Page 1

MULTI-PURPOSE

4-IN. SAW

MODEL #KMC 124B-03

ATTACH YOUR RECEIPT HERE

Serial Number Purchase Date

Questions, problems, missing parts? Before returning to your retailer, call our customer

service department at 1-888-3KOBALT (1-888-356-2258), 8 a.m. - 8 p.m., EST,

Monday - Friday.

JW1898

ITEM #0961863

Español p. 19

Page 2

TABLE OF CONTENTS

Product Specications ......................................................................................2

Package Contents ............................................................................................ 3

Safety Information ............................................................................................ 4

Preparation .....................................................................................................10

Operating Instructions .................................................................................... 11

Care and Maintenance ................................................................................... 17

Troubleshooting..............................................................................................18

Warranty ........................................................................................................ 18

PRODUCT SPECIFICATIONS

COMPONENT SPECIFICATION

Rated voltage 24 V d.c.

Rated speed

Max. abrasive wheel size 4 in. (100 mm) dia.

Wheel arbor 7/16 in. (11 mm)

Max. cutting depth 7/8 in.

12,000/min

3/64 in. (1.2 mm) thickness

2

Page 3

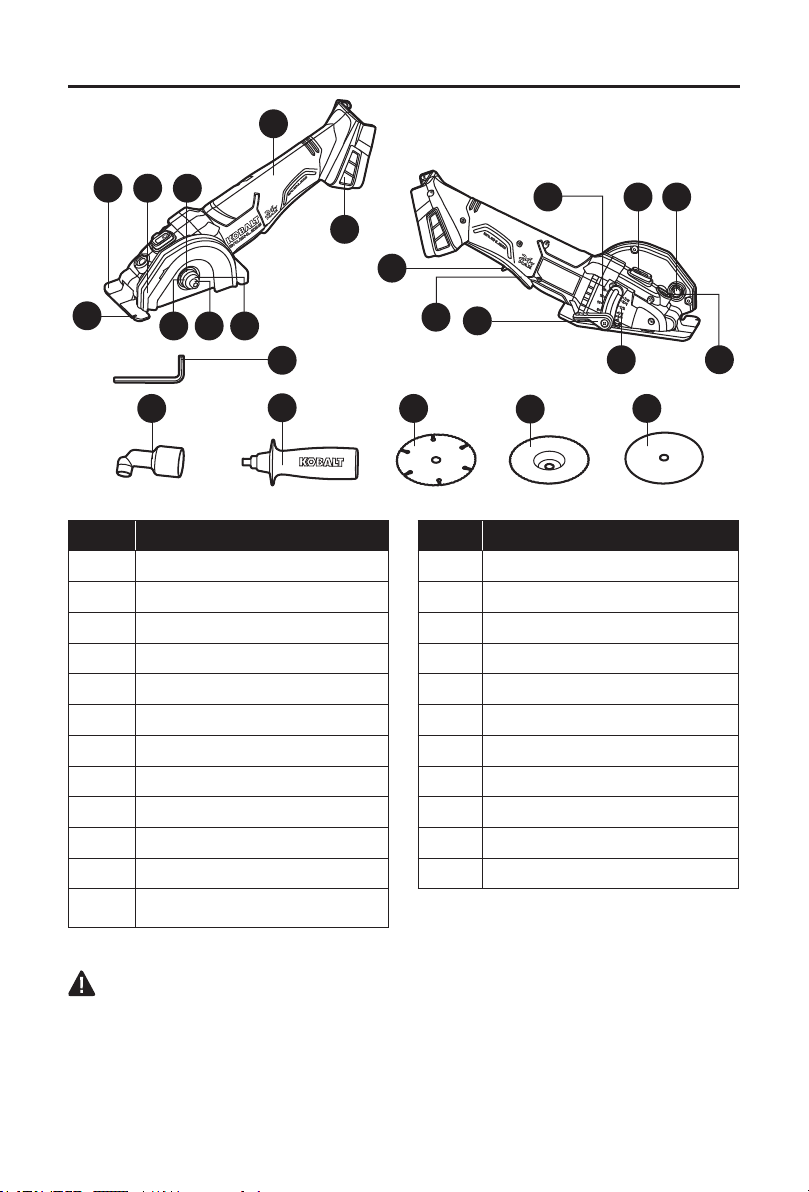

PACKAGE CONTENTS

C

A

D

I

M

H

J

Q P

B

PART DESCRIPTION PART DESCRIPTION

A Base plate M Depth indicator

B Guide notch N Depth scale

C Wheel guard O Auxiliary-handle socket

D Inner ange P Dust socket

E Outer ange Q Spindle-lock button

F Blade bolt R Wrench

G Washer S Dust-exhaust Adapter

H Inlet-vent guard T Auxiliary handle

I Main handle U Wood Cutting Wheel

J Lock-off lever V Wood Flush Cut Wheel

K Paddle switch W Metal Cut-off Wheel

E F G

S

R

T

K

L

U

V

N

W

O

L Depth-lock lever

WARNING

• Remove the tool from the package and examine it carefully. Do not discard the carton or any

packaging material until all parts have been examined.

• If any part of the tool is missing or damaged, do not attach the battery pack or use the tool

until the part has been repaired or replaced. Failure to heed this warning could result in

serious injury.

3

Page 4

SAFETY INFORMATION

Please read and understand this entire manual before attempting to assemble or operate

this product. If you have any questions regarding the product, please call customer service at

1-888-3KOBALT, 8 a.m. - 8 p.m., EST, Monday - Friday.

WARNING

• The operation of any power tool can result in foreign objects being thrown into your eyes,

which can result in severe eye damage. Before beginning power-tool operation, always wear

safety goggles or safety glasses with side shields and a full-face shield, when needed. It is

recommended to use a wide vision safety mask over eyeglasses or standard safety glasses

with shields. Always use eye protection marked to comply with ANSI Z87.1.

• Some dust created by power sanding, sawing, grinding, drilling, and other construction

activities contains chemicals known to the state of California to cause cancer, birth defects,

or other reproductive harm. Some examples of these chemicals are:

– Lead from lead-based paints

– Crystalline silica from bricks, cement, and other masonry products

– Arsenic and chromium from chemically-treated lumber

• Your risk from these exposures varies, depending upon how often you do this type of work.

To reduce your exposure to these chemicals:

– Work in a well-ventilated area.

– Work with approved safety equipment, such as dust masks that are specially designed to

lter out microscopic particles.

– Avoid prolonged contact with dust from power sanding, sawing, grinding, drilling, and

other construction activities. Wear protective clothing and wash exposed areas with soap

and water. Allowing dust to get into your mouth or eyes or to lie on the skin may promote

absorption of harmful chemicals.

• ALWAYS use safety glasses. Everyday eyeglasses are NOT safety glasses. Also use face

or dust mask if cutting operation is dusty.

• Always wear proper personal hearing protection that conforms to ANSI during use.

Under some conditions and duration of use, noise from this product may contribute to

hearing loss.

Know the Tool

To operate this tool, carefully read this manual and all labels afxed to the tool before using it.

Keep this manual available for future reference.

Important

This tool should be serviced only by a qualied service technician.

Read All Instructions Thoroughly

4

Page 5

SAFETY INFORMATION

Some of the following symbols may be used on this tool. Please study them and their meaning.

Proper interpretation of these symbols will allow you to operate the tool better and more safely.

SYMBOL DEFINITION SYMBOL DEFINITION

V Volts n Rated Speed

or d.c.

General Power Tool Safety Warnings

WARNING

• Read all safety warnings and all instructions. Failure to follow the warnings and

instructions may result in electric shock, re and/or serious injury.

Save all warnings and instructions for future reference

The term “power tool” in the warnings refers to your mains-operated (corded) power tool or

battery-operated (cordless) power tool.

Work Area Safety

• Keep work area clean and well lit. Cluttered or dark areas invite accidents.

• Do not operate power tools in explosive atmospheres, such as in the presence of

ammable liquids, gases or dust. Power tools create sparks, which may ignite the dust

or fumes.

• Keep children and bystanders away while operating a power tool. Distractions can

cause you to lose control.

Electrical Safety

• Power tool plugs must match the outlet. Never modify the plug in any way. Do not use

any adaptor plugs with earthed (grounded) power tools. Unmodied plugs and matching

outlets will reduce the risk of electric shock.

• Avoid body contact with earthed or grounded surfaces such as pipes, radiators, range

sand refrigerators. There is an increased risk of electric shock if your body is earthed or

grounded.

• Do not expose power tools to rain or wet conditions. Water entering a power tool will

increase the risk of electric shock.

• Do not abuse the cord. Never use the cord for carrying, pulling or unplugging the

power tool. Keep cord away from heat, oil, sharp edges or moving parts. Damaged or

entangled cords increase the risk of electric shock.

• When operating a power tool outdoors, use an extension cord suitable for outdoor use.

Use of a cord suitable for outdoor use reduces the risk of electric shock.

• If operating a power tools in a damp location is unavoidable, use a ground-fault circuit

interrupter (GFCI) protected supply. Use of a GFCI reduces the risk of electric shock.

Direct Current /min Revolutions per Minute

WARNING - Always

wear eye protection.

WARNING – To reduce

the risk of injury, user

must read instruction

manual.

5

Spindle Thread Size

A danger, warning or caution.

It means ‘Attention! Your

safety is involved.’

Page 6

SAFETY INFORMATION

Personal Safety

• Stay alert, watch what you are doing and use common sense when operating a power

tool. Do not use a power tool while you are tired or under the inuence of drugs,

alcohol or medication. A moment of inattention while operating power tools may result in

serious personal injury.

