Page 1

ITEM #0232741

KOBALT® and the K Design® are registered

trademarks of LF, LLC. All Rights Reserved.

ATTACH YOUR RECEIPT HERE

Serial Number Purchase Date

Questions, problems, missing parts? Before returning to your retailer, call our customer

service department at 1-888-3KOBALT (1-888-356-2258), 8 a.m. - 8 p.m., EST,

Monday - Friday.

AB14858B

AIRLESS PAINT

SPRAYER

MODEL #SGY-APS41

Français p. 34

Español p. 69

kobalttools.com

Page 2

TABLE OF CONTENTS

......................................................................................................... 2

Package Contents............................................................................................................... 3

Safety Information ............................................................................................................... 4

Preparation.........................................................................................................................10

Understanding Airless Paint Sprayer Components ...........................................................11

21 .........................................................................................................snoitcurtsnI ylbmessA

Operating Instructions ........................................................................................................

Spraying Techniques......................................................................................................... 23

Care and Maintenance......................................................................................................25

Troubleshooting................................................................................................................. 29

Warranty............................................................................................................................ 31

Exploded View .................................................................................................................32

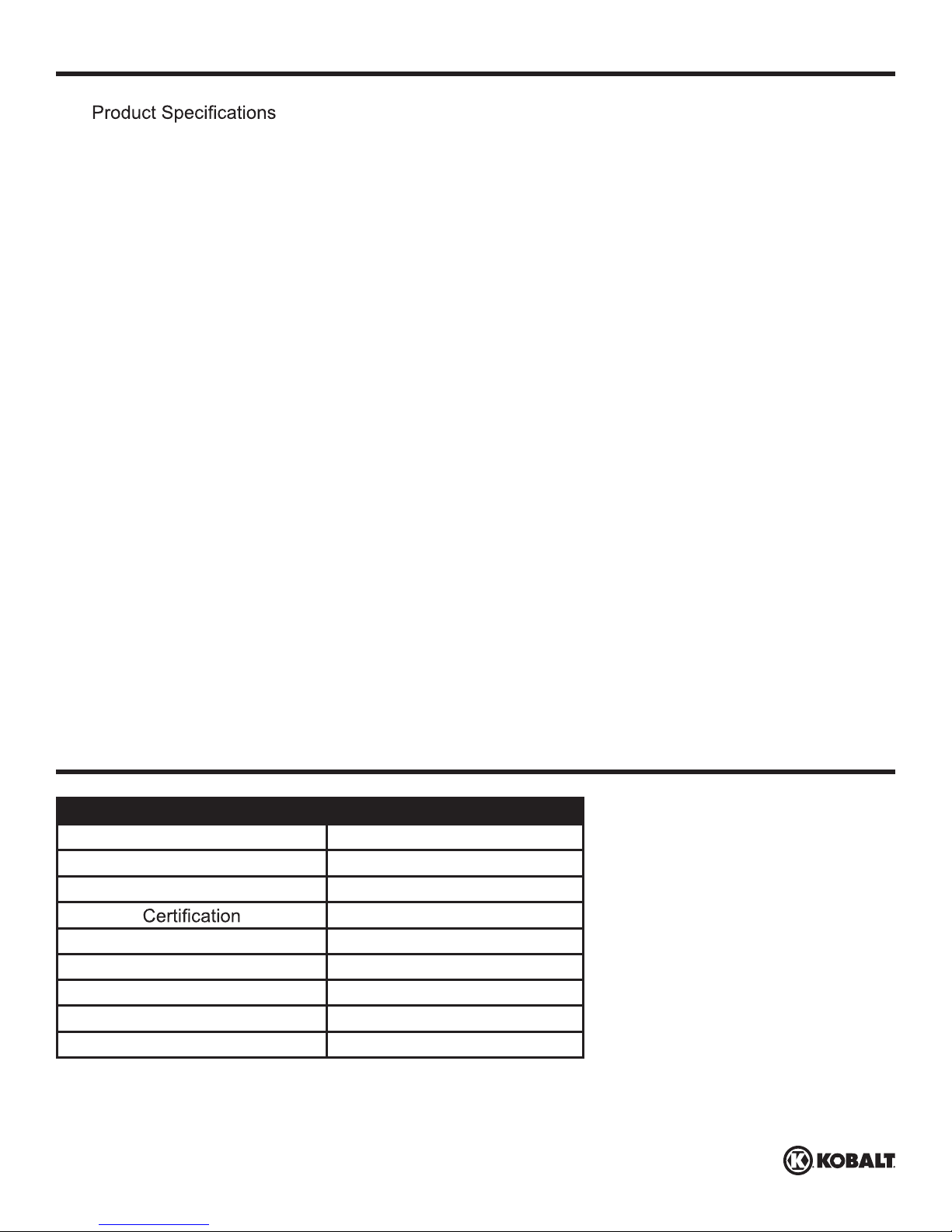

PRODUCT SPECIFICATIONS

COMPONENTS SPECIFICATIONS

Motor Size 5/8 HP

Max Pressure 3,000 PSI

Voltage 120 V, 60 Hz

ETL

Power Cord Length 28 in. (0.73 m)

Nozzle Size Included 517 and 513

Sprayer Width 250 – 310 mm

Flow Rate 0.28 GPM (1.06 L/Min)

Maximum Hose Pressure 3,300 PSI (22.8 Mpa)

