Page 1

AB17985

Questions, problems, missing parts? Before returning to your retailer, call our customer

service department at 1-888-3KOBALT (1-888-356-2258), 8 a.m. - 8 p.m., EST,

Monday - Friday.

ATTACH YOUR RECEIPT HERE

Serial Number Purchase Date

ITEM #0953776

7-AMP

ROTARY HAMMER

MODEL #K7RH-03

Español p. 29

Français p. 14

Page 2

2

TABLE OF CONTENTS

Product Specications ......................................................................................2

Package Contents ............................................................................................3

Safety Information ............................................................................................ 4

Preparation .......................................................................................................7

Operating Instructions ...................................................................................... 8

Care and Maintenance ...................................................................................13

Troubleshooting..............................................................................................13

Warranty ........................................................................................................ 13

PRODUCT SPECIFICATIONS

COMPONENT SPECIFICATION

Rated power input 120 V ~ 60 Hz, 7A

No-load speed 0 - 1,150/min

Rated impact 0 - 4,000 IPM

Maximum drilling diameter Concrete: 1-1/32 in. (26mm)

Wood: 1-3/16 in. (30mm)

Steel: 1/2 in. (13mm)

Brickwork with hollow bit: 2-11/16 in. (68mm)

Tool holder SDS-plus

Page 3

3

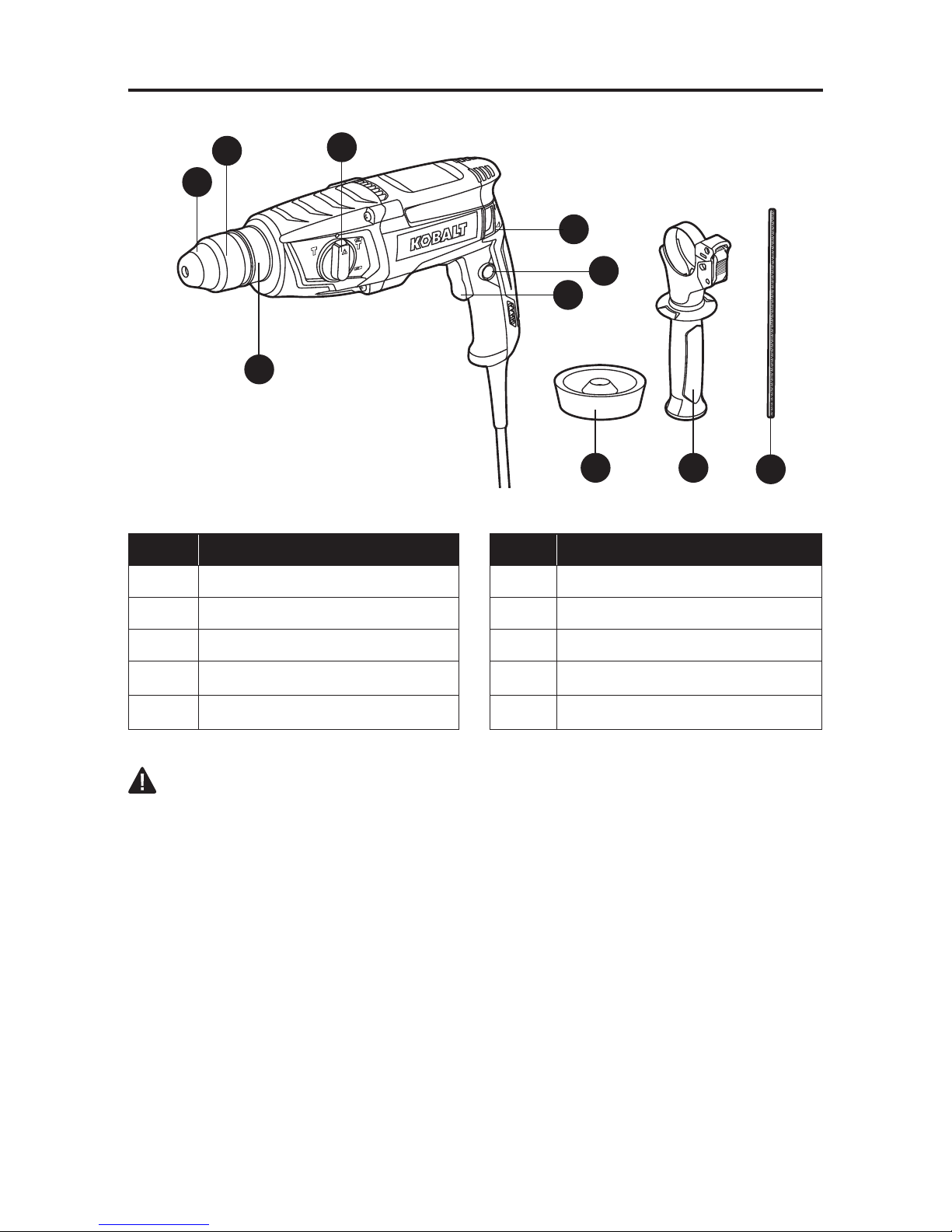

PACKAGE CONTENTS

PART DESCRIPTION PART DESCRIPTION

A Dust-protection cap F Direction-of-rotation selector

B Locking sleeve G Dust receptacle

C Mode selector H Auxiliary handle

D Variable-speed trigger switch I

Auxiliary handle recess

E Lock-on button J

Depth gauge

WARNING

• Remove the tool from the package and examine it carefully. Do not discard the carton or any

packaging material until all parts have been examined.

• If any part of the tool is missing or damaged, do not connect the plug to the power source or

use the tool until the part has been repaired or replaced. Failure to heed this warning could

result in serious injury.

