Page 1

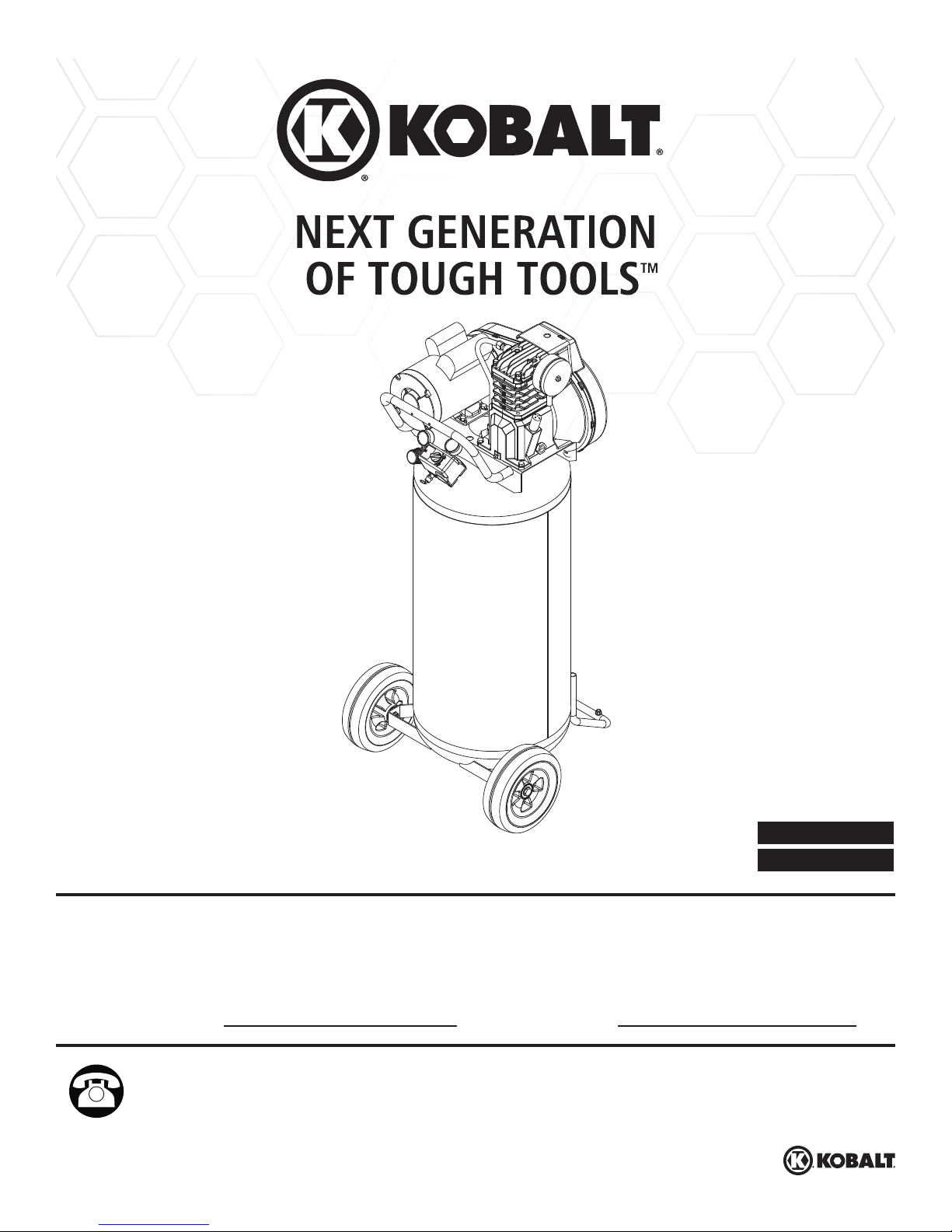

ITEM #0268707

PORTABLE

AIR

COMPRESSOR

MODEL #VT6389

KOBALT® and the K Design® are registered

trademarks of LF, LLC. All Rights Reserved.

ATTACH YOUR RECEIPT HERE

Serial Number Purchase Date

Questions, problems, missing parts? Before returning to your retailer, call our customer

service department at 1-888-3KOBALT (1-888-356-2258), 8 a.m. - 8 p.m., EST,

Monday - Friday.

AB13473

Français p. 29

Español p. 59

kobalttools.com

1

IN638401AV 5/13

Page 2

TABLE OF CONTENTS

Safety Guidelines .......................................................................................................................... 3

Safety Information ......................................................................................................................... 3

Package Contents ......................................................................................................................... 6

Hardware Contents........................................................................................................................ 6

Preparation .................................................................................................................................... 7

Assembly Instructions.................................................................................................................... 8

Operating Instructions ................................................................................................................... 13

Care and Maintenance .................................................................................................................. 15

Troubleshooting ............................................................................................................................. 16

Warranty ........................................................................................................................................ 20

Replacement Parts List ................................................................................................................. 22

PRODUCT SPECIFICATIONS

COMPONENT SPECIFICATIONS

Model VT6389

HP 2

Number of Cylinders 2

Air Delivery @ 90 psi 5.5 CFM

Voltage 120 Volts / 15 Amps

Max Pressure 155 psi

COMPONENT SPECIFICATIONS

Oil Capacity 8.5 oz.

Tank Outlet Size 1/4 NPT

Depth 23 in.

Width 24 in.

Height 46 in.

Weight 178 lbs.

2

kobalttools.com

Page 3

SAFETY GUIDELINES

Please read and understand this entire manual before attempting to assemble, operate or install

the product. If you have any questions regarding the product, please call customer service at

1-888-3KOBALT (1-888-356-2258), 8:00 am - 8:00 pm, EST, Monday - Friday.

This manual contains information that is very important to know and understand. This information

is provided for SAFETY and to PREVENT EQUIPMENT PROBLEMS. To help recognize this

information, observe the following symbols.

DANGER

Danger indicates an imminently hazardous

situation which, if not avoided, WILL result in

death or serious injury.

CAUTION

Caution indicates a potentially hazardous

situation which, if not avoided, MAY result in

minor or moderate injury.

SAFETY INFORMATION

CALIFORNIA PROPOSITION 65

WARNING

Handle with Care. This product or its power

cord may contain chemicals known to the

State of California to cause cancer and birth

defects or other reproductive harm. Wash

hands after handling.

GENERAL SAFETY

WARNING

Warning indicates a potentially hazardous

situation which, if not avoided, COULD result

in death or serious injury.

NOTICE

Notice indicates important information,

that if not followed, may cause damage to

equipment.

WARNING

Wear eye and mask protection.

You can create dust when you cut,

sand, drill or grind materials such

as wood, paint, metal, concrete,

cement, or other masonry. This

dust often contains chemicals

known to cause cancer, birth

defects, or other reproductive

harm. Wear protective gear.

Since the air compressor and other components (material pump, spray guns, filters, lubricators,

hoses, etc.) used, make up a high pressure pumping system, the following safety precautions must be

observed at all times:

1. Read all manuals included with this product carefully. Be thoroughly familiar with the controls

and the proper use of the equipment.

2. Follow all local electrical and safety codes as well as in the United States, the National Electrical

Codes (NEC) and Occupational Safety and Health Act (OSHA).

3. Only persons well acquainted with these rules of safe operation should be allowed to use the

compressor.

4. Keep visitors away and NEVER allow children in the work area.

5. Wear safety glasses and use hearing protection when operating the unit.

3

kobalttools.com

Page 4

SAFETY INFORMATION

GENERAL SAFETY (Continued)

6. Do not stand on or use the unit as a handhold.

7. Before each use, inspect compressed air system and electrical components for signs of damage,

deterioration, weakness or leakage. Repair or replace defective items before using.

8. Check all fasteners at frequent intervals for proper tightness.

9. Do not wear loose clothing or jewelry that will get caught in the moving parts of the unit.

10. Keep fingers away from a running compressor; fast moving and hot parts will cause injury and/or

burns.

11. If the equipment should start to vibrate abnormally, STOP the engine/motor and check

immediately for the cause. Vibration is generally a warning of trouble.

12. To reduce fire hazard, keep engine/motor exterior free of oil, solvent, or excessive grease.

13. Never attempt to adjust ASME safety valve. Keep safety valve free from paint and other

accumulations.

14. Tanks rust from moisture build-up, which weakens the tank. Make sure to drain tank regularly and

inspect periodically for unsafe conditions such as rust formation and corrosion.

15. Fast moving air will stir up dust and debris which may be harmful. Release air slowly when

draining moisture or depressurizing the compressor system.

DANGER

Risk of Personal Injury. This compressor/

pump is NOT equipped and should NOT be

used “as is” to supply breathing quality air. For

any application of air for human consumption,

you must fit the air compressor/pump with

suitable in-line safety and alarm equipment.

This additional equipment is necessary

to properly filter and purify the air to meet

minimal specifications for Grade D breathing

as described in Compressed Gas Association

Commodity Specification G 7.1, OSHA 29

CFR 1910. 134, and/or Canadian Standards

Associations (CSA).

DISCLAIMER OF WARRANTIES

In the event the compressor is used for the

purpose of breathing air application and

proper in-line safety and alarm equipment is

not simultaneously used, existing warranties

are void, and the Manufacturer disclaims any

liability whatsoever for any loss, personal injury

or damage.

WARNING

DANGER

Risk of Explosion. Never attempt

to repair or modify a tank! Welding,

drilling or any other modifi cation

will weaken the tank resulting in

damage from rupture or explosion.

Always replace worn, cracked or

damaged tanks.

WARNING

Risk of Fire. Motors, electrical

equipment and controls can cause

electrical arcs that will ignite a

fl ammable gas or vapor. Never

operate or repair in or near a

fl ammable gas or vapor. Never

store fl ammable liquids or gases in

the vicinity of the compressor.

WARNING

Risk of Explosion. Never use plastic (PVC)

pipe for compressed air. Serious injury or

death could result.

Risk of Personal Injury and/or Equipment

Damage. Never install a shut-off valve

between the compressor pump and the tank.

4

kobalttools.com

Page 5

SAFETY INFORMATION

GENERAL SAFETY (Continued)

WARNING

Risk of Personal Injury. Never

operate compressor without a

beltguard. This unit can start

automatically without warning.

Personal injury or property

damage could occur from contact

with moving parts.

CAUTION

Do Not Overpressure. See compressor

specifi cation decal for maximum operating

pressure. Do not operate with pressure switch

or safety valves set higher than the maximum

operating pressure.

WARNING

Risk of Explosion. An ASME code safety

relief valve with a setting no higher than

the maximum allowable working pressure

(MAWP) MUST be installed in the tank for

this compressor. The ASME safety valve must

have suffi cient fl ow and pressure ratings to

protect the pressurized components from

bursting.

CAUTION

Risk of Personal Injury.

Compressor parts may be hot

even if the unit is stopped.

NOTICE

Unit Care and Maintenance. Drain liquid from

tank daily.

SPRAYING PRECAUTIONS

1. Do not smoke when spraying paint, insecticides, or other flammable substances.

2. Use a face mask/respirator when spraying and spray in a well-ventilated area to prevent health

and fire hazards.

3. Do not direct paint or other sprayed material at the compressor. Locate compressor as far away

from the spraying area as possible to minimize overspray accumulation on the compressor.

4. When spraying or cleaning with solvents or toxic chemicals, follow the instructions provided by

the chemical manufacturer.

WARNING

Risk of Fire. Do not spray

fl ammable materials in vicinity

of open fl ame or near ignition

sources including the compressor

unit.

5

kobalttools.com

Page 6

PACKAGE CONTENTS

D

C

E

K

J

H

I

A

G

B

F

PART DESCRIPTION QTY.

A Pressure Switch - AUTO/OFF Switch - In the AUTO position, the compressor

1

shuts off automatically when tank pressure reaches the maximum preset pressure.

After air is used from the tank and drops to a preset low level, the pressure switch

automatically turns the motor back on. In the OFF position, the compressor will not

operate. This switch should be in the OFF position when connecting or disconnecting

the power from the unit.

When the pressure switch turns the motor off you will hear air leaking out of the

pressure switch unloader valve for a short time. This releases the air pressure from

the discharge tube and allows the compressor to restart easier.

B ASME Safety Valve - This valve automatically releases air if the tank pressure

1

exceeds the preset maximum.

C Discharge tube - This tube carries compressed air from the pump to the check valve.

1

This tube becomes very hot during use. To avoid the risk of severe burns, never touch

the discharge tube.

6

kobalttools.com

Page 7

PACKAGE CONTENTS

PART DESCRIPTION QTY.

D Check valve - One-way valve that allows air to enter the tank, but prevents air in the

tank from flowing back into the compressor pump.

E Belt Guard - Covers the belt, motor pulley and flywheel. 1

F Tank Drain Valve - This valve is located on the bottom of the tank. Use this valve to

drain moisture from the tank daily to reduce the risk of corrosion.

G Tank Pressure Gauge - Indicates amount of air pressure stored in tank. 1

H Hose Pressure Gauge - Indicates amount of air pressure in hose used to operate

tools. This pressure is increased or decreased by the regulator.

I Regulator - The regulator controls the amount of air pressure released at the hose

outlet.

J Air Filter - Keeps debris and particulates out of the air flowing into the compressor. 1

K Breather - Vent for crankcase. 1

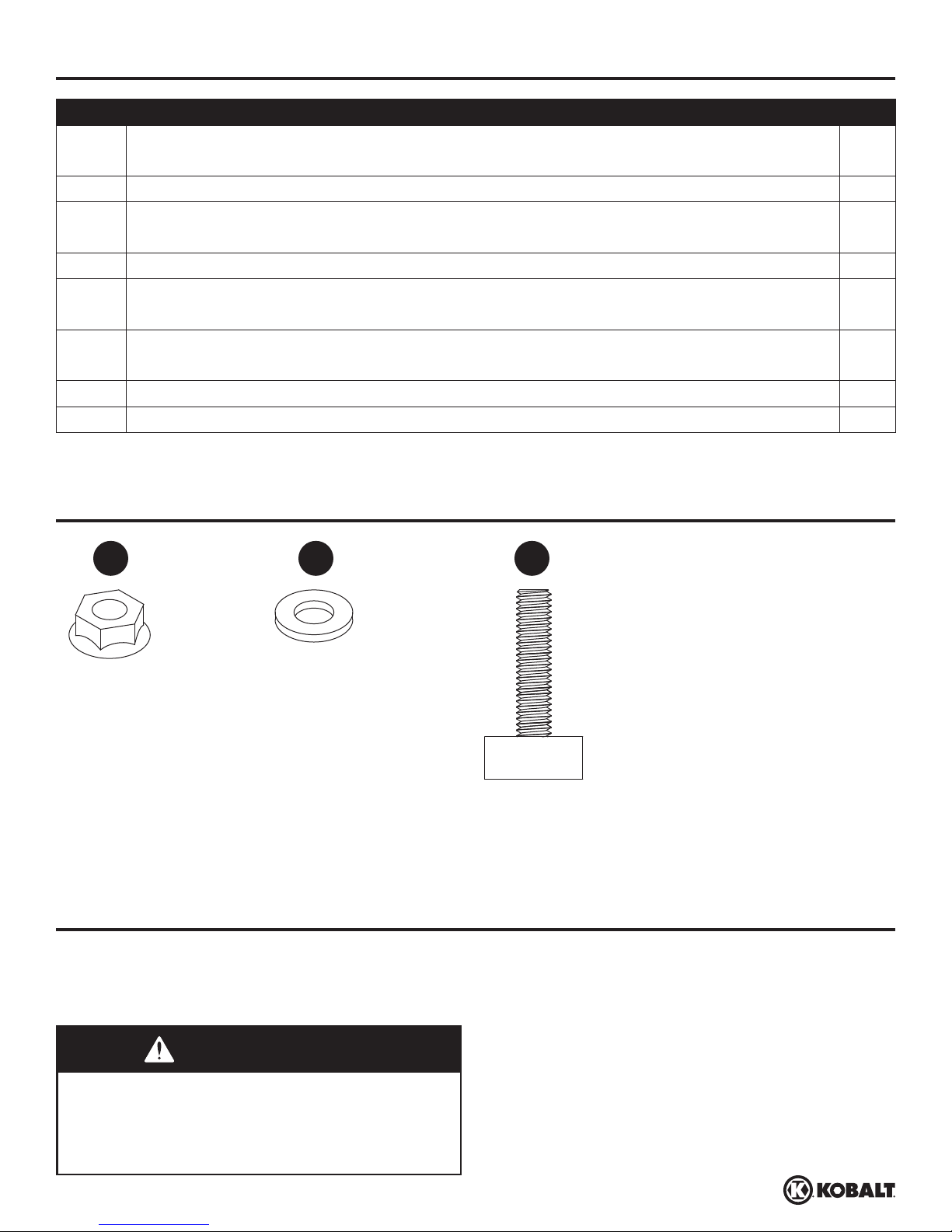

HARDWARE CONTENTS (shown actual size)

1

1

1

1

AA BB CC

5/16 inch x

18 Spinlock Nut

Qty. 2

PREPARATION

Before beginning installation and/or assembly of product, make sure all parts are present. Compare

parts with package contents list. If any part is missing or damaged, do not attempt to assemble or use

the product. Contact customer service for replacement parts and assistance.