17

kobalttools.com

2

Page 3

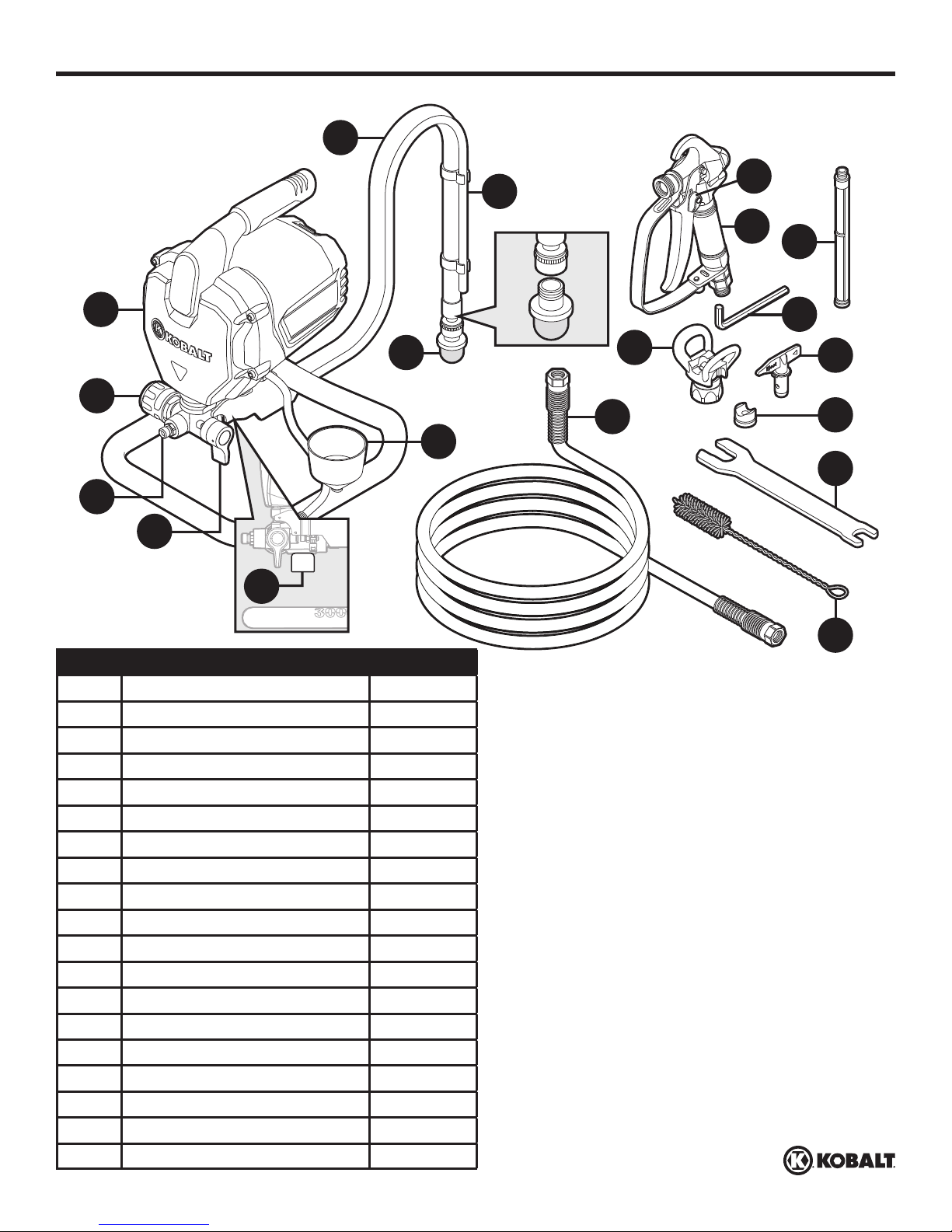

PACKAGE CONTENTS

B

F

G

A

H

N

C

S

D

E

R

K

J

L

M

I

P

O

PART DESCRIPTION QUANTITY

A Airless Paint Sprayer 1

B Suction Tube 1

C Prime Tube 1

D Spray Gun Housing 1

E Internal Gun Filter 1

F Pressure Control Knob 1

G Fluid Outlet 1

H Prime Spray Valve Switch 1

I Inlet Screen 1

J Spray Guard 1

K High Pressure Fluid Hose 1

L Spray Tip 2

M Single Seal Tip 1

N Pressure Release Button 1

O Wrench 1

P Inlet Screen Holder 1

Plastic Bristle Cleaning Brush

Q

1

R Hex Key 1

S Safety Lock 1

Q

kobalttools.com

3

3

Page 4

4

kobalttools.com

Please read and understand this entire manual before attempting to assemble, operate or maintain this

product. If you have any questions, please call our Customer Service Department at 1-888-3KOBALT,

8:00 a.m. – 8:00 p.m. EST, Monday – Friday.

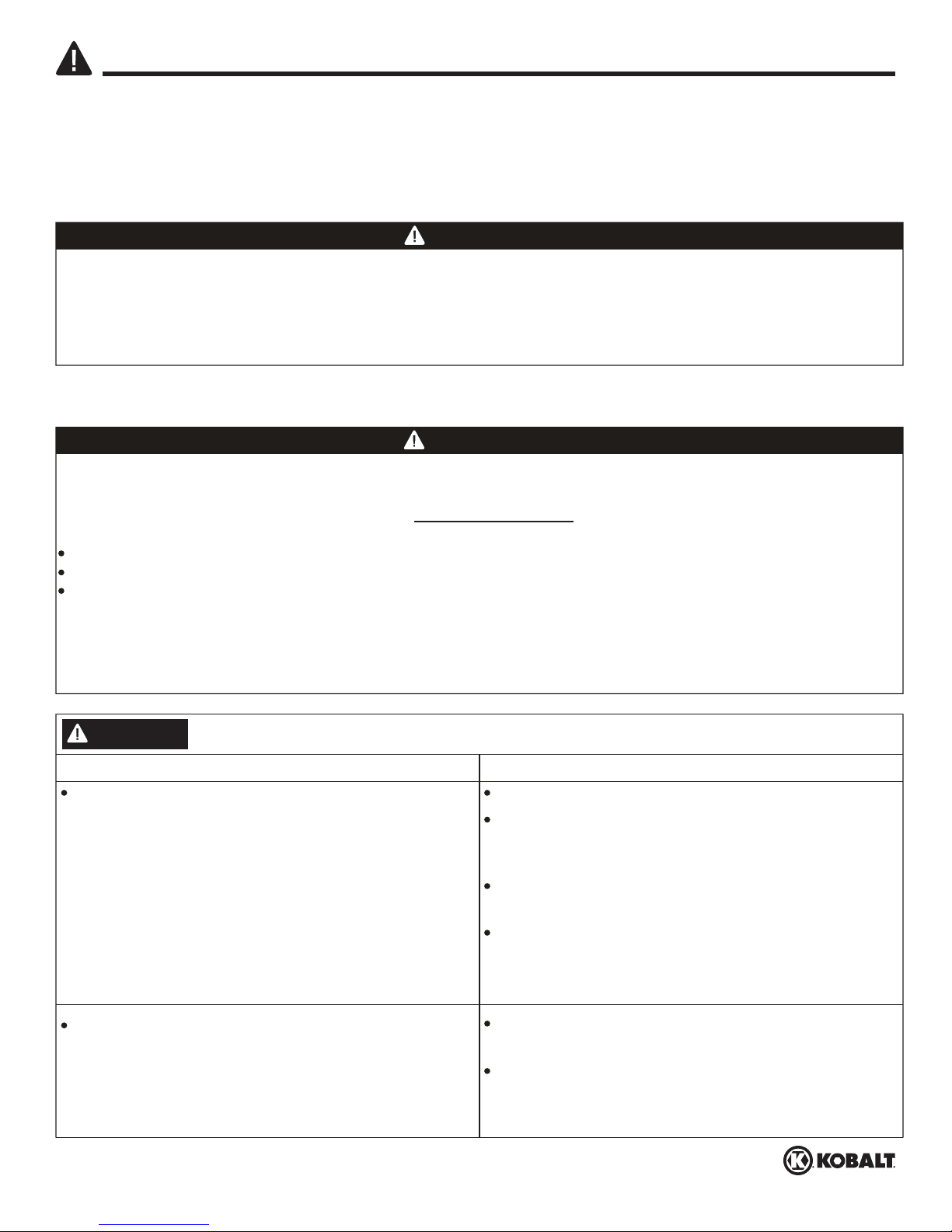

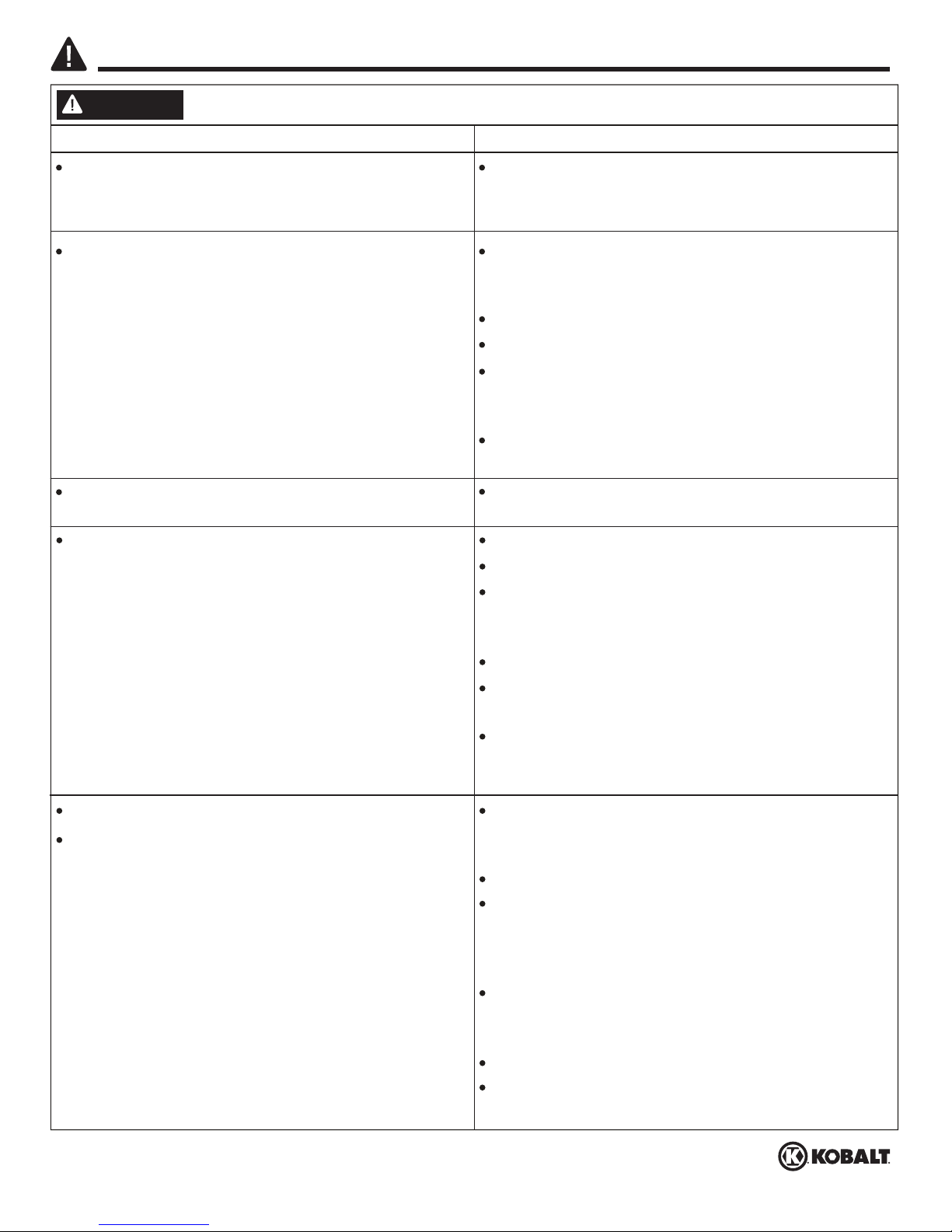

SAFETY INFORMATION

WARNING

Improper operation or maintenance of this tool could result in serious injury and property damage.

