Page 1

AB15867

Questions, problems, missing parts? Before returning to your retailer, call our customer

service department at 1-888-3KOBALT (1-888-356-2258), 8 a.m. - 8 p.m., EST,

Monday - Friday.

ATTACH YOUR RECEIPT HERE

Serial Number Purchase Date

ITEM #0672830/0864453/0877730

6-1/2 in Brushless

Circular Saw

MODEL #KCS 6524B-03

Español p. 19

Page 2

2

TABLE OF CONTENTS

Product Specications ......................................................................................2

Package Contents ............................................................................................3

Safety Information ............................................................................................ 4

Preparation .......................................................................................................9

Operating Instructions .................................................................................... 10

Care and Maintenance ...................................................................................17

Troubleshooting..............................................................................................18

Warranty ......................................................................................................... 18

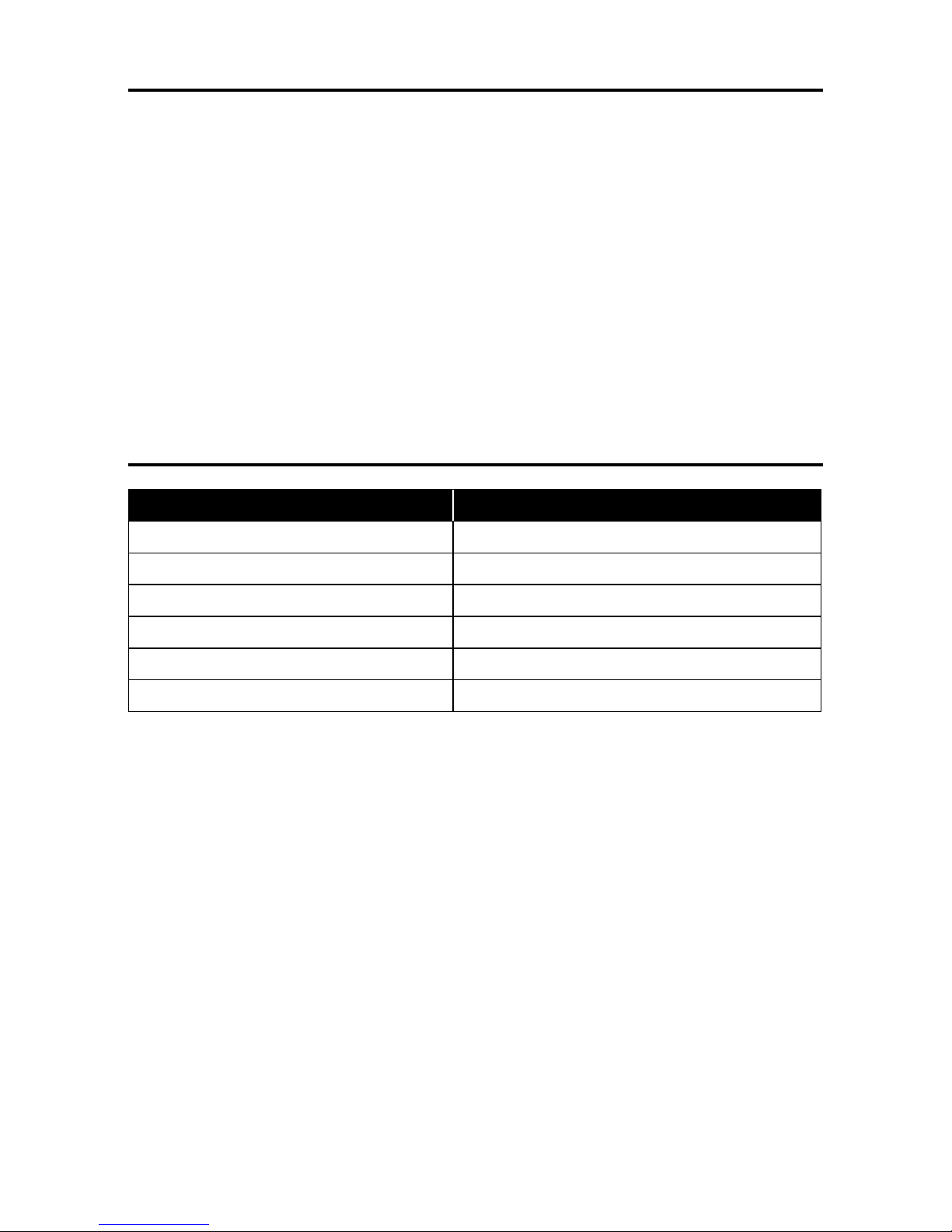

PRODUCT SPECIFICATIONS

COMPONENT SPECIFICATION

Rated voltage 24 V d.c.

No-load speed 5,400 RPM

Saw blade size 6-1/2 in.

Cutting angle 0˚ - 50˚

Depth of cut at 90° 2-7/16 in.

Depth of cut at 45° 1-11/16 in.

Page 3

3

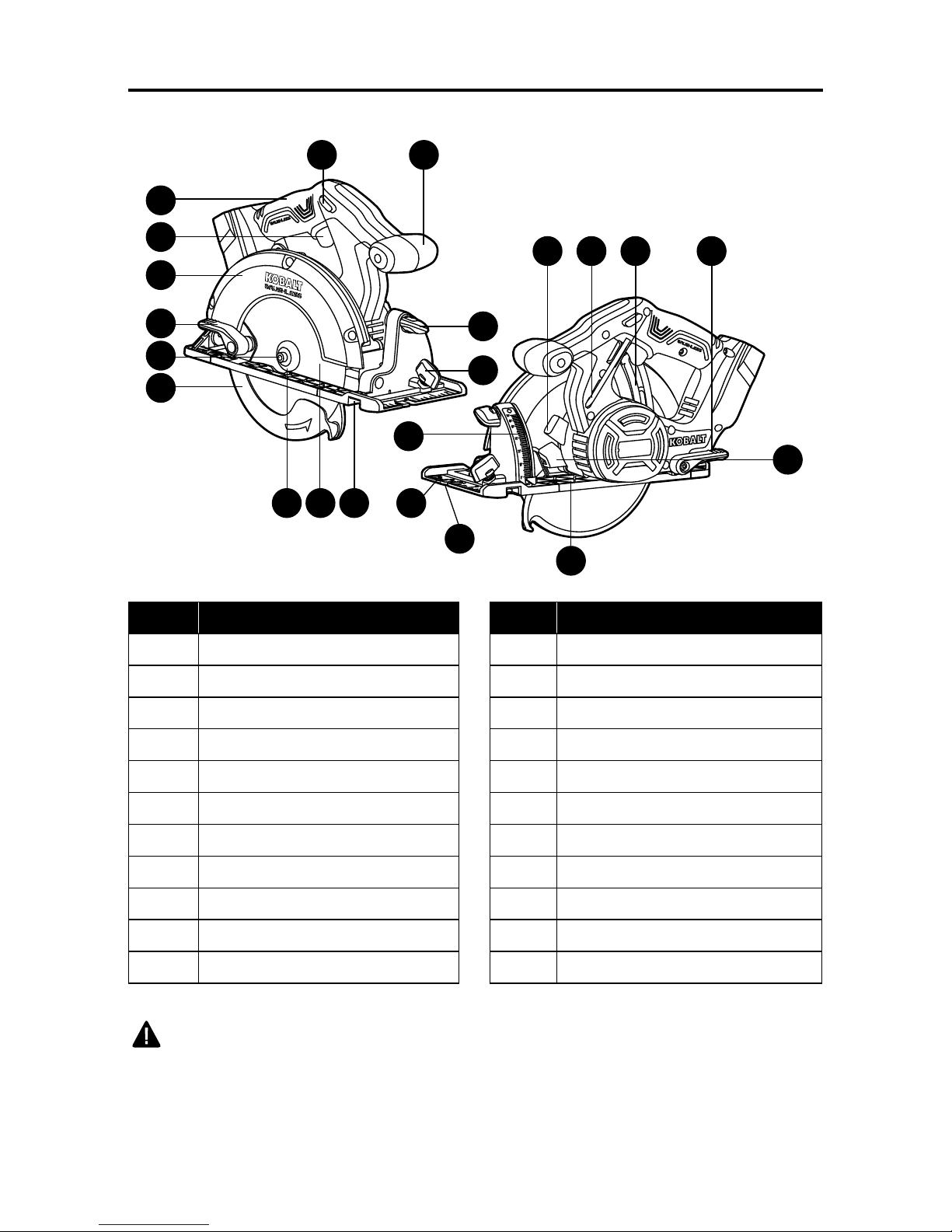

PACKAGE CONTENTS

Q

P

O

R S T U

V

C

D

E

F

G

H

B

I J K N

L

M

A

PART DESCRIPTION PART DESCRIPTION

A Auxiliary handle L 45° blade-guide notch

B Lock-off button M Base shoe

C Main handle N 90° blade-guide notch

D Trigger switch O Bevel scale

E Upper blade guard P Edge-guide locking knob

F Blade-guard lever Q Bevel-locking knob

G Blade bolt R Spindle-lock button

H Lower blade guard S Blade wrench

I Blade outer ange T Depth scale

J Blade U Depth-locking lever

K Edge-guide slot V LED worklight

WARNING

• Remove the tool from the package and examine it carefully. Do not discard the carton or any

packaging material until all parts have been examined.

• If any part of the tool is missing or damaged, do not attach the battery pack or use the tool

until the part has been repaired or replaced. Failure to heed this warning could result in

serious injury.

Page 4

4

SAFETY INFORMATION

Please read and understand this entire manual before attempting to assemble or operate

this product. If you have any questions regarding the product, please call customer service at

1-888-3KOBALT, 8 a.m. - 8 p.m., EST, Monday - Friday.