5/16 inch Washer

Qty. 2

Rubber Foot

Qty. 2

WARNING

Risk of Personal Injury. Do not operate unit

if damaged during shipping, handling or use.

Damage may result in bursting and cause

injury or property damage.

7

kobalttools.com

Page 8

PREPARATION

Estimated Installation and Assembly Time: 20 minutes

Tools Required for Installation and Assembly (not included): Safety Glasses; Work Gloves; 9/16 inch

Socket and Ratchet; Adjustable Wrench

ADDITIONAL PARTS REQUIRED FOR USE [not included]

Parts - available at local hardware store.

1. Air Hose

2. Pipe Thread Sealant

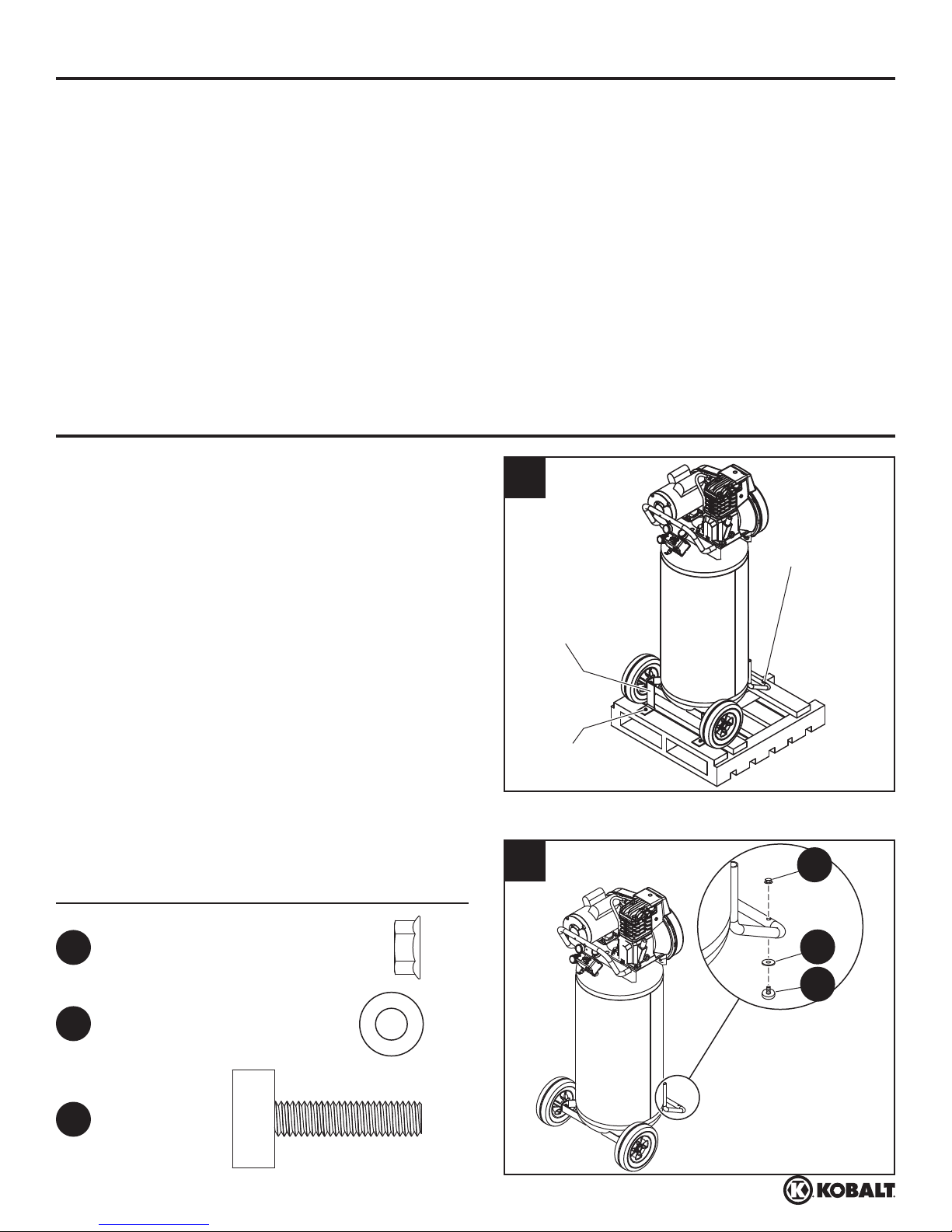

ASSEMBLY INSTRUCTIONS

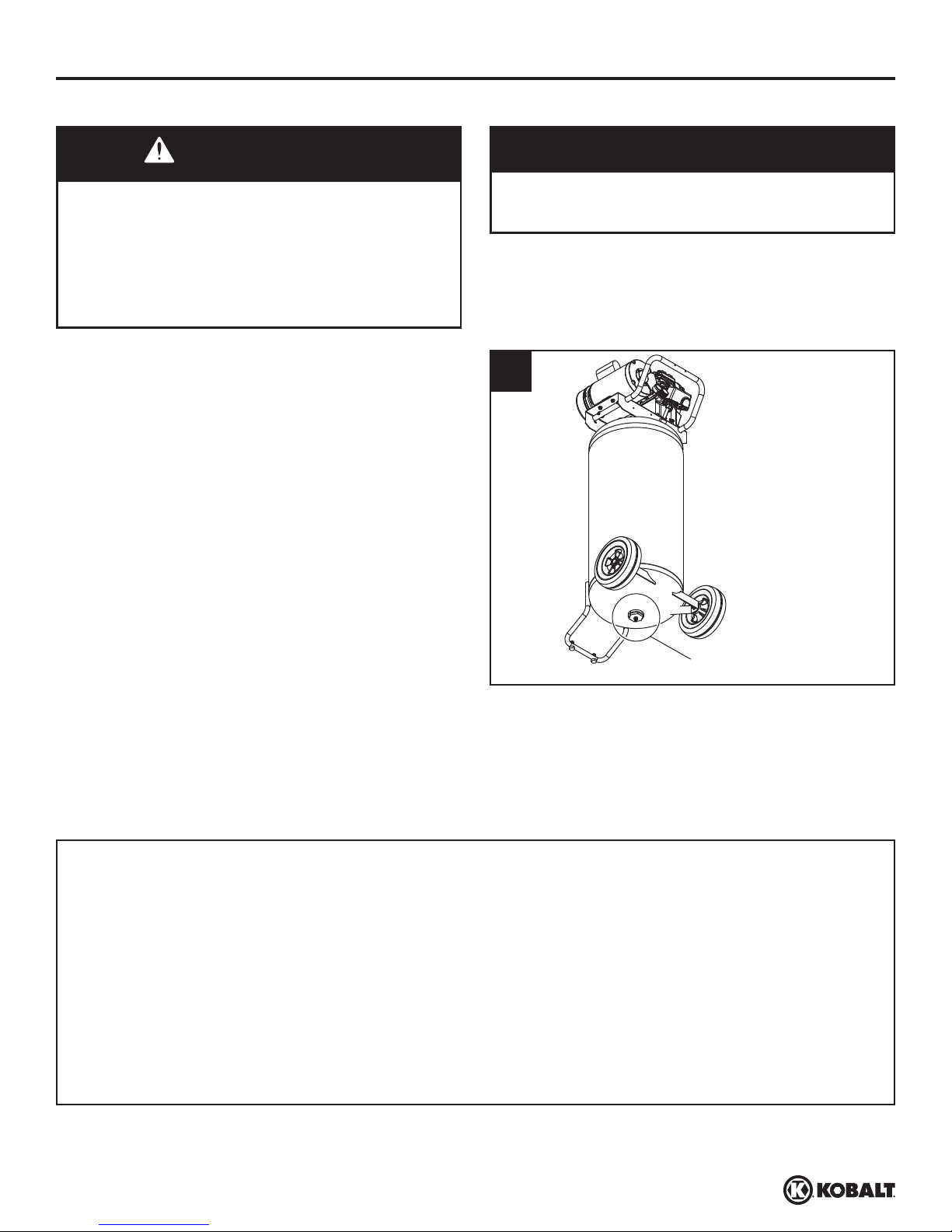

1. Unbolt the unit from the shipping skid. Use a

ratchet with a 9/16 inch socket. Remove the

unit from the skid. Discard shipping hardware

once removed.

