Page 1

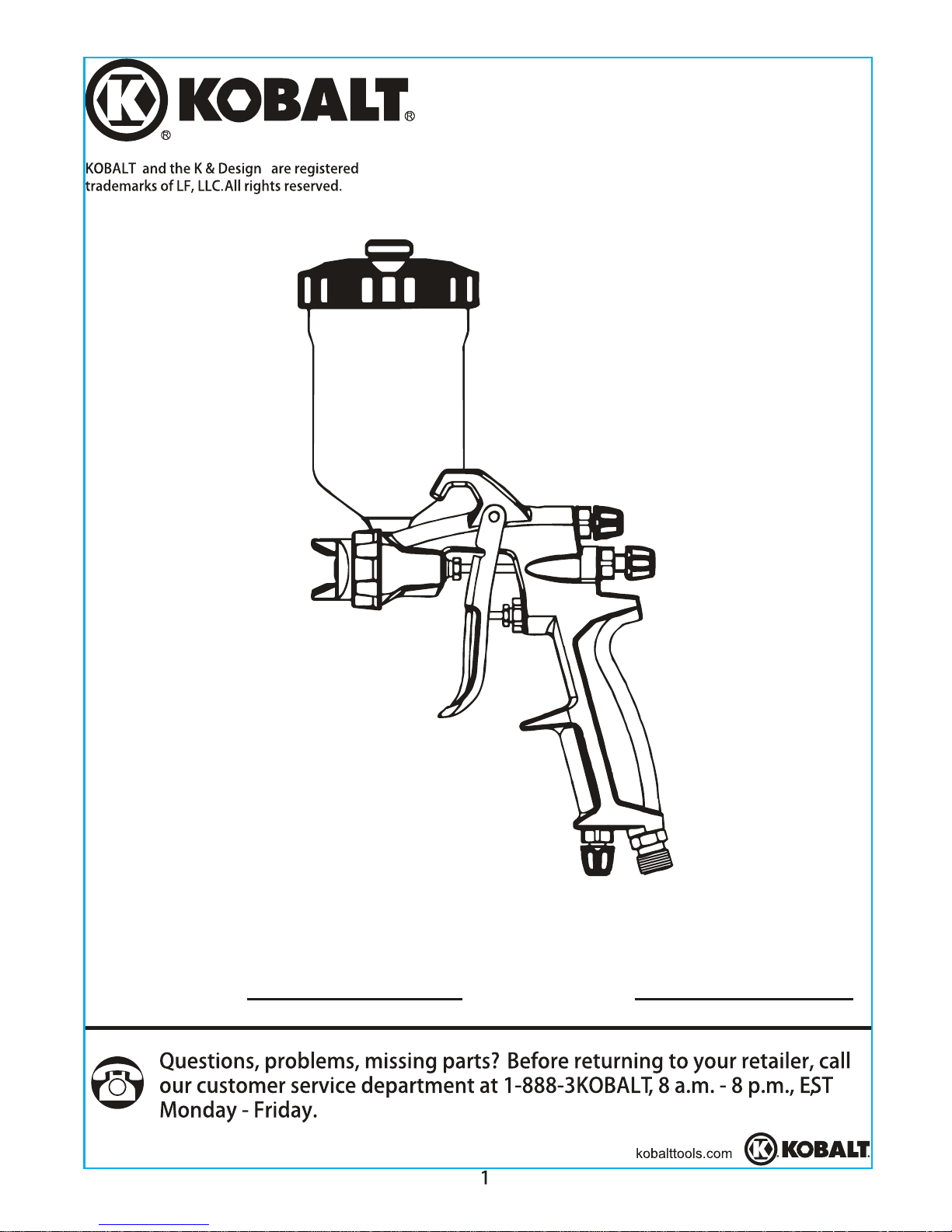

SMALL GRAVITY

FEED SPRAY GUN

ITEM #0301339

MODEL #SGY-AIR87TZ

ATTACH YOUR RECEIPT HERE

Serial Number Purchase Date

® ®

Page 2

2

TABLE OF CONTENTS

Safety Information ............................................................................................... 3

Assembly Instructions ..........................................................................................

Package Contents ................................................................................................ 5

Product Specifications .......................................................................................... 5

Preparation ..........................................................................................................

Operating Instructions ........................................................................................

Care and Maintenance .......................................................................................

Repair Instructions ..............................................................................................

Troubleshooting ...................................................................................................

Replacement Parts List ........................................................................................

Warranty ................................................................................................................

5

6

7

8

10

10

12

13

IMPORTANT: To operate correctly, this tool requires airflow that is at least 3.3 cubic feet per

minute (CFM) at 40 pounds per square inch (PSI). Check the specifications of your air compressor

to be sure that it can support both the minimum CFM and PSI required. An air hose may cause

up to 15 PSI drop in pressure, so you may need to set the output higher to maintain the required

pressure at the tool.

de maintenir un niveau adéquat.

IMPORTANTE: Para funcionar de manera correcta, esta herramienta requiere un flujo de aire de

por lo menos 3,3 pies cúbicos por minutos (CFM por sus siglas en inglés) para 40 libras por

pulgada cuadrada(PSI, por sus siglas en inglés). Revise las especificaciones de su compresora

de aire para asegurarse de que puede soportar tanto los CFM como las PSI mínimas requeridas.

Una manguera de aire comprimido puede causar una caída de hasta 15 PSI en la presión, de

manera que puede necesitar configurar la potencia más alta para mantener la presión requerida

en la herramienta.

IMPORTANT : Cet outil nécessite un débit d'air d'au moins 3,3 pi par minute à une pression de

3

3

aux exigencies minimales (pi /min et lb/psi ). L'utilisation d'un tuyau à air peut entraîner une chute

2

40 lb/psi . Vérifiez les spécifications de votre compresseur d'air afin de vous assurer qu'il satisfait

2

de pression de jusqu'à 15 lb/psi . Il peut donc s'avérer nécessaire d'augmenter la pression afin

2

3.3

CFM40PSI

Tool Requirements

Exigences relatives aux outils

Requisitos de herramientas

@

Page 3

3

SAFETY INFORMATION

Please read and understand this entire manual before attempting to assemble, operate

or install the product. If you have any questions regarding the product, please call

customer service at 1-888-3KOBALT, 8:00 a.m.-8:00 p.m., EST, Monday-Friday.

Do not allow children to operate tool, and keep children away from the work area.

Noise can harm your hearing. To safe guard your hearing always wear proper ear

protection.

Whenever doing maintenance on tool, proper impact resistant safety glasses and face

protection must be used.

During cleaning and flushing, be sure operator and others in the work areas are wearing

proper impact resistant eye and face protection. Solvents can be forcefully expelled

from fluid and air passages which may cause eye injury. Even small objects can in

jure

eyes and cause blindness.

Do not wear loose clothing, jewelry, or anything that may get caught or tangled when

using tool.

Before changing accessories, when making repairs, or when tool is not in use, always

first shut off air supply and release / drain air pressure from hose. Then disconnect too

l

from air supply or hose and store in a safe location.

Always have control of the air hose.

Never spray or direct air at yourself or anyone else.

Whipping hoses can cause serious injury. Always check for damaged or loose hoses

and fittings before use. Never use quick change couplings at tool. They add weight and

could fail due to vibration. Instead, add a hose whip connect coupling between air

supply and hose whip, or between hose whip and leader hose.

Always use the tool at a safe distance from other people in the work area.

Maintain tools with care, never use a tool that is leaking air, has missing or damaged

parts, or requires repairs.

Keep tools clean and properly oiled for best and safest performance. Follow lubrication

instructions for best and safest operation.

Follow assembly and repair instructions on how to properly change accessories.

Wiping or cleaning rags and other flammable waste materials that may have been

used on tool must be placed in a tightly closed metal container, and disposed of in a

proper manner.

Keep proper footing at all times. Do not overreach, as slipping, tripping, and or falling

can be a major cause of serious injury and or death. Be aware of excess hose in the

working area or work surface.

Check hoses for weak or worn connections before each use, and make certain that all

connections are secure.

Whenever possible, secure work with clamps, or vise so both hands can be free to

operate tool.

Repetitive motions, awkward positions and exposure to vibration can be harmful to

hands and arms.

Adequate exhaust must be provided to keep the air free of toxic materials. Use proper

work clothin t g o avoid direct skin contact.

Do not abuse hoses or connectors. Never carry the tool by the house or yank it to

disconnect it from a power supply. Keep hoses away from heat, oil, sharp edges, and

other sharp objects.

Page 4

4

SAFETY INFORMATION

Do not remove Brass baffle attached to front of gun body as special technical training

and tools are required. Only authorized service centers should remove this part.

To avoid cross-threading, all spray gun parts should be initially screwed in by hand

and hand tightened only. If the parts cannot be easily turned by hand, be sure you have

the correct parts, unscrew, realign, and secure properly in matching parts.

WARNING

CAUTION

SOME DUST CREATED BY PAINT SPRAYING, POWER SANDING, SAWING,

GRINDING, DRILLING, AND OTHER RELATED ACTIVITIES KNOWN TO THE

STATE OF CALIFORNIA TO CAUSE CANCER, BIRTH DEFECTS, AND OTHER

REPRODUCTIVE HARM. A LISTING OF CHEMICALS CAN BE OBTAINED FROM

www.oehha.ca.gov UNDER PROPOSITION 65. SOME EXAMPLES OF THESE

CHEMICALS ARE:

YOUR RISK FROM THESE EXPOSURES VARIES, DEPENDING ON HOW OFTEN

YOU DO THIS TYPE OF WORK. TO REDUCE YOUR EXPOSURE TO THESE

CHEMICALS WORK IN A WELL VENTILATED AREA, AND WORK WITH

WHICH ARE SPECIALLY DESIGNED TO FILTER MICROSOPIC PARTICLES.

LEAD FROM LEAD BASED PAINTS

PRODUCTS

CRYSTALLINE SILICA FROM BRICKS, CEMENT AND OTHER MASONRY

ARSENIC AND CHROMIUM FROM CHEMICALLY TREATED LUMBER

APPROVED SAFETY EQUIPMENT, SUCH AS A RESPRIATOR OR DUST MASKS

Use proper respirator whenever possible, or if there is a chance of inhaling sprayed

materials. The mask must be compatiblewith the materials being sprayed. Contact the

materials supplier for further details.

Solvent and coating can be highly combustibleespecially when sprayed.

Adequate exhaust must beprovided to keep air freeof flammable vapors.

Do not smoke in or near work area.

Always keep a fire extinguisher present in thework area.

Never spray near sources of ignition such sources such as pilot lights, welders, etc.

Halogenated hydrocarbonsolvents, andmethylene chloride, are not chemically

compatible with the aluminum that might beused in may spray system components.

The chemical reaction caused by thesesolventsreacting with aluminum can become

da

ngerous and lead to equipment failure and or equipment explosion.

Guns with stainless steel fluid passages may be used with thesesolvents; however

aluminum is widelyused in other spray applications suchas material pumps, cups, and

regulators, valves etc. Check all other equipment items before use and make sure they

can alsobe safely used with these solvents. Read the label or materialsafety data

sheet for the materials you intend to spray.

Operators andmaintenance personnel must be physically able to handle the bulk

weight, and power of the tool.

This tool is not intended forusing in explosive atmospheres andis not insulated for

contact with electricalpower sources.

