Page 1

80 V LITHIUM-ION CORDLESS 18 IN. CHAIN SAW

ATTACH YOUR RECEIPT HERE

ITEM #0670251

MODEL #KCS 180B

Français p. 34

Español p. 69

Serial Number Purchase Date

Questions, problems, missing parts? Before returning to your retailer, call our customer

service department at 1-888-3KOBALT (1-888-356-2258) 8 a.m. - 8 p.m., EST,

Monday - Friday.

AB15153

kobalttools.com

1

Page 2

TABLE OF CONTENTS

.......... 2

Package Contents...................................................................................................................... 3

Symbols...................................................................................................................................... 4

Safety Information...................................................................................................................... 5

Preparation.................................................................................................................................9

Operating Instructions.............................................................................................................. 12

Care and Maintenance............................................................................................................. 23

Troubleshooting........................................................................................................................ 32

Warranty................................................................................................................................... 33

Replacement Parts List............................................................................................................ 33

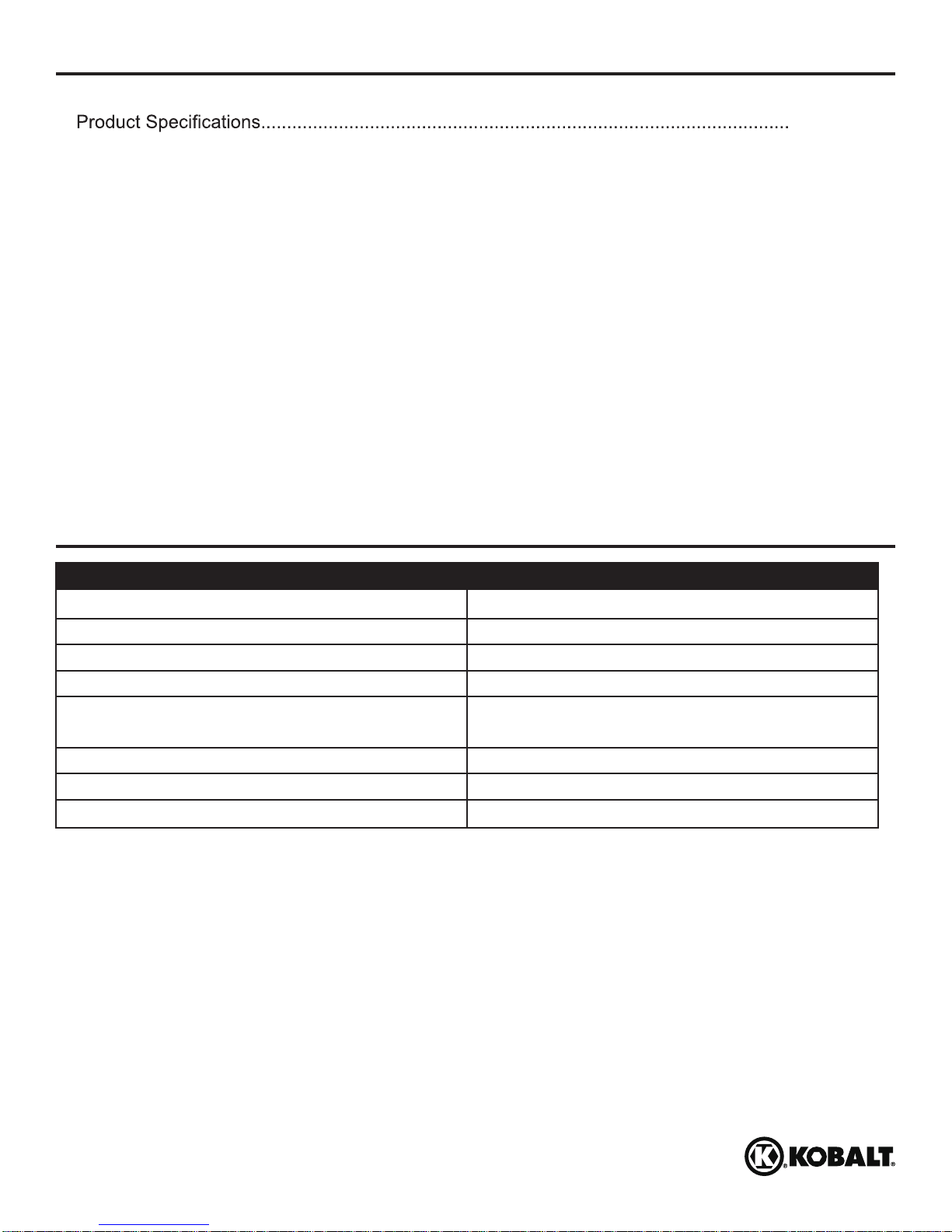

PRODUCT SPECIFICATIONS

SPECIFICATIONS

Motor

B

ar length

Chain pitch

Chain gauge

80V DC

1

8 in. (458mm)

3/8 in. (9,50 mm)

0.05 in. (1,27 mm)

Chain type Replacement Part Model: 91P062X, Oregon®

Accessory Model: S62

Guide bar type Model: 180SCEA041, Oregon®

Chain oil tank capacity

Unit weight (without battery)

6 oz. (177,44 ml)

11 lbs. (4,98 kg)