• Use personal protective equipment. Always wear eye protection. Protective equipment

such as dust mask, non-skid safety shoes, hard hat, or hearing protection, used for

appropriate conditions, will reduce personal injuries.

• Prevent unintentional starting. Ensure the switch is in the off-position before

connecting to power source and/or battery pack, picking up or carrying the tool.

Carrying power tools with your nger on the switch or energizing power tools that have the

switch on invites accidents.

• Remove any adjusting key or wrench before turning the power tool on. A wrench or a

key left attached to a rotating part of the power tool may result in personal injury.

• Do not overreach. Keep proper footing and balance at all times. This enables better

control of the power tool in unexpected situations.

• Dress properly. Do not wear loose clothing or jewelry. Keep your hair, clothing and

gloves away from moving parts. Loose clothes, jewelry or long hair can be caught in

moving parts.

• If devices are provided for the connection of dust extraction and collection facilities,

ensure that these are connected and properly used. Use of these devices can reduce

dust-related hazards.

Power Tool Use and Care

• Do not force the power tool. Use the correct power tool for your application. The

correct power tool will do the job better and safer at the rate for which it was designed.

• Do not use the power tool if the switch does not turn it on and off. Any power tool that

cannot be controlled with the switch is dangerous and must be repaired.

• Disconnect the plug from the power source and/or the battery pack from the power

tool before making any adjustments, changing accessories, or storing power tools.

Such preventive safety measures reduce the risk of starting the power tool accidentally.

• Store idle power tools out of the reach of children and do not allow persons

unfamiliar with the power tool or these instructions to operate the power tool. Power

tools are dangerous in the hands of untrained users.

• Maintain power tools. Check for misalignment or binding of moving parts, breakage

of parts and any other condition that may affect the power tool’s operation. If

damaged, have the power tool repaired before use. Many accidents are caused by

poorly maintained power tools.

• Keep cutting tools sharp and clean. Properly maintained cutting tools with sharp cutting

edges are less likely to bind and are easier to control.

• Use the power tool, accessories, tool bits, etc., in accordance with these instructions,

taking into account the working conditions and the work to be performed. Use of the

power tool for operations different from those intended could result in a hazardous situation.

Battery Tool Use and Care

• Recharge only with the charger specied by the manufacturer. A charger that is suitable

for one type of battery pack may create a risk of re when used with another battery pack.

• Use power tools only with specically designated battery packs. Use of any other

battery packs may create a risk of injury and re.

6

Page 7

SAFETY INFORMATION

• When battery pack is not in use, keep it away from other metal objects, like paper clips,

coins, keys, nails, screws or other small metal objects, that can make a connection

from one terminal to another. Shorting the battery terminals together may cause burns or a

re.

• Under abusive conditions, liquid may be ejected from the battery; avoid contact. If

contact accidentally occurs, ush with water. If liquid contacts eyes, additionally seek

medical help. Liquid ejected from the battery may cause irritation or burns.

Service

• Have your power tool serviced by a qualied repair person using only identical

replacement parts. This will ensure that the safety of the power tool is maintained.

Safety instructions for all operations

Safety Warnings Common for Grinding, Polishing and Abrasive Cutting-Off Operations

• This power tool is intended to function as a grinder, polisher or cut-off tool. Read all

safety warnings, instructions, illustrations and specications provided with this power

tool. Failure to follow all instructions listed below may result in electric shock, re and/or

serious injury.

• Operations such as sanding and wire brushing are not recommended to be performed

with this power tool. Operations for which the power tool was not designed may create a

hazard and cause personal injury.

• Do not use accessories which are not specically designed and recommended by the

tool manufacturer. Just because the accessory can be attached to your power tool, it does

not ensure safe operation.

• The rated speed of the accessory must be at least equal to the maximum speed marked

on the power tool. Accessories running faster than their rated speed can break and y apart.

• The outside diameter and the thickness of your accessory must be within the capacity

rating of your power tool. Incorrectly sized accessories cannot be adequately guarded or

controlled.

• Threaded mounting of accessories must match the grinder spindle thread. For

accessories mounted by anges, the arbour hole of the accessory must t the locating

diameter of the ange. Accessories that do not match the mounting hardware of the power

tool will run out of balance, vibrate excessively and may cause loss of control.

• Do not use a damaged accessory. Before each use inspect the accessory such as

abrasive wheels for chips and cracks, backing pad for cracks, tear or excess wear,

wire brush for loose or cracked wires. If power tool or accessory is dropped, inspect

for damage or install an undamaged accessory. After inspecting and installing an

accessory, position yourself and bystanders away from the plane of the rotating

accessory and run the power tool at maximum no-load speed for one minute. Damaged

accessories will normally break apart during this test time.

• Wear personal protective equipment. Depending on application, use face shield, safety

goggles or safety glasses. As appropriate, wear dust mask, hearing protectors, gloves

and workshop apron capable of stopping small abrasive or workpiece fragments. The

eye protection must be capable of stopping ying debris generated by various operations. The

dust mask or respirator must be capable of ltrating particles generated by your operation.

Prolonged exposure to high intensity noise may cause hearing loss.

7

Page 8

SAFETY INFORMATION

• Keep bystanders a safe distance away from work area. Anyone entering the work

area must wear personal protective equipment. Fragments of workpiece or of a broken

accessory may y away and cause injury beyond immediate area of operation.

• Hold the power tool by insulated gripping surfaces only, when performing an operation

where the cutting tool may contact hidden wiring. Contact with a “live” wire will also make

exposed metal parts of the power tool “live” and could give the operator an electric shock.

• Never lay the power tool down until the accessory has come to a complete stop. The

spinning accessory may grab the surface and pull the power tool out of your control.

• Do not run the power tool while carrying it at your side. Accidental contact with the

spinning accessory could snag your clothing, pulling the accessory into your body.

• Regularly clean the power tool’s air vents. The motor’s fan will draw the dust inside the

housing and excessive accumulation of powdered metal may cause electrical hazards.

• Do not operate the power tool near ammable materials. Sparks could ignite these materials.

• Do not use accessories that require liquid coolants. Using water or other liquid coolants

may result in electrocution or shock.

Further safety instructions for all operations

Kickback and Related Warnings

Kickback is a sudden reaction to a pinched or snagged rotating wheel, backing pad, brush

or any other accessory. Pinching or snagging causes rapid stalling of the rotating accessory

which in turn causes the uncontrolled power tool to be forced in the direction opposite of the

accessory’s rotation at the point of the binding.

For example, if an abrasive wheel is snagged or pinched by the workpiece, the edge of the

wheel that is entering into the pinch point can dig into the surface of the material causing the

wheel to climb out or kick out. The wheel may either jump toward or away from the operator,

depending on direction of the wheel’s movement at the point of pinching. Abrasive wheels may

also break under these conditions.

Kickback is the result of power tool misuse and/or incorrect operating procedures or conditions

and can be avoided by taking proper precautions as given below:

• Maintain a rm grip on the power tool and position your body and arm to allow you to

resist kickback forces. Always use auxiliary handle, if provided, for maximum control

over kickback or torque reaction during start up. The operator can control torque reaction

or kickback forces, if proper precautions are taken.

• Never place your hand near the rotating accessory. Accessory may kickback over your

hand.

• Do not position your body in the area where power tool will move if kickback occurs.

Kickback will propel the tool in direction opposite to the wheel’s movement at the point of

snagging.

• Use special care when working corners, sharp edges, etc. Avoid bouncing and

snagging the accessory. Corners, sharp edges or bouncing have a tendency to snag the

rotating accessory and cause loss of control or kickback.

• Do not attach a saw chain woodcarving blade or toothed saw blade. Such blades create

frequent kickback and loss of control.

Additional safety instructions for grinding and cutting-off operations

Safety Warnings Specic for Grinding and Abrasive Cutting-Off Operations

• Use only wheel types that are recommended for your power tool and the specic guard

designed for the selected wheel. Wheels for which the power tool was not designed cannot

be adequately guarded and are unsafe.

8

Page 9

SAFETY INFORMATION

• The guard must be securely attached to the power tool and positioned for maximum

safety, so the least amount of wheel is exposed towards the operator. The guard helps

to protect operator from broken wheel fragments, accidental contact with wheel fragments,

accidental contact with wheel and sparks that could ignite clothing.

• Wheels must be used only for recommended applications. For example: do not grind

with the side of cut-off wheel. Abrasive cut-off wheels are intended for peripheral grinding,

side forces applied to these wheels may cause them to shatter.

• Always use undamaged wheel anges that are of correct size and shape for your

selected wheel. Proper wheel anges support the wheel thus reducing the possibility of

wheel breakage. Flanges for cut-off wheels may be different from grinding wheel anges.

• Do not use worn down wheels from larger power tools. Wheel intended for larger power

tool is not suitable for the higher speed of a smaller tool and may burst.

Additional safety instructions for cutting-off operations

Additional Safety Warnings Specic for Abrasive Cutting-Off Operations

• Do not “jam” the cut-off wheel or apply excessive pressure. Do not attempt to

make an excessive depth of cut. Overstressing the wheel increases the loading and

susceptibility to twisting or binding of the wheel in the cut and the possibility of kickback or

wheel breakage.

• Do not position your body in line with and behind the rotating wheel. When the wheel,

at the point of operation, is moving away from your body, the possible kickback may propel

the spinning wheel and the power tool directly at you.

• When wheel is binding or when interrupting a cut for any reason, switch off the power

tool and hold the power tool motionless until the wheel comes to a complete stop.