Page 5

5

PREPARATION

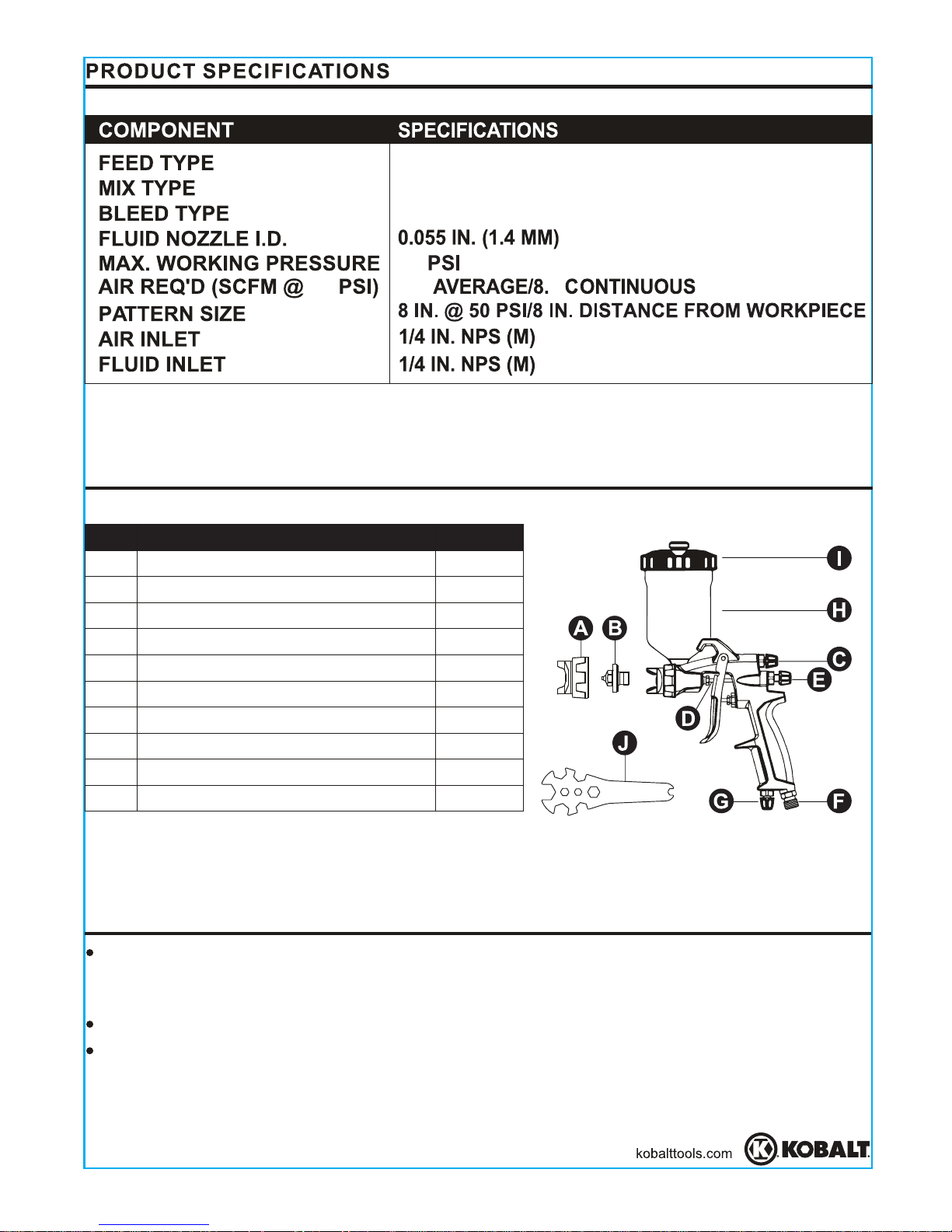

Before beginning assembly and operation of product, make sure all parts are present. Compare

parts with package contents list and diagram above. If any part is missing or damaged, do not

attempt to assemble or operate the product. Contact customer service for replacement parts.

Estimated Assembly Time: 3 minutes

Tools Required for Assembly: Wrench (included)

Quantity

1

1

1

1

1

1

1

1

1

1

Part

A

B

C

D

E

F

G

H

I

J

Description

PACKAGE CONTENTS

Air Cap w/Ring

Fluid Nozzle

Spray Pattern Adjustment Knob

Paint Needle

Fluid Adjustment Knob

Air Connection

Air Adjustment Knob

Plastic Cup

Cover

Wrench

3.3

6

40

40

GRAVITY

EXTERNAL

BLEEDER

Page 6

6

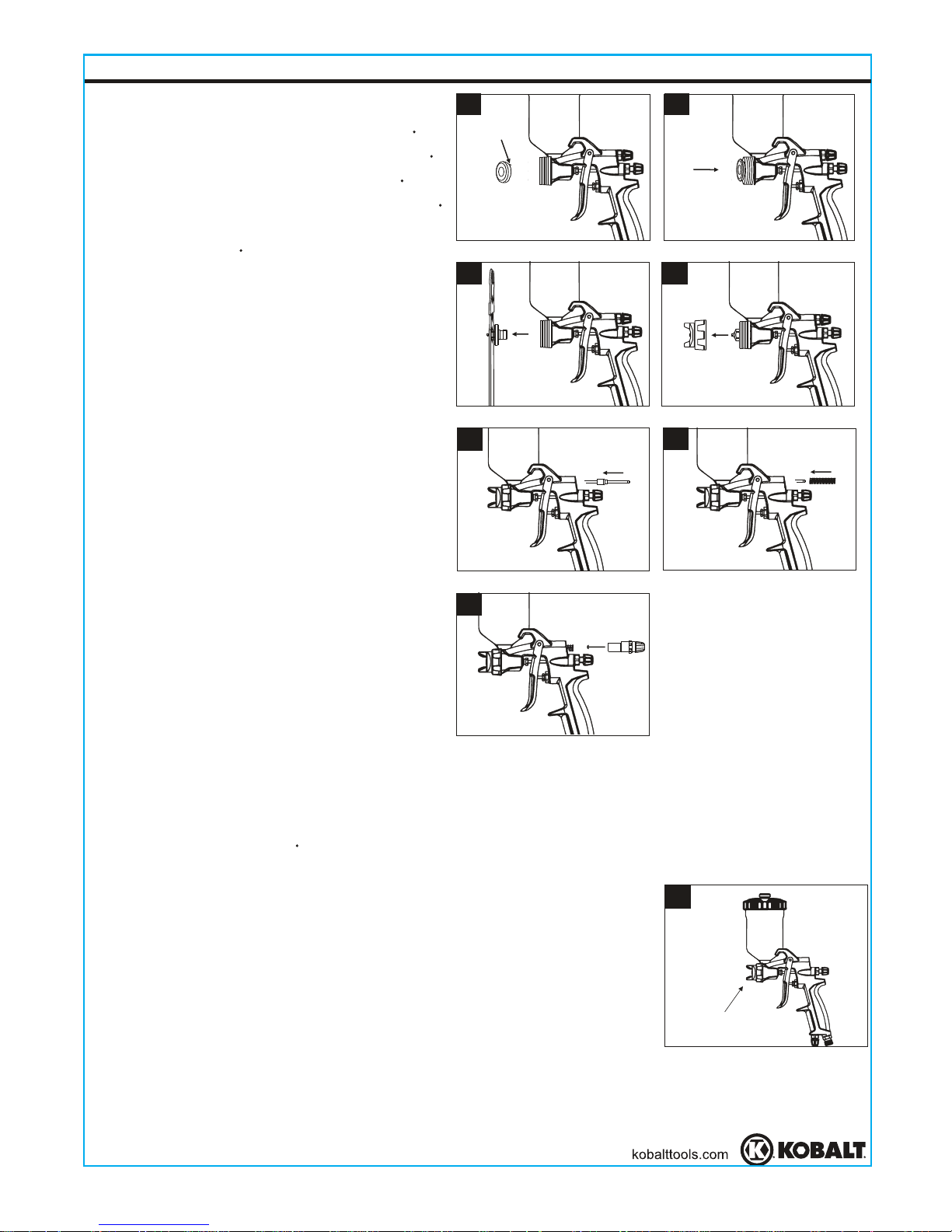

ASSEMBLY INSTRUCTIONS

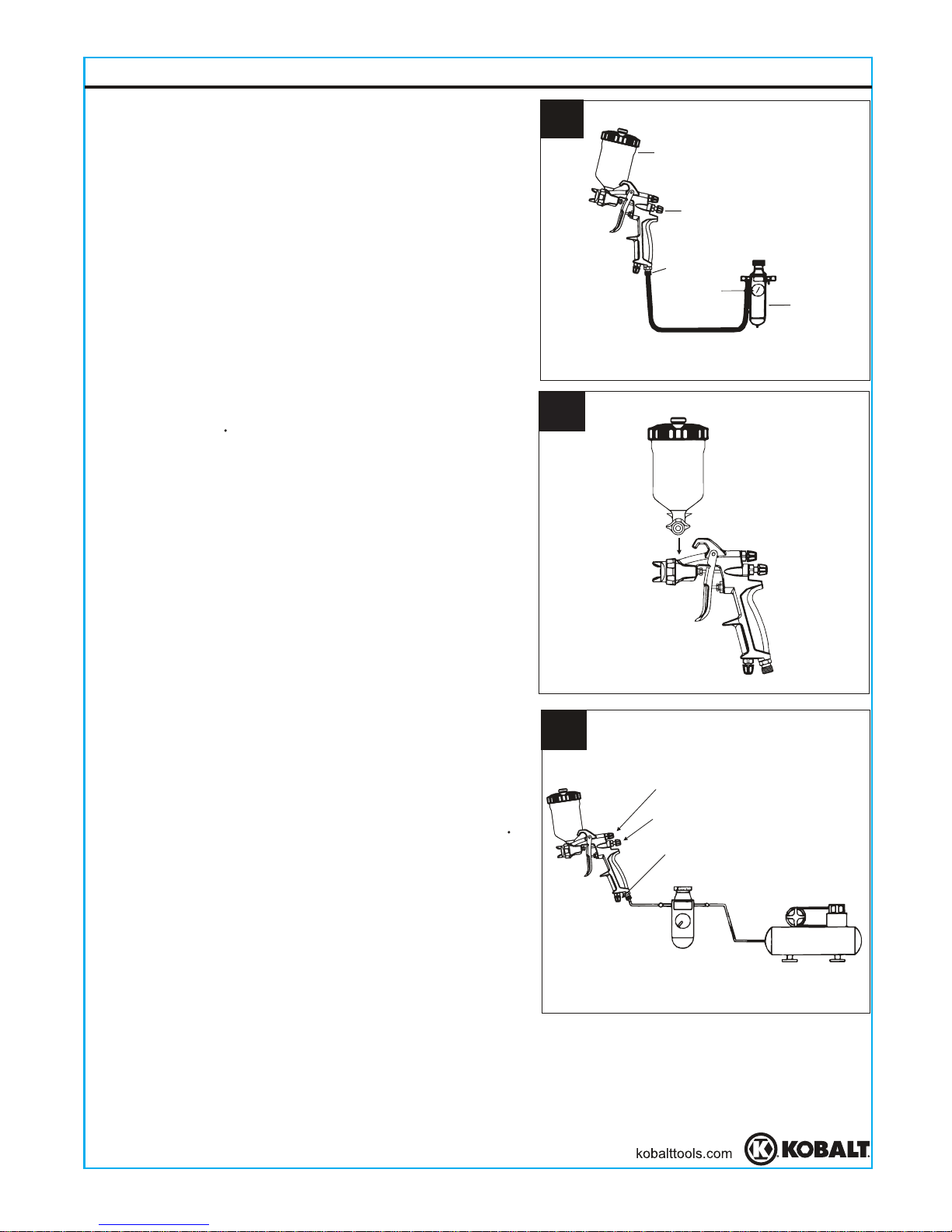

1

1. Take out spray gun and put on paint cup

(see Figure 2)

3

The life of this product and the efficiency of its

operation depend upon the knowledge of its

construction

,

usage and maintenance (See Figure 1.

Not all accessories shown are included).

2

Gravity Feed Cup

Fluid Adjustment Knob

Oil and

Water

Extractor

Atomization

Pressure Gauge

Air Hose

Air Inlet

Spray Pattern Adjustment Knob

Air Adjustment Knob

Fluid Adjustment Knob

2. Connect air tube to air intake connector from air

compressor; set pressure to 43 psi. Fully open air

adjustment knob and adjust the spray pattern

adjustment knob to proper range (See Fig 3. Oil and

water extractor and air compressor not included.)

Read and follow all directions before assembly or use

Page 7

7

ASSEMBLY INSTRUCTIONS

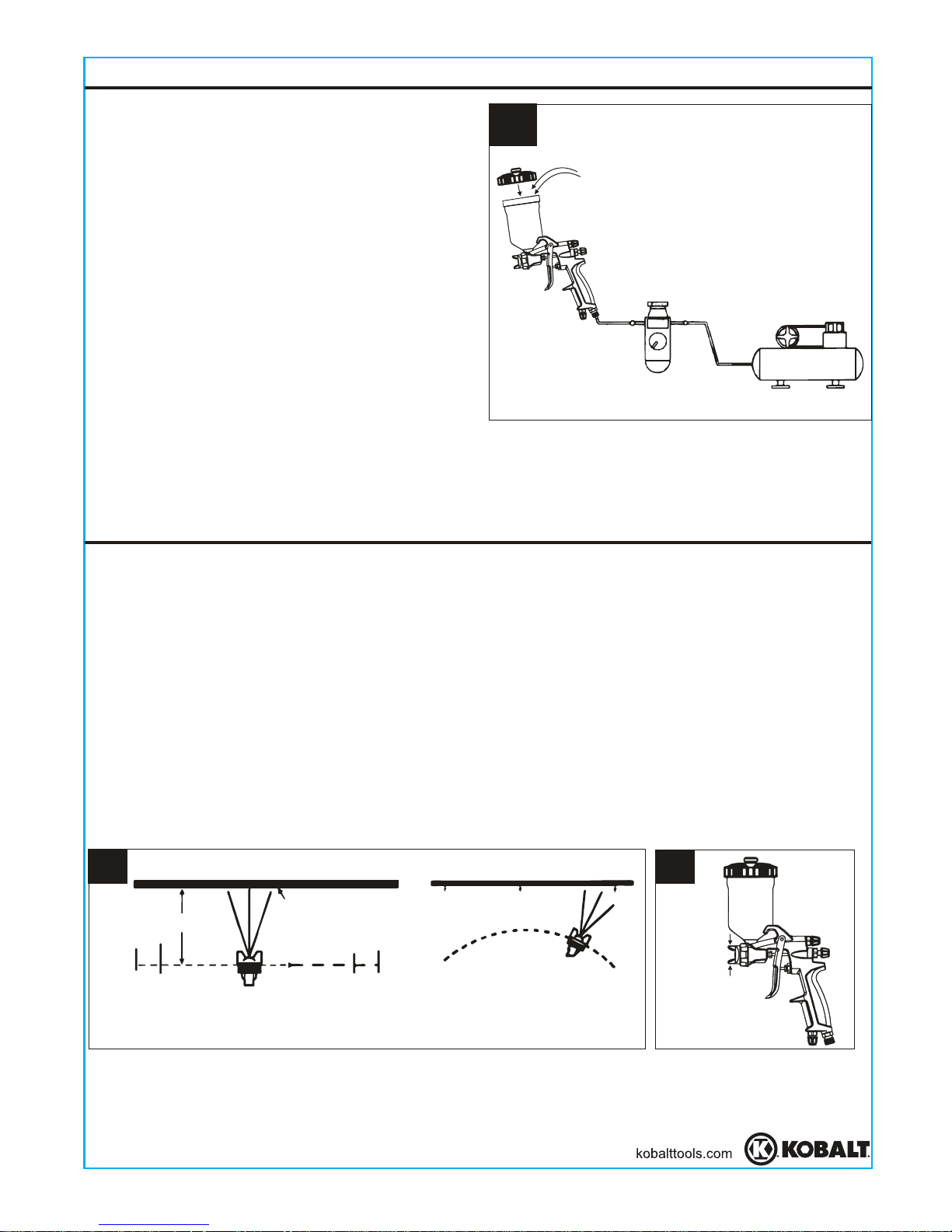

4

4. Pour paint into paint cup and put on cover

(See Fig 4. Oil and water extractor and air

compressor not included).