1

Shipping

Bolt

2. Install rubber feet with nuts and washers.

Hardware Used

AA

Nut

BB

Washer x2

x2

Shipping

Bracket

Shipping

2

Bolt

AA

BB

CC

CC

Rubber Foot x2

8

kobalttools.com

Page 9

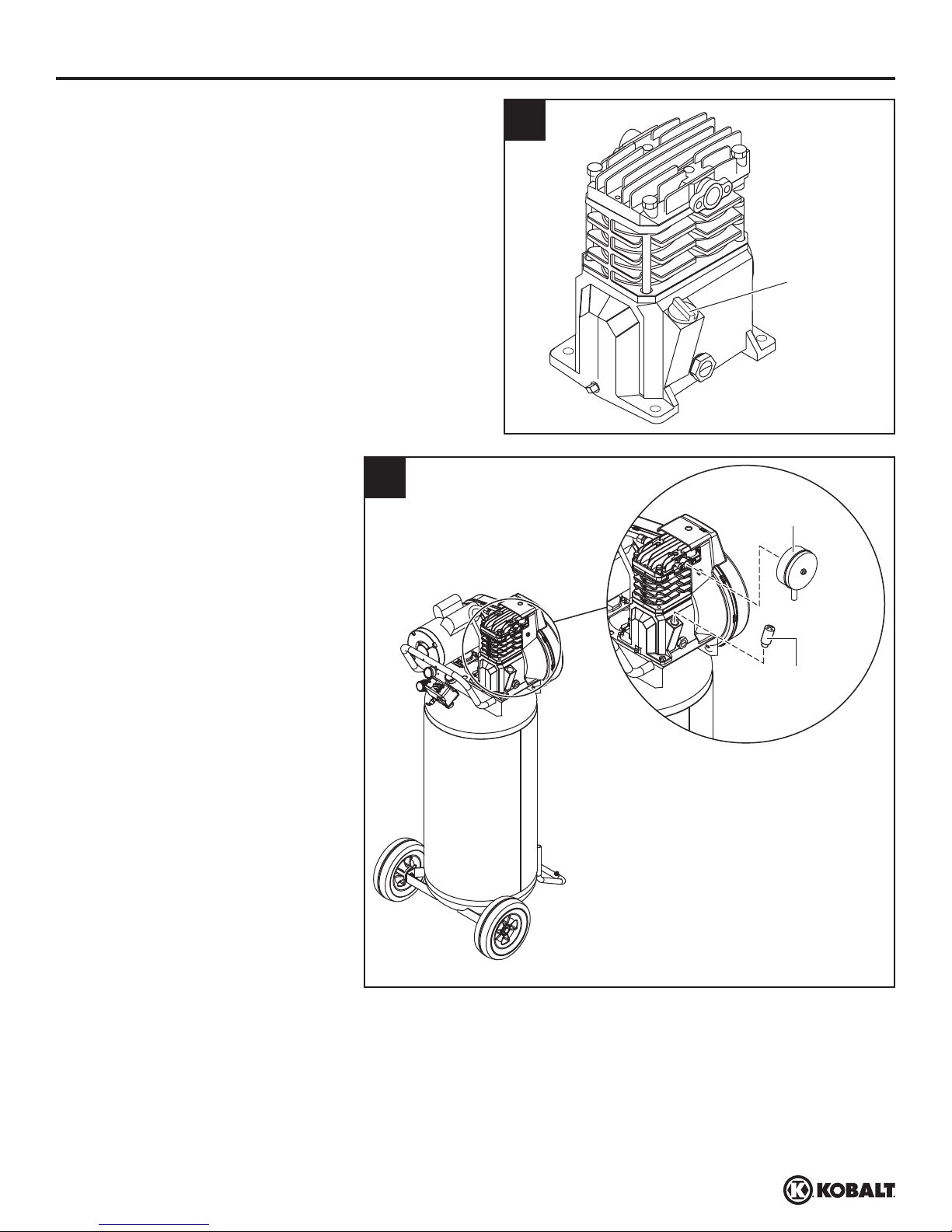

ASSEMBLY INSTRUCTIONS

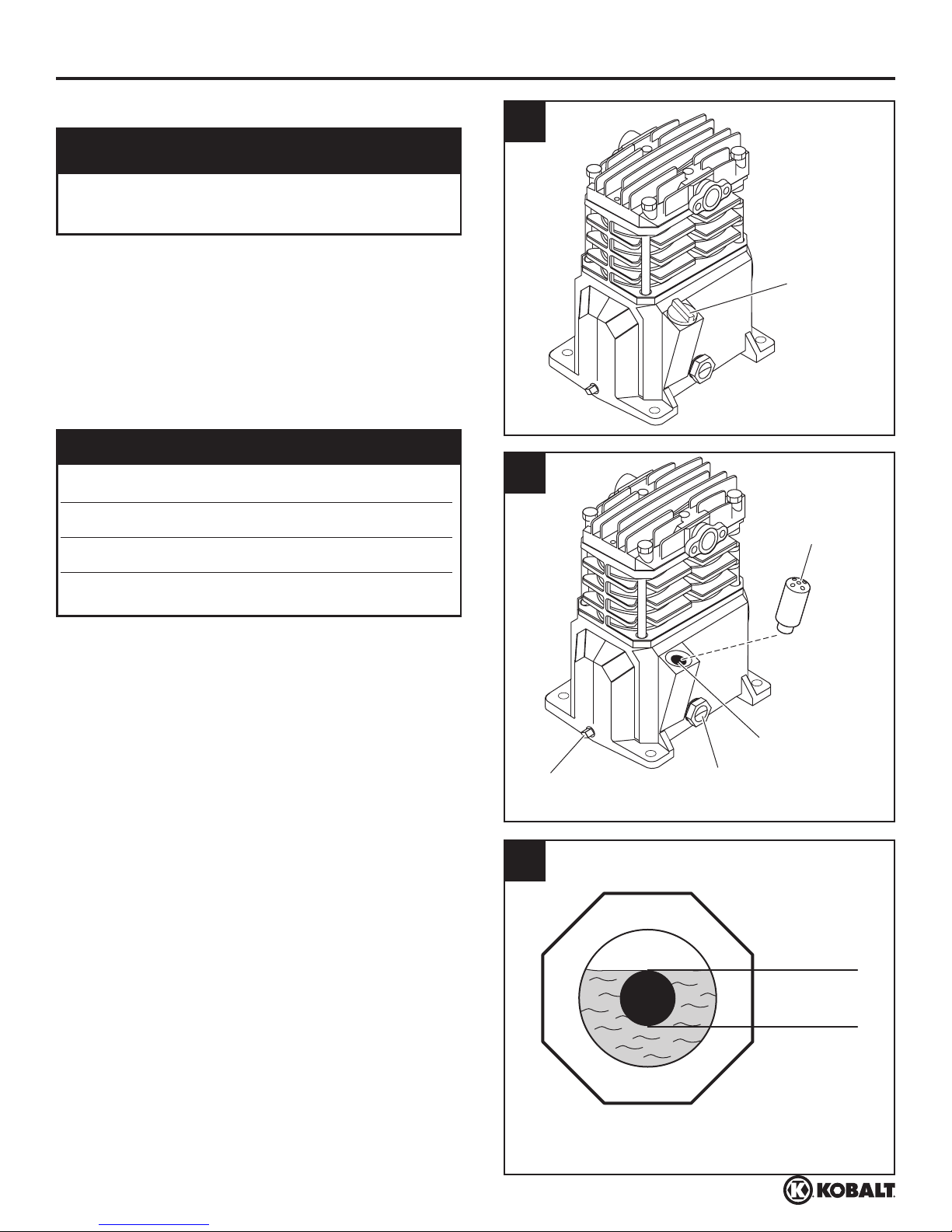

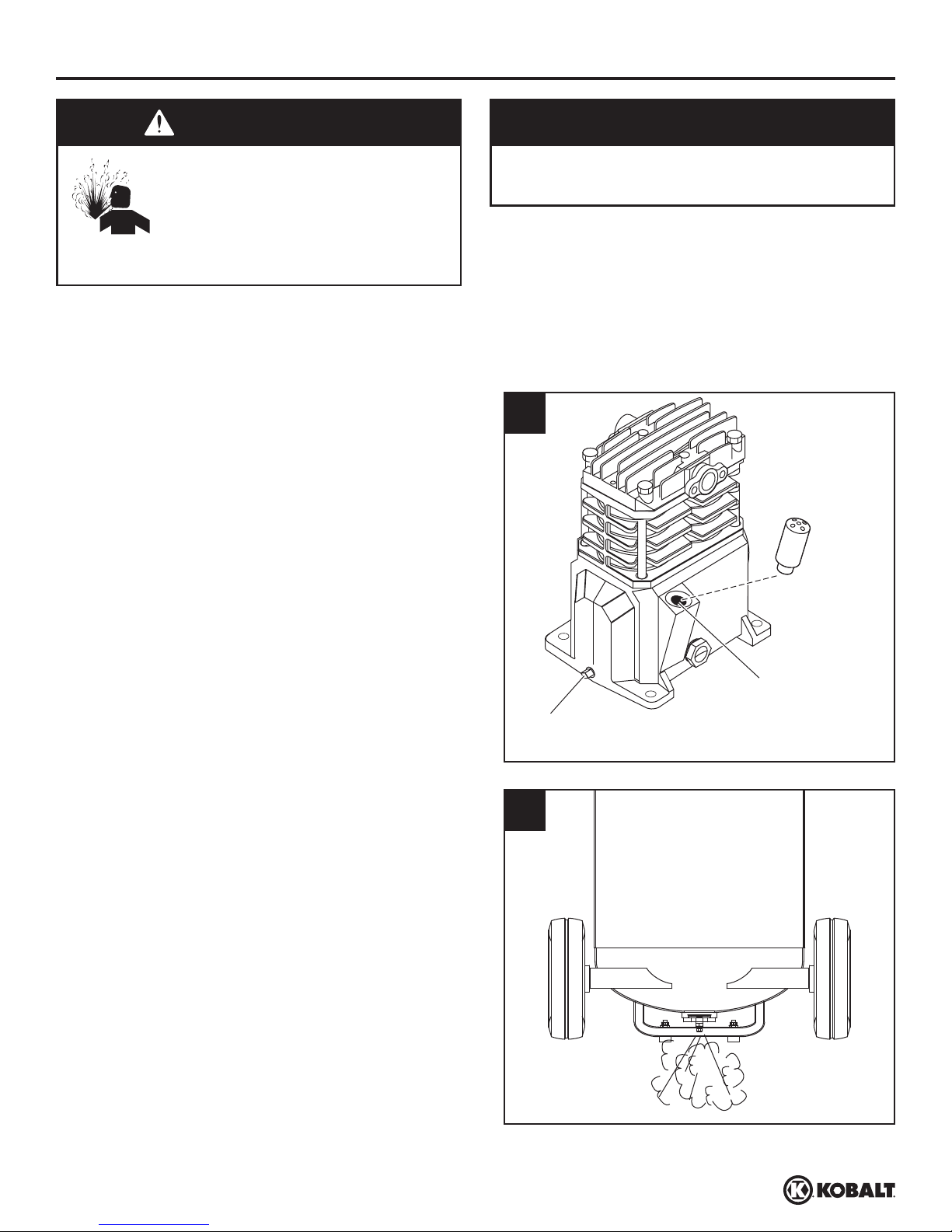

3. Remove cap from pump.

4. Install breather. Install air

fi lter.

3

Cap

4

Air Filter

Breather

9

kobalttools.com

Page 10

ASSEMBLY INSTRUCTIONS

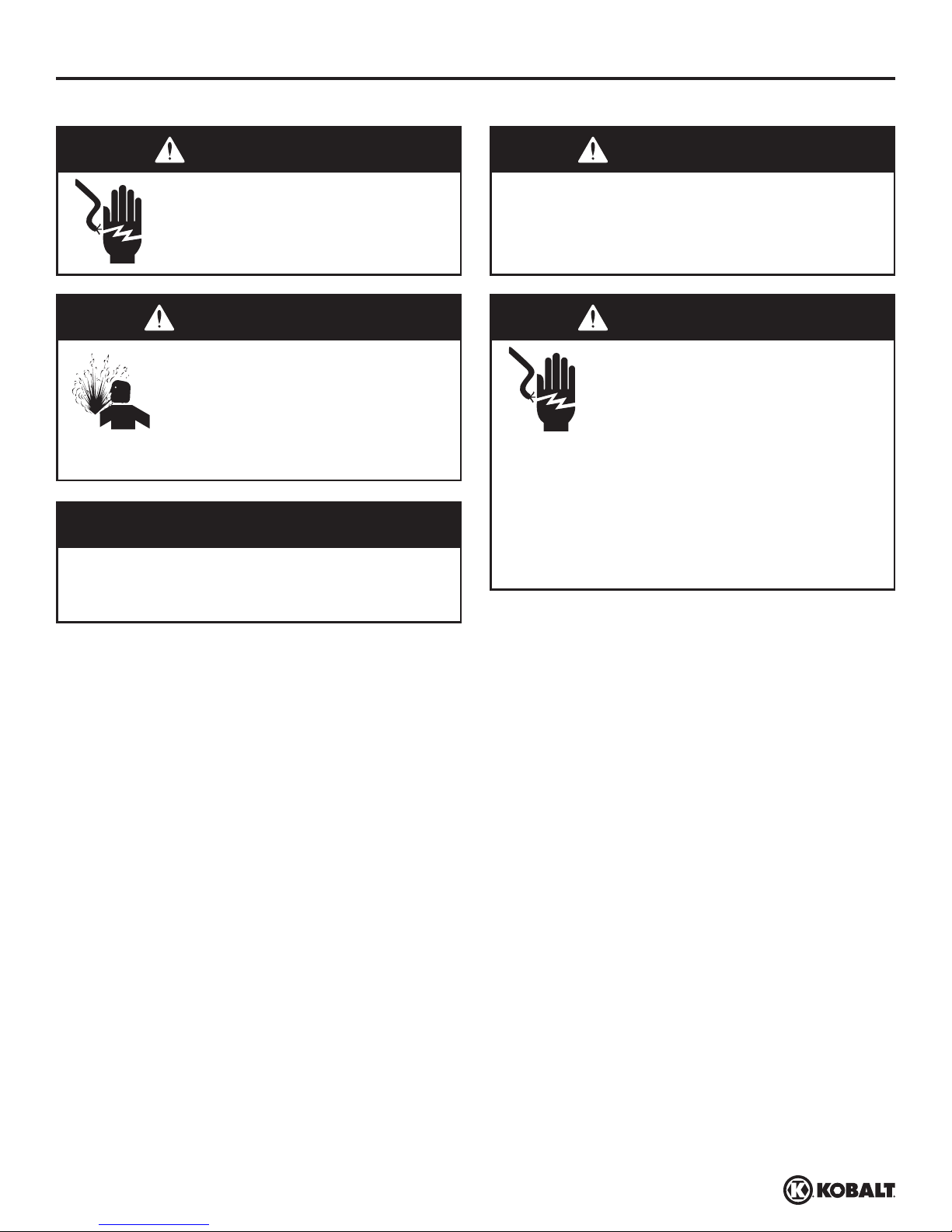

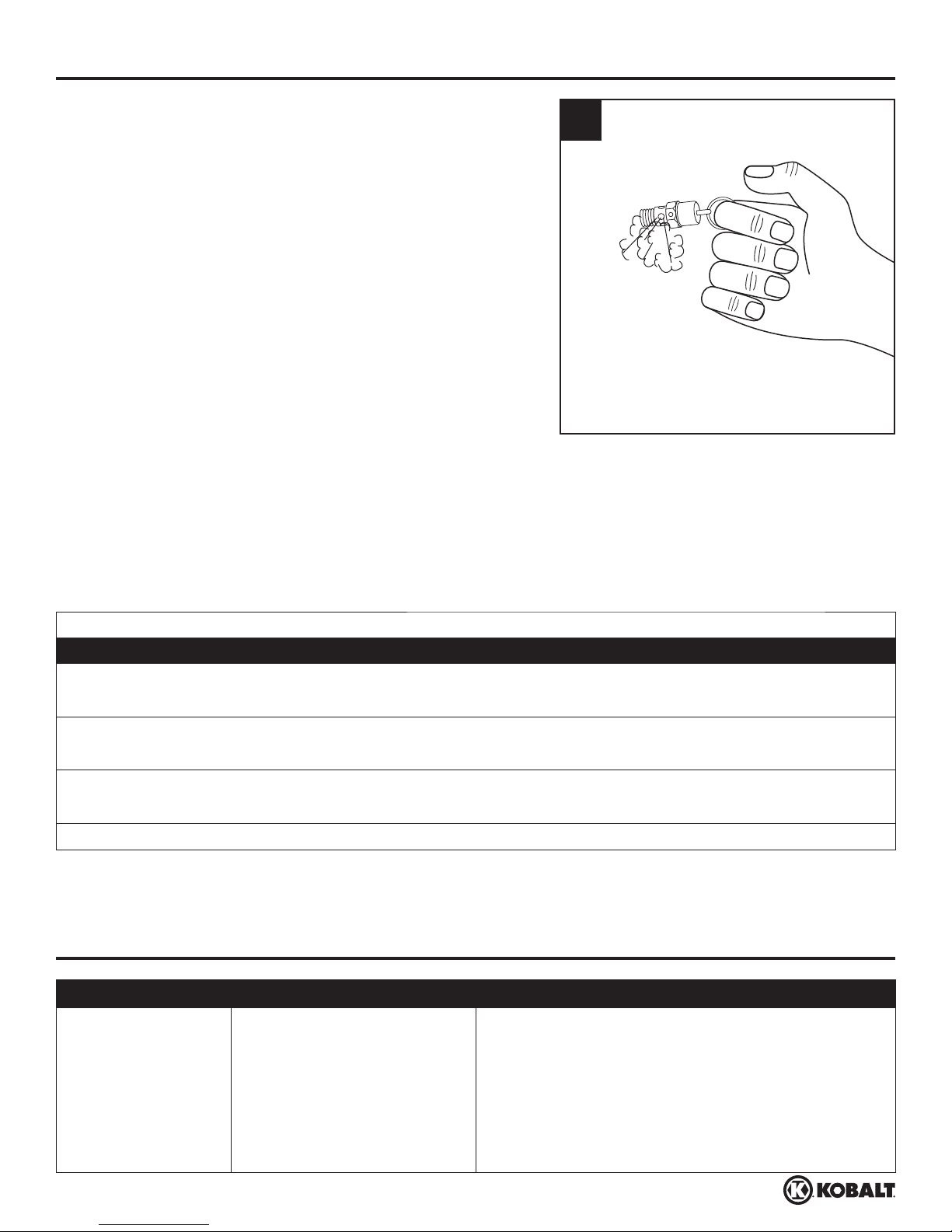

LUBRICATION

CAUTION

Inspect Before Use. Check for proper oil level

before operating!

1

Remove cap from oil fill opening. See Figure

1. Install breather (found in parts bag with this

manual). See Figure 2. Check oil level; some

models are shipped with oil in the pump. See

specification label on compressor pump for the

proper oil capacity and oil type.

OIL INFORMATION

Kobalt Air Compressor Oil SKU 221008

Kobalt Synthetic Blend Oil SKU 221009

Mobil 1® synthetic 10W30

Oil Capacity 8.5 ounces

Do not use regular automotive oil. Additives in

regular motor oil can cause valve deposits and

reduce pump life. For maximum pump life, drain

and replace oil after the first hour of run time.

Cap

2

Breather

This pump has an oil sight glass as shown

in Figure 2. Oil level can be monitored and

maintained as shown in Figure 3.

10

Oil Drain

Plug

3

Oil Fill Area

Sight

Glass

Full

Low

Sight Glass

kobalttools.com

Page 11

ASSEMBLY INSTRUCTIONS

ELECTRICAL INFORMATION

DANGER WARNING

Risk of Shock. Improperly

grounded motors are shock

hazards. Make sure all the

equipment is properly grounded.

WARNING

Risk of Explosion. Disconnect,

tag and lock out power source,

then release all pressure from the

system before attempting to install,

service, relocate or perform any

maintenance.

NOTICE

Unit care and maintenance. Damage to the

motor from improper electrical voltage or

connection will void the warranty.

Risk of Personal Injury or Damage to

Personal Property. Overheating, short

circuiting and fi re damage will result from

inadequate wiring.

WARNING

Risk of Shock. Improper

installation of the grounding plug

is able to result in a risk of electric

shock. When repair or replacement

of the cord or plug is required, do

not connect the grounding wire

to either fl at blade terminal. The

wire with insulation having an

outer surface that is green with

or without yellow stripes is the

grounding wire.

Do not use an extension cord, use a longer air hose.

The 120 volt, 15 amp units can be operated on a 120 volt 15 amp circuit under the following conditions:

1. No other electrical appliances or lights are connected to the same branch circuit.

2. Voltage is 120 Volts.

3. Circuit is equipped with a 15 amp circuit breaker or a 15 amp slow blow fuse type T (For Canada

use Type D).

4. The length of copper wire between the outlet and circuit breaker is not longer than 40 feet of

14 AWG or 70 feet of 12 AWG.

11

kobalttools.com

Page 12

ASSEMBLY INSTRUCTIONS

GROUNDING

This product must be grounded. In the event of an electrical short circuit, grounding reduces the risk of

electric shock by providing an escape wire for the electric current. This product is equipped with a cord

having a grounding wire with an appropriate grounding plug. The plug must be plugged into an outlet

that is properly installed and grounded in accordance with all local codes and ordinances. Do not use

grounding adapter.