A

B

C

F

E

D

G H

J

I

Page 4

4

SAFETY INFORMATION

Please read and understand this entire manual before attempting to assemble or operate

this product. If you have any questions regarding the product, please call customer service at

1-888-3KOBALT, 8 a.m. - 8 p.m., EST, Monday - Friday.

WARNING

• The operation of any power tool can result in foreign objects being thrown into your eyes,

which can result in severe eye damage. Before beginning power-tool operation, always wear

safety goggles or safety glasses with side shields and a full-face shield, when needed. It is

recommended to use a wide vision safety mask over eyeglasses or standard safety glasses

with shields. Always use eye protection marked to comply with ANSI Z87.1.

• Some dust created by power sanding, sawing, grinding, drilling, and other construction

activities contains chemicals known to the state of California to cause cancer, birth defects,

or other reproductive harm. Some examples of these chemicals are:

– Lead from lead-based paints

– Crystalline silica from bricks, cement, and other masonry products

– Arsenic and chromium from chemically-treated lumber

• Your risk from these exposures varies, depending upon how often you do this type of work.

To reduce your exposure to these chemicals:

– Work in a well-ventilated area.

– Work with approved safety equipment, such as dust masks that are specially designed to

lter out microscopic particles.

– Avoid prolonged contact with dust from power sanding, sawing, grinding, drilling, and

other construction activities. Wear protective clothing and wash exposed areas with soap

and water. Allowing dust to get into your mouth or eyes or to lie on the skin may promote

absorption of harmful chemicals.

Know the Tool

To operate this tool, carefully read this manual and all labels afxed to the tool before using it.

Keep this manual available for future reference.

Important

This tool should be serviced only by a qualied service technician.

Read All Instructions Thoroughly

Page 5

5

SAFETY INFORMATION

Some of the following symbols may be used on this tool. Please study them and their meaning.

Proper interpretation of these symbols will allow you to operate the tool better and more safely.

SYMBOL DEFINITION SYMBOL DEFINITION

V Volts n

0

No-load Speed

A Amps /min Revolutions or Strokes per Minute

Hz Hertz IPM Impact per Minute

W Watts

Direct Current

Class II Construction Alternating Current

A danger, warning,

or caution. It means

‘Attention! Your safety

is involved.’

To reduce the risk of injury, user

must read instruction manual.

General Power Tool Safety Warnings

WARNING

• Read all safety warnings and all instructions. Failure to follow the warnings and

instructions may result in electric shock, re and/or serious injury.

Save all warnings and instructions for future reference

The term “power tool” in the warnings refers to your mains-operated (corded) power tool or

battery-operated (cordless) power tool.

Work Area Safety

• Keep work area clean and well lit. Cluttered or dark areas invite accidents.

• Do not operate power tools in explosive atmospheres, such as in the presence of

ammable liquids, gases or dust. Power tools create sparks which may ignite the dust or

fumes.

• Keep children and bystanders away while operating a power tool. Distractions can cause

you to lose control.

Electrical Safety

• Power tool plugs must match the outlet. Never modify the plug in any way. Do not use

any adaptor plugs with earthed (grounded) power tools. Unmodied plugs and matching

outlet will reduce the risk of electric shock.

• Avoid body contact with earthed or grounded surfaces, such as pipes, radiators,

ranges and refrigerators. There is an increased risk of electric shock if your body is

earthed or grounded.

• Do not expose power tools to rain or wet conditions. Water entering a power tool will

increase the risk of electric shock.

• Do not abuse the cord. Never use the cord for carrying, pulling or unplugging the

power tool. Keep cord away from heat, oil, sharp edges or moving parts. Damaged or

entangled cords increase the risk of electric shock.

Page 6

6

SAFETY INFORMATION

• When operating a power tool outdoors, use an extension cord suitable for outdoor

use. Use of a cord suitable for outdoor use reduces the risk of electric shock.

• If operating a power tool in a damp location is unavoidable, use a ground fault circuit

interrupter (GFCI) protected supply. Use of a GFCI reduces the risk of electric shock.

Personal Safety

• Stay alert, watch what you are doing and use common sense when operating a power

tool. Do not use a power tool while you are tired or under the inuence of drugs,

alcohol or medication. A moment of inattention while operating power tools may result in

serious personal injury.

• Use personal protective equipment. Always wear eye protection. Protective equipment

such as dust mask, non-skid safety shoes, hard hat, or hearing protection used for

appropriate conditions will reduce personal injuries.

• Prevent unintentional starting. Ensure the switch is in the off-position before

connecting to power source and/or battery pack, picking up or carrying the tool.

Carrying power tools with your nger on the switch or energizing power tools that have the

switch on invites accidents.

• Remove any adjusting key or wrench before turning the power tool on. A wrench or a

key left attached to a rotating part of the power tool may result in personal injury.

• Do not overreach. Keep proper footing and balance at all times. This enables better

control of the power tool in unexpected situations.

• Dress properly. Do not wear loose clothing or jewelry. Keep your hair, clothing and

gloves away from moving parts. Loose clothes, jewelry or long hair can be caught in

moving parts.

• If devices are provided for the connection of dust extraction and collection facilities,

ensure that these are connected and properly used. Use of dust connection can reduce

dust-related hazards.

Power Tool Use and Care

• Do not force the power tool. Use the correct power tool for your application. The

correct power tool will do the job better and safer at the rate for which it was designed.

• Do not use the power tool if the switch does not turn it on and off. Any power tool that

cannot be controlled with the switch is dangerous and must be repaired.

• Disconnect the plug from the power source and/or the battery pack from the power

tool before making any adjustments, changing accessories, or storing power tools.

Such preventive safety measures reduce the risk of starting the power tool accidentally.

• Store idle power tools out of the reach of children and do not allow persons

unfamiliar with the power tool or these instructions to operate the power tool. Power

tools are dangerous in the hands of untrained users.