WARNING

• The operation of any power tool can result in foreign objects being thrown into your eyes,

which can result in severe eye damage. Before beginning power-tool operation, always wear

safety goggles or safety glasses with side shields and a full-face shield, when needed. It is

recommended to use a wide vision safety mask over eyeglasses or standard safety glasses

with shields. Always use eye protection marked to comply with ANSI Z87.1.

• Some dust created by power sanding, sawing, grinding, drilling, and other construction

activities contains chemicals known to the state of California to cause cancer, birth defects,

or other reproductive harm. Some examples of these chemicals are:

– Lead from lead-based paints

– Crystalline silica from bricks, cement, and other masonry products

– Arsenic and chromium from chemically-treated lumber

• Your risk from these exposures varies, depending upon how often you do this type of work.

To reduce your exposure to these chemicals:

– Work in a well-ventilated area.

– Work with approved safety equipment, such as dust masks that are specially designed to

lter out microscopic particles.

– Avoid prolonged contact with dust from power sanding, sawing, grinding, drilling, and

other construction activities. Wear protective clothing and wash exposed areas with soap

and water. Allowing dust to get into your mouth or eyes or to lie on the skin may promote

absorption of harmful chemicals.

Know the Tool

To operate this tool, carefully read this manual and all labels afxed to the tool before using it.

Keep this manual available for future reference.

Important

This tool should be serviced only by a qualied service technician.

Read All Instructions Thoroughly

Page 5

5

SAFETY INFORMATION

Some of the following symbols may be used on this tool. Please study them and their meaning.

Proper interpretation of these symbols will allow you to operate the tool better and more safely.

SYMBOL DEFINITION SYMBOL DEFINITION

V Volts n

0

No-load Speed

A Amps /min Revolutions or Strokes per Minute

Hz Hertz

Direct Current

W Watts

Alternating Current

General Power Tool Safety Warnings

WARNING

• Read all safety warnings and all instructions. Failure to follow the warnings and

instructions may result in electric shock, re and/or serious injury.

Save all warnings and instructions for future reference

The term “power tool” in the warnings refers to your mains-operated (corded) power tool or

battery-operated (cordless) power tool.

Work Area Safety

• Keep work area clean and well lit. Cluttered or dark areas invite accidents.

• Do not operate power tools in explosive atmospheres, such as in the presence of

ammable liquids, gases or dust. Power tools create sparks, which may ignite the dust or

fumes.

• Keep children and bystanders away while operating a power tool. Distractions can

cause you to lose control.

Electrical Safety

• Power tool plugs must match the outlet. Never modify the plug in any way. Do not use

any adaptor plugs with earthed (grounded) power tools. Unmodied plugs and matching

outlets will reduce the risk of electric shock.

• Avoid body contact with earthed or grounded surfaces such as pipes, radiators, ranges

and refrigerators. There is an increased risk of electric shock if your body is earthed or

grounded.

• Do not expose power tools to rain or wet conditions. Water entering a power tool will

increase the risk of electric shock.

• Do not abuse the cord. Never use the cord for carrying, pulling or unplugging the

power tool. Keep cord away from heat, oil, sharp edges or moving parts. Damaged or

entangled cords increase the risk of electric shock.

Page 6

6

SAFETY INFORMATION

• When operating a power tool outdoors, use an extension cord suitable for outdoor

use. Use of a cord suitable for outdoor use reduces the risk of electric shock.

• If operating a power tool in a damp location is unavoidable, use a ground-fault circuit

interrupter (GFCI) protected supply. Use of a GFCI reduces the risk of electric shock.

Personal Safety

• Stay alert, watch what you are doing and use common sense when operating a power

tool. Do not use a power tool while you are tired or under the inuence of drugs,

alcohol or medication. A moment of inattention while operating power tools may result in

serious personal injury.

• Use personal protective equipment. Always wear eye protection. Protective equipment

such as dust mask, non-skid safety shoes, hard hat, or hearing protection, used for

appropriate conditions, will reduce personal injuries.

• Prevent unintentional starting. Ensure the switch is in the off-position before

connecting to power source and/or battery pack, picking up or carrying the tool.

Carrying power tools with your nger on the switch or energizing power tools that have the

switch on invites accidents.

• Remove any adjusting key or wrench before turning the power tool on. A wrench or a

key left attached to a rotating part of the power tool may result in personal injury.

• Do not overreach. Keep proper footing and balance at all times. This enables better

control of the power tool in unexpected situations.

• Dress properly. Do not wear loose clothing or jewelry. Keep your hair, clothing and

gloves away from moving parts. Loose clothes, jewelry or long hair can be caught in

moving parts.

• If devices are provided for the connection of dust extraction and collection facilities,

ensure that these are connected and properly used. Use of these devices can reduce

dust-related hazards.

Power Tool Use and Care

• Do not force the power tool. Use the correct power tool for your application. The

correct power tool will do the job better and safer at the rate for which it was designed.

• Do not use the power tool if the switch does not turn it on and off. Any power tool that

cannot be controlled with the switch is dangerous and must be repaired.

• Disconnect the plug from the power source and/or the battery pack from the power

tool before making any adjustments, changing accessories, or storing power tools.

Such preventive safety measures reduce the risk of starting the power tool accidentally.

• Store idle power tools out of the reach of children and do not allow persons

unfamiliar with the power tool or these instructions to operate the power tool. Power

tools are dangerous in the hands of untrained users.

• Maintain power tools. Check for misalignment or binding of moving parts, breakage of

parts and any other condition that may affect the power tool’s operation. If damaged,

have the power tool repaired before use. Many accidents are caused by poorly maintained

power tools.

• Keep cutting tools sharp and clean. Properly maintained cutting tools with sharp cutting

edges are less likely to bind and are easier to control.

• Use the power tool, accessories, tool bits, etc., in accordance with these instructions,

taking into account the working conditions and the work to be performed. Use of the

power tool for operations different from those intended could result in a hazardous situation.

Page 7

7

SAFETY INFORMATION

Battery Tool Use and Care

• Recharge only with the charger specied by the manufacturer. A charger that is suitable

for one type of battery pack may create a risk of re when used with another battery pack.

• Use power tools only with specically designated battery packs. Use of any other

battery packs may create a risk of injury and re.

• When battery pack is not in use, keep it away from other metal objects like paper

clips, coins, keys, nails, screws or other small metal objects that can make a

connection from one terminal to another. Shorting the battery terminals together may

cause burns or a re.

• Under abusive conditions, liquid may be ejected from the battery; avoid contact. If

contact accidentally occurs, ush with water. If liquid contacts eyes, additionally seek

medical help. Liquid ejected from the battery may cause irritation or burns.

Service

• Have your power tool serviced by a qualied repair person using only identical

replacement parts. This will ensure that the safety of the power tool is maintained.

Specic Safety Warnings for Circular Saws

Safety Instructions for All Saws

DANGER

• Keep hands away from cutting area and the blade. Keep your second hand on the

auxiliary handle or motor housing. If both hands are holding the saw, they cannot be cut

by the blade.

• Do not reach underneath the workpiece. The guard cannot protect you from the blade

below the workpiece.

• Adjust the cutting depth to the thickness of the workpiece. Less than a full tooth of the

blade teeth should be visible below the workpiece.

• Never hold the piece being cut in your hands or across your leg. Secure the

workpiece to a stable platform. It is important to support the work properly to minimize

body exposure, blade binding, and loss of control.

• Hold the power tool by insulated gripping surfaces only, when performing an

operation where the cutting tool may contact hidden wiring. Contact with a “live” wire

will also make exposed metal parts of the power tool “live” and could give the operator an

electric shock.

• When ripping, always use a rip fence or straight-edge guide. This improves the

accuracy of cut and reduces the chance of blade binding.

• Always use blades with arbor holes of the correct size and sharp (diamond versus

round).Blades that do not match the mounting hardware of the saw will run eccentrically,

causing loss of control.

• Never use damaged or incorrect blade washers or bolt. The blade washers and bolt

were specially designed for your saw for optimum performance and safe operation.

Further Safety Instructions for All Saws

Page 8

8

SAFETY INFORMATION

Cause and operator prevention of kickback:

– Kickback is a sudden reaction to a pinched, bound or misaligned saw blade, causing an

uncontrolled saw to lift up and out of the workpiece toward the operator.

– When the blade is pinched or bound tightly by the kerf closing down, the blade stalls and

the motor reaction drives the unit rapidly back toward the operator.

– If the blade becomes twisted or misaligned in the cut, the teeth at the back edge of the

blade can dig into the upper surface of the wood, causing the blade to climb out of the

kerf and jump back toward the operator.

Kickback is the result of saw misuse and/or incorrect operating procedures or conditions and

can be avoided by taking proper precautions, as given below.

• Maintain a rm grip with both hands on the saw and position your arms to resist

kickback forces. Position your body to either side of the blade, but not in line with

the blade. Kickback could cause the saw to jump backward, but kickback forces can be

controlled by the operator if proper precautions are taken.

• When blade is binding, or when interrupting a cut for any reason, release the trigger and

hold the saw motionless in the material until the blade comes to a complete stop. Never

attempt to remove the saw from the work or pull the saw backward while the blade is in

motion or kickback may occur. Investigate and take corrective actions to eliminate the cause

of blade binding.

• When restarting a saw in the workpiece, center the saw blade in the kerf and check

that the saw teeth are not engaged in the material. If the saw blade is binding, it may

walk up or kickback from the workpiece as the saw is restarted.

• Support larger panels to minimize the risk of blade pinching and kickback. Larger

panels tend to sag under their own weight. Supports must be placed under the panel on

both sides: near the line of cut and near the edge of the panel.

• Do not use dull or damaged blades. Dull or improperly set blades produce narrow kerf,

causing excessive friction, blade binding and kickback.

• Blade-depth and bevel-adjusting locking levers must be tight and secure before

making a cut. If the blade adjustment shifts while cutting, it may cause binding and

kickback.

• Use extra caution when making a “plunge cut” into existing walls or other blind

areas. The protruding blade may contact hidden objects that can cause kickback.

