Page 1

AB14871

Questions, problems, missing parts? Before returning to your retailer,

please call our Customer Service Department at 1-888-3KOBALT,

8:00 a.m. – 8:00 p.m. EST, Monday – Friday.

17

34

Page 2

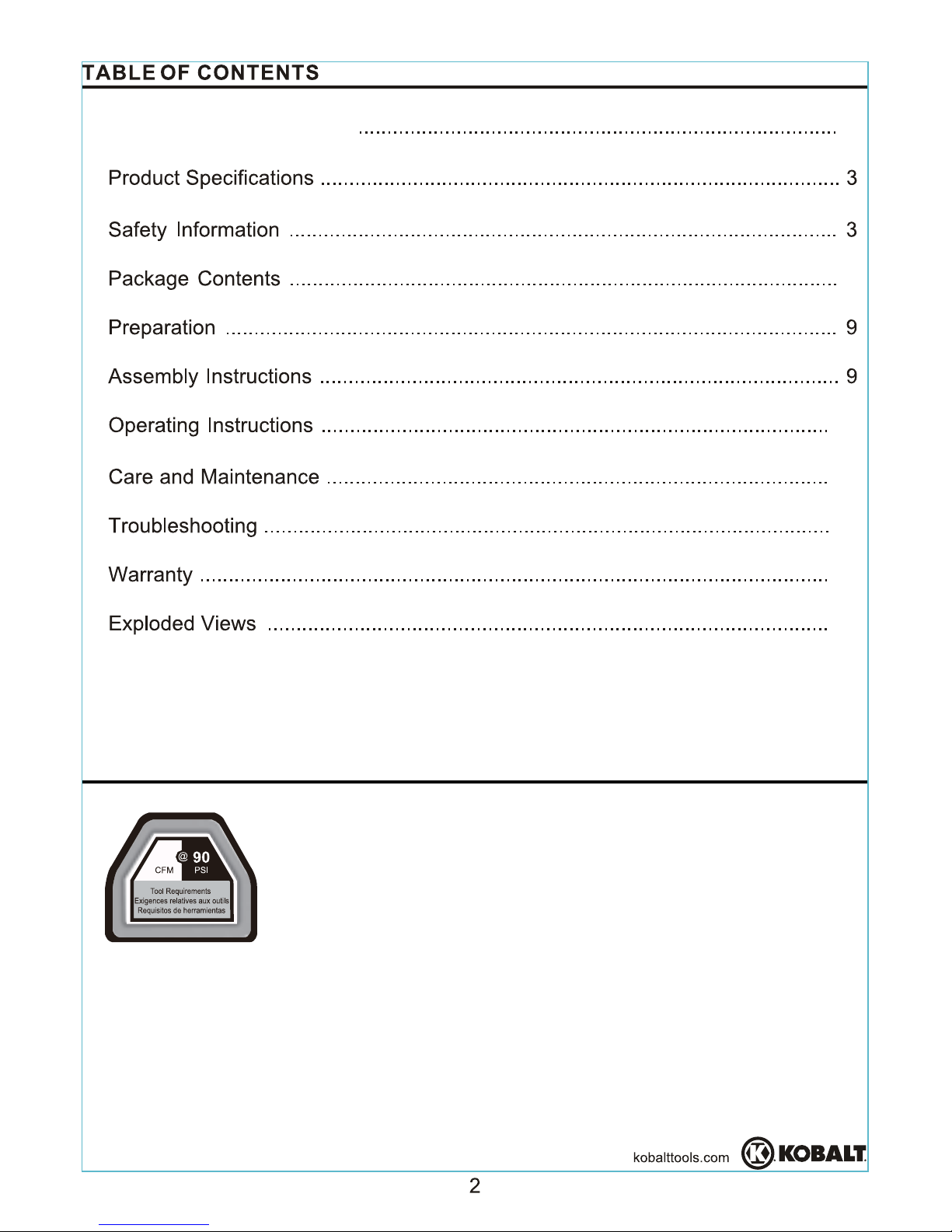

COMPRESSOR REQUIREMENTS

Compressor Requirements

2

8.5

9

16

15

15

14

12

IMPORTANT: To operate correctly, this tool requires airflow of at least 8.5 cubic feet per

minute (CFM) at 90 pounds per Square Inch (PSI) at the tool.

