Page 1

ITEM #0220964

MODEL #SGY-AIR70TZ

1

Français p. 15

Español p. 30

KOBALT® and the K & Design® are registered

trademarks of LF, LLC. All rights reserved.

LATEX SPRAY GUN KIT

ATTACH YOUR RECEIPT HERE

Serial Number Purchase Date

Questions, problems, missing parts? Before returning to your retailer, call

our customer service department at 1-888-3KOBALT, 8:00 a.m.-8:00 p.m.,

EST, Monday-Friday.

Page 2

TABLE OF CONTENTS

2

Safety Information ............................................................................................... 3

Package Contents ............................................................................................... 4

Preparation .......................................................................................................... 6

Assembly Instructions .......................................................................................... 7

Operating Instructions ........................................................................................ 7

Care and Maintenance ....................................................................................... 10

Troubleshooting .................................................................................................. 12

Warranty ............................................................................................................. 13

Replacement Parts List ...................................................................................... 14

Page 3

3

SAFETY INFORMATION

Please read and understand this entire manual before attempting to assemble, operate

or install the product. If you have any questions regarding the product, please call

customer service at 1-888-3KOBALT, 8:00 a.m.-8:00 p.m., EST, Monday-Friday.

Follow all local electrical and safety codes as well as the United States National

Electrical Codes (NEC) and Occupational Safety and Health Act (OSHA).

When spraying and cleaning, always follow the manual and safety precautions

provided by the material manufacturer (Refer to Material Safety Data Sheets --- MSDS).

Do not use this product with other people, children or pets in the working area.

Always work in a clean environment. To avoid any injury or damage to workpiece,

do not aim the spray gun at any dust or debris.

Always use a pressure regulator on the air supply to the spray gun.

WARNING

No not operate tool if damaged during shipping, handling or use. Damage could

result in bursting and cause injury and/or property damage.

Use a face mask/respirator and proctective clothing when spraying. Always spray in

a well ventilated area to prevent health and fire hazards. Refer to Material Safety

Data Sheets (MSDS) of spray material for details.

Never spray flammable materials in vicinity of open flame or near ignition sources.

Never store flammable liquids or gases near air compressor.

Do not spray acids, corrosive materials, toxic chemicals, fertilizers or pesticides.

Using these materials could result in death or serious injury.

Never aim or spray at yourself or anyone else, which could result in serious injury.

If eyes or face come into direct contact with sprayed material, contact your local

doctor and or emergency room for immediate help.

Do not use pressure exceeding the operating pressure of any of the parts (hoses,

fittings, etc.) in the painting system.

Keep proper footing at all times, do not overreach, as slipping, tripping, and or falling

can be a major cause of serious injury and or death. Be aware of excess hose left in

the working area or work surface. Do not abuse hoses or connectors. Never carry the

tool by hose or yank it to disconnect it from power supply. Keep hoses away from

heat, oil, and sharp edgess. Check hoses for weak or worn connections before each

use and make certain that all connections are secure.

Certain materials that can be used with this device if coming in direct contact with

skin may cause skin irritation. Read the label or materials sagety data sheet for the

materials you intent to find out which materials may cause skin irritation.

YOUR RISK FROM THESE EXPOSURES VARIES, DEPENDING ON HOW OFTEN

YOU DO THIS TYPE OR WORK. TO REDUCE YOUR EXPOSURE TO THESE

CHEMICALS, WORK IN A WELL VENTILATED AREA, AND WORK WITH

APPROVED SAFETY EQUIPMENTS, SUCH AS THOSE DUST MASKS THAT ARE

SPECIALLY DESIGNED TO FILTER OUT MICROSCOPIC PARTICLES.

DANGER

Never spray closer than 25 feet to the

air compressor. If possible, place

compressor in separate room.

CAUTION

Keep hose away from sharp objects.

Bursting air hose could result in personal

injury. Examine air hoses regularly and

replace them if damaged or broken.

Page 4

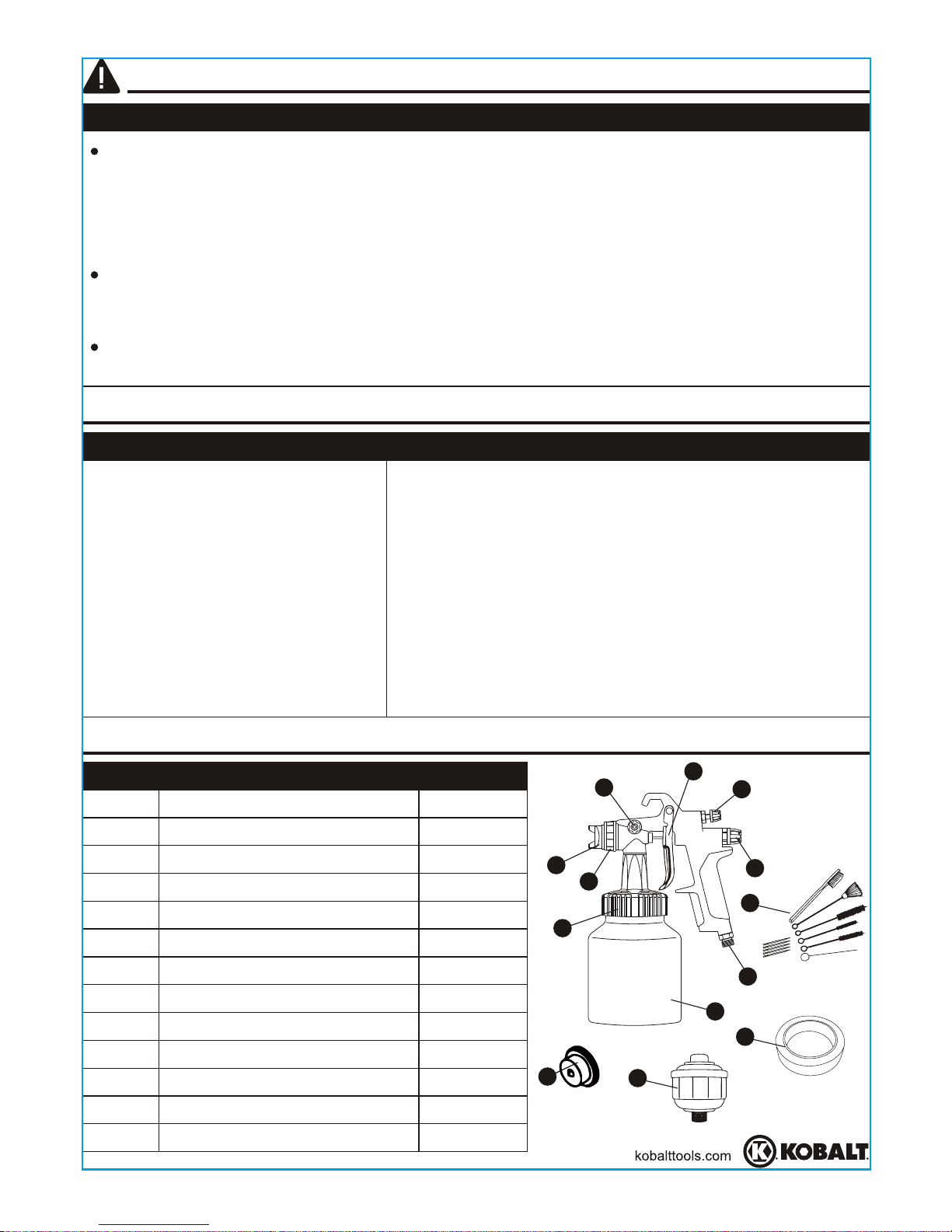

SPECIFICATIONS

PRESSURE/SIPHON

INTERNAL/EXTERNAL

BLEEDER/NON-BLEEDER

0.055 IN. (1.4 MM)

50 PSI

3.5 AVERAGE/8.6 CONTINUOUS

8 IN. @ 50 PSI/8 IN. DISTANCE FROM WORKPIECE

1/4 IN. NPS (M)

3/8 IN. NPS (M)

COMPONENT

FEED TYPE

MIX TYPE

BLEED TYPE

FLUID NOZZLE I.D.

MAX. WORKING PRESSURE

40 TO 50 PSI

WORKING PRESSURE

AIR REQ'D (SCFM @ 50 PSI)

PATTERN SIZE

AIR INLET

FLUID INLET

PRODUCT SPECIFICATIONS

4

NOTE

This latex spray gun is designed for home, farm and commercial use. It handles

all kinds of latex paints. It can be easily and quickly converted from non-bleeder

to bleeder, pressure to siphon feed and internal or external mix air caps. It also

features pattern size control. It can also be converted for use with a separate

pressure paint tank.

The pressure for atomization is controlled by the regulator on the air source. The

amount of fluid is adjusted by the fluid control knob, the paint viscosity, and the

air pressure.

Failure to install appropriate water/oil removal equipment could result in damage

to product or workpiece.

SAFETY INFORMATION

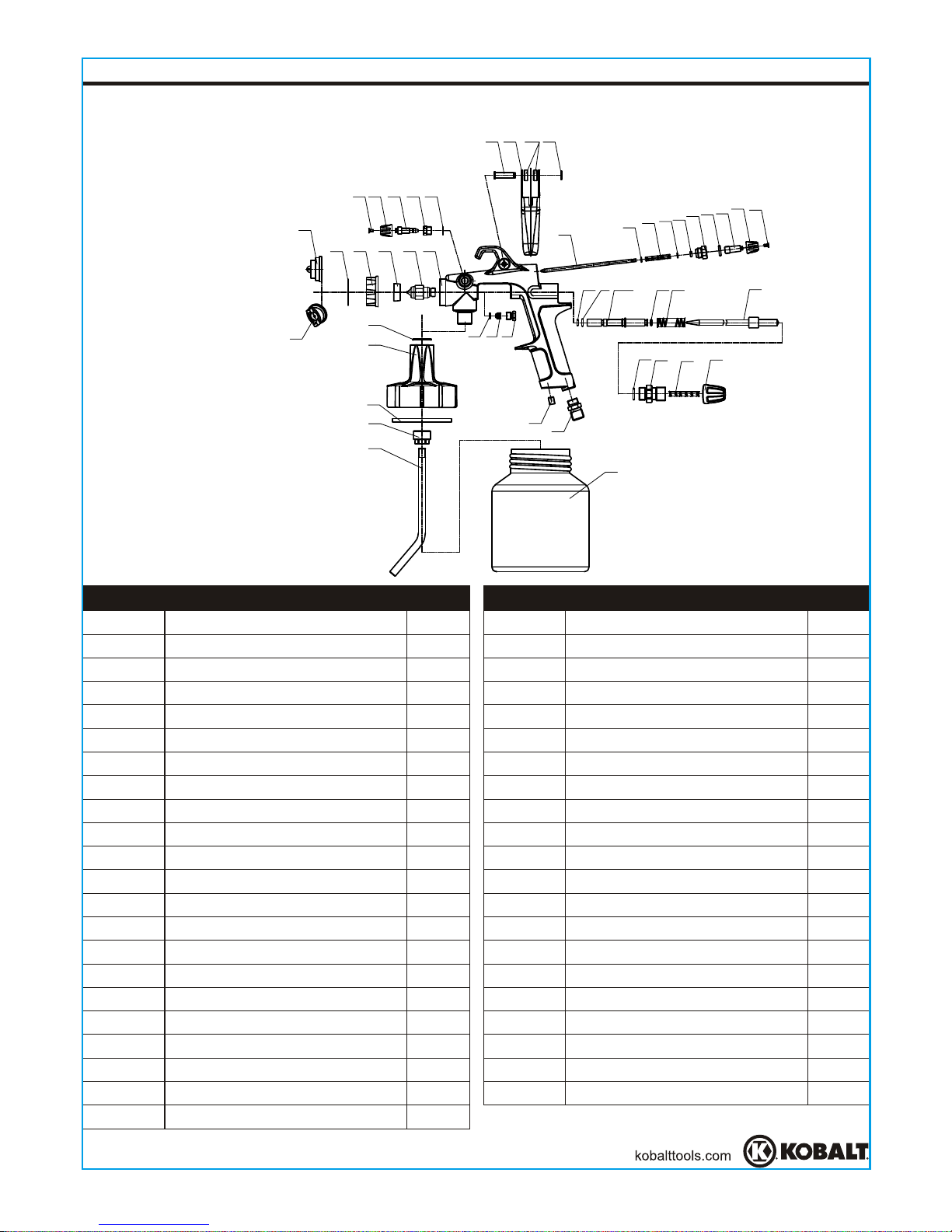

PACKAGE CONTENTS

DESCRIPTION

Latex Spray Gun

Spray Gun Cleaning Kit

Spray Gun Filter

Masking Tape

Air cap (external mix)

Pattern Control Knob

Fluid Control Knob

Side Knob

Air Inlet

Air Cap Ring

Trigger

Canister

QUANTITY

1

1

1

1

1

1

1

1

1

1

1

1

PART

A

B

C

D

E

F

G

H

I

J

K

L

Air cap (internal mix)

1

M

B

C

D

A

E

F

G

H

I

J

K

L

M

Page 5

5

SPRAY GUN TERMS

Internal Mix

Process where the air and paint are mixed inside the air cap just before being

sprayed. This method is best for heavy bodied, slow drying paints and can only be

used with the pressure feed method. Do not use fast drying latex paints with internal

mix. The paint will dry inside and quickly clog the air cap.