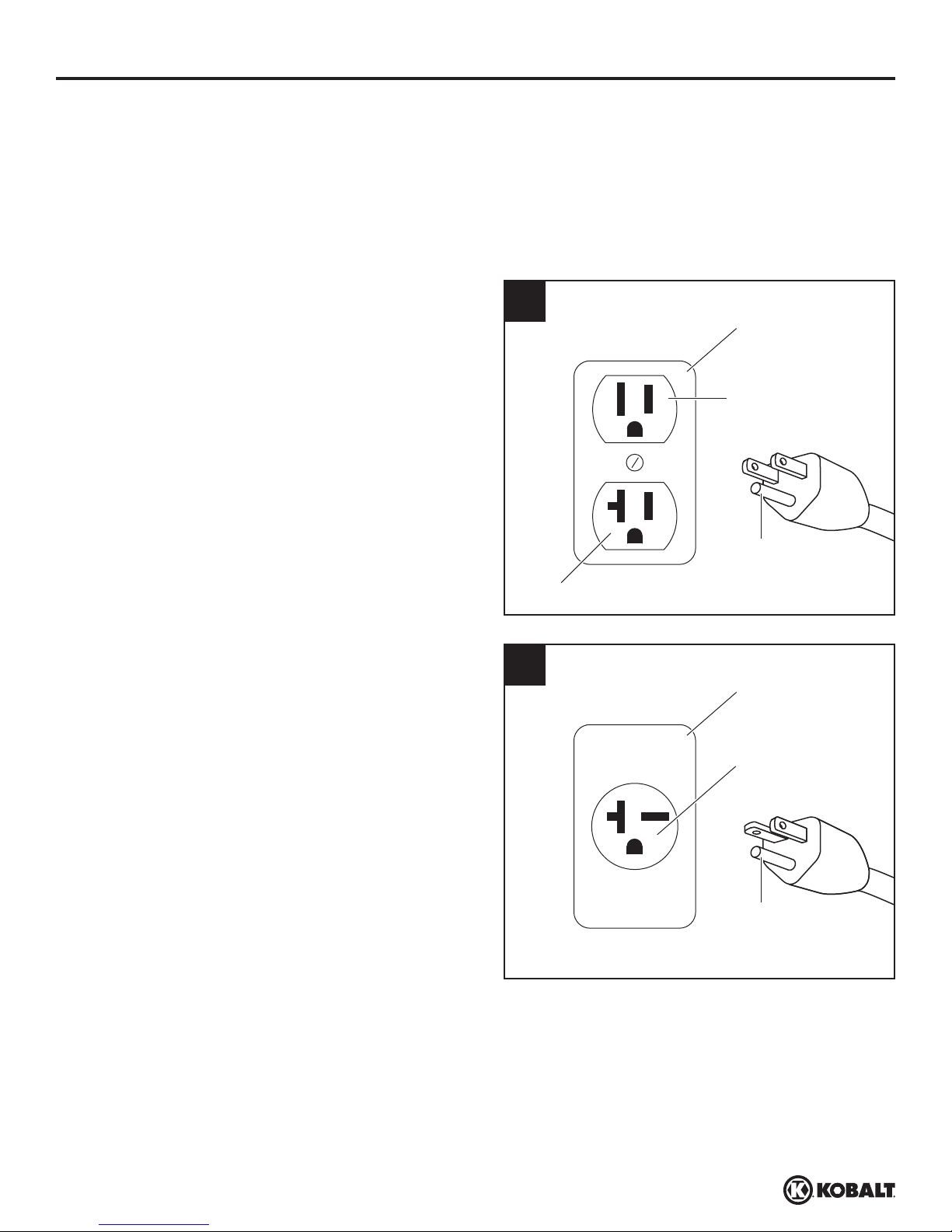

This product is for use on a nominal 120 volt

circuit and has a grounding plug similar to the

plug illustrated in Figure 1. If the listed conditions

cannot be met or if nuisance tripping of the

current protection device occurs, it may be

possible to operate the compressor from a 120

volt 20 amp circuit. See Figure 1.

Check motor data plate for 240 volt compatability.

A 240 volt unit must be operated on a 240 volt

circuit. The cord must only plug into a 240 volt

grounded outlet and may require a new cord and

plug. See Figure 2.

1

Outlet - 120V / 20A

2

Grounded

Outlet

Outlet - 120V / 15A

Ground

Pin

Grounded

Outlet

Outlet - 240V

Check with a qualified electrician or serviceman when the grounding instructions are not completely

understood, or when in doubt as to whether the product is properly grounded. Do not modify the plug

provided; if it does not fit the outlet, have the proper outlet installed by a qualified electrician. Only

connect the product to an outlet having the same configuration as the plug. Do not use an adapter with

this product.

12

Ground

Pin

kobalttools.com

Page 13

OPERATING INSTRUCTIONS

START-UP / BREAK-IN PROCEDURE

WARNING

Risk of Personal Injury. Do not attach air

tools to open end of the hose until start-up is

completed and the unit checks okay.

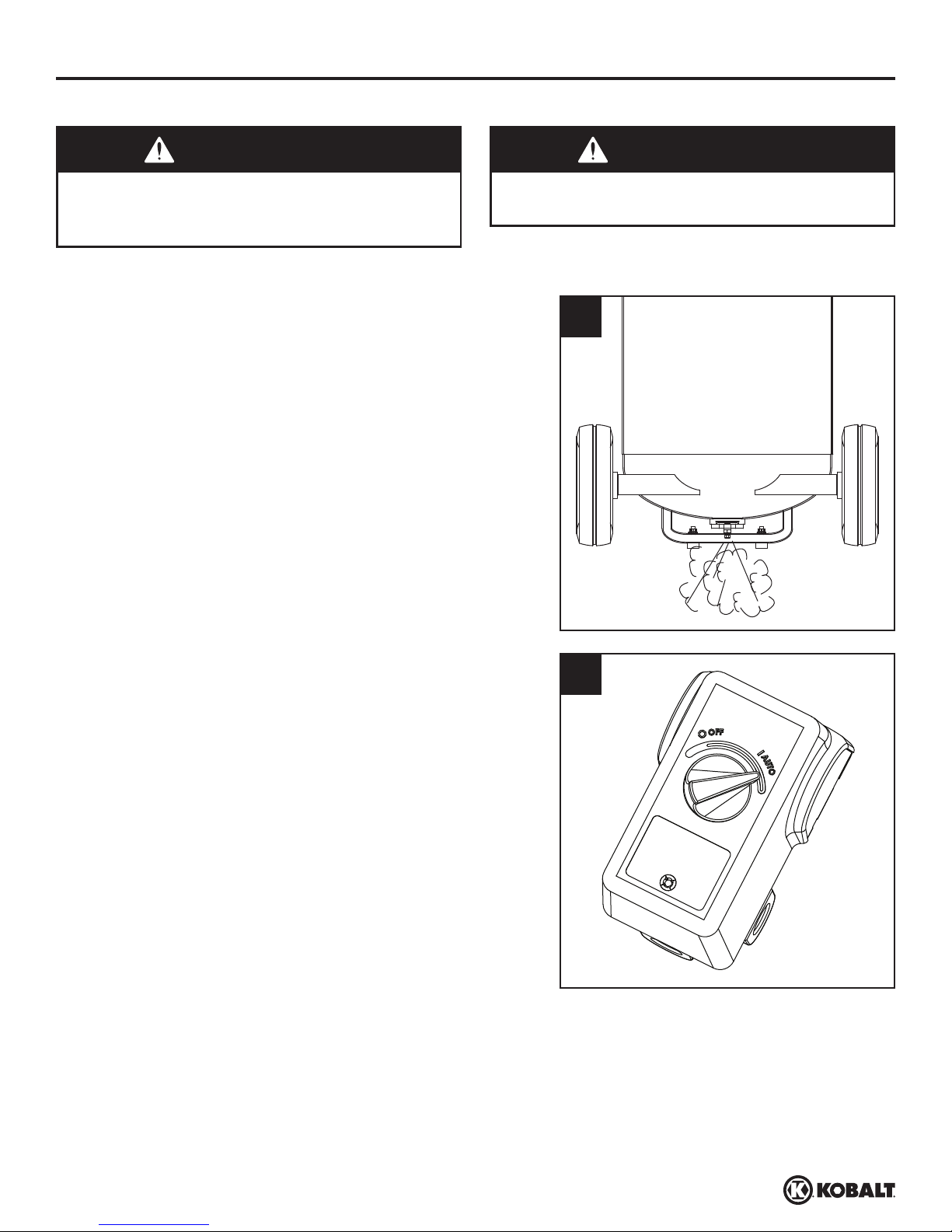

1. Check oil level per the Lubrication Section of this

manual.

2. Open the bottom tank drain valve (see Figure 1).

Turn outlet valve to open air flow.

3. Plug unit in.

WARNING

Risk of Personal Injury. Never disconnect

threaded joints with pressure in tank!

1

4. Move pressure switch to the AUTO position to run the

unit (see Figure 2).

5. Run the unit for thirty (30) minutes at zero (0) psi

(under no load) to break in pump parts.

6. Move the pressure switch lever or knob to OFF

and turn tank drain valve to shut off air flow. The

compressor is now ready for use.

7. Change oil after first fifty (50) hours of operation.

Then perform oil changes every three (3) months.

COMPRESSOR USE

It is extremely important to operate the compressor in a clean, well-ventilated area where the

surrounding air temperature will not be more than 100°F. Do not locate the compressor air inlet near

steam, paint spray, sandblast areas or any other source of contamination.

2

13

kobalttools.com

Page 14

OPERATING INSTRUCTIONS

ON/OFF CYCLING OF COMPRESSOR

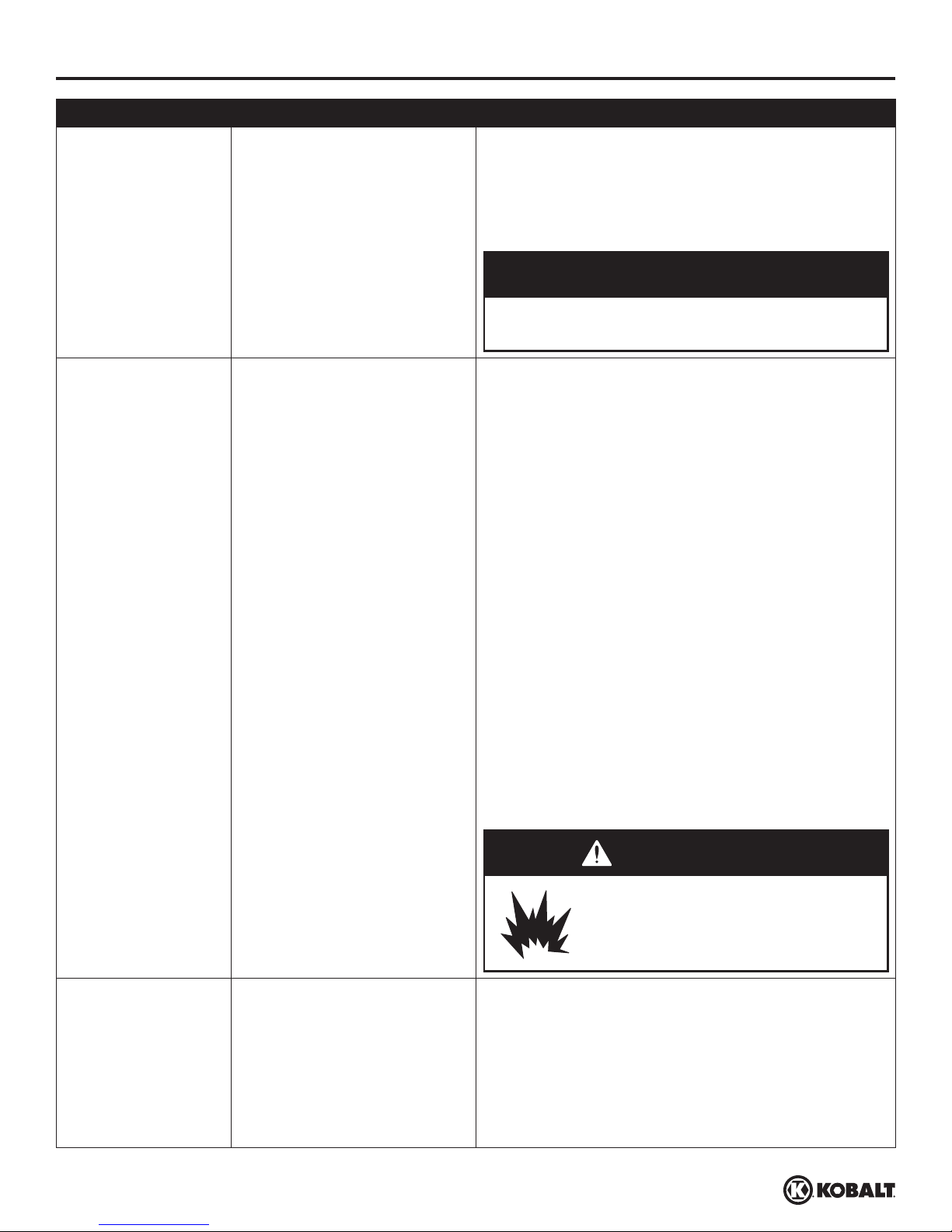

WARNING

Risk of Bursting. Drain tank every day to

prevent corrosion and possible injury due to

tank damage. Do not operate drain with more

than 40 psi in tank or drain valve may be

damaged. Drain tank of moisture daily using

the drain valve in the bottom of the tank.

In the AUTO position, the compressor pumps air

into the tank. When a shut-off (preset “cut-out”)

pressure is reached, the compressor automatically

shuts off.

If the compressor is left in the AUTO position

and air is depleted from the tank by use of a

tire chuck, tool, etc., the compressor will restart

automatically at its preset “cut-in” pressure. When

a tool is being used continuously, the compressor

will cycle on and off automatically.

NOTICE

Unit care and maintenance. Drain liquid from

tank daily.

1

In the OFF position, the compressor will not

operate.

Bottom Drain Valve

Drain Tank. Disconnect, tag, unplug and lock out

power source; release pressure. Drain moisture

from tank by opening drain valve underneath tank

(See Figure 1).

MOISTURE IN COMPRESSED AIR

Moisture in compressed air will form into droplets as it comes from an air compressor pump.

When humidity is high or when a compressor is in continuous use for an extended period of time,

this moisture will collect in the tank. When using a paint spray or sandblast gun, this water will

be carried from the tank through the hose, and out of the gun as droplets mixed with the spray

material.

IMPORTANT: This condensation will cause water spots in a paint job, especially when spraying

other than water based paints. If sandblasting, it will cause the sand to cake and clog the gun,

rendering it ineffective. A fi lter in the air line, located as near to the gun as possible, will help

eliminate this moisture.

14

kobalttools.com

Page 15

CARE AND MAINTENANCE

WARNING

Risk of Explosion. Disconnect,

tag and lock out power source,

then release all pressure from the

system before attempting to install,

service, relocate or perform any

maintenance.

All repairs should be performed by an authorized service representative.

For efficient operation, perform the following maintenance.

1. Disconnect, tag, unplug and lock out power

source; clean debris from motor, flywheel,

tank, air lines and pump cooling fins.

2. Maintain proper oil level. Refer to Lubrication

section for details.

3. Change oil.

a. Allow compressor to run and warm up

oil. Disconnect, tag and lock out power

source.

b. Position a pan under pump.

c. Remove oil drain plug (See Figure 1).

Allow oil to collect in pan.

d. Replace drain plug, fill pump to full level

(See Figure 1). See Lubrication section of

this manual.

4. Drain Tank. Disconnect, tag and lock out

power source; release pressure. Drain

moisture from tank by opening drain valve

underneath tank (See Figure 2).

5. Check air filter to be sure it is clean. Replace

filter if filter is dirty.

Unit care and maintenance. Drain liquid from

tank daily.

1

Oil Drain

Plug

2

NOTICE

Oil Fill Area

15

kobalttools.com

Page 16

CARE AND MAINTENANCE

6. Check the safety valve by performing the following

steps:

a. Restore power to unit; turn pressure switch to the

AUTO position. Run until unit reaches 90 psi.

Turn pressure switch to OFF position.

b. Wearing safety glasses and hearing protection,

pull the ring on the safety valve to release

pressure from compressor tank. Protect yourself

from fast-moving air being released; do not allow

fast-moving air to be directed toward your face

(See Figure 3).

c. The safety valve should automatically close at

approximately 40-50 psi. If the safety valve does

not allow air to be released when you pull on the

ring, or if it does not close automatically, it MUST

be replaced.

7. Check belt for signs of excessive wear. If belt shows

signs of wear, replace it. Check belt for proper

tension / alignment.

3

TECHNICAL SERVICE

For information regarding the operation or repair of this product, please call 1-888-3KOBALT

(1-888-356-2258).

MAINTENANCE SCHEDULE

OPERATION DAILY WEEKLY MONTHLY 3 MONTHS

CHECK OIL LEVEL

DRAIN TANK

CHECK AIR FILTER

CHECK SAFETY VALVE

CLEAN UNIT

CHECK BELT TIGHTNESS

CHANGE OIL*

●

●

●

●

●

●

●

* Change oil after fi rst fi fty (50) hours of operation then perform oil changes every three (3)

months.