Air hoses may cause loss in pressure up to 15 PSI, requiring a higher compressor output to

compensate and maintain required pressure at the tool. Check the specifications of your air

compressor to be sure that it can support both the CFM and PSI required by this specific tool.

Page 3

8.5

Please read and understand this entire manual before attempting to assemble, operate

or maintain this product. If you have any questions, please call our Customer Service

Department at 1-888-3KOBALT, 8:00 a.m. – 8:00 p.m. EST, Monday – Friday.

Improper operation or maintenance of this tool could result in serious injury and

property damage. Read and understand all warnings and operation instructions

before using this tool. When using any tool, basic safety precautions should always

be followed to reduce the risk of personal injury. Use each tool for its intended

function only. Do not use this product in unsafe work conditions. It is always

recommended to keep a fire extinguisher and first aid kit near work areas.

Some dust created by paint spraying, power sanding, sawing, grinding, drilling and

other related activities is known to the State of California to cause cancer, birth

defects and other reproductive harm. A listing of chemicals can be obtained from

www.oehha.ca.gov under proposition 65.

Some examples of these chemicals are:

• Lead from lead based paints

• Crystalline silica from bricks, cement and other masonry products

•

Arsenic and chromium from chemically treated lumber

Your risk from these exposures varies, depending on how often you do this type of

work. To reduce your exposure to these chemicals, work in a well ventilated area

and wear appropriate/approved safety equipment such as respirators or dust masks

which are specially designed to filter microscopic particles.

FAILURE TO OBSERVE AND FOLLOW SAFETY INSTRUCTIONS COULD

RESULT IN INJURY OR DEATH.