Safety Instructions for Lower Blade Guard

• Check the lower guard for proper closing before each use. Do not operate the saw if

the lower guard does not move freely and close instantly. Never clamp or tie the lower

guard into the open position. If the saw is accidentally dropped, the lower guard may be

bent. Raise the lower guard with the retracting handle and make sure that it moves freely

and does not touch the blade or any other part, in all angles and all depths of cut.

• Check the operation of the lower guard spring. If the guard and the spring are not

operating properly, they must be serviced before use. A lower guard may operate

sluggishly due to damaged parts, gummy deposits, or a build-up of debris.

• The lower guard should be retracted manually only for special cuts, such as “plunge

cuts” and “compound cuts.” Raise the lower guard with the retracting handle and,

as soon as blade enters the material, the lower guard must be released. For all other

sawing, the lower guard should be allowed to operate automatically.

• Always observe that the lower guard is covering the blade before placing the saw down

on the bench or oor. An unprotected, coasting blade will cause the saw to walk backwards,

cutting whatever is in its path. Be aware of the time it takes for the blade to stop after switch is

released.

Page 9

9

SAFETY INFORMATION

Additional Safety Warnings for Circular Saws

a. Always wear a dust mask

b. Only use recommended saw blades

c. Always wear hearing protection

d. Do not use with any abrasive wheels

PREPARATION

Know Your Circular Saw

Before attempting to use the circular saw, familiarize yourself with all of its operating features

and safety requirements.

WARNING

• Do not allow familiarity with the circular saw to cause carelessness. Remember that one

careless moment is enough to cause severe injury. Before attempting to use any tool, be sure

to become familiar with all of the operating features and safety instructions.

• Do not attempt to modify this tool or create accessories not recommended for use with this

tool. Any such alteration or modication is misuse and could result in a hazardous condition

leading to possible serious personal injury.

Page 10

10

OPERATING INSTRUCTIONS

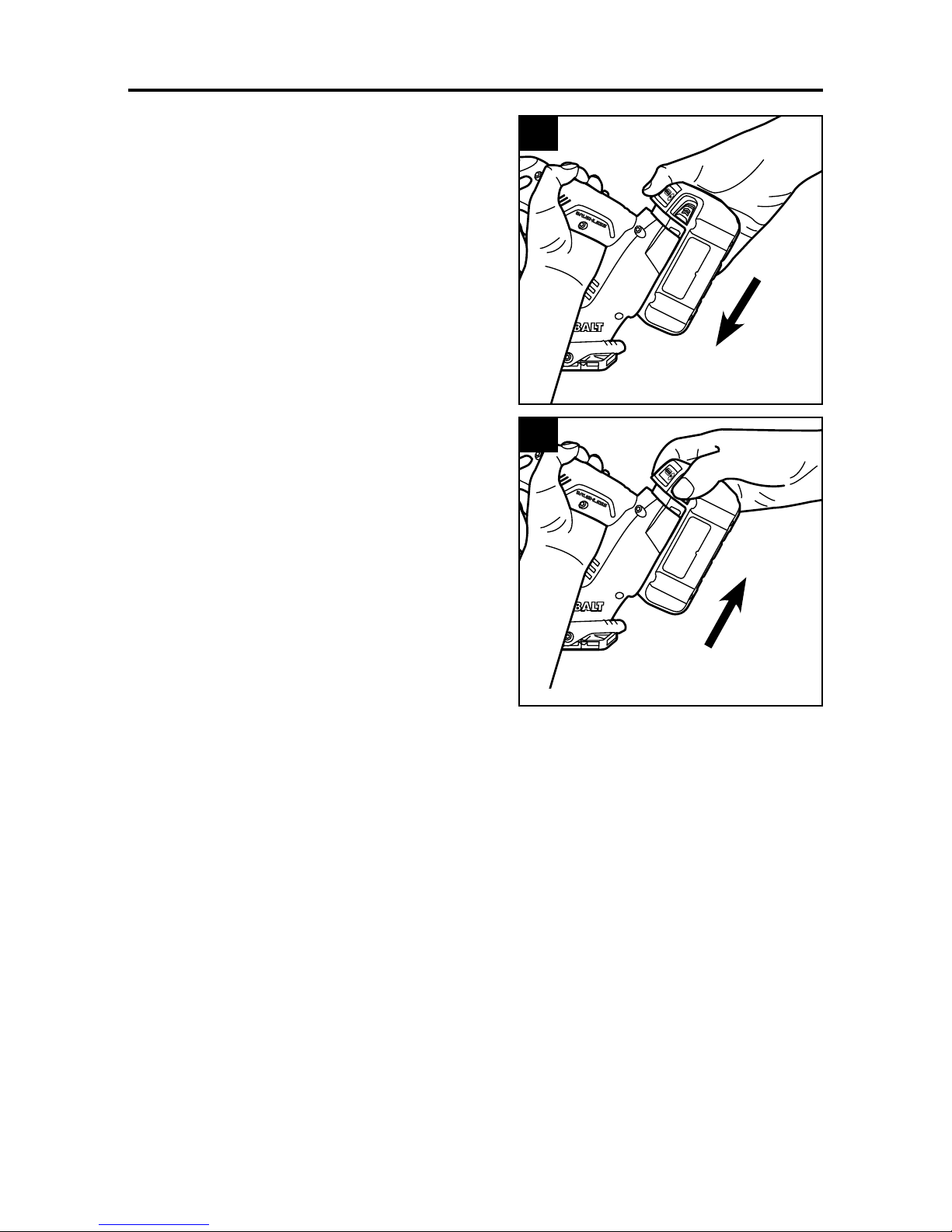

1. Battery Pack

To Attach Battery Pack

a. Ensure that the trigger switch (D) is in the

“OFF” position.

b. Align the raised portion on the battery pack

with the grooves on the bottom of the tool, then

slide the battery pack onto the saw as shown.

c. Make sure that the latches on the battery pack

snap into place and the battery pack is secured

to the tool before beginning operation.

NOTICE: When placing the battery pack on the

tool, be sure that the raised rib on battery pack

aligns with the groove on the tool and the latches

snap into place properly. Improper assembly of

the battery pack can cause damage to internal

components.

To Detach Battery Pack

a. Ensure that the trigger switch (D) is in the

“OFF” position.

b. Press the battery-release buttons to release the

battery pack.

c. Pull forward on the battery pack to remove it

from the tool.

1a

1b

Page 11

11

OPERATING INSTRUCTIONS

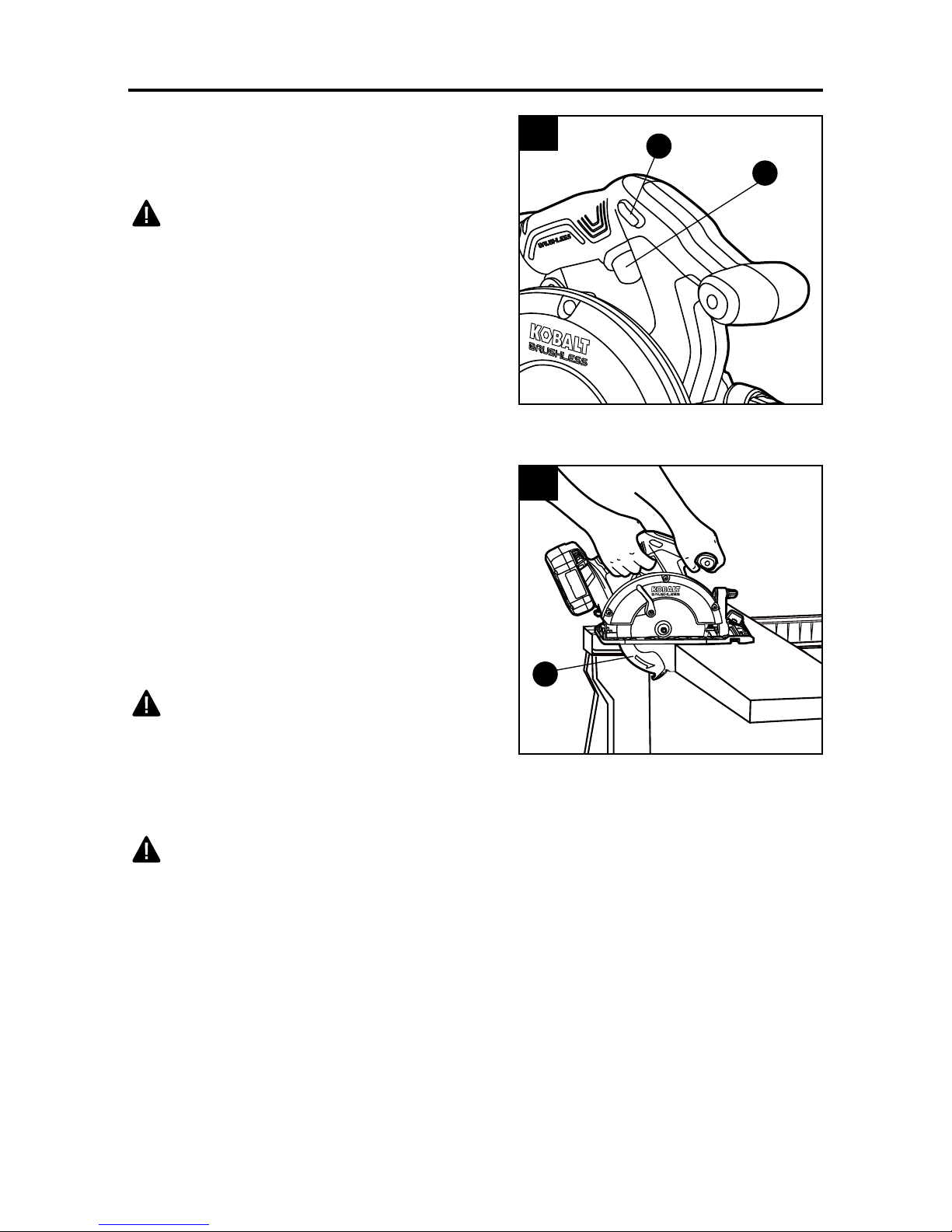

2. Trigger Switch

a. To turn the saw ON, press the lock-off button

(B), then squeeze the trigger switch (D).