• Maintain power tools. Check for misalignment or binding of moving parts, breakage

of parts and any other condition that may affect the power tool’s operation. If

damaged, have the power tool repaired before use. Many accidents are caused by

poorly maintained power tools.

• Keep cutting tools sharp and clean. Properly maintained cutting tools with sharp cutting

edges are less likely to bind and are easier to control.

• Use the power tool, accessories, tool bits, etc. in accordance with these instructions,

taking into account the working conditions and the work to be performed. Use of the

power tool for operations different from those intended could result in a hazardous situation.

Page 7

7

SAFETY INFORMATION

Service

• Have your power tool serviced by a qualied repair person using only identical

replacement parts. This will ensure that the safety of the power tool is maintained.

Specic Safety Warnings for Rotary Hammer

• Wear ear protectors. Exposure to noise can cause hearing loss.

• Use auxiliary handle(s), if supplied with the tool. Loss of control can cause personal

injury.

• Hold power tool by insulated gripping surfaces, when performing an operation

where the cutting tool may contact hidden wiring or its own cord. Cutting accessory

contacting a “live” wire may make exposed metal parts of the power tool “live” and could

give the operator an electric shock.

• Use suitable detectors to determine if utility lines are hidden in the work area or call

the local utility company for assistance. Contact with electric lines can lead to re and

electric shock. Damaging a gas line can lead to explosion. Penetrating a water line causes

property damage or may cause an electric shock.

• When working with the power tool, always hold it rmly with both hands and provide

for a secure stance. The power tool is guided more securely with both hands.

• Secure the workpiece. A workpiece clamped with clamping devices or in a vice is held

more secure than by hand.

• Always wait until the power tool has come to a complete stop before placing it down.

The tool insert can jam and lead to loss of control over the power tool.

• Do not use the power tool with a damaged cord. Do not touch the damaged cord and pull

the plug from the outlet when the cord is damaged while working. Damaged cords increase

the risk of an electric shock.

PREPARATION

Know Your Rotary Hammer

This rotary hammer can be used for hammer drilling in concrete, brick and stone, as well as for

light chiseling work; and for drilling in wood, metal and plastic, as well as for screw driving with

specied accessories.

Before attempting to use the rotary hammer, familiarize yourself with all of its operating

features and safety requirements.

WARNING

• Do not allow familiarity with the rotary hammer to cause carelessness. Remember that one

careless moment is enough to cause severe injury. Before attempting to use any tool, be

sure to become familiar with all of the operating features and safety instructions.

• Do not attempt to modify this tool or create accessories not recommended for use with this

tool. Any such alteration or modication is misuse and could result in a hazardous condition

leading to possible serious personal injury.

Page 8

8

OPERATING INSTRUCTIONS

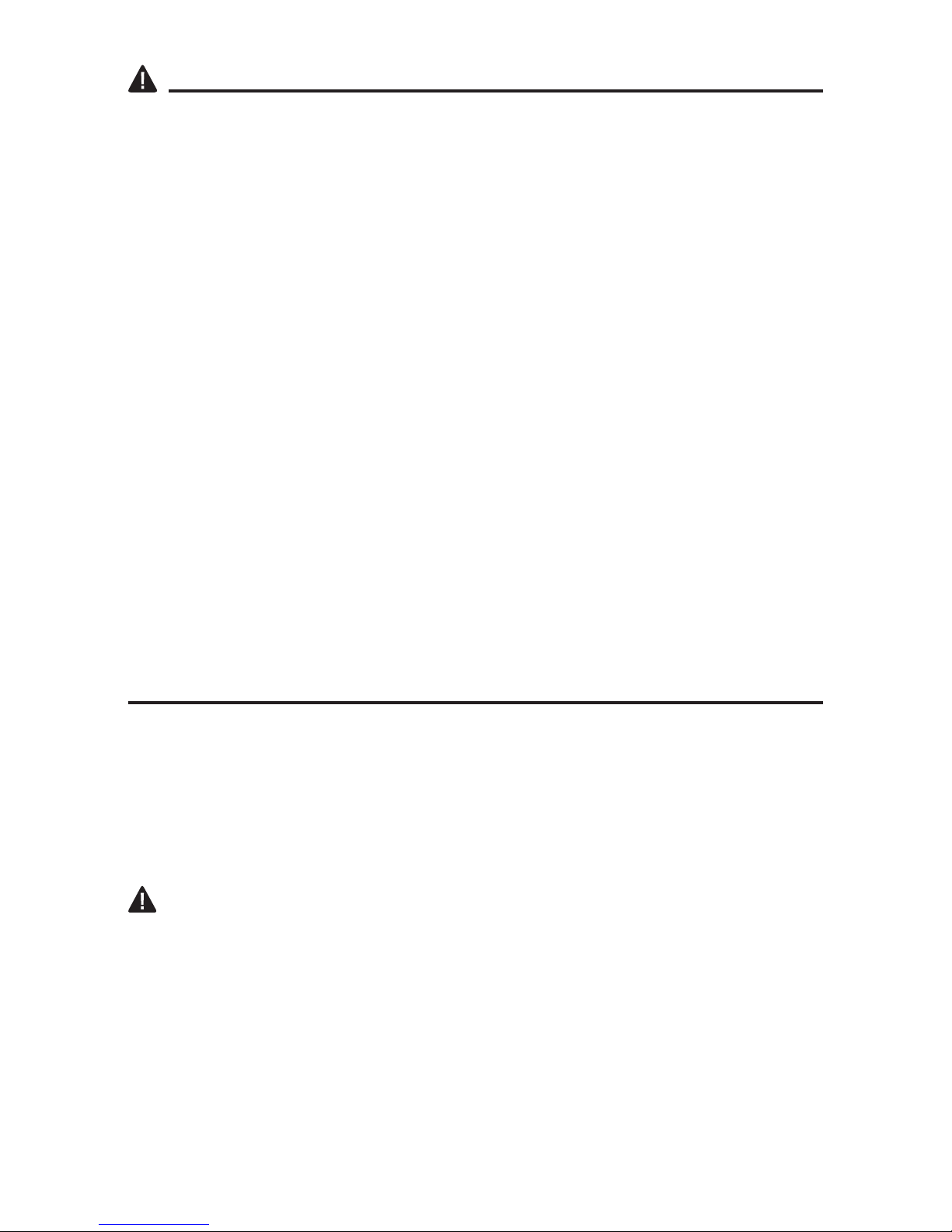

1. Variable-speed Trigger Switch

a. To turn the rotary hammer ON, press the

variable-speed trigger switch (D).