TROUBLESHOOTING

PROBLEM POSSIBLE CAUSE CORRECTIVE ACTION

Low discharge

pressure

1. Air demand exceeds

pump capacity

2. Restricted air intake 2. Clean or replace the air filter element.

3. Air leaks (fittings,

tubing on compressor,

or plumbing outside of

system)

1. Reduce air demand or use a compressor with

more capacity.

3. Listen for escaping air. Apply soap solution to

all fittings and connections. Bubbles will appear

at points of leakage. Tighten or replace leaking

fittings or connections. Use pipe thread sealant.

16

kobalttools.com

Page 17

TROUBLESHOOTING

PROBLEM POSSIBLE CAUSE CORRECTIVE ACTION

Low discharge

pressure

(Continued)

Excessive noise

(knocking)

4. Blown gaskets 4. Replace any gaskets proven faulty on

inspection.

5. Leaking or damaged

valves

5. Remove head and inspect for valve breakage,

misaligned valves, damaged valve seats, etc.

Replace defective parts and reassemble.

CAUTION

Unit care and maintenance. Install a new

head gasket each time the head is removed.

1. Loose motor pulley or

flywheel

2. Loose fasteners on pump

or motor

3. Lack of oil in crankcase 3. Check for proper oil level; if low, check for

4. Worn connecting rod 4. Replace connecting rod. Maintain oil level and

5. Worn piston pin bores 5. Remove piston assemblies from the

6. Piston hitting the valve

plate

7. Noisy check valve in

compressor system

1. Tighten pulley / flywheel clamp bolts and setscrews.

2. Tighten fasteners.

possible damage to bearings. Dirty oil can

cause excessive wear.

change oil more frequently.

compressor and inspect for excess wear.

Replace excessively worn piston pin or pistons,

as required. Maintain oil level and change oil

more frequently.

6. Remove the compressor head and valve plate

and inspect for carbon deposits or other foreign

matter on top of piston. Replace head and

valve plate using new gasket. See Lubrication

section for recommended oil.

7. Replace check valve.

Large quantity of oil

in the discharge air

NOTE: In an oillubed compressor

there will always be

a small amount of

oil in the air stream.

1. Worn piston rings 1. Replace with new rings. Maintain oil level and

2. Compressor air intake

restricted

3. Excessive oil in

compressor

4. Wrong oil viscosity 4. Use Mobil 1

DANGER

Risk of Explosion. Do not

disassemble check valve with air

pressure in tank.

change oil more frequently.

2. Clean or replace filter. Check for other

restrictions in the intake system.

3. Drain down to full level.

®

10W-30 or full synthetic.

17

kobalttools.com

Page 18

TROUBLESHOOTING

PROBLEM POSSIBLE CAUSE CORRECTIVE ACTION

Water in discharge

air / tank

Motor hums and

runs slowly or not

at all

Normal operation. The

amount of water increases

with humid weather

1. Low voltage 1. Check incoming voltage. It should be

2. Use of extension cord 2. Do not use an extension cord. Use longer air

3. Too many devices on

same circuit

4. Loose electrical

connections

5. Malfunctioning pressure

switch - contacts will not

close

6. Malfunctioning check

valve

1. Drain tank more often. At least daily.

2. Add a filter to reduce the amount of water in the

air line.

approximately 230 volts. Motor will not run

properly on 208 volts. Low voltage could

be due to wires (from electrical source to

compressor) being too small in diameter and /

or too long. Have a qualified electrician check

these conditions and make repairs as needed.

hose with larger diameter.

3. Limit the circuit to the use of compressor only

4. Check all electrical connections.

5. Replace pressure switch.

6. Replace check valve.

Reset mechanism

cuts out repeatedly

or circuit breaker

trips repeatedly

DANGER

Risk of Explosion. Do not

disassemble check valve with air

pressure in tank.

7. Defective unloader valve

on pressure switch

8. Defective motor

capacitor(s)

9. Defective motor 9. Replace motor.

1. Lack of proper

ventilation / room

temperature too high

2. Too many devices on

same circuit

3. Restricted air intake 3. Clean or replace filter element.

4. Loose electrical

connection

5. Pressure switch shut-off

pressure set too high

7. Replace unloader valve.

8. Replace capacitor(s).

1. Move compressor to well-ventilated area.

2. Limit the circuit to the use of only the air

compressor.

4. Check all electrical connections.

5. Replace pressure switch.

18

kobalttools.com

Page 19

TROUBLESHOOTING

PROBLEM POSSIBLE CAUSE CORRECTIVE ACTION

Reset mechanism

cuts out repeatedly

or circuit breaker

trips repeatedly

(Continued)

Tank does not hold

pressure when

compressor is off

and the shut off

valve is closed

6. Malfunctioning check

valve

6. Replace check valve.

DANGER

Risk of Explosion. Do not

disassemble check valve with air

pressure in tank.

7. Defective unloader valve

on pressure switch

8. Defective motor

capacitor(s)

9. Malfunctioning motor 9. Replace motor.

1. Air leaks (fittings, tubing

on compressor, or

plumbing outside system)

2. Worn check valve 2. Replace check valve.

7. Replace unloader valve.

8.Replace capacitor(s).

1. Check all connections with soap and water

solution. Tighten; or remove and apply sealant

to threads, then reassemble.

DANGER

3. Check tank for cracks or

pin holes

Pressure switch

continuously

blows air out the

unloader valve

Excessive vibration 1. Loose fasteners on pump

Malfunctioning check valve Replace the check valve if the unloader valve on

or motor

2. Belt needs replaced 2. Replace with correct size.

3. Belt alignment 3. Align flywheel and pulley.

Risk of Explosion. Do not

disassemble check valve with air

pressure in tank.

3. Replace tank. Never repair a damaged tank.

the pressure switch bleeds off constantly when

unit shuts off.

DANGER

Risk of Explosion. Do not

disassemble check valve with air

pressure in tank.

1. Tighten fasteners.

19

kobalttools.com

Page 20

TROUBLESHOOTING

PROBLEM POSSIBLE CAUSE CORRECTIVE ACTION

Pressure switch

does not release

air when the unit

shuts off

Malfunctioning unloader

valve on pressure switch

Replace the unloader valve if it does not release

the pressure for a short period of time when the

unit shuts off.

DANGER

Risk of Explosion. Do not

disassemble unloader valve with

air pressure in tank.

WARRANTY

1. DURATION: From the date of purchase by the original purchaser as follows: Three Years.

2. WHO GIVES THIS WARRANTY: Campbell Hausfeld / Scott Fetzer Company, 100 Production

Drive, Harrison, Ohio, 45030.

3. WHO RECEIVES THIS WARRANTY (PURCHASER): The original purchaser (other than for

purposes of resale) of the compressor.

4. WHAT PRODUCTS ARE COVERED BY THIS WARRANTY: This air compressor.

5. WHAT IS COVERED UNDER THIS WARRANTY: Parts and Labor to remedy substantial

defects due to material and workmanship during the first year of ownership with the exceptions

noted below. Parts only to remedy substantial defects due to material and workmanship during

remaining term of coverage with exceptions noted below.

6. WHAT IS NOT COVERED UNDER THIS WARRANTY:

A. Implied warranties, including those of merchantability and FITNESS FOR A PARTICULAR

PURPOSE ARE LIMITED FROM THE DATE OF ORIGINAL PURCHASE AS STATED IN

THE DURATION. If the compressor is used for commercial, industrial or rental purposes, the

warranty will apply for ninety (90) days from the date of purchase. Four cylinder single stage

compressors and two-stage compressors are not limited to a ninety (90) day warranty when

used in commercial or industrial applications. Some States do not allow limitations on how

long an implied warranty lasts, so the above limitations may not apply to you

B. ANY INCIDENTAL, INDIRECT, OR CONSEQUENTIAL LOSS, DAMAGE, OR EXPENSE

THAT MAY RESULT FROM ANY DEFECT, FAILURE, OR MALFUNCTION OF THE

CAMPBELL HAUSFELD PRODUCT. Some States do not allow the exclusion or limitations of

incidental or consequential damages, so the above limitation or exclusion may not apply to

you.

C. Any failure that results from an accident, purchaser’s abuse, neglect or failure to operate

products in accordance with instructions provided in the owner’s manual(s) supplied with

compressor.

D. Pre-delivery service, e.g. assembly, oil or lubricants, and adjustment.

E. Items or service that is normally required to maintain the product, i.e. lubricants, filters and

gaskets, etc.

F. Gasoline engines and components are expressly excluded from coverage under this limited

warranty. The Purchaser must comply with the warranty given by the engine manufacturer

which is supplied with the product

20

kobalttools.com

Page 21

WARRANTY

G. Additional items not covered under this warranty:

1. Excluded items pertaining to All Compressors

a. Any component damaged in shipment or any failure caused by installing or operating

unit under conditions not in accordance with installation and operation guidelines or

damaged by contact with tools or surroundings.

b. Pump or valve failure caused by rain, excessive humidity, corrosive environments or

other contaminants.

c. Cosmetic defects that do not interfere with compressor functionality.

d. Rusted tanks, including but not limited to rust due to improper drainage or corrosive

environments.

e. The following components are considered normal wear items and are not covered

after the first year of ownership. Electric motor, check valve, pressure switch, regulator,

pressure gauges, hose, tubing, pipe, fittings and couplers, screws, nuts, hardware

items, belts, pulleys, flywheel, air filter and housing, gaskets, seals, oil leaks, air leaks,

oil consumption or usage, piston rings.

f. Tank drain valves.

g. Damage due to incorrect voltage or improper wiring.

h. Other items not listed but considered general wear parts.

i. Pressure switches, air governors, load/unload devices, throttle control devices and

safety valves modified from factory settings.

j. Damage from inadequate filter maintenance.

k. Induction motors operated with electricity produced by a generator.

2. Excluded items specific to Lubricated Compressors:

a. Pump wear or valve damage caused by using oil not specified.

b. Pump wear or damage caused by any oil contamination.

c. Pump wear or damage caused by failure to follow proper oil maintenance guidelines,

operation below proper oil level or operation without oil.

H. Labor, service call, or transportation charges after the first year of ownership of stationary

compressors. Stationary compressors are defined as not including a handle or wheels.

7. RESPONSIBILITIES OF WARRANTOR UNDER THIS WARRANTY: Repair or replace, at

Warrantor’s option, compressor or component which is defective, has malfunctioned and/or

failed to conform within the duration of the specific warranty period.

8. RESPONSIBILITIES OF PURCHASER UNDER THIS WARRANTY:

A. Provide dated proof of purchase and maintenance records.

B. Call customer service at 1-888-3KOBALT (1-888-356-2258) to obtain your warranty service

options. Freight costs must be borne by the purchaser.

C. Use reasonable care in the operation and maintenance of the products as described in the

owner’s manual(s).

D. Repairs requiring overtime, weekend rates, or anything beyond the standard manufacturer

warranty repair labor reimbursement rate.

E. Time required for any security checks, safety training, or similar for service personnel to gain

access to facility.

F. Location of unit must have adequate clearance for service personnel to perform repairs and

be easily accessible.

9. WHEN WARRANTOR WILL PERFORM REPAIR OR REPLACEMENT UNDER THIS

WARRANTY: Repair or replacement will be scheduled and serviced according to the normal

work flow at the servicing location, and depending on the availability of replacement parts.

This Limited Warranty applies in the U.S., Canada and Mexico only and gives you specific legal

rights. You may also have other rights which vary from state to state or country to country.