kobalttools.com

2

Page 3

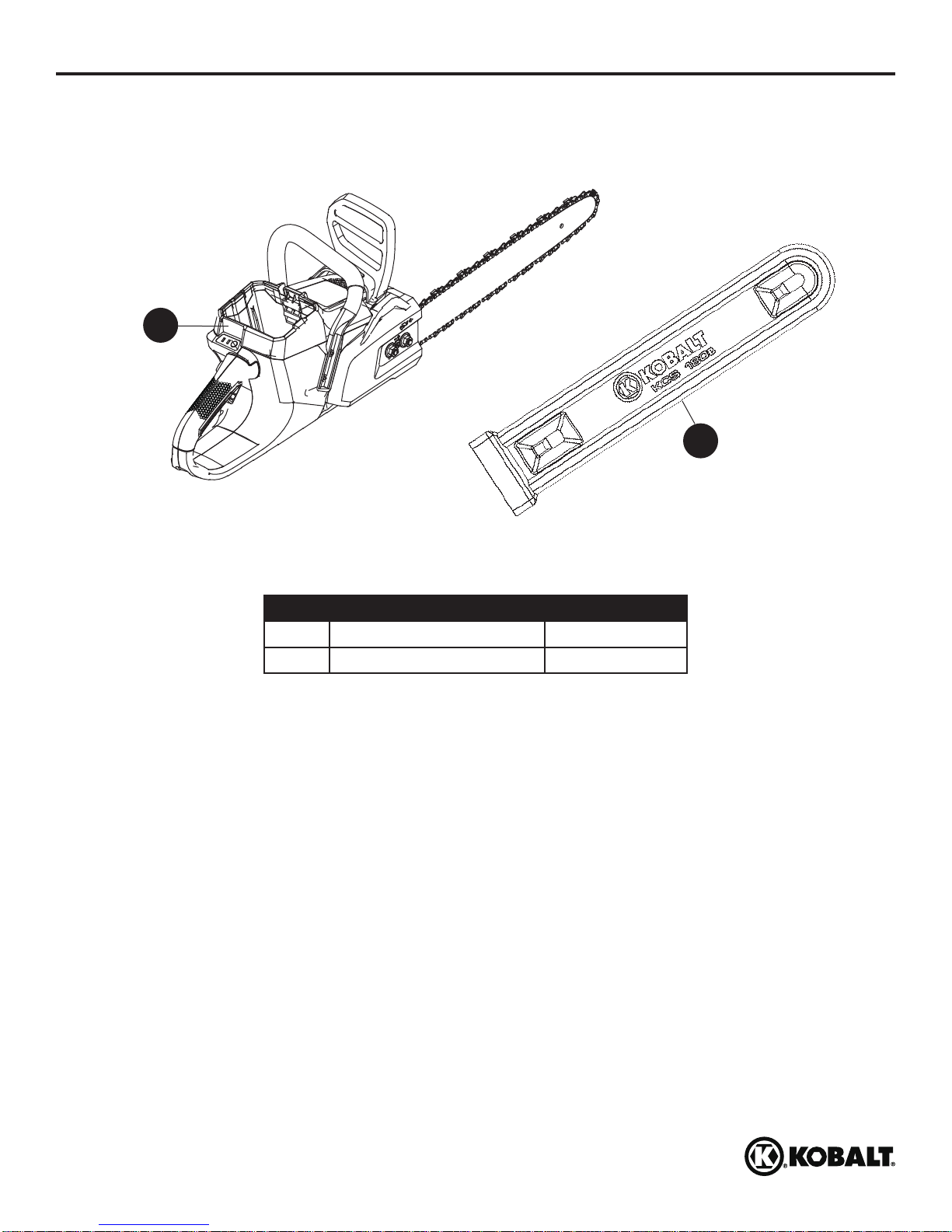

PACKAGE CONTENTS

A

B

PART DESCRIPTION QUANTITY

A Chainsaw 1

B Scabbard 1

kobalttools.com

3

Page 4

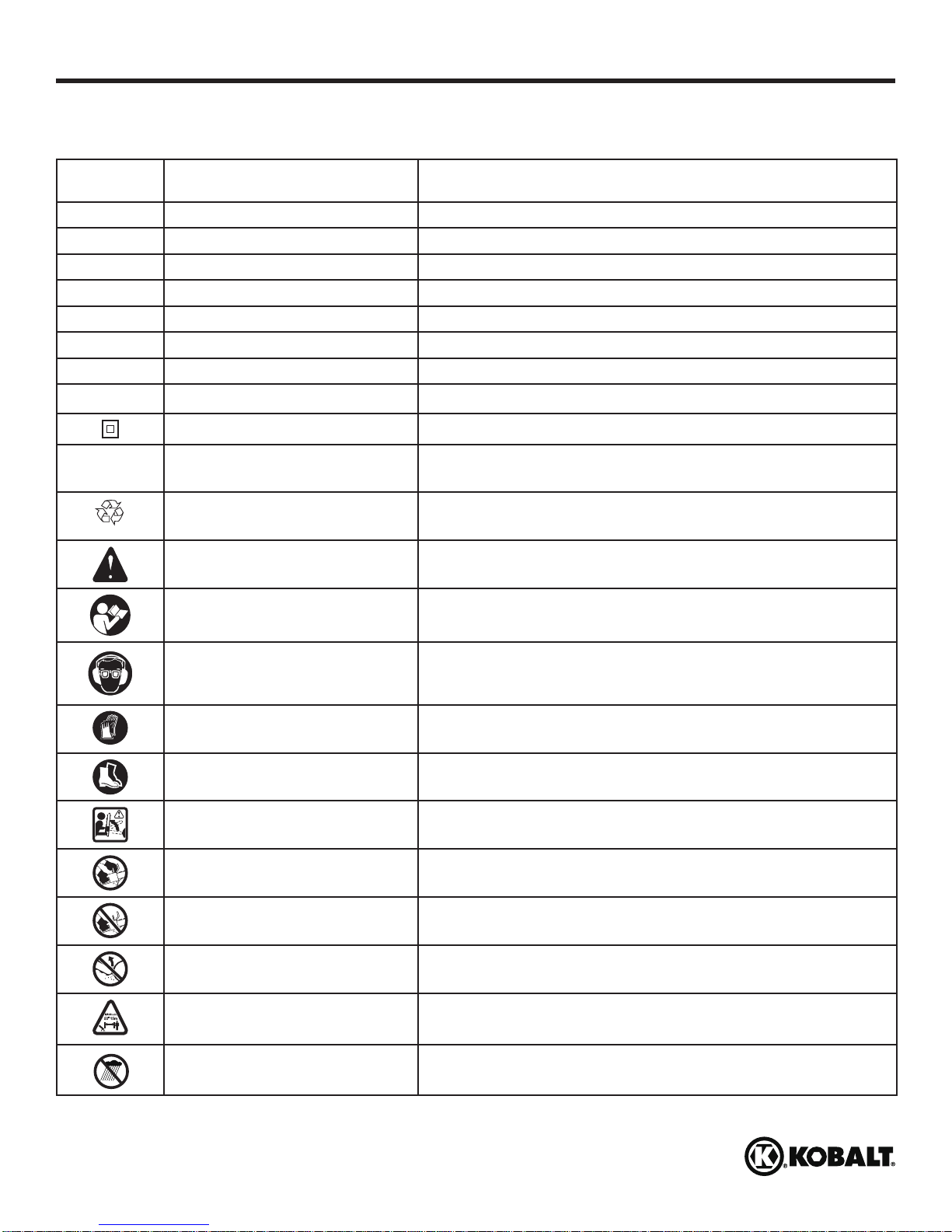

SYMBOLS

Some of the following symbols may be used on this product. Please study them and learn their

meaning. Proper interpretation of these symbols will allow you to operate the product better and safer.

SYMBOLS DESIGNATION EXPLANATION

V Volts Voltage

A Amperes Current

Hz Hertz Frequency (cycles per second)

W Watts Power

hrs Hours Time

Wh Watt Hours Energy Storage Capacity

Ah Amp Hours Current Capacity

n

o

No Load Speed Rational speed, at no load

Class II Construction Double-insulated construction

/ min

Per Minute

Lithium-Ion Battery Recycling

Revolutions, strokes, surface speed, orbits etc., per

minute.

Designates that this tool is in compliance with

Lithium-Ion battery recycling program requirements.

Safety Alert Symbol Precautions that involve your safety.

Read the Operator’s Manual

To reduce the risk of injury, user must read and

understand operator’s manual before using this product.

Wear eye protection that is marked to comply with

Eye and Hearing Protection

ANSI Z87.1 as well as hearing protection when operating

this product

Gloves

Safety Footwear

Kickback

Wear non-slip, heavy-duty protective gloves when

handling the chain saw and the blade.

Wear non-slip safety footwear when using this

equipment.

Tip contact can cause the guide bar to move suddenly

upward and backward, which can cause serious injury.

Operate With Two Hands Hold and operate the saw properly with both hands.

One Handed Do not operate the saw using only one hand.

Bar Nose Contact

Keep Bystanders Away Keep all bystanders at least 50 ft. (15 m) away.

Wet conditions Alert Do not expose to rain.

Contact of the guide bar tip with any object should be

avoided.

kobalttools.com

4

Page 5

kobalttools.com

SYMBOLS

Save these Instructions

The following signal words and meanings are intended to explain the levels of risk associated with

this product.

SYMBOL SIGNAL MEANING

DANGER

WARNING

CAUTION

CAUTION

Indicates an imminently hazardous situation, which, if not avoided, will

result in death or serious injury.

Indicates a potentially hazardous situation, which, if not avoided, could

result in death or serious injury.

Indicates a potentially hazardous situation, which, if not avoided, may

result in minor or moderate injury.

(Without Safety Alert Symbol) Indicates a situation that may result in

property damage.

WARNING

• To avoid serious personal injury, do not attempt to use this product until you have read this

Owner’s Manual thoroughly and understand it completely. If you do not understand the warnings and

instructions in this Owner’s Manual, do not use this product. Call 1-888-356-2258 for assistance.

The operation of any power tool can result in foreign objects being thrown into your eyes,

which can result in severe eye damage. Before beginning power tool operation, always wear

safety goggles or safety glasses with side shields and, when needed, a full face shield. We

recommend a wide vision safety mask for use over eyeglasses or standard safety glasses with

side shields. Always use eye protection which is marked to comply with ANSI Z87.1.

SAFETY INFORMATION

IMPORTANT

Read and understand all instructions. Failure to follow all instructions listed below may result in

electric shock, re, and/or serious personal injury.

WARNING

When using a cordless chain saw, basic safety precaution should be always followed to reduce the

risk of re, electric shock, and injury to persons, including the following:

• Do not start cutting until you have a clear work area, secure footing, and a planned retreat path

from a falling tree. Cluttered areas invite accidents.

• Keep all children, bystanders, and animals out of the work area while starting or cutting with the

chain saw.

• Do not operate chain saw in explosive atmospheres, such as in the presence of ammable liquids,

gases, or dust. Power tools create sparks which may ignite the dust or fumes.