WARNING

• The blade should reach full speed before it

comes into contact with the workpiece.

b. To turn the saw OFF, release the trigger switch

and allow the blade to come to a complete

stop.

Electric Brake

The circular saw is equipped with an electric brake.

When the trigger switch is released, the electric

brake engages automatically to quickly stop the rotation.

3. Blade Guard System

The lower blade guard (H) on the circular saw is

there for the operator’s protection and safety. Do

not alter it for any reason.

If the lower blade guard becomes damaged or if the

blade begins to run slowly or sluggishly, DO NOT

operate the saw until the damaged part has been

repaired or replaced. ALWAYS leave the guard in its

correct operating position when using the saw.

DANGER

• When sawing through a workpiece, the lower

blade guard does not cover the blade on the

underside of the workpiece. ALWAYS keep hands and body away from the cutting area.

Serious injury will result if any part of the body comes into contact with the moving blade.

WARNING

• To avoid possible serious injury, never use the saw when the lower blade guard is not

operating correctly. Check the lower blade guard for correct operation before each use. It

should move freely and instantly return to the closed position. If the saw is dropped, check

the lower blade guard and bumper for damage at all depth settings before using it.

If the lower blade guard does not snap closed at any time, take it to a qualied service

technician for repair.

3

H

2

B

D

Page 12

12

OPERATING INSTRUCTIONS

4. Adjusting the Cutting Depth

WARNING

• Always maintain the correct blade-depth setting.

The correct blade-depth setting for all cuts should

not exceed the thickness of the material being cut

by more than 1/4 in. (6.5 mm). Greater blade depth

will increase the chance of kickback and cause the

cut to be rough.

a. Remove the battery pack from the saw.

b. Raise the depth-locking lever (U) to release it.

c. Hold the base shoe (M) against the workpiece

and raise or lower the saw until the indicator mark

on the saw aligns with the desired depth on the

depth scale (T).

d. Lower the depth-locking lever to lock it into

position.

5. Adjusting the Cutting Angle

a. Remove the battery pack from the saw.

b. Loosen the bevel-locking knob (Q), located on

the 0°-50° bevel scale (O).

c. Tilt the body of the saw until the indicator mark

on the saw aligns with the required angle on

the bevel-angle scale.

d. Tighten the bevel-locking knob to secure the

saw.

6. LED worklight

The circular saw is equipped with an LED worklight

(V) that will illuminate when the trigger switch is

depressed. This provides additional light on the

surface of the workpiece for operation in lower-light

areas.

The LED worklight will turn off after the trigger

switch is released.

a. The LED worklight will blink rapidly if the tool

has stopped working in order to protect internal

circuits; please wait for the tool to cool down, at

which point it can be started again.

b. The LED worklight will blink slowly to indicate

that the battery charge is very low.

6

V

5

Q

O

4

U

M

T

Page 13

13

OPERATING INSTRUCTIONS

7. Saw Blades

The best saw blades will not cut efciently if they

are not kept clean, sharp, and properly set. Using

a dull blade will place a heavy load on the saw and

increase the danger of kickback. Keep extra blades

on hand so sharp blades are always available.

Gum and resin on blades will slow the saw down.

Follow the instructions for removing a saw blade,

then use gum and resin remover, hot water, or

kerosene to remove the accumulations.

WARNING

• Do not use gasoline to clean the blade.

Installing a Saw Blade

a. Remove the battery pack from the saw.

b. Depress and hold the spindle-lock button (R).

c. Loosen the blade bolt (G) by turning it counterclockwise with the blade wrench (S)

(included).

d. Remove the blade bolt, washer and outer ange (I).

WARNING

• If the inner ange has been removed, replace it before placing the blade on the spindle.

Failure to do so will prevent the blade from tightening properly and could result in serious

personal injury.

e. Use the blade-guard lever (F) to retract the lower blade guard (H) into the upper blade guard

(E).

f. Fit the saw blade (J) inside the lower blade guard and onto the spindle. Verify that the

saw teeth, the arrow on the saw blade and the blade-rotation indicator arrow on the blade

guard are all pointing in the same direction.

NOTICE: The saw teeth should point upward at the front of the saw.

g. Replace the outer blade ange with the protuberant facing outward.

h. Depress and hold the spindle-lock button, and replace the washer and blade bolt.

i. Tighten the blade bolt securely by turning it clockwise with the blade wrench.

NOTICE: Never use a blade that is too thick to allow the outer blade ange to engage with the

at section of the spindle.

WARNING

• To prevent personal injury, always remove the battery pack before installing or removing the

saw blade.

7

G I F

J

E

R

Page 14

14

OPERATING INSTRUCTIONS

Removing the Saw Blade

a. Remove the battery pack from the saw.

b. Depress and hold the spindle-lock button (R).

c. Loosen the blade bolt (G) by turning it

counterclockwise with the blade wrench (S).

d. Remove the blade bolt and outer blade ange

(I).

e. Lift the lower blade guard (H) and then remove

the blade (J).

8. Cutting With the Circular Saw

Refer to the gures in this section to learn the

correct and incorrect ways of handling the saw.

WARNING

• To make sawing easier and safer, always

maintain proper control of the saw. Loss of

control could cause an accident resulting in

serious injury.

DANGER

• When lifting the saw from the workpiece, the

blade is exposed on the underside of the saw

until the lower blade guard (H) closes. Make

sure that the lower blade guard is closed before

setting the saw down.

To make the safest and best possible cut, follow

these helpful hints:

a. Hold the saw rmly with both hands.

b. Avoid placing your hand on the workpiece while

making a cut (Fig. 8a).

c. Support the workpiece so that the cut is always

to the operator’s side and not directly in line

with the operator’s body.

d. Support the workpiece near the cut.

e. Clamp the workpiece securely so that the

workpiece will not move during the cut (Fig.

8b).

f. Always place the saw on the portion of the

workpiece that is supported and not on the “cut

off” piece (Fig. 8c).

g. Place the workpiece with the “good” side down.

h. Draw a guideline along the desired cutting line before beginning the cut.

8a

8b

8c

F

Page 15

15

OPERATING INSTRUCTIONS

9. Cross-Cutting/Rip Cutting

When making a cross-cut or a rip cut, align the

guideline with the 90˚ blade-guide notch (N) on the

base shoe (T). The distance from the saw blade to

the saw base is approximately 3-5/8 in. (9.2 cm) on

the left side of the saw and 1-1/2 in. (3.7 cm) on the

right side.

Blade thicknesses vary, so you should always

make a trial cut in scrap material along a guideline

to determine how much the guideline must be offset

from the guide to produce an accurate cut.

NOTICE: Use a guide when making long or wide

rip cuts.

10. Rip Cutting Using a Straight Edge

a. Secure the workpiece.

b. Clamp a straight edge to the workpiece using

C-clamps (not included).

NOTICE: Position the C-clamps so that they will not

interfere with the saw housing during the cut.

c. Press the lock-off button (B) and depress the

trigger switch (D) to start the saw.

d. Allow the blade (J) to reach full speed, then

guide the saw into the workpiece and make the

cut.

e. Saw along the straight edge to achieve a

straight rip cut.

f. Release the trigger switch and allow the blade

to come to a complete stop.

g. Lift the saw from the workpiece.

NOTICE: Do not bind the blade in the cut.

9

N

10

Page 16

16

OPERATING INSTRUCTIONS

11. Bevel Cutting

a. Remove the battery pack.

b. Adjust the angle of cut to any desired setting

between 0° and 50°. Securely tighten the

bevel-locking knob (Q).

c. Replace the battery pack.

d. Align the cutting line with the 45° blade-guide

notch (L) on the base shoe (M) when making

45° bevel cuts.

e. Make a trial cut in scrap material along a

guideline to determine the amount to offset the

guideline on the cutting material.

WARNING

• Attempting a bevel cut without having the bevel-locking knob securely locked in place can

result in serious injury.

f. Hold the saw rmly with both hands, as shown.

g. Rest the front edge of the base shoe on the workpiece without touching the blade to the

workpiece.

h. Start the saw and allow the blade to reach full speed.

i. Guide the saw into the workpiece and make the cut.

j. Release the trigger switch and allow the blade to come to a complete stop.

k. Lift the saw from the workpiece.

11

L

Page 17

17

OPERATING INSTRUCTIONS

12. Pocket Cutting

WARNING

• Always adjust the bevel setting to 0° before

making a pocket cut. Attempting a pocket cut at

any other setting can result in loss of control of

the saw and possible serious injury.

a. Adjust the bevel setting to 0° and tighten the

bevel-locking knob (Q).

b. Set the blade to the correct blade cutting depth.

c. Swing the lower blade guard (H) up using the

blade-guard lever (F).

d. Hold the lower blade guard in place with the

blade-guard lever.

e. Rest the front of the base shoe (M) against the workpiece, with the rear of it raised so that

the blade (J) does not touch the workpiece.

f. Press the lock-off button (B) and depress the trigger switch (D) to start the saw.

g. Allow the blade to reach full speed, then guide the saw into the workpiece and make the

cut.

h. Release the trigger switch and allow the blade to come to a complete stop.

i. Lift the saw from the workpiece.

WARNING

• Always cut in a forward direction when pocket cutting. Cutting in the reverse direction could

cause the saw to climb up on the workpiece and kick back toward the operator.

• As the blade starts cutting the material, release the blade-guard lever immediately. When

the foot of the guard rests at on the surface being cut, proceed cutting in a forward

direction to the end of the cut.

• Never tie the lower blade guard in a raised position. Leaving the blade exposed could lead

to serious injury.