Load paint

OPERATION INSTRUCTIONS

Proper handling of the gun is essential for obtaining a good finish. The gun should be held at a

90 angle the surface being covered, and moved parallel to it. For precise control of the gun and

material, the trigger should be released before the end of the stroke. Hold the gun 6 to 12 inches

away from the surface depending on material and atomizing pressure. For a uniform finish, lap

each stroke over the preceding stroke, making sure the spray is smooth and wet. Using the

lowest possible atomizing air pressure will reduce over spray and provide maximum efficiency

(See Fig. 5).

O

6 to 12 inches

Start

stroke

Pull

trigger

Even and wet coat

Release

trigger

End of

stroke

RIGHT

Light coat Heavy coat

WRONG

5

During normal use, the air cap wings are horizontal and the air cap should be pointed up as

shown here (See Fig. 6). This provides a vertical fan-shaped pattern which gives maximum and

even material coverage as the gun is moved back and forth parallel to the surface being finished.

The air cap wings

are horizontal.

6

Page 8

8

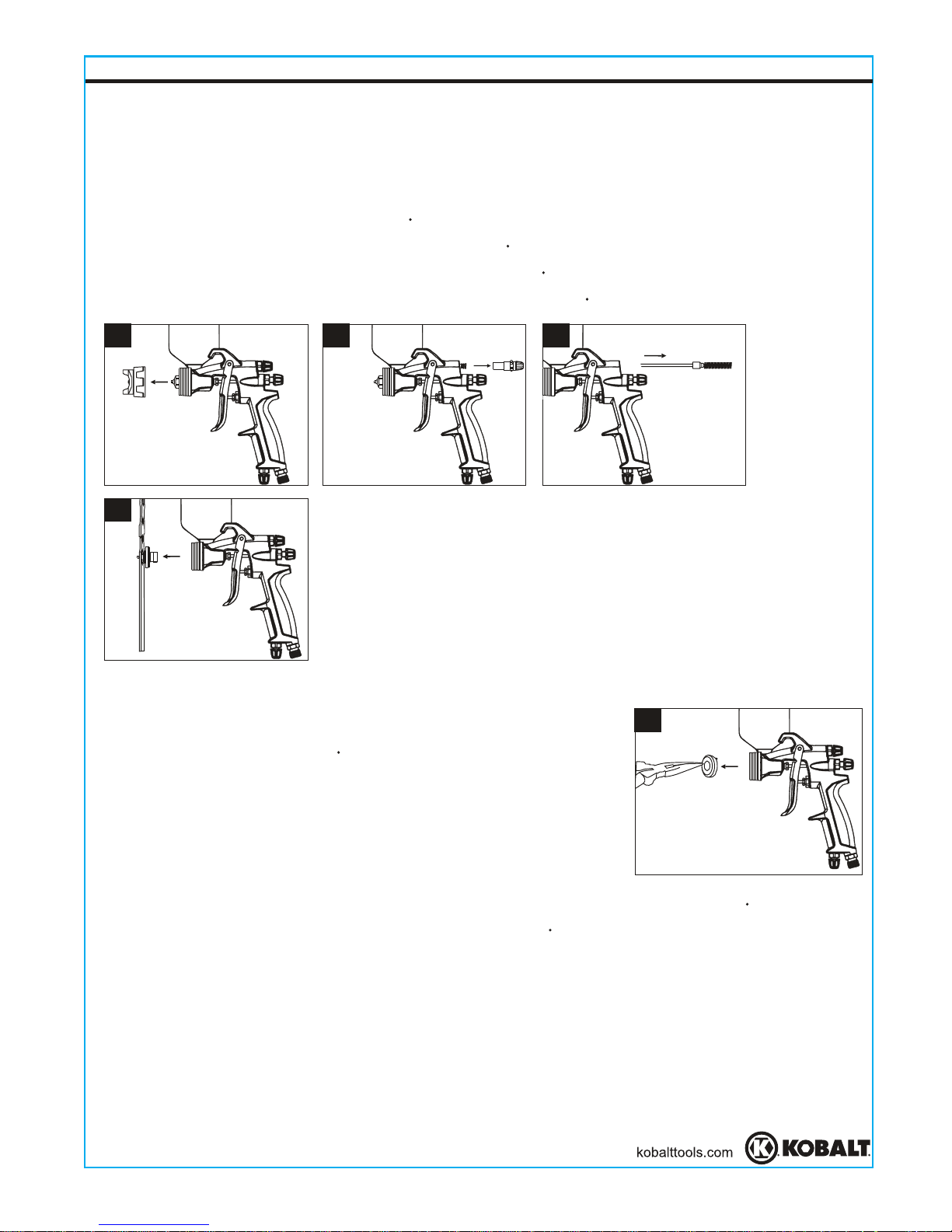

REPAIR INSTRUCTIONS

CAUTION:

Remove air pressure from air hose / gun.

Take care not to damage the seals on the gun body when

removing the air distribution ring.

1. Remove the nozzle set:

a. Remove air cap w/ring (See Fig. 1)

b. Unscrew the fluid adjustment knob (See Fig. 2)

c. Pull out needle spring and paint needle (See Fig. 3)

d. Remove paint nozzle using wrench provided (See Fig. 4)

1 2 3

4

2. Pull out the air distribution ring using needle-nose pliers,

and remove dirt (See Fig. 5)

NOTE: Make sure that dirt has not settled in the sealing surfaces

and no scratches prevent optimum sealing performance.

5

pin marked with an arrow (1) fits smoothly into the hole marked (2) (See Fig. 6)

Then firmly push in the air distribution ring (See Fig. 7) Insert the paint nozzle and

tighten slightly. Then remove it again. Make sure the air distribution ring

fits securely against the gun body.

Reconnect air hose with spray gun and set to desired PSI.

Page 9

9

REPAIR INSTRUCTIONS

8

9

10

11

12

6

7

4. Mount the nozzle set:

a. Screw on paint nozzle (See Fig. 8)

b. Attach the air cap w/ring (See Fig. 9)

c. Put on paint needle (See Fig. 10)

d. Attach the needle spring (See Fig. 11)

e. Screw on the fluid adjustment knob

(See Fig. 12)

NOTE: Test spray pattern before use again.

During normal use, the air cap wings are horizontal and the air cap should be pointed up as

shown here (See Fig. 13)

This provides a vertical fan-shaped pattern which gives maximum

and even material coverage as the gun is moved back and forth parallel to the surface being

finished.

The air cap wings

are horizontal.

13

Page 10

10

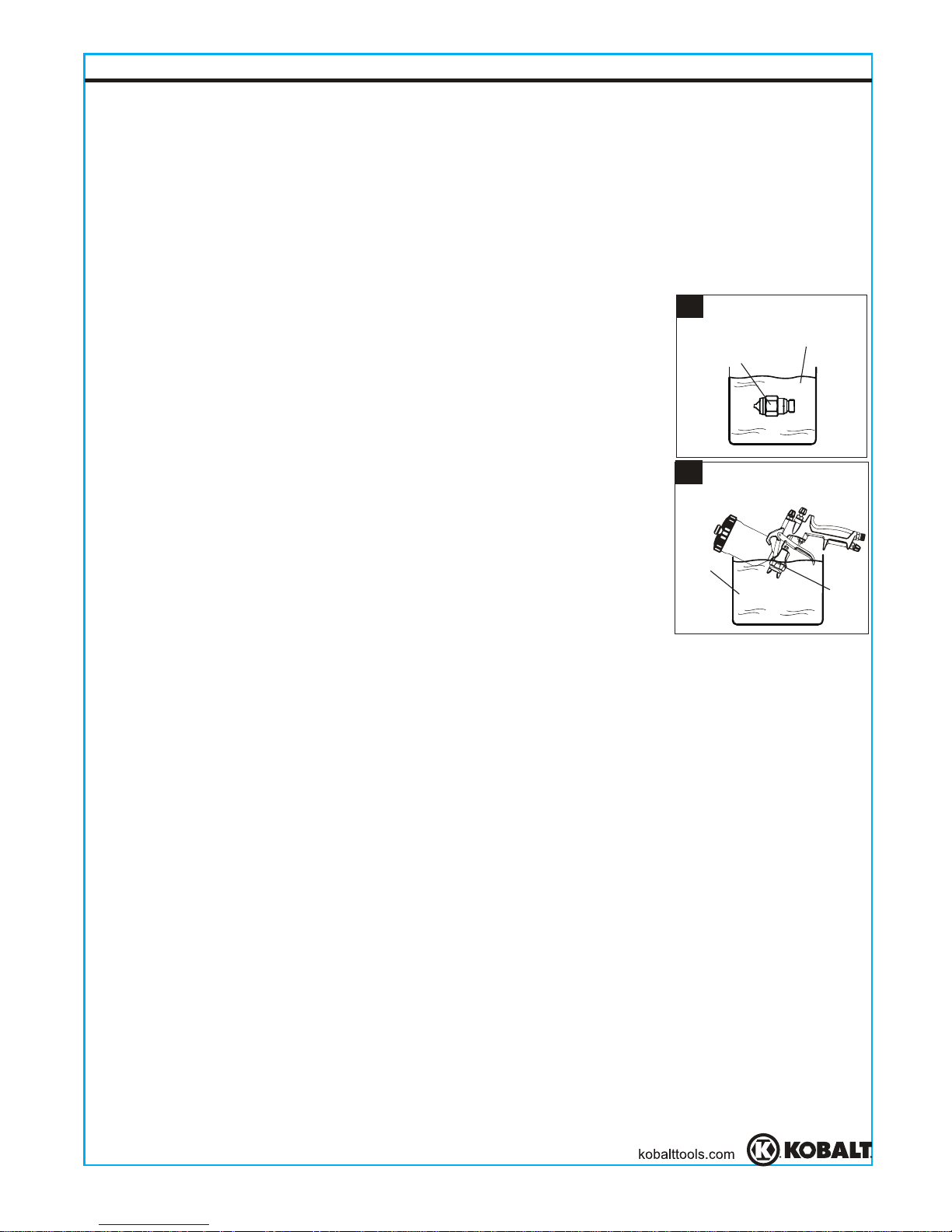

CARE AND MAINTENANCE

To properly maintain and keep your small gravity feed sprayer working at its optimal performance,

it is recommended that the spray gun nozzle be cleaned and cleared of any clogs or debris buildup

using paint thinner, or lacquer thinner. DO NOT USE ANY ACID BASED SOLVENTS, AS ACID

BASED SOLVENTS CAN DAMAGE THE SPRAYER. Please consult with your local Lowes

retailer in choosing the right solvent materials.

15

14

1. Pour enough solvent material(s) into container so that nozzle will be completely submerge in

solvent material

NOTE: There are two methods for properly submerging spray gun nozzle into cleaning solvent

material(s). The manufacturer recommends method 1:

Nozzle

Nozzle

Solvent material

Solvent

material

Method 2: Keeping the Spray gun nozzle attached to the spray gun

housing, submerge the front end of the spray gun only (See Fig. 15).

Make sure that only the spray gun nozzle is submerged in solvent

material(s). IF USING METHOD 2, AND NOT COMPLETELY

REMOVING SPRAY GUN NOZZLE, MAKE SURE A SUITALBLE

CONTAINER IS USED WHICH CAN NOT EASILY TIP OVER. IF

THE CONTAINER USED DOES TIP OVER, YOU WILL SPIL

SOLVENT MATERAIL(S), CAUSING A POTENTIAL SAFETY HAZZARD.