Read and understand all warnings and operation instructions before using this tool. When using any

tool, basic safety precautions should always be followed to reduce the risk of personal injury. Use each

tool for its intended function only. Do not use this product in unsafe work conditions. It is always

recommended to keep a fire extinguisher and first aid kit near work areas.

FAILURE TO OBSERVE AND FOLLOW SAFETY INSTRUCTIONS COULD RESULT IN INJURY OR

DEATH.

WARNING

Some dust created by paint spraying, power sanding, sawing, grinding, drilling and other related

activities is known to the state of California to cause cancer, birth defects and other reproductive harm.

A listing of chemicals can be obtained from www.oehha.ca.gov under Proposition 65.

Some examples of these chemicals are:

Lead from lead based paints

Crystalline silica from bricks, cement and other masonry products

Arsenic and chromium from chemically treated lumber

Your risk from these exposures varies, depending on how often you do this type of work. To reduce

your exposure to these chemicals work in a well-ventilated area and wear appropriate/approved safety

equipment such as respirators or dust masks which are specially designed to filter microscopic particles.

Wash hands after handling.

WARNING PAINT SPRAYER HAZARDS

WHAT COULD HAPPEN HOW TO PREVENT IT

Eyes and face can come into direct contact with

sprayed materials, causing serious injury.

Never aim or spray at yourself or anyone else.

Always wear ANSI approved Z87.1 safety glasses

with side shields, appropriate face mask/respirator

and protective clothing when spraying.

Always spray in a well-ventilated area to prevent

health and fire hazards.

If eyes or face come into direct contact with

sprayed materials, contact your local doctor or

emergency room for immediate help.

SAVE THESE INSTRUCTIONS – To reduce the risks of fire or explosion, electrical shock, and personal

injury, read and understand all instructions included in this manual. Be familiar with the controls and

proper usage of the equipment.

Do not spray acids, corrosive materials, toxic

chemicals, fertilizers or pesticides.

Always read the label or Safety Data

Sheet (SDS) for the materials and/or chemicals

before spraying to ensure they are safe to use.

Spraying improper materials or materials not

intended for spray application could result in

serious injury or death.

Page 5

5

kobalttools.com

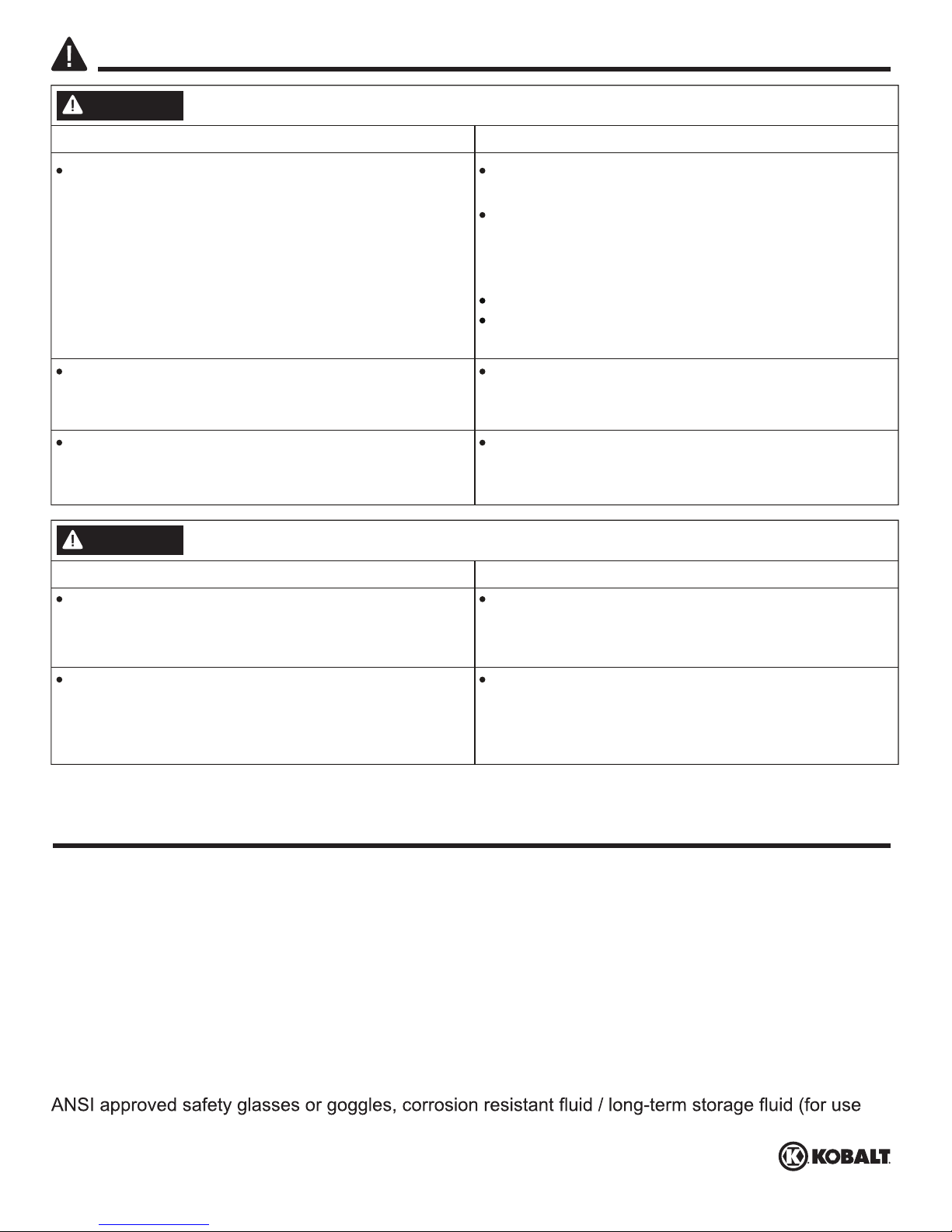

SAFETY INFORMATION

WARNING

PAINT SPRAYER HAZARDS

WHAT COULD HAPPEN HOW TO PREVENT IT

Certain materials that can be used with sprayers

may cause skin irritation if they come in direct

contact with skin.

Always use a face mask/respirator and protective

clothing when spraying.

Always read the label or Safety Data

Sheet (SDS) for the materials and/or chemicals

before spraying to determine if they pose a risk of

cause skin irritation.

Never operate sprayer in the vicinity of open flame

or near ignition sources (pilot lights, cigarettes,

portable electric lamps, etc).

Never operate tools near flammable substances

such as gasoline, naphtha, cleaning solvents, etc.

Work in a clean, well-ventilated area free of

combustible materials.

Ground all equipment in the work area.

This tool is capable of spraying flammable

materials which can result in fire or explosion.

WARNING

RISK OF EYE OR HEAD INJURY

WHAT COULD HAPPEN HOW TO PREVENT IT

Tool attachments can become loose or break and

fly apart, becoming projectiles or propelling other

objects at the operator or bystanders in the work

area.

Make sure all attachments are properly assembled

and securely fastened before use.

Always use the tool at a safe distance from others

in the work area. Maintain awareness of work area

safety at all times.