Never attempt to remove the cut-off wheel from the cut while the wheel is in motion

otherwise kickback may occur. Investigate and take corrective action to eliminate the

cause of wheel binding.

• Do not restart the cutting operation in the workpiece. Let the wheel reach full speed

and carefully re-enter the cut. The wheel may bind, walk up or kickback if the power tool is

restarted in the workpiece.

• Support panels or any oversized workpiece to minimize the risk of wheel pinching

and kickback. Large workpieces tend to sag under their own weight. Supports must be

placed under the workpiece near the line of cut and near the edge of the workpiece on both

sides of the wheel.

• Use extra caution when making a “pocket cut” into existing walls or other blind areas. The

protruding wheel may cut gas or water pipes, electrical wiring or objects that can cause

kickback.

Additional safety instructions for polishing operations

Safety Warnings Specic for Polishing Operations:

• Do not allow any loose portion of the polishing bonnet or its attachment strings

to spin freely. Tuck away or trim any loose attachment strings. Loose and spinning

attachment strings can entangle your ngers or snag on the workpiece.

Additional Safety Warnings

• Do no use standard at wheels for face grinding. Side forces applied to these wheels may

cause them to shatter or burst.

9

Page 10

PREPARATION

Know Your Multi-Purpose Saw

This Multi-Purpose Saw can be used for these purposes: cutting wood products, PVC pipe,

and ceramic tile, as well as concrete and masonry surface preparation. Before attempting to

use the tool, familiarize yourself with all of its operating features and safety requirements.

WARNING

• This product is only designed for grinding, polishing and cutting-off. Use for any other

purpose is not recommended and will result in serious injury.

• Do not attempt to modify this tool or create accessories not recommended for use with this

tool. Any such alteration or modication is misuse and could result in a hazardous condition

leading to possible serious personal injury.

• Do not allow familiarity with the tool to cause carelessness. Remember that one careless

moment is enough to cause severe injury. Before attempting to use any tool, be sure to

become familiar with all of the operating features and safety instructions.

10

Page 11

OPERATING INSTRUCTIONS

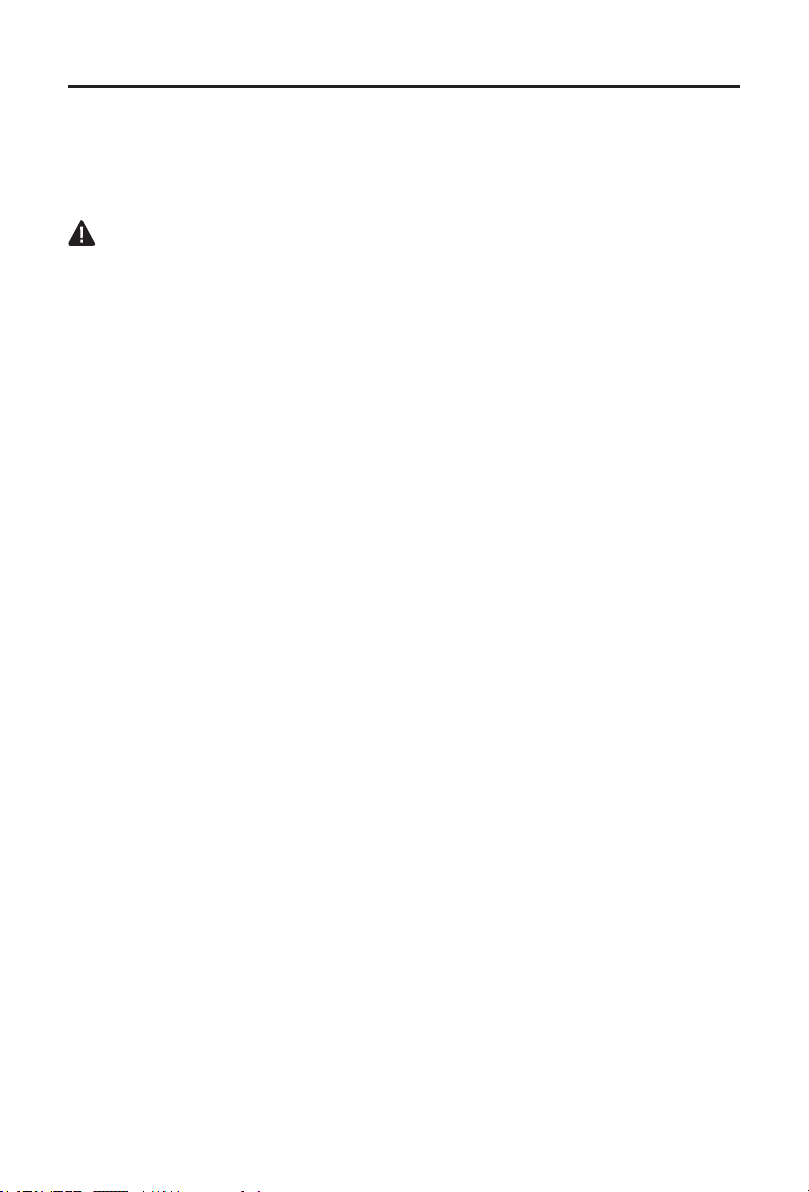

1. To Attach Battery Pack

a. Ensure that the paddle switch (K) is in the OFF

position.

b. Align the raised portion on the battery pack

with the grooves on the bottom of the tool,

then slide the battery pack onto the tool, as

shown.

c. Make sure that the latches on the battery

pack snap into place and the battery pack is

secured to the tool before beginning operation.

NOTICE: When placing the battery pack on the

tool, be sure that the raised rib on battery pack

aligns with the groove on the tool and the latches

snap into place properly. Improper assembly of

the battery pack can cause damage to internal

components.

To Detach Battery Pack

a. Ensure that the paddle switch (K) is in the OFF position.

b. Press the battery-release buttons to release the battery pack.

c. Pull forward on the battery pack to remove it from the tool.

WARNING

• To reduce the risk of injury, always remove the battery pack before making any adjustments

or changing accessories.

2. Paddle Switch Operation

The saw is equipped with a paddle switch (K) to

turn the tool on and off.

a. To turn the tool ON, push the lock-off lever (J)

forward, then squeeze the paddle switch.

b. To turn it OFF, release the paddle switch and

allow it to return to the OFF position. Make

sure that the tool comes to a complete stop

before laying the tool down.

NOTICE: If the battery is inserted when the tool

switch is in the “ON” position, the tool will not run.

Turn the tool off, then turn it on to begin work.

1

battery-release button

2

K

J

WARNING

• To reduce the risk of injury, hold the handle and auxiliary handle rmly with both hands to

provide a secure support during operation.

• To reduce the risk of injury, wear safety goggles or glasses with side shields during power

tool operation.

11

Page 12

OPERATING INSTRUCTIONS

3. Inlet-Vent Guard

Using the inlet-vent guards (H) will improve the

performance and extend the life of the tool.

a. To attach the guard, snap the guard onto the

tool’s foot.

b. To remove the guard, insert a athead

screwdriver (not included) into the notch at the

top of the guard, then pry the guard away from

the tool.

Clean the inlet-vent guard

To clean the guard, tap it against a hard surface or

blow it clean with compressed air.

WARNING

• To reduce the risk of injury, wear safety goggles or glasses with side shields when cleaning

with compressed air.

• To reduce the risk of injury, always remove the battery pack before any adjusting or

accessory changing.

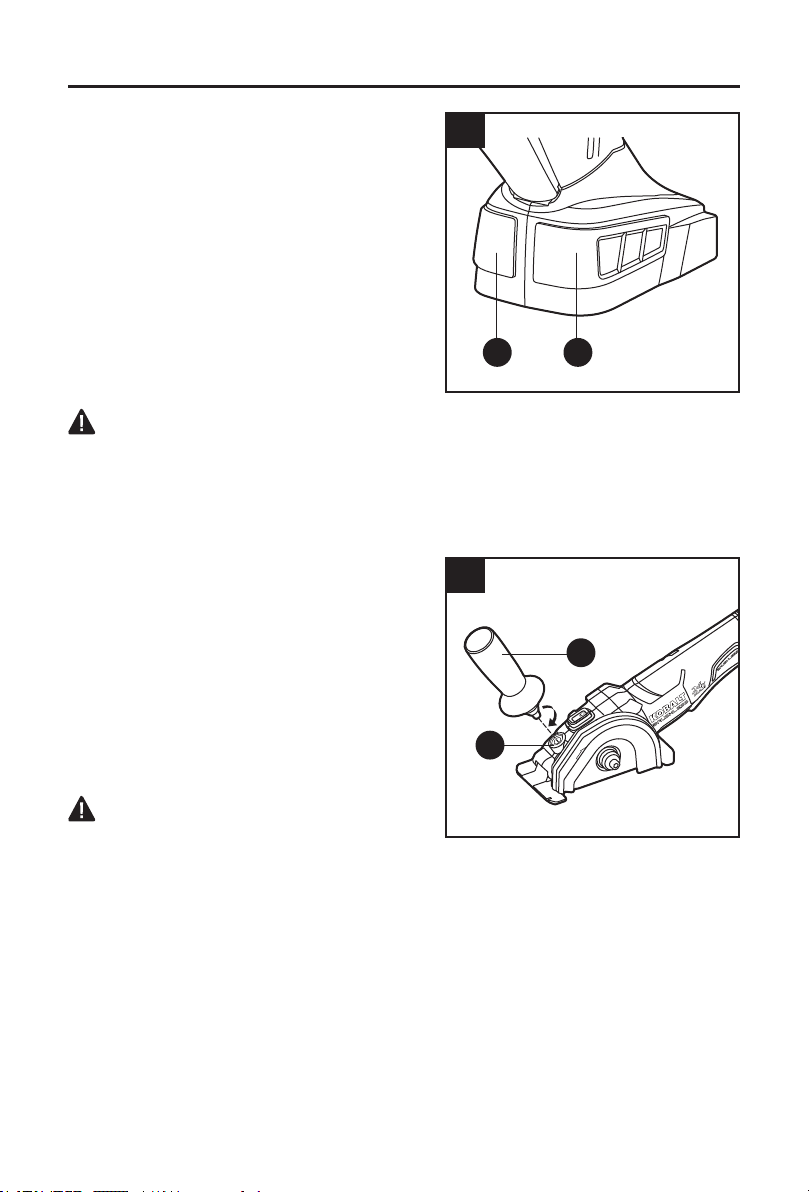

4. Auxiliary Handle

This saw is equipped with an auxiliary handle (T).