Page 4

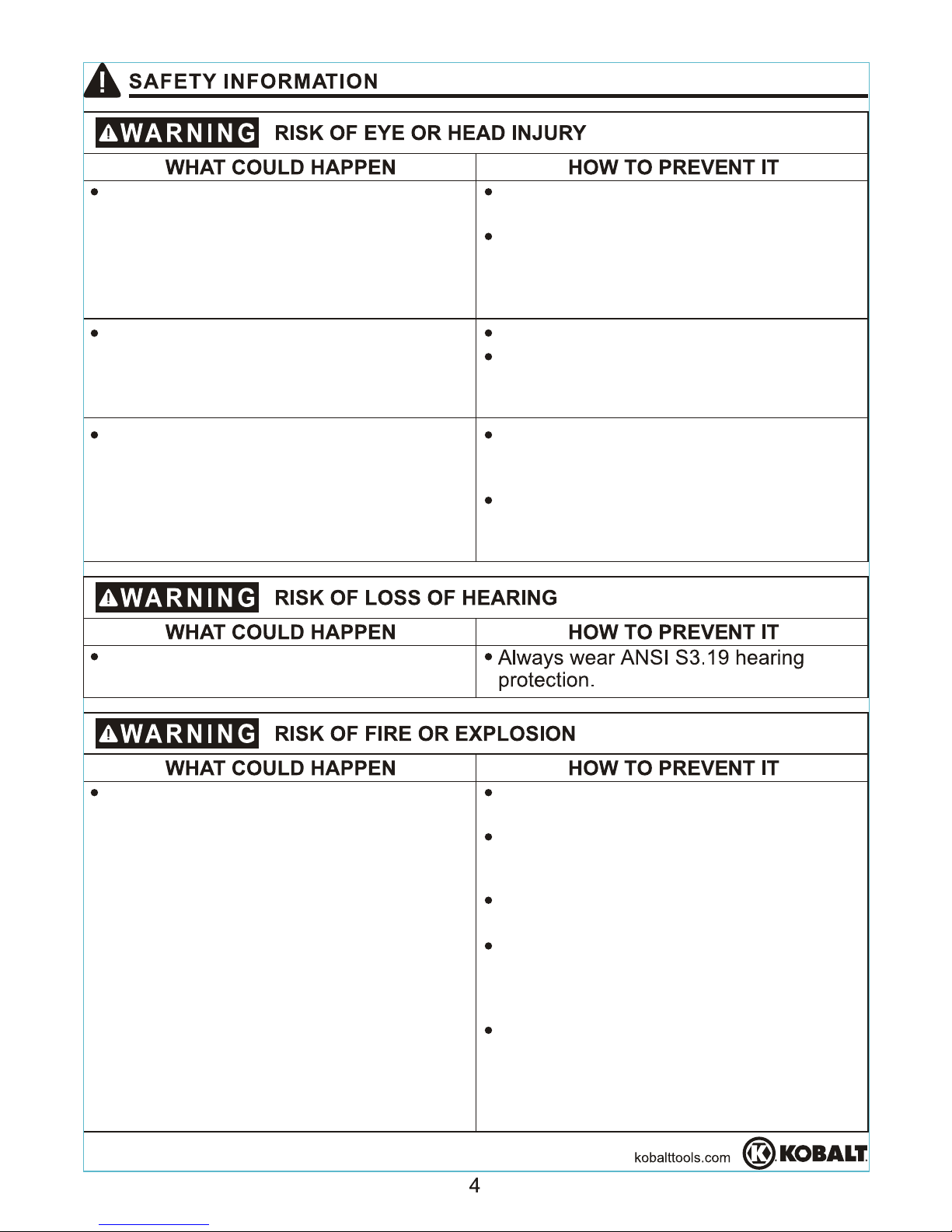

This air powered tool is capable of

propelling materials such as fasteners,

metal chips, sawdust and other debris at

high speed which could result in serious

injury.

Always wear ANSI approved Z87.1

safety glasses with side shields.

Never leave a pressurized tool unattended.

Disconnect tool from air supply when tool

is not in use or when changing accessories

to prevent accidental operation.

Compressed air can be hazardous,

propelling objects or particles that can

cause injury into soft tissues such as

eyes and ears.

Never direct air at yourself or anyone else.

For additional protection, use an approved

face shield in addition to safety glasses.

Tool attachments can become loose

or break and fly apart, becoming

projectiles or propelling other objects

at the operator or bystanders in the work

area.

Make sure all attachments are properly

assembled and securely fastened before

use.

Always use the tool at a safe distance

from others in the work area. Maintain

awareness of work area safety at all times.

Exposure to noise produced by air tools

can lead to permanent hearing loss.

This tool is capable of generating sparks

which can result in ignition of flammable

materials.

Work in a clean, well ventilated area

free of combustible materials.

Never operate tools near flammable

substances such as gasoline, naphtha,

cleaning solvents, etc.

This tool is not recommended for use in

explosive atmospheres or underwater.

Never use oxygen, carbon dioxide or

other bottled gasses as a power source

for air tools. Use only clean, dry air at

the specified pressure.

Wiping or cleaning rags and other

flammable waste materials that may have

been used on the tool must be placed in

a tightly closed metal container, and

disposed of in a proper manner.

Page 5

Air tools which contain moving elements

or drive other moving parts (such as

impact sockets) can become entangled

in hair, clothing, jewelry and other loose

objects, resulting in severe injury.

Do not wear loose clothing, jewelry, or

anything that may get caught or tangled

in the tool, hose or workpiece.

Always keep hands and body parts

away from moving parts.

Always wear properly fitted clothing and

other properly fitted safety equipment

when using tools.

Whipping hoses can cause serious

injury. Always check for damaged or

loose hose fittings before using tools.

Air tools are capable of causing

serious injury if operated improperly,

or in a manner for which the tool is

not intended. Accessories can

become extremely hot through

friction where they contact the

workpiece.

Wear gloves when using tools.

Keep the working part of the tool away

from hands and body.

Do not touch accessories with bare

hands during or immediately after use.

This tool is NOT electrically insulated.

Contact with a “live” wire will also make

exposed metal parts of the tool “live”

and can result in electrical shock,

electrocution injury or death.

Never use air tools where they may

come in contact with energized

electrical wiring.

Avoid body contact with grounded

surfaces such as pipes, radiators,

refrigerators, and ranges. There is

an increased risk of electrical shock if

your body is grounded.

Whenever possible, it is recommended

that electrically non-conductive clothing

and non-skid foot wear be worn when

using tools.

Air tool accessories such as impact

sockets or drills that come into contact

with hidden electrical wiring could

cause electrocution or death.

Thoroughly investigate workpieces and

work areas for possible hidden wiring

before performing work.

Page 6

An unattended tool could be activated

by unauthorized/untrained persons,

leading to their injury or injury to others.

Remove air hose when the tool is not in

use and store tool in a secure location

away from reach of children and

untrained users.

Air tools can propel fasteners,

loose/broken accessories or other

objects throughout the work area.

Never run the tool off the workpiece.