• Wear snug tting clothing. Always wear heavy, long pants, overalls, jeans or chaps made of cut

resistant material or ones that contain cut resistant inserts. Wear non-slip safety footwear. Wear

non-slip heavy duty gloves to improve your grip and to protect your hands. Do not wear jewelry,

short pants, sandals, or go barefoot. Do not wear loose tting clothing, which could be drawn into

the motor or catch the chain or underbrush. Secure hair so it is above shoulder level.

5

Page 6

kobalttools.com

SAFETY INFORMATION

• During weather that is hot and humid, heavy work should be scheduled for early morning or late

afternoon hours when temperatures are cooler.

• Wear eye protection which is marked to comply with ANSI Z87.1 as well as hearing and head

protection when operating this equipment.

• Always be aware of what you are doing when using the chain saw. Use common sense. Do not

operate the chain saw when you are tired, ill, or under the inuence of alcohol, drugs, or

medication.

• Do not expose the chain saw to rain.

• Do not use the chain saw in damp or wet locations.

• Keep all parts of your body away from the saw chain when the unit is running.

• Always carry the chain saw by the front handle with the battery removed and the guide bar and saw

chain positioned to the rear.

• Never let anyone use your chain saw who has not received adequate instructions in its proper use.

• Before you start the unit, make sure the saw chain is not contacting any object.

• Stop the chain saw before setting it down.

• To avoid accidental starting, never carry the unit with your nger on the trigger switch.

• Maintain the unit with care. Keep the cutting edge sharp and clean for best performance and to

reduce the risk of injury. Follow instructions for lubricating and changing accessories.

• Keep handles dry, clean, and free of oil and grease.

• Use only 80 V Kobalt batteries and chargers.

• Do not dispose of batteries in a re as the cell may explode. Check with local codes for possible

special disposal instruction.

• Do not open or damage the batteries; released electrolyte is corrosive and may cause damage to

the eyes or skin, and may be toxic if swallowed.

• Exercise care in handling battery in order not to short the battery with conducting material such as

rings, bracelets and keys. The battery or conductor may overheat and cause burns.

• Do not operate a chain saw with one hand. Use a rm grip with thumbs and ngers encircling the

chain saw handles. Serious injury to the operator, helpers, bystanders, or any combination of these

persons may result from one-handed operation. A chain saw is intended for two handed use.

• Avoid body contact with grounded surfaces such as metal pipes and wire fences. There is an

increased risk of electric shock if your body is grounded.

• Do not operate a chain saw that is damaged, improperly adjusted, or not completely and securely

assembled. The chain should slow to a stop when the trigger switch is released. If the chain

continues to turn after the trigger switch has been released, have the unit serviced by an authorized

service center.

• Check for damaged parts. Check for alignment of moving parts, binding of moving parts, breakage

of parts, mounting, and any other conditions that may affect its operation. A guard or other part that

is damaged should be properly repaired or replaced by an authorized service dealer unless

otherwise indicated elsewhere in this manual.

• Always maintain a proper stance.

• Do not use chain saw if switch does not turn it on and off. If switch is defective, have it replaced by

an authorized service center.

6

Page 7

kobalttools.com

SAFETY INFORMATION

• Remove the battery when not in use, before servicing, and when making adjustments and changing

attachments, such as saw chain and bar.

• Do not cut vines and/or small underbrush.

• Do not operate a chain saw in a tree, on a ladder, or scaffold; this is extremely dangerous.

Note: The size of the work area depends on the job being performed as well as the size tree or work

piece involved. For example, felling a tree requires a larger work area than making bucking cuts.

• Use extreme caution when cutting small size brush and saplings because the small material may

catch the saw chain and be whipped toward you or pull you off balance.

• When cutting a limb that is under tension, be alert for spring back so that you will not be struck

when the tension in the wood bers is released.

• Do not force the chain saw. The job can be performed better and safer at the rate for which it was

intended.

• Always use the right product for your application. The chain saw should be used for cutting wood

only. Never use the chain saw to cut plastic, masonry or non-wood building materials.

• Store chain saw when not in use. Chain saw should be stored in a dry and high or locked area out

of the reach of children.

• Save these instructions. Refer to them frequently and use them to instruct others who may use this

tool. If you loan someone this tool, loan them these instructions also.

WARNING Proposition 65

Some dust created by power sanding, sawing, grinding, drilling, and other construction activities

contain chemicals known to cause cancer, birth defects or other reproductive harm. Some examples

of these chemicals are:

• Lead from lead-based paints,

• Crystalline silica from bricks and cement and other masonry products, and

• Arsenic and chromium from chemically-treated lumber.

• Your risk from these exposures varies, depending on how often you do this type of work. To reduce

your exposure to these chemicals, work in a well-ventilated area, and work with approved safety

equipment, such as those dust masks that are specially designed to lter out microscopic particles.

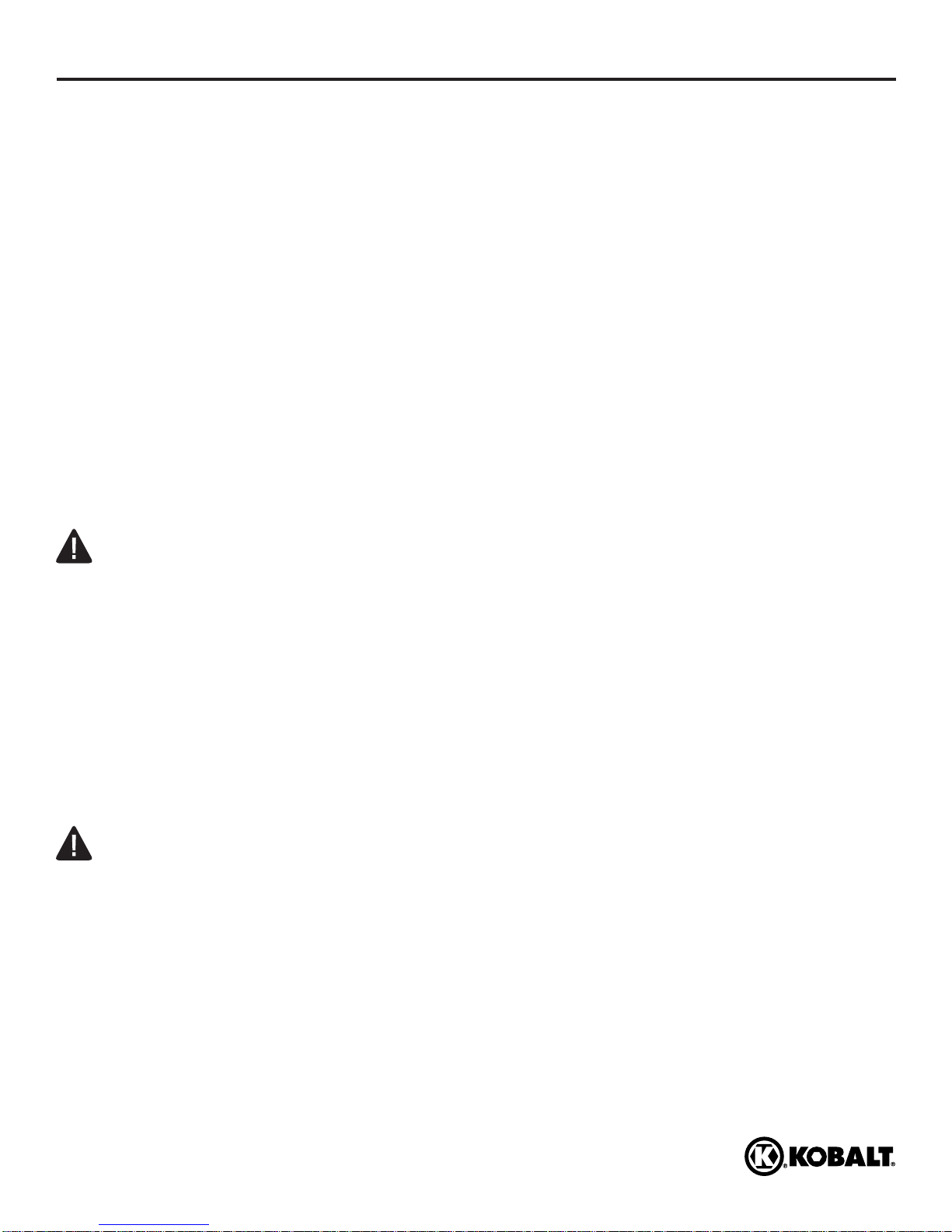

Kickback

WARNING

Kickback may occur when the moving chain contacts an object at the upper portion of the tip of the

guide bar or when the wood closes in and pinches the saw chain in the cut. Contact at the upper

portion of the tip of the guide bar can cause the chain to dig into the object and stop the chain for an

instant. The result is a lightning fast reverse reaction which kicks the guide bar up and back toward

the operator. If the saw chain is pinched along the top of the guide bar, the guide bar can be driven

rapidly back toward the operator. Either of these reactions can cause loss of saw control which can

result in serious injury. Do not rely exclusively upon the safety devices built into the saw. As a chain

saw user, you should take several steps to keep your cutting jobs free from accident or injury.