NOTE: Make sure that you never submerge any part of the spray gun

housing into solvent material(s), as air passages would become clogged

with dirty solvent. This would also cause the lubricant in the leather

packaging, and other gaskets inside the gun housing to dry out,

resulting in difficult operation and faster wear on the item which will cause poor spray performance.

2. Let nozzle sit in solvent material(s) for 3-5 minutes allowing solvent material(s) to break up any

build up of dirt and or debris on spray nozzle.

3. Remove nozzle from solvent material(s) and closely inspect the spray gun nozzle to ensure any

dirt or debris build up has been cleared.

NOTE: Depending on the paint and solvent material(s) used, steps 1-4 may need to be repeated

multiple times.

BEFORE PERFORMING ANY CLEANING OR MAINTENANCE REMOVE SPRAY GUN FROM

AIR SUPPLY AND KEEP AWAY FROM ANY INGITION SOURCES.

Method 1: Remove the spray gun nozzle completely from spray gun

and place into a container that will not cause solvent derogation when

solvent material(s) are added (See Fig. 14).

4. If debris or build up is still present use a non wire soft bristle brush and brush area of nozzle

that still contains dirt or debris, and repeat steps 1-4.

5. Once spray gun nozzle has been completely cleared of any dirt or debris, and is clean, wipe

nozzle clean with a clean cloth or rag.

6. Once nozzle has been properly cleaned reconnect nozzle to spray gun, and reconnect spray

gun to air supply, and test sprayer ensuing that sprayer is working properly. If you are at the

end of a project, when test spraying make sure you do not test spray having paint go through

the system as this will require you to begin the cleaning process again.

7. Once sprayer is working properly, make sure you follow the solvent manufactures

recommendations for properly discarding any dirty cloths, or rags that were used in the

cleaning process.

Storing

1. When not using spray gun, turn the fluid adjustment knob counterclockwise to open

which will reduce spring tension on needle fluid tip.

2. Spray gun must be well cleaned and lightly lubricated.

3. Store spray gun in a dry and safe place out of reach of children.

Page 11

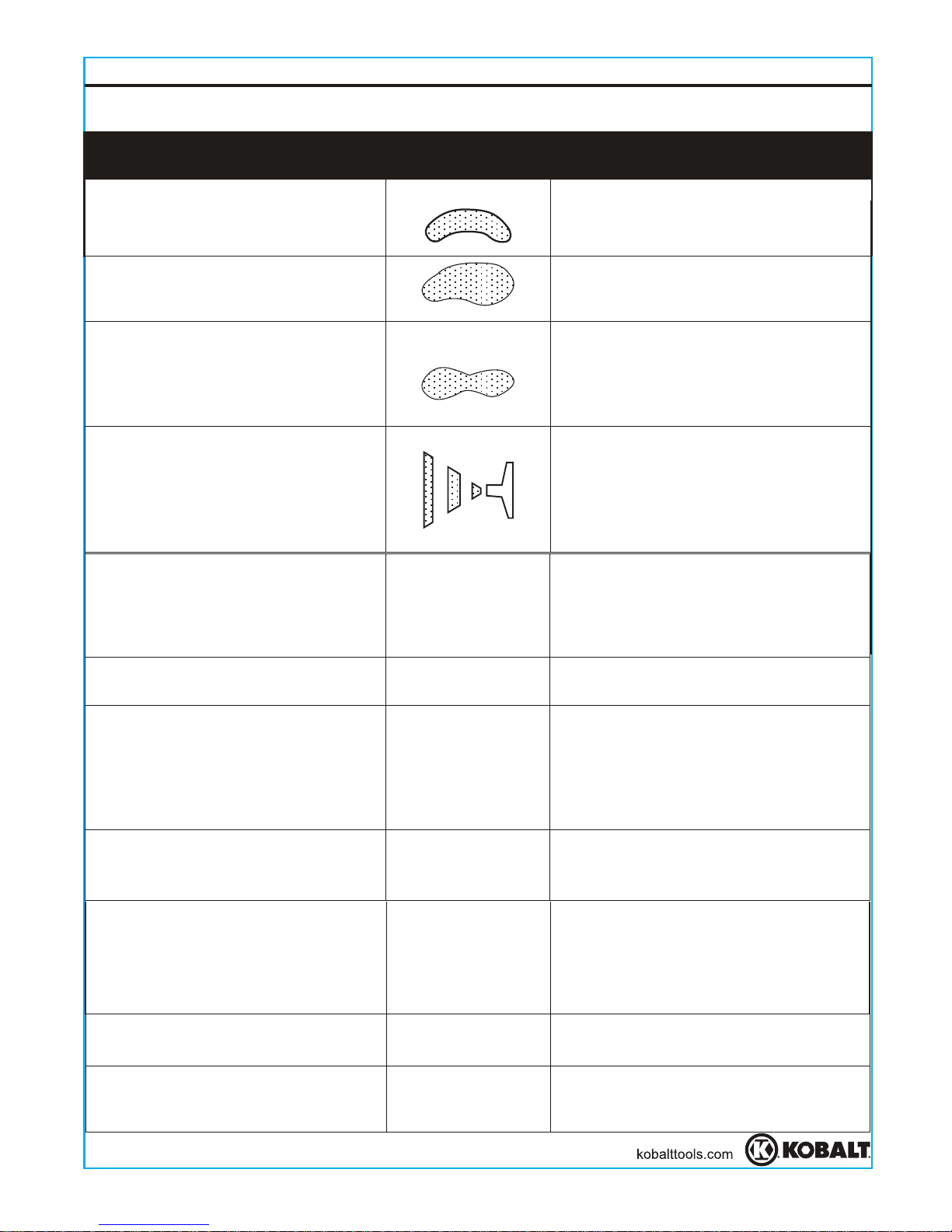

TROUBLESHOOTING

11

a) Gun improperly adjusted.

b) Dirty air cap.

c) Fluid tip obstructed.

d) Sluggish needle.

Fan adjustment screw not seating

properly.

a) No air pressure at gun.

b) Fluid pressure too low with internal

mix cap and pressure tank.

c) Fluid control screw not open

enough.

d) Fluid too heavy for suction feed.

a) Packing nut loose.

b) Packing worn or dry.

a) Tighten, but not so tight as to grip

needle.

b) Replace packing or lubricate.

a) Check air supply and air lines.

b) Increase fluid pressure at tank.

c) Open fluid control screw.

d) Thin material or change to

pressure feed.

Clean or replace.

a) Re-adjust gun. Follow instructions

carefully.

b) Clean air cap.

c) Clean.

d) Lubricate.

Unable to get

round spray.

Improper spray

pattern.

Will not spray.

Fluid leakage

from packing nut.

PROBLEM

SOLUTION

SPRAY PATTERN/

CONDITION

If you have any questions regarding the product, please call customer service at 1-888-3KOBALT,

8 a.m. - 8 p.m., EST, Monday - Friday.

Gun held too close to surface.

a) Dry packing.

b) Sluggish needle.

c) Tight packing nut.

d) Worn fluid nozzle or needle.

a) Gun held too far from surface.

b) Atomization pressure set too high.

Move gun further from surface.

a) Move gun closer to surface.

b) Adjust atomization pressure.

a) Lubricate.

b) Lubricate.

c) Adjust.

d) For pressure feed, replace with

new fluid nozzle and needle.

Dripping from

fluid tip.

Thick, dimpled

finish resembling

orange peel.

Thin, sandy

coarse finish.

a) Loose air nozzle.

b) Material around outside of air

nozzle has dried.

a) Atomization air pressure is set too

high.

b) Trying to spray a thin material in

too wide a pattern.

a) Packing around needle valve is dried

out.

b) Fluid nozzle loosely installed, or dirt

between nozzle and body.

c) Needle sealing damaged.

a) Back up knurled nut, put a few drops of

machine oil on packing, retighten nut.

b) Take off fluid nozzle, clean rear of nozzle

and seat in gun body. Replace nozzle

and bring in tight to body.

c) Replace seal.

a) Reduce air pressure.

b) Increase material control by turning fluid

adjustment knob to left, while reducing

spray width by turning spray pattern

adjustment knob to right.

a) Trigger air nozzle.

b) Take off air nozzle and wipe off fluid tip,

using a rag moistened with thinner.

Intermittent spray

Soak nozzle in solvent to loosen clog, then

blow air through until clean. To clean orifices

use a broom straw or toothpick. Never try to

detach dried material with sharp tool.

One side of nozzle is clogged.

Page 12

WARRANTY

12

This tool is warranted by the manufacturer to the original purchaser from the original

purchase date for three (3) years subject to the warranty coverage described herein.

This tool is warranted to the original user to be free from defect in material and

workmanship. If you believe that a tool is defective, return the tool, with proper proof

of purchase to the point of purchase. If it is determined that the tool is defective and

covered by this warranty, the distributor will replace the tool or refund the

purchase price.

This warranty is void if: defects in materials or workmanship or damages result from

repairs or alterations which have been made or attempted by others or the

unauthorized use of nonconforming parts; the damage is due to normal wear,

damage is due to abuse (including overloading of the tool beyond capacity), improper

maintenance, neglect or accident; or the damage is due to the use of the tool after

partial failure or use with improper accessories or unauthorized repair or alteration.

This warranty gives you specific legal rights, and you may also have other rights that

vary from state to state.

For warranty questions, call our customer service department at 1-888-3KOBALT,

8:00 a.m.-8:00 p.m. EST, Monday-Friday.

Page 13

REPLACEMENT PARTS LIST

13

Washer D=3

1 43 Non-drip control device 1

12

Spring

1 44

Washer D=3

1

13

Washer D=3

1 I Cover 1

14 O-ring2.5x2.1 1 46

Air Valve Spring

1

15 O-ring 8x1.5 1 47

Washer D=3

1

16 Pattern Adj. Knob 1 48 O-ring 2.5x2.1 1

17 Pattern Adj.Screw 1 49 O-ring 8x1.5 1

C

Spray pattern adj. knob

1 50

Pattern Adj. Knob

1

19 Screw M 5X2.5

5X2.5

1 51

Air Adj. Screw

1

20 Screw M 1 H

J

CPlastic up 1

E

Fluid adj. knob

1 G Air Adj. Knob 1

22

Fluid Adj. Screw Plug

1 54 Screw M2.5x5 1

23

Needle Housing Fluid

1 55 Fluid nipple 1

24 O-ring 10x1.8 1 56

Butterfly Nut

1

25 Snap Retainer d=4 1 57

Paint inlet Nozzle

1

26 Trigger 1 58 Cup holder 1

27 Gasket 1 59 Plug 1

28 O-ring 7x1.5 1 60

61

63

Plug 1

1

1

1

29 Needle spring 1

1

1

1

30 Washer

31 Washer

32 Trigger pin

Part No. Description Qty. Part No. Description Qty.

A Air cap w/Ring 1 D Paint Needle 1

2 Air nozzle washer 1 34 Spring 1

3 Air cap 1 35

Air Valve

1

4 Air cap washer 1 36 O-ring 6x1.5 1

B Fluid nozzle 1 37 O-ring 8x1.5 1

6 Gun body 1 38

Switch Seat

1

7

Washer

1 39 O-ring 2.5x1.5 1

8

Sealing gasket

1 40

Switch Screw Seat

1

9

Direction Screw

1 F Air connection 1

10

Pattern Needle

1 42

Air Inlet Valve

1

11

Printed in China

Gun holder

Wrench

Brush

Page 14

SMALL GRAVITY

FEED SPRAY GUN

14

Article #0301339

MODÈLE #SGY-NS87TZ

Numéro de série Date d'achat

KOBALT et le motif de K sont des marques

de commerce déposées de LF, LLC Tous droits

réservés.

JOIGNEZ VOTRE REÇU ICI

Des questions, des problèmes, des pièces manquantes? Avant de

retourner l'article au détaillant, communiquez avec notre service à la

clientèle au 1 888 3KOBAL , entre 8 h et 20 h (HNE), du lundi au vendredi.

® ®

Page 15

15

TABLE DES MATIÈRES

Consignes de sécurité

....................................................................................... 16

Caractéristiques du produit .................................................................................. 18

Contenu de l'emballage ....................................................................................... 18

Préparation .......................................................................................................... 18

Directives d’assemblage ..................................................................................... 19

Instructions d’utilisation ...................................................................................... 20

Entretien .............................................................................................................. 23

Dépannage ......................................................................................................... 24

Garantie ............................................................................................................. 25

Liste des pièces de rechange ............................................................................... 26

Instructions pour la réparation ........................................................................... 21

Page 16

16

CONSIGNES DE SÉCURITÉ

Veuillez vous assurer de lire et de comprendre l'intégralité du présent guide avant

u

d'assembler, d' tiliser ou d'installer ce produit. Si vous avez des questions concernant

ce produit, veuillez téléphoner au service à la clientèle au 1 888 3KOBALT, entre 8 h et

20 h (HNE), du lundi au vendredi.