The handle can be installed in the auxiliary-handle

socket (O).

a. To install the auxiliary handle, thread the

auxiliary handle into the auxiliary-handle

socket and tighten the handle securely by

turning it clockwise.

b. To remove the auxiliary handle, loosen

the auxiliary handle by turning the handle

counterclockwise and remove it from the tool.

3

HH

4

T

O

WARNING

• For safety and ease of operation, securely

tighten the auxiliary handle by turning the handle clockwise before use.

• To reduce the risk of injury, always remove battery pack before any adjusting or accessory

changing.

12

Page 13

OPERATING INSTRUCTIONS

5. Dust-Exhaust Adapter

This versatile saw is equipped with a dust-exhaust

Adapter (S) to collect the dust created during

operation. The dust-exhaust Adapter can be

connected to a 1-1/4 in. diameter vacuum hose to

help keep the work area clean.

To attach a 1-1/4 in. vacuum hose

a. Remove the battery from the tool.

b. Insert the dust-exhaust Adapter into the dust

socket (P) in the saw as far as possible.

c. Attach a 1-1/4 in. vacuum hose (not included)

to the dust-exhaust Adapter.

6. Installing/Removing Accessories

DANGER

• This product is only designed for grinding, polishing

and cutting-off. Use for any other purpose is not

recommended and may result in serious injury.

WARNING

• Only use accessories with a Maximum Safe

Operating Speed rated at least equal to the

maximum speed marked on the tool.

• Only use accessories that comply with the correct

size marked on the tool and described in the Product

Specication chart located on page 2 of the manual.

The multi-purpose saw can be used with the cutting

wheel oriented in 2 different positions. One position

uses a standard at wheel for typical straight and

plunge cuts (Fig. 6b). The second wheel position may

be used for making ush cuts along ooring or against

walls and for surface preparation. (Fig. 6c).

5

6a

6b

QDC

U

W

P

S

V

F

E

G

R

To Install a Wheel

a. Remove the battery pack.

b. Depress and hold the spindle-lock button (Q) and

remove the blade bolt (F) by turning it clockwise

with the wrench (R).

c. Remove the washer (G) and the outer ange (E).

WARNING

• If the inner ange (D) has been removed, replace it

before placing the blade on the spindle. Failure to do so could result in serious personal injury.

d. Fit the wheel (U, V, or W) inside the guard and onto the spindle.

e. Replace the outer ange with the protruding section facing outward.

f. Depress and hold the spindle-lock button and replace the blade bolt.

g. Tighten the bolt securely by using the wrench to turn it counterclockwise.

13

standard at wheel (U, W)

Page 14

OPERATING INSTRUCTIONS

To Remove Wheel

a. Remove the battery pack.

b. Depress and hold the spindle-lock button (Q)

and remove the blade bolt (F) by turning it

clockwise with the wrench (R).

c. Remove the washer (G) and the outer ange

and remove the wheel.

7. Adjusting the Cutting Depth

WARNING

• Always maintain the correct cutting-depth

setting.

The correct cutting-depth setting for all cuts should

not exceed the thickness of the material being cut

by more than 1/4 in. (6.5 mm). Greater cutting depth

will increase the chance of dangerous kickback and

will cause the cut to be rough.

a. Remove the battery pack from the saw.

b. Raise the depth-lock lever (L) to release it.

c. Hold the tip of the base plate (A) tip against the

workpiece and raise or lower the saw until the

indicator mark (M) on the saw aligns with the desired depth on the depth scale (N).

d. Lower depth-lock lever to lock the selected cutting depth.

6c

7

wood ush cut wheel (V)

N

M

A

L

8. General Cutting

WARNING

• To make cutting easier and safer, always

maintain proper control of the saw. Loss of

control could cause an accident resulting in

serious injury. Never force the tool. Use a light

and continuous pressure.

DANGER

• Always make sure that the wheel has come to

a complete stop before setting the tool down.

A spinning blade contacting a hard surface will

cause the tool to walk back and may injure you.

14

8a

Page 15

OPERATING INSTRUCTIONS

WARNING

• Always wear safety goggles or safety glasses with

side shields during power tool operation. If the

operation is dusty, also wear a dust mask.

• The cut-off wheel (W) is suited for small cut-off

operations only. Using the cut-off wheel in a

grinding operation will cause the wheel to crack and

break, resulting in serious personal injury.

To make the safest and best possible cut, follow

these directions:

a. Clamp the workpiece securely so that the

workpiece will not move during the cut. If the

workpiece is too small to clamp it securely, do

not use this tool to cut it.

b. Support the workpiece near the cut.

c. Support the workpiece so that the cut is always to the operator’s side and not directly in

line with the operator’s body

d. Hold the tool rmly while cutting and always be ready and able to manage the cut. Use the

auxiliary handle (T) if needed.

e. Avoid placing your hand on the workpiece while making a cut. (Fig. 8a).

f. Always place the saw on the portion of the workpiece that is supported, not on the “cut off”

piece (Fig. 8b).

g. Draw a guideline along the desired cutting line before beginning the cut.

h. The guide notch (B) will only give an approximate line of cut when used with standard

wheels (such as parts U and W). Make sample cuts in scrap lumber to verify the actual line

of cut.

i. Avoid jamming, twisting or pinching the wheel within the workpiece or otherwise applying

excessive side pressure to the wheel.

NOTICE: If the battery is inserted when the tool switch is in the “ON” position, the tool will not

run. Turn the tool off, then turn it on to begin work.

Cutting tile

a. Score the tile rst along your cut line, making multiple passes to progressively cut through

the tile.

b. For cuts that extend to the edge of a tile, cut all the way through edge(s) along your cut line

c. This tool does not use wheels designed for face-grinding. If your cut requires a smooth,

nished edge, use an appropriate tile nishing tool to rene the tile edge.

Cutting metal

It is possible to perform limited cutting on small stock such as copper pipe, conduit, rebar,

threaded rod, coated wire shelving, aluminum sheet with this tool.

a. Work with a moderate rate of feed, adapted to the material being cut. Do not exert side

pressure onto the cutting wheel, tilt, or wiggle the tool.

b. When cutting proles and square bar stock, it is best to start at the smallest cross section.

Always follow precautions for kickback.

c. Do not apply side pressure to the cutting wheel to reduce wheel speed.

d. The tool should always be used so that sparks are directed away from user.

e. After each use, remove the wheel and clean the inside and outside of the guard with

compressed air. Preventive maintenance of the guard will reduce the possibility of an accident.

8b

B

15

Page 16

OPERATING INSTRUCTIONS

9. Plunge Cutting

Your saw is ideal for plunge cutting directly into a

workpiece, such as walls or oors.

WARNING

• Do not plunge cut into metal surfaces or tile.

Draw a guideline along the desired cutting line

before beginning the cut.

a. Loosen the depth-lock lever (L) so that the

base plate (A) releases and goes to the zero-

depth setting. Leave the depth-lock lever loose

during this cut.

b. Rest the base plate of the tool on the

workpiece and align the guide notch (B) with

the cut line.

c. While holding the tool rmly, make sure that

the wheel does not touch the workpiece.

d. Push forward the lock-off lever (J) and press

the paddle switch (K) to start the saw.

e. Allow the wheel to come to full speed, then

slowly lower the wheel into the workpiece and

make the cut.

f. Release the paddle switch and allow the wheel

to come to a complete stop.

g. Lift the tool from the workpiece.

h. Repeat steps b-g as required to complete the

cuts.

9a

9b

L

A

K

B

10. Flush Cutting

First, consider the desired height of the ush cut.

For ooring installation, take into account the

thickness of your ooring adhesive, the ooring

itself, and any underlayment or other material that

will add to the thickness of the nished oor.

a. Install the wood ush cut wheel (V) on the

tool as described in “Installing/Removing

Accessories”.

b. Adjust the depth of the blade to the desired

depth setting.

c. Turn the tool on its side so that the wheel

guard (C) rests against the ooring.

d. Firmly grip the tool, using the auxiliary handle

(T) if needed. Turn the tool on and allow it to

come to full speed before allowing the blade to enter the workpiece.

e. Complete the cut, release the paddle switch and allow the wheel to come to a complete

stop.

f. Lift the tool from the workpiece.

10

16

Page 17

OPERATING INSTRUCTIONS

11. Surface Preparation (optional)

WARNING

• To reduce the risk of injury, read all safety warnings

and all instructions in the use, care, and protection

of wheels.

• Always wear safety goggles or safety glasses with

side shields during power tool operation. If the

operation is dusty, also wear a dust mask.