21

kobalttools.com

Page 22

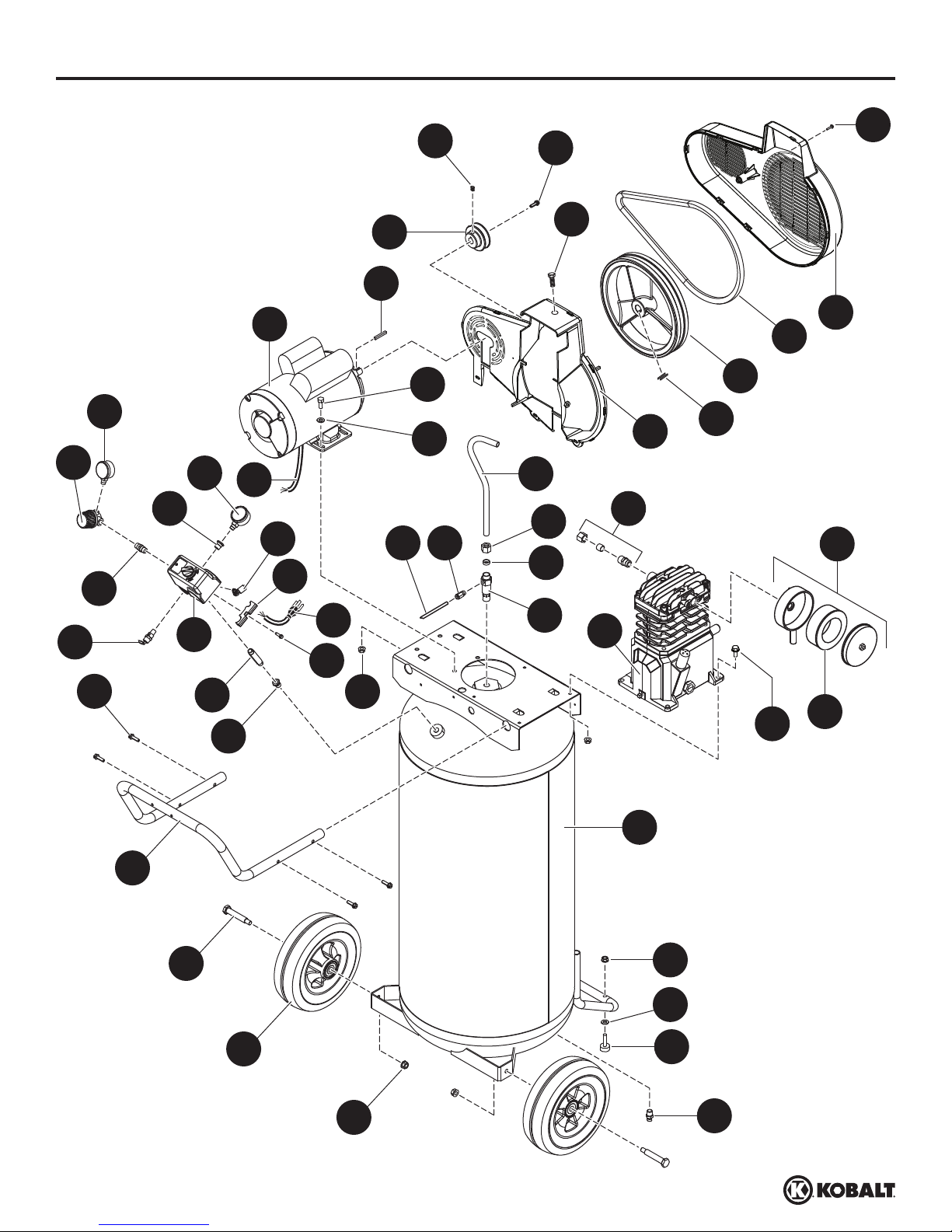

REPLACEMENT PARTS LIST

35

23

24

34

25

36

37

52

32

50

7

16

26

17

15

29

40

31

33

30

28

18

14

22

21

44

19

8

9

13

11

10

20

41

12

5

48

51

49

42

43

1

6

4

49

39

3

38

27

2

22

kobalttools.com

Page 23

REPLACEMENT PARTS LIST

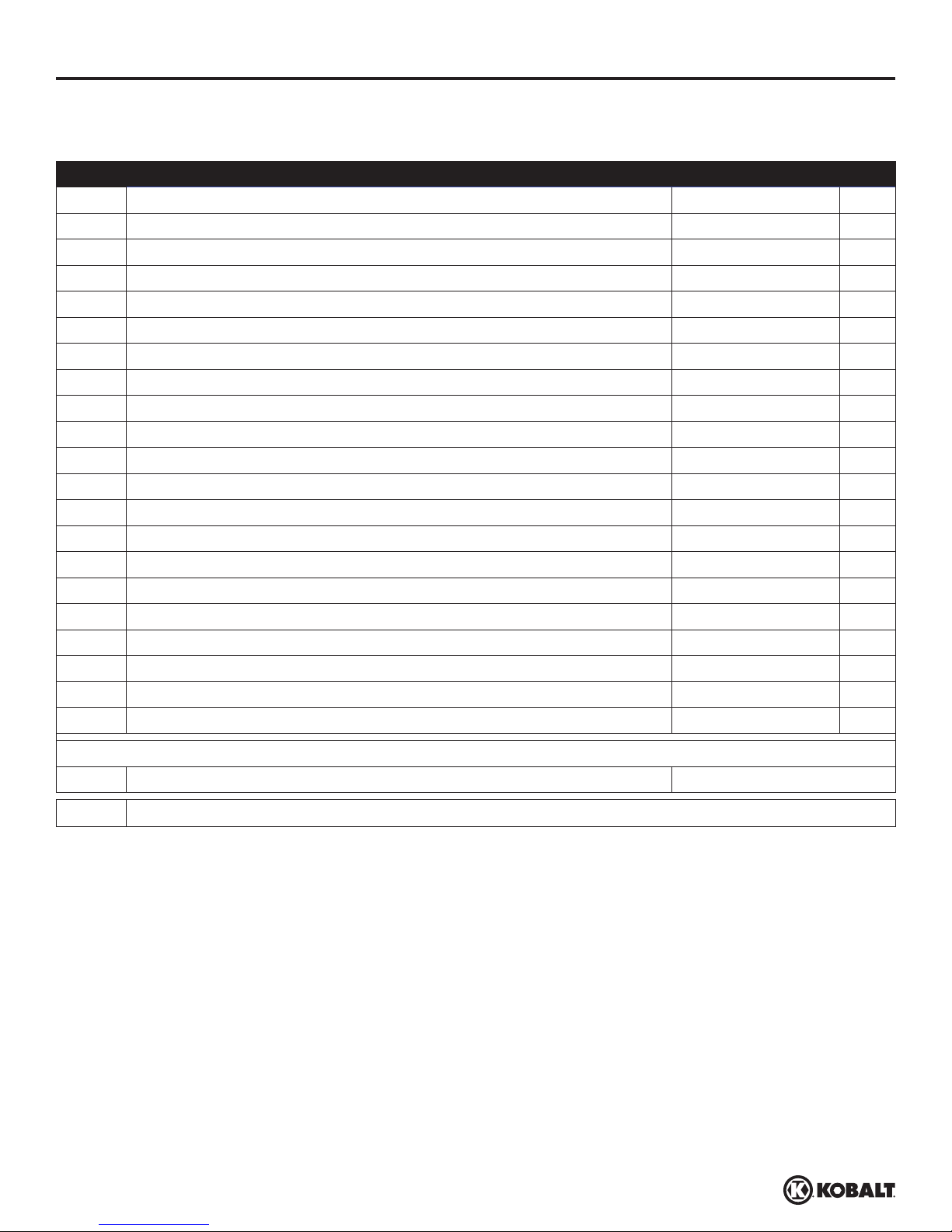

For replacement parts, call our customer service department at 1-888-3KOBALT (1-888-356-2258),

8:00 am - 8:00 pm, EST, Monday - Friday.

PART DESCRIPTION PART NUMBER QTY.

1 Tank AR066500CG 1

2 Drain valve D-1403 1

3 Wheel WA006000AV 2

4 Axle bolt ST084700AV 2

5 Handle screw ST073273AV 4

6 Handle HL038101AV 1

7 Regulator RE300900AV 1

8 1/4 inch Nipple HF002401AV 1

9 ASME Safety Valve V-215109AV 1

10 Power cord EC012602AV 1

11 Strain relief CW209600AV 1

12 Strain relied screw ST209800AV 1

13 Pressure switch CW218700AV 1

14 Unloader CW210001AV 1

15 Reducer ST071407AV 1

16 Gauge GA016310AV 1

17 Exhaust tube VT046800AP 1

18 Compression nut ST033001AV 1

19 Ferrule ST085200AV 1

20 Check valve CV221502AJ 1

21 Push-in fitting ST081301AV 1

22 Unloader tube ST117802AV 1

23 Plascrew ST058502AV 1

24 #10 - 24 Selftapping screw ST073278AV 3

25 Self tapping screw ST073269AV 1

26 Motor cord EC012800AV 1

27 Rubber foot ST162601AV 2

28 Beltguard (front) BG222200AV 1

29 Beltguard (back) BG222300AV 1

30 Belt BT013000AV 1

31 Flywheel with key PU015901SJ 1

32 Gauge GA016300AV 1

33 Key (included with flywheel) Not Available 1

34 Pulley PU015200AV 1

23

Continued on next page

kobalttools.com

Page 24

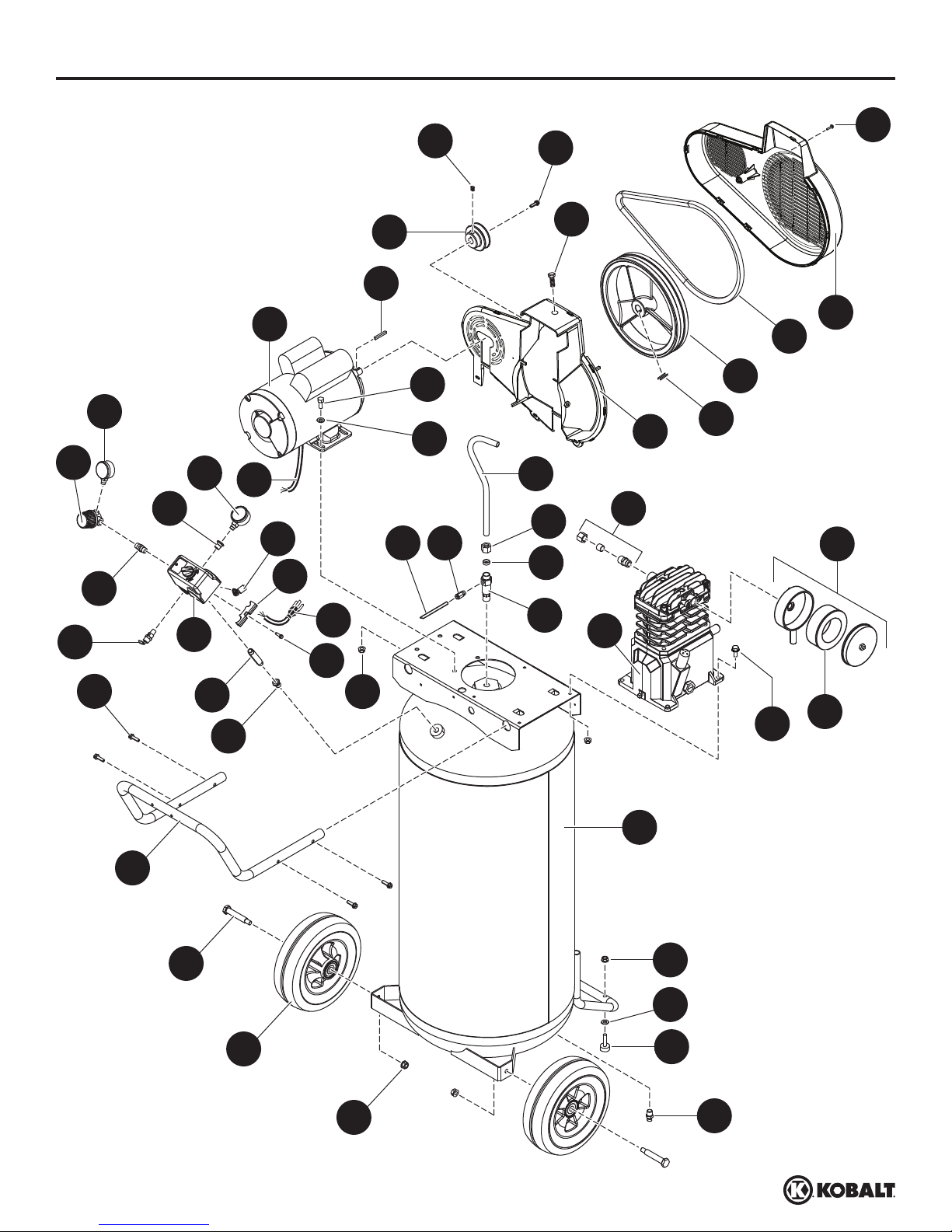

REPLACEMENT PARTS LIST

35

23

24

34

25

36

37

52

32

50

7

16

26

17

15

29

40

31

33

30

28

18

14

22

21

44

19

8

9

13

11

10

20

41

12

5

48

51

49

42

43

1

6

4

49

39

3

38

27

2

24

kobalttools.com

Page 25

REPLACEMENT PARTS LIST

▲

▲

For replacement parts, call our customer service department at 1-888-3KOBALT (1-888-356-2258),

8:00 am - 8:00 pm, EST, Monday - Friday.

PART DESCRIPTION PART NUMBER QTY.

35 1/4 inch - 20 x 1/2 inch Square head ST012200AV 1

36 Key KE000903AV 1

37 Electric motor MC015502SJ 1

38 Nut ST033500AV 2

39 Washer ST070930AV 2

40 Compression connector assembly ST018300AV 1

41 Pump VT480000AV 1

42 Tapping screw ST073275AV 4

43 Filter Element VH901800AV 1

44 Filter VH901700AV 1

45

46

47

Inspection port reducer (

)

Inspection port o-ring (▲)

Inspection port reducer 1-1/2 inch (▲)

PG150006AV 1

ST070191AV 2

PG150008AV 1

48 1/4 inch Nipple ST016800AV 1

49 5/16 inch x 18 Spinlock nut ST146001AV 6

50 5/16 inch Washer ST011200AV 4

51 1/2 inch - 14 x 1/4 inch Reducer ST071428AV 1

52 5/16 inch - 18 x 3/4 inch Hex head screw ST070692AV 4

53

Warning label (▲)

Not shown

DK711200AV 1

25

kobalttools.com

Page 26

REPLACEMENT PARTS LIST

16

17

20

14

15

21

5

13

10

11

12

9

7

4

6

3

2

8

19

26

1

18

kobalttools.com

Page 27

REPLACEMENT PARTS LIST

For replacement parts, call our customer service department at 1-888-3KOBALT (1-888-356-2258),

8:00 am - 8:00 pm, EST, Monday - Friday.

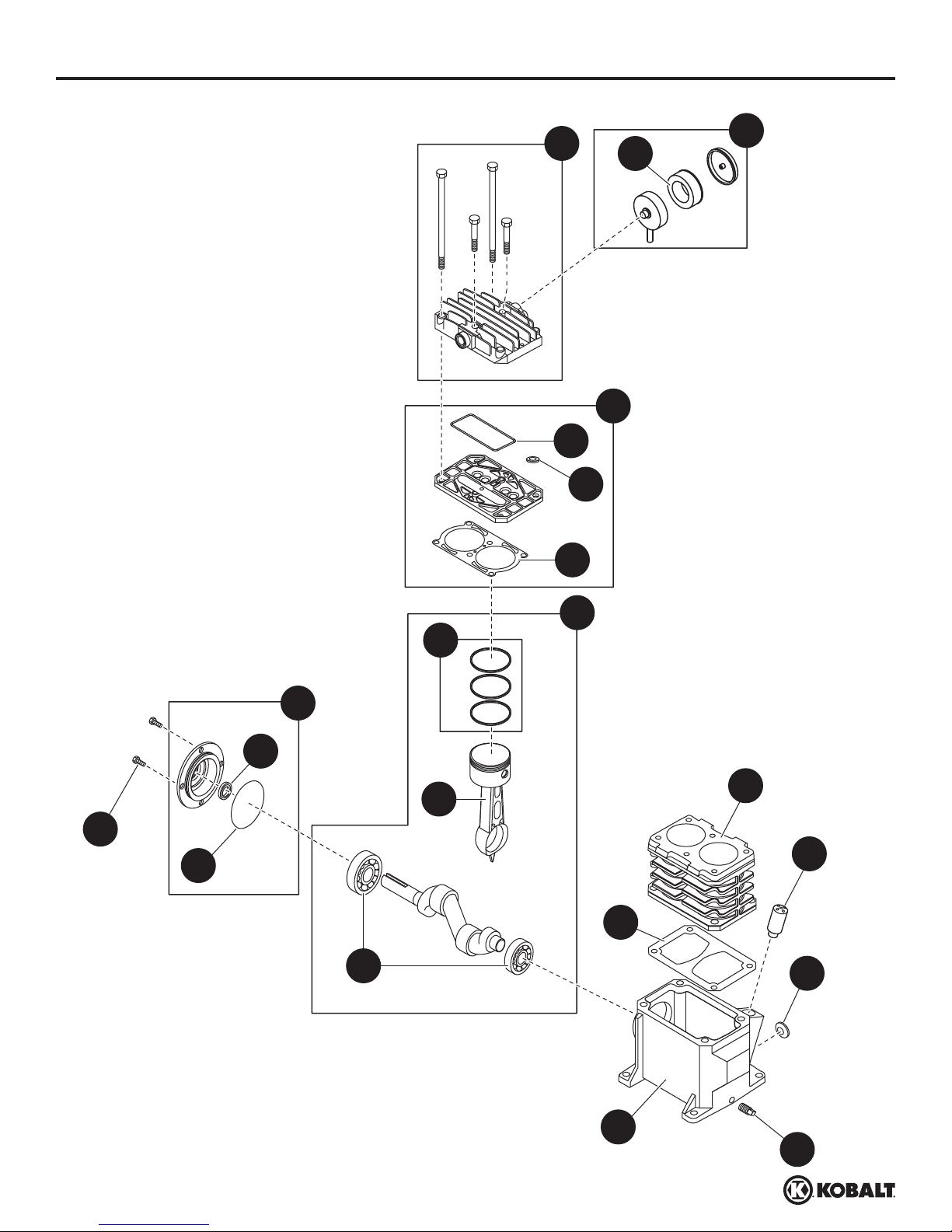

PART DESCRIPTION PART NUMBER QTY.

1 Crankcase VT040300AV 1

2 Crankcase gasket

▲

3 Breather VH901100AV 1

4 Cylinder VT040715AV 1

5 Cylinder gasket

▲

6 Connecting rod and piston assembly VT020500AV 2

7 Piston ring set VT911200AV 2

8 Ball bearing ST084202AV 2

9 Crankshaft, bearings, rods, piston, rings assembly VT040650AV 1

10 O-ring

▲

11 Oil seal ST129700AV 1

12 Bearing cap assembly VT040200AJ 1

13 M6 x 10 mm screw

❋

14 Valve plate assembly VT491100AV 1

15 Valve plate molded seal

▲

16 Cylinder head and fasteners TQ900800AJ 1

17 Air fi lter assembly VH901700AV 1

18 1/8 inch - 27 Oil drain plug ST022300AV 1

19 Sight glass ST191700AV 1

20 Air fi lter element VH901800AV 1

21 O-ring VT036700AV 1

1

1

1

4

1

REPLACEMENT PARTS KITS

▲

❋

Gasket Kit VT470900AJ

Standard hardware item

27

kobalttools.com

Page 28

NOTES

KOBALT® and the K Design® are registered

trademarks of LF, LLC. All Rights Reserved.

28

Printed in U.S.A.

kobalttools.com

Page 29

ARTICLE #0268707

COMPRESSEUR

D’AIR

PORTATIF

MODÈLE #VT6389

Kobalt® et le motif K&Design® sont des marques de

commerce déposées de LF, LLC. Tous droits réservés.

JOIGNEZ VOTRE REÇU ICI

Numéro de série Date d’achat

Des questions, des problèmes, des pièces manquantes? Avant de retourner l’article

au détaillant, appelez notre service à la clientèle au 1 888 3KOBALT (1 888 356-2258),

entre 8 h et 20 h (HNE), du lundi au vendredi.