Ne laissez pas les enfants utiliser l’outil et gardez les enfants à distance de l’aire de travail.

Le bruit peut détériorer votre ouïe. Afin de protéger votre ouïe, portez toujours des

protecteurs auditifs appropriés.

Lorsque vous entretenez l’outil, portez un protecteur facial et des lunettes de sécurité

résistant aux chocs.

Lors du nettoyage et du rinçage, assurez-vous que l’utilisateur et les autres personnes

présentes dans l’air de travail portent un protecteur facial et des lunettes de sécurité

résistant aux chocs appropriés. Les solvant

s peuvent être expulsés sous la pression de

l’air et des fluides et causer des blessures aux

yeux. Les petits objets peuvent ég

alement

blesser les yeux et entraîner la cécité.

Ne portez pas de vêtements amples, de bijoux ni tout autre article qui pourrait

s’accrocher ou s’emmêler dans l’outil lors de son utilisation.

Coupez l’alimentation en air et évacuez la pression d’air du tuyau avant de changer les

accessoires ou d’effectuer des réparations, ainsi que lorsque vous n’utilisez pas l’outil.

Débranchez ensuite l’outil de l’alimentation en air et rangez-le dans un endroit sécuritaire.

Gardez toujours la maîtrise du tuyau à air.

Ne pointez jamais le jet d’air vers vous-même ou une autre personne.

Le cinglage des tuyaux souples peut entraîner de graves blessures.Vérifiez toujours les

tuyaux et les raccords pour déceler des dommages ou desserrages éventuels. N'utilisez

jamais de raccords à changement rapide sur l'outil. Ils ajoutent du poids et pourraient

Gardez toujours l’outil à une distance sécuritaire des personnes présentes dans l’aire

de travail.

Entretenez soigneusement les outils. N’utilise

z jamais un outil qui présente une fuite d’air,

auquel il manque des pièces, dont des pièces son

t endommagées ou qui nécessite des réparations

.

Gardez les outils propres et adéquatement huilés pour un rendement optimal et sécuritaire.

Suivez les instructions pour la lubrification afin d’assurer un fonctionnement optimal et sécuritaire.

Suivez les instructions pour l’assemblage et les réparations pour changer les

accessoires correctement.

Demeurez stable sur vos pieds et gardez l'équilibre en tout temps. Glisser, trébucher ou

Vérifiez les tuyaux souples pour déceler tout signe de faiblesse ou d'usure avant de les

utiliser et assurez-vous que toutes les connexions sont sûres.

Prenez soin des tuyaux souples et des connecteurs. Ne transportez jamais l'outil par le

tuyau souple et ne le tirez pas d'un coup sec pour le débrancher de l'alimentation électrique.

tenez les tuyaux éloignés des sources de chaleur, de l’huile, des rebords coupants

et d’autres objets tranchants.

se desserrer en raison des vibrations. Ajoutez plutôt une amorce de tuyau et fixez le

raccord entre l'arrivée d'air et l'amorce ou entre l'amorce et le tuyau principal.

chuter peut causer des blessures graves ou le décès. Faites attention au surplus de

tuyau laissé sur le passage ou la surface de travail.

Si possible, fixez la pièce sur laquelle vous travaillez avec des pinces ou un étau afin de

pouvoir vous servir de vos mains pour faire fonctionner l'outil.

Les mouvements répétitifs effectués pendant le travail, les positions inconfortables et

l'exposition aux vibrations peuvent se révéler douloureux pour les mains et les bras.

Une sortie de ventilation doit être prévue pour maintenir l'air exempt de matériaux toxiques.

Gardez une posture sécuritaire en tout temps. Ne vous étirez pas pour étendre votre

portée; vous risqueriez de glisser, de trébucher ou de tomber et de subir des blessures

graves ou mortelles. Faites attention à l’excédent du tuyau à air et aux prises

d’alimentation de l’aire de travail.

Portez des vêtements de travail appropriés pour éviter le contact direct avec la peau.

Page 17

17

ING

Portez un masque respiratoire approprié lorsque possible, ainsi que lorsqu’il y a un risque

d’inhalation des matériaux vaporisés. Le masque doit être compatible avec les matériaux

vaporisés. Communiquez avec le fournisseur des matériaux pour plus de détails.

Les solvants et les apprêts peuvent se révéler très combustibles, tout particulièrement

lorsqu'ils sont pulvérisés.

Une sortie de ventilation doit être prévue pour maintenir l'air exempt de vapeurs inflammables.

Ne fumez pas sur le lieu de travail ou à proximité.

Ayez toujours un extincteur sur le lieu de travail.

Ne pulvérisez jamais près des sources d'inflammation telles que les flammes de veilleuses,

les machines à souder, etc.

Les halons, par exemple les dichlorométhanes, ne sont pas chimiquement compatibles avec

l'aluminium qui pourrait être utilisé dans de nombreux composants du système. La réaction

chimique causée par ces solvants réagissant à l'aluminium peut se révéler dangereuse et

provoquer une explosion de l'équipement.

Les pistolets munis de conduites de fluide en acier inoxydable peuvent être utilisés avec ces

solvants. Toutefois, l'aluminium est largement utilisé dans d'autres outils de pulvérisation tels

q

ue les pompes à pulvériser, les godets et les régulateurs, les soupapes, etc. Vérifiez toutes

les pièces de l'équipement avant de vous en servir et assurez-vous qu'elles peuvent être

utilisées en toute sécurité avec ces solvants. Lisez l'étiquette et la fiche signalétique de sécurité

du matériau que vous avez l'intention de pulvériser.

Les opérateurs et le personnel d'entretien doivent avoir les capacités physiques

nécessaires pour manier un outil de ce volume, de ce poids et de cette puissance.

Cet outil n'est pas conçu pour être utilisé dans des atmosphères explosives et n'est pas isolé

de façon à pouvoir supporter un contact avec les sources d'alimentation électrique.

CONSIGNES DE SÉCURITÉ

AVERTISSEMENT

LA POUSSIÈRE CRÉÉE PENDANT LE PONÇAGE, LE SCIAGE, LE POLISSAGE, LE

PERÇAGE ET D'AUTRES ACTIVITÉS PEUT CONTENIR DES PRODUITS CHIMIQUES

RECONNUS PAR L'ÉTAT DE LA CALIFORNIE COMME ÉTANT LA CAUSE DE CANCERS,

D'ANOMALIES CONGÉNITALES ET D'AUTRES PROBLÈMES LIÉS AUX FONCTIONS

AU www.oehha.ca.gov, CONFORMÉMENT À LA PROPOSITION 65. VOICI

QUELQUES-UNS DE CES PRODUITS CHIMIQUES :

DU PLOMB PROVENANT DE PEINTURES À BASE DE PLOMB;

DE LA SILICE CRISTALLINE PROVENANT DE LA BRIQUE, DU CIMENT OU

D

'AUTRES MATÉRIAUX DE MAÇONNERIE;

DE L'ARSENIC ET DU CHROME PROVENANT DU BOIS D'ŒUVRE TRAITÉ AVEC

UN PRODUIT CHIMIQUE.

REPRODUCTRICES. VOUS POUVEZ OBTENIR LA LISTE DES PRODUITS CHIMIQUES

LES RISQUES LIÉS À L’EXPOSITION À CES PRODUITS VARIENT SELON LE NOMBRE

DE FOIS OÙ VOUS PRATIQUEZ CES ACTIVITÉS. AFIN DE LIMITER VOTRE

EXPOSITION À CES PRODUITS CHIMIQUES, TRAVAILLEZ DANS UN ENDROIT BIEN

VENTILÉ ET UTILISEZ DE L’ÉQUIPEMENT DE SÉCURITÉ APPROUVÉ, TEL QU’UN

APPAREIL RESPIRATOIRE OU UN MASQUE ANTIPOUSSIÈRE CONÇUS

SPÉCIALEMENT POUR FILTRER LES PARTICULES MICROSCOPIQUES.

Page 18

18

CARACTÉRISTIQUES DU PRODUIT

CARACTÉRISTIQUES

COMPOSANTE

ENTRÉE D’AIR

.

NE RETIREZ PAS le déflecteur en laiton fixé à l'avant du corps du pistolet car une

formation technique spéciale et certains outils

sont nécessaires. Le retrait de cette

pièce devrait être confié aux centres de réparation et d'entretien autorisés.

CONSIGNES DE SÉCURITÉ

1

1

1

1

1

1

1

1

1

1

A

B

C

D

E

F

G

H

I

J

Quantité

Pièce Description

Obturateur d’air avec anneau

Buse à fluide

Pointeau à peinture

Bouton de réglage du fluide

Raccord d'air

Bouton de réglage de l’air

Recipiente de plástico

Cubierta

Clé

Bouton de réglage du jet

CONTENU DE L'EMBALLAGE

PRÉPARATION

Avant de commencer l'assemblage et d'utiliser le produit, assurez-vous de disposer de toutes les

pièces. Comparez les pièces dans l'emballage avec la liste et le tableau ci-dessus. Si des pièces

sont manquantes ou endommagées, ne tentez pas d'assembler ou d'utiliser le produit.

Communiquez avec le service à la clientèle pour obtenir des pièces de rechange.

Temps d'assemblage approximatif : 3 minutes

Accessoires requis pour l'assemblage : Clé (comprise)

Pour éviter de déformer le filetage, toutes les pièces du pistolet de pulvérisation

devraient d’abord être serrées solidement à la main. Si le serrage à la main s’avère

difficile, assurez-vous qu’il s’agit des bonnes pièces. Dévissez-les, ajustez-les et

tentez de les visser de nouveau avec plus de force.

TYPE D’ALIMENTATION

TYPE DE MÉLANGE

TYPE DE PURGE

DIAMÈTRE INTÉRIEUR DE

LARGEUR DU JET

ENTRÉE DE FLUIDE

LB/PO )

2

AIR REQUIS (PI /MIN À 40

3

PRESSION DE SERVICE MAXIMALE

GRAVITÉ

EXTERNE

PURGEUR

1,4 MM (0,055 PO)

40 LB/PO

2

3,3 EN MOYENNE/8,6 EN CONTINU

20,32 CM (8 PO) À 50 LB/PO /À 20,32 CM (8 PO)

DE LA PIÈCE

2

1/4 PO NPS (M)

1/4 PO NPS (M)

MISE EN GARDE

Page 19

19

1

3

2

Godet de pistolet

à gravitation

Molette de réglage du fluide

Extracteur

d'huile

et d'eau

Manomètre

de pulvérisation

Tuyau d'air souple

Arrivée d'air

DIRECTIVES D'ASSEMBLAGE

3. Raccordez le tube d’air au connecteur d’entrée

d’air du compresseur d’air et réglez la pression

à 60 lb/po2. Tournez complètement le bouton

de réglage du débit d’air en position ouverte et

tournez le bouton de réglage du jet en position

adéquate. (Consultez la figure. 3. L’extracteur

d’huile et d’eau et le compresseur d’air ne

sont pas inclus.)

Molette de réglage de la répartition

de la pulvérisation

Molette de régulation de l'air

Molette de réglage du fluide

Ce pistolet de pulvérisation est d'une fabrication

robuste; il a été conçu pour offrir une valeur

exceptionnelle. La durée de vie et l'efficacité de ce

produit dépendent des connaissances qu'ont les

utilisateurs relativement à sa fabrication, à son

utilisation et à son entretien. (Consultez la figure 1..

Certains accessoires illustrés ne sont pas inclus.)

2.

Prenez le pistolet de pulvérisation et placez-le sur

le réservoir à peinture. (Consultez la figure 2.)

Page 20

20

4

La manipulation appropriée du pistolet est essentielle à l’obtention d’un fini adéquat. Le pistolet

doit être tenu à un angle de 90° de la surface couverte et il doit être déplacé parallèlement à

celle-ci. Pour plus de précision, gardez le pistolet à une distance de 15,24 cm à 30,48 cm de la

surface et des matériaux. Relâchez la gâchette avant la fin du trait pour obtenir une couverture

uniforme. Pour obtenir une couverture uniforme, tenez le pistolet à une distance de 15,24 cm à

30,48 cm, selon le matériau pulvérisé, la pression de pulvérisation et la surface couverte. Pour

un fini uniforme, faites chevaucher chaque trait sur le trait précédent, en vous assurant que la

couverture est lisse et humide. En utilisant le réglage de pression de vaporisation le plus faible,

vous réduirez les risques de surpulvérisation et vous jouirez d’une efficacité maximale.

(Consultez la fig. 5.)

5

Lors de l’utilisation normale, les ailettes de l’obturateur d’air sont à l’horizontale et l’obturateur

d’air est orienté vers le haut, tel qu’il est illustré. (Consultez la fig. 6) Ainsi, vous obtiendrez un

jet vertical en forme d’éventail et vous vous assurerez d’obtenir une couverture optimale et

uniforme (déplacez le pistolet dans un mouvement de va-et-vient parallèle à la surface).