Check the surface prep wheels (not included)

before application. Discard wheels that have been

dropped, bumped, subjected to extreme changes in

temperature, or come into contact with solvents or

wetness.

a. Before beginning a period of work, test the tool

by letting it spin for one minute before applying it to the workpiece.

b. Make sure that the workpiece is rmly clamped in place.

c. Hold the tool securely with both hands.

d. Start the tool.

NOTICE: If the battery is inserted when the tool switch is in the “ON” position, the tool will not

run. Turn the tool off, then turn it on to begin work.

e. Allow the accessory to reach full speed before beginning work.

f. For a uniform nish, hold tool at an angle of approximatley 10° to 15° to the workpiece

and apply constant pressure. Too great an angle causes concentrated pressure on small

areas, which may gouge or burn the work surface.

g. Control the pressure and surface contact between accessory and workpiece.

WARNING

• Do not apply excessive pressure. Too much pressure will cause the tool to overload and may

cause personal injury.

11

h. When nished, turn off the tool and make sure that it comes to a complete stop before

laying it down.

CARE AND MAINTENANCE

All maintenance should only be carried out by a qualied service technician.

Care of Wheels

The wheels should be stored in an organized way so that wheels can be removed without

disturbing or damaging other wheels.

Cleaning

Before cleaning or performing any maintenance, remove battery from the tool. For safe

and proper operation, always keep the tool and its ventilation slots clean.

Always use only a soft, dry cloth to clean your saw; never use detergent or alcohol.

17

Page 18

TROUBLESHOOTING

WARNING

• Make sure that the paddle switch (K) is in the “OFF” position and detach the battery pack

from the tool before performing troubleshooting procedures.

PROBLEM POSSIBLE CAUSE CORRECTIVE ACTION

The tool does not

work.

1. Battery capacity is low. 1. Charge the battery pack.

2. Battery is overheating. 2. Release the switch, wait for the battery

to cool down, then start the tool again.

Wheels cannot be

installed.

Auxiliary handle

cannot be installed.

Wheel is the wrong size. Refer to specication chart for proper

wheel size.

There is dust in the

Clean and clear the socket.

auxiliary handle socket.

Motor overheating. Cooling vents are

obstructed.

Clean and clear vents. Do not cover vents

with hand during operation.

WARRANTY

For 5 years from the date of purchase, the power tool is warranted for the original purchaser

to be free from defects in material and workmanship. This guarantee does not cover damage

due to abuse, normal wear, improper maintenance, neglect, unauthorized repair/alteration, or

expendable parts and accessories expected to become unusable after a reasonable period of

use.

If you think your product meets the above guarantee criteria, please return it to the place of

purchase with valid proof of purchase and the defective product will be repaired or replaced at

no charge. This guarantee gives you specic legal rights, and you may also have other rights

that vary from state to state.

L G Sourcing, Inc., N. Wilkesboro, NC 28659

18

Printed in China

Page 19

ARTÍCULO #0961863

SIERRA MULTIUSO

DE 4 PULG.

MODELO #KMC 124B-03

ADJUNTE SU RECIBO AQUÍ

Número de serie

¿Preguntas, problemas, piezas faltantes? Antes de volver a la tienda, llame a nuestro

Departamento de Servicio al Cliente al 1-888-3KOBALT (1-888-356-2258), de lunes a

viernes de 8 a.m. a 8 p.m., hora estándar del Este.

Fecha de compra

Page 20

ÍNDICE

Especicaciones del producto ........................................................................20

Contenido del paquete ................................................................................... 21

Información de seguridad ...............................................................................22

Preparación .................................................................................................... 29

Instrucciones de funcionamiento ....................................................................30

Cuidado y mantenimiento ..............................................................................38

Solución de problemas ...................................................................................38

Garantía. ........................................................................................................ 39

ESPECIFICACIONES DEL PRODUCTO

COMPONENTE ESPECIFICACIONES

Rango de voltaje 24 V de CC

Rango de velocidad 12.000/mín.

Tamaño de disco abrasivo máximo 100 mm (4 pulg.) de diámetro.

3/64 pulg. (1,2 mm) de grosor

Husillo del disco 7/16 pulg. (11 mm)

Profundidad máx. de corte 22 mm (7/8 pulg.)

20

Page 21

CONTENIDO DEL PAQUETE

C

A

D

I

M

H

J

Q P

B

PIEZA DESCRIPCIÓN PIEZA DESCRIPCIÓN

A Placa de base M Indicador de profundidad

B Ranura guía N Escala de profundidad de corte

C Protector del disco O Receptáculo de la manija auxiliar

D Brida interna P Receptáculo para polvo

E Brida externa Q Botón de bloqueo del husillo

F Perno de la hoja R Llave inglesa

G Arandela S Adaptador para extracción de polvo

H

I Manija principal U Disco de corte para madera

J Palanca de bloqueo V Disco de corte al ras para madera

K Interruptor de paleta W Disco de corte para metal

L

E F G

R

S

Protector de la entrada de

ventilación

Palanca de bloqueo de

profundidad

T

K

L

U

T Manija auxiliar

N

V

W

O

ADVERTENCIA

• Retire la herramienta del paquete y examínela con cuidado. No deseche la caja ni ningún

material de embalaje hasta después de examinar todas las piezas.

• Si falta alguna pieza de la herramienta o si alguna pieza está dañada, no conecte el

enchufe a la fuente de alimentación ni use la herramienta hasta reparar o reemplazar la

pieza. El incumplimiento de esta advertencia podría provocar lesiones graves.

21

Page 22

INFORMACIÓN DE SEGURIDAD

Lea y comprenda completamente este manual antes de intentar ensamblar u operar este

producto. Si tiene preguntas relacionadas con el producto, llame al Departamento de Servicio

al Cliente al 1-888-3KOBALT, de lunes a viernes de 8 a.m. a 8 p.m., hora estándar del Este.

ADVERTENCIA

• Durante el funcionamiento de cualquier herramienta eléctrica, pueden entrar objetos

extraños a los ojos y causar graves daños oculares. Use siempre lentes o gafas de

seguridad con protecciones laterales y, cuando sea necesario, una mascarilla que cubra

todo el rostro antes de comenzar a operar una herramienta eléctrica. Recomendamos

usar una máscara de seguridad de visión amplia sobre los lentes o las gafas de seguridad

estándar con protección. Siempre use lentes de protección que cumplan con la norma

ANSI Z87.1.

• Parte del polvo producido por el lijado, el aserrado, la trituración y el taladrado, así como

también otras actividades de construcción, contiene productos químicos reconocidos por el

estado de California como causantes de cáncer, defectos congénitos u otros daños en el

aparato reproductivo. Algunos ejemplos de estos productos químicos son:

– Plomo de pinturas a base de plomo

– Sílice cristalina de ladrillos, cemento y otros productos de mampostería

– Arsénico y cromo de madera tratada con químicos

• El riesgo que corre debido a la exposición a estos químicos varía según la frecuencia con

que realiza este tipo de trabajo. Para reducir la exposición a estas sustancias químicas:

– Trabaje en un área bien ventilada.

– Trabaje con un equipo de seguridad aprobado, como las mascarillas antipolvo

especialmente diseñadas para ltrar partículas microscópicas.

– Evite estar en contacto prolongado con el polvo provocado por el lijado, el aserrado,

la trituración y el taladrado, y otras actividades de construcción. Use ropa protectora y

lave todas las áreas expuestas del cuerpo con agua y jabón. Si permite que el polvo

llegue a su boca o a sus ojos, o que caiga sobre la piel, podría fomentar la absorción de

productos químicos dañinos.

• SIEMPRE use gafas de seguridad. Los lentes de uso diario NO son lentes de seguridad.

También use una mascarilla antipolvo si la operación de corte libera demasiado polvo.

• Durante el uso, utilice siempre protección personal adecuada para los oídos que

cumpla con la norma del Instituto Nacional Estadounidense de Estándares ANSI, por

sus siglas en inglés. El ruido que genera este producto puede contribuir a la pérdida de la

audición en algunas condiciones y períodos de uso.

Conozca la herramienta

Para operar esta herramienta, lea cuidadosamente este manual y las etiquetas jadas a la

herramienta antes de usarla.

Guarde este manual para referencia futura.

Importante

Solo un técnico calicado puede reparar esta herramienta.

Lea por completo todas las instrucciones

22

Page 23

INFORMACIÓN DE SEGURIDAD

Algunos de los siguientes símbolos pueden aplicarse al uso de esta herramienta. Obsérvelos

y aprenda su signicado. La interpretación correcta de estos símbolos le permitirá utilizar la

herramienta de manera ecaz y segura.

SÍMBOLO DEFINICIÓN SÍMBOLO DEFINICIÓN

V Voltios n Rango de velocidad

or d.c.

Advertencias de seguridad general en el manejo de herramientas eléctricas

ADVERTENCIA

• Lea todas las advertencias de seguridad y todas las instrucciones. El incumplimiento

de las advertencias y las instrucciones podría provocar descargas eléctricas, incendios o

lesiones graves.

Guarde todas las advertencias e instrucciones para referencia futura

El término “herramienta eléctrica” que aparece en las advertencias se reere a la herramienta

eléctrica que se conecta a la línea principal (con cable) o a la herramienta eléctrica que

funciona con batería (inalámbrica).

Seguridad en el área de trabajo

• Mantenga el área de trabajo limpia y bien iluminada. Las áreas desordenadas u oscuras

aumentan las posibilidades de accidentes.

• No utilice herramientas eléctricas en atmósferas en las que exista riesgo de

explosión, como por ejemplo en presencia de líquidos inamables, gases o polvo.