External Mix

Process where the air and paint are mixed just after leaving the nozzle. This type of

mix should be used for fast drying latex paint and when a high quality finish is needed.

Pressure Feed

Method of material feed where a canister or paint tank is pressurized to force material

to the gun. Either internal or external mix air caps are used with this method. Pressure

feed is generally used for heavy bodied latex paints or for larger size projects.

Siphon Feed

Method of material feed where atmospheric pressure creates a partial vacuum to

siphon material to the gun. Only external mix air caps are used with this method.

Siphon feed is used with light bodied latex paints.

Bleeder

In this mode, air passes continuously through the gun whether spraying or not. This

mode is generally used when the

air is supplied by a continuously running air

compressor without tank.

Non-Bleeder

In this mode, air flows only when the trigger is pulled. This type of operation is

used with an air compressor equipped with a tank or with a large factory air system.

Do not use with a continuously running air compressor that does not have a tank.

Use of Air Caps

Internal Mix - Generally used with slow drying, heavy bodied latex

paints and for faster material application. NOT to be used with fast

drying latex paints which will clog the opening in the air cap. Internal

mix caps must be used with pressure feed operation.

External Mix - Used for quick drying, light bodied latex paints. Better

for fine finish work. These caps can be used with either siphon or

pressure feed.

SPRAY GUN SET-UP

Internal mix air cap

external mix air cap

Page 6

Air Valve Spring

Pattern Control

Knob

Fluid

Control

Knob

Fluid Needle

Spring

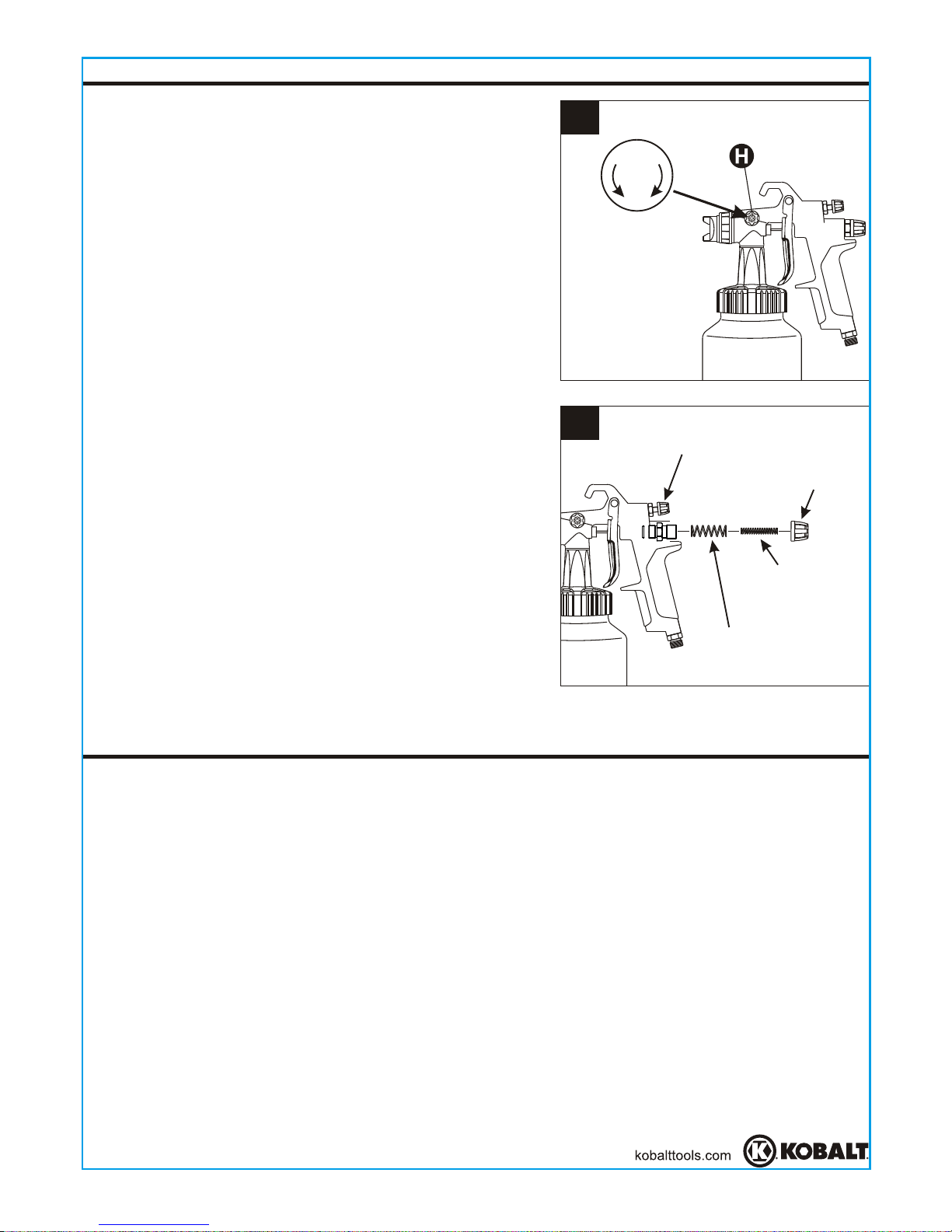

Change of Feed Method

This latex spray gun is capable of pressure or

siphon feed. The feed method can be easily

changed by fully turning the side knob. You should

be sure before using the desired feed method.

(See Figure 1)

SPRAY GUN SET-UP

P: Pressure feed

S: Siphon feed

P

S

1

2

Non-Bleeder to Bleeder Conversion

(See Figure 2)

1. Remove spray gun from air supply.

2. Remove fluid control knob and the fluid needle

spring.

3. Remove air valve spring and store it in a safe

place so it can be replaced when necessary to

convert back to a non-bleeder type arrangement.

4. Insert fluid needle spring and replace fluid

control knob.

Before beginning assembly ofproduct, make sure allparts are present. Compare

parts with package contents list. Ifany part is missing ordamaged,do notattemptto

assemble the product. Contactcustomerservice forreplacementparts.

EstimatedAssembly Time:5-10 minutes

Tools Required forAssembly (notincluded):Adjustable wrench

PREPARATION

6

Page 7

ASSEMBLY INSTRUCTIONS

7

2

1

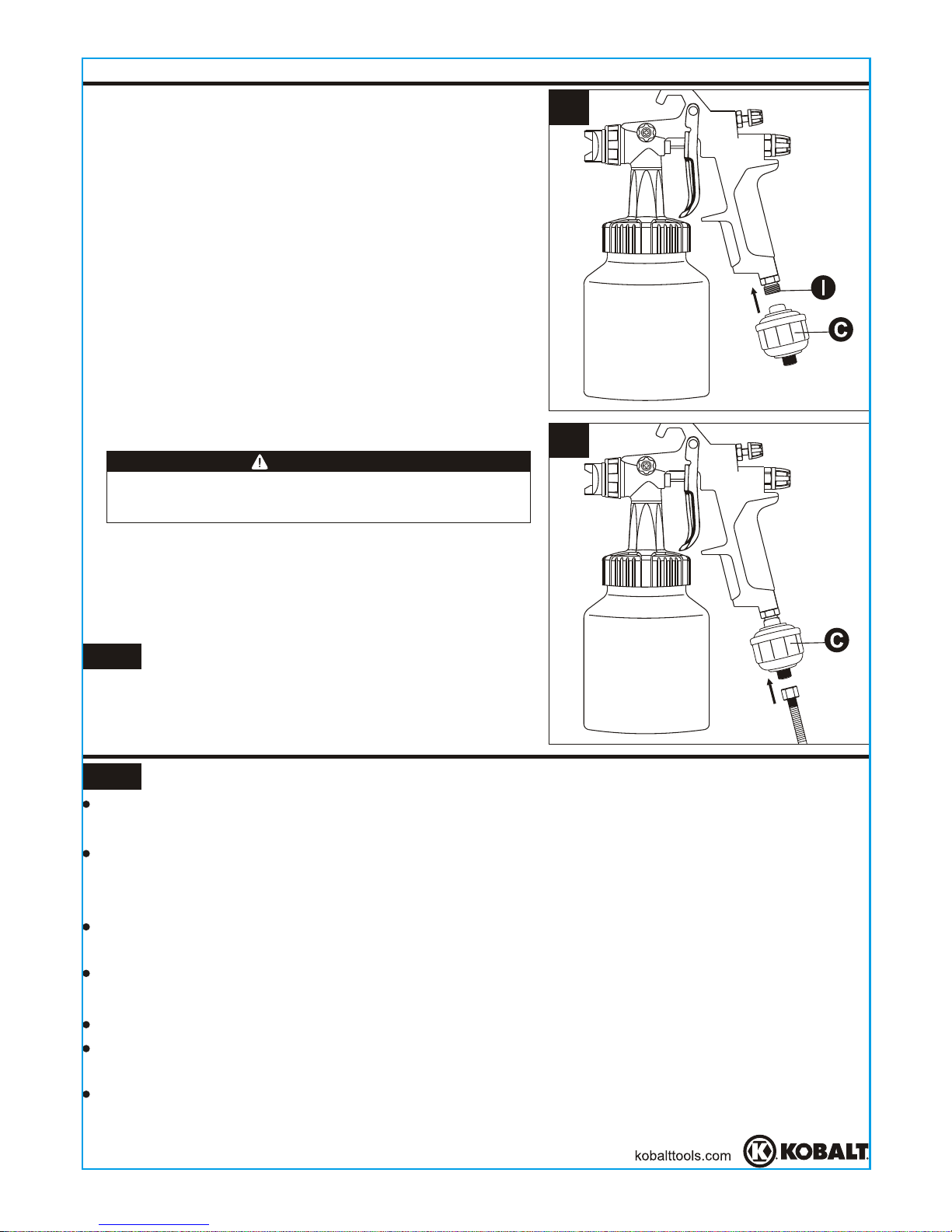

1. Mount the spray gun filter (C) with hand onto

the air inlet (I) of spray gun by connecting the

female threads of filter (C) with the male

threads of air inlet (I). Use thread sealant tape

(not provided) for airtight connection.

(See Figure 1)

2. Connect air hose with the male threads of the

filter (C). Use thread sealant tape (not

provided) for airtight connection. (See Figure 2)

NOTE The working pressure refers to the air line

pressure when the spray gun trigger (K) is pulled

fully under working conditions.

3. Set the working pressure to 30-50 psi

depending on the amount of fluid flow and

atomization as required. Do not exceed spray

gun maximum pressure.

Do not overtighten when connecting the filter

(C) with spray gun air inlet (I) and with air hose.

WARNING

OPERATING INSTRUCTIONS

NOTE

Before using desired paint in the spray gun, spray a compatible thinner or solvent

through the gun to remove any contaminants and residues.

Thin latex paints properly in accordance with the paint manufacturer's instructions

before spraying. If paint can not be thinned, the paint should not be used in

the sprayer.

Before adding paint, make sure all thinner or solvents are removed from the

spray canister.

that if any paint spills you can easily collect the paint to properly discard.

Its recommended to place drop cloth or other collection device under canister so

Fill the canister (L) about 3/4 full and start the air compressor.

Set up a piece of cardboard or other scrap material to use as as a target and

adjust for best spray pattern.

Test the consistency of the paint by making a few strokes on a cardboard target. If

paint still appears too thick, add a small amount of thinner. Do not exceed paint

manufacturer's thinning recommendations.