6

4. Versez la peinture dans le réservoir à peinture

et mettez le couvercle en place. (Consultez la

fig. 4. L’extracteur d’huile et d’eau et le

compresseur d’air ne sont pas inclus.)

Chargez la peinture

DIRECTIVES D'ASSEMBLAGE

INSTRUCTIONS D'UTILISATION

Commencez

le passage

Tirezla

gâchette

Couche uniforme

et mouillée

Relâchez

la gâchette

Findu

passage

Couche

légère

Couche

épaisse

INADÉQUAT

15,25 à 30,50 cm

(6 à 12 po)

Les ailettes du

capuchon d'air

sont à l'horizontale.

DROITE

Page 21

21

MISE EN GARDE: Veillez à ne pas endommager les joints du corps du

pistolet lorsque vous retirez la bague de distribution d'air.

1. Retirez l'ensemble de la buse :

a. Retirez le bouchon d'air avec bague (Voir fig. 1)

b. Dévissez la molette de réglage du fluide. (Voir fig. 2)

c. Retirez le ressort de l'aiguille et l'aiguille à peinture. (Voir fig. 3)

d. Retirez la buse à peinture à l'aide de la clé fournie. (Voir fig. 4)

2. Retirez la bague de distribution d'air à l'aide de pinces à becs

pointus et enlevez la saleté. (Voir fig. 5)

REMARQUE: Assurez-vous que la saleté ne s'est pas accumulée

sur les surfaces des joints et que des rayures n'altèrent pas la

performance de l'étanchéité.

marquée d'une flèche (1) s'engage sans entrave dans l'orifice marqué (2). (Voir fig. 6.) Ensuite,

enfoncez fermement la bague de distribution d'air. (Voir fig. 7.) Insérez la buse à peinture et

serrez légèrement. Retirez-la de nouveau. Assurez-vous que la bague de distribution d'air est

bien ajustée contre le corps de la bague.

Éliminez la pression d’air des tuyaux à air du pistolet de pulvérisation.

Raccordez le tuyau à air au pistolet de pulvérisation et réglez à la

pression en lb/po souhaitée.

INSTRUCTIONS POUR LA RÉPARATION

2

1 2 3

4

5

Page 22

22

13

4. Montez l'ensemble de la buse :

a. Vissez la buse à peinture. (Voir fig. 8)

a. Fixez le bouchon d'air avec bague.

(Voir fig. 9)

c. Mettez l'aiguille à peinture en place.

(Voir fig. 10)

d. Fixez le ressort d'aiguille. (Voir fig. 11)

e. Vissez la molette de réglage du fluide.

(Voir fig. 12)

REMARQUE: Effectuez un essai de pulvérisation pour vérifier la répartition avant d'utiliser de

nouveau l'outil.

Pendant l'utilisation normale, les ailettes du bouchon d'air sont à l'horizontale et le bouchon d'air

devrait pointer tel qu'il est illustr. (Voir fig. 13.) Vous obtenez ainsi la répartition verticale en forme

d'éventail qui procure une couverture maximale et uniforme tandis que le pistolet fait des

aller-retour parallèlement à la surface qui est revêtue.

Les ailettes du

capuchon d'air

sont à l'horizontale.

INSTRUCTIONS POUR LA RÉPARATION

8

9

10

11

12

6

7

Page 23

23

15

14

La buse

La buse

Solvant

Solvant

ENTRETIEN

Pour bien entretenir et garder votre pulvérisateur de travail à sa performance optimale, nettoyez

la buse de pulvérisation et enlevez-en les obstructions et les débris à l’aide d’un diluant à peinture

ou d’un diluant à peinture-laque seulement. N’UTILISEZ PAS DE SOLVANT À BASE D’ACIDE,

CAR CES PRODUITS PEUVENT ENDOMMAGER LE PISTOLET DE PULVÉRISATION.

N’hésitez pas à consulter votre détaillant Lowes afin de choisir le bon solvant.

1. Versez suffisamment de solvant dans un récipient pour que la buse soit complètement immergée.

REMARQUE : Il existe deux moyens d’immerger correctement la buse du pistolet de pulvérisation

dans le solvant. Le fabricant recommande l’utilisation de la méthode 1.

Méthode 2 : laissez la buse du pistolet de pulvérisation fixée au

boîtier du pistolet et immergez complètement la partie avant de

celui-ci (consultez la figure 15). Assurez-vous que seule la buse du

pistolet de pulvérisation se trouve immergée dans le solvant. SI VOUS

CHOISISSEZ LA MÉTHODE 2 ET NE RETIREZ PAS

COMPLÈTEMENT LA BUSE, ASSUREZ-VOUS D’UTILISER UN

CONTENANT ADÉQUAT QUI NE SE RENVERSE PAS

FACILEMENT. SI LE CONTENANT SE RENVERSAIT, LE SOLVANT

RÉPANDU ENTRAÎNERAIT UN RISQUE POUR LA SÉCURITÉ.

REMARQUE : Assurez-vous de ne jamais immerger aucune partie du

boîtier du pistolet de pulvérisation dans le solvant, car le solvant souillé

pourrait boucher les conduits d’air. Cela pourrait également assécher le

lubrifiant de la garniture en cuir et des autres joints se trouvant à

l’intérieur du pistolet, ce qui rendrait l’utilisation difficile, accélérerait l’usure de l’article et

entraînerait un mauvais rendement.

2. Laissez la buse reposer durant 3 à 5 minutes, afin de permettre au solvant de dissoudre les

débris et les accumulations.

3. Remove nozzle from solvent material(s) and closely inspect the spray gun nozzle to ensure any

dirt or debris build up has been cleared.

REMARQUE : Selon la peinture et le solvant utilisés, vous devrez peut-être répéter les étapes 1

à 4 plusieurs fois.

VANT DE PROCÉDER AU NETTOYAGE OU À L’ENTRETIEN, DÉBRANCHEZ LE PISTOLET

DE PULVÉRISATION DE L’ALIMENTATION EN AIR ET TENEZ-LE LOIN DES SOURCES

D’INFLAMMATION.

Méthode 1: retirez la buse du pistolet de pulvérisation et déposez-la

dans un récipient qui n’altérera pas le solvant (consultez la figure 14).

4. S’ils ne sont pas complètement dissous, brossez l’endroit où se trouvent les saletés à l’aide

d’une brosse à soies souples et répétez les étapes 1 à 4.

5. Une fois la buse complètement nettoyée, essuyez-la avec un linge propre.

6. Une fois le nettoyage terminé, raccordez la buse au pistolet de pulvérisation ainsi que

l’alimentation en air, puis testez le pistolet afin de vérifier s’il fonctionne correctement. Si vous

avez terminé votre projet, assurez-vous qu’il n’y a pas de peinture dans le système lorsque

vous le testez. Si tel est le cas, vous devrez recommencer le processus de nettoyage.

7. Lorsque le pistolet de pulvérisation fonctionne correctement, suivez les consignes du fabricant

de solvant afin de vous débarrasser adéquatement des linges utilisés pendant le nettoyage.

Entreposage

1. Lorsque vous n'utilisez pas le pistolet de pulvérisation, tournez le bouton de réglage

du fluide dans le sens contraire des aiguilles d'une montre afin de réduire la tension

du ressort sur le bout du pointeau du fluide.

2. Il faut bien nettoyer et légèrement lubrifier le pistolet de pulvérisation.

3. Rangez le pistolet de pulvérisation dans un endroit sec et sûr, hors de la portée des

enfants.

Page 24

24

DÉPANNAGE

Pour obtenir des pièces de rechange, communiquez avec notre service à la clientèle

au 1 888 3KOBALT, entre 8 h et 20 h (HNE), du lundi au vendredi.

PROBLÈME SOLUTION

RÉPARTITION/ÉTAT

DE LA PULVÉRISATION

Faites tremper la buse dans du solvant pour

la déboucher, puis nettoyez à l'air comprimé.

Pour nettoyer les orifices, utilisez une paille

de balai ou un cure-dent. N'essayez pas de

détacher du matériau sec à l'aide d'un outil

coupant.

Un côté de la buse est obstrué.

a) La pression d'air de pulvérisation est

réglée à un niveau trop élevé.

b) Vous essayez de pulvériser un

matériau fin selon une répartition

trop large.

a) Réduisez la pression de l'air.

b) Contrôlez davantage le matériau en

tournant la molette de réglage du fluide

vers la gauche tout en réduisant la

largeur de la pulvérisation en tournant la

molette de réglage de la répartition de la

pulvérisation vers la droite.

A) La buse à air est mal ajustée.

b) Le matériau a séché sur le pourtour

extérieur de la buse à air.

a) Faites basculer la buse à air.

b) Retirez la buse à air et essuyez la pointe

de la buse avec un chiffon humecté de

diluant.

a) La garniture du pourtour de la soupape

de l'aiguille a séché.

b) La buse à fluide n'a pas été assez

serrée à l'installation ou il y a de la

saleté entre la buse et le corps de l'outil.

c) Le joint de l'aiguille est endommagé.

a) Desserrez l'écrou moleté, versez

quelques gouttes d'huile

sur la garniture et resserrez l'écrou.

b) Enlevez la buse à fluide, nettoyez

l'arrière de la buse et posez le corps du

pistolet. Remettez la buse en place et

ajustez-la contre le corps du pistolet.

c) Replacez le joint.

pour machines

Pulvérisation

intermittente

a) Le pistolet n'est pas réglé

correctement.

b) Le bouchon d'air est sale.

c) La pointe de la buse à fluide est

obstruée.

d) L'aiguille est lente.

La vis de réglage du jet en éventail

n'est pas correctement assise.

a) Il n'y a pas de pression d'air au pistolet.

b) La pression du fluide est trop basse

lorsque le bouchon du mélange interne

est en place et le godet est sous pression.

c) La vis de commande du fluide n'est pas

suffisamment ouverte.

d) Le fluide est trop lourd pour l'aspiration.

a) L'écrou de la garniture est desserré.

b) La garniture est usée ou sèche.

a) La garniture est sèche.

b) L'aiguille est lente.

c) L'écrou de la garniture est trop

serré.

d) La buse ou l'aiguille à fluide est

usée.

a) Lubrifiez.

b) Lubrifiez.

c) Réglez.

d) Pour l'alimentation sous pression,

remplacez la buse et l'aiguille à fluide.

a) Serrez, mais pas excessivement pour

éviter que l'aiguille ne se grippe.

b) Remplacez la garniture ou lubrifiez.

a) Réglez de nouveau le pistolet. Suivez

attentivement les instructions.

b) Nettoyez le bouchon d'air.

c)

Nettoyez.

d) Lubrifiez.

Des gouttes fuient

de la buse à fluide.

Il est impossible

d'obtenir une

pulvérisation ronde.

La répartition de la

pulvérisation est

inadéquate.

Il est impossible de

pulvériser.

Du fluide fuit de

l'écrou de la garniture.

a) Vérifiez l'arrivée et les conduites d'air.

b) Augmentez la pression du fluide dans

le godet.

c) Ouvrez la vis de commande du fluide.

d) Amincissez le matériau ou optez pour

l'alimentation sous pression.

Nettoyez-la ou remplacez-la

Page 25

25

Le pistolet est tenu trop près de la

surface.

a) Le pistolet est tenu trop loin de la

surface.

b) La pression de la pulvérisation est

réglée à un niveau trop élevé.

Éloignez le pistolet de la surface.

a) Avancez le pistolet plus près de la surface.

b) Réglez la pression de la pulvérisation.

La finition est épaisse,

alvéolée et ressemble

à de la peau d'orange.

La finition est à gros

grains grossiers.

TROUBLESHOOTING

Pour obtenir des pièces de rechange, communiquez avec notre service à la clientèle

au 1 888 3KOBALT, entre 8 h et 20 h (HNE), du lundi au vendredi.

PROBLÈME SOLUTION

RÉPARTITION/ÉTAT

DE LA PULVÉRISATION

Cet outil est garanti par le fabricant pour une période de trois (3) ans à partir de la

date d'achat, selon les modalités décrites aux présentes.

Cet outil est garanti contre les défauts de matériaux et de fabrication. Si vous croyez

qu'il est défectueux, retournez-le, accompagné d'une preuve d'achat acceptable, au

point de vente d'origine. Si l'outil est jugé défectueux et qu'il est couvert par la

présente garantie, le distributeur l'échangera ou vous remboursera le prix d'achat.

Cette garantie sera annulée si : les défauts de matériaux ou de fabrication ou les

dommages résultent de réparations ou de modifications non autorisées, de

l'utilisation de pièces non conformes, de l'usure normale, d'un usage abusif

(notamment une surcharge de l'outil), d'un entretien inadéquat, d'une négligence,

d'un accident, d'une utilisation après une défaillance partielle ou de l'utilisation

d'accessoires inappropriés.

Cette garantie vous confère des droits précis. Il est possible que vous disposiez

également d'autres droits, qui varient d'un État ou d'une province à l'autre.