Las herramientas eléctricas producen chispas que podrían encender el polvo o humo.

• Mantenga a los niños y los transeúntes alejados durante la operación de una

herramienta eléctrica. Las distracciones pueden hacerle perder el control.

Corriente continua /min Revoluciones por minuto

ADVERTENCIA: use

siempre lentes de

protección.

ADVERTENCIA: para

reducir el riesgo de

lesiones, el usuario

debe leer el manual de

instrucciones.

Tamaño de la rosca de eje

Peligro, advertencia o

precaución. Signica:

“¡Atención! Su seguridad está

comprometida”.

Seguridad eléctrica

• Los enchufes de las herramientas eléctricas deben encajar en el tomacorriente.

Nunca modique el enchufe de ninguna manera. No utilice ningún enchufe adaptador

con herramientas eléctricas con puesta a tierra. Los enchufes sin modicaciones y que

encajan en los tomacorrientes reducen el riesgo de descarga eléctrica.

• Evite el contacto del cuerpo con supercies con puesta a tierra, como tuberías,

radiadores, extractores o refrigeradores. Existe un riesgo adicional de descarga eléctrica

si su cuerpo tiene puesta a tierra.

23

Page 24

INFORMACIÓN DE SEGURIDAD

• No maltrate el cable. Nunca use el cable para transportar, jalar ni desenchufar la

herramienta eléctrica. Mantenga el cable alejado del calor, el aceite, los bordes

losos o las piezas en movimiento. Los cables dañados o enredados aumentan el riesgo

de descarga eléctrica.

• Cuando utilice una herramienta eléctrica en exteriores, use una extensión eléctrica

apta para uso en exteriores. El uso de un cable apto para uso en exteriores reduce el

riesgo de descarga eléctrica.

• Si debe utilizar herramientas eléctricas en un área húmeda, use un suministro

protegido con un interruptor de circuito de falla de puesta a tierra (GFCI, por sus

siglas en inglés). El uso de un GFCI disminuye el riesgo de descarga eléctrica.

Seguridad personal

• Manténgase alerta, preste atención a lo que hace y utilice el sentido común cuando

use una herramienta eléctrica. No utilice una herramienta eléctrica si está cansado

o bajo los efectos de drogas, alcohol o medicamentos. Un momento de desatención

mientras opera herramientas eléctricas puede provocar lesiones personales graves.

• Use un equipo de protección personal. Use siempre lentes de protección. Los equipos

de protección, como las mascarillas antipolvo, los zapatos de seguridad antideslizantes, un

casco protector o protección auditiva, utilizados en las condiciones adecuadas, disminuyen

las lesiones personales.

• Evite los arranques accidentales. Asegúrese de que el interruptor esté en la posición

de apagado antes de conectar la herramienta a la fuente de alimentación o la batería,

o antes de levantarla o transportarla. Transportar herramientas eléctricas con el dedo

en el interruptor o enchufar herramientas eléctricas que tienen el interruptor encendido

aumenta las posibilidades de accidentes.

• Retire todas las llaves de ajuste o llaves inglesas antes de encender la herramienta

eléctrica. Si se deja una llave inglesa o una llave conectada a una pieza giratoria de la

herramienta eléctrica, se podrían producir lesiones personales.

• No se extienda demasiado. Mantenga una postura y un equilibrio adecuados en

todo momento. Esto permite un mejor control de la herramienta eléctrica en situaciones

inesperadas.

• Use ropa adecuada. No use ropa holgada ni joyas. Mantenga el cabello, la ropa y los

guantes lejos de las piezas en movimiento. La ropa holgada, las joyas o el cabello largo

pueden quedar atrapados en las piezas en movimiento.

• Si se proporcionan dispositivos para la conexión de equipos de extracción y

recolección de polvo, asegúrese de conectarlos y usarlos de manera adecuada. El

uso de estos dispositivos puede disminuir los peligros relacionados con el polvo.

Uso y cuidado de las herramientas eléctricas

• No fuerce la herramienta eléctrica. Utilice la herramienta eléctrica adecuada para

su tarea. La herramienta eléctrica adecuada realizará un trabajo más seguro y de mejor

calidad al ritmo para el que se diseñó.

• No utilice la herramienta eléctrica si el interruptor no la enciende o apaga. Cualquier

herramienta eléctrica que no pueda controlarse con el interruptor es peligrosa y debe

repararse.

• Desconecte el enchufe de la fuente de alimentación o la batería de la herramienta

eléctrica antes de realizar cualquier ajuste, cambiar accesorios o almacenar

herramientas eléctricas. Este tipo de medidas de seguridad preventivas reduce el riesgo

de arranques accidentales de la herramienta eléctrica.

24

Page 25

INFORMACIÓN DE SEGURIDAD

• Almacene las herramientas eléctricas que no estén en uso alejadas del alcance de

los niños y no permita que las personas no familiarizadas con la herramienta o estas

instrucciones la operen. Las herramientas eléctricas son peligrosas en manos de usuarios

sin capacitación.

• Realice mantenimiento a las herramientas eléctricas. Revise si hay piezas móviles

desalineadas o torcidas, si hay piezas rotas y cualquier otra condición que pueda

afectar el funcionamiento de la herramienta eléctrica. Si se daña la herramienta

eléctrica, hágala reparar antes de usarla. Muchos accidentes son producto del

mantenimiento incorrecto de las herramientas eléctricas.

• Mantenga las herramientas de corte aladas y limpias. Las herramientas de corte que

se mantienen adecuadamente, con sus bordes de corte alados, son menos propensas a

trabarse y son más fáciles de controlar.

• Use la herramienta eléctrica, los accesorios, las brocas, etc., de acuerdo con estas

instrucciones, considerando las condiciones de funcionamiento y el trabajo que

desea realizar. El uso de la herramienta eléctrica en operaciones distintas para las que fue

diseñada podría crear una situación de peligro.

Uso y cuidado de herramientas a batería

• Recargue solo con el cargador especicado por el fabricante. Un cargador adecuado

para un tipo de paquete de baterías puede crear un riesgo de incendio cuando se usa con

otro paquete de baterías.

• Use las herramientas eléctricas solo con paquetes de baterías designados

especícamente. El uso de cualquier otro paquete de baterías puede crear un riesgo de

lesión e incendio.

• Cuando el paquete de baterías no esté en uso, aléjelo de objetos metálicos, como

sujetapapeles, monedas, llaves, clavos, tornillos u otros objetos metálicos pequeños

que pudieran crear una conexión entre los terminales. Es posible que conectar los

terminales de la batería entre sí produzca quemaduras o un incendio.

• En condiciones de maltrato, es posible que salga líquido de la batería; evite el

contacto. Si se produce un contacto accidental, enjuague con agua. Si el líquido entra

en contacto con los ojos, solicite atención médica adicional. El líquido que sale de la

batería puede provocar irritación o quemaduras.

Reparación

• Permita que solo una persona capacitada repare la herramienta eléctrica, utilizando

solo piezas de repuesto idénticas. Esto mantendrá la seguridad de la herramienta

eléctrica.

Advertencias de seguridad para todas las operaciones

Advertencias de seguridad comunes para operaciones de amolado, pulido y corte

abrasivo

• Esta herramienta eléctrica está diseñada para operar como una herramienta amoladora,

pulidora o de corte. Lea todas las advertencias de seguridad, las instrucciones, las

ilustraciones y las especicaciones que se incluyen esta herramienta eléctrica. No

seguir todas las instrucciones que se detallan a continuación podría provocar descargas

eléctricas, incendios o lesiones graves.

• No se recomienda realizar operaciones como lijado o cepillado con alambre con esta

herramienta eléctrica. Utilizar esta herramienta eléctrica para operaciones para las que no

fue diseñada puede producir peligros y causar lesiones personales.

25

Page 26

INFORMACIÓN DE SEGURIDAD

• No utilice accesorios que no estén especícamente diseñados o recomendados

por el fabricante de esta herramienta. El hecho de que el accesorio pueda jarse a la

herramienta eléctrica no signica que esto garantice una operación segura.

• El rango de velocidad del accesorio debe ser, al menos, igual a la velocidad máxima

marcada en la herramienta eléctrica. Los accesorios que funcionen por sobre el rango de

velocidad recomendada pueden romperse y desprenderse.

• El diámetro externo y el grosor del accesorio deben encontrarse dentro de la

capacidad recomendada de la herramienta eléctrica. No es posible proteger ni controlar

de manera adecuada accesorios de un tamaño incorrecto.

• El montaje roscado de los accesorios debe coincidir con la rosca del husillo de la

amoladora. Para accesorios montados con bridas, el oricio para el eje del accesorio

se debe ajustar al diámetro de la brida. Los accesorios que no calcen con los aditamentos

de montaje de la herramienta eléctrica perderán equilibrio, vibrarán en exceso y causarán una

pérdida de control.

• No utilice un accesorio dañado. Antes de cada uso, verique que los accesorios

como los discos abrasivos no tengan astillas o grietas, que las almohadillas de

refuerzo no estén agrietadas, rasgadas o muy desgastadas, ni que el cepillo tenga

alambres sueltos o agrietados. Si la herramienta eléctrica o el accesorio caen al

suelo, compruebe que no haya sufrido daños o instale un accesorio nuevo. Después

de revisar e instalar un accesorio, usted y otros deben ubicarse lejos del alcance del

accesorio giratorio y operar la herramienta eléctrica a velocidad máxima sin carga

durante un minuto. Normalmente, los accesorios dañados se desprenderán durante este

período de prueba.