Page 8

Air Cap

Air Cap Ring

Horizontal Fan

Vertical Fan

1

2

3

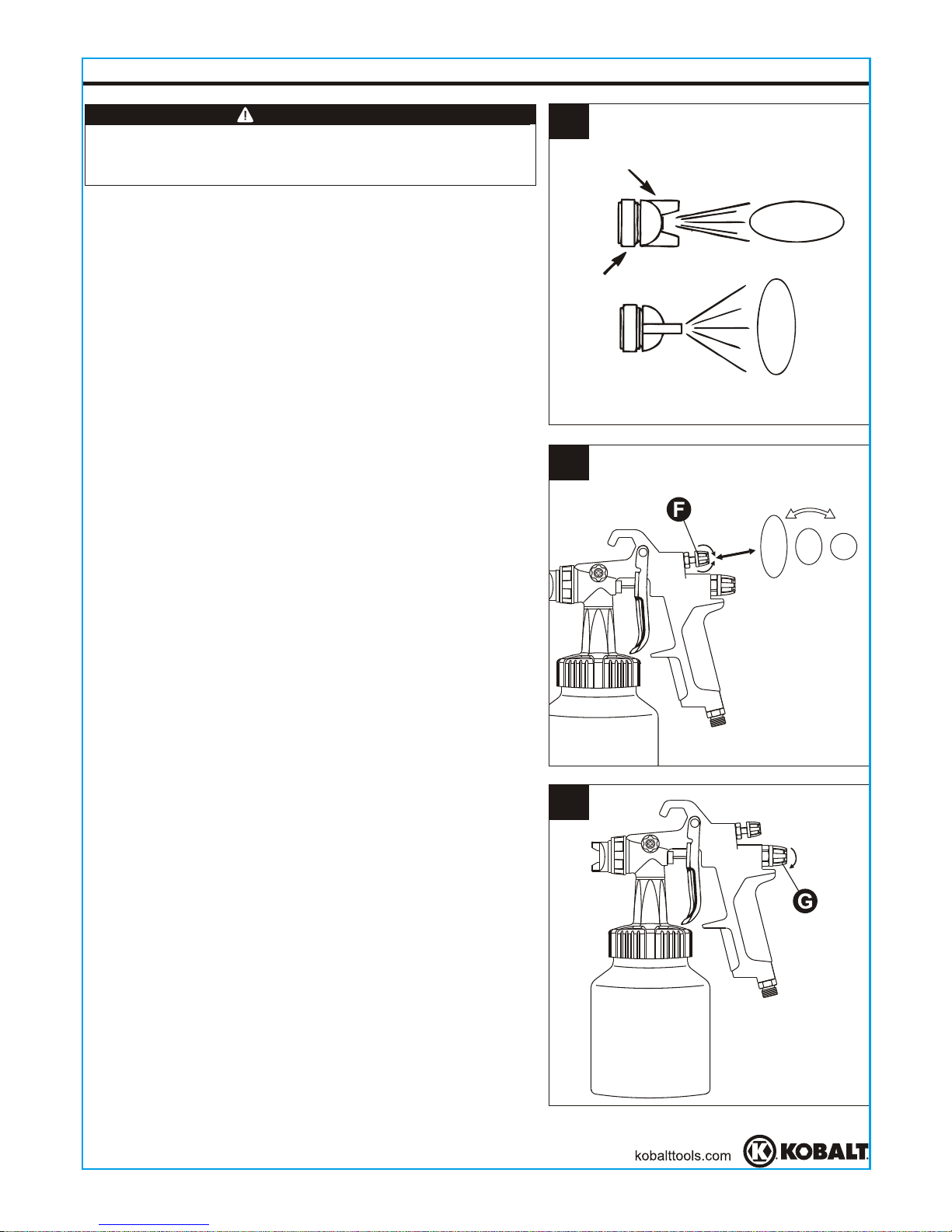

1. Adjust the direction of fan to be either horizontal

or vertical as required by loosening the air cap

ring (J) 90 degrees. Hand tighten the air cap

ring (J) after adjustment. (See Figure 1)

OPERATING INSTRUCTIONS

2. Set pattern size for desired shape. For full

pattern, open pattern control knob (F) by turning

counterclockwise. For a round pattern, turn

pattern control knob (F) clockwise.

(See Figure 2)

3. Turn the fluid control knob (G) fully clockwise

until closed. (See Figure 3)

8

The paint sprayer will not properly spray unless

the fan direction is either horizontal or vertical.

WARNING

Page 9

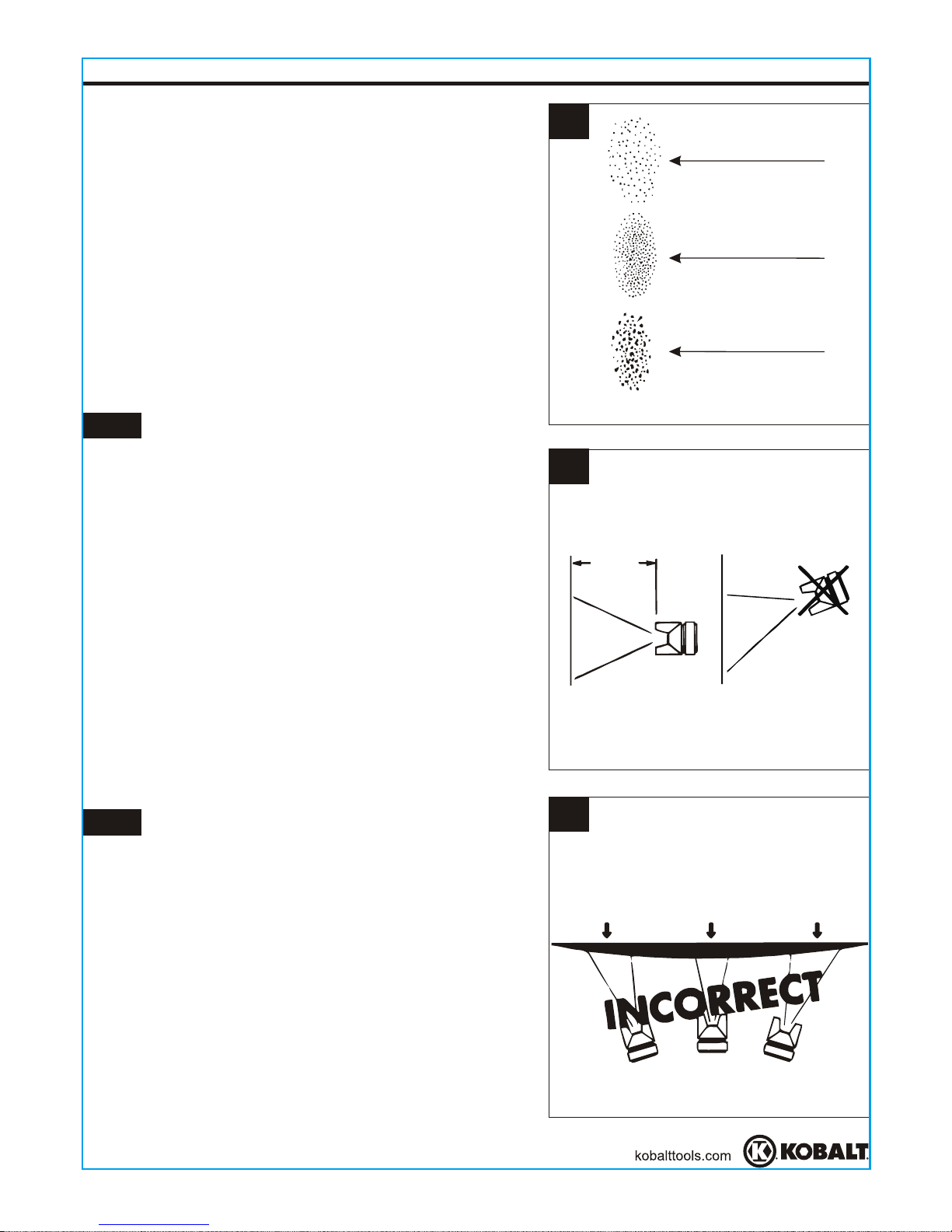

Paint too fine

Correct

Paint too coarse

Pattern Consistency (Atomization)

6-9 in.

Thin coat Heavy coat Thin coat

4

5

6

4. With gun 6-9 in. away from workpiece, spray a

short burst while turning the fluid knob

counterclockwise. Observe the spray pattern on

the workpiece and adjust the fluid control knob (G)

until desired pattern/atomization is obtained. If the

spray is too fine, which is caused by too much air

from the amount of paint being sprayed, reduce

the air pressure or open the fluid control knob (G)

to spray more paint. If the spray is too coarse/

spitting blobs, reduce the amount of paint with

the fluid control knob (G) or thin the paint more.

(See Figure 4)

OPERATING INSTRUCTIONS

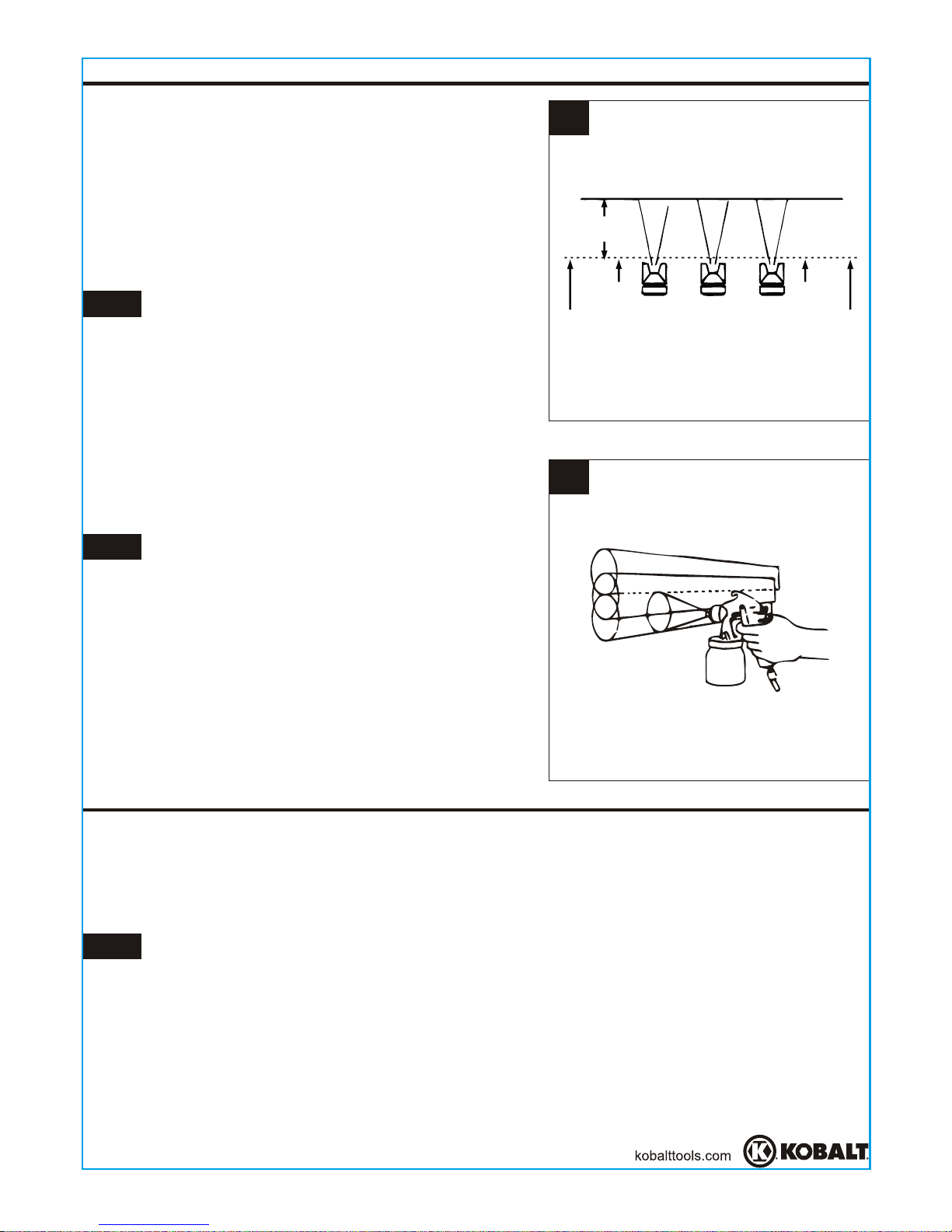

5. Keep the gun at the right angle as shown while

spraying. (See Figure 5)

NOTE The fluid control knob (G) can be adjusted

either clockwise or counterclockwise to finely

adjust pattern consistency. Before spraying on

workpiece, practice a few minutes on a cardboard

target to ensure that the pattern size and

consistency are set correctly.

NOTE Always keep the gun in motion while

spraying. Stopping gun movement in mid-stroke

will cause a build-up of paint and will result in runs.