7

Page 8

kobalttools.com

SAFETY INFORMATION

The following precautions should be followed to minimize

kickback:

• Always grip the saw rmly with both hands. Place your

right hand on the rear handle and your left hand on the

front handle with your thumbs and ngers encircling

the chain saw handles. A rm grip together with a stiff

left arm will help you maintain control of the saw if

kickback occurs.

• Make sure that the area in which you are cutting is free

from obstructions. Do not let the nose of the guide bar

contact a log, branch, fence, or any other obstruction

that could be hit while you are operating the saw.

•

Always cut with the unit running. Fully squeeze the

trigger switch and maintain cutting speed.

• Use only the replacement guide bars and low

kickback chains specied by the manufacturer for the

saw.

• With a basic understanding of kickback, you can

reduce or eliminate the element of surprise. Sudden

surprise contributes to accidents.

• Keep proper footing and balance at all times.

• Do not cut above shoulder height or overreach when

cutting.

• Follow the sharpening and maintenance instructions

for the saw chain.

8

Page 9

kobalttools.com

SAFETY INFORMATION

• Push and Pull - This reaction force is always

opposite to the direction the chain is moving where

wood contact is made. Thus, the operator must be

ready to control the PULL when cutting on the bottom

edge of the bar, and PUSH when cutting along the

top edge.

Understanding your chain saw safety devices

Low kickback saw chain

The rakers (depth gauges) ahead of each cutter can

minimize the force of a kickback reaction by preventing

the cutters from digging in too deeply at the kickback

zone. Only use replacement chain that is equivalent

to original chain or has been certied as low kickback

chain per ANSI B175.1. Low kickback chain is a chain

that has met the kickback performance requirements of

ANSI B175.1 - 1991. (American National Standard for

Power Tools - Gasoline-Powered Chain Saws-Safety

Requirements) when tested on the representative

sample of chain saws below 3.8 c.i.d. specied in ANSI

B175.1 - 1991. As saw chains are sharpened during their

useful life, they lose some of the low kickback qualities

and extra caution should be used.

PREPARATION

Before beginning to operate this product, make sure all parts are present. Compare parts with

package contents list. If any part is missing or damaged, do not attempt to operate the product.

9

Page 10

kobalttools.com

SAFETY INFORMATION

UNPACKING

This product has been shipped completely assembled.

• Carefully remove the product and any accessories from the box. Make sure that all items listed in

the package contents section are included.

• Inspect the product carefully to make sure no breakage or damage occurred during shipping.

• Do not discard the packing material until you have carefully inspected and satisfactorily operated

the product.

• If any parts are damaged or missing, please call 1-888-3KOBALT (1-888-356-2258) for assistance.

WARNING

• If any parts are damaged or missing, do not operate this product until the parts are replaced.

Failure to heed this warning could result in serious personal injury.

• Do not attempt to modify this product or create accessories not recommended for use with this

product. Any such alteration or modication is misuse and could result in a hazardous condition

leading to possible serious personal injury.

10

Page 11

KNOW YOUR CHAIN SAW

Read this operator’s manual and safety rules before operating your chain saw. Compare the

illustration below to your chain saw in order to familiarize yourself with the location of various controls

and adjustments. Save this manual for future reference.

H

G

I

M

E

N

P

J

L

K

F

O

PART DESCRIPTION

E Safety lock

F Trigger switch

G Front handle

H Low kickback chain

I Guard/Chain brake

J Guide bar

K Chain cover lock nuts

L Chain cover

M Battery release button

N Oil cap

O Wrench (13 mm)

P Adjustment screw

kobalttools.com

11

Page 12

OPERATING INSTRUCTIONS

WARNING

• Do not allow familiarity with this product to make you careless. Remember that a careless fraction

• Always wear safety goggles or safety glasses with side shields when operating power tools.

Failure to do so could result in objects being thrown into your eyes, resulting in possible serious

injury.

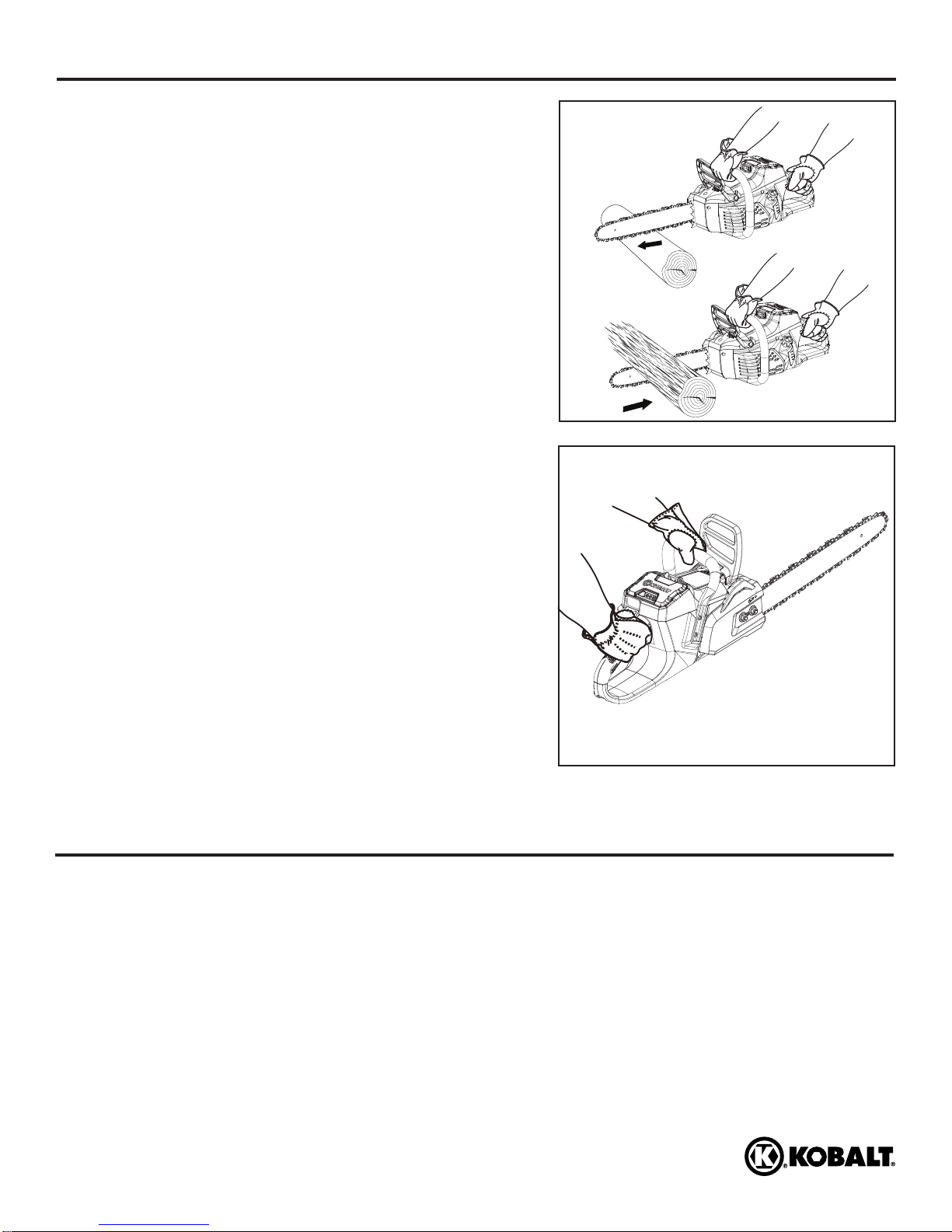

Adding bar and chain lubricant

Use a bar and chain lubricant (not included) with this

product. It is designed for chains and chain oilers,

and is formulated to perform over a wide temperature

N

range with no dilution required.