WARNING

RISK OF LOSS OF HEARING

WHAT COULD HAPPEN HOW TO PREVENT IT

Exposure to noise produced by this tool can lead

to permanent hearing loss.

Always wear ANSI S3.19 hearing protection.

WARNING

RISK OF FIRE OR EXPLOSION

WHAT COULD HAPPEN HOW TO PREVENT IT

This tool is capable of generating sparks which

can result in ignition of flammable materials.

Work in a clean, well-ventilated area free of

combustible materials.

Never operate tools near flammable substances

such as gasoline, naphtha, cleaning solvents, etc.

This tool is not recommended for use in explosive

atmospheres or underwater.

Page 6

6

kobalttools.com

SAFETY INFORMATION

WARNING

RISK OF FIRE OR EXPLOSION

WHAT COULD HAPPEN HOW TO PREVENT IT

This tool is capable of generating

sparks which can result in ignition

of flammable materials.

Wiping or cleaning rags and other flammable waste materials that

may have been used on the tool must be placed in a tightly closed

metal container, and disposed of in a proper manner.

Do not spray flammable or combustible materials near an open

flame or sources of ignition such as cigarettes, motors, and

electrical equipment.

Do not spray or clean with flammable liquids. For use with

water-based liquids only.

Do not spray or clean with liquids having a flash point less than

38°C (100°F).

Paint or solvent flowing through the equipment is able to result in

static electricity. Static electricity creates a risk of fire or explosion

in the presence of paint or solvent fumes. All parts of the spray

system, including the pump, hose assembly, spray gun, and

objects in and around the spray area shall be properly grounded

to protect against static discharge and sparks. Use only

conductive or grounded high-pressure airless paint sprayer hoses

specified by the manufacturer.

Verify that all containers and collection systems are grounded to

prevent static discharge.

Connect to a grounded outlet and use grounded extension cords.

Do not use a 3 to 2 adapter.

Do not use a paint or a solvent containing halogenated

hydrocarbons. See operating instructions for examples of these

types of materials.

Keep spray area well ventilated. Keep a good supply of fresh air

moving through the area. Keep pump assembly in a well ventilated

area. Do not spray pump assembly.

Do not smoke in the spray area.

Do not operate light switches, engines, or similar spark producing

products in the spray area.

Keep area clean and free of paint or solvent containers, rags, and

other flammable materials.

Know the contents of the paints and solvents being sprayed. Read

all Safety Data Sheet (SDS) and container labels provided with

the paints and solvents. Follow the paint and solvent

manufacturer’s safety instructions.

Fire extinguisher equipment shall be present and working.

Page 7

7

kobalttools.com

SAFETY INFORMATION

WARNING

RISK OF ENTANGLEMENT

WHAT COULD HAPPEN HOW TO PREVENT IT

Tools and hoses can become entangled in hair,

clothing, jewelry and other loose objects, resulting

in severe injury.

Remove any jewelry or loose objects which may

become entangled with the tool.

Always keep hands and body parts away from

discharge.

Always wear properly fitted clothing and other

properly fitted safety equipment when using tools.

WARNING

RISK OF CUT OR BURNS

WHAT COULD HAPPEN HOW TO PREVENT IT

Sprayers are capable of causing serious injury if

operated in an improper way, or used in a manner

which is not intended for the tool.

Keep the working part of the tool away from hands

and body. Never aim or spray at yourself or anyone

else.

WARNING

RISK OF ELECTRIC SHOCK

WHAT COULD HAPPEN HOW TO PREVENT IT

Improper connection of the equipment-grounding

conductor can result in a risk of electric shock.

All wiring, electrical connections, and system

grounding must comply with the National Electrical

Code (NEC) and with any local codes and ordinances.

A qualified electrician should be consulted if there is

any doubt as to whether an outlet box is properly

grounded.

Do not expose to rain; store indoors.

A ground fault interrupter (GFI) protected circuit is

recommended for all outdoor electrical devices.

Keep motor operating area as dry as possible.

Always disconnect the power before servicing.

WARNING

RISK OF PERSONAL INJURY

WHAT COULD HAPPEN HOW TO PREVENT IT

An unattended tool could be activated by

unauthorized/untrained persons, leading to their

injury or injury to others.

This tool can propel liquids, loose/broken

accessories or other objects throughout the work

area.

Keep tool out of reach of children and NEVER allow

children to handle equipment or tool.

Maintain awareness of work area safety at all times.

Always be aware of other people around the work

area to ensure safety.

Use only parts, fasteners and accessories

recommended by the manufacturer.

Page 8

8

kobalttools.com

SAFETY INFORMATION

WARNING

RISK OF PERSONAL INJURY

WHAT COULD HAPPEN HOW TO PREVENT IT

This tool can propel liquids, loose/broken

accessories or other objects throughout the work

area.

High pressure spray is able to inject paint and

other toxins into the body, which can cause serious

injury and/or death.

Do not attempt to stop leaks with any body parts. If

machine is leaking, turn off and unplug, and set to

the prime position.

Keep work area clean, free of clutter and well lit. Do

not allow children to operate any tool, and keep

children away from work areas.

If spray is injected in body, seek immediate medical

attention.

ALWAYS use nozzle tip guard when spraying with

spray gun.

ALWAYS engage trigger lock when not spraying, or

before moving item to prevent accidental spraying.

Do not aim the gun at or spray any person or animal.

Keep hands and other body parts away from the

discharge. For example, do not try to stop leaks with

any part of the body.

Always use the nozzle tip guard. Do not spray

without nozzle tip guard in place.

Only use a nozzle tip specified by the manufacturer.

Use caution when cleaning and changing nozzle tips.

In the case where the nozzle tip clogs while spraying,

follow the manufacturer’s instructions for turning off

the unitand relieving the pressure before removing

the nozzle tip to clean.

Do not leave the unit energized or under pressure

while unattended. When the unit is not in use, turn

off the unit and relieve the pressure in accordance

with the manufacturer’s instructions.

High-pressure spray is able to inject toxins into the

body and cause serious bodily injury. In the event

that injection occurs, seek medical attention

immediately.

Check hoses and parts for signs of damage.

Replace any damaged hoses or parts.

This system is capable of producing 3,000 PSI. Only

use replacement parts or accessories that are

specified by the manufacturer and that are rated a

minimum of 3,000 PSI.

Always engage the trigger lock when not spraying.

Verify the trigger lock is functioning properly.

Verify that all connections are secure before

operating the unit.

Know how to stop the unit and bleed pressure

quickly. Be thoroughly familiar with the controls.

Page 9

9

kobalttools.com

SAFETY INFORMATION

WARNING

RISK OF PERSONAL INJURY

WHAT COULD HAPPEN HOW TO PREVENT IT

Wrenches and adjusting keys that are left attached

to the tool may fly off and increase the risk of

personal injury.

This tool can become activated by accident while

being handled, during accessory changes, tool

changes, maintenance or repair.

Extension cords and hoses may present tripping

hazards.

Always remove and secure adjusting keys and

wrenches before operating the tool.

Disconnect the tool from the power supply during

accessory changes, tool changes, maintenance or

repair.

Never carry the tool by the hose or power cord.

Always carry the tool by the handle.

Avoid unintentional operation. Never carry the tool

with the trigger depressed or engaged. Do not lock,

tape or wire the trigger for continuous operation.

Only an authorized service representative should do

repair servicing.

Be aware of excess hose, electrical power sources

and other obstacles or hazards in the work area.

Loss of control of the tool can lead to operator

injury or injury to others in the work area.

There is a risk of bursting if the tool is damaged.

Poor quality, improper or damaged attachments

can detach or fly apart during operation, sending

projectiles through the work area and causing

serious injury.

Never operate tools while using drugs or alcohol.

Do not overreach or stretch to operate the tool.

Keep proper footing at all times when handling tools.

Slipping, tripping and/or falling are major causes of

serious injury and or death.

Keep tool handles dry, clean and free from oil/grease.

Stay alert. Watch what you are doing. Use common

sense. Do not operate tools when you are tired.

Operators must be able to easily handle the entire

weight of the tool in operation, to maintain full control

of the tool 100% of the time.

Check for misalignment or binding of parts, broken

parts and other conditions that affect safe tool

operation.

Always use paint sprayer on a level, stable surface.