Maintain awareness of work area safety

at all times. Always be aware of other

people around the work area to ensure

safety.

Use only parts, fasteners and accessories

recommended by the manufacturer.

Keep work area clean, free of clutter and

well lit. Do not allow children to operate

any tool, and keep children away from

work areas.

Wrenches and adjusting keys that are

left attached to a rotating part of the tool

may fly off and increase the risk of

personal injury.

Always remove and secure adjusting

keys and wrenches before operating

the tool.

Using inflator nozzles for duster

applications can cause serious injury.

DO NOT use inflator nozzles for duster

applications. Do not use inflator nozzles

for any use other than the one intended.

Air tools can become activated by

accident while being handled, during

accessory changes, tool changes,

maintenance or repair.

Disconnect the tool from the air supply

during accessory changes, tool changes,

maintenance or repair.

Never carry the tool by the air hose.

Never yank the air hose to disconnect it

from the tool or the air supply.

Always carry the tool by the handle.

Avoid unintentional operation. Never carry

the tool with the trigger depressed or

engaged. Do not lock, tape or wire the

trigger for continuous operation.

Only an authorized service representative

should do repair servicing.

Air tools can cause the workpiece to

move upon contact, leading to injury.

Always make sure the workpiece is

secure. Use clamps or other devices to

prevent movement.

Page 7

Loss of control of the tool can lead to

operator injury or injury to others in the

work area.

Always shut off the air supply and

release/drain air pressure from the hose

before changing accessories,

making repairs. When tool is not in

use, disconnect it from the air supply and

store the tool in a safe location.

Never operate tools while using drugs or

alcohol.

Do not overreach or stretch to operate

the tool.

Keep proper footing at all times when

handling tools. Slipping, tripping and/or

falling are major causes of serious injury

and or death.

Keep tool handles dry, clean and free

from oil/grease.

Be aware of excess air hose, electrical

power sources and other obstacles or

hazards in the work area.

Stay alert. Watch what you are doing.

Use common sense. Do not operate

tools when you are tired.

Operators must be able to easily handle

the entire weight of the tool in operation,

to maintain full control of the tool 100%

of the time.

There is a risk of bursting if the tool is

damaged.

Check for misalignment or binding of

moving parts, broken parts and

other conditions that affect safe

tool operation.

Poor quality, improper or damaged

attachments can detach or fly apart

during operation, sending projectiles

through the work area and causing

serious injury.

Never use a tool which has been

dropped, damaged or appears to

malfunction. Never use tools which are

leaking air or have missing parts.

Remove damaged or malfunctioning

tools from the workplace immediately.

Do not use pressure exceeding the

recommended operating pressure of

any of the parts (hoses, fittings, etc) in

the system.

Page 8

Use only impact-grade sockets with air

impact tools. Always use attachments

rated for the speed of the tool. Do not

modify tools or attachments.

Do not apply excessive force to the tool;

let the tool perform the work.

Follow lubrication instructions for best

and safest operation.

Always follow assembly, operation,

maintenance and repair instructions.

Improperly maintained tools and

accessories can cause serious injury.

Maintain the tool and accessories with

care. Do not abuse hoses or connectors.

Keep hoses away from heat, oil and

sharp edges. Always check air hoses for

weak or worn connections before each

use and make certain that all connections

are secure.

Keep tools clean and properly oiled for

best and safest performance.

Using an accessory not intended for a

specific tool increases the risk of injury

to the operator and everyone else in

the work area.

Always use accessories and

attachments designed for the tool and

the work at hand. Do not improvise or

modify tools or accessories.

Repetitive motions, awkward positions

and exposure to vibration can be

harmful to hands and arms.

Discontinue use of tool if discomfort,

tingling feeling or pain occurs. Consult

a physician before resuming use if any

of these symptoms occur.

INHALATION HAZARD

Abrasive tools such as grinders,

sanders and cut-off tools generate dust

and abrasive materials which can be

harmful to the lungs and respiratory

system. Paint spraying tools generate

paint vapors which can be harmful to the

lungs and respiratory system.

Always wear a properly fitting facemask

or respirator rated for the application

when using such tools.

Some materials such as adhesives and

tar give off vapors which could cause

serious injury with prolonged exposure.

Always work in a clean, dry, well-ventilated

area. Be aware of chemicals in the work

area and read all Materials Safety Data

Sheets (MSDS) for the materials and/or

chemicals that may be present.