WARNING

• The blade should reach full speed before it

comes into contact with the workpiece.

b. To turn the rotary hammer OFF, release the

variable-speed trigger switch.

c. The variable-speed trigger switch delivers higher

speed with increased trigger pressure and lower

speed with decreased trigger pressure.

2. Lock-on Button

This rotary hammer is equipped with a lock-on

button (E), which is convenient for continuous

drilling or hammer drilling for extended periods of

time.

a. To drill or hammer drill continuously, press and

hold the variable-speed trigger switch (D) and

then press the lock-on button. Release the

trigger switch.

b. To unlock the lock-on button and stop

continuous operation, press the trigger switch.

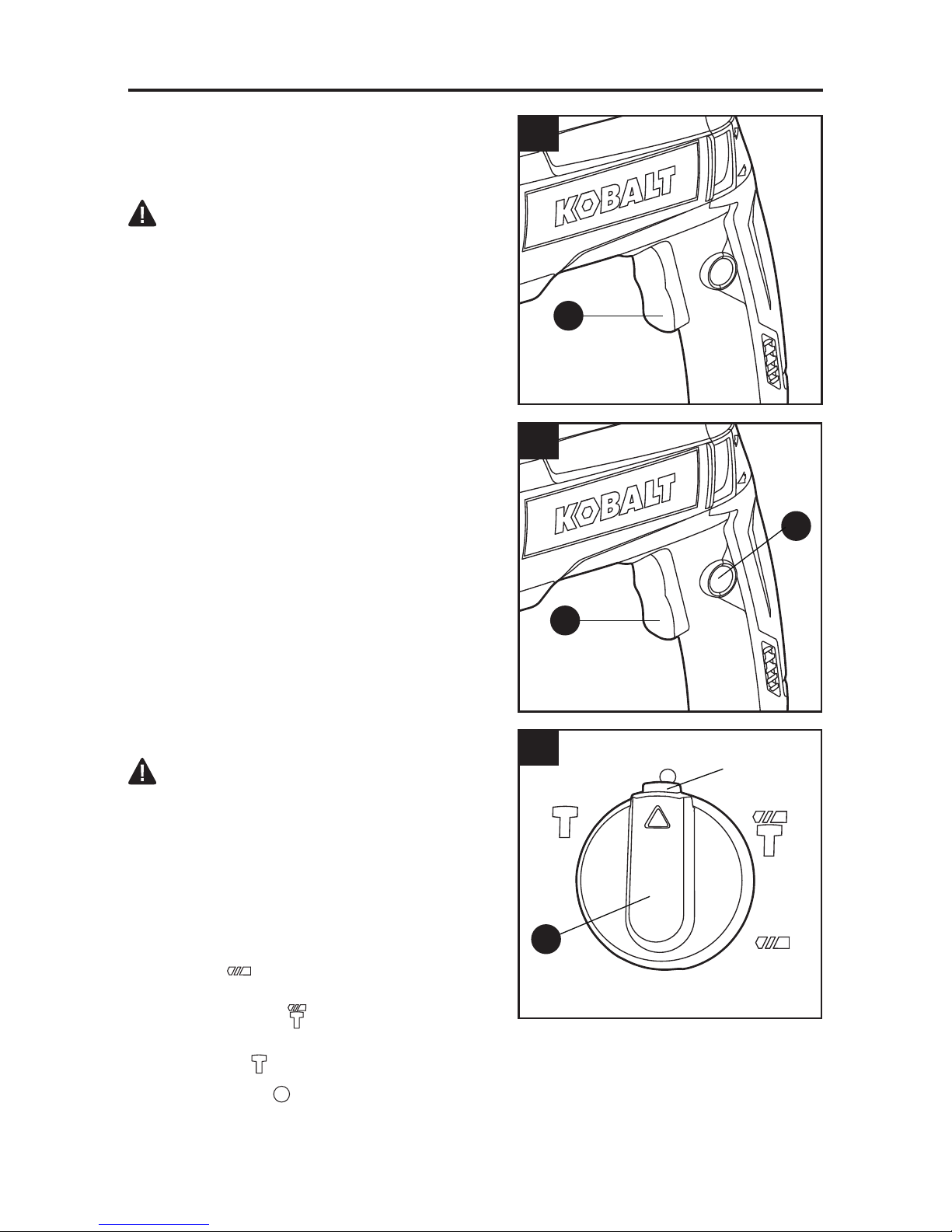

3. Mode Selector

WARNING

• ALWAYS unplug the rotary hammer before

making any adjustments. Failure to unplug the

rotary hammer could result in accidental starting,

which can cause serious personal injury.

The mode selector (C) allows the tool to be set for

various applications. To change the operating mode,

press the button on the mode selector, then rotate

the selector until the button snap-locks.

Drilling mode

: For drilling action in woods, metals,

plastics or other materials, as well as for screw driving.

Hammer-drilling mode

: For drilling with hammer

action in concrete, brick or similar hard materials.

Chiseling mode

: For light chipping and chiseling applications.