Pour toute question concernant la garantie, communiquez avec le service à la

clientèle au 1 888 3KOBALT, entre 8 h et 20 h (HNE), du lundi au vendredi.

GARANTIE LIMITÉE DE TROIS ANS

Page 26

26

D=3

1 43 Dispositif anti-goutte 1

12 1 44

Arandela D=3

Arandela D=3

1

13

D=3

1

1

1

I Cubierta 1

14 46

Ressort de la soupape d’air

Junta tórica de 2.5x2.1

1

15 47

1

1

16

48

17

49 Junta tórica de 8x1.5 1

C 1

1

1

1

1

50 1

19 Vis M 5X2.5

5X2.5

51

Vis de réglage de l'air

Perilla de ajuste de modalidad

1

20 H

J

Recipiente de plástico 1

1

1

E

Bouton de réglage du fluide

1 G

22

Bouchon à vis du fluide

1 54

23

Pointeau du fluide

1

1

1

55

Boquilla acopladora de fluido

1

24 56

Écrou à ailettes

1

25 57

Embout d’entrée de la peinture

1

26 Gâchette 1 58 Support du gobelet 1

27 Joint 1

1

1

1

1

1

59 Fiche

Fiche

1

28 60

61

63

1

1

1

1

29

30

31

32

Pieza No.

A D Pointeau à peinture

Descripción Cant.Pieza No. Descripción Cant.

1

2 34 Resorte 1

3 1

1

1

1

1

1

35

Soupape d'air

1

4 36 Junta tórica de 6x1.5 1

B 37 Junta tórica de 8x1.5 1

6 38

39

Siège de l’interrupteur

Junta tórica de2.5x1.5

1

17 1

8 1 40

Vis du siège de l’interrupteur

1

9 1 F Raccord d’air 1

10

Motif de l'aiguille

1 42

Robinet d’entrée d’air

1

11

Obturateur d’air avec anneau

Rondelle de buse à air

Obturateur d’air

Rondelle d’obturateur d’air

Buse à fluide

Corps du pistolet

Rondelle

Joint d’étanchéité

Vis d’orientation

Rondelle

Rondelle

Ressort

Joint torique de 2,5 x2,1

Joint torique de 8 x1,5

Joint torique de 10 x1,8

Joint torique de 7 x1,5

Bouton de réglage du jet

Vis de réglage du jet

Bouton de réglage du jet

Vis M

Dispositif de retenue à pression p=4

Ressort de pointeau

Rondelle

Rondelle

Goupille de gâchette

Imprimé en Chine

Bouton de réglage de

l’air

Vis M2.5x5

LISTE DES PIÈCES DE RECHANGE

Support à pistolet

Clé

Douille

Page 27

27

ARTÍCULO #0301339

MODELO #SGY-AIR87TZ

PISTOLA ATOMIZADORA

GRANDE ALIMENTADA

POR GRAVEDAD

ADJUNTE SU RECIBO AQUÍ

Número de serie Fecha de compra

KOBALT y K & Design son marcas

registradas de LF, LLC. Todos los derechos

reservados.

¿Preguntas, problemas, piezas faltantes? Antes de volver a la tienda,

llame a nuestro Departamento de Servicio al Cliente al 1-888-3KOBALT, de

8:00 a.m. a 8:00 p.m. hora estándar del Este, de lunes a viernes.

® ®

Page 28

28

Especificaciones del producto ............................................................................31

Instrucciones de reparación................................................................................34

Cuidado y mantenimiento ................................................................................. 36

Solución de problemas ..................................................................................... 37

Garantía ............................................................................................................ 38

Lista de piezas de repuesto ............................................................................. 39

Información de seguridad .................................................................................. 29

Contenido del paquete ...................................................................................... 31

Preparación ...................................................................................................... 31

Instrucciones de ensamblaje ............................................................................ 32

Instrucciones de funcionamiento ...................................................................... 33

ÍNDICE

Page 29

29

No permita que los niños operen la herramienta y manténgalos alejados del área de trabajo.

El ruido puede dañar su audición. Para cuidarla, use siempre protección para los oídos adecuada.

Cada vez que realice mantenimiento en una herramienta, debe utilizar gafas de seguridad

resistente a los impactos y máscaras de protección adecuadas.

Durante la limpieza y la descarga, asegúrese de que el operador y las demás personas

que

estén en el área de trabajo usen una protección facial y ocular resistente a los impactos

adecuada.

Los solventes pueden ser expulsados con fuerza de los conductos de aire y fluido, lo que puede

provocar lesiones oculares. Incluso los objetos pequeños puede dañar los ojos y causar ceguera.

No use vestimenta suelta, joyas o elementos que puedan atascarse o enredarse cuando

utilice la herramienta.

Siempre cierre el paso del suministro de aire, libere/drene la presión de aire de la

manguera

antes de cambiar los accesorios, realizar reparaciones o cuando la herramienta

no esté en uso. Luego

desconecte la herramienta del suministro de aire o de la manguera y almacene en una ubicación segura.

Siempre controle debidamente la manguera de aire.

Nunca rocíe o dirija el aire a usted mismo ni a otras personas.

Siempre use la herramienta a una distancia segura de las demás personas que se encuentran

en el área de trabajo. de aire y la manguera flexible, o bien, entre ésta y la manguera principal.

Mantenga las herramientas con cuidado; nunca use una herramienta que tenga fugas de

aire,

que le falten piezas o tenga piezas dañadas o que requiera reparaciones.

Mantenga las herramientas limpias y bien lubricadas para obtener un rendimiento óptimo y

seguro.

Siga las instrucciones de lubricación para un funcionamiento óptimo y seguro.

Siga las instrucciones de ensamblaje y reparación sobre cómo cambiar adecuadamente los

accesorios.

Los paños de limpieza y otros residuos inflamables que puedan haberse usado con la

herramienta deben colocarse en un recipiente metálico herméticamente cerrado y desecharse

de manera adecuada.

Mantenga un apoyo de pies adecuado en todo momento. No se extienda demasiado, ya

que podría resbalarse, tropezarse o caer y estos pueden ser la causa principal de lesiones

graves y/o la muerte. Tenga cuidado con las mangueras de aire y enchufes de alimentación

excedentes en el área o superficie de trabajo.

manguera ni jale de ella para desconectarla de la fuente de suministro eléctrico.

Mantenga la

manguera alejada del calor, aceite, bordes filosos y otros objetos afilados.

INFORMACIÓN DE SEGURIDAD

Lea y comprenda completamente este manual antes de intentar ensamblar, usar o

instalar el producto. Si tiene preguntas relacionadas con el producto, llame al

Departamento de Servicio al Cliente al 1-888-3KOBALT, de lunes a viernes de

8:00 a.m. a 8:00 p.m., hora estándar del Este.

No maltrate las mangueras ni los conectores- Nunca transporte la herramienta junto a la

Los latigazos de las mangueras pueden causar lesiones graves. Siempre compruebe que

no haya mangueras ni conectores dañados o flojos. Nunca use acopladores de cambio rápido

en la herramienta. Agregan peso y pueden fallar debido a la vibración. Por el contrario,

agregue una manguera flexible y conecte el acoplador entre el suministro.

Inspeccione las mangueras en busca de indicios de desgaste o deterioro antes de cada uso,

asegurándose de que todas las conexiones estén seguras.

Cuando sea posible, asegure las piezas de trabajo con abrazaderas o prensas de modo que

ambas manos queden libres para usar la herramienta.

Los movimientos de trabajo repetidos, las posiciones incómodas y la exposición a la vibración

pueden ser perjudiciales para las manos y brazos.

Se debe proporcionar una ventilación adecuada para mantener el aire libre de materiales

tóxicos.

Use ropa de trabajo adecuada para evitar el contacto directo con la piel.

Page 30

30

Use una máscara siempre que sea posible o si existe el riesgo de inhalar los materiales rociados.

La máscara debe ser compatible con los materiales rociados. Póngase en contacto con su

proveedor de materiales para mayor información.

Para evitar que se dañen las roscas, todas las piezas de la pistola rociadora primero

se deben atornillar a mano solo hasta que estén apretadas. Si las piezas no se pueden

girar fácilmente con la mano, asegúrese de tener las piezas correctas. Desenrosque,

realinee y vuelva a intentar con fuerza adicional la fijación correcta.

Los solventes y recubrimientos pueden ser altamente combustibles, especialmente cuando se rocían.

Se debe proporcionar una ventilación adecuada para mantener el aire libre de vapores inflamables.

No fume dentro o cerca del lugar de trabajo.

Siempre tenga un extinguidor de incendios en el lugar de trabajo.

Nunca rocíe cerca de fuentes de ignición, como luces piloto, soldadoras, etc.

Los solventes de hidrocarburo halogenado, como el cloruro de metileno, no son químicamente

compatibles con el aluminio que puede ser usado en varios componentes del sistema. La

reacción química generada por estos solventes que reaccionan con el aluminio puede ser

peligrosa y ocasionar una explosión en el equipo.

Con estos solventes, se pueden usar pistolas con conductos para fluido de acero inoxidable.

sin embargo, el aluminio se usa mucho en otros equipos de aplicación de rocío, como bombas

de material, ventosas y reguladores, válvulas, etc. Verifique los demás artículos del equipo antes

de usarlos y asegúrese de que también se puedan usar de manera segura con estos solventes.

Los operadores y el personal de mantenimiento deben estar capacitados físicamente para

manipular la masa, el peso y la potencia de la máquina.

Esta herramienta no está diseñada para ser utilizada en atmósferas explosivas y no está

equipada con aislamiento para evitar el contacto con fuentes de alimentación eléctrica.

NO RETIRE la placa de latón amarrada a la parte delantera del cuerpo de la pistola puesto

que se requieren herramientas y capacitación técnica especiales para hacerlo. Estas piezas

deben ser retiradas únicamente por centros de servicio autorizados.

PARTE DEL POLVO PRODUCIDO POR EL LIJADO, EL SERRUCHADO, LA

TRITURACIÓN Y LA PERFORACIÓN ELÉCTRICA Y OTRAS ACTIVIDADES

RELACIONADAS CONTIENE QUÍMICOS RECONOCIDOS POR EL ESTADO DE

CALIFORNIA COMO CAUSANTES DE CÁNCER, DEFECTOS CONGÉNITOS U OTROS

DAÑOS EN EL APARATO REPRODUCTIVO. SE PUEDE OBTENER UNA LISTA DE LAS

SUSTANCIAS QUÍMICAS EN www.oehha.ca.gov BAJO PROPOSITION 65 (PROPUESTA 65).

ALGUNOS EJEMPLOS DE ESTAS SUSTANCIAS QUÍMICAS SON:

PLOMO DE PINTURAS A BASE DE PLOMO

SÍLICE CRISTALINA DE LADRILLOS, CEMENTO Y OTROS PRODUCTOS DE

MAMPOSTERÍA

ARSÉNICO Y CROMO DE MADERA TRATADA CON QUÍMICOS

PRECAUCIÓN

INFORMACIÓN DE SEGURIDAD

ADVERTENCIA

SU RIESGO LUEGO DE ESTAS EXPOSICIONES VARÍA, DEPENDIENDO DE CUÁN

A MENUDO REALICE ESTE TIPO DE TRABAJO. PARA REDUCIR SU EXPOSICIÓN

A ESTOS QUÍMICOS, UTILICE UN EQUIPO DE SEGURIDAD APROBADO, COMO UN

RESPIRADOR O LAS MÁSCARAS PARA POLVO ESPECIALMENTE DISEÑADAS

PARA FILTRAR PARTÍCULAS MICROSCÓPICAS

Page 31

31

ESPECIFICACIONES DEL PRODUCTO

ESPECIFICACIONES

COMPONENTE

1

1

1

1

1

1

1

1

1

1

A

B

C

D

E

F

G

H

I

J

Anillo de la tapa de aire

Boquilla de fluido

Ajuste de la modalidad de rociado perilla

Aguja para pintura

Perilla de ajuste de fluido

Conexión de aire

Perilla de ajuste de aire

Recipiente de plástico

Cubierta

Llave de tuercas

Cantidad

Pieza

Descripción

CONTENIDO DEL PAQUETE

Antes de ensamblar y hacer funcionar el producto, asegúrese de contar con todas las piezas.

Compare las piezas con la lista del contenido del paquete y el diagrama. Si faltan piezas o están

dañadas, no intente armar ni usar el producto. Comuníquese con el departamento de Servicio al

Cliente para obtener las piezas de repuesto.

Tiempo aproximado de ensamblado: 3 minutos

Herramientas necesarias para el ensamblado: Llave (incluida)

PREPARACIÓN

GRAVEDAD

EXTERNO

CON PURGA

0,14 CM (0,055 PULG)

NPS de 1/4 PULG (M)

NPS de 1/4 PULG (M)

TIPO DE ALIMENTACIÓN

TIPO MIXTO

TIPO PURGA

I.D. DE LA BOQUILLA DE

FLUIDO

MÁXIMA

TAMAÑO DE LA

MODALIDAD

ENTRADA DE AIRE

ENTRADA DE FLUIDOS

@40PSI)

3,3 PROMEDIO/8,6 CONTINUO

AIRE NECESARIO (SCF,

PRESIÓN DE TRABAJO

40 PSI

20,32 CM @ 50PSI/20,32 CM DISTANCIA DE LA

PIEZA DE TRABAJO

Page 32

32

1

2. Extraiga la pistola rociadora y coloque el recipiente.

3

2

Figura. 1.