CARE AND MAINTENANCE

All maintenance should only be carried out by a qualied service technician.

Cleaning

Before cleaning or performing any maintenance, remove the battery pack from the circular

saw. For safe and proper operation, always keep the tool and its ventilation slots clean.

Always use only a soft, dry cloth to clean your circular saw; never use detergent or alcohol.

12

F

F

M

Page 18

18

Printed in China

TROUBLESHOOTING

WARNING

• Turn the switch to the “OFF” position and remove the battery pack from the circular saw before

performing troubleshooting procedures.

PROBLEM POSSIBLE CAUSE CORRECTIVE ACTION

The circular saw does

not work.

Battery is depleted. Charge the battery.

Blade binds, jams, or

burns the wood.

1. Improper operation.

2. Dull blade.

3. Improper blade.

1. See “OPERATING

INSTRUCTIONS” section.

2. Replace or sharpen blade.

3. Replace blade.

Saw vibrates or

shakes.

1. Improper blade.

2. Improper operation of

installing blade.

1. Replace blade.

2. Remove the blade and reinstall it,

ensuring no part was missed.

The LED worklight

blinks rapidly.

The tool has stopped

working to protect internal

circuits.

Release the trigger switch, wait for

the tool to cool down, then and start

the tool again.

The LED worklight

blinks slowly.

The battery charge is very

low.

Charge the battery.

WARRANTY

For 5 years from the date of purchase, the circular saw is warranted for the original purchaser

to be free from defects in material and workmanship. This guarantee does not cover damage

due to abuse, normal wear, improper maintenance, neglect, unauthorized repair/alteration, or

expendable parts and accessories expected to become unusable after a reasonable period of

use.

If you think your product meets the above guarantee criteria, please return it to the place of

purchase with valid proof of purchase and the defective product will be repaired or replaced at

no charge. This guarantee gives you specic legal rights, and you may also have other rights

that vary from state to state.

Page 19

19

ARTÍCULO #0672830/0864453/0877730

SIERRA CIRCULAR SIN

CEPILLO DE 6-1/2 PULG.

MODELO #KCS 6524B-03

¿Preguntas, problemas, piezas faltantes? Antes de volver a la tienda, llame a nuestro

departamento de servicio al cliente al 1-888-3KOBALT (1-888-356-2258), de lunes a

viernes de 8 a. m. a 8 p. m., hora estándar del Este.

ADJUNTE SU RECIBO AQUÍ

Número de serie Fecha de compra

Page 20

20

ÍNDICE

Especicaciones del producto ........................................................................20

Contenido del paquete ................................................................................... 21

Información de seguridad ...............................................................................22

Preparación .................................................................................................... 28

Instrucciones de funcionamiento ....................................................................28

Cuidado y mantenimiento ..............................................................................35

Solución de problemas ...................................................................................36

Garantía ......................................................................................................... 36

ESPECIFICACIONES DEL PRODUCTO

COMPONENTE ESPECIFICACIONES

Rango de voltaje 24 V CC

Velocidad sin carga 5,400 RPM

Tamaño de la hoja de sierra 16,51 cm

Ángulo de corte 0˚ - 50˚

Profundidad del corte a 90° 6,19 cm

Profundidad del corte a 45° 4,28 cm

Page 21

21

CONTENIDO DEL PAQUETE

Q

P

O

R S T U

V

C

D

E

F

G

H

B

I J K N

L

M

A

PIEZAS DESCRIPCIÓN PIEZAS DESCRIPCIÓN

A Manija auxiliar L Ranura guía de la hoja en 45º

B Botón de bloqueo/apagado M Listoncillo de base

C Manija principal N Ranura guía de la hoja en 90º

D Interruptor de gatillo O Escala de biselado

E Protección de hoja superior P

Perilla de bloqueo de la guía del

borde

F Palanca de protección de hoja Q Perilla de bloqueo de biselado

G Perno de la hoja R Botón de bloqueo del husillo

H Protección de hoja inferior S Llave para hoja

I Brida de hoja externa T Escala de profundidad de corte

J Hoja U

Palanca de bloqueo de

profundidad

K Ranura guía del borde V Luz de trabajo con bombilla LED

ADVERTENCIA

• Retire la herramienta del paquete y examínela con cuidado. No deseche la caja ni ningún

material de embalaje hasta después de examinar todas las piezas.

• Si falta alguna pieza de la herramienta o si alguna pieza está dañada, no coloque

el paquete de baterías ni use la herramienta hasta reparar o reemplazar la pieza. El

incumplimiento de esta advertencia podría provocar lesiones graves.

Page 22

22

INFORMACIÓN DE SEGURIDAD

Lea y comprenda por completo este manual antes de intentar ensamblar u operar este

producto. Si tiene preguntas relacionadas con el producto, llame al Departamento de Servicio

al Cliente al 1-888-3KOBALT, de lunes a viernes de 8 a.m. a 8 p.m., hora estándar del Este.

ADVERTENCIA

• Durante el funcionamiento de cualquier herramienta eléctrica, pueden entrar objetos

extraños a los ojos y causar graves daños oculares. Use siempre gafas de seguridad con

protecciones laterales y, cuando sea necesario, use una máscara que cubra todo el rostro

antes de comenzar a operar una herramienta eléctrica. Recomendamos usar una máscara

de seguridad de visión amplia sobre los lentes o las gafas de seguridad estándar con

protección. Siempre use lentes de protección que cumplan con la norma ANSI Z87.1.

• Parte del polvo causado por el lijado eléctrico, el serruchado, la trituración, el taladro y

otras actividades de construcción contiene sustancias químicas que, según el estado

de California, causan cáncer, defectos congénitos u otros daños reproductivos. Algunos

ejemplos de estos químicos son los siguientes:

– Plomo de pinturas a base de plomo.

– Sílice cristalina de ladrillo, cemento y otros productos de mampostería.

– Arsénico y cromo de madera tratada con sustancias químicas.

• El riesgo que corre debido a la exposición a estos químicos varía según la frecuencia con

que realiza este tipo de trabajo. Para disminuir su exposición a estas sustancias químicas:

– Trabaje en un área bien ventilada.

– Trabaje con equipo de seguridad aprobado, como mascarillas antipolvo especialmente

diseñadas para ltrar partículas microscópicas.

– Evite estar en contacto prolongado con el polvo provocado por las lijas, sierras,

trituradoras, taladros eléctricos y otras actividades de construcción. Use ropa protectora

y lave todas las áreas expuestas del cuerpo con agua y jabón. Si permite que el polvo

llegue a su boca, ojos o piel, puede fomentar la absorción de químicos dañinos.

Conozca la herramienta

Para operar esta herramienta, lea con atención este manual y todas las etiquetas de la

herramienta antes de usarla. Conserve este manual para tenerlo como referencia futura.

Importante

Solo un técnico de servicio calicado puede reparar esta herramienta.

Lea por completo todas las instrucciones

Page 23

23

INFORMACIÓN DE SEGURIDAD

Algunos de los siguientes símbolos pueden aparecer en esta herramienta. Obsérvelos y

aprenda su signicado. La interpretación correcta de estos símbolos le permitirá utilizar la

herramienta de manera ecaz y segura.

SÍMBOLO DEFINICIÓN SÍMBOLO DEFINICIÓN

V Voltios n

0

Velocidad sin carga

A Amperios /min Revoluciones o pasadas por minuto

Hz Hertz

Corriente continua

W vatios

Corriente alterna

Advertencias de seguridad general en el manejo de herramientas eléctricas

ADVERTENCIA

• Lea todas las advertencias de seguridad y todas las instrucciones. El incumplimiento

de las advertencias y de las instrucciones podría provocar descargas eléctricas, incendios o

lesiones graves.

Guarde todas las advertencias e instrucciones para referencia futura

El término “herramienta eléctrica” que aparece en las advertencias se reere a la herramienta

eléctrica que se conecta a la línea principal (con cable) o a la herramienta eléctrica que

funciona con batería (inalámbrica).

Seguridad en el área de trabajo

• Mantenga el área de trabajo limpia y bien iluminada. Las áreas desordenadas u oscuras

aumentan las posibilidades de accidentes.

• No utilice herramientas eléctricas en atmósferas en las que exista riesgo de

explosión, como por ejemplo en presencia de líquidos inamables, gases o polvo. Las

herramientas eléctricas producen chispas que podrían encender el polvo o humo.

• Mantenga a los niños y a las personas cercanas alejadas durante el funcionamiento

de una herramienta eléctrica. Las distracciones pueden hacerle perder el control.

Seguridad eléctrica

• El enchufe de la herramienta eléctrica debe encajar en el tomacorriente. Nunca

modique el enchufe de ninguna manera. No utilice ningún enchufe adaptador con

herramientas eléctricas con puesta a tierra. Los enchufes sin modicaciones y que

encajan en los tomacorrientes reducen el riesgo de descarga eléctrica.

• Evite el contacto del cuerpo con supercies conectadas a tierra, como tuberías,

radiadores, extractores o refrigeradores. Existe un gran riesgo de descarga eléctrica si su

cuerpo tiene conexión a tierra.

Page 24

24

INFORMACIÓN DE SEGURIDAD

• No exponga las herramientas eléctricas a la lluvia o a condiciones de humedad. El

ingreso de agua en una herramienta eléctrica aumentará el riesgo de descarga eléctrica.

• No maltrate el cable. Nunca use el cable para transportar, jalar o desenchufar la

herramienta eléctrica. Mantenga el cable alejado del calor, el aceite, los bordes

losos o las piezas en movimiento. Los cables dañados o enredados aumentan el riesgo

de descarga eléctrica.

• Cuando opere una herramienta eléctrica en exteriores, utilice una extensión eléctrica

para uso en exteriores. La utilización de un cable apto para uso en exteriores reduce el

riesgo de descarga eléctrica.