Never use a tool which has been dropped, damaged

or appears to malfunction. Never use tools which are

leaking or have missing parts. Remove damaged or

malfunctioning tools from the workplace immediately.

Do not use pressure exceeding the recommended

operating pressure of the lowest rated system

component (hoses, fittings, etc.)

Do not modify tools or attachments.

Always follow assembly, operation, maintenance and

repair instructions.

Page 10

10

kobalttools.com

SAFETY INFORMATION

WARNING

RISK OF PERSONAL INJURY

WHAT COULD HAPPEN HOW TO PREVENT IT

Improperly maintained tools and accessories can

cause serious injury.

Maintain the tool and accessories with care. Do not

abuse hoses or connectors.

Keep hoses away from heat, oil and sharp edges.

Always check hoses for weak or worn connections

before each use and make certain that all connections

are secure.

Do not kink or over-bend the hose.

Do not use the hose as a strength member to pull or

lift the equipment.

Using an accessory not intended for a specific tool

increases the risk of injury to the operator and

everyone else in the work area.

Repetitive motions, awkward positions and exposure

to vibration can be harmful to hands and arms.

Always use accessories and attachments designed for

the tool and the work at hand. Do not improvise or

modify tools or accessories.

Discontinue use of tool if discomfort, tingling feeling or

pain occurs. Consult a physician before resuming use

if any of these symptoms occur.

WARNING

INHALATION HAZARD

WHAT COULD HAPPEN HOW TO PREVENT IT

Paint spraying tools generate paint vapors which

can be harmful to the lungs and respiratory

system.

Some materials give off vapors which could cause

serious injury with prolonged exposure.

Always wear a properly fitting facemask or respirator

rated for the application when using such tools.

Always work in a clean, dry, well-ventilated area. Be

aware of chemicals in the work area and read all

Safety Data Sheets (SDS) for the materials and/or

chemicals that may be present.

PREPARATION

Before beginning assembly of product, make sure all parts are present. Compare parts with package

contents list. If any components which are listed are missing, please contact 1-888-356-2258 for a

missing parts request. DO NOT use the item if parts are missing.

Estimated Assembly Time: 25-30 minutes

Tools Recommended for Operation (not included): 5 gallon utility bucket, paint strainer, latex gloves,

dust mask, ANSI approved safety glasses or goggles, paint drop cloth

Tools Recommended for Cleaning (not included): Three to four 5 gallon buckets, soft (non-wire) bristle

brush, cleaning rags, clean water, paint drop cloth, plastic bag, rubber band, respirator or dust mask,

during long-term storage periods)

respirator or

Page 11

11

kobalttools.com

UNDERSTANDING AIRLESS PAINT SPRAYER COMPONENTS

A

B

I

C

F

G

H

N

K

D

S

R

E

J

L

Q

O

M

P

1. The suction tube (B) draws material for spraying from the container holding the material.

2. The prime tube (C) dispenses material during the flushing, priming, and cleaning stages. It must

remain in the waste pail during use.

3. The inlet screen (I) serves as a strainer for the material to be sprayed. The inlet screen can be

4. The pressure control knob (F) controls pressure/PSI. Adjusting this knob regulates the flow rate of

material.

5. The prime spray valve switch (H) directs the output of material to the prime tube or the spray gun.

6. The spray gun housing (D) consists of a spray guard (J), spray tip (L), internal gun filter (E), and

single seal tip (M).

7. The spray guard (J) holds the spray tip (L) and allows for change of spray pattern direction.

8. The spray tip (L) orifice size determines the flow rate. Included are two tips: 513 and 517.

Selecting Proper Spray Tip Size

This tool comes with two spray tip sizes (513 and 517). The lifespan ofaspray tip varies depending

on the types of materials being sprayed, and how well the tip is cleanedafter each use. With proper

maintenance,spray tips generally can spray 15 to 40 gallons before needing to be replaced.

It is recommended to use the below coating selection diagram to best selectthe proper tip size you

intend to use for your particular spraying application.Please consult your local retailerif you are unsure

of the proper tip size which should be

used.

removed to allow for outdoor garden hose connection during flushing and cleaning.

Page 12

12

kobalttools.com

UNDERSTANDING AIRLESS PAINT SPRAYER COMPONENTS

Coating Selection

Tip Hole Size

(expressed as diameter, based

Stains Enamels Oil-based

primers

and paints

Interior

latex

paints

Exterior

latex

paints

Acrylics

0.011 in. (0.28 mm) X

0.013 in. (0.33 mm) XXX X

0.015 in. (0.38 mm) X X X X

0.017 in. (0.43 mm) X XXX

0.019 in. (0.48 mm) X X

• ezispiT 513 – Designed to be used with lighter materials; mostlystains, lacquers and enamels, along

with some lighter oil-basedpaints.

• ezispiT 517 – Designed to be used with paint and acrylics(both oil based and latex).

Note: ALWAYS

of the paint sprayer. Heavier materials will require a larger tip size. Lighter materials such as stains

and enamels may require a smaller tip size. Most spray material labels indicate the suggested or

recommended tip size for proper spraying. If you are uncertain which tip size is correct, consult your

local retailer for additional assistance.

ASSEMBLY INSTRUCTIONS

1.

connections are properly secure. Fully tighten

using wrench (O).

1

G

O

K

SETUP

Page 13

13

kobalttools.com

ASSEMBLY INSTRUCTIONS

2.

to spray gun housing (D). Hand tighten, making

sure connections are properly secure. Fully

tightenusing wrench (O).

O

2

D

ANSI approved

safety glasses or ANSI approved safety goggles for protection. NEVER point the spray nozzle at

anyone at any time. NEVER put any body parts in front of spray gun at any time.

Note: The manufacturer has added a lightweight coating of oil to protect the motor and internal

paint sprayer to prevent any oil debris from contaminating your paint and/or stain.

Be sure to use the correct

spray tip (L) for the particular painting application.

See table on "Coating Selection" to determine the

proper tip size.

Proper maintenance

after each use is essential for optimal performance. It is recommended that the airless paint sprayer be

cleaned thoroughly after each use. See cleaning instructions for more details.

3

3. Make sure power switch is turned off.

FLUSHING

Page 14

14

ASSEMBLY INSTRUCTIONS

kobalttools.com

5. Adjust pressure control knob (F) to lowest PSI

(below roll) by turning counterclockwise.

4. Turn nut on spray guard (J), then remove spray

guard (J) and spray tip (L) from spray gun

housing (D).

Hi

Spray

Low

Spray

Prime/

Clean

Roll

5

F

2

4

D

J

L

6

H

6. Turn prime spray valve switch (H) to prime

position.

PRIME

SPRAY

Page 15

15

ASSEMBLY INSTRUCTIONS

kobalttools.com

7. Separate prime tube (C) from suction tube (B)

and place prime tube (C) into a waste pail.

8a. For Water-Based Paint:

If outdoor garden hoseconnectionwith water supply is

available,unscrewinlet screen(I) turning clockwise at

the end of the suction tube(B).Connect the suction tube

to garden hoseend (not included) and tighten turning

counterclockwise.Connect theotherend of garden hose

(not included) towaterspigotand tighten by turning

counterclockwise.

Note: If garden hose connection is unavailable, follow

Step 8B and use water instead of cleaning solvents.

3

2

1

8a

B

B

I

7

B

C

C

8b. For Oil-Based Paint:

Place suction tube (B) in mineral spirits or other

compatible cleaning solvents (not included). Consult

local retailer if unsure which mineral spirits or cleaners

are compatible with particular oil-based paint.

8b

B

Page 16

16

ASSEMBLY INSTRUCTIONS

kobalttools.com

9. Plug airless paint sprayer (A) into grounded

outlet. Turn on power switch.

9

A

10. Slowly turn pressure control knob (F) clockwise

to prime/clean position.

10

F

Hi

Spray

Low

Spray

Prime/

Clean

Roll

11. Once motor is running, allow fluid to flow through

sprayer system and out through the prime tube (C)

into a waste pail for at least 45 seconds. This flushing

will remove any debris or oil in the system.

C

11

Page 17

17

ASSEMBLY INSTRUCTIONS

kobalttools.com

1

12

12. Once flushed fluid is clear, turn pressure control

knob (F) to the lowest pressure setting, and turn

off power switch. See Figure 5.