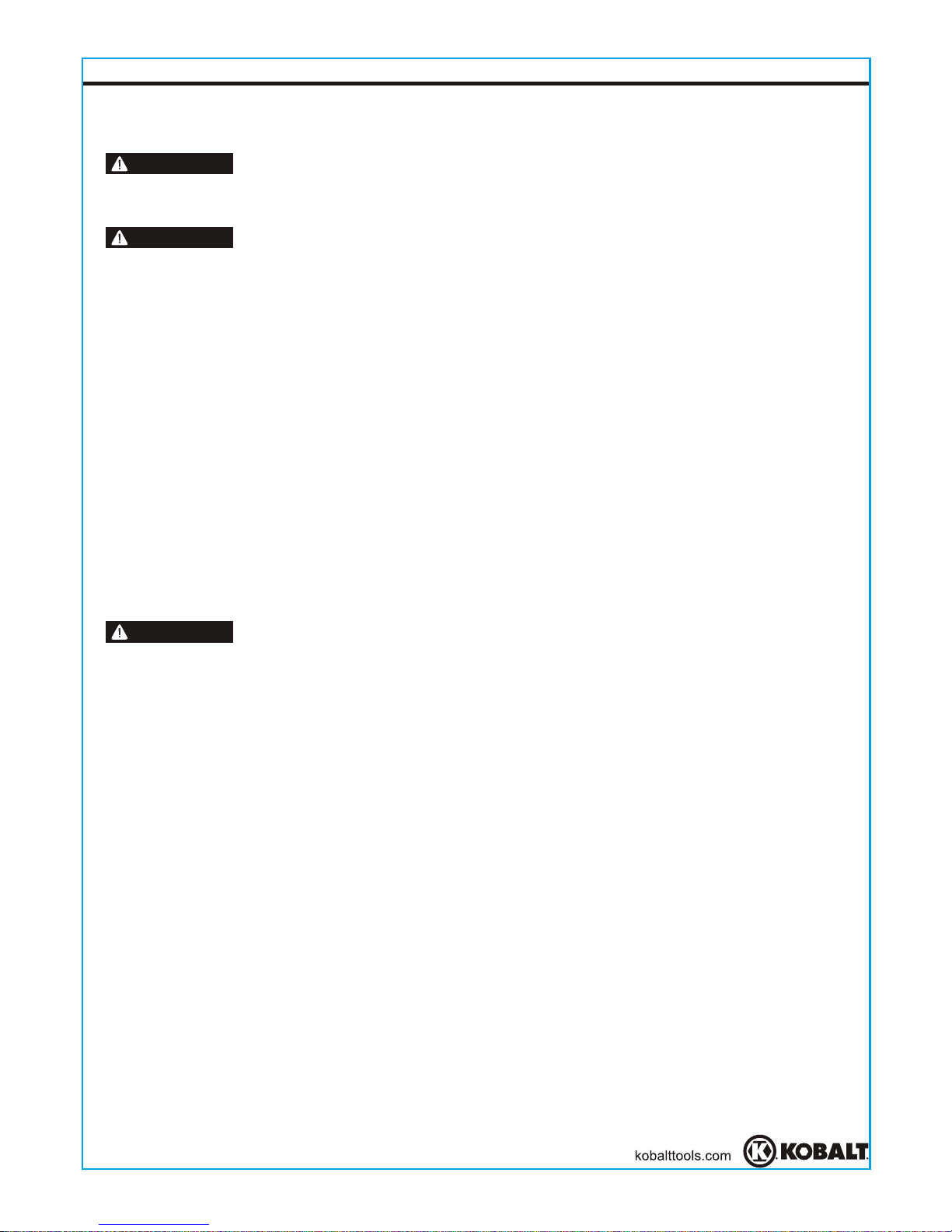

Do not fan the gun from side to side while painting.

This will cause a build-up of paint in the center of

stroke and an insufficient coating at each end.

(See Figure 6)

9

Page 10

6-9 in.

Pull

Trigger

Start Stroke

Release

Trigger

End Stroke

7

8

6. Trigger the gun properly. Start the gun moving

at the beginning of the stroke before squeezing

the trigger (K) and release the trigger (K) before

stopping gun movement at the end of the stroke.

This procedure will feather/blend each stroke

with the next without showing overlap or

unevenness. (See Figure 7)

OPERATING INSTRUCTIONS

7. Overlap strokes just enough to obtain an even

coat. (See Figure 8)

8. Use a piece of cardboard as a shield to catch

overspray at the edges of workpiece to protect

other surfaces. Use masking tape (D) to cover

other areas if needed.

NOTE The amount of paint being applied can be

varied by the speed of stroke, distance from

workpiece and adjustment of the fluid control knob

(G). If speed of stroke is too slow, paint will be wet

on workpiece and may run. If speed of stroke is too

fast, paint will be dry and uneven on workpiece.

NOTE Two thin coats of paint will yield better

spraying results and have less chance of runs than

one heavy layer.

10

CARE AND MAINTENANCE

Local codes may require specific cleaning methods and equipment. Follow local

codes and manufacturer's recommendations for the use and disposal of spray paints

and solvent.

Daily Clean-Up

NOTE Clean spray gun immediately after use. Paint and other materials dry quickly in

the small passages rendering gun useless due to the difficulty of removing hardened

paint from the passages inside the gun.

1. Remove and empty the canister; then rinse with a solvent recommended for

the paint.

2. Refill canister with clean solvent and attach to the gun. Spray solvent through the

gun while shaking the gun vigorously. Wipe the gun exterior with a solvent-soaked

rag. Repeat until the gun is clean.

Page 11

CARE AND MAINTENANCE

3. Remove the air cap and soak in solvent until clean. Use a small brush for stubborn

stains if necessary. Toothpicks or small brushes may be used to clean air passages.

Never use metal objects to clean precisely drilled passages.

Damaged passages will cause improper spraying.

4. Clean gaskets with a solvent soaked rag.

Never immerse gaskets or spray gun body in solvents to prevent

equipment damage.

5. After using water to clean out spray gun, spray mineral spirits through the gun to

prevent corrosion.

6. Clean and flush gun thoroughly to neutralize any contaminants corrosive to the

spray gun.

7. Use a non-silicone oil on all moving parts when reassembling. Use Vaseline® or

light grease on all threaded connections prior to storage.

WARNING

WARNING

Periodic Clean-Up

Due to improper cleaning and paint it may be necessary to inspect and clean the

internal parts and the gun body.

1. Examine openings in air cap and fluid tip. If clogged, remove any o-rings and soak

the air cap or fluid tip in solvent.

2. A brush, toothpick or something similar may be used to dislodge the dried paint

from holes and passages.

Never use metal objects to clean precisely drilled passages.

Damaged passages will cause improper spraying.

3. Remove and check fluid needle for excessive wear at the tip and straightness.

IMPORTANT: If the needle tip is worn more on one side than the other, either the

needle is bent or the gun body has been dropped or knocked out-of-line. There are

no adjustments that can be made to a bent gun body. Test the needle by rolling on

a flat surface. Replace if necessary.

4. Check and replace any damaged o-rings and seals. O-rings and seals can be

wiped clean but not be soaked in solvent.

5. Unscrew packing nuts and replace the packing only if a leak will not stop when the

nut is tightened. Do not overtighten

a packing nut because this will restrict

movement of the needle.

6. Re-assemble in reverse order of above and use a non-silicone oil on moving parts.

Apply Vaseline® or light grease on threaded joints and hose connections.

WARNING

Storing

1. When not using spray gun, turn the fluid adjustment knob counterclockwise to open

which will reduce spring tension on needle fluid tip.

2. Spray gun must be well cleaned and lightly lubricated.

3. Store spray gun in a dry and safe place out of reach of children.

11

Page 12

12

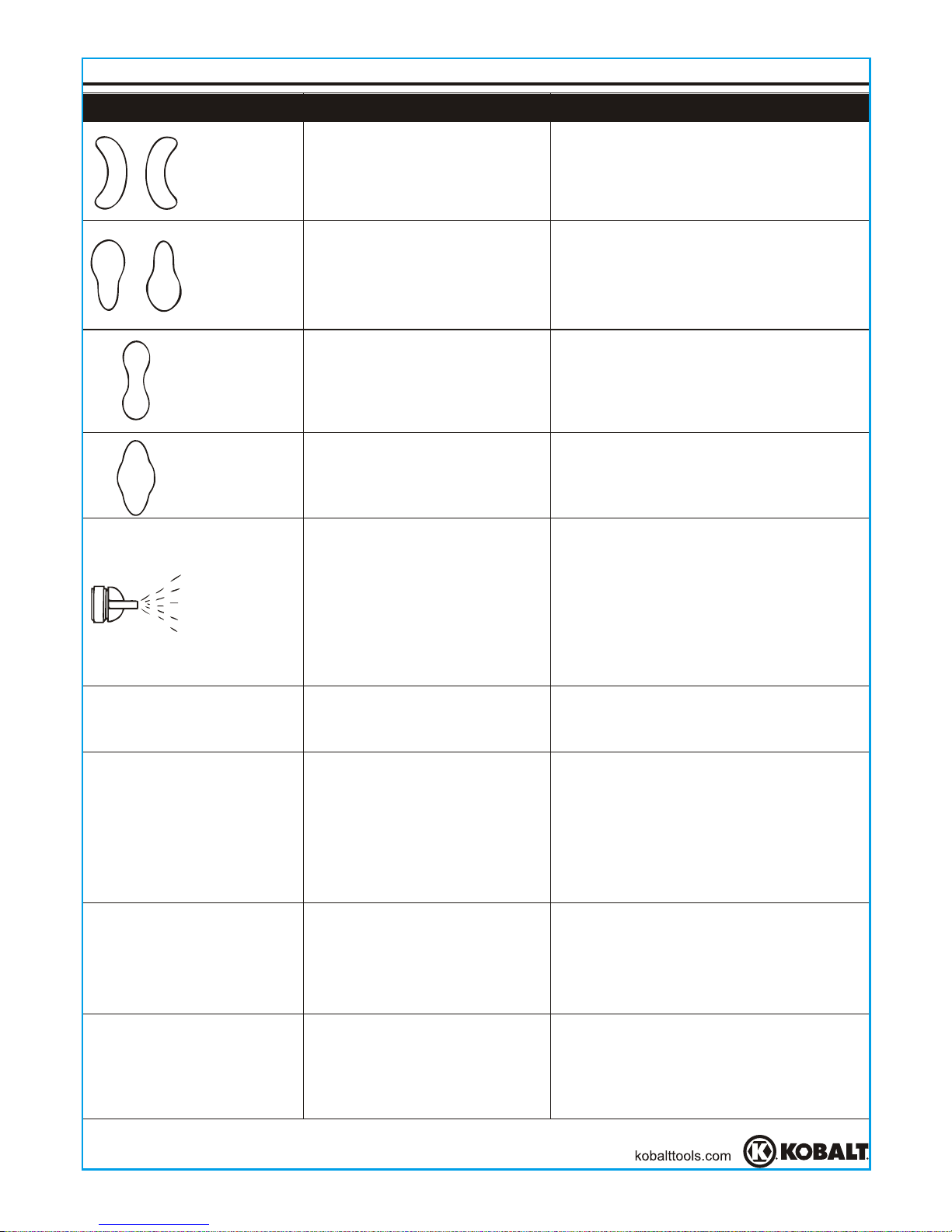

PROBLEM

TROUBLESHOOTING

CORRECTIVE ACTIONPOSSIBLE CAUSE

Right or left

heavy spray

pattern

Top or bottom

heavy spray

pattern

Split spray

pattern

Center

heavy spray

pattern

Sputtering

spray

Fluid leaking from

packing nut

Air leaking from air cap

without pulling trigger

Excessive overspray

Will not spray

1. Holes in left or right side of

the air cap are plugged

2. Dirt on left or right side of

fluid tip

1. Dried material at top or

bottom of fluid tip

2. Loose air cap or dirty seat

3. Air cap plugged

1. Fan pattern open too far

2. Fluid adjustment turned in

too far

3. Atomization air too high

1. Fan adjustment partially

closed

2. Material too thick

3.Atomization pressure too low

1. Material level too low

2. Container tipped too far

3. Loose fluid inlet connection

4. Loose or damaged fluid

tip/seat

5. Dry or loose fluid needle

packing nut

6. Air vent clogged

1. Packing nut loose

2. Packing worn or dry

1. Sticking air valve stem

2. Contaminate on air valve

or seat

3. Worn or damaged air valve

or seat

4. Broken air valve spring

5. Bent valve stem

1. Too high atomization

pressure

2. Too far from work surface

3. Improper stroking (arcing,

gun motion too fast)

1. No pressure in gun

2. Fluid control not open

enough

3. Fluid too heavy

1. Clean using only a non-metallic pick

2. Clean

1. Clean

2. Clean and tighten

3. Clean using only a non-metallic pick

1. Partially close the pattern adjustment

2. Open fluid adjustment

3. Reduce atomization air pressure

1. Open fan pattern adjustment

2. Thin to proper viscosity

3. Increase atomization pressure

1. Refill

2. Hold more upright

3. Tighten

4. Adjust or replace

5. Lubricate and or tighten

6. Clear vent hole

1. Tighten, but do not restrict, needle

2. Replace or lubricate (non-silicone oil)

1. Lubricate

2. Clean

3. Replace

4. Replace

5. Replace

1. Reduce pressure

2. Adjust to proper distance

3. Move at moderate pace, parallel to

surface

1. Check air lines

2. Open fluid control

3. Thin fluid or change to pressure feed

system

Page 13

THREE-YEAR LIMITED WARRANTY

13

This tool is warranted by the manufacturer to the original purchaser from the original

purchase date for three (3) years subject to the warranty coverage described herein.

This tool is warranted to the original user to be free from defect in material and

workmanship. If you believe that a tool is defective, return the tool, with proper proof

of purchase to the point of purchase. If it is determined that the tool is defective and

covered by this warranty, the distributor will replace the tool or refund the

purchase price.

This warranty is void if: defects in materials or workmanship or damages result from

repairs or alterations which have been made or attempted by others or the

unauthorized use of nonconforming parts; the damage is due to normal wear,

damage is due to abuse (including overloading of the tool beyond capacity), improper

maintenance, neglect or accident; or the damage is due to the use of the tool after

partial failure or use with improper accessories or unauthorized repair or alteration.