Note: Chain saw comes from the factory with no bar

and chain oil added.

The level should also be checked after every 20

• Remove oil cap (N).

• Carefully pour the bar and chain oil into the tank.

Oil indicator

• Wipe off excess oil and replace cap.

•

indicator is below the MIN. line.

• Repeat as needed.

Note:

• Do not use dirty, used or otherwise contaminated oils. Damage may occur to the bar or chain.

• It is normal for oil to seep from the saw when not in use. To prevent seepage, empty the oil tank

after each use then run for one minute. When storing the unit for a long period of time (three

months or longer) be sure the chain is lightly lubricated; this will prevent rust on the chain and bar

sprocket.

IMPORTANT

To preserve natural resources, please recycle or dispose of oil properly. Consult your local waste

authority for information regarding available recycling and/disposal options.

kobalttools.com

12

Page 13

OPERATING INSTRUCTIONS

Battery

IMPORTANT

The battery will only be half charged when it is purchased. Before using the chain saw for the

. Be sure to read all safety

precautions and follow the instructions in the battery and charger manuals. When storing the chain

saw for a prolonged period of time, remove the battery. When the chain saw is going to be used

again, fully charge the battery prior to use. The battery has no memory effect.

To install the battery:

1. Align the battery (not included) with the battery opening.

2. Insert the battery into the battery opening until the

battery release button (M) locks into place.

3. Push down on the battery until it locks into place. You

should hear a “click” once it is installed.

M

To remove the battery:

1. Press the battery release button (M) on the chain saw.

This will cause the battery to raise out of the tool

slightly.

2.

the battery opening.

WARNING

• Replace the battery or the charger immediately if the battery case or charger cord is damaged.

• Verify that the battery is removed before inspecting, adjusting, or performing maintenance on any

part of the chain saw.

• Read, understand, and follow the instructions contained in the charger manual.

IMPORTANT

This Lithium-ion battery is equipped with an internal protection, which will automatically shut off the

power to the tool and then reset itself once cooled. Follow these steps if an overload occurs while

under heavy use:

1. Release the power switch and restart tool by depressing switch.

2. The battery may need to be removed for approximately 1 minute, allowed to cool and then

reinstalled for use.

kobalttools.com

13

Page 14

OPERATING INSTRUCTIONS

Starting and stopping the chain saw

WARNING

Keep body to the left of the chain line. Never straddle the saw or chain, or lean over past the chain line.

A. To start the chain saw:

• Ensure the battery is not installed in the tool.

• Make sure chain tension is at desired setting. Refer to

Power Button

I

adjusting the chain tension in the Care and

Maintenance section of this manual.

E

• Make sure the chain cover lock nuts (K) are tight to the

chain cover.

• Make sure no objects or obstructions are in the

immediate vicinity which could come in contact with

the bar and chain.

• Insert the battery into the chain saw.

F

K

• Press the power button to the left of the rear handle.

You will hear two audible beeps signaling the chain

saw is active.

• Press in the safety lock (E). This makes the trigger

switch (F) operational.

• Make sure that the chain brake (I) is not engaged. If

it is, pull back on the chain brake (I) to disengage the

brake.

• Press and hold the trigger switch (F) and keep it

pressed for continued operation.

• Release the safety lock (E) during operation.

B. To stop the chain saw:

• Release the trigger switch (F).

Upon release of the trigger switch, the safety lock will be automatically reset to the lock position.

Note: It is normal for the chain to coast to a stop once the trigger switch is released.

LED Indicator Lights

• Power Indicator – LED will illuminate GREEN

indicating that the chain saw is active.

• Alert Indicator – LED will illuminate RED indicating an

abnormal condition. Refer to the Troubleshooting

section on page 32.

Alert Indicator

Power Button

Power Indicator

kobalttools.com

14

Page 15

OPERATING INSTRUCTIONS

Electronic Chain Brake

• This saw is equipped with an electronic chain brake (I).

• The chain brake (I) is activated if kick back occurs

during use.

• To disengage the chain brake (I), pull back on the

guard.

Disengage

Engage

I

Preparing for cutting

A. Proper grip on handles

See General Safety Rules for appropriate safety equipment.

• Wear non-slip gloves for maximum grip and protection.

•

left hand on the front handle and your right hand on

the rear handle so that your body is to the left of the

chain line.

• Maintain a proper grip on the saw whenever the motor

the thumb is wrapped under the handlebar. This grip is

least likely to be broken by a kickback or other sudden

reaction of the saw. Any grip in which the thumb and

dangerous because a slight kick of the saw can cause

loss of control.

Proper hand grip position

Proper grip

Improper grip

kobalttools.com

15

Page 16

kobalttools.com

OPERATING INSTRUCTIONS

WARNING

• DO NOT operate the trigger switch with your left hand and hold the front handle with your right hand.

• Never allow any part of your body to be in the chain line while operating a saw.

• Never use a left-handed (cross-handed) grip or any stance that would place your body or arm across

the chain line.

Proper cutting stance

• Balance your weight with both feet on solid ground.

• Keep left arm with elbow locked in a “straight arm”

position to withstand any kickback force.

Thumb on

underside of

Handle Bar

Chain Line

Straight Arm

• Keep your body to the left of the chain line.

• Keep your thumb on underside of front handle.

Basic operating/cutting procedures

Practice cutting a few small logs using the following

technique to get the “feel” of using the saw before you

begin a major sawing operation.

• Take the proper stance in front of the wood.

• Press the safety lock and squeeze the trigger switch

and let the chain accelerate to full speed before

entering the cut.

• Release the safety lock during operation.

• Begin cutting with the saw against the log.

• Keep the unit running the entire time you are cutting, maintain a steady speed.

• Allow the chain to cut for you; exert only light downward pressure. Forcing the cut could result

in damage to the bar, chain, or motor.

• Release the trigger switch as soon as the cut is completed, allowing the chain to stop. If you

run the saw without a cutting load, unnecessary wear can occur to the chain, bar, and unit.

• Do not put pressure on the saw at the end of the cut.

Work area precautions

• Cut only wood or materials made from wood; no sheet

metal, no plastics, no masonry, no nonwood building

materials.

• Never allow children to operate the saw. Allow no

person to use this chain saw who has not read this

operator’s manual or received adequate instructions

for the safe and proper use of this chain saw.

• Keep everyone – helpers, bystanders, children, and

animals – a SAFE DISTANCE from the cutting area.

During felling operations, the safe distance should be

at least twice the height of the largest trees in the

felling area. During bucking operations, keep a

minimum distance of 15 ft. (4.57 m) between workers.

• Always cut with both feet on solid ground to prevent

being pulled off balance.

• Do not cut above chest height as a saw held higher is difcult to control against kickback forces.

• Do not fell trees near electrical wires or buildings. Leave this operation for professionals.

• Cut only when visibility and light are adequate for you to see clearly.

16

Page 17

kobalttools.com

OPERATING INSTRUCTIONS

Felling trees

Hazardous conditions

WARNING

Do not fell trees during periods of high wind or heavy precipitation. Wait until the hazardous weather has

ended.

When felling a tree, it is important that you heed the following warnings to prevent possible serious injury.

• Do not cut down trees having an extreme lean or large trees with rotten limbs, loose bark, or

hollow trunks. Have these trees pushed or dragged down with heavy equipment, then cut them up.

• Do not cut trees near electrical wires or buildings.

• Check the tree for damaged or dead branches that could fall and hit you during felling.

• Periodically glance at the top of the tree during the backcut to assure the tree is going to fall in the

desired direction.

• If the tree starts to fall in the wrong direction, or if the saw gets caught or hung up during the fall,

leave the saw and save yourself.

Removing buttress roots

A buttress root is a large root extending from the trunk of

the tree above the ground. Remove large buttress roots

prior to felling. Make the horizontal cut into the buttress

rst, followed by the vertical cut. Remove the resulting

loose section from the work area. Follow the correct tree

felling procedure as stated in Proper Procedure For Tree

Felling after you have removed the large buttress roots.