Non-working mode

: For use only to rotate a at chisel attachment to the desired position.

NOTE: Never change the mode setting when the tool is running. Otherwise, the machine can

be damaged.

2

3

1

D

C

E

D

button

Page 9

9

OPERATING INSTRUCTIONS

4. Direction-of-Rotation Selector

The direction of bit rotation is reversible and is

controlled by a selector located above the lock-on

button (E). With the rotary hammer held in the

normal operating position:

a. Position the direction-of-rotation selector (F) to

the position marked

for forward rotation.

b. Position the direction-of-rotation selector to

position marked for reverse rotation.

The rotation direction setting is not available while

in chiseling mode.

NOTE: To prevent gear damage, always allow the

rotary hammer to come to a complete stop before

changing the direction of rotation.

NOTE: The rotary hammer will not run unless the direction-of-rotation selector is fully engaged to

the left or to the right.

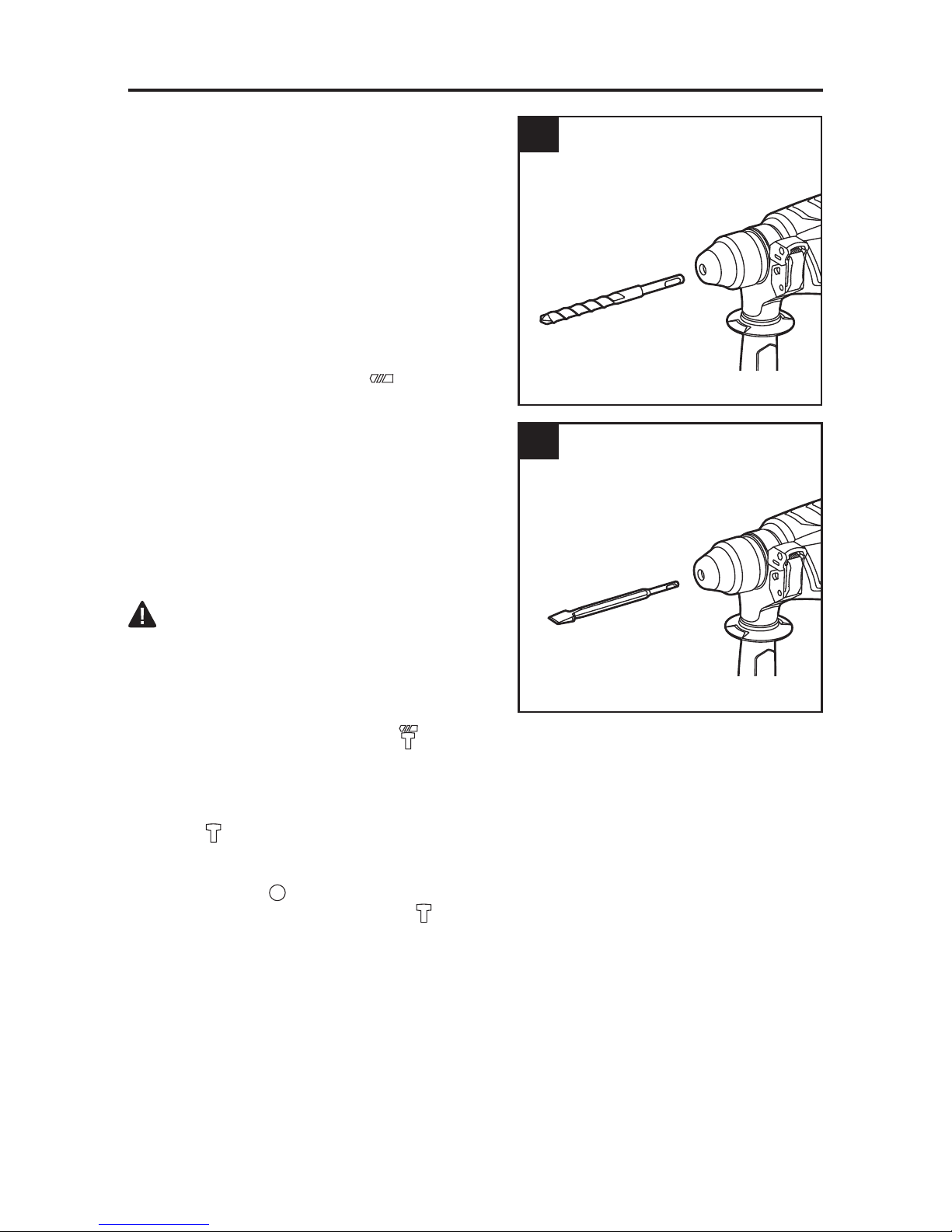

5. Auxiliary Handle

WARNING

• ALWAYS unplug the rotary hammer before

making any adjustments. Failure to unplug the

rotary hammer could result in accidental starting,

which can cause serious personal injury.

This rotary hammer is equipped with an auxiliary

handle (H). For ease of operation, you can use the

handle with either the left or right hand. For optimal

operation, the handle can be positioned at any

location around the tool.

To assemble the auxiliary handle:

a. Disconnect the plug from the power source.

b. Loosen the auxiliary handle by turning the handle counterclockwise.

c. Insert the rotary hammer through the auxiliary handle ring. Slide the auxiliary handle over

the locking sleeve (B) until it is resting in the auxiliary handle recess (I).

d. Hand-tighten the handle by turning the handle clockwise.

To adjust the auxiliary handle assembly:

a. Disconnect the plug from the power source.

b. Loosen the auxiliary handle (H) by turning the handle counterclockwise.

c. With the handle loosened, rotate the auxiliary handle to the desired position.

d. Hand-tighten the handle by turning it clockwise.