Page 9

9

Before assembling this tool, make sure all parts are present. Compare parts with

package contents list. If any part is missing or damaged, do not attempt to assemble

the tool.

Tools and Materials Required for Assembly (not included):

•

Adjustable wrench

•

1/4 in. male plug

•

Thread sealant tape

•

Air tool oil (NOTE: Air tool oil is NOT compressor oil. Use of compressor oil in this tool

can damage the tool and/or shorten tool life. Use only air tool oil in this tool.)

1. Remove plastic air inlet protective cap from air

inlet (E) as shown in Fig. 1.

Page 10

2. Prepare a 1/4 in. male plug (not included) by

applying sealant tape to the threading, wrapping

clockwise. Screw threaded male air plug by

hand into air inlet as shown in Fig. 2 and tighten

with a wrench (not included) for an airtight

connection. DO NOT OVERTIGHTEN.

NOTE: Sealant tape must be used on this

connection.

3. Select the correct impact socket (not included)

for the threaded fastener to be tightened or

loosened and mount it onto the anvil (B) until it

clicks into place as shown in Fig. 3.

4. If necessary for a longer reach, mount an

extension bar (not provided) onto the anvil until

it clicks into place, then mount the socket on the

adapter as shown in Fig. 4.

Use only adapters and sockets with a torque

rating equal to or greater than the tool itself.

Always make sure adapters and sockets are

properly mounted and secure before using

the tool. Loose attachments can break or fly

off, causing serious injury to the operator or

bystanders in the work area. Always follow

all manufacturers’ specifications for proper

attachment and use.

Page 11

6. Make sure compressor air supply hose has

correct fittings installed at each end: male

coupler goes to compressor, 1/4 in. female

coupler matches up to 1/4 in. male plug installed

on the tool.

7. Connect the air supply hose to the male air

plug as shown in Fig. 6, making sure it is

completely seated and secure. Set the working

pressure at 90 PSI for best tool performance.

NOTE: To operate correctly, this tool requires

airflow of at least 8.5 cubic feet per

minute (CFM) at 90 pounds per square

inch (PSI) at the tool.

11

5. Place 2 – 3 drops of air tool oil (not included)

into the male air plug before each use, as

shown in Fig. 5.

NOTE: Proper lubrication is EXTREMELY

important to assure proper tool performance and

avoid tool damage. ALWAYS lubricate the tool

before each use if not using an in-line oiler.

Page 12

1. This tool features a torque setting switch (D)

which has two functions:

•

Control the direction of spin: Forward (“F”) to

tighten or Reverse (“R”) to loosen the fastener

•

Set the amount of torque applied to the

fastener: LO, MED or HI

The direction of spin is controlled by pushing the

switch to the left or right, through the tool body, so

it extends further from the tool on one side.

Indicators on the back of the tool show which

direction to push the switch. (See Fig. 2 and Fig. 3

on the next page.)

•

When the switch extends further on the left side,

the direction of spin is Forward (“F”) or clockwise.

•

When the switch extends further on the right side, the direction of spin is Reverse (“R”)

or counterclockwise.

The amount of torque is controlled by turning the switch on the extended side until it

clicks into place at one of the settings: LO, MED and HI. To control the amount of torque,

turn the switch on the extended side while reading the indicator on the opposite side.

Choose the correct torque setting to mount and remove fasteners properly on the

workpiece as shown in Fig 1.

Setting Torque in Forward (“F”) Torque in Reverse (“R”)

LO

MED

HI

NOTE: Impact wrenches are NOT torque wrenches. Fasteners requiring a specific

torque must be checked with an appropriate torque meter after fitting on the workpiece

with an impact wrench.

12

Page 13

2. To install and tighten a threaded fastener, push

the torque setting switch to the left so it extends

further out on the left side of the tool. Then turn

the LEFT switch while reading the torque

settings on the RIGHT side of the tool until it

clicks into place at the desired setting: the notch

on the RIGHT side switch will point to the

setting LO, MED or HI. Place the socket over

the threaded fastener on the workpiece, apply

pressure and press the trigger. The tool anvil

(B) will spin clockwise to tighten the treaded

fastener down as shown in Fig 2.

3. To loosen or remove a threaded fastener, push

the torque setting switch to the right so it

extends further out on the right side of the tool.