Turn prime spray valve switch (H) to spray position.

See Figure 6.

Slowly turn pressure control knob (F) to clockwise to

prime/clean position. See Figure 10.

Once motor is running, squeeze trigger and allow fluid

to run through spray system and out through the spray

gun (D) for at least 45 seconds. See Figure 12.

Once flushed fluid is clear, turn pressure control

knob (F) to the lowest pressure setting, and turn off

power switch. See Figure 5.

process,reattach inlet screen

to suction tube and turn counterclockwise to tighten.

13. Remove suction tube from spigot, clean water, or

flushing fluid. See Figure 13.

B

I

13

OPERATING INSTRUCTIONS

PRIMING SPRAYER WITH PAINT

Note: Before beginning any paint project, properly stir paint and/or strain paint

to make sure any contaminants or debris are thoroughly removed to avoid

clogging the spray tip. Check to make sure the color is correct. The pressure

release button (N) is designed to allow the user to release suction in the

system at times of an emergency. It is not intended to be used as a regular

form of releasing suction in the sprayer system.

Wear protective gear, goggles, latex gloves, and respirator or dust

mask when using equipment.

N

Page 18

18

kobalttools.com

OPERATING INSTRUCTIONS

1. Turn prime spray valve switch (H) to prime position,

releasing the pressure in the machine (See Figure 1).

Turn pressure control knob (F) to the lowest pressure

setting.

2. Separate prime tube (C) from suction tube (B) and place

prime tube into a waste pail (See Figure 2).

2

B

C

C

1

F

Hi

Spray

Low

Spray

Prime/

Clean

Roll

H

PRIME

SPRAY

3. Place suction tube (B) into paint bucket (See Figure 3).

3

B

Page 19

OPERATING INSTRUCTIONS

4. Turn on power switch.

5. Slowly turn pressure control knob (F) clockwise until

motor begins to run.

Allow paint to flow through sprayer system and out

through the prime tube (C) for 15 seconds.

4

A

5

6. Turn down pressure control knob (F) and turn off sprayer.

6

F

2

F

1

19

Hi

Spray

kobalttools.com

Low

Spray

Prime/

Clean

Roll

Page 20

OPERATING INSTRUCTIONS

sition. 7. Turn prime spray valve switch (H) to spray po

Adjust pressure control knob (F) to lowest PSI (below

roll).

7

Counterclockwise

SPRAY

PRIME

8. Turn safety lock (S) on spray gun to locked position.

8

Spray

Lock

Hi

S

Lock

clockwise

Low

Spray

H

Clockwise

Prime/

Clean

Roll

F

S

9. Turn nut on spray guard (J) then remove spray guard (J)

from spray gun.

9

D

L

J

Counterclockwise

kobalttools.com

20

Page 21

21

OPERATING INSTRUCTIONS

kobalttools.com

10. Unlock the safety lock (S).

11

D

S

11. Turn power switch on.

Slowly, turn pressure control knob (F) clockwise

until motor begins to run or until prime/clean setting.

Release the trigger while the paint sprays into the

waste pail. Let the paint run for 15 seconds.

Let go of trigger. Turn pressure control knob (F) down

to the lowest setting. Turn off power switch.

10

Counterclockwise

S

D

S

12. While connecting spray guard (J), spray tip (L) and

single seal tip (M), make sure the safety lock (S) is

locked.

Lock

Lock

clockwise

12

S

S

Page 22

OPERATING INSTRUCTIONS

13. Reconnect spray guard (J), spray tip (L) and single seal

tip (M) making sure connection is properly secured.

Adjust the spray tip (L) so the arrow on tip housing is

backwards, and unlock the safety lock (S).

Continue

spraying into waste pail 5-10 seconds to make sure the

hole in the tip is not jammed.

14. Adjust the spray tip (L) so the arrow on the housing is

facing forward. The sprayer is now primed and ready

for use.

13

J

14

L

M

L

S

Lock

Lock

Counterclockwise

S

Adjusting Spray Pattern Vertical Or

Horizontal Spray

1. To adjust spray angle, set safety lock to locked

position. Loosen nut on spray guard (J). Turn

spray guard to vertical or horizontal position.

Position spray tip at the top of the housing for

horizontal pattern. Turn housing 90° so that

spray tip is positioned along the side for

vertical pattern.

Counterclockwise

1

3

3

J

2

1

kobalttools.com

22

Page 23

OPERATING INSTRUCTIONS

2. Hand tighten nut on spray guard (J). Unlock

safety lock and continue to spray.

SPRAYING TECHNIQUES

2

J

1

2

Before you begin, clean the surface area to remove any debris or dirt buildup for optimal results.

Protect and cover any surfaces that you do not intend to spray.

How to Set Proper Spray Pattern

If you do not have much experience using a paint sprayer, practice by using water and spraying on a

system and that the surface is completely dry.

Spray Pattern

A good spray pattern results when paint is applied consistently and evenly to the surface without

any runs in the pattern, which occurs when too much or too little paint is sprayed in a single area.

To properly set your spray pattern, start the sprayer at the lowest possible PSI pressure setting and

gradually increase the PSI pressure setting until you reach an even and consistent spray pattern.

Proper Spray Diagram

Increase pressure until you achieve the correct full even spray pattern.

CorrectCorrect IncorrectIncorrect

Note: Do a few spray tests on a sheet of cardboard to

make sure you achieve a good spray pattern. If you reach

the maximum PSI pressure setting and the spray pattern is

Consistent

spray pattern

Uneven

spray pattern

tip size may be required.

kobalttools.com

23

Page 24

24

kobalttools.com

DO NOT try to increase the spray coverage areaby holding the spray gun furtheraway from the surface

being sprayed. If held further away than 12-14 inches, less paint will reach the surface and more paint

will be wasted as overspray (spray that does not properly get sprayed to the spraying surface).

Proper Coverage

• Before you begin, make sure you understand the technique for proper spraying application.

• Make sure your arm is moving before squeezing and before releasing the trigger on the spray gun

as not doing so will increase the chance for paint build up or inconsistent spraying in certain areas.

Note: Practice may be needed to make sure that you are able to achieve the proper technique before

spraying the surface area you intend to paint.

areas that can easily be reached. Work from the top to the bottom in a consistent and even motion.

Once the outer edges are properly covered, begin working your way toward the middle of the surface,

remembering to spray from top to bottom.

1.

squeezing technique.

2.

overlapping the previous row by 50% to provide consistent

paint coverage through each passing row.

3. When spraying, keep arm motion movements, angle of

spraying, and speed at which you spray across the surface

as consistent as possible.

Repeat the above process until you have reached the bottom of the surface you intend to paint.

Note: When working on outside structures or where there is

an eave or overhang, properly cover the eave or overhang

before spraying the surface area you wish to paint.

When painting outdoor structures, spray horizontally. When

spraying moulding or surfaces which are uneven (siding),

Removal of anypre-spray preparation materials should only bedone after the sprayed surface has had

adequate time to properly dry. Please reference your materials supplier’s recommendationson how

much time is needed for properly drying. Removal of any pre-spray preparationmaterials before surface

is completely dry can affect the outcome of the sprayed surface area.

Spray corners

and outer

edge first

Spray corners

and outer

edge first

Spray at a slightly

upward angle to

properly cover surface

Spray at a slightly

upward angle to

properly cover surface

SPRAYING TECHNIQUES

The spray gun should be held 12-14 inches away from the surface and held at a 90° angle from the

surface area.

12”- 14”12”- 14”

CorrectCorrect IncorrectIncorrect

X

Thin coatThin coat Thin coatThin coatHeavy coatHeavy coat

IncorrectIncorrect

Start

stroke

Start

stroke

End

stroke

End

stroke

Pull

trigger

Pull

trigger

Release

trigger

Release

trigger

12-14”12-14”

CorrectCorrect

Page 25

25

kobalttools.com

CARE AND MAINTENANCE

ALWAYS wear proper eye protection during cleanup process.