4

5

I

B

F

F

H

Page 10

10

OPERATING INSTRUCTIONS

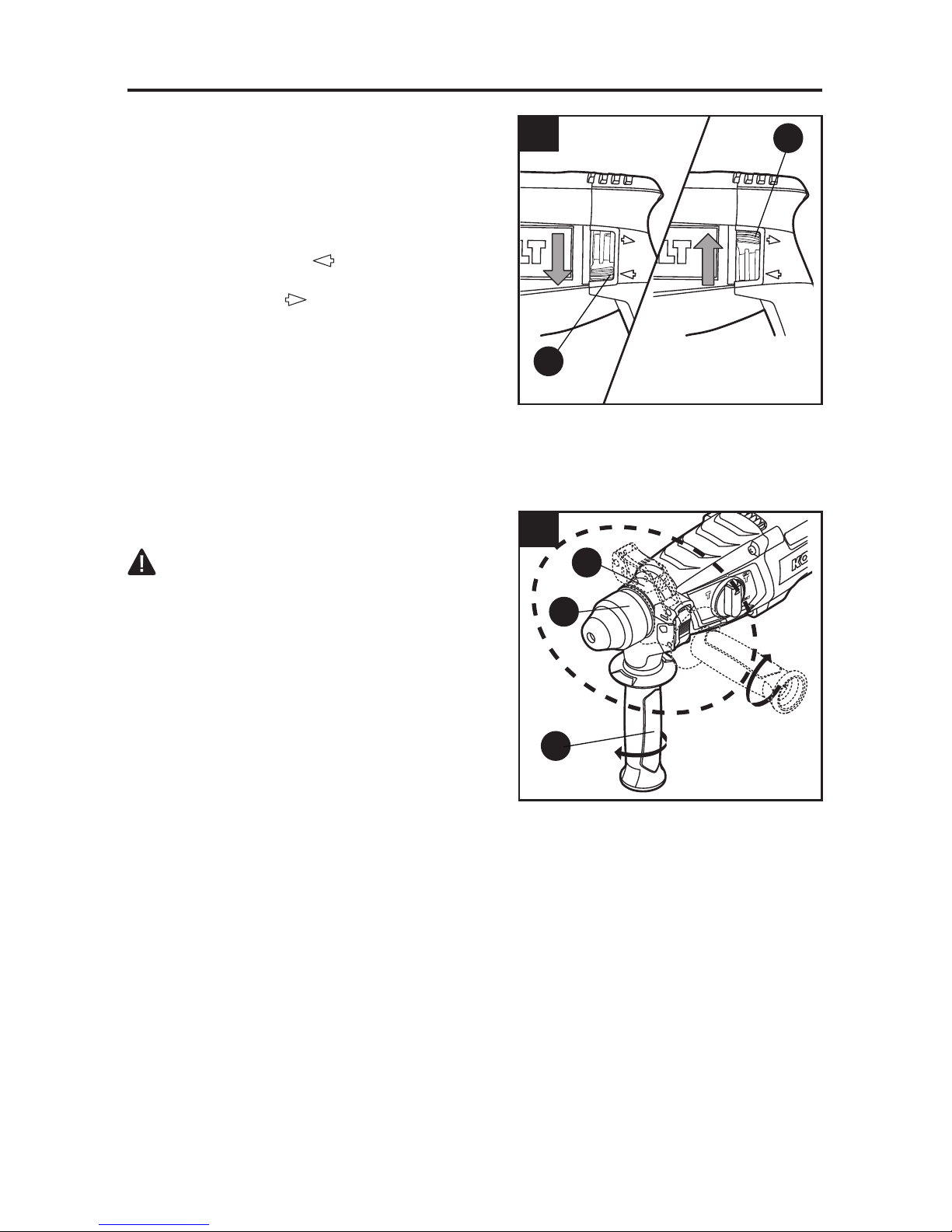

6. Depth Gauge

WARNING

• ALWAYS unplug the rotary hammer before making

any adjustments. Failure to unplug the rotary

hammer could result in accidental starting, which

can cause serious personal injury.

The rotary hammer is equipped with a depth gauge

(J) to set the drilling depth when using the tool.

a. Disconnect the plug from the power source.

b. Press the clamp button on the auxiliary handle

(H), then insert the depth gauge through the

hexagonal hole in the handle. Position the

depth gauge with the ribs oriented as shown.

Make sure that the side with ribs is facing

downward.

c. Adjust the depth gauge to the desired position, then release the clamp button. The depth

gauge will be secured in position.