This warranty gives you specific legal rights, and you may also have other rights that

vary from state to state.

For warranty questions, call our customer service department at 1-888-3KOBALT,

8:00 a.m.-8:00 p.m. EST, Monday-Friday.

Page 14

REPLACEMENT PARTS LIST

Printed in China

14

For replacement parts, call our customer service department at 1-888-3KOBALT,

8:00 a.m.-8:00 p.m., EST, Monday-Friday.

23

24

25

26

27

28

29

30

31

G

I

34

35

36

37

38

A

40

41

42

Air cap (external mix)

Air cap (internal mix)

Air cap seal

Air cup ring

Air separating ring

Fluid nozzle

Gun body

Phillips Screw

Side knob

Air adjusting valve

Air adjusting seat

Snap Retainer

Trigger pin

Trigger

Washer

Snap retaining ring (E-ring)

Pattern control needle

Retaining ring

Pattern control spring

O-ring 2.5 × 2.1

Pattern control seat

Pattern control screw

O-ring 4.5 × 1.8

O-ring 5.2 × 1.9

Fluid needle seat

Air valve spring

Fluid needle

O-ring 10 × 1.8

Fluid needle adjusting seat

Fluid needle spring

Fluid control knob

Air inlet

Seal nut

Packing nut

Sealing washer

Washer

O-ring 19 × 1.8

Canister top

Canister gasket

Retaining nut

Material tube

E

M

3

J

5

6

7

8

H

10

12

11

13

K

15

16

17

18

19

20

21

1

1

1

1

1

1

1

2

2

1

1

1

1

1

1

1

1

2

1

1

1

O-ring 9 × 1.8

22

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

L

Canister

1

Part No.

Description Qty.

Part No.

Description Qty.

E

M

3 J 5

88HH10 11 12

13 K 15 16

17

18

19

24

24 27

29

30

31 G

I

34

L

353637

38

40

41

42

A

28

25 26

18

20

21

22

23

6 7

Page 15

ARTICLE #0220964

MODÈLE #SGY-AIR70TZ

JOIGNEZ VOTRE REÇU ICI

Numéro de série Date d'achat

15

KOBALT® et le motif de K® sont des marques

de commerce déposées de LF, LLC. Tous droits

réservés.

Des questions, des problèmes, des pièces manquantes? Avant de

retourner l'article au détaillant, communiquez avec notre service à la

clientèle au 1 888 3KOBALT, entre 8 h et 20 h (HNE), du lundi au vendredi.

ENSEMBLE DE

PISTOLET DE

PULVÉRISATION

POUR LATEX

Page 16

TABLE DES MATIÈRES

16

Consignes de sécurité ....................................................................................... 17

Contenu de l'emballage ..................................................................................... 19

Préparation ........................................................................................................ 21

Instructions pour l'assemblage .......................................................................... 21

Mode d'emploi ................................................................................................... 22

Entretien ........................................................................................................... 25

Dépannage ....................................................................................................... 27

Garantie ............................................................................................................ 28

Liste des pièces de rechange ........................................................................... 29

Page 17

17

CONSIGNES DE SÉCURITÉ

Assurez-vous de lire et de comprendre l'intégralité de ce manuel avant de tenter

d'assembler, d'utiliser ou d'installer le produit. Si vous avez des questions concernant ce

produit, veuillez appeler notre service à la clientèle au 1 888 3KOBALT, entre 8 h et 20 h

(HNE), du lundi au vendredi.

Veuillez suivre tous les codes d'électricité et de sécurité de votre région ainsi que le

Code canadien de l'électricité et la Loi sur la santé et la sécurité du travail.

Au moment de la pulvérisation et du nettoyage, suivez les directives du manuel et

respectez les mesures de sécurité du fabricant. (Reportez-vous à la fiche signalétique

du produit [FS].)

N'utilisez pas ce produit si d'autres personnes (notamment des enfants) ou des

animaux se trouvent dans l'aire de travail.

Travaillez toujours dans un endroit propre. Pour éviter tout risque de blessure et de

dommage à la pièce, ne pulvérisez jamais sur une surface poussiéreuse ou

encombrée de débris.

Utilisez toujours un régulateur de pression pour l'alimentation en air du pistolet de

pulvérisation.

AVERTISSEMENT

N'utilisez jamais le produit s'il a été endommagé pendant la manutention, le transport

ou l'utilisation. Un produit endommagé pourrait éclater et, par conséquent, causer des

blessures et des dommages matériels.

Portez un masque facial ou un masque anti-vapeurs ainsi que des vêtements de

protection pendant la pulvérisation. Utilisez toujours le pistolet de pulvérisation dans

un endroit bien aéré afin de prévenir les risques d'incendie et les dangers pour la santé.

Pour de plus amples renseignements, consultez la fiche signalétique (FS) du pistolet.

Ne pulvérisez jamais de matières inflammables à proximité d'une flamme nue ou d'une

source d'inflammation. N'entreposez jamais de liquides ou de gaz inflammables à

proximité du compresseur.

Ne pulvérisez pas de l'acide, des matières corrosives, des produits chimiques toxiques,

des fertilisants ou des pesticides.

L'utilisation de ces matières peut causer de graves blessures, voire entraîner la mort.

Si vos yeux ou toute autre partie de votre visage entre en contact direct avec la matière

pulvérisée, communiquez avec un médecin ou une salle d’urgence pour obtenir de

l’aide immédiate.

N’excédez pas la pression de fonctionnement des pièces (p. ex., tuyaux et raccords)

de l’outil de peinture.

Conservez un bon équilibre en tout temps. Ne vous étirez pas pour étendre votre

portée, ce qui pourrait vous faire glisser, basculer ou tomber et causer des blessures

graves, voire mortelles. Prenez garde à l’excédent de tuyau laissé dans l’aire de travail

ou sur la surface de travail. Ne faites pas un usage abusif des tuyaux ou des raccords.

Ne transportez jamais l’outil par son tuyau et ne tirez jamais sur le tuyau pour le

débrancher de la source d’alimentation. Tenez les tuyaux éloignés des sources de

chaleur, de l’huile et des objets coupants. Vérifiez l’état des tuyaux avant chaque

utilisation et assurez-vous que tous les raccords sont solides.

Certaines matières pouvant être utilisées avec l’outil risquent de causer des irritations

cutanées si elles entrent en contact direct avec la peau. Lisez l’étiquette ou la fiche

signalétique des matières que vous prévoyez utiliser afin de savoir si elles peuvent

provoquer de telles irritations.

Page 18

REMARQUE

Ce pistolet de pulvérisation est conçu pour la maison, la ferme et les commerces.

Il peut contenir tout type de peinture au latex. Il peut facilement et rapidement

être converti de non purgeur à purgeur, d'un pistolet à pression à un pistolet à

siphon et d'un pistolet à mélange interne à un pistolet à mélange externe, et vice

versa. Il comprend également une commande de réglage du jet. Il peut aussi

être utilisé avec un autre réservoir sous pression.

La pression de pulvérisation est déterminée par le régulateur de la source

d'alimentation en air. Le bouton de réglage du fluide, la viscosité de la peinture

et la pression d'air permettent de régler la quantité de fluide pulvérisée.

Si vous ne nettoyez pas adéquatement la pièce après chaque utilisation, vous

risquez d’endommager le produit.

CONSIGNES DE SÉCURITÉ

CARACTÉRISTIQUES

À PRESSION/À SIPHON

INTERNE/EXTERNE

PURGEUR/NON PURGEUR

1,4 MM (0,055 PO)

2

2

50 LB/PO

3,5 EN MOYENNE/8,6 EN CONTINU

2

21,66 CM (8 PO) À 50 LB/PO /À 21,66 CM

(8 PO) DE LA PIÈCE

1/4 PO NPS (M)

3/8 PO NPS (M)

COMPOSANT

TYPE D'ALIMENTATION

TYPE DE MÉLANGE

TYPE DE PURGE

DIAMÈTRE INTÉRIEUR DE

LA BUSE À PEINTURE

PRESSION DE SERVICE MAXIMALE

40 À 50 LB/PO

PRESSION DE SERVICE

AIR REQUIS (PI /MIN À 50 LB/PO )

2

3

LARGEUR DU JET

ENTRÉE D'AIR

ENTRÉE DE FLUIDE

CARACTÉRISTIQUES DU PRODUIT

18

AVERTISSEMENT

LES RISQUES LIÉS À L’EXPOSITION À CES PRODUITS VARIENT SELON LE

NOMBRE DE FOIS OÙ VOUS PRATIQUEZ CES ACTIVITÉS. AFIN DE LIMITER

VOTRE EXPOSITION À CES PRODUITS CHIMIQUES, TRAVAILLEZ DANS UN

ENDROIT BIEN VENTILÉ ET UTILISEZ DE L’ÉQUIPEMENT DE SÉCURITÉ

APPROUVÉ, TEL QU’UN MASQUE ANTIPOUSSIÈRE CONÇU SPÉCIALEMENT

POUR FILTRER LES PARTICULES MICROSCOPIQUES.

DANGER

Ne pulvérisez jamais de peinture à

moins de 8 m du compresseur. Si c'est

possible, placez le compresseur dans

une autre pièce.

MISE EN GARDE

Gardez le tuyau loin des objets

tranchants. Vous risquez de subir de

graves blessures si vous percez le tuyau

à air. Examinez le tuyau à air

régulièrement et remplacez-le s'il est

endommagé ou rompu.

Page 19

CONTENU DE L'EMBALLAGE

DESCRIPTION

Pistolet de pulvérisation

pour latex

Trousse pour le nettoyage

du pistolet de pulvérisation

Filtre pour pistolet de

pulvérisation

Ruban-cache

Obturateur d’air

(mélange externe)

Bouton de réglage du jet

Bouton de réglage du fluide

Bouton latéral

Entrée d'air

Anneau de l'obturateur d'air

Gâchette

Réservoir

QUANTITÉ

1

1

1

1

1

1

1

1

1

1

1

1

PIÈCE

A

B

C

D

E

F

G

H

I

J

K

L

Obturateur d’air

(mélange interne)

1

M

TERMES RELATIFS AU PISTOLET DE PULVÉRISATION

Mélange interne

Procédé au cours duquel l'air et la peinture sont mélangés dans l'obturateur d'air,

juste avant que le fluide soit pulvérisé. Ce procédé convient aux peintures épaisses à

séchage lent et ne peut être utilisé qu'en mode d'alimentation sous pression. Ne

l'utilisez pas pour une peinture au latex à séchage rapide, car celle-ci sécherait à

l'intérieur et bloquerait rapidement l'obturateur d'air.

Mélange externe

Procédé au cours duquel l'air et la peinture sont mélangés dès qu'ils sont expulsés de

la buse. Ce procédé s'utilise pour les peintures à séchage rapide. Il doit également

être employé lorsqu'il est nécessaire d'obtenir une finition de qualité supérieure.

Alimentation sous pression

Procédé d'alimentation au cours duquel le réservoir de peinture est mis sous pression

de manière à pousser le fluide jusqu'au pistolet. Ce procédé peut être utilisé avec un

obturateur d'air pour mélange interne et mélange externe. On s'en sert généralement

pour les peintures au latex épaisses ou dans des projets à grande échelle.

19

B

A

E

F

G

H

I

J

K

L

C

D

M

Page 20

TERMES RELATIFS AU PISTOLET DE PULVÉRISATION

Utilisation d'un obturateur d'air

Mélange interne - Généralement utilisé pour les peintures au latex

épaisses à séchage lent ou pour une application rapide. N'UTILISEZ

PAS ce type de mélange avec une peinture au latex à séchage

rapide, car elle bloquerait l'ouverture de l'obturateur d'air. Le mode

d'alimentation sous pression doit être utilisé avec les obturateurs

d'air pour mélange interne.

Mélange externe - Utilisé pour les peintures au latex fluides à

séchage rapide. Idéal pour les travaux de finition de qualité. Le

mode d'alimentation sous pression ou à siphon peut être utilisé avec

les obturateurs d'air pour mélange externe.

ASSEMBLAGE DU PISTOLET DE PULVÉRISATION

Obturateur d'air pour

mélange interne

Obturateur d'air pour

mélange externe

Alimentation à siphon

Procédé d'alimentation au cours duquel la pression atmosphérique crée un vide partiel

qui permet de siphonner le fluide jusqu'au pistolet. Ce procédé ne peut être utilisé

qu'avec un obturateur d'air pour mélange externe. L'alimentation à siphon est

employée avec les peintures en latex fluides.

Purgeur

Dans ce mode, l'air passe continuellement dans le pistolet, que vous pulvérisiez ou

non de la peinture. Il est généralement utilisé lorsque l'air provient d'un compresseur

d'air sans réservoir qui fonctionne continuellement.

Non purgeur

Dans ce mode, l'air passe seulement lorsqu'on tire la gâchette. Ce procédé est utilisé

avec un compresseur d'air muni d'un réservoir ou un gros système de production d'air.

Ne l'utilisez pas avec un compresseur d'air sans réservoir qui fonctionne

continuellement.