29

kobalttools.com

IN638401AV 5/13

Page 30

TABLE DES MATIÈRES

Consignes de sécurité ................................................................................................................... 31

Contenu de l’emballage ................................................................................................................. 34

Quincaillerie incluse....................................................................................................................... 35

Préparation .................................................................................................................................... 36

Instructions pour l’assemblage ...................................................................................................... 36

Mode d’emploi ............................................................................................................................... 42

Entretien ........................................................................................................................................ 44

Dépannage .................................................................................................................................... 46

Garantie ......................................................................................................................................... 50

Liste des pièces de rechange ........................................................................................................ 52

CARACTÉRISTIQUES DU PRODUIT

COMPOSANTE CARACTÉRISTIQUES

Modèle VT6389

HP 2

Nombre de cylindres 2

Débit d’air à 90 lb/po

2

5,5 pi3/min

Tension 120 volts / 15 A

Pression maximale 155 lb/po

COMPOSANTE CARACTÉRISTIQUES

Volume maximal

251,38 ml (8,5 oz)

d’huile

Taille du raccord de

sortie du réservoir

NPT de 0,63 cm

(1/4 po)

Profondeur 58,42 cm

2

Largeur 60,96 cm

Hauteur 116,84 cm

Poids 80,74 kg

30

kobalttools.com

Page 31

CONSIGNES DE SÉCURITÉ

Assurez-vous de lire et de comprendre l’intégralité de ce manuel avant de tenter d’assembler, d’installer

ou d’utiliser le produit. Si vous avez des questions concernant ce produit, veuillez appeler notre service à

la clientèle au 1 888 3KOBALT (1 888 356-2258), entre 8 h et 20 h (HNE), du lundi au vendredi.

Ce manuel contient des renseignements qu’il est important de lire et de comprendre.

Ces renseignements sont fournis pour votre SÉCURITÉ et afi n de PRÉVENIR LES PROBLÈMES LIÉS

AU MATÉRIEL. Afi n de trouver ces renseignements, repérez les symboles suivants.

DANGER

DANGER indique un risque imminent qui

entraînera la mort ou des blessures graves

s’il n’est pas prévenu.

MISE EN GARDE

MISE EN GARDE indique un risque potentiel

qui, s’il n’est pas éliminé, POURRAIT

provoquer des blessures mineures ou

moyennement graves.

CONSIGNES DE SÉCURITÉ

PROPOSITION 65 DE LA CALIFORNIE

AVERTISSEMENT

Manipulez avec soin. Ce produit ou son

cordon d’alimentation peuvent contenir

des produits chimiques reconnus par l’État

de la Californie comme étant la cause de

cancers, d’anomalies congénitales et d’autres

problèmes liés aux fonctions reproductrices.

Lavez-vous les mains après l’avoir manipulé.

CONSIGNES DE SÉCURITÉ GÉNÉRALES

AVERTISSEMENT

Indique des conditions qui représentent un risque

d’accident pouvant entraîner la mort ou des

blessures graves si elles ne sont pas prévenues.

REMARQUE

Cette mention désigne des indications

importantes qui, si elles ne sont pas

respectées, pourraient se traduire par des

dommages à l’équipement.

AVERTISSEMENT

Portez des gants et un masque.

Vous pouvez produire de la

poussière lorsque vous coupez,

poncez, percez ou meulez

des matériaux comme le bois,

la peinture, le métal, le béton,

le ciment ou d’autres matériaux de

maçonnerie. Cette poussière peut

contenir des produits chimiques

reconnus comme étant la cause de

cancers, d’anomalies congénitales et

d’autres problèmes liés aux fonctions

reproductrices. Portez l’équipement

de protection nécessaire.

Puisque le compresseur à air et les autres composants (pompes de matériaux, pistolets de

pulvérisation, filtres, lubrificateurs, tuyaux, etc.) utilisés forment un système de pompage à haute

pression, les consignes de sécurité suivantes doivent être observées en tout temps :

1. Lisez soigneusement tous les guides liés à ce produit. Familiarisez-vous avec les commandes et

l’utilisation adéquate de l’appareil.

2. Veuillez suivre tous les codes de sécurité et d’électricité de votre région, ainsi que le Code

canadien de l’électricité et la Loi sur la santé et la sécurité du travail.

3. Seules les personnes connaissant bien ces règles pour une utilisation sécuritaire devraient être

autorisées à utiliser le compresseur.

31

kobalttools.com

Page 32

CONSIGNES DE SÉCURITÉ

CONSIGNES GÉNÉRALES DE SÉCURITÉ (suite)

4. Gardez les visiteurs à l’écart et ne laissez JAMAIS les enfants s’approcher de la zone de travail.

5. Portez des lunettes de sécurité et des protecteurs d’oreilles lorsque vous utilisez cet appareil.

6. Ne vous tenez pas sur l’appareil, et ne l’utilisez pas comme appui.

7. Avant chaque utilisation, vérifiez si le système à air comprimé et ses composantes électriques

sont endommagés ou présentent des signes de détérioration ou de faiblesse ou des fuites.

Réparez ou remplacez tout élément défectueux avant utilisation.

8. Vérifiez fréquemment si toutes les fixations sont bien serrées.

9. Ne portez pas de vêtements amples ou des bijoux qui pourraient s’accrocher dans les pièces

en mouvement.

10. Gardez les doigts loin d’un compresseur en marche; les pièces en mouvement rapide et chaudes

peuvent causer des blessures et des brûlures.

11. Si l’appareil se met à vibrer de façon anormale, ARRÊTEZ le moteur et cherchez immédiatement

la cause de la vibration. La vibration indique généralement qu’il y a un problème.

12. Afin de réduire les risques d’incendie, ne laissez pas d’huile, de solvant ou de graisse excessive

sur la paroi extérieure du moteur.

13. Ne tentez jamais de régler la soupape de sûreté ASME. Laissez la soupape de sûreté libre de

peinture et d’autres résidus accumulés.

14. Les réservoirs tendent à rouiller avec l’accumulation d’humidité, ce qui les affaiblit. Videz le

réservoir régulièrement et vérifiez périodiquement l’existence de conditions dangereuses, comme

la formation de rouille et la corrosion.

15. L’air qui se déplace rapidement soulèvera des poussières et des débris qui peuvent représenter

un danger. Laissez l’air sortir lentement lorsque vous éliminez l’humidité ou que vous soulagez la

pression du système de compresseur.

DANGER

Risque de blessure. Ce compresseur NE

permet PAS de produire de l’air de qualité

respirable, et il NE doit PAS être utilisé à cette

fin. Si vous devez produire de l’air de qualité

respirable, vous devez raccorder le compresseur

à un équipement de sécurité et d’alarme

approprié. Cet équipement est nécessaire pour

filtrer et purifier l’air de façon appropriée afin

de répondre aux exigences minimales pour la

qualité de l’air de classe D, selon des critères

établis par la norme Air Specification G-7.1 1 de

la Compressed Gas Association, Inc., la norme

29 CFR 1910.134 de l’OSHA, ou l’Association

canadienne de normalisation (CSA).

AVIS DE NON-RESPONSABILITÉ

DES GARANTIES

Si le compresseur est utilisé aux fins de

production d’air respirable sans utilisation

simultanée d’équipement de sécurité et d’alarme

approprié, toutes les garanties sont annulées et

le fabricant décline toute responsabilité quant aux

pertes, aux blessures ou dommages consécutifs.

DANGER

Risque d’explosion. Ne tentez

jamais de réparer ni de modifi er un

réservoir! La soudure, le perçage ou

toute autre modifi cation fragiliseront

le réservoir, ce qui entraînera des

dommages attribuables à une

rupture ou à une explosion.

Remplacez toujours les réservoirs

fi ssurés, usés ou endommagés.

AVERTISSEMENT

Risque d’incendie. Les moteurs,

appareils électriques et contrôles

peuvent générer des arcs électriques

qui enfl ammeront un gaz ou une

vapeur infl ammable. Ne faites

jamais fonctionner l’appareil

à proximité d’un gaz ou d’une vapeur

infl ammable. N’entreposez jamais

de liquides ou de gaz infl ammables

à proximité du compresseur.

32

kobalttools.com

Page 33

CONSIGNES DE SÉCURITÉ

CONSIGNES GÉNÉRALES DE SÉCURITÉ (suite)

AVERTISSEMENT

Risques de blessures ou de dommages

à l’appareil. N’installez jamais de vanne

d’arrêt entre le compresseur et le réservoir.

AVERTISSEMENT

Risque de blessure. Ne faites

jamais fonctionner le compresseur

sans garde-courroie. Cet appareil

peut se mettre en marche

automatiquement. Les pièces en

mouvement peuvent causer des

blessures ou des dommages.

MISE EN GARDE

Évitez d’utiliser une pression excessive.

Voir la pression de fonctionnement maximale

indiquée sur l’autocollant de spécifi cations du

compresseur. Ne réglez pas le pressostat ou les

soupapes de sécurité à une pression excédant

la pression de fonctionnement maximale.

AVERTISSEMENT

Risque d’explosion. N’utilisez jamais des

tuyaux de plastique (PVC) pour faire circuler de

l’air comprimé. Le non-respect de cette consigne

peut entraîner des blessures graves ou la mort.

AVERTISSEMENT

Risque d’explosion. Une soupape de sûreté

conforme au code ASME avec un réglage ne

dépassant pas la pression maximale de service

autorisée (PMSA) DOIT être installée sur le

réservoir de ce compresseur. La soupape

de sûreté ASME doit avoir une pression et

un débit nominaux suffi sants pour empêcher

l’éclatement du contenu sous pression.

MISE EN GARDE

Risque de blessure. Les pièces

du compresseur peuvent être

chaudes même si l’appareil n’est

plus en marche.

REMARQUE

Entretien. Évacuez tout liquide du réservoir

chaque jour.

PRÉCAUTIONS POUR LA PULVÉRISATION

1. Ne fumez pas lorsque vous pulvérisez de la peinture, des insecticides ou d’autres

substances inflammables.

2. Portez un masque facial ou un masque anti-vapeurs et pulvérisez vos produits dans un endroit

bien aéré afin de prévenir les risques d’incendie et les dangers pour la santé.

3. Ne dirigez pas le jet de peinture ou d’un autre matériau pulvérisé vers le compresseur. Placez le

compresseur aussi loin que possible de la zone de pulvérisation pour minimiser l’accumulation

de résidus sur le compresseur.

4. Lorsqu’un solvant ou un produit chimique toxique est utilisé pour la pulvérisation ou le

nettoyage, suivez les instructions fournies par le fabricant du produit.

AVERTISSEMENT

Risque d’incendie. Ne pulvérisez

pas de matières infl ammables

à proximité d’une fl amme nue

ou d’une source d’infl ammation,

y compris le compresseur.

33

kobalttools.com

Page 34

CONTENU DE L’EMBALLAGE

D

C

E

K

J

H

I

A

G

B

F

PIÈCE DESCRIPTION QTÉ

A Pressostat - INTERRUPTEUR AUTO/OFF – Dans la POSITION d’arrêt

1

automatique (AUTO), le compresseur s’arrête automatiquement lorsque la pression

dans le réservoir atteint la pression maximale préréglée. L’utilisation de l’air contenu

dans le réservoir fait descendre la pression. Lorsque la pression descend sous le

niveau préréglé, le pressostat remet automatiquement le moteur en marche. Lorsque

l’interrupteur est en position OFF, le compresseur ne fonctionne pas. Cet interrupteur

doit se trouver à la position OFF lorsque vous branchez ou que vous débranchez le

cordon d’alimentation.

Lorsque le pressostat éteint le moteur, de l’air s’échappe de la soupape de décharge

en émettant un son pendant un court moment. La pression d’air dans le tuyau

d’évacuation s’en trouve diminuée, ce qui permet au compresseur de redémarrer

plus facilement.

B Soupape de sûreté ASME - Cette soupape évacue de l’air automatiquement

1

lorsque la pression du réservoir dépasse le maximum préréglé.

34

kobalttools.com

Page 35

CONTENU DE L’EMBALLAGE

PIÈCE DESCRIPTION QTÉ

C Tuyau d’évacuation - Ce tuyau transporte l’air comprimé de la pompe vers le clapet

de non-retour. Ce tuyau devient très chaud pendant l’utilisation du compresseur.

Pour éviter les risques de brûlures graves, n’y touchez jamais.

D Clapet de non-retour - Clapet à sens unique qui permet l’entrée de l’air dans le

réservoir mais qui l’empêche de ressortir vers la pompe du compresseur.

E Garde-courroie - Recouvre la courroie, ainsi que la poulie et le volant du moteur. 1

F Robinet de vidange - Se trouve sous le réservoir. Ce robinet permet d’évacuer

l’humidité du réservoir chaque jour afin de réduire les risques de corrosion.

G Manomètre du réservoir - Indique la pression d’air à l’intérieur du réservoir. 1

H Manomètre du tuyau - Indique la pression utilisée pour faire fonctionner les

appareils. Cette pression est augmentée ou réduite par le régulateur.

I Régulateur - Le régulateur contrôle la pression de l’air à la sortie du tuyau. 1

J Filtre à air - Empêche les débris et particules d’entrer dans le compresseur. 1

K Valve d’insufflation d’air - Évent pour le carter. 1

1

1

1

1

QUINCAILLERIE INCLUSE (grandeur réelle)

AA BB CC

Écrou autofreiné

de 5/16 po x 18

Qté : 2

Rondelle

de 5/16 po

Qté : 2

Pied en caoutchouc

Qté : 2

35

kobalttools.com

Page 36

PRÉPARATION

Avant de commencer l’assemblage ou l’installation du produit, assurez-vous d’avoir toutes les pièces.

Comparez les pièces dans l’emballage avec la liste des pièces. S’il y a des pièces manquantes ou

endommagées, n’essayez pas d’assembler ni d’utiliser le produit. Pour obtenir de l’aide ou des pièces

de rechange, communiquez avec le service à la clientèle.

AVERTISSEMENT

Risque de blessure. N’utilisez jamais

l’appareil s’il a été endommagé pendant

la manutention, le transport ou l’utilisation.

Un appareil endommagé pourrait éclater et,

par conséquent, causer des blessures ou

des dommages matériels.

Temps d’assemblage et d’installation approximatif : 20 minutes

Outils nécessaires pour l’assemblage et l’installation (non inclus) : lunettes de sécurité, gants de

travail, clé à cliquet et douille de 9/16 po, clé à molette.

AUTRES PIÈCES NÉCESSAIRES À L’UTILISATION (non incluses)

Vous pouvez vous procurer ces pièces à votre quincaillerie locale.

1. Tuyau à air

2. Pâte d’étanchéité pour joints filetés

INSTRUCTIONS POUR L’ASSEMBLAGE

1. Déboulonnez l’appareil de la palette de

manutention. Utilisez une clé à cliquet et une

douille de 9/16 po. Retirez l’appareil de la

palette. Jeter la quincaillerie de manutention

une fois qu’elle a été retirée.

1

Support de

fi xation pour

l’expédition

Boulon de

fi xation pour

l’expédition

Boulon de fi xation

pour l’expédition

36

kobalttools.com

Page 37

INSTRUCTIONS POUR L’ASSEMBLAGE

2. Installez les pieds en caoutchouc au moyen

d’écrous et de rondelles.

Quincaillerie utilisée

AA

Écrou

BB

Rondelle x 2

Pied en

CC

caoutchouc

x 2

x 2

2

AA

BB

CC

3. Retirez le bouchon de la pompe.

3

Bouchon

37

kobalttools.com

Page 38

INSTRUCTIONS POUR L’ASSEMBLAGE

4. Installez la valve d’insuffl ation

d’air. Installez le fi ltre à air.

4

Filtre à air

Valve

d’insuffl ation

d’air

38

kobalttools.com

Page 39

INSTRUCTIONS POUR L’ASSEMBLAGE

LUBRIFICATION

MISE EN GARDE

Effectuez une inspection avant la première

utilisation. Vérifi ez le niveau d’huile avant

d’utiliser l’appareil.