• Si debe utilizar una herramienta eléctrica en un área húmeda, use un suministro

protegido con un interruptor de circuito de falla de puesta a tierra (GFCI, por sus

siglas en inglés). El uso de un GFCI disminuye el riesgo de descarga eléctrica.

Seguridad personal

• Manténgase alerta, preste atención a lo que hace y utilice el sentido común cuando

use una herramienta eléctrica. No utilice una herramienta eléctrica si está cansado

o bajo los efectos de drogas, alcohol o medicamentos. Un momento de desatención

mientras opera herramientas eléctricas puede provocar lesiones personales graves.

• Use un equipo de protección personal. Utilice siempre lentes de protección.

Los equipos de protección, como una mascarilla antipolvo, zapatos de seguridad

antideslizantes, casco protector o protección auditiva, utilizados para condiciones

adecuadas, disminuyen las lesiones personales.

• Evite un arranque accidental. Asegúrese de que el interruptor esté en la posición

de apagado antes de conectar la fuente o la batería, levantar la herramienta o

transportarla. Transportar herramientas eléctricas con el dedo en el interruptor o enchufar

herramientas eléctricas que tienen el interruptor encendido aumenta las posibilidades de

accidentes.

• Retire todas las llaves de ajuste o llaves inglesas antes de encender la herramienta

eléctrica. Si se deja una llave inglesa o una llave conectada a una pieza giratoria de la

herramienta eléctrica, se pueden producir lesiones personales.

• No se incline demasiado. Mantenga una posición y un equilibrio adecuados en

todo momento. Esto permite un mejor control de la herramienta eléctrica en situaciones

inesperadas.

• Use ropa adecuada. No use ropa holgada ni joyas. Mantenga el cabello, la ropa y los

guantes lejos de las piezas en movimiento. La ropa holgada, las joyas o el cabello largo

pueden quedar atrapados en las piezas giratorias.

• Si se proporcionan dispositivos para la conexión de equipos de extracción y

recolección de polvo, asegúrese de que se conecten y se usen debidamente. El uso

de estos dispositivos puede disminuir los peligros relacionados con el polvo.

Uso y cuidado de las herramientas eléctricas

• No fuerce la herramienta eléctrica. Utilice la herramienta eléctrica adecuada para su

aplicación. La herramienta eléctrica adecuada realizará un trabajo más seguro y de mejor

calidad a la velocidad para la cual fue diseñada.

• No utilice la herramienta eléctrica si el interruptor no la enciende o apaga. Cualquier

herramienta eléctrica que no pueda controlarse con el interruptor es peligrosa y debe

repararse.

• Desconecte el enchufe de la fuente de alimentación o la batería de la herramienta

eléctrica antes de realizar cualquier ajuste, cambiar accesorios o almacenar

herramientas eléctricas. Este tipo de medidas de seguridad preventivas reduce el riesgo

de arranques accidentales de la herramienta eléctrica.

Page 25

25

INFORMACIÓN DE SEGURIDAD

• Almacene las herramientas eléctricas que no estén en uso fuera del alcance de los

niños y no permita que las personas que no estén familiarizadas con la herramienta o

con estas instrucciones la operen. Las herramientas eléctricas son peligrosas en manos

de usuarios sin capacitación.

• Realice mantenimiento a las herramientas eléctricas. Revise si hay desalineación o

atascamiento de piezas móviles o si están rotas, así como cualquier otra condición

que pueda afectar la operación de la herramienta eléctrica. Si se daña, haga reparar la

herramienta eléctrica antes de usarla. Muchos accidentes son producto del mantenimiento

incorrecto de las herramientas eléctricas.

• Mantenga las herramientas de corte aladas y limpias. Las herramientas de corte que

se mantienen de forma adecuada, con sus bordes de corte alados, tienen un riesgo menor

de trabarse y son más fáciles de controlar.

• Use la herramienta eléctrica, los accesorios, las brocas, etc., de acuerdo con estas

instrucciones y según las condiciones de trabajo y el tipo de trabajo que desea

realizar. El uso de la herramienta eléctrica en operaciones distintas para las que se diseñó

podría crear una situación de peligro.

Uso y cuidado de herramientas con batería

• Recargue solo con el cargador especicado por el fabricante. Un cargador adecuado

para un tipo de paquete de baterías puede generar riesgo de incendio cuando se usa con

otro paquete de baterías.

• Use las herramientas eléctricas solo con paquetes de baterías designados

especícamente. El uso de cualquier otro paquete de baterías puede generar riesgo de

lesión e incendio.

• Cuando el paquete de baterías no está en uso, aléjelo de objetos metálicos, como

sujetapapeles, monedas, llaves, clavos, tornillos u otros objetos metálicos pequeños

que pudieran crear una conexión entre los terminales. Es posible que una conexión

entre los terminales produzca quemaduras o un incendio.

• En condiciones de maltrato, es posible que salga líquido de la batería; evite el

contacto. Si se produce un contacto por accidente, enjuague con agua. Si el líquido

entra en contacto con los ojos, además de lo mencionado con anterioridad, debe

buscar atención médica. El líquido que sale de la batería puede provocar irritación o

quemaduras.

Reparación

• Permita que solo una persona capacitada repare la herramienta eléctrica, utilizando

solo piezas de repuesto idénticas. Esto mantendrá la seguridad de la herramienta

eléctrica.

Advertencias especícas de seguridad para sierras circulares

Instrucciones de seguridad para todas las sierras

PELIGRO

• Mantenga las manos alejadas del área de corte y de la hoja. Mantenga la otra mano

en la manija auxiliar o la carcasa del motor. Si ambas manos sujetan la sierra, no

pueden sufrir cortes por parte de la hoja.

• No se coloque bajo la pieza de trabajo. La protección no puede protegerlo de la hoja

debajo de la pieza de trabajo.

Page 26

26

INFORMACIÓN DE SEGURIDAD

• Ajuste la profundidad de corte de acuerdo con el grosor de la pieza de trabajo. Se

debe ver menos que un diente completo de la hoja bajo la pieza de trabajo.

• Nunca sostenga la pieza que desea cortar con las manos o contra su pierna. Asegure

la pieza de trabajo a una plataforma estable. Es importante que apoye de forma

adecuada la pieza para minimizar la exposición del cuerpo, el atascamiento de la hoja y la

pérdida de control.

• Sostenga las herramientas eléctricas por las supercies de sujeción aisladas al

realizar una operación en la que la herramienta de corte pueda entrar en contacto con

alambres ocultos o con su propio cable. Sostenga las herramientas eléctricas por las

supercies de sujeción aisladas al realizar una operación en la que la herramienta de corte

pueda entrar en contacto con alambres ocultos o con su propio cable.

• Al cortar al hilo, siempre use una guía para cortes al hilo o una guía con borde recto.

Esto mejora la precisión del corte y reduce la posibilidad de atascos de la hoja.

• Siempre utilice hojas con oricios para el eje del tamaño y forma correctos (diamante

en comparación con redondo). Las hojas que no coinciden con los aditamentos de

montaje de la sierra funcionarán de manera irregular y causarán una pérdida de control.

• Nunca use arandelas o pernos de hojas dañados o incorrectos. Nunca use arandelas o

pernos de hojas dañados o incorrectos.

Instrucciones de seguridad adicionales para todas las sierras

Causa y prevención del operador ante una situación de retroceso:

– El retroceso es una reacción repentina a una hoja de sierra apretada, atascada o

desalineada, lo cual hace que una sierra descontrolada se levante y salga de la pieza de

trabajo hacia el operador.

– Cuando la hoja se aprieta o atasca por la entalladura que se cierra, la hoja se detiene y la

reacción del motor impulsa la unidad rápidamente hacia el operador.

– Si la hoja se tuerce o desalinea en el corte, los dientes del borde posterior de la hoja se

pueden enterrar en la supercie superior de la madera, lo que hace que la hoja salga de

la entalladura y salte hacia el operador.

El retroceso es la consecuencia del uso inadecuado de la sierra o de condiciones o

procedimientos de funcionamiento incorrectos y se puede evitar al tomar precauciones

adecuadas, como las que se indican a continuación:

• Agarre rmemente la sierra con las dos manos y ubique sus brazos para resistir la

fuerza de retroceso. Ubique su cuerpo a cualquier lado de la hoja, pero no alineado

con la misma. Un retroceso puede provocar que la sierra salte hacia atrás, pero el

operador puede controlar la fuerza de retroceso, si toma las precauciones correctas.

• Cuando la hoja se atasque, o cuando interrumpa un corte por cualquier motivo, suelte el

gatillo y sujete la sierra sin movimiento en el material hasta que la hoja se detenga por

completo. Nunca intente retirar la sierra de la pieza ni jale la sierra hacia atrás mientras

la hoja esté en movimiento ya que puede producirse un retroceso. Investigue y tome

acciones correctivas para eliminar la causa del atascamiento de la hoja.

• Al volver a arrancar una sierra en la pieza de trabajo, centre la hoja de sierra en

la entalladura y verique que los dientes de la sierra no estén enganchados en el

material. Si la hoja de la sierra se atasca, puede elevarse o retroceder de la pieza de

trabajo mientras la sierra vuelve a arrancar.

INFORMACIÓN DE SEGURIDAD

• Apoye los paneles más grandes para minimizar el riesgo de que la hoja se apriete o

Page 27

27

sufra un retroceso. Los paneles más largos tienden a doblarse debido a su propio

peso. Los soportes deben colocarse bajo el panel a ambos lados: Bajo la línea de corte

y cerca del borde del panel.

• No utilice hojas desaladas o dañadas. Las hojas roma o mal instaladas generan una

entalladura angosta, lo que provoca una fricción excesiva, atascamiento de la hoja y

retroceso.

• La profundidad de la hoja y las palancas de bloqueo del bisel deben estar apretadas

y jas antes de realizar un corte. Si el ajuste de la hoja cambia durante un corte, puede

provocar un atascamiento de la hoja o un retroceso.