Changement du mode d'alimentation

Le mode d'alimentation du pistolet de pulvérisation

pour latex peut être sous pression ou à siphon.

Vous pouvez facilement changer le mode

d'alimentation en tournant complètement le bouton

latéral. Soyez certain du mode choisi avant

l'utilisation. (Consultez la figure 1.)

P

S

P : Alimentation

sous pression

S : Alimentation à

siphon

1

20

Page 21

Conversion de non purgeur à purgeur

(Consultez la figure 2.)

1. Séparez le pistolet de l'alimentation en air.

2. Retirez le bouton de réglage du fluide et le

ressort du pointeau du fluide.

3. Pour revenir au type non purgeur, retirez le

ressort du reniflard et rangez-le dans un endroit

sûr pour que vous puissiez le remettre lorsque

cela sera nécessaire.

4. Insérez le ressort du pointeau du fluide, puis

replacez le bouton de réglage du fluide.

Avant de commencer l'assemblage du produit, assurez-vous d'avoir toutes les pièces.

Comparez les pièces dans l'emballage avec la liste des pièces. S'il y a des pièces

manquantes ou endommagées, ne tentez pas d'assembler le produit. Communiquez

avec le service à la clientèle pour obtenir des pièces de rechange.

Temps d'assemblage approximatif : de 5 à 10 minutes.

Outils nécessairespourl'assemblage (non inclus): clé à molette.

PRÉPARATION

ASSEMBLAGE DU PISTOLET DE PULVÉRISATION

INSTRUCTIONS POUR L'ASSEMBLAGE

1

1. Fixez manuellement le filtre (C) à l'entrée d'air

du pistolet (I) en assemblant l'extrémité filetée

femelle du filtre (C) et l'extrémité filetée mâle

de l'entrée d'air (I). Utilisez du ruban

d'étanchéité (non fourni) pour que l'assemblage

soit étanche à l'air. (Consultez la figure 1.)

21

Bouton de

réglage du

fluide

Ressort du reniflard

Ressort du

pointeau du

fluide

Bouton de réglage

du jet

2

Page 22

2

2. Branchez le tuyau à air sur l'extrémité filetée

mâle du filtre (C). Utilisez du ruban d'étanchéité

(non fourni) pour que l'assemblage soit étanche

à l'air. (Consultez la figure 2.)

REMARQUE La pression de service correspond à

la pression dans la conduite d'air quand la gâchette

du pistolet de pulvérisation (K) est complètement tirée.

3. Réglez la pression de service entre 30 et

2

50 lb/po , selon le débit voulu. N'excédez pas la

pression maximale du pistolet de pulvérisation.

Évitez de serrer excessivement lors de la

fixation du filtre (C) à l'entrée d'air (I) du pistolet

de pulvérisation et au tuyau à air.

AVERTISSEMENT

MODE D'EMPLOI

REMARQUE

Avant d'utiliser la peinture souhaitée dans le pistolet, pulvérisez un diluant ou un

solvant compatible afin d'éliminer tous les contaminants et résidus.

Diluez correctement la peinture au latex, conformément aux instructions du

fabricant, avant de la pulvériser. S'il n'est pas possible de diluer la peinture, celle-ci

ne doit pas être utilisée avec le pistolet.

Nous vous recommandons de placer une toile de protection ou tout autre dispositif

récepteur sous le réservoir afin de pouvoir facilement ramasser et jeter la peinture

si vous en renversez.

Utilisez un morceau de carton ou tout autre matériel mis au rebut comme cible afin

de régler le jet.

Vérifiez la consistance de la peinture en effectuant quelques pulvérisations sur le

morceau de carton. Si la peinture semble encore trop épaisse, ajoutez un peu de

diluant. Suivez les recommandations du fabricant de la peinture en ce qui a trait à

l'utilisation de diluant.

Remplissez environ les trois quarts du réservoir (L), puis démarrez le compresseur

d'air.

Avant d’ajouter de la peinture, assurez-vous de retirer tous les diluants et solvants

du réservoir.

INSTRUCTIONS POUR L'ASSEMBLAGE

22

Page 23

MODE D'EMPLOI

Obturateur d'air

Anneau de

l'obturateur d'air

Jet en éventail

horizontal

Jet en éventail

vertical

1

2

3

1. Réglez l'orientation (horizontale ou verticale) du

jet en éventail en dévissant l'anneau de

l'obturateur d'air de 90 degrés (J). Vissez

manuellement l'anneau (J) après le réglage.

(Consultez la figure 1.)

2. Réglez le jet à la forme voulue. Pour un jet

complet, tournez le bouton de réglage du jet (F)

dans le sens contraire des aiguilles d'une

montre. Pour un jet de forme ronde, tournez le

bouton de réglage du jet (F) dans le sens des

aiguilles d'une montre. (Consultez la figure 2.)

3. Tournez jusqu'au bout le bouton de réglage du

fluide (G), dans le sens des aiguilles d'une

montre. (Consultez la figure 3.)

23

Le pistolet à peinture ne fonctionnera

correctement que si l’orientation du jet en éventail

est horizontale ou verticale.

AVERTISSEMENT

Page 24

24

Jet trop fin

Jet adéquat

Jet trop épais

Consistance du jet (pulvérisation)

15 à

23 cm

Couche

mince

Couche

épaisse

Couche

mince

INADEQUAT

4

5

6

4. En tenant le pistolet à une distance de 15 à

23 cm de la pièce, pulvérisez un jet court tout en

tournant le bouton de réglage du fluide dans le

sens contraire des aiguilles d'une montre.

Observez le jet sur la pièce et tournez le bouton

de réglage du fluide (G) jusqu'à ce que vous

obteniez la pulvérisation ou le jet souhaité. Si

le jet est trop fin, ce qui est causé par une trop

grande quantité d'air présente dans la peinture

pulvérisée, réduisez la pression d'air ou tournez

le bouton de réglage du fluide (G) pour pulvériser

plus de peinture. Si le jet est trop épais ou si le

pistolet projette de grosses gouttes, réduisez la

quantité de peinture à l'aide du bouton de réglage

du fluide (G) ou diluez davantage la peinture.

(Consultez la figure 4.)

5. Maintenez le pistolet au bon angle pendant que

vous pulvérisez le fluide. (Consultez la figure 5.)

REMARQUE Il est possible de

tourner le bouton

de réglage du fluide (G) dans un sens ou dans

l'autre pour obtenir la bonne consistance de jet.

Avant de pulvériser le fluide sur une pièce,

exercez-vous pendant quelques minutes sur un

morceau de carton pour vous assurer que la

largeur du jet et la consistance sont bien réglées.

REMARQUE Maintenez toujours le pistolet en

mouvement lorsque vous pulvérisez le fluide. Si

vous arrêtez de bouger pendant la pulvérisation,

de la peinture s'accumulera, ce qui pourrait

entraîner des coulures. Ne bougez pas la buse du

pistolet d'un côté à l'autre pendant que vous

peignez, sinon la peinture s'accumulera au centre

du jet et sera insuffisante à chaque extrémité.

(Consultez la figure 6.)

MODE D'EMPLOI

Page 25

Relâchement

de la gâchette

15 à

23 cm

Déclenchement

de la gâchette

Début du

mouvement

Fin du

mouvement

7

8

6. Appuyez correctement sur la gâchette. Amorcez

le mouvement du pistolet avant d'appuyer sur la

gâchette (K), et arrêtez-le après avoir relâché la

gâchette. Cette méthode produira un dégradé en

biseau ou uniformisera chaque jet, sans créer de

chevauchement ni d'irrégularités.

(Consultez la figure 7.)

7. Chevauchez chaque jet de manière à obtenir

une couche égale. (Consultez la figure 8.)

8. Afin d'éviter de pulvériser au-delà des bords

dela pièce ou pour protéger d'autres surfaces,

utilisez un morceau de carton comme écran de

protection; vous pouvez également utiliser du

ruban-cache (non fourni).

REMARQUE Deux minces couches de peinture

donneront de meilleurs résultats et risquent moins

d'entraîner des coulures qu'une couche épaisse.

ENTRETIEN

La réglementation locale peut exiger l'utilisation de méthodes et d'équipement de

nettoyage précis. Respectez la réglementation de votre région ainsi que les

recommandations du fabricant en ce qui a trait à l'utilisation et à l'élimination de

peintures à pulvériser et de solvants.

Nettoyage quotidien

REMARQUE Nettoyez le pistolet de pulvérisation immédiatement après l'avoir utilisé.

La peinture et les autres matières sèchent rapidement à l'intérieur du pistolet et sont

par la suite difficiles à déloger, ce qui peut rendre le pistolet inutilisable.

1. Retirez et videz le réservoir; rincez-le ensuite avec un solvant qui convient au type

de peinture.

2. Remplissez le réservoir d'un solvant propre, puis remettez-le en place. Pulvérisez du

solvant tout en agitant le pistolet vigoureusement. Essuyez le pistolet avec un linge qui

a été trempé dans un solvant. Répétez ces étapes jusqu'à ce que le pistolet soit propre.

MODE D'EMPLOI

REMARQUE La quantité de peinture appliquée

peut varier selon la vitesse du mouvement, la

distance entre vous et la pièce et le réglage du

fluide (G). Si la vitesse de mouvement est trop

lente, la peinture sera humide sur la pièce, ce qui

pourrait entraîner des coulures. Si la vitesse de

mouvement est trop rapide, la peinture sera sèche

et inégale sur la pièce.

25

Page 26

3. Retirez l'obturateur d'air et trempez-le dans le solvant jusqu'à ce qu'il soit propre.

Au besoin, utilisez une petite brosse pour éliminer les taches tenaces. Il est possi ble d'employer un cure-dent ou une petite brosse pour nettoyer les conduits d'air.

N'utilisez jamais d'objets en métal pour nettoyer les conduits

percés. Des conduits endommagés entraîneront une pulvérisation inadéquate.

4. Nettoyez les joints avec un linge qui a été trempé dans un solvant.

Ne trempez jamais les joints ou le corps du pistolet de

pulvérisation dans un solvant pour éviter de les endommager.

5. Après avoir nettoyé le pistolet avec de l'eau, remplissez-le d'essence minérale, puis

pulvérisez-la pour prévenir la corrosion.

6. Nettoyez soigneusement le pistolet et rincez-le abondamment afin de neutraliser

les contaminants corrosifs.

7. Enduisez toutes les pièces amovibles d'une huile sans silicone lorsque vous les

réassemblez. Enduisez tous les raccords filetés de Vaseline® ou d'un léger

lubrifiant avant d'entreposer l'outil.

AVERTISSEMENT

AVERTISSEMENT

Nettoyage périodique

Il peut être nécessaire d'inspecter et de nettoyer les pièces internes et le corps du

pistolet en raison d'un mauvais nettoyage ou de l'utilisation d'une peinture inadéquate.

1. Examinez les ouvertures de l'obturateur d'air et la buse. Si elles sont obstruées,

retirez le joint torique et trempez l'obturateur d'air ou la buse dans le solvant.

2. Il est possible d'utiliser un cure-dent, une brosse ou un objet semblable pour

déloger la peinture sèche des trous et des conduits.

N'utilisez jamais d'objets en métal pour nettoyer les conduits

percés. Des conduits endommagés entraîneront une pulvérisation inadéquate.

3. Retirez le pointeau du fluide pour vérifier qu'il est droit et que le bout ne présente

pas de traces d'usure excessive.

IMPORTANT : Si le bout du pointeau est plus usé d'un côté que de l'autre, soit le

pointeau est plié, soit le pistolet a été échappé ou a été frappé durement. Il est

impossible de réparer un corps de pistolet déformé. Vérifiez le pointeau en le

faisant rouler sur une surface plane. Remplacez-le si nécessaire.

4. Vérifiez les joints toriques et les joints d'étanchéité et remplacez ceux qui sont

endommagés. Vous pouvez les nettoyer avec un linge,

mais ne les trempez pas

dans un solvant.

5. Dévissez les écrous de presse-garniture et remplacez le presse-garniture

seulement si la fuite persiste après avoir vissé les écrous. Ne vissez pas

excessivement les écrous pour ne pas limiter le mouvement du pointeau.

6. Réassemblez les pièces dans l'ordre inverse et enduisez les pièces amovibles

d'une huile sans silicone. Enduisez tous les raccords de tuyaux et les joints filetés

de Vaseline® ou d'un léger lubrifiant.

AVERTISSEMENT

Entreposage

1. Lorsque vous n'utilisez pas le pistolet de pulvérisation, tournez le bouton de réglage

du fluide dans le sens contraire des aiguilles d'une montre afin de réduire la tension

du ressort sur le bout du pointeau du fluide.

2. Il faut bien nettoyer et légèrement lubrifier le pistolet de pulvérisation.

3. Rangez le pistolet de pulvérisation dans un endroit sec et sûr, hors de la portée des

enfants.