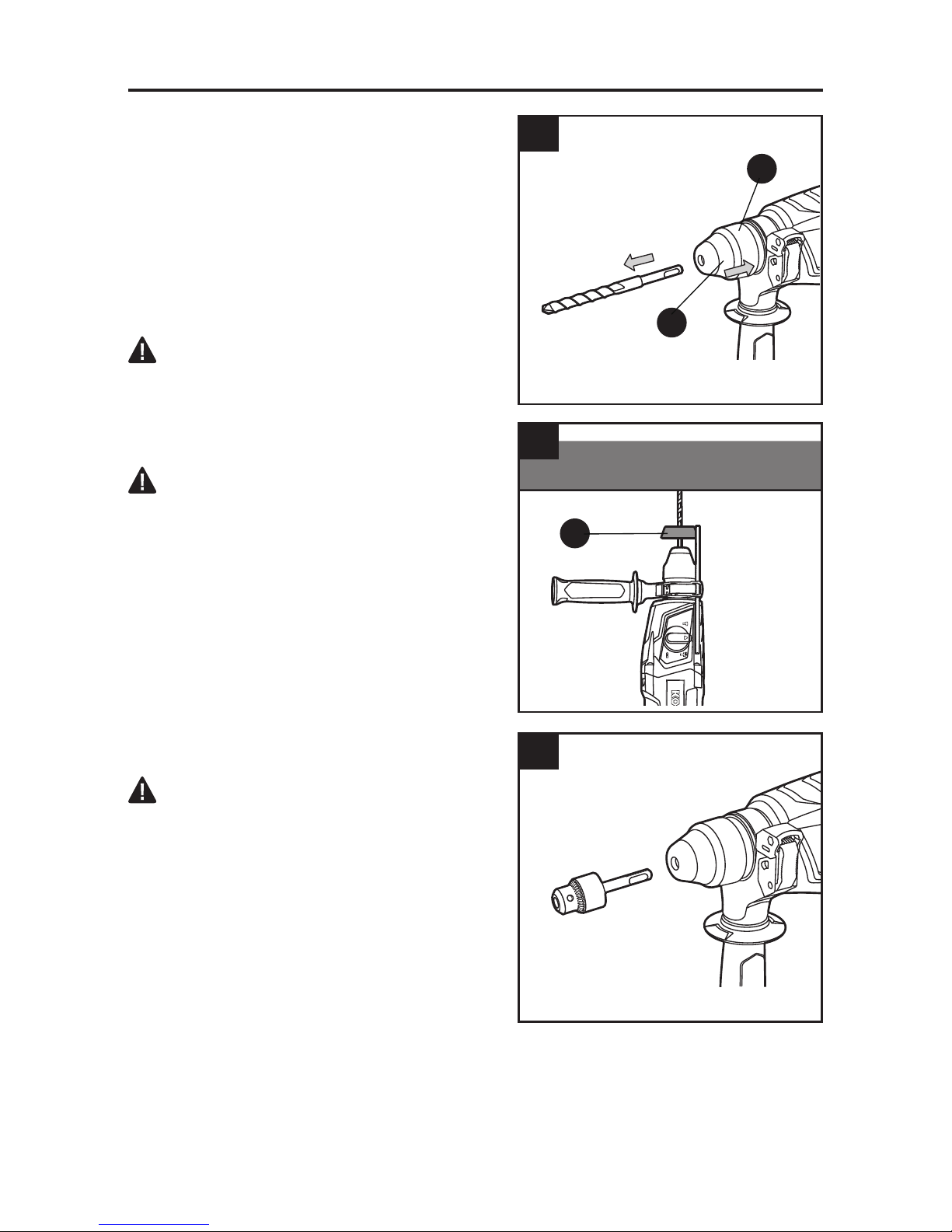

7. Changing Accessories

WARNING

• ALWAYS unplug the rotary hammer before making

any adjustments or installing accessories. Failure to

unplug the rotary hammer could result in accidental

starting, which can cause serious personal injury.

Accessory selection

For drilling in wood, metal and plastic and for screw

driving, use the corresponding SDS-plus adapter (not

included) to use a normal bit that is not SDS-plus type.

For hammer drilling and chiseling, use SDS-plus

bits.

To Install the Accessory

The dust-protection cap (A) helps to prevent the entry of drilling dust into the tool holder

during operation. When installing the bit/adapter, take care that the dust protection cap is

not damaged. Replace it immediately if it is damaged. Please contact our customer service

department at 1-888-3KOBALT.

a. Clean and lightly grease the shank end of the SDS-plus accessory.

b. Insert the accessory into the chuck with a turning motion until it engages. The accessory

locks in position automatically.

c. Pull on the accessory to check that it is installed securely.