Tools Recommended for Cleaning (not included):Three to four5gallon buckets, soft (non-wire) bristle

brush, cleaning rags, clean water, paint drop cloth, plastic bag, rubber band, respirator or dust mask,

id (for after use storage)

This device is designed to work with water-based and oil-based paints, as well as stains. Use these

cleaning solvents for proper cleaning:

Latex-based paint – water

Oil-base – Soapy water/mineral spirits

Stain/lacquer – Lacquer thinner or other mineral spirits

CLEANING INSTRUCTIONS: Temporary Break (Under 48 hours)

Note: Use a drop cloth or other material to protect the paint from debris while not in use so that when

starting back after taking a break, you may use the same paint.

1. Leave suction tube and prime tube submerged in paint.

2. Relieve pressure in spray system by turning the prime spray valve switch from the spray position

to the prime position.

3. Power off the machine.

4. Place only the tip of the gun into a pail of water or mineral spirits (depending on the material you

are using) to prevent buildup of paint and/or debris.

5. Before starting the following day (less than 48 hour period) clean just the tip of gun with a

non-wire bristle brush.

Note: If using water-based paint, leave the tip of the gun in water only for a short period of time

(under 48 hours). Exposure to water for an extended period of time can be corrosive to the internal

components of the nozzle and spray gun. Clean the tip of the gun with water or mineral spirit with

a small non-wire brush and wipe gun clean before using. After the temporary break, ALWAYS test

GENERAL PAINT CLEARING/CLEANING INSTRUCTIONS : Break over 48 hours and/or Long

Term Storage

There are three main stages for properly cleaning and maintaining your sprayer. If changing paints

or taking a break longer than 48 hours and planning to continue painting, follow Stages 1 and 2 of

the cleaning process.

When paint project is completed and you are ready to store sprayer for an extended period,

complete Stage 3. Stage 3 is an additional step which is required for your machine to operate

properly.

Stage 1: Clearing Excess Paint

Stage 2: Cleaning Sprayer and Components Before Storage

proper storage and care and maintenance of the sprayer.

spray an area to ensure the gun is not clogged before continuing.

Page 26

26

kobalttools.com

Water-Based Paint:

. For long-

suited for your sprayer.

Oil-Based Paint:

Follow cleaning stages exactly. When cleaning after using oil-based paint or stains, using mineral

spirits or a cleaning mixture is recommended. Consult your local retailer for additional information on

the cleaning solvent materials best suited for proper cleaning. Consult your local retailer for additional

.

CARE AND MAINTENANCE

STAGE 1: Clearing Excess Paint

Flush any remaining paint or stain from the sprayer into waste pails to clear excess paint from the

system.

Note: If outdoor garden hose connection with water supply is available, unscrew inlet screen (I)

turning clockwise at the end of the suction tube (B). Connect the suction tube to garden hose end (not

included) and tighten turning counterclockwise. Connect the other end of garden hose (not included)

to water spigot and tighten by turning counterclockwise. If no garden hose connection is available,

use water in a 5 gallon bucket.

NEVER let the clean water bucket run out of clean water.

7. Turn power switch on and allow excess paint to flow out of prime tube (C) into waste pail.

8.

the system.

9.

sure both tubes are in the clean water bucket.

Waste Pails

Clean Water

Removing Excess Paint from Prime Tube

1. Relieve the pressure by turning prime spray valve

switch (H) to prime position.

2. Turn power switch off. Set safety lock to locked position.

3. Turn pressure control knob (F) clockwise to prime/

clean position.

4. Fill one 5 gallon bucket with clean water. Place suction

tube (B) in clean water bucket.

5. n Set two empty buckets, side by side, next to the clea

water bucket. These two buckets are the waste pails.

6. Place prime tube (C) in waste pail.

If mineral spirits or thinner is

used, brush components clean and thoroughly rinse with clean water to prevent seals from drying out.

Page 27

27

kobalttools.com

CARE AND MAINTENANCE

Note:

Paint from Prime Tube” and before proceeding to “Removing Excess Paint from

High Pressure Spray Hose”.

Removing Excess Paint from High Pressure Spray Hose

1. Make sure safety lock is in locked position.

Note: Remove spray guard (J), single seal tip (M), and spray tip (L). Unscrew safety screw at base

of handle housing using hex key (R) to release handle housing, making the cleaning process

easier. Set aside for additional cleaning (see “Cleaning Sprayer and Components Before

Storage”).

2. Fill clean water bucket and turn prime spray valve switch (H) to spray position.

3. Turn pressure control knob (F) to prime/clean position.

4. .liap etsaw revo n Unlock safety lock and place the spray gu

5. Depress trigger on spray gun BEFORE turning the machine on. This will decrease the possibility

of high pressure buildup in the system and any overspray.

6.

7. DO NOT release the trigger. The trigger should remain depressed, allowing water to continuously

spray.

8.

the system.

9.

STAGE 2: Cleaning Sprayer and Components Before Storage

4

3

2

1

E

R

1

1. Fill 5 gallon bucket with water.

2. Unscrew spray gun handle turning counterclockwise to

remove internal filter (E) from the handle as shown in

Figure 1.

3. (Spray guard should already be removed from spray gun

housing.) Using the pointed eject end of the spray tip (L),

press against the single seal tip (M) to remove it from the

spray tip housing as shown in Figure 2.

4. Thoroughly clean the single seal tip (M), the spray tip (L),

the internal filter (E), as well as the threading and head

of spray gun with cleaning brush (Q) removing any paint,

stain, or debris. Set components aside and allow to dry.

Page 28

28

kobalttools.com

CARE AND MAINTENANCE

2

J

3

2

1

L

L

M

J

2

3

1

L

M

5. Using cleaning brush (Q), thoroughly brush suction tube

(B), inlet screen (I), and prime tube (C) until all heavy

paint or stain residue is removed.

6. After components have dried, insert the single seal tip

into the spray guard housing with the metal end facing

down. Using the pointed eject end of the spray tip, press

against the rubber opening of the single seal tip until it fits

perfectly into the housing, as shown in Figure 3.

7. Insert the spray tip (L) into the opening of the spray gun

housing, making sure the orifice is facing forward.

8. Screw the spray guard (J) to the spray gun housing by

turning counterclockwise. Tighten by hand until the single

seal tip (M) is secure.

9. Re-insert clean internal gun filter (E) into spray gun

handle.

10. Tighten safety screw at base of handle housing using

hex key (R).

11. Set prime spray valve switch (H) to prime/clean position.

12. Place prime tube (C) into waste pail.

13. Turn power switch on and allow water to flow though

spray system until water coming out of prime tube (C)

is clear.

Note: It may take several gallons of water depending on

the type of paint used. Continue to refill clean water

bucket as needed.

14. Set the prime spray valve switch (H) to the spray position

and unlock safety lock on squeeze trigger.

15. While placing spray gun over waste pail, depress trigger

and turn power switch on.

16. While spraying, shake the spray gun to loosen any paint

that may be trapped inside.

17. With the arrow on the spray tip facing forward, continue

spraying for 10-15 seconds. Stop spraying and rotate

the spray tip so the arrow is facing the operator, as

shown in Figure 4. Spray again for 10-15 seconds.

Repeat this several times until the single seal tip is

completely cleared.

L

4

Page 29

29

kobalttools.com

CARE AND MAINTENANCE

STAGE 3: Long-Term Storage

Make sure unit is completely clean by following Stages 1 and 2 of the Care and Maintenance section.

For long-term storage of your sprayer, DO NOT leave water in the sprayer system. The use of mineral

1. Make sure safety lock is in locked position, spray valve switch (H) is set to prime position, and the

power switch off.

2. Separate prime tube (C) from suction tube (B) and place prime tube (C) into a waste pail.

3.

4. Turn pressure control knob (F) counterclockwise to lowest setting.

5.

through the sprayer until it comes out of the prime tube (C).

6. Immediately turn power switch off.

7. Unlock safety lock and reconnect prime tube (C) to suction tube (B). Make sure prime tube (C)

8. Point spray gun housing (D) into waste pail and squeeze spray gun housing (D) trigger. Continue

squeezing trigger and turn prime spray valve switch (H) to spray position.

9.

10. , turn power

switch off, and set safety lock to locked position.

Note: Place a plastic bag (not included) over bottom of the suction tube (B) using a

PROBLEM POSSIBLE CAUSE CORRECTIVE ACTION

Motor does not run;

sprayer does not spray.

1. Machine is not plugged in.

2. Power switch is turned off.

3. Control knob is set to low

position.