ENTRETIEN

26

Page 27

PROBLÈME

DÉPANNAGE

MESURE CORRECTIVECAUSE POSSIBLE

Gros jet vers

la gauche ou

la droite

Gros jet vers

le haut ou le

bas

Jet réduit au

centre

Gros jet au

centre

Pulvérisation

en gouttes

Fuite de fluide de l'écrou

de presse-garniture

Fuite d'air de l'obturateur

sans que la gâchette ait

été tirée

1. Vous avez trop tourné le

bouton de réglage du jet en

éventail.

2. Vous avez trop tourné le

bouton de réglage du fluide.

3. La pression d'air de

pulvérisation est trop élevée.

1. Le bouton de réglage du jet en

éventail est partiellement fermé.

2. Le fluide est trop épais.

3. La pression de pulvérisation est

trop basse.

1. Le niveau de fluide est trop

bas.

2. Le réservoir est trop renversé.

3. Le raccord d'entrée du

fluide est dévissé.

4. Le régulateur ou la buse est

endommagé ou dévissé.

5. Un écrou de presse garniture du pointeau du

fluide est dévissé ou sec.

6. L'évent d'aération est obstrué.

1. L'écrou de presse-garniture

est dévissé.

2. Le presse-garniture est usé

ou sec.

1. La tige du reniflard est

collante.

2. Le reniflard ou le régulateur

est contaminé.

3. Le reniflard ou le régulateur

est usé ou endommagé.

4. Le ressort du reniflard

est brisé.

5. La tige du reniflard est pliée.

1. Nettoyez avec un pic non métallique

uniquement.

2. Nettoyez.

1. Nettoyez.

2. Nettoyez et serrez.

3. Nettoyez avec un pic non métallique

uniquement.

1. Fermez partiellement le bouton de

réglage du jet.

2. Ouvrez le bouton de réglage du fluide.

3. Réduisez la pression d'air de

pulvérisation.

1. Ouvrez le bouton de réglage du jet en

éventail.

2. Diluez le fluide jusqu'à l'obtention d'une

viscosité adéquate.

3. Augmentez la pression de pulvérisation.

1. Remplissez le réservoir.

2. Tenez le réservoir en position

verticale.

3. Serrez.

4. Ajustez ou remplacez.

5. Lubrifiez ou serrez.

6. Nettoyez le trou d'aération.

1. Serrez sans restreindre le

mouvement du pointeau.

2. Remplacez ou lubrifiez (huile sans

silicone).

1. Lubrifiez.

2. Nettoyez.

3. Remplacez.

4. Remplacez.

5. Remplacez.

1. Il y a de la matière sèche

dans la partie inférieure ou

supérieure de la buse.

2. L'obturateur d'air est dévissé

ou le régulateur est sale.

3. L'obturateur d'air est bloqué.

1. Les trous situés du côté

gauche ou droit de

l'obturateur d'air sont bloqués.

2. Il y a de la poussière du

côté gauche ou droit de la

buse.

27

Page 28

Cet outil est garanti par le fabricant pour une période de trois (3) ans à partir de la

date d'achat, selon les modalités décrites aux présentes.

Cet outil est garanti contre les défauts de matériaux et de fabrication. Si vous croyez

qu'il est défectueux, retournez-le, accompagné d'une preuve d'achat acceptable, au

point de vente d'origine. Si l'outil est jugé défectueux et qu'il est couvert par la

présente garantie, le distributeur l'échangera ou vous remboursera le prix d'achat.

Cette garantie sera annulée si : les défauts de matériaux ou de fabrication ou les

dommages résultent de réparations ou de modifications non autorisées, de

l'utilisation de pièces non conformes, de l'usure normale, d'un usage abusif

(notamment une surcharge de l'outil), d'un entretien inadéquat, d'une négligence,

d'un accident, d'une utilisation après une défaillance partielle ou de l'utilisation

d'accessoires inappropriés.

Cette garantie vous confère des droits précis. Il est possible que vous disposiez

également d'autres droits, qui varient d'un État ou d'une province à l'autre.

Pour toute question concernant la garantie, communiquez avec le service à la

clientèle au 1 888 3KOBALT, entre 8 h et 20 h (HNE), du lundi au vendredi.

GARANTIE LIMITÉE DE TROIS ANS

28

PROBLÈME

DÉPANNAGE

MESURE CORRECTIVECAUSE POSSIBLE

Pulvérisation excessive

Aucune pulvérisation

1. La pression de pulvérisation

est trop élevée.

2. Vous êtes trop loin de la

surface de travail.

3. Votre mouvement est

inadéquat (mouvement en

forme d'arc ou mouvement

trop rapide).

1. Il n'y a pas de pression

dans le pistolet.

2. Le bouton de réglage du

fluide n'est pas assez ouvert.

3. Le fluide est trop épais.

1. Réduisez la pression.

2. Placez-vous à la bonne distance.

3. Bougez à un rythme modéré,

parallèlement à la surface.

1. Vérifiez les conduites d'air.

2. Ouvrez le bouton de réglage du

fluide.

3. Diluez le fluide ou changez la

pression dans le système

d'alimentation.

Page 29

29

LISTE DES PIÈCES DE RECHANGE

Printed in China

Pour obtenir des pièces de rechange, communiquez avec notre service à la clientèle

au 1 888 3KOBALT, entre 8 h et 20 h (HNE), du lundi au vendredi.

23

24

25

26

27

28

29

30

31

G

I

34

35

36

37

38

A

40

41

42

Obturateur d’air (mélange

externe)

Obturateur d’air (mélange

interne)

Joint de l’obturateur d’air

Anneau de l’obturateur d’air

Anneau séparateur d’air

Buse à peinture

Corps du pistolet

Vis Phillips

Bouton latéral

Soupape à air

Siège de la soupape à air

Dispositif d’arrêt

Goupille de la gâchette

Gâchette

Rondelle

Bague de retenue en E

Pointeau de commande

du jet

Bague de retenue

Ressort de commande

du jet

Vis de commande du jet

Joint torique 4,5 x 1,8

Joint torique 5,2 x 1,9

Siège du pointeau

Ressort de soupape à air

Pointeau

Joint torique 10 x 1,8

Siège de réglage du

pointeau

Ressort du pointeau

Bouton de réglage

du fluide

Entrée d’air

Écrou d’étanchéité

Écrou de presse-garniture

Rondelle d’étanchéité

Rondelle

Joint torique 19 x 1,8

Bouchon du réservoir

Joint du réservoir

Écrou de retenue

Tube

E

M

3

J

5

6

7

8

H

10

12

11

13

K

15

16

17

18

19

1

1

1

1

1

1

1

2

2

1

1

1

1

1

1

1

1

2

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

L

Réservoir

1

Joint torique 2,5 x 2,1

Siège de commande du jet

20

21

1

1

Joint torique 9 x 1,8

22

1

No de pièce

Description Qté

No de pièce

Description Qté

E

M

3 J 5

88HH10 11 12

13 K 15 16

17

18

19

24

24 27

29

30

31 G

I

34

L

353637

38

40

41

42

A

28

25 26

18

20

21

22

23

6 7

Page 30

ARTÍCULO #0220964

MODELO #SGY-AIR70TZ

ADJUNTE SU RECIBO AQUÍ

Número de serie Fecha de compra

30

¿Preguntas, problemas, piezas faltantes? Antes de volver a la tienda,

llame a nuestro Departamento de Servicio al Cliente al 1-888-3KOBALT, de

lunes a viernes de 8:00 a.m. a 8:00 p.m., hora estándar del Este

KOBALT® y K & Design® son marcas

registradas de LF, LLC. Todos los derechos

reservados.

KIT DE LIMPIEZA PARA

PISTOLA DE RO CIADO

Page 31

ÍNDICE

Información de seguridad .................................................................................. 32

Contenido del paquete ...................................................................................... 34

Preparación ...................................................................................................... 36

Instrucciones de ensamblaje ............................................................................ 36

Instrucciones de funcionamiento ...................................................................... 37

Cuidado y mantenimiento ................................................................................. 40

Solución de problemas ..................................................................................... 42

Garantía ............................................................................................................ 44

Lista de piezas de repuesto ............................................................................. 45

31

Page 32

32

SAFETY INFORMATION

Lea y comprenda completamente este manual antes de intentar ensamblar, usar o

instalar el producto. Si tiene preguntas relacionadas con el producto, llame al

Departamento de Servicio al Cliente al 1-888-3KOBALT, de lunes a viernes de 8 a.m.

a 8 p.m., hora estándar del Este.

Respete todos los códigos locales eléctricos y de seguridad, además de los códigos

eléctricos nacionales (NEC, por sus siglas en inglés) y el de la Administración de Salud

y Seguridad Ocupacional (OSHA, por sus siglas en inglés), en los EE.UU.

Al rociar y limpiar, siga siempre el manual y las precauciones de seguridad

proporcionadas por el fabricante del material (consulte las hojas de datos de seguridad

de materiales (MSDS, por sus siglas en inglés)).

No utilice este producto cuando haya otras personas, niños o mascotas en el área de

trabajo.

Trabaje siempre en un ambiente limpio. Para evitar lesiones o daños a la pieza de

trabajo, no dirija la pistola de rociado hacia el polvo o desechos.

Use siempre un regulador de presión en el suministro de aire para la pistola de rociado.

WARNING

No opere la herramienta si se ha dañado durante el envío, manipulación o uso.

Podría causar una explosión y provocar lesiones y/o daño a la propiedad.

Utilice una máscara/respirador y ropa protectora al rociar. Rocíe siempre en un área

bien ventilada para prevenir riesgos en la salud y de incendio. Consulte las hojas de

datos de seguridad de materiales (MSDS, por sus siglas en inglés) del material de

rociado para obtener información adicional.

Nunca rocíe materiales inflamables en las cercanías de llamas abiertas o cerca de

fuentes de ignición. Nunca almacene líquidos o gases inflamables cerca del

compresor de aire.

No rocíe ácidos, materiales corrosivos, químicos tóxicos ni fertilizantes o pesticidas.

El uso de estos materiales puede provocar la muerte o lesiones graves.

Nunca dirija o rocíe hacia usted mismo ni hacia a otras personas, ya que podría

provocar lesiones graves.

Si los ojos o la cara entran en contacto directo con el material rociado, póngase en

contacto con su doctor y/o la sala de emergencias local para solicitar ayuda inmediata.

No use una presión que exceda la presión de trabajo de cualquiera de las partes

(mangueras, conectores, etc.) en el sistema de pintura.

Mantenga una posición de los pies estable en todo momento; no se extienda

demasiado o podría resbalarse, tropezarse y/o caerse y esto podría resultar lesiones

mayores o la muerte. Tenga presente el exceso de manguera que queda en el área o

superficie de trabajo. No dé mal uso a las mangueras o conectores. Nunca transporte

la herramienta de la manguera ni jale de ella para desconectarla de la fuente de

alimentación. Mantenga las mangueras alejadas del calor, el aceite y los bordes

filosos. Inspeccione las mangueras en busca conexiones deterioradas antes de cada

uso y asegúrese de que todas las conexiones estén seguras.

Si algunos de los materiales que pueden usarse con este dispositivo entra en

contacto directo con la piel puede causar irritación. Lea las etiquetas o las hojas

de datos de seguridad de materiales de los materiales que va a usar para conocer

cuáles materiales pueden causar irritación a la piel.

Page 33

INFORMACIÓN DE SEGURIDAD

NOTA

Esta pistola de rociado para látex está diseñada para el uso doméstico, agrícola

y comercial. Se puede utilizar con todo tipo de pinturas de látex. La pistola se

puede convertir fácil y rápidamente en un purgador de aire. Además se puede

cambiar el tipo de alimentación (de presión o por sifón) y se pueden intercambiar

las tapas de aire para realizar una mezcla interna o externa. Esta pistola posee

un control del tamaño de la modalidad de rociado. También se puede convertir

para utilizarla con un tanque de pintura a presión.

La presión para la atomización se controla con el regulador en la fuente de aire.

La cantidad de líquido se regula con la perilla de control de líquido, la viscosidad

de la pintura y la presión del aire.

No limpiar adecuadamente la pieza de trabajo después de cada uso puede

resultar en daños al producto.

ESPECIFICACIONES

PRESIÓN/SIFÓN

INTERNA/EXTERNA

PURGADO/SIN PURGADOR

1,40 mm (0,055")

50 PSI

40 A 50 PSI

3,5 PROMEDIO/8,6 CONTINUA

20,32 CM a 50 PSI/A 20,32 CM DE DISTANCIA DE

LA PIEZA DE TRABAJO

NPS de 1/4” (M)

NPS de 3/8” (M)

COMPONENTE

TIPO DE ALIMENTACIÓN

TIPO DE MEZCLA

TIPO DE PURGA

BOQUILLA DE LIQUIDO D.I.

PRESIÓN DE TRABAJO MÁX.