INSTRUCCIONES DE ENSAMBLADO

Recipiente de

alimentación por gravedad

Perilla de ajuste de fluido

Extractor de

aceite y agua

Indicador de

presión de

atomización

Manguera de aire comprimido

Admisión

de aire

(Consulte la Figura. 2)

3. Conecte el tubo de aire al conector de la

la entrada de aire desde la compresora;

configure la presión en 43 PSI. Abra

completamente la perilla de ajuste de aire y

ajuste la perilla de ajuste de modalidad de

rociado en el rango adecuado. (Consulte la

figura 3. Extractor de aceite y agua y

compresora de aire no incluidos)

Perilla de ajuste de

modalidad de chorro

Perilla de ajuste de aire

Perilla de ajuste de fluido

No se muestran todos los accesorios

incluidos.)

Esta pistola atomizadora tiene una estructura resistente

y está diseñada para representar un valor excepcional.

La vida útil de este producto y la eficacia de su

funcionamiento dependen del conocimiento de su

fabricación, uso y mantenimiento. (Consulte la

Page 33

33

4

.

5

Durante el uso normal, los alerones de la tapa del aire están en posición horizontal y la tapa

del aire debe colocarse hacia arriba, según se muestra. (Consulte la Fig. 6). Esto proporciona

un diseño vertical en forma de ventilador, lo cual brinda una cobertura total y uniforme del

material puesto que la pistola se mueve hacia delante y atrás paralelamente a la superficie

sobre la que se está aplicando el acabado.

Es esencial manipular correctamente la pistola para obtener un buen acabado. La pistola se

debe sostener en un ángulo de 90° con respecto a la superficie donde se rociará y se debe

mover paralelamente a ella. Para un control preciso, sostenga la pistola a una distancia de

15,24 a 30,48 cm de la superficie y del material. El gatillo se debe liberar antes del final de

la aplicación para obtener una cobertura uniforme y consistente. Para lograr una cobertura

consistente se recomienda sostener la pistola a una distancia de 15,24 a 30,48 cm,

dependiendo del material y la presión de atomización y del artículo que se está rociando.

Para lograr un acabado uniforme, aplique una vez más sobre la aplicación previa,

asegurándose de que el rocío esté suave y húmedo. Si usa la menor presión de aire de

atomización, es posible reducir el exceso de rocío y brindar una máxima eficiencia.

(Consulte la figura 5).

6

4. Vierta pintura en el recipiente y coloque la

tapa. (Consulte la figura 5. No se muestran

todos los accesorios incluidos)

INSTRUCCIONES DE ENSAMBLADO

Carga de pintura

INSTRUCCIONES DE FUNCIONAMIENTO

Aplicación

inicial

Gatillo de

disparo

Capa uniforme y húmeda

Gatillo de

liberación

Final de la

aplicación

Capa

liviana

Capa

pesada

DERECHA

INCORRECTO

6 a 12 pulg.

Los alerones

de la tapa del

aire están en

posición horizontal.

(15,24 a 30,48 cm)

Page 34

34

PRECAUCIÓN: Tenga cuidado para no dañar los sellos del cuerpo de la pistola al retirar el

anillo de distribución de aire.

1. Retire el conjunto de boquillas:

a. Retire la tapa de aire con anillo. (Consulte la Figura. 1)

b. Desatornille la perilla de ajuste de fluido. (Consulte la Figura. 2)

c. Retire el resorte de la aguja y la aguja de pintura. (Consulte la Figura. 3)

d. Retire la boquilla de pintura con la llave incluida. (Consulte la Figura. 4)

2. Retire el anillo de distribución de aire con un alicate de punta

fina y elimine la suciedad. (Consulte la Figura. 5)

NOTA: Asegúrese de que no haya suciedad asentada en las

superficies de sellado ni rayones que impidan un

rendimiento óptimo del sellado.

3. Con una flecha (1) encaje suavemente en el orificio marcado (2). (Consulte la Figura. 6). Luego,

presione firmemente el anillo de distribución de aire. (Consulte la Figura. 7). Inserte la boquilla

de pintura y apriete levemente. Luego vuelva a quitarla. Asegúrese de que el anillo de

distribución de aire encaje de forma segura contra el cuerpo de la pistola.

INSTRUCCIONES DE REPARACIÓN

Retire la presión de aire de la manguera de aire comprimido /pistola.

Vuelva a conectar la manguera de aire comprimido con

la pistola rociadora y establezca los PSI que desea.

1 2 3

4

5

Page 35

35

13

4. Monte el conjunto de boquillas:

a. Atornille la boquilla de pintura.

(Consulte la Figura. 8)

b. Conecte la tapa de aire con anillo.

(Consulte la Figura. 9)

c. Coloque la aguja de pintura.

(Consulte la Figura. 10)

d. Conecte el resorte de la aguja.

(Consulte la Figura. 11)

e. Atornille la perilla de ajuste de fluido.

(Consulte la Figura. 12)

NOTA: Pruebe la modalidad de rocío antes de volver a usar.

Durante el uso normal, los alerones de la tapa del aire están en posición horizontal y la tapa del

aire debe colocarse hacia arriba, según se muestra. (Consulte la Figura. 13). Esto proporciona un

diseño vertical en forma de ventilador, lo cual brinda una cobertura total y uniforme del material

puesto que la pistola se mueve hacia adelante y atrás paralelamente

a la superficie sobre la que se está aplicando el acabado.

Los alerones

de la tapa del

aire están en

posición horizontal.

INSTRUCCIONES DE REPARACIÓN

8

9

10

11

12

6

7

Page 36

36

14

Boquilla

Material disolvente

15

Boquilla

Material

disolvente

CUIDADO Y MANTENIMIENTO

Para mantener adecuadamente y mantener su rociador de trabajo en su rendimiento óptimo,

se recomienda limpiar la boquilla de la pistola rociadora y eliminar cualquier obstrucción o

acumulación de desechos con disolvente de pintura o disolvente de laca. NO USE NINGÚN

SOLVENTE A BASE DE ÁCIDO, YA QUE ESTOS PUEDEN DAÑAR EL ROCIADOR. Consulte

con el local minorista Lowes local para escoger los materiales disolventes adecuados.

1. Vierta suficiente material disolvente en el contenedor, de modo que la boquilla esté

completamente sumergida en material disolvente

NOTA: Existen dos métodos para sumergir adecuadamente la boquilla de la pistola rociadora en

el material disolvente de limpieza. El fabricante recomienda el método 1:

Método 2: Mantenga la boquilla de la pistola rociadora fija en la

carcasa de la pistola rociadora, sumerja solo el extremo frontal de la

pistola rociadora (consulte la Fig. 15). Asegúrese de sumergir solo la

boquilla de la pistola rociadora en el material disolvente. SI USA EL

MÉTODO 2, Y NO RETIRA COMPLETAMENTE LA BOQUILLA DE

LA PISTOLA ROCIADORA, ASEGÚRESE DE USAR UN

CONTENEDOR ADECUADO QUE NO SE VUELQUE FÁCILMENTE.

SI EL CONTENEDOR USADO SE VUELCA, DERRAMARÁ EL

MATERIAL DISOLVENTE, PROVOCANDO UN POSIBLE PELIGRO

DE SEGURIDAD.

NOTA: Asegúrese de nunca sumergir ninguna pieza de la carcasa de la

pistola rociadora en el material disolvente, ya que los pasajes de aire se

obstruirían con el disolvente sucio. Esto también provocaría que el lubricante en el empaque de

cuero y otras empaquetaduras dentro de la carcasa de la pistola se sequen, provocando un

funcionamiento difícil y un desgaste más rápido en el artículo, lo que causará en mal rendimiento

del rociador.

2. Deje que la boquilla se asiento durante 3 a 5 minutos, permitiendo que el material solvente

destruya desechos y cualquier acumulación en la boquilla del rociador).

3. Retire la boquilla del material disolvente e inspeccione cuidadosamente la boquilla de la pistola

rociadora para asegurarse de que se haya eliminado toda la suciedad o la acumulación de

desechos.

NOTA: Dependiendo de la pintura y el material disolvente usado, es posible que deba repetir

varias veces los pasos 1 a 4.

ANTES DE REALIZAR CUALQUIER LIMPIEZA O MANTENIMIENTO, RETIRE LA PISTOLA

ROCIADORA DEL SUMINISTRO DE AIRE Y ALÉJELA DE CUALQUIER FUENTE DE

IGNICIÓN.

Método 1: Retire completamente la boquilla de la pistola rociadora de

la pistola rociadora y colóquela en un contenedor que no se dañe con

el disolvente cuando se agregue el material disolvente (consulte la

Fig. 14).

4. Si aún están los desechos o la acumulación, use un cepillo de cerdas suaves no metálico y

cepille el área de la boquilla que aún contiene suciedad o desechos y repita los pasos 1 a 4.

5. Una vez que se haya eliminado toda la suciedad o los desechos de la boquilla de la pistola

rociadora, y esté limpia, pásele un trapo o paño a la boquilla.

6. Una vez que la boquilla se ha limpiado adecuadamente, vuelva a conectarla a la pistola

rociadora y vuelva a conectar la pistola rociadora al suministro de aire. Luego, pruebe el

rociador para asegurarse de que funcione correctamente. Si está al final de un proyecto, al

probar el rociador, asegúrese de no probarlo con pintura dirigiéndose al sistema, ya que esto

requerirá que comience el proceso de limpieza nuevamente.

7. Una vez que el rociador funcione correctamente, asegúrese de seguir las recomendaciones

del fabricante del disolvente para desechar correctamente cualquier paño o trapo sucio usado

en el proceso de limpieza.

Page 37

37

SOLUCIÓN DE PROBLEMAS

Para obtener piezas de repuesto, llame a nuestro Departamento de Servicio al Cliente

al 1-888-3KOBALT, de lunes a viernes de 8:00 a.m. a 8:00 p.m., Hora estándar del Este.

NÓICULOSAMELBORP

MODALIDAD DE

ROCÍO/CONDICIÓN

Obstrucción en un lateral de la

boquilla.

a) La presión de aire de atomización

está ajustada en un nivel muy

elevado.

b) Se intenta rociar un material

delgado en una modalidad

demasiado amplia.

a) Boquilla de aire floja.

b) El material alrededor de la parte

externa de la boquilla de aire está

seco.

a) La empaquetadura alrededor de la

válvula de la aguja está seca.

b) La boquilla de fluido está floja o hay

suciedad entre la boquilla y el

cuerpo.

c) El sello de la aguja está dañado.

Sumerja la boquilla en solvente para liberar

la obstrucción y luego sople aire hasta

limpiarla. Para limpiar los orificios, use una

pajilla o palillo. Nunca intente retirar el

material seco con una herramienta afilada.

a) Reduzca la presión de aire.

b) Aumente el control del material girando

la perilla de ajuste de fluido hacia la

izquierda mientras reduce la amplitud

del chorro girando la perilla de ajuste de

modalidad hacia la derecha.

a) Presione la boquilla de aire.

b) Retire la boquilla de aire y elimine la

punta de fluido usando un paño

humedecido con diluyente.

a) Desatornille ligeramente la tuerca

moleteada, aplique unas gotas de aceite

lubricante en la empaquetadura y vuelva

a ajustar la tuerca.

b) Retire la boquilla de fluido, limpie su

parte posterior y asiéntela en el cuerpo

de la pistola. Vuelva a colocar la boquilla

y ajústela al cuerpo.

c) Vuelva a colocar el sello.

Rocío intermitente

a) La pistola no está bien ajustada.

b) La tapa de aire está sucia.

c) La punta de fluido está obstruida.

d) La aguja está floja.

El tornillo de ajuste del ventilador no

está asentado correctamente.

a) No hay presión de aire en la pistola.

b) La presión de fluido es demasiado

baja para la tapa de mezcla interna y

el tanque de presión.

c) El tornillo para control de fluidos no

está suficientemente abierto.

d) El fluido es demasiado pesado para la

alimentación de succión.

a) Verifique el suministro y los

conductos de aire.

b) Aumente la presión de fluido en el

tanque.

c) Abra el tornillo de control de fluidos.

d) Diluya el material o ajuste la

alimentación de presión.

Limpie o reemplace.

a) Vuelva a ajustar la pistola. Siga

cuidadosamente las instrucciones.

b) Limpie la tapa de aire.

c) Limpie.

d) Lubrique.

No se logra un

rociado circular.

Modalidad de chorro

incorrecta.

No sale rocío.

CUIDADO Y MANTENIMIENTO

Almacenamiento

1. Cuando no utilice la pistola de rociado, gire la perilla de ajuste de liquido en la dirección contraria