• Use equipo de protección personal. Según la aplicación, utilice una careta protectora,

gafas o lentes de seguridad. Según corresponda, utilice una mascarilla antipolvo,

protectores auditivos, guantes y un faldón para taller que puedan detener pequeños

fragmentos de pieza de trabajo abrasivos. Los lentes de protección deben ser capaces

de detener los desechos eyectados que se generan en diversas operaciones. La mascarilla

antipolvo o el respirador deben ltrar las partículas generadas durante la operación. La

exposición prolongada a ruidos de alta intensidad puede causar la pérdida de la audición.

• Mantenga a los espectadores a una distancia segura del área de trabajo. Toda

persona que ingrese al área de trabajo debe usar un equipo de protección personal.

Fragmentos de piezas de trabajo o de un accesorio de trabajo pueden salir eyectados y

causar lesiones incluso más lejos del área de operación.

• Sostenga la herramienta eléctrica solo de las supercies de agarre aisladas al

realizar una operación en la que la herramienta de corte pueda entrar en contacto con

cableado oculto. Es posible que el contacto con un cable “energizado” haga que también

“se energicen” las piezas de metal expuestas de la herramienta eléctrica, lo que podría

provocar una descarga eléctrica al operador.

• Nunca coloque la herramienta eléctrica en el suelo hasta que el accesorio se detenga

por completo. Es posible que el accesorio giratorio se enganche a la supercie, lo que

podría provocar que usted pierda el control de la herramienta eléctrica.

• No opere la herramienta eléctrica mientras la lleve a su lado. El contacto accidental

con el accesorio giratorio puede hacer que se enganche en su ropa y jalar el accesorio hacia

usted.

• Limpie periódicamente los conductos de ventilación de la herramienta eléctrica. El

ventilador del motor atrae el polvo hacia dentro de la carcasa y la acumulación excesiva de

metal en polvo puede producir peligros eléctricos.

• No use la herramienta eléctrica cerca de materiales inamables. Las chispas podrían

encender estos materiales.

26

Page 27

INFORMACIÓN DE SEGURIDAD

• No utilice accesorios que requieran líquido refrigerante. El agua y otros líquidos

refrigerantes puede causar electrocución y descargas eléctricas.

Instrucciones de seguridad adicionales para todo tipo de operaciones

Contragolpe y advertencias relacionadas

El contragolpe es una reacción repentina de un disco de rotación, base, cepillo u otro

accesorio atascado o enganchado. El enganche o el atrapamiento causan atascamientos en

el accesorio giratorio que a su vez provoca la pérdida de control de la herramienta eléctrica,

pues la fuerza en la dirección opuesta de giro del accesorio en el punto de atascamiento.

Por ejemplo, si un disco abrasivo se engancha o atasca debido a la pieza de trabajo, el borde

del disco que ingresa en el punto de atascamiento puede penetrar la supercie del material y

provocar que el disco se monte o desprenda. Es posible que el disco salte hacia el operador

o lejos de este, dependiendo de la dirección del movimiento de la rueda en el punto de

enganche. Los discos abrasivos pueden romperse bajo estas condiciones.

El contragolpe es la consecuencia del uso inadecuado de la herramienta eléctrica, o

condiciones o procedimientos de funcionamiento incorrectos. Se puede evitar al tomar las

precauciones adecuadas como se indica a continuación:

• Agarre rmemente la herramienta eléctrica y coloque su cuerpo y brazo de manera que

resista la fuerza de contragolpe. Siempre use una manija auxiliar, si se incluye, para

obtener un máximo control de la reacción del contragolpe o fuerza de torsión durante

el arranque. El operador puede controlar la reacción de fuerza de torsión o el contragolpe si

toma las precauciones correctas.

• Nunca coloque su mano cerca del accesorio giratorio. Es posible que el accesorio

produzca un contragolpe en su mano.

• Si ocurre un contragolpe, no coloque su cuerpo en el área donde la herramienta

eléctrica se moverá. El contragolpe impulsará la herramienta en dirección opuesta al

movimiento del disco en el punto de enganche.

• Tenga especial cuidado cuando trabaje en esquinas, bordes losos, entre otros. Evite

saltos y enganches del accesorio. Las esquinas, los bordes losos o los saltos tienden a

enganchar el accesorio giratorio y provocan pérdida de control o contragolpe.

• No instale hojas para trinchar para cadenas de motosierras ni hojas de sierra dentadas.

Estas hojas crean contragolpe y pérdida de control.

Instrucciones de seguridad adicionales para operaciones de amolado y corte

Advertencias de seguridad especícas para operaciones de amolado y corte abrasivo

• Use solamente tipos de discos recomendados para su herramienta eléctrica y el tope

especíco diseñado para el disco seleccionado. Los discos que no fueron diseñados para

la herramienta eléctrica no pueden protegerse de manera adecuada y no son seguros.

• El tope debe estar instalado rmemente en la herramienta eléctrica y debe colocarse

con el n de obtener la máxima seguridad, de manera que la exposición del disco hacia

el operador sea mínima. El tope ayuda a proteger al operador contra fragmentos rotos del

disco y del contacto accidental con estos y con el disco y las chispas que puedan encender la

ropa.

• Los discos solo deben usarse para las aplicaciones recomendadas. Por ejemplo: no

amole con el costado del disco de corte. Los discos de corte abrasivo están diseñados

para amolados periféricos; aplicar fuerza lateral a estos discos podría provocar que se

rompan.

27

Page 28

INFORMACIÓN DE SEGURIDAD

• Siempre use bridas de discos que no estén dañadas y que sean del tamaño y forma

correctos para el disco seleccionado. Una brida correcta ofrece soporte al disco, por lo

tanto se reduce la posibilidad de rompimiento del disco. Las bridas para discos de corte

pueden ser diferentes a las bridas para discos de pulido.

• No use discos desgastados de herramientas eléctricas más grandes. Un disco diseñado

para herramientas eléctricas más grandes no es el adecuado para la alta velocidad de una

herramienta más pequeña y puede explotar.

Instrucciones de seguridad adicionales para operaciones de corte

Advertencias de seguridad adicionales especícas para operaciones de corte abrasivo

• No “atasque” el disco de corte ni aplique presión en exceso. No intente lograr

un corte con profundidad excesiva. Forzar en exceso el disco aumenta la carga y la

vulnerabilidad al giro o atascamiento del disco en el corte además de la posibilidad de

contragolpe o rompimiento de disco.

• No ubique su cuerpo junto al disco giratorio ni detrás de este. Cuando el disco, en el

punto de operación, se aleja de su cuerpo, el posible contragolpe puede impulsar el disco

giratorio junto con la herramienta eléctrica directamente hacia usted.

• Cuando el disco se atasque o cuando se interrumpa un corte por cualquier motivo,

desconecte la energía de la herramienta eléctrica y sujétela sin moverla hasta que el

disco se detenga completamente. Nunca intente retirar el disco de corte mientras corta y

está en movimiento; de lo contrario puede generarse un contragolpe. Investigue las causas y

aplique medidas correctivas para evitar que el disco se atasque.

• No reinicie la operación de corte en la pieza de trabajo. Permita que el disco alcance

velocidad plena y retome el corte cuidadosamente. Es posible que el disco se atasque,

se eleve o produzca contragolpe si la herramienta eléctrica se reinicia en la pieza de trabajo.

• Apoye los paneles o cualquier pieza de trabajo de gran tamaño para minimizar el

riesgo de que el disco se apriete o sufra un contragolpe. Las piezas de trabajo tienden

a doblarse debido a su propio peso. Los soportes deben colocarse bajo la pieza de trabajo,

cerca de la línea de corte y el borde la pieza de trabajo en ambos costados del disco.

• Tome precauciones adicionales al realizar un “corte de cavidad” en paredes existentes u otras

áreas ciegas. El disco sobresaliente puede cortar tuberías de gas o agua, cableado eléctrico

u objetos que pueden causar contragolpe.

Instrucciones de seguridad adicionales para operaciones de pulido

Advertencias de seguridad especícas para operaciones de pulido:

• No permita que ninguna porción suelta del bonete de pulido o las cuerdas de jación

giren libremente. Pliegue o recorte cualquier cuerda de jación suelta. Las cuerdas

de jación sueltas o giratorias pueden enredarse en sus dedos o atascarse en la pieza de

trabajo.

Advertencias de seguridad adicionales

• No use los discos lisos estándar para amolar. La fuerza lateral que se aplica a estos

discos puede ocasionar que se quiebren o exploten.

28

Page 29

PREPARACIÓN

Conozca su sierra multiuso

Esta sierra multiuso se puede usar para los siguientes propósitos: cortar productos de

madera, tubería de PVC y baldosas de cerámica, además de concreto y preparación de

supercies de mampostería. Antes de intentar usar la herramienta, familiarícese con todas sus

características de operación y requisitos de seguridad.

ADVERTENCIA

• Este producto se diseñó solo para amolar, pulir y cortar. No se recomienda su uso para otro

n, lo que podría provocar lesiones graves.

• No intente modicar esta herramienta ni crear accesorios que no sean los recomendados

para la misma. Cualquier alteración o modicación es considerada un mal uso y podría

causar una condición peligrosa que podría producir lesiones personales graves.

• Sea cuidadoso, incluso si está familiarizado con la herramienta. Recuerde que un momento

de descuido es suciente para causar lesiones graves. Antes de intentar utilizar cualquier

herramienta, asegúrese de familiarizarse con todas las características de funcionamiento e

instrucciones de seguridad.