Then turn the RIGHT switch while reading the

torque settings on the LEFT side of the tool

until it clicks into place at the desired setting:

the notch on the LEFT side switch will point to

the setting LO, MED or HI. Place the socket

over the threaded fastener on the workpiece,

apply pressure and press the trigger. The tool

anvil will spin counterclockwise to loosen the

threaded fastener up as shown in Fig 3.

Always make sure the workpiece is secure. Never run the tool off the workpiece.

Do not apply excessive force to the tool; let the tool perform the work.

NOTE: This tool has a flush-type grease fitting. The tool should be greased generously

following every 48 hours of use. Consult your local retailer for further assistance in

selecting a grease gun and grease to use with this tool.

13

R

F

2

3

R

F

Page 14

14

ALWAYS DISCONNECT TOOL FROM THE AIR SUPPLY BEFORE PERFORMING

ANY MAINTENANCE ON THE TOOL.

Always make sure the tool is properly lubricated during operation. Proper lubrication is

shown in this instruction manual.

An in-line oiler (not included) is recommended to help increase tool life and keep the

tool properly lubricated. The in-line oiler should be regularly checked and filled with air

tool oil as needed. Proper adjustment of the in-line oiler can be performed by placing a

sheet of paper next to the tool’s exhaust ports while holding the throttle completely

open for 30 seconds. When a light stain of oil collects on the paper, the oiler is properly

adjusted. Excessive amounts of oil should be avoided.

Clean the entire tool with a cotton rag after each use. If storing the tool for an extended

period, it should be lubricated and run for approximately 30 seconds to ensure oil has

been evenly distributed throughout the tool. Always store tools in a clean, dry

environment away from the reach of children.

Recommended lubricants: air-tool oil or any other high grade turbine oil

containing moisture absorbent, rust inhibitors, metal wetting agents and an EP

(Extreme Pressure) additive. Consult your local retailer for further assistance

in selecting air tool oil best suited for proper lubrication.

STORAGE:

Tool must be well cleaned and lightly lubricated before

storing.

Store tool in a dry, safe place out of the reach of children.

Page 15

15

If the tool runs slowly or will not operate, check these possible problems and take the

required corrective action:

POSSIBLE PROBLEM SOLUTION

Grit or gum in tool. Flush the tool with air-tool oil or gum solvent.

No oil in tool. Lubricate the tool.

Low air pressure.

Adjust the regulator on the tool to the maximum setting.

Adjust the compressor regulator to tool maximum of 90 PSI.

NOTE: Air hoses may cause up to 15 PSI loss in

pressure, so you may need to set a higher compressor

output to maintain the required pressure at the tool.

Air hose leaks. Tighten and seal hose fittings if leaks are found. Use

sealing tape.

Pressure drops. Be sure the hose is the proper size. Long hoses or tools

using large volumes of air may require an internal

diameter of 1/2 in. I.D. or larger, depending on total

hose length.

Do not use multiple hoses connected together with

quick-connect fittings. This causes additional loss of

pressure and reduces the tool power. Use single hoses

of the proper length.

Worn rotor blade. Replace rotor blade.

Moisture blowing out of

tool exhaust.

Water in compressor tank; drain tank. (See air

compressor manual.)

Oil the tool and run until no water is evident. Oil the tool

again and run 1 – 2 seconds.

This tool is warranted by the manufacturer to the original purchaser from the original

purchase date for three (3) years subject to the warranty coverage described herein.

This tool is warranted to the original user to be free from defect in material and

workmanship. If you believe that a tool is defective, return the tool, with proper proof

of purchase to the point of purchase. If it is determined that the tool is defective and

covered by this warranty, the distributor will replace the tool or refund the

purchase price.

This warranty is void if: defects in materials or workmanship or damages result from

repairs or alterations which have been made or attempted by others or the

unauthorized use of nonconforming parts; the damage is due to normal wear, damage

is due to abuse (including overloading of the tool beyond capacity), improper

maintenance, neglect or accident; or the damage is due to the use of the tool after

partial failure or use with improper accessories or unauthorized repair or alteration.

This warranty gives you specific legal rights, and you may also have other rights that

vary from state to state.

For warranty questions, call our Customer Service Department at 1-888-3KOBALT,

8:00 a.m. – 8:00 p.m. EST, Monday – Friday.

Page 16

16

Loading...

Loading...