1

Retirez le bouchon de l’orifice de remplissage

d’huile. Consultez la figure 1. Installez la valve

d’insufflation d’air (comprise dans le sac de

pièces). Consultez la figure 2. Vérifiez le niveau

d’huile; certains modèles contiennent déjà de

l’huile lorsqu’ils sont expédiés. Le volume maximal

et le type d’huile à utiliser sont indiqués sur

l’étiquette apposée à la pompe du compresseur.

RENSEIGNEMENTS SUR L’HUILE

Huile pour compresseur

d’air Kobalt

Huile à mélange

synthétique Kobalt

Huile synthétique Mobil 1

10W30

Volume maximal d’huile 255 millilitres

N’utilisez pas de lubrifiant pour automobile

ordinaire. Les additifs qui y sont présents

pourraient former des dépôts sur la soupape et

user la pompe prématurément. Pour prolonger

au maximum la durée de vie de cette dernière,

vidangez l’huile et remplacez-la après la

première heure d’utilisation.

UGS 221008

UGS 221009

®

2

Bouchon de

vidange d’huile

Bouchon

Valve

d’insuffl ation

d’air

Orifi ce de

remplissage

d’huile

Indicateur de

niveau d’huile

Cette pompe comporte un indicateur permettant

de voir le niveau d’huile (figure 2) afin de la

maintenir au niveau indiqué à la figure 3.

39

3

Niveau

maximum

Niveau bas

Indicateur de niveau d’huile

kobalttools.com

Page 40

INSTRUCTIONS POUR L’ASSEMBLAGE

INFORMATION SUR LES ÉLÉMENTS ÉLECTRIQUES

DANGER AVERTISSEMENT

Risque de choc électrique.

Les moteurs qui ne sont pas

correctement mis à la terre

présentent des risques de chocs.

Assurez-vous que l’équipement

est correctement mis à la terre.

AVERTISSEMENT

Risque d’explosion. Débranchez

l’appareil, verrouillez-le et placez-y

une étiquette d’avertissement,

puis libérez toute la pression

de l’appareil avant d’essayer de

l’installer, de le réparer, de le

déplacer ou de l’entretenir.

REMARQUE

Entretien de l’appareil. Une tension ou

un branchement électrique inadéquats

causant des dommages au moteur annuleront

la garantie.

Risques de blessures ou de dommages

matériels. Un câblage inadéquat entraînera

une surchauffe, un court-circuit et des

dommages causés par le feu.

AVERTISSEMENT

Risque de choc électrique.

L’installation inadéquate de

la fi che de mise à la terre du

compresseur entraîne un risque

de choc électrique. Si le cordon

d’alimentation ou la fi che doivent

être réparés ou remplacés,

ne branchez pas le fi l de mise

à la terre du compresseur sur une

borne d’alimentation (broche).

Le fi l possédant une isolation et

dont la surface est verte, avec ou

sans rayures jaunes, est le fi l de

mise à la terre.

Ne vous servez pas d’une rallonge électrique; utilisez plutôt un tuyau plus long.

Les appareils de 120 volts et de 15 A peuvent être branchés à un circuit de 120 volts et de 15 A dans

les conditions suivantes :

1. Aucun autre appareil électrique ou d’éclairage ne doit être branché au même circuit de dérivation.

2. La tension est de 120 volts.

3. Le circuit est muni d’un disjoncteur de 15 A ou d’un fusible à fusion lente de 15 A de type T

(de type D au Canada).

4. La longueur du fil en cuivre reliant la prise et le disjoncteur ne doit pas excéder 12,20 m

(calibre 14) ou 21,34 m (calibre 12).

40

kobalttools.com

Page 41

INSTRUCTIONS POUR L’ASSEMBLAGE

MISE À LA TERRE

Cet appareil doit être mis à la terre. En cas de court-circuit, la mise à la terre permet de dévier le

courant électrique et donc de réduire les risques de choc électrique. Le cordon d’alimentation du

compresseur est muni d’un fil et d’une fiche de mise à la terre. Vous devez brancher la fiche sur

une prise correctement installée et mise à la terre conformément aux lois et aux codes en vigueur.

N’utilisez pas d’adaptateur de mise à la terre.

Cet appareil est conçu pour être utilisé sur un

circuit d’une tension nominale de 120 volts et est

équipé d’une fiche avec broche de mise à la terre

tel qu’il est illustré à la figure 1. Si les conditions

précédentes ne peuvent être satisfaites ou

si le dispositif de protection ampérimétrique

se déclenche, il est possible d’utiliser ce

compresseur sur un circuit de 120 volts et de

20 ampères. Consultez le figure1.

1

Prise mise à la terre

Prise – 120 V / 15 A

La plaque signalétique du moteur fournit des

indications quant à la compatibilité à 240 volts.

Un appareil de 240 volts doit être utilisé sur un

circuit de 240 volts. Le cordon doit être branché

seulement sur une prise de 240 volts mise

à la terre, ce qui peut nécessiter l’installation

d’un nouveau cordon et d’une nouvelle fiche.

Consultez la figure 2.

Broche de mise

à la terre

Prise – 120 V / 20 A

2

Prise mise à la terre

Prise – 240 V

Broche de mise

à la terre

Consultez un électricien ou un technicien qualifié si vous ne comprenez pas les instructions pour

la mise à la terre ou si vous avez un doute sur la mise à la terre du compresseur. Ne modifiez

pas la fiche de la pompe. Si elle ne se loge pas dans la prise, faites installer une prise appropriée

par un électricien qualifié. Branchez le compresseur uniquement sur une prise ayant les mêmes

caractéristiques que la fiche. N’utilisez pas d’adaptateur avec ce compresseur.

41

kobalttools.com

Page 42

MODE D’EMPLOI

PROCÉDURE DE DÉMARRAGE ET DE RODAGE

AVERTISSEMENT

Risque de blessure. Ne fi xez pas d’outils à air

comprimé à l’extrémité libre du tuyau avant que

la procédure de démarrage n’ait été exécutée et

que l’appareil fonctionne correctement.

1. Vérifiez le niveau d’huile selon les instructions

figurant à la section Lubrification du présent guide.

2. Ouvrez le robinet de vidange inférieur (voir la

figure 1). Tournez la soupape de sortie afin de laisser

passer l’air.

3. Branchez l’appareil.

AVERTISSEMENT

Risque de blessure. Ne desserrez jamais les

joints fi letés lorsqu’il y a de la pression dans

le réservoir!

1

4. Réglez l’interrupteur du pressostat à AUTO afin de

démarrer l’appareil (voir la figure 2).

5. Faites fonctionner l’appareil pendant trente minutes

2

à 0 lb/pi

de la pompe.

6. Réglez le pressostat à OFF et fermez le robinet

de vidange inférieur. Le compresseur est prêt

à être utilisé.

7. Changez l’huile après les cinquante (50) premières

heures d’utilisation. Par la suite, changez l’huile tous

les trois (3) mois.

UTILISATION DU COMPRESSEUR

Il est extrêmement important d’utiliser le compresseur dans un endroit propre, bien aéré, et dont la

température ne dépassera pas 37,78 °C. L’entrée d’air du compresseur doit se trouver loin de toute

source de contamination ou de vapeur, et de tout endroit où l’on effectue des travaux de sablage ou

de peinture par pulvérisation.

(aucune charge) afin de roder les pièces

2

42

kobalttools.com

Page 43

MODE D’EMPLOI

CYCLE DE MARCHE/ARRÊT DU COMPRESSEUR.

AVERTISSEMENT

Risque d’éclatement. Vidangez le réservoir

tous les jours afi n d’éviter la corrosion et les

blessures que pourrait causer un réservoir

endommagé. N’effectuez pas la vidange si le

2

réservoir est à plus de 40 lb/po

de vidange pourrait être endommagé. Évacuez

l’humidité du réservoir tous les jours à l’aide du

robinet de vidange inférieur.

Lorsque l’interrupteur du pressostat est

en position AUTO le compresseur pompe

de l’air dans le réservoir. Le compresseur

s’arrête automatiquement lorsqu’il atteint la

pression préréglée.

Si l’interrupteur du pressostat demeure en

position AUTO et que l’utilisation d’un outil

à air comprimé diminue la quantité d’air

dans le réservoir, le compresseur redémarre

automatiquement dès que la pression minimale

préréglée est atteinte. Lorsqu’un outil est

utilisé sans interruption, le compresseur suit

automatiquement un cycle de marche/arrêt.

Lorsque l’interrupteur du pressostat est réglé

à OFF le compresseur ne se met pas en marche.

ou le robinet

REMARQUE

Entretien de l’appareil. Évacuez tout liquide

du réservoir chaque jour.

1

Robinet de

vidange inférieur

Videz le réservoir. Débranchez l’appareil,

verrouillez-le et placez-y une étiquette

d’avertissement; évacuez la pression. Évacuez

l’humidité du réservoir en ouvrant le robinet de

vidange sous le réservoir (consultez la figure 1).

HUMIDITÉ PRÉSENTE DANS L’AIR COMPRIMÉ

L’humidité présente dans l’air comprimé se transforme en gouttelettes en sortant de la pompe du

compresseur. Lorsque le taux d’humidité de l’air ambiant est élevé ou que le compresseur fonctionne

sans relâche pendant une longue période, cette humidité s’accumule dans le réservoir. Si vous

utilisez un pistolet-pulvérisateur à peinture ou un pistolet de sablage, ces gouttelettes passeront dans

le tuyau reliant le réservoir au pistolet et se retrouveront mélangées au matériau pulvérisé.

IMPORTANT : Ces gouttelettes produiront des traces d’eau lors de travaux de peinture,

particulièrement si vous utilisez une peinture qui n’est pas à base d’eau. Si vous utilisez un

pistolet à sablage, les gouttelettes d’eau aggloméreront le sable, ce qui obstruera le pistolet et le

rendra inutilisable. Pour éliminer l’humidité, installez un fi ltre dans la conduite d’air, aussi près que

possible du pistolet.

43

kobalttools.com

Page 44

ENTRETIEN

AVERTISSEMENT

Risque d’explosion. Débranchez

l’appareil, verrouillez-le et placez-y

une étiquette d’avertissement,

puis libérez toute la pression

de l’appareil avant de tenter de

l’installer, de le réparer, de le

déplacer ou de l’entretenir.

Seuls des représentants autorisés devraient effectuer les réparations de l’appareil.

Pour que l’appareil fonctionne efficacement, effectuez les tâches d’entretien suivantes :

1. Débranchez l’appareil, verrouillez-le et

placez-y une étiquette d’avertissement; retirez

tout débris du moteur, du volant, du réservoir,

des conduites d’air et des ailettes de

refroidissement de la pompe.

2. Maintenez un niveau d’huile adéquat. Pour

en savoir davantage, reportez à la section

Lubrification du présent guide.

3. Changez l’huile.

a. Faites fonctionner le compresseur afin que

l’huile se réchauffe. Débranchez l’appareil,

verrouillez-le et placez-y une étiquette

d’avertissement.

b. Placez un bac sous la pompe.

c. Retirez le bouchon de vidange d’huile (voir

la figure 1). Laissez l’huile s’égoutter dans

le bac.

d. Remettez le bouchon de vidange en place

et remplissez la pompe jusqu’à ce que

l’huile atteigne le niveau maximum (voir

la figure 1). Reportez-vous à la section

Lubrification du présent guide.

4. Videz le réservoir. Débranchez l’appareil,

verrouillez-le et placez-y une étiquette

d’avertissement; évacuez la pression.

Évacuez l’humidité du réservoir en ouvrant

le robinet de vidange inférieur (consultez

la figure 2).

5. Vérifiez si le filtre à air est propre. S’il ne l’est

pas, remplacez-le.

Entretien de l’appareil. Évacuez tout liquide

du réservoir chaque jour.

1

Bouchon de

vidange d’huile

2

REMARQUE

Orifi ce de

remplissage

d’huile

44

kobalttools.com

Page 45

ENTRETIEN

6. Vérifiez l’état de la soupape de sûreté en exécutant les

étapes suivantes :

a. Rétablissez l’alimentation électrique; réglez

l’interrupteur du pressostat à la position AUTO.

Faites fonctionner l’appareil jusqu’il atteigne une

2

pression de 90 lb/po

. Réglez l’interrupteur du

pressostat à OFF.

b. Portez des lunettes de sécurité et des protecteurs

auditifs, puis tirez l’anneau de la soupape de

sûreté afin d’évacuer la pression d’air du réservoir

du compresseur. L’air s’échappera rapidement.

Éloignez-vous et n’exposez pas votre visage

(voir la figure 3).

c. La soupape de sûreté se refermera

automatiquement lorsque la pression atteindra

2

entre 40 et 50 lb/po

. Si l’air ne s’évacue pas après

que vous avez tiré sur l’anneau ou si la soupape

ne se referme pas automatiquement, vous DEVEZ

la remplacer.

7. Surveillez les signes d’usure susceptibles d’apparaître

sur la courroie. Remplacez-la dès que vous vous en

apercevez. Assurez-vous que la tension et l’alignement

de la courroie sont adéquats.

3

SOUTIEN TECHNIQUE

Pour obtenir des renseignements sur le fonctionnement et la réparation de ce produit, veuillez

téléphoner au 1 888 3KOBALT (1 888 356-2258).

PROGRAMME D’ENTRETIEN

ACTION QUOTIDIEN HEBDOMADAIRE MENSUEL 3 MOIS

VÉRIFICATION DU NIVEAU

●

D’HUILE

VIDANGE DU RÉSERVOIR

VÉRIFICATION DU FILTRE À AIR

VÉRIFICATION DE LA SOUPAPE

●

●

●

DE SÛRETÉ

NETTOYAGE DE L’APPAREIL

VÉRIFICATION DE LA TENSION

●

●

DE LA COURROIE

CHANGEMENT DE L’HUILE*

●

* Changez l’huile après les cinquante (50) premières heures de fonctionnement, puis tous les

trois (3) mois.

45

kobalttools.com

Page 46

DÉPANNAGE

PROBLÈME CAUSE POSSIBLE MESURE CORRECTIVE

La pression de

refoulement est

faible

1. La demande d’air excède

la capacité de la pompe

2. La prise d’air est obstruée 2. Nettoyez ou remplacez le filtre à air.

3. L’air fuit (par les raccords,

les tuyaux fixés au

compresseur ou la

tuyauterie extérieure

au système)

4. Des joints d’étanchéité

sont endommagés

5. Les soupapes fuient ou

sont endommagées

1. Réduisez la demande d’air ou utilisez un

compresseur de capacité supérieure.

3. Tendez l’oreille pour repérer les fuites d’air.

Appliquez de l’eau savonneuse sur tous les

raccords et branchements. Des bulles se

forment là où il y a une fuite. Resserrez ou

remplacez les raccords ou les branchements

présentant des fuites. Utilisez de la pâte

d’étanchéité pour joints filetés.

4. Remplacez les joints d’étanchéité

endommagés.

5. Retirez la tête de cylindre et vérifiez si des

soupapes sont brisées, mal alignées ou des

sièges endommagés. Remplacez les pièces

défectueuses et remettez la tête de cylindre

en place.

MISE EN GARDE

Entretien de l’appareil. Installez un nouveau

joint chaque fois que la tête est retirée.

Le compresseur

produit un

bruit excessif

(cognement)

1. La poulie ou le volant du

moteur sont lâches

2. Les fixations de la pompe

ou du moteur sont lâches

3. Il manque d’huile dans

le carter

4. La bielle est usée 4. Remplacez la bielle. Maintenez l’huile au niveau

5. L’alésage de l’axe des

pistons est usé

6. Un piston percute la

plaque porte-soupape

1. Resserrez tous les boulons et les vis de calage

de la poulie et du volant du moteur.

2. Serrez toutes les fixations.

3. Vérifiez le niveau d’huile; s’il est bas, vérifiez si

les roulements sont endommagés. Une huile

sale peut entraîner une usure excessive.

approprié et changez l’huile plus fréquemment.

5. Retirez l’assemblage des pistons et

recherchez-y des signes d’usure excessive.

Au besoin, remplacez l’axe des pistons ou les

pistons eux-mêmes. Maintenez l’huile au niveau

approprié et changez l’huile plus fréquemment.

6. Retirez la tête de compresseur ainsi que la

plaque porte-soupape, et vérifiez s’il y a des