29

Page 30

INSTRUCCIONES DE FUNCIONAMIENTO

1. Para jar el paquete de baterías

a. Asegúrese de que el interruptor de paleta (K)

esté en la posición OFF (apagado).

b. Alinee la parte elevada del paquete de

baterías con las ranuras de la parte inferior de

la herramienta y luego deslice el paquete de

baterías en la herramienta, como se muestra.

c. Asegúrese de que los pestillos del paquete de

baterías encajen en su lugar y que el paquete

de baterías esté jo en la herramienta antes

de comenzar la operación

AVISO: cuando coloque el paquete de baterías en

la herramienta, asegúrese de que la varilla elevada

del paquete de baterías quede alineada con la

ranura de la herramienta y de que los pestillos

encajen en su lugar adecuadamente. El ensamblaje inadecuado del paquete de baterías puede

provocar daños a los componentes internos.

Para retirar el paquete de baterías

a. Asegúrese de que el interruptor de paleta (K) esté en la posición OFF (apagado).

b. Presione el botón de liberación de la batería para liberar el paquete de baterías.

c. Jale el paquete de baterías hacia delante para retirar la batería de la herramienta.

ADVERTENCIA

• Para reducir el riesgo de lesiones, siempre retire el paquete de baterías antes de realizar

cualquier ajuste o cambio de accesorios.

2. Funcionamiento del interruptor de la paleta

La sierra está equipada con un interruptor de

paleta (K) para encender y apagar la herramienta.

a. Para ENCENDER la herramienta, empuje la

palanca de bloqueo (J) hacia delante y luego

apriete el interruptor de paleta.

b. Para APAGARLA, suelte el interruptor de

paleta y permita que vuelva a la posición de

OFF. Asegúrese de que la herramienta se

detenga completamente antes de dejarla en el

suelo.

AVISO: si la batería se inserta cuando el

interruptor de la herramienta se encuentra en

la posición “ON” (encendido), la herramienta no

funcionará. Apague la herramienta y luego vuelva a

encenderla para comenzar a trabajar.

1

2

K

Botón de liberación

de la batería

J

ADVERTENCIA

• Para reducir el riesgo de lesiones, sostenga la manija y la manija auxiliar rmemente con

ambas manos para proporcionar soporte y control seguros durante la operación.

• Para reducir el riesgo de lesiones, use gafas o lentes de seguridad con protección lateral

durante el funcionamiento de la herramienta eléctrica

30

Page 31

INSTRUCCIONES DE FUNCIONAMIENTO

3. Protector de la entrada de ventilación

El uso de los protectores de la entrada de

ventilación (H) mejorará el rendimiento y

extenderá la vida útil de la herramienta.

a. Para jar el protector, colóquelo a presión en

la base de la herramienta.

b. Para retirar el protector, inserte un

destornillador de cabeza plana (no se incluye)

en la ranura de la parte superior del protector

y sepárelo de la herramienta haciendo

palanca.

Limpieza del protector de la entrada de

ventilación

Para limpiar el protector, golpéelo suavemente contra una supercie dura o sóplelo con aire

comprimido.

ADVERTENCIA

• Para reducir el riesgo de lesiones, use gafas o lentes de seguridad con protección lateral

cuando limpie con aire comprimido.

• Para reducir el riesgo de lesiones, siempre retire el paquete de baterías antes de realizar

cualquier ajuste o cambio de accesorio.

4. Manija auxiliar

Esta sierra está equipada con una manija auxiliar

(T). la manija puede instalarse en el receptáculo

de la manija auxiliar (O).

a. Para instalar la manija auxiliar, enrósquela

en el receptáculo y apriétela rmemente

girándola en dirección de las manecillas del

reloj.

b. Para retirar la manija auxiliar, aójela girándola

en dirección contraria a las manecillas del

reloj y despréndala de la herramienta.

3

HH

4

T

O

ADVERTENCIA

• Para su seguridad y para una operación más

fácil, apriete bien la manija auxiliar girándola en

dirección de las manecillas del reloj antes de cada uso.

• Para reducir el riesgo de lesiones, siempre retire el paquete de baterías antes de realizar

cualquier ajuste o cambio de accesorio.

31

Page 32

INSTRUCCIONES DE FUNCIONAMIENTO

5. Adaptador para extracción de polvo

Esta versátil sierra está equipada con un

adaptador para extracción de polvo (S) para

recolectar el polvo que se produce durante el

funcionamiento. El adaptador para extracción

de polvo puede conectarse a una manguera

de aspiradora de 31,75 mm (1-1/4 de pulg.) de

diámetro para ayudar a mantener el área de

trabajo limpia.

Para jar una manguera de aspiradora de 31,75

mm (1-1/4 de pulg.)

a. Retire la batería de la herramienta.

b. Inserte el adaptador para extracción de polvo

en el receptáculo para polvo (P) en la sierra lo más alejado posible.

c. Fije una manguera de aspiradora de 31,75 mm (1-1/4 de pulg.) (no se incluye) en el

adaptador para extracción de polvo.

6. Cómo instalar o retirar los accesorios

PELIGRO

• Este producto se diseñó solo para amolar, pulir y

cortar. No se recomienda su uso para otro n, ya

que podría provocar lesiones graves.

ADVERTENCIA

• Use los accesorios solo a una velocidad máxima de

funcionamiento seguro, que sea como mínimo igual

a la velocidad máxima marcada en la herramienta

use solo accesorios que cumplan con el tamaño

correcto indicado en la herramienta.

• Use solo accesorios que cumplan con el tamaño

correcto marcado en la herramienta y descrito en

la tabla de especicaciones del producto que se

encuentra en la página 2 del manual

La sierra multiuso puede usarse con el disco de

corte orientado en dos posiciones distintas. Una

posición utiliza un disco plano estándar para cortes

rectos y perforaciones comunes (Fig. 6b). La

segunda posición del disco puede utilizarse para

realizar cortes al ras en pisos o paredes, y para

preparación de supercies (Fig. 6c).

5

6a

6b

QDC

U

W

P

S

V

E

G

F

R

Instalación de un disco

a. Retire el paquete de baterías.

b. Mantenga presionado el botón de bloqueo

del husillo (Q) y retire el tornillo de la hoja

(F) girándolo en dirección contraria a las

manecillas del reloj con la llave inglesa (R).

c. Retire la arandela (G) y la brida externa (E).

disco plano estándar(U,W)

32

Page 33

INSTRUCCIONES DE FUNCIONAMIENTO

ADVERTENCIA

• Si retiró la brida interna (D), vuelva a colocarla

antes de ubicar la hoja en el husillo. No hacerlo

podría provocar lesiones personales graves.

d. Ajuste el disco (U, V o W) dentro de la

protección y en el husillo.

e. Vuelva a colocar la brida externa con la

sección sobresaliente apuntando hacia fuera.

f. Mantenga presionado el botón de bloqueo del

husillo y vuelva a colocar el perno de la hoja.

g. Apriete con rmeza el perno con la llave

inglesa, girándolo en dirección contraria a las

manecillas del reloj.

Cómo retirar el disco

a. Retire el paquete de baterías.

b. Mantenga presionado el botón de bloqueo del husillo (Q) y retire el tornillo de la hoja (F)

girándolo en dirección contraria a las manecillas del reloj con la llave inglesa (R).

c. Retire la arandela (G) y la brida externa y retire el disco.

7. Ajuste de la profundidad de corte

ADVERTENCIA

• Siempre mantenga el ajuste de profundidad de

corte correcto.

El ajuste de profundidad de corte correcto para

todos los cortes no debe exceder el grosor del

material que se corta en más de 6,35 mm (1/4 de

pulg.). Una profundidad de corte mayor aumentará

la posibilidad de retrocesos peligrosos y provocará

que el corte sea áspero.

a. Retire el paquete de baterías de la sierra.

b. Levante la palanca de bloqueo de profundidad

(L) para liberarla.

c. Sostenga la punta de la placa base (A) contra

la pieza de trabajo y levante o baje la sierra hasta que la marca indicadora (M) en la

misma se alinee con la profundidad deseada en la escala de profundidad (N).

d. Baje la palanca de bloqueo de profundidad para bloquearla en la profundidad de corte

deseada.

6c

7

disco de corte al ras (V)

N

M

A

L

33

Page 34

INSTRUCCIONES DE FUNCIONAMIENTO

8. Cortes en general

ADVERTENCIA

• Para que el corte sea más fácil y seguro,

siempre mantenga un control adecuado de la

sierra. La pérdida de control puede provocar

un accidente y causar lesiones graves. Nunca

fuerce la herramienta. Ejerza una presión ligera

y constante.

PELIGRO

• Asegúrese siempre de que el disco se detenga

completamente antes de dejar la herramienta en

el suelo.

• Si el disco entra en contacto con una supercie

dura mientras gira, la herramienta podría

retroceder y provocarle lesiones.

ADVERTENCIA

• Cuando utilice herramientas eléctricas, use siempre

gafas o lentes de seguridad con protecciones

laterales. Si hay demasiado polvo durante la

operación, use también una mascarilla antipolvo.

• El disco de corte (W) es adecuado solo para

operaciones de cortes pequeños. El uso del disco

de corte para una operación de amolado causará

que el disco se agriete y se rompa, produciendo

lesiones personales graves.

Para lograr el mejor corte posible y de la manera

más segura, siga estas instrucciones:

a. Sujete rmemente con abrazaderas la pieza de trabajo, de manera que no se mueva

mientras realiza el corte. Si la pieza de trabajo es demasiado pequeña para sujetarla con

abrazaderas, no utilice esta herramienta para cortarla.

b. Apoye la pieza de trabajo cerca del corte.