1. Plug into grounded outlet.

2. Turn power switch on.

3. Turn pressure control knob

clockwise.

Motor is running and

trigger is squeezed,

but spray gun does not

spray.

1. Pressure control knob is set

too low.

1. Turn pressure control knob clockwise

and increase power.

Trigger does not move. 1. Safety trigger is not on. 1. Turn safety lock on spray gun

housing to unlocked position.

If you have any questions regarding the product, please call customer service at

1-888-3KOBALT (1-888-356-2258), 8:00 a.m. - 8:00 p.m., EST, Monday - Friday.

TROUBLESHOOTING

Page 30

30

kobalttools.com

TROUBLESHOOTING

PROBLEM POSSIBLE CAUSE CORRECTIVEACTION

Pump does not prime. 1. Prime spray valve is set to

spray position.

2. Sprayer is turned off.

3. Prime tube is clogged.

4. Suction tube is not submerged.

5. Inlet screen on suction tube is

clogged.

1. Set prime spray valve to prime

position.

2. Turn sprayer on.

3. Unclog prime tube.

4. Submerge suction tube.

5. Check and clear any clogs in inlet

screen.

Sprayer is functioning

and spraying, but

spray pressure drops

while in use.

1. Material being sprayed is

running low.

2. Single seal tip is worn and

needs to be cleaned or

replaced.

3. Spray gun housing may be

clogged.

4.

clogged or not inserted

properly.

5. Material being sprayed may

be too thick.

6. Suction tube is not connected

properly.

7. Suction tube may be

damaged.

1. Add or replace material being

sprayed.

2. Turn off machine. Remove and

inspect single seal tip. Clean and/or

replace.

3. Clean spray gun housing. Flush

spray gun housing clear of any

debris.

4. Turn off machine. Remove internal

properly and not clogged.

5. Check material data sheet from

material supplier to make sure single

seal tip size is compatible.

6. Check suction tube. Reconnect if

loose.

7. Check suction tube. Replace if

damaged.

Prime spray valve is

set, but does not allow

1. Prime spray valve is damaged

or connection to prime spray

valve is damaged.

1. Contact local paint repair store or

local retailer for suitable replacement

components.

Spray gun housing

leaks.

1. Incorrect connection with high

parts are worn.

1. Check connection with high pressure

contact local paint repair store or

local retailer for suitable replacement

components.

Single seal tip and tip

housing leak.

1. Incorrectly tightened or

threaded, or worn single seal

tip.

1. Check connection to make sure

connection is not misthreaded.

Replace if single seal tip is worn.

Paint pattern is uneven. 1. Pressure is not set correctly.

2. The inlet screen on the

suction tube may be clogged.

3. Suction tube connection is

loose.

4. Material being spraye

d is too

thick for single seal tip size.

5.

Single seal tip is worn and

needs to be cleaned or replaced.

1. Adjust pressure on machine so

pattern is even/consistant.

2. Unclog inlet screen.

3. Make sure suction tube is properly

connected.

4. Check material data sheet to make

sure single seal tip is compatible.

5. Clean or replace single seal tip.

Page 31

31

kobalttools.com

TROUBLESHOOTING

This tool is warranted by the manufacturer to theoriginal purchaser from the original purchase date for

ninety (90) days subject to the warranty coverage described herein.

This tool is warranted to the original user to be free from defect in material and workmanship. If you

believe thata tool is defective, return the tool,with proper proof of purchase to the point of purchase. If

it is determined that the toolis defective and covered by this warranty, the distributorwill replace the tool

or refund thepurchase price.

This warranty is void if: defects in materials or workmanship or damages result fr

om repairsor

alterationswhich have been made or attempted by othersor the unauthorized use of nonconforming

parts; the damage is due to normal wear,damage is due to abuse (including overloading of the tool

beyond capacity), improper maintenance, neglect or accident; or the damage is due to the use of the

use of the toolafter partial failureor use with improper accessories of unauthorizedrepair or alteration.

have other rights that vary from state to

state.

For warranty questions, call our customer service department at 1-888-3KOBALT, 8:00 a.m. - 8:00 p.m.

EST, Monday - Friday.

WARRANTY

PROBLEM POSSIBLE CAUSE CORRECTIVE

Pressure is not building

up properly and sprayer

spraying properly.

1. Machine has been in use for

extended periods of time and/

or multiple pressure settings

have been set in a short

period of time.

1. Press the pressure release button

and hold down for 3 seconds,

allowing the pressure in the system

to be released and to be built up

properly.

Page 32

32

kobalttools.com

EXPLODED VIEW

PART DESCRIPTION

24 Plunger Pole

25 Plunger Spring

26 Copper Washer

27 Retainer Ring

28 O-ring (2.4x1.8)

29 Shield

30 Pump Body

31 Plastic Washer

32 Insert Block

33 Pressure Relief Pole

34 Plastic Ring

35 Pressure Relief Valve

36 Thimble

37 Pressure Relief Spring

38 Spring Seat

39 Pin 3x8

40 Control Valve Seat

H Prime Spray Valve Switch

42 Pin

43 Nylon Rope

44 Inlet Spring Holder

45 Inlet Spring

1

3

4

5

6

13

15

16

17

18

7

8

9

6

10

11

10

19

20

31

32

33

34

35

36

37

38

39

40

42

44

45

46

47

48

49

50

51

52

53

119

56

16 06

62

63

64

65

67

68

69

70

72

73

74

75

72

76

77

78

79

80

82

84

85

86

87

88

89

90

91

92

93

94

97

98

99

100

101

89

105

106

12

71

107

108

102

103

104

30

43

95

66

81

P

G

K

Q

H

C

B

I

110

111

21

22

23

24

25

26

27

28

29

83

58

112

113

114

116

57

115

@

@

RFO

PART DESCRIPTION

1

K

3

4

5

6

7

8

9

10

11

12

13

G

15

16

17

18

19

20

21

22

23

Spray Gun

High Pressure Fluid Hose

Base Frame

Screw M6x25

Housing Cover

Big Copper Bushing

Retainer Ring

Connecting Rod

Gear Assembly

Small Copper Bushing

Output Gear Bushing

Pin 5x12

Screw Thread Rubber

Fluid Outlet

O-ring (10x1.8)

Output Spring

Mandrill

Steel Ball (Dw=6.4)

Seal Seat

Output Washer

Plunger Handle

Plunger Seat

O-ring (10x1.5)

Page 33

33

kobalttools.com

EXPLODED VIEW

Printed in China

KOBALT® and the K Design® are registered

trademarks of LF, LLC. All Rights Reserved.

PART DESCRIPTION

P

111

112

119

86

87

88

89

90

91

92

93

94

95

F

97

98

99

100

101

102

103

104

105

106

107

108

110

113

114

115

116

R

O

Q

Cable Tie

PCB Assembly

Washer

Hex Key

O-ring

O-ring (27x2.4)

Hex Screw M3x10

Cap

Micro Switch

Micro Switch Cover

Adjustable Seat

Pressure Control Spring

Spring Pusher

Pressure Control Knob

Pressure Control Bolt

Grip

Handle

PCB Supporter

Hex Bolt M4x10

Connector

Safety Cap ø5

Hex Bolt

Base Board

Screw

Inlet Screen Holder

Gasket

Screw

Screw

Mat

Connect Nut

Support Components

Wrench

Connector

Plastic Bristle Cleaning Brush

DESCRIPTIONPART

47

46

48

49

50

51

52

53

C

B

56

57

58

I

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

Steel Ball (Dw=12.7)

Input Seat

Input Washer

O-ring (17x1.8)

Paint Input Adaptor

Pressure Alu. Joints

Lock Ring Components

Hose Clamp (16-25)

Prime Tube

Suction Tube

Clip

Jacket

Foam Gasket

Inlet Screen

Power Plug

Washer D=4.3

Screw M4x8

Power Supply Seat

Hex Screw

Housing

Fan Cover

Motor Assembly

Power Switch

Pin 3x12

Hex Screw M5x14

Spring Washer D=5.0

Retainer Ring

O-ring (22.5x1.8)

Retainer Ring Cover

Piston Washer

Washer

O-ring

Felt

Piston Seat

Guide Copper Bushing

Piston

Lock Sleeve

White Seal

Black Seal

Switch Lever

Loading...

Loading...