jusqu'à l'expiration de la garantie de l'acheteur d'origine.

CONDITIONS