• Tenga extremada precaución al realizar un “corte con perforación” en paredes

existentes u otras áreas ciegas. La hoja sobresaliente puede entrar en contacto con

objetos ocultos que pueden causar retroceso.

Instrucciones de seguridad para la protección de hoja inferior

• Verique que la protección inferior se cierre de forma adecuada antes de cada uso.

No opere la sierra si la protección inferior no se mueve con facilidad ni cierra de

forma instantánea. Nunca sujete ni amarre la protección inferior en una posición

abierta. Si la sierra se cae accidentalmente, se puede torcer la protección inferior.

Levante la protección inferior con la manija de retracción y asegúrese de que se mueva

con facilidad y no toque la hoja o alguna otra pieza, en todos los ángulos y todas las

profundidades de corte.

• Verique el funcionamiento del resorte de la protección inferior. Si la protección y la

hoja no funcionan de forma adecuada, se deben reparar antes de usar. La protección

inferior puede operar lentamente debido a piezas dañadas, depósitos de goma o una

acumulación de desechos.

• La protección inferior se debe retraer de forma manual solo para cortes especiales,

como “cortes con penetración” y “cortes compuestos”. Levante la protección inferior

con la manija de retracción y tan pronto la hoja ingrese en el material, se debe soltar

la protección inferior. Para todos los demás cortes, la protección inferior debería funcionar

de forma automática.

• Asegúrese siempre de que el protector inferior cubra la hoja antes de apoyar la sierra

en el banco o el piso. Una hoja sin protección y en movimiento causará el retroceso

de la sierra, cortando todo lo que se le cruce. Tenga conocimiento del tiempo que la hoja

tarda en detenerse luego de soltar el interruptor.

Advertencias de seguridad adicionales para sierras circulares

a. Utilice siempre una mascarilla antipolvo

b. Use solamente hojas de sierra recomendadas

c. Use siempre protección para los oídos

d. No use la sierra con ruedas abrasivas

Page 28

28

PREPARACIÓN

Información acerca de la sierra circular

Antes de intentar utilizar la sierra circular, familiarícese con todas las funciones de operación y

los requisitos de seguridad.

ADVERTENCIA

• Sea cuidadoso, incluso si está familiarizado con la sierra circular. Recuerde que un

momento de descuido es suciente para causar lesiones graves. Antes de intentar utilizar

cualquier herramienta, asegúrese de familiarizarse con todas las funciones de operación e

instrucciones de seguridad.

• No intente modicar esta herramienta ni crear accesorios que no sean los recomendados

para esta. Cualquier alteración o modicación es considerada un mal uso y podría causar

una condición peligrosa que podría conllevar lesiones personales graves.

INSTRUCCIONES DE FUNCIONAMIENTO

1. Paquete de baterías

Colocación del paquete de baterías

a. Asegúrese de que el interruptor de gatillo (D)

esté en la posición “OFF” (apagado).

b. Alinee la parte elevada del paquete de baterías

con las ranuras de la parte inferior de la

herramienta, luego deslice el paquete de

baterías en la sierra, como se muestra.

c. Asegúrese de que los pestillos del paquete de

baterías encajen en su lugar y que el paquete

de baterías esté jo en la herramienta antes de

comenzar la operación.

AVISO: Al colocar el paquete de baterías en la

herramienta, asegúrese de que la varilla elevada

del paquete de baterías se alinee con la ranura de

la herramienta y que los pestillos encajen en su

lugar adecuadamente. El ensamblaje inadecuado

del paquete de baterías puede provocar daños a

los componentes internos.

Extracción del paquete de baterías

a. Asegúrese de que el interruptor de gatillo (D)

esté en la posición “OFF” (apagado).

b. Presione los botones de liberación de la batería

para liberar el paquete de baterías.

c. Jale el paquete de baterías hacia delante para

retirar la batería de la herramienta.

1a

1b

Page 29

29

INSTRUCCIONES DE FUNCIONAMIENTO

2. Interruptor de gatillo

a. Para encender la sierra, presione el botón

de bloqueo-apagado (B) y luego apriete el

interruptor de gatillo (D).

ADVERTENCIA

• La hoja debe alcanzar velocidad plena antes de

entrar en contacto con la pieza de trabajo.

b. Para apagar la sierra, suelte el interruptor

de gatillo y deje que la hoja se detenga por

completo.

Freno eléctrico

Esta sierra circular está equipada con un freno

eléctrico.

Cuando se suelta el interruptor de gatillo, el freno

eléctrico se activa de manera automática para

detener rápidamente la rotación.

3. Sistema protector de la hoja

La protección de hoja inferior (H) en la sierra

circular está diseñada para brindar protección y

seguridad al operador. No la modique por ningún

motivo.

Si la protección de hoja inferior se daña o si la

hoja comienza a girar lentamente, NO opere la

sierra hasta que se haya reparado o reemplazado

la pieza dañada. SIEMPRE deje la protección en

su posición de funcionamiento correcta al usar la

sierra.

PELIGRO

• Al cortar a través de una pieza de trabajo, la protección de hoja inferior no cubre la hoja en

la parte inferior de la pieza de trabajo. SIEMPRE mantenga las manos y el cuerpo alejados

del área de corte. Se provocarán lesiones graves si cualquier parte del cuerpo entra en

contacto con la hoja en movimiento.

ADVERTENCIA

• Para evitar posibles lesiones graves, nunca use la sierra cuando la protección de hoja

inferior no funcione correctamente. Verique el correcto funcionamiento de la protección de

hoja inferior antes de cada uso. Debe moverse con facilidad y regresar instantáneamente

a la posición cerrada. Si la sierra se cae, verique que la protección de hoja inferior y el

paragolpes no tengan daños en todos los ajustes de profundidad antes de usarla.

Si la protección de hoja inferior no encaja de forma cerrada en algún momento, llévela a un

técnico de servicio autorizado para su reparación.

3

H

2

B

D

Page 30

30

INSTRUCCIONES DE FUNCIONAMIENTO

4. Ajuste de la profundidad de corte

ADVERTENCIA

• Siempre mantenga el ajuste correcto de

profundidad de la hoja.

El ajuste de profundidad de hoja correcto para

todos los cortes no debe exceder el grosor del

material que se corta en más de 1/4 pulg. (6,5

mm). Una profundidad de hoja mayor aumentará

la posibilidad de retroceso y hará que el corte sea

áspero.

a. Retire el paquete de baterías de la sierra.

b. Levante la palanca de bloqueo de profundidad

(U) para liberarla.

c. Sostenga el listoncillo de base (M) contra la

pieza de trabajo y levante o baje la sierra hasta

que la marca indicadora de la sierra se alinee

con la profundidad deseada en la escala de

profundidad (T).

d. Baje la palanca de bloqueo de profundidad

para bloquearla en su posición.

5. Ajuste del ángulo de corte

a. Retire el paquete de baterías de la sierra.

b. Suelte la perilla de bloqueo de biselado (Q),

ubicada en la escala de biselado de 0° a 50°

(O).

c. Incline el cuerpo de la sierra hasta que la

marca indicadora de la sierra se alinee con el

ángulo requerido en la escala de ángulo del

bisel.

d. Apriete la perilla de bloqueo de biselado para

jar la sierra.

6. Luz de trabajo con bombilla LED

La sierra circular está equipada con una luz de

trabajo con bombilla LED (V) que se iluminará

cuando presione el interruptor de gatillo. Esto

brinda más iluminación en la supercie de la pieza

de trabajo para usar la herramienta en áreas con

poca iluminación.

La luz de trabajo con bombilla LED se apagará

cuando suelte el interruptor de gatillo.

a. La luz de trabajo con bombilla LED titilará con rapidez si la herramienta deja de funcionar

para proteger los circuitos internos; espere a que la herramienta se enfríe para que pueda

volver a funcionar.

b. La luz de trabajo con bombilla LED titilará más lento para indicar que el nivel de batería

está muy bajo.

6

V

5

Q

O

4

U

M

T

Page 31

31

INSTRUCCIONES DE FUNCIONAMIENTO

7. Hojas de sierra

Las mejores hojas de sierra no cortarán lo

suciente si no se mantienen limpias, aladas

y ajustadas de forma adecuada. El uso de una

hoja roma colocará una carga pesada en la sierra

y aumentará el peligro de retroceso. Mantenga

hojas adicionales a mano de forma que siempre

disponga de hojas aladas.

La goma y resina en las hojas disminuirán la

velocidad de la sierra. Siga las instrucciones para

retirar la hoja de la sierra, luego use un limpiador

de goma y resina, agua caliente o queroseno para

eliminar las acumulaciones.

ADVERTENCIA

• No use gasolina para limpiar la hoja.

Instalación de una hoja de sierra

a. Retire el paquete de baterías de la sierra.

b. Mantenga presionado el botón de bloqueo del husillo (R).

c. Aoje el perno de la hoja (G) girándolo en dirección contraria a las manecillas del reloj con

la llave para hoja (S) (incluida).

d. Retire el perno de la hoja, arandela o brida externa (I).

ADVERTENCIA

• Si se ha retirado la brida interna, reemplácela antes de colocar la hoja en el husillo. Si no

lo hace, la hoja no quedará apretada correctamente y puede causar lesiones personales

graves.

e. Use la palanca de protección de hoja (F) para retraer la protección de hoja inferior (H) en

la protección de hoja superior (E).

f. Ajuste la hoja de sierra (J) dentro de la protección de hoja inferior y en el husillo. Verique

que los dientes de la sierra, la echa en la hoja de la sierra y la echa en el indicador de

rotación en la protección de hoja apunten en la misma dirección.

AVISO: Los dientes de la sierra deben apuntar hacia arriba en la parte delantera de la sierra.

g. Vuelva a colocar la brida de hoja externa con la sección sobresaliente apuntando hacia

fuera.

h. Mantenga presionado el botón de bloqueo del husillo y reemplace la arandela y el perno

de la hoja.

i. Apriete con rmeza el perno de la hoja girándolo en dirección de las manecillas del reloj

con la llave para hoja.