PRESIÓN DE TRABAJO

AIRE REQUERIDO

(SCFM a 50 PSI)

TAMAÑO DE LA MODALIDAD

DE ROCIADO

ENTRADA DE AIRE

ENTRADA DE LIQUIDO

ESPECIFICACIONES DEL PRODUCTO

33

EL RIESGO DE EXPONERSE A ESTOS QUÍMICOS VARÍA SEGÚN LA FRECUENCIA

CON QUE REALIZA ESTE TIPO DE TRABAJOS. PARA REDUCIR SU EXPOSICIÓN A

ESTAS SUSTANCIAS QUÍMICAS TRABAJE EN UN ÁREA BIEN VENTILADA Y UTILICE

UN EQUIPO DE SEGURIDAD APROBADO, COMO LAS MÁSCARAS PARA POLVO

ESPECIALMENTE DISEÑADAS PARA FILTRAR PARTÍCULAS MICROSCÓPICAS.

PELIGRO

Nunca rocíe a menos de 7,62 m del

compresor de aire. Si es posible, coloque

el compresor en otra habitación.

PRECAUCIÓN

Mantenga la manguera alejada de

objetos filosos. Una manguera de aire

comprimido rota puede provocar lesiones

personales. Revise las mangueras de

aire comprimido periódicamente y

reemplácelas si están dañadas o rotas.

Page 34

CONTENIDO DEL PAQUETE

DESCRIPCIÓN

Pistola de rociado para látex

Kit de limpieza para la

pistola de rociado

Filtro para la pistola de

rociado

Cinta adhesiva

Perilla de control de

modalidad de rociado

Perilla de control de líquido

Perilla lateral

Entrada de aire

Anillo de la tapa de aire

Gatillo

Recipiente

CANTIDAD

1

1

1

1

1

1

1

1

1

1

1

1

PIEZA

A

B

C

D

E

F

G

H

I

J

K

L

1

L

TERMINOLOGÍA DE LA PISTOLA DE ROCIADO

Mezcla interna

Proceso en el cual el aire y la pintura se mezclan al interior de la tapa de aire antes

de rociar. Este método es adecuado para pinturas de textura pesada y secado lento y

sólo se puede usar con el método de alimentación de presión. No use pinturas de

látex de secado rápido con la mezcla interna. La pintura se secará al interior y

obstruirá rápidamente la tapa de aire.

Mezcla externa

Proceso en el cual el aire y la pintura se mezclan al salir de la boquilla. Este tipo de

mezcla debería usarse con pinturas de látex de secado rápido y cuando es necesario

un acabado de alta calidad.

Alimentación de presión

Método de alimentación de material en el cual se presuriza un recipiente o un tanque

de pintura para forzar el material hacia la pistola. Se usan con este método tanto las

tapas de aire de mezcla interna como las de mezcla externa. La alimentación de

presión generalmente se usa con pinturas de látex de textura pesada o para

proyectos de gran tamaño.

34

B

C

D

A

E

F

G

H

I

J

K

L

M

Tapa de aire (mezcla externa)

Tapa de aire (mezcla interna)

Page 35

Uso de las tapas de aire

Mezcla interna: Generalmente se usa con pinturas de látex de

secado lento y de textura pesada y para una aplicación de

materiales más rápida. No use con pinturas de látex de secado

rápido, ya que obstruirán la abertura de la tapa de aire. Las tapas

de mezcla interna deben usarse con la operación de alimentación

de presión.

Mezcla externa: Se usa con pinturas de látex de secado rápido y

de textura liviana. Es ideal para un trabajo de acabado fino. Estas

tapas pueden usarse tanto con la alimentación por sifón como con

la alimentación de presión.

CONFIGURACIÓN DE LA PISTOLA DE ROCIADO

Tapa de aire de

mezcla interna

Tapa de aire de

mezcla externa

TERMINOLOGÍA DE LA PISTOLA DE ROCIADO

Alimentación por sifón

Método de alimentación de material en el cual la presión atmosférica crea un vacío

parcial para dirigir el material por sifón hacia la pistola. Sólo se utilizan tapas de aire

de mezcla externa con este método. La alimentación por sifón se usa con pinturas de

látex de textura liviana.

Purgador

En este modo, el aire pasa de forma continua por la pistola, incluso cuando no se

rocía. Este modo generalmente se usa cuando el aire es suministrado por un

compresor de aire de funcionamiento continuo, sin un tanque.

Sin purgador

En este modo, el aire sólo fluye cuando se jala el gatillo. Este tipo de operación se

usa con un compresor de aire equipado con un tanque o con un sistema de aire

grande instalado de fábrica. No use con un compresor de aire de funcionamiento

continuo sin un tanque.

Para cambiar el método de alimentación

Esta pistola de rociado para látex se puede usar

con alimentación de presión o con alimentación por

sifón. El método de alimentación se puede cambiar

fácilmente girando por completo la perilla lateral.

Debe estar seguro antes de usar el método de

alimentación

deseado. (Consulte la Figura 1)

P: Alimentación

de presión

S: Alimentación

por sifón

P

S

1

35

Page 36

Para convertir de sin purgador a purgador

(consulte la Figura 2)

1. Retire la pistola de rociado del suministro de aire.

2. Retire la perilla de control de líquido y el resorte

de la aguja de líquido.

3. Retire el resorte de la válvula de aire y guárdelo

en un lugar seguro para que pueda volver a

colocarlo cuando sea necesario volver a convertir

la pistola a la configuración sin purgador.

4. Inserte el resorte de la aguja de líquido y vuelva

a colocar la perilla de control de líquido.

PREPARACIÓN

CONFIGURACIÓN DE LA PISTOLA DE ROCIADO

Antes de comenzar el ensamblaje del producto, asegúrese de tener todas las piezas.

Compare las piezas con la lista del contenido del paquete. No intente ensamblar el

producto si falta alguna pieza o si éstas están dañadas. Comuníquese con el

Departamento de Servicio al Cliente para obtener piezas de repuesto.

Tiempo aproximado de ensamblaje: 5 a 10 minutos

Herramientas necesarias para el ensamblaje (no se incluyen): Llave inglesa

INSTRUCCIONES DE ENSAMBLAJE

1

1. Monte el filtro para la pistola de rociado (C) con

una mano sobre la entrada de aire (I) de la

pistola de rociado y conecte las roscas hembra

del filtro (C) con las roscas macho de la entrada

de aire (I). Use cinta selladora para roscas (no

se incluye) para lograr una conexión hermética.

(Consulte la Figura 1)

36

Resorte de la

válvula de aire

Perilla de control de

modalidad de rociado

Perilla de

control de

líquido

Resorte de la

aguja de líquido

2

Page 37

2

2. Conecte la manguera de aire comprimido con

las roscas macho del filtro (C). Use cinta

selladora para roscas (no se incluye) para lograr

una conexión hermética. (Consulte la Figura 2)

NOTA La presión de trabajo se refiere a la

presión de la manguera de aire cuando se jala del gatillo (K) de la pistola de rociado,

cuando ésta está en funcionamiento.

3. Ajuste la presión de trabajo entre 30 a 50 psi

dependiendo de la cantidad de flujo de líquido y

atomización que necesite. No exceda la presión

máxima de la pistola de rociado.

No ajuste demasiado al conectar el filtro (C)

con la entrada de aire (I) de la pistola de

rociado y con la manguera de aire comprimido.

ADVERTENCIA

INSTRUCCIONES DE FUNCIONAMIENTO

INSTRUCCIONES DE ENSAMBLAJE

37

NOTE

Antes de usar la pintura deseada en la pistola de rociado, rocíe con la pistola un

disolvente o un solvente compatible para remover contaminantes o residuos.

Antes de rociar, disuelva las pinturas de látex de forma adecuada en conformidad

con las instrucciones del fabricante de la pintura. Si no se puede disolver la pintura,

no podrá usar la pintura con la pistola de rociado.

Antes de aplicar pintura, asegúrese de eliminar todos los disolventes o solventes

del recipiente de rociado.

recipiente, de manera que si ocurren salpicaduras usted pueda recolectar

fácilmente la pintura para desecharla adecuadamente.

Se recomienda colocar un paño u otro dispositivo de recolección debajo del

Llene el recipiente (L) hasta 3/4 de su capacidad y encienda el compresor de aire.

Utilice un pedazo de cartón u otro material que no use para realizar una prueba y

ajústelo para obtener una mejor modalidad de rociado.

Pruebe la consistencia de la pintura realizando algunas aplicaciones en un cartón. Si

la pintura aun es demasiado espesa, agregue una pequeña cantidad de diluyente.

Respete las recomendaciones del fabricante al diluir la pintura.

Page 38

Tapa de aire

Anillo de la

tapa de aire

Modalidad de

rociado horizontal

Modalidad de

rociado vertical

1

2

3

1. Regule la dirección del rociado para que sea

horizontal o vertical, aflojando el anillo de la tapa

de aire (J) en 90°. Apriete con la mano el anillo de

la tapa de aire (J) después de regular la dirección.

(Consulte la Figura 1)

2. Ajuste el tamaño del rociado a la forma

deseada. Para una modalidad de rociado

completa, abra la perilla de control de rociado

(F) girándola en dirección contraria a las

manecillas del reloj. Para un modalidad de

rociado circular, gire la perilla de control de

modalidad de rociado (F) en la dirección de las

manecillas del reloj. (Consulte la Figura 2)

3. Gire por completo la perilla de control de líquido

(G) en la dirección de las manecillas del reloj

hasta cerrarla. (Consulte la Figura 3)

INSTRUCCIONES DE FUNCIONAMIENTO

38

El rociador de pintura no rociará adecuadamente

a menos que la dirección del ventilador sea

horizontal o vertical.

ADVERTENCIA

Page 39

Pintura demasiado fina

Correcto

Pintura demasiado gruesa

Consistencia de la modalidad de

rociado (atomización)

15,24 a

22,86 cm

4

5

4. Con la pistola a una distancia entre 15, 24 a 22,

86 cm de la pieza de trabajo, rocíe un chorro

corto mientras gira la perilla de líquido en

dirección contraria de las manecillas del reloj.

Observe la modalidad de rociado en la pieza de

trabajo y ajuste la perilla de control de líquido (G)

hasta obtener la modalidad o la atomización

deseada. Si el rociado es demasiado fino, (esto

ocurre cuando se utiliza demasiado aire en

relación a la cantidad de pintura que se rocía),

reduzca la presión del aire o abra la perilla de

control de líquido (G) para rociar más pintura.

Si el rociado es demasiado grueso o si salpican

gotas de pintura, reduzca la cantidad de pintura

con la perilla de control de líquido (G) o diluya

más la pintura. (Consulte la Figura 4)

5. Mantenga la pistola en el ángulo correcto

mientras rocía, como se muestra en la imagen.

(Consulte la Figura

5)

NOTA La perilla de control de liquido (G) se

puede girar en la dirección de las manecillas del

reloj o viceversa para regular de forma precisa la

consistencia de la modalidad de rociado. Antes

de rociar la pieza de trabajo, practique por unos

minutos con un cartón para asegurarse de que

el tamaño y la consistencia de la modalidad de

rociado estén ajustados correctamente.

NOTA Siempre mueva la pistola al rociar. Si deja

de mover la pistola en la mitad de la aplicación, la

pintura se acumulará y se escurrirá. No abanique

la pistola de lado a lado al rociar. Se acumulará

pintura en el centro de la aplicación y se creará

una capa delgada en cada extremo.

(Consulte la Figura 6)

INSTRUCCIONES DE FUNCIONAMIENTO

Capa

delgada

Capa

gruesa

Capa

delgada

INCORRECTO

6

39

Page 40

8

6. Presione el gatillo de forma adecuada. Mueva la

pistola al comienzo de la aplicación antes de

presionar el gatillo (K) y suelte el gatillo (K)

antes de detener el movimiento de la pistola al

final de la aplicación. Este procedimiento

impregnará y mezclará cada aplicación con la

siguiente, sin producir superposición o desnivel.

(Consulte la Figura 7)

7. Superponga las aplicaciones sólo lo suficiente

para obtener una capa pareja.

(consulte la Figura 8).

8. Coloque un pedazo de cartón en los bordes de

la pieza de trabajo para contener el exceso de

rociado y proteger otras superficies. Use cinta adhesiva (D) para cubrir otras áreas si

es necesario.

NOTA La cantidad de pintura que se aplica puede

variar dependiendo de la velocidad de aplicación,

la distancia de la pieza de trabajo y el ajuste de la

perilla de control de líquido (G). Si la velocidad de

aplicación es demasiado lenta, la pintura quedará

húmeda en la pieza de trabajo y se puede escurrir.

Si la velocidad de aplicación es demasiado rápida,

la pintura se secará en la pieza de trabajo y

quedará dispareja.

NOTA Si aplica dos capas delgadas de pintura en

vez de una capa gruesa, obtendrá mejores

resultados de rociado y es menos probable que la

pintura se escurra.

CUIDADO Y MANTENIMIENTO

Los códigos locales pueden solicitar métodos y equipos de limpieza específicos.

Respete los códigos locales y las recomendaciones del fabricante sobre el uso y la

eliminación de pinturas en aerosol y solventes.

Limpieza diaria

NOTA Limpie la pistola de rociado inmediatamente después de usarla. La pintura y