Vertical Cut

Proper procedure for tree felling

• Felling a tree — When bucking and felling operations

are being performed by two or more persons at the

same time, the felling operation should be separated

from the bucking operation by a distance of at least

twice the height of the tree being felled. Trees should

not be felled in a manner that would endanger any

person, strike any utility line or cause any property

damage. If the tree does make contact with any utility

line, the utility company should be notied

immediately.

• Operator should keep on the uphill side of terrain as

the tree is likely to roll or slide after it is felled.

• Pick your escape route (or routes in case the intended

route is blocked). Clear the immediate area around the

tree and make sure there are no obstructions in your

planned path of retreat. Clear the path of safe retreat

approximately 135° from the planned line of fall.

PLANNED LINE OF FALL

135° FROM

PLANNED

LINE OF

FALL

PATH OF

SAFE

RETREAT

90°

Loose section

Horizontal Cut

135°

45°

90°

45°

135°

Path of safe

retreat

17

Page 18

kobalttools.com

OPERATING INSTRUCTIONS

• Consider the force and direction of the wind, the lean

and balance of the tree, and the location of large

limbs. These things inuence the direction in which the

tree will fall. Do not try to fell a tree along a line

different from its natural line of fall.

• Remove dirt, stones, loose bark, nails, staples, and

wire from the tree where felling cuts are to be made.

• Notched Undercut. Cut a notch about 1/3 the diameter

of the trunk on the side of the tree. Make the notch

cuts so they intersect at a right angle to the line of fall.

This notch should be cleaned out to leave a straight

line. To keep the weight of the wood off the saw,

always make the lower cut of the notch before the

upper cut.

• Felling Backcut. As the felling cut gets close to the

hinge, the tree should begin to fall. If there is any

chance the tree may not fall in the desired direction or

it may rock back and bind the saw chain, stop cutting

before the felling cut is complete and use wedges of

wood, plastic or aluminum to open the cut and drop

the tree along its desired line of fall. Make the backcut

level and horizontal, and at a minimum of 2 in. (5 cm)

above the horizontal cut of the notch.

HINGE 2 in. (5 cm) OR 1/10 DIA

Notch Approx.

1/3 Diameter

of trunk

Back cut 2" (5cm)

Back cut

Hinge

Note: Never cut through to the notch. Always leave a

band of wood between the notch and back cut

(approximately 2 in. (5 cm) or 1/10 the diameter of the

tree). This is called “hinge” or “hingewood.” It controls the

fall of the tree and prevents slipping or twisting or shoot

back of the tree off the stump.

• On large diameter trees, stop the back cut before it is

deep enough for the tree to either fall or settle back on

the stump by inserting soft wooden or plastic wedges

into the cut.

• As tree starts to fall, stop the chain saw and put it

down immediately. Retreat along the cleared path, but

watch the action in case something falls your way.

Wedge

18

Page 19

kobalttools.com

OPERATING INSTRUCTIONS

Bucking

Bucking is the term used for cutting a fallen tree to the

desired log length.

• Always make sure your footing is secure and your

weight is distributed evenly on both feet.

• Cut only one log at a time.

• Support small logs on a saw horse or another log while

bucking.

• Keep a clear cutting area. Make sure that no objects

can contact the guide bar nose and chain during

cutting as this can cause kickback. Refer to Kickback

earlier in this manual.

• When bucking on a slope, always stand on the uphill

side of the log. To maintain complete control of the

chain saw when cutting through the log, release the

cutting pressure near the end of the cut without

relaxing your grip on the chain saw handles. Do not

let the chain contact the ground. After completing the

cut, wait for the saw chain to stop before you move the

chain saw. Always stop the motor before moving from

tree to tree.

Bucking with a wedge

WEDGE

If the wood diameter is large enough for you to insert

a soft bucking wedge without touching the chain, you

should use the wedge to hold the cut open to prevent

pinching.

Bucking logs under stress

When the log is supported on one end, cut 1/3 the

diameter from the underside. Then make the nished cut

by overbucking to meet the rst cut. When the log is

supported on both ends, cut 1/3 of the diameter from the

top overback. Then make the nished cut by under

bucking the lower 2/3 to meet the rst cut.

LOG SUPPORTED AT ONE END

FINISHING CUT

LOG SUPPORTED AT BOTH ENDS

LOAD

LOAD

1ST CUT 1/3 DIA

1ST CUT 1/3 DIA

FINISHING CUT

19

Page 20

kobalttools.com

OPERATING INSTRUCTIONS

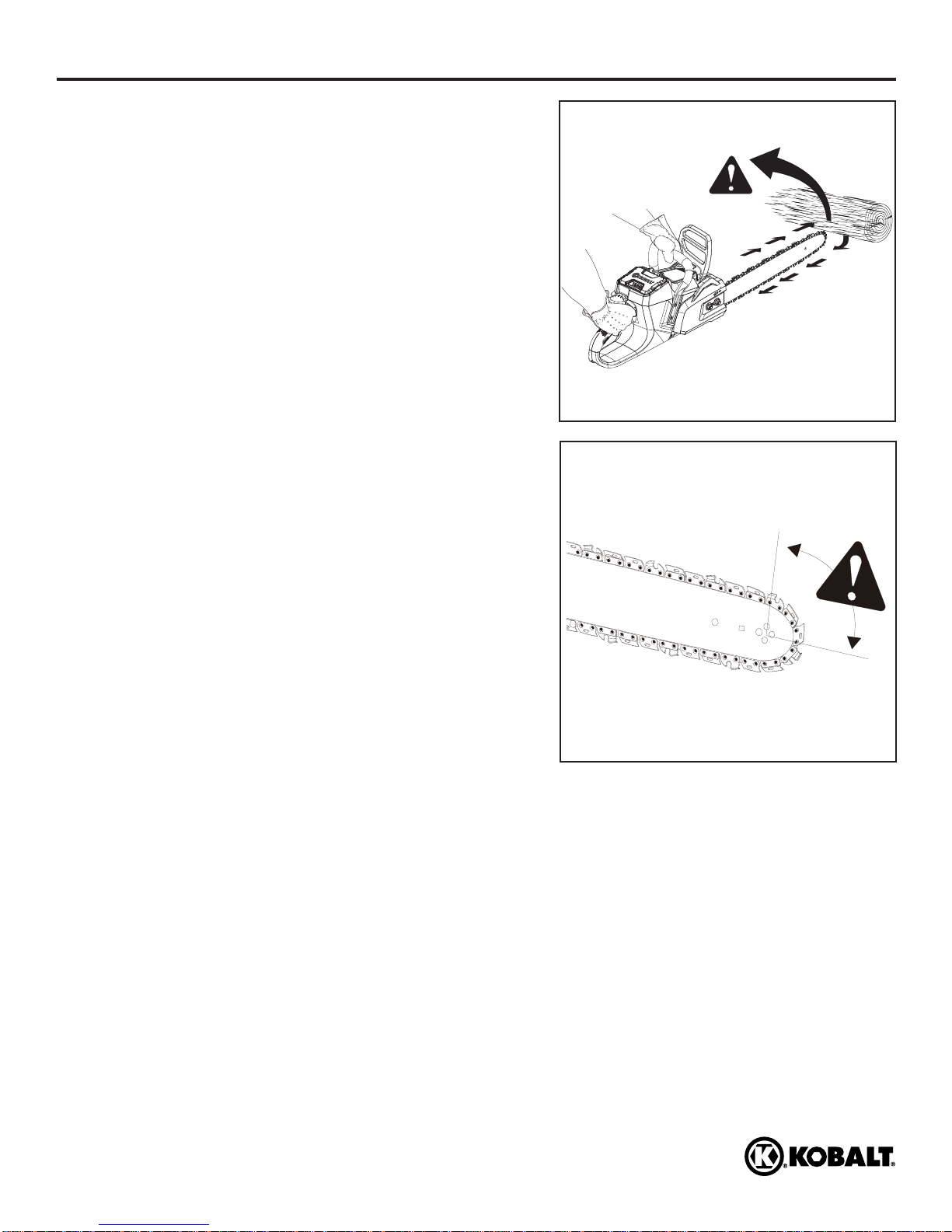

Overbucking

Begin on the top side of the log with the bottom of the saw

against the log; exert light pressure downward. Note that

the saw will tend to pull away from you.