AVISO: Nunca use una hoja demasiado gruesa para permitir que la brida de hoja externa se

enganche con la sección plana del husillo.

ADVERTENCIA

• Para evitar lesiones corporales, siempre retire el paquete de baterías antes de instalar o

retirar la hoja de la sierra.

7

G I F

J

E

R

Page 32

32

INSTRUCCIONES DE FUNCIONAMIENTO

Retirar la hoja de la sierra.

a. Retire el paquete de baterías de la sierra.

b. Mantenga presionado el botón de bloqueo del

husillo (R).

c. Aoje el perno de la hoja (G) girándolo en

dirección contraria a las manecillas del reloj

con la llave para hoja (S).

d. Retire el perno de la hoja y la brida de hoja

externa (I).

e. Levante el protector de hoja inferior (H) y luego

retire la hoja (J).

8. Cómo cortar con la sierra circular

Consulte las guras de esta sección para conocer

la forma correcta e incorrecta de manipular la

sierra.

ADVERTENCIA

• Para que el uso de la sierra sea más fácil y

seguro, siempre mantenga un control adecuado

del producto. La pérdida de control puede

provocar un accidente que cause posibles

lesiones graves.

PELIGRO

• Al levantar la sierra de la pieza de trabajo, la

hoja se expone en la parte inferior de la sierra

hasta que se cierra la protección de hoja inferior

(H). Asegúrese de que la protección de hoja

inferior esté cerrada antes de apoyar la sierra.

Para lograr el mejor corte posible de la forma más

segura, siga estos consejos útiles:

a. Sostenga rmemente la sierra con ambas

manos.

b. Evite colocar su mano en la pieza de trabajo

mientras realiza un corte (Fig. 8a).

c. Apoye la pieza de trabajo de forma que el

corte siempre esté al lado del operador y no

directamente en línea con su cuerpo.

d. Apoye la pieza de trabajo cerca del corte.

e. Sujete la pieza de trabajo con rmeza de forma

que no se mueva mientras realiza el corte (Fig.

8b).

f. Siempre coloque la sierra en la parte de la pieza de trabajo que está apoyada y no en la

pieza “de corte” (Fig. 8c).

g. Coloque la pieza de trabajo con el lado “bueno” hacia abajo.

h. Trace una línea de referencia a lo largo de la línea de corte deseada antes de comenzar el

corte.

8a

8b

8c

F

Page 33

33

INSTRUCCIONES DE FUNCIONAMIENTO

9. Corte transversal/Corte al hilo

Al realizar un corte trasversal o al hilo, alinee la

línea de referencia con el corte con la ranura guía

de la hoja en 90° (N) en el listoncillo de base (T).

La distancia desde la hoja de la sierra hasta la

base de la sierra es de aproximadamente 3-5/8

pulg. (9,2 cm) en el lado izquierdo de la sierra y

1-1/2 pulg. (3,7 cm) en el lado derecho.

Los grosores de las hojas varían, por lo que

siempre debe realizar un corte de prueba en

un material que no use a lo largo de una línea

de referencia para determinar cuánto se debe

compensar de la línea de referencia respecto de la

guía para producir un corte preciso.

AVISO: Use una guía al realizar cortes al hilo largos o anchos.

10. Cortes al hilo con borde recto

a. Asegure la pieza de trabajo.

b. Fije un borde recto a la pieza de trabajo con

abrazaderas en C (no incluidas).

AVISO: Coloque las abrazaderas en C de forma

que no intereran con la carcasa de la sierra

durante el corte.

c. Presione el botón de bloqueo-apagado (B)

y presione el gatillo de interruptor (D) para

arrancar la sierra.

d. Permita que la hoja (J) alcance una velocidad

plena, luego oriente la sierra hacia la pieza de

trabajo y haga el corte.

e. Corte a lo largo del borde recto para lograr un

corte al hilo recto.

f. Suelte el interruptor de gatillo y permita que la hoja se detenga por completo.

g. Levante la sierra de la pieza de trabajo.

AVISO: No presione la hoja contra el corte.

9

N

10

Page 34

34

INSTRUCCIONES DE FUNCIONAMIENTO

11. Corte biselado

a. Retire el paquete de baterías.

b. Ajuste el ángulo de corte a cualquier valor

deseado entre 0° y 50°. Apriete con rmeza la

perilla de bloqueo de biselado (Q).

c. Reemplace el paquete de las baterías.

d. Alinee la línea de corte con la ranura guía de la

hoja en 45° (L) en la zapata de la base (M) al

realizar cortes biselados en 45°.

e. Realice un corte de prueba en un material que

no use a lo largo de una línea de referencia

para determinar cuánto se debe compensar de

la línea de referencia en el material de corte.

ADVERTENCIA

• Si intenta realizar un corte biselado sin tener la perilla de bloqueo de biselado trabada con

rmeza en su lugar puede provocar lesiones graves.

f. Sostenga rmemente la sierra con ambas manos, como se muestra.

g. Apoye el borde delantero de la zapata de base en la pieza de trabajo sin que la hoja haga

contacto con la pieza de trabajo.

h. Arranque la sierra y permita que la hoja alcance velocidad plena.

i. Guíe la sierra hacia la pieza de trabajo y realice el corte.

j. Suelte el interruptor de gatillo y permita que la hoja se detenga por completo.

k. Levante la sierra de la pieza de trabajo.

11

L

Page 35

35

INSTRUCCIONES DE FUNCIONAMIENTO

12. Corte de cavidades

ADVERTENCIA

• Siempre ajuste el valor de biselado en 0° antes

de realizar el corte de una cavidad. Si intenta

cortar una cavidad en cualquier otro ajuste

puede perder el control de la sierra y provocar

posibles lesiones graves.

a. Ajuste el valor del biselado en 0° y apriete la

perilla de bloqueo del bisel (Q).

b. Coloque la hoja en la profundidad de corte

correcto.

c. Mueva la protección de la hoja inferior hacia

arriba (H) con la palanca de protección de hoja

(F).

d. Sujete la protección de hoja inferior en su lugar con la palanca de protección de hoja.

e. Apoye la parte delantera de la zapata de la base (M) contra la pieza de trabajo, con la

parte posterior de la misma levantada, de forma que la hoja (J) no toque la pieza de

trabajo.

f. Presione el botón de bloqueo-apagado (B) y presione el gatillo de interruptor (D) para

arrancar la sierra.

g. Permita que la hoja alcance la velocidad máxima y luego oriente la sierra hacia la pieza de

trabajo y haga el corte.

h. Suelte el interruptor de gatillo y permita que la hoja se detenga por completo.

i. Levante la sierra de la pieza de trabajo.

ADVERTENCIA

• Siempre corte hacia delante al cortar cavidades. Si corta en dirección inversa puede causar

que la sierra se suba sobre la pieza de trabajo y retroceda hacia el operador.

• Cuando la hoja comience a cortar el material, suelte la palanca de protección de hoja de

inmediato. Cuando la pata de la protección se apoye de forma plana sobre la supercie que

desea cortar, comience a cortar hacia delante hasta el extremo del corte.

• Nunca amarre el protector de hoja inferior en posición levantada. Si deja la hoja expuesta

se pueden provocar lesiones graves.

CUIDADO Y MANTENIMIENTO

Todas las tareas de mantenimiento deben estar a cargo únicamente de un técnico de

servicio calicado.

Limpieza

Antes de limpiar o realizar cualquier mantenimiento, retire el paquete de baterías de la sierra

circular. Para un uso seguro y adecuado, siempre mantenga limpias la herramienta y sus

ranuras de ventilación.

Siempre use un paño suave y seco para limpiar la sierra circular; nunca use detergente ni

alcohol.

12

F

F

M

Page 36

36

SOLUCIÓN DE PROBLEMAS

ADVERTENCIA

• Coloque el interruptor en la posición “OFF” (Apagado) y retire el paquete de baterías de la

sierra circular antes de realizar procedimientos de solución de problemas.

PROBLEMA CAUSA POSIBLE ACCIÓN CORRECTIVA

La sierra circular no

funciona.

La batería está agotada. Cargue la batería

La hoja se atasca o

quema la madera.

1. Funcionamiento

inadecuado.

2. Hoja roma.

3. Hoja inadecuada.

1. Consulte la sección

“INSTRUCCIONES DE

FUNCIONAMIENTO”.

2. Reemplace o ale la hoja.

3. Reemplace la hoja.

La sierra vibra o se

agita.

1. Hoja inadecuada.

2. Funcionamiento de la

hoja instalada de forma

incorrecta.

1. Reemplace la hoja.

2. Retire la hoja y vuelva a instalarla,

asegúrese de que no falte ninguna

pieza.

La luz de trabajo con

bombilla LED titila

con rapidez.

La herramienta ha dejado

de funcionar para proteger

los circuitos internos.

Suelte el interruptor de gatillo, espere

a que la herramienta se enfríe y luego

enciéndala de nuevo.

La luz de trabajo con

bombilla LED titila

con lentitud.

El nivel de batería está

muy bajo.

Cargue la batería.

GARANTÍA

La sierra circular está garantizada contra defectos de fabricación en materiales y mano de

obra por 5 años desde la fecha de compra para el comprador original. La garantía no cubre

daños producidos por abuso, desgaste normal, mantenimiento inapropiado, negligencia,

alteración o reparación no autorizada o piezas fundibles y accesorios que se esperan que

sean inutilizables después de un período de uso razonable.

Si cree que este producto cumple con la garantía mencionada con anterioridad, devuelva

el producto al lugar donde lo compró con un comprobante de compra válido y el producto

defectuoso se reparará o reemplazará sin cargo. Esta garantía le otorga derechos legales

especícos, pero también podría tener otros derechos que varían según el estado.

Impreso en China

Loading...

Loading...