Underbucking

Begin on the under side of the log with the top of the saw

against the log; exert light pressure upward. During under

bucking, the saw will tend to push back at you. Be

prepared for this reaction and hold the saw rmly to

maintain control.

Avoid cutting earth overbucking

Limbing

Limbing is removing branches from a fallen tree.

• Work slowly, keeping both hands on the chain saw

with a rm grip. Always make sure your footing is

secure and your weight is distributed evenly on both

feet.

• Leave the larger support limbs under the tree to keep

the tree off the ground while cutting.

• Limbs should be cut one at a time. Remove the cut

limbs from the work area often to help keep the work

area clean and safe.

• Branches under tension should be cut from the bottom

up to avoid binding the chain saw.

• Keep the tree between you and the chain saw while

limbing. Cut from the side of the tree opposite the

branch you are cutting.

Push underbucking

CUT LIMBS ONE AT A TIME AND

LEAVE SUPPORT LIMBS

UNDER TREE UNTIL LOG IS CUT

20

Page 21

kobalttools.com

OPERATING INSTRUCTIONS

Pruning

Pruning is trimming limbs from a live tree.

• Work slowly, keeping both hands on the chain saw

with a rm grip. Always make sure your footing is

secure and your weight is distributed evenly on both

feet.

• Do not cut from a ladder. This is extremely dangerous.

Leave this operation for professionals.

• Do not cut above chest height as a saw held higher is

difcult to control against kickback.

• When pruning trees it is important not to make the

nishing cut next to the main limb or trunk until you

have cut off the limb further out to reduce the weight.

This prevents stripping the bark from the main

member.

• Underbuck the branch 1/3 through for your rst cut.

• Your second cut should overbuck to drop the branch

off.

• Now make your nishing cut smoothly and neatly

against the main member so the bark will grow back to

seal the wound.

LOAD

Second Cut

First Cut

1/3 Diameter

Finishing Cut

WARNING

If the limbs to be pruned are above chest height, hire a professional to perform the pruning.

When bucking on a slope always stand on the uphill side

of the log. When cutting through to maintain

control, release the cutting pressure near the end of the cut

complete

Bucking a log

without relaxing your grip on the chain saw handle. Don’t let

the chain contact the ground. After completing the cut, wait

for the saw chain to stop before you move the chain saw.

Always stop the motor before moving from tree to tree.

Stand on uphill side when cutting

because log may roll

21

Page 22

kobalttools.com

OPERATING INSTRUCTIONS

Cutting springpoles

A springpole is any log, branch, rooted stump, or

sapling which is bent under tension by other wood so that

it springs back if the wood holding it is cut or removed.

On a fallen tree, a rooted stump has a high potential of

springing back to the upright position during the bucking

cut that separates the log from the stump. Watch out for

springpoles — they are dangerous.

SPRINGPOLE

WARNING

Springpoles are dangerous and could strike the operator, causing the operator to lose control of the

chain saw. This could result in severe or fatal injury to the operator.

22

Page 23

CARE AND MAINTENANCE

WARNING

• When servicing, use only identical replacement parts. Use of any other parts may create a hazard

or cause product damage.

• Always wear safety goggles or safety glasses with side shields during power tool operation or

when blowing dust. If the operation is dusty, also wear a dust mask.

General maintenance

Avoid using solvents when cleaning plastic parts. Most plastics are susceptible to damage from

various types of commercial solvents and may be damaged by their use. Use clean cloths to remove

dirt, dust, lubricant, grease, etc.

•

come in contact with plastic parts. Chemicals can damage, weaken, or destroy plastic, which may

result in serious personal injury.

Lubrication

of the unit under normal operating conditions. Therefore, no further lubrication is required for the

bearings.

Replacing the guide bar and chain

DANGER

Never start the motor before installing the guide bar, chain, chain cover, and chain cover lock knob.

injury.

WARNING

• To avoid serious personal injury, read and understand all the safety instructions in this section.

• Before performing any maintenance, make sure the battery is removed. Failure to heed this

warning could result in serious personal injury.

CAUTION

Always wear gloves when handling the bar and chain; these components are sharp and may contain

burrs.

WARNING

Never touch or adjust the chain while the motor is running. The saw chain is very sharp; always wear

protective gloves when performing maintenance to the chain to avoid possible serious lacerations.

Note:

bar and chain combinations section later in this manual.

kobalttools.com

23

Page 24

kobalttools.com

CARE AND MAINTENANCE

Replacing the guide bar and chain (contd.)

• Remove the battery from the chain saw.

• Remove the supplied wrench (O) from the rear handle.

• Remove the two chain cover lock nuts (K) from the

chain cover by rotating them counterclockwise with the

wrench (O).

• Remove the chain cover from the mounting surface.

• The bar and chain can now be removed by lifting it

away from the main body of the saw and releasing the

chain from the sprocket.

• Remove the old chain from the bar.

K

O

Chain

Sprocket Bar

24

Page 25

kobalttools.com

CARE AND MAINTENANCE

• Lay out the new saw chain in a loop and straighten

any kinks. The cutters should face in the direction of

chain rotation. If they face backwards, turn the loop

over.

• Place the chain drive links into the bar groove.

Note: Make certain of direction of the chain.

• Position the chain so there is a loop at the back of

the bar.

• Hold the chain in position on the bar and place the

loop around the sprocket.

• Fit the bar ush against the mounting surface so that

the bar studs are in the long slot of the bar. Ensure

that the chain is over the sprocket.

Note: When placing the bar on the bar studs, ensure

that the adjusting pin is in the chain tension pin hole.

• Replace the chain cover.

• Remove all slack from the chain by turning the chain

adjustment screw (P) clockwise until the chain seats

snugly against the bar with the drive links in the bar

groove.

Cutters Chain Rotation

Chain Drive Links

Bar Groove

Chain Drive Links

• Lift the tip of the guide bar up to check for sag.

• Release the tip of the guide bar and turn the chain

adjustment screw 1/2 turn clockwise. Repeat this

process until sag does not exist.

• Hold the tip of the guide bar up and tighten the chain

cover lock nuts (K) by turning them with the wrench

(O). The chain is correctly tensioned when there is

no sag on the underside of the guide bar, the chain is

snug, but it can be turned by hand without binding.

25

Page 26

kobalttools.com

CARE AND MAINTENANCE

Note: If the chain is too tight, it will not rotate. Loosen the

chain cover lock nuts (K) slightly and turn the chain

adjustment screw 1/4 turn counterclockwise. Lift the tip of

the guide bar up and retighten the chain cover lock nuts

(K). Ensure that the chain will rotate without binding.

Adjusting the chain tension

WARNING

Never touch or adjust the chain while the motor is running.

The saw chain is very sharp. Always wear protective

gloves when performing maintenance on the chain.

• Loosen the chain cover lock nuts (K) with the supplied

wrench (O). The chain cover lock nuts (K) do not have

to be completely removed in order to adjust the chain

tension.

• Rotate the chain adjustment screw (P) clockwise to

increase the chain tension and rotate counterclockwise

to decrease the chain tension.

• Once the chain is at the desired tension, tighten the

chain cover lock nuts (K).

O

K

O

K

P

26

Page 27

kobalttools.com

CARE AND MAINTENANCE

Note: During normal saw operation, the temperature of

the chain increases. The drive links of a correctly

tensioned warm chain will hang approximately 1/16 in.

(1,58 mm) out of the bar groove.

Note: New chains tend to stretch; check the chain tension

frequently and tension as required.

1/16 in. (1,58 mm)

CAUTION

A chain tensioned while warm may be too tight upon cooling. Check the “cold tension” before next

use. Never tension a warm chain before storing as chains shrink when cool. This can damage the

chain, bar and saw.

Chain maintenance

Use only a low-kickback chain on this saw. This

fast-cutting chain provides kickback reduction when

properly maintained. For smooth and fast cutting,

maintain the chain properly. The chain requires

sharpening when the wood chips are small and powdery,

the chain must be forced through the wood during cutting,

or the chain cuts to one side. During maintenance of the

chain, consider the following:

• Improper ling angle of the side plate can increase the

risk of severe kickback.

• Raker (depth gauge) clearance:

- Too low– increases the potential for kickback.

- Not low enough– decreases cutting ability.

• If the cutter teeth hit hard objects such as nails or

stones, or are abraded by mud or sand on the wood,

have an authorized service center sharpen the chain.

Raker (Depth Gauge) Clearance

1/32 in. (0,79 mm)

27

Page 28

kobalttools.com

CARE AND MAINTENANCE

Note:

• Inspect the drive sprocket for wear or damage when replacing the chain. Have the drive sprocket

replaced by an authorized service center if there are any signs of wear or damage.

• If you do not fully understand the correct procedure for sharpening the chain after reading the

instructions that follow, have the saw chain sharpened by an authorized service center or replace

with a recommended low-kickback chain.

Sharpening the cutters

Be careful to le all cutters to the specied angles and

to the same length, as fast cutting can be obtained only

when all cutters are uniform.

CAUTION

Make sure the battery is removed from the chain saw

before you work on the saw.

WARNING

The saw chain is very sharp. Always wear protective

gloves when performing maintenance to the chain to

prevent serious personal injury.

• Tension the chain prior to sharpening. Refer to the

Adjusting the chain tension section on page 26.

• Use a 5/32 in. (4 mm) diameter round le and holder.

Do all of your ling at the midpoint of the bar.

• Keep the le level with a top plate of the tooth. Do not

let the le dip or rock.

• Using light but rm pressure, stroke towards the front

corner of the tooth.

Top Place

Rivet Hole

Heel

PARTS OF A CUTTER

Gullet

Cutting Corner

Side Plate

Depth Gauge

Toe

28

Page 29

kobalttools.com

CARE AND MAINTENANCE

• Lift the le away from the steel on each return stroke.

• Put a few rm strokes on every tooth. File all left hand

cutters in one direction. Then move to the other side

and le the right hand cutters in the opposite direction.

• Remove lings from the le with a wire brush.

CAUTION

A dull or improperly sharpened chain can cause excessive

motor speed during cutting, which may result in severe

motor damage.

Left hand Cutters

WARNING

• Improper chain sharpening increases the potential of

kickback.

• Failure to replace or repair a damaged chain can

cause serious injury.

Top plate ling angle

• CORRECT 30° – le holders are marked with guide

marks to align le properly to produce correct top plate

angle.

Right hand Cutters

TOP PLACE FILLING ANGLE

30°

SIDE PLATE FILLING ANGLE

CORRECT

LESS THAN 30°

80°

INCORRECT

MORE THAN 30°

29

Page 30

kobalttools.com

CARE AND MAINTENANCE

Side plate angle

• Correct 80° – Produced automatically if you use the

correct diameter le in the le holder.

• Hook – “Grabs” and dulls quickly; increases the

potential of kickback. Results from using a le with a

diameter too small or a le held too low.

• Backward Slope – Needs too much feed pressure;

causes excessive wear to the bar and chain. Results

from using a le with a diameter too large or le held

too high.

Side plate angle

• Maintain the depth gauge at a clearance of 1/32 in.

(0,79 mm). Use a depth gauge tool for checking the

depth gauge clearances.

• Every time the chain is led, check the depth gauge

clearance.

Hook

Incorrect

Backward Slope

Raker (Depth Gauge) Clearance

• Use a at le and a depth gauge jointer to lower all

gauges uniformly. Use a 1/32 in. (0,79 mm) depth

gauge jointer.

1/32”

(0,79 mm)

Depth Gauge Jointer

Flat le

30

Page 31

CARE AND MAINTENANCE

• After lowering each depth gauge, restore original

shape by rounding the front. Be careful not to damage

•

•

adjusting depth gauges.

Maintaining the guide bar

Every week of use, reverse the guide bar on the saw to

distribute the wear for maximum bar life. The bar should

be cleaned every day of use and checked for wear and

damage. Feathering or burring of the bar rails is a normal

process of bar wear. Such faults should be smoothed

following faults should be replaced:

• Wear inside the bar rails that permits the chain to lay

over sideways

• Bent guide bar

• Cracked or broken rails

• Spread rails

Lubricate guide bars after each use with a sprocket at

their tip. Using a grease syringe, lubricate weekly in the

lubricating hole. Turn the guide bar and check that the

lubrication holes and chain groove are free from

impurities.

Restore

Original shape

by Rounding

the front

Lubricating hole

Transport

When storing or transporting the chainsaw, always place the protective cover over the chain saw blade.

Storage

• Ensure the battery is removed from the chainsaw.

• Wipe any debris off of the chainsaw, including built up wood chips under the chain cover.

• Store in a dry cool place out of the reach of children.

• Store with the scabbard on to prevent damage to the chain and potential damage to other.

kobalttools.com

31

Page 32

TROUBLESHOOTING

If you still have questions or an unresolved issue after going through this troubleshooting guide, or just

want to speak to a Kobalt product expert, please call our customer service department at

1-888-3KOBALT (1-888-356-2258), 8 a.m. - 8 p.m., EST, Monday – Friday.

PROBLEM POSSIBLE CAUSE CORRECTIVE ACTION

Bar and chain

running hot and

smoking.

1. Check chain tension for

overtightened condition.

2. Chain oil tank empty.

1. Tension chain. Refer to the

Adjusting the chain tension section

on page 26.

2. Check oil tank.

Motor runs, but

chain is not

rotating.

Motor runs, chain

rotates but does

not cut.

Chain saw does

not run.

1. Chain tension too tight.

2. Check guide bar and chain

assembly.

3. Check guide bar and chain for

damage.

1. Dull chain.

2. Chain on backwards.

1. Battery is not charged.

2. Battery is not correctly installed in

the chain saw.

1. Re-tension chain. Refer to the

Adjusting the chain tension section

on page 26.

2. Refer to the Replacing the guide

bar and chain section on page 23.

3. If damaged, refer to the Replacing

the guide bar and chain section on

page 23.

1. Sharpen chain.

2. Reverse direction of chain.

1. Check the battery charge.

If there is no charge, remove the

battery and follow the charging

procedures in the charger manual.

2. Make sure the battery is

completely installed in the chain

saw. Refer to page 13.

3. Chain brake is engaged.

Alert Indicator

LED is on.

1. Battery requires charging.

2. Chain saw is overloaded.

3. Pull back on the chain brake to

disengage.

1. Check the battery charge. If

there is no charge, remove the

battery and follow the charging

procedures in the charger manual.

2. Overload protection is active.

Release trigger to reset the internal

circuit breaker in order to continue.

kobalttools.com

32

Page 33

kobalttools.com

WARRANTY

5-YEAR HASSLE-FREE WARRANTY

This 80 V Lithiuim-Ion Cordless 18 in. Chain saw is warranted to the original purchaser from the

original purchase date for ve (5) years subject to the warranty coverage described herein.

This 80 V Lithiuim-Ion Cordless 18 in. Chain saw is warranted for the original user to be free from

defects in material and workmanship.

If you believe that the 80 V Lithiuim-Ion Cordless 18 in. Chain saw is defective at any time during the

specied warranty period, simply return the 80 V Lithiuim-Ion Chain saw along with proof of purchase

to the place of purchase for a free replacement or refund, or call 1-888-3KOBALT (1-888-356-2258)

for warranty service.

This warranty is void if: defects in materials or workmanship or damages result from repairs or

alterations which have been made or attempted by others or the unauthorized use of nonconforming

parts; the damage is due to normal wear, damage is due to abuse (including overloading of the tool

beyond capacity), improper maintenance, neglect or accident; or the damage is due to the use of the

tool after partial failure or use with improper accessories or unauthorized repair or alteration.

This warranty excludes bar and chain.

This warranty gives you specic legal rights, and you may also have other rights that vary from state

to state.

REPLACEMENT PARTS LIST

For replacement parts, call our customer service department at 1-888-3KOBALT (1-888-356-2258),

8 a.m. - 8 p.m., EST, Monday - Friday.

BA C

PART DESCRIPTION PART #

A Side cover 341071075

B Bar nut 322091063

C Wrench 333031063

Printed in China

Kobalt® is a registered trademark of LF, LLC. All Rights Reserved.

33

Loading...

Loading...