6

7a

J

H

clamp button

B

A

Page 11

11

OPERATING INSTRUCTIONS

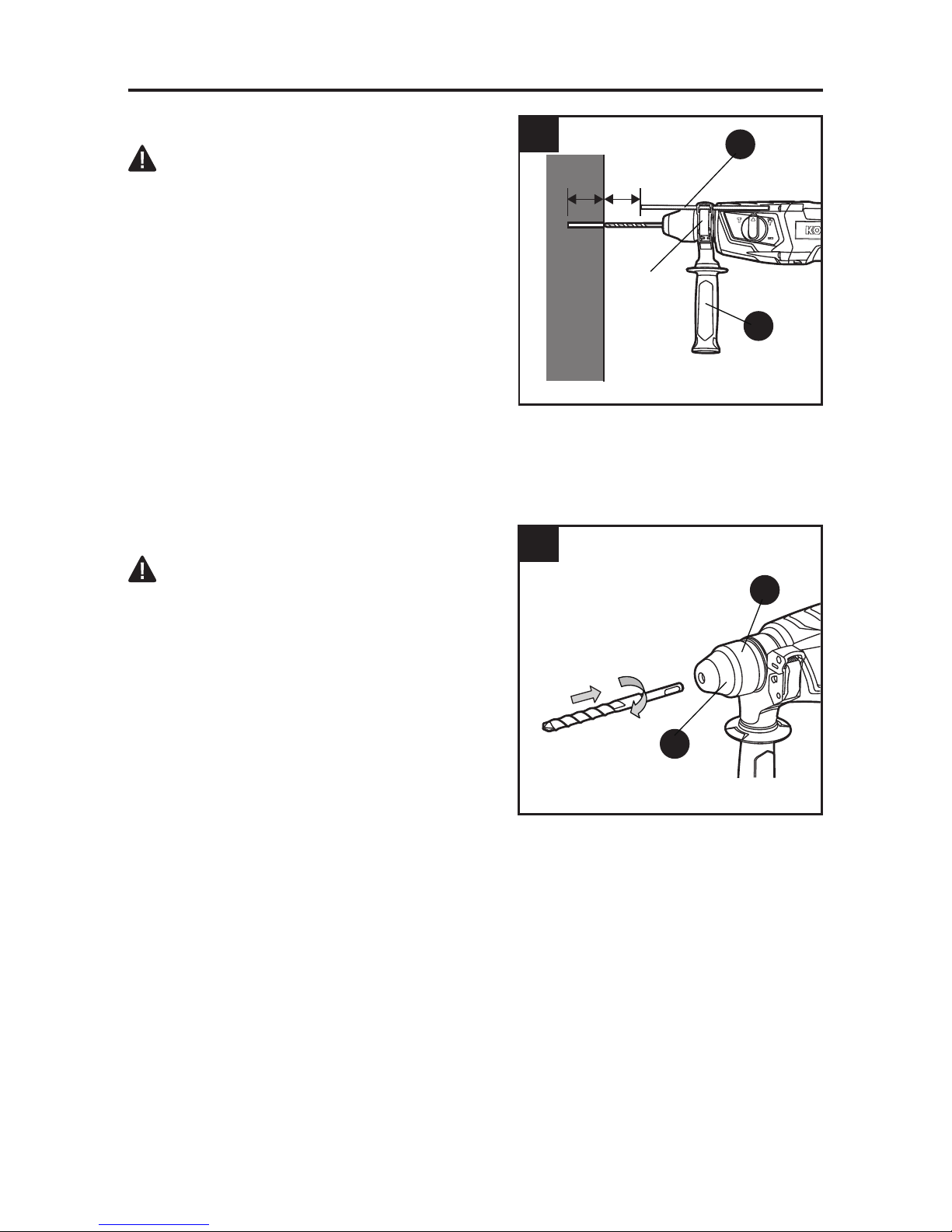

To Remove the Accessory

a. Pull back on the locking sleeve (B).

b. Hold the locking sleeve and remove the

accessory.

An SDS-plus accessory is designed for freedom

of movement, which causes eccentricity when

the tool is off-loaded; however, the accessory

automatically centers itself during operation without

affecting drilling precision.

WARNING

• Do not use bits/chisels with a damaged shank.

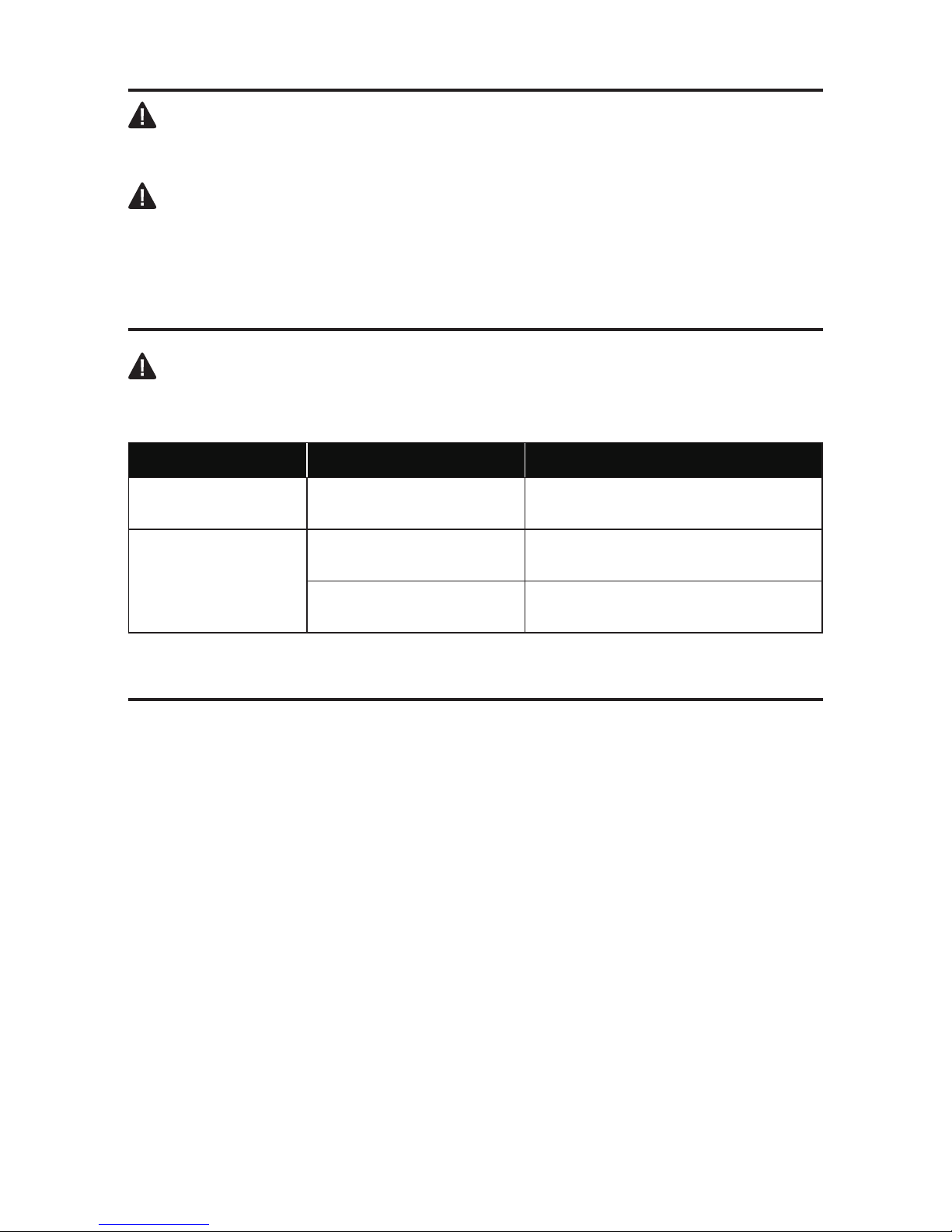

8. Using with the Dust Receptacle

WARNING

• The dust receptacle (G) is to be used exclusively

for concrete drilling work. Do not use this item for

wood or metal drilling work.

• Discard the accumulated particles after every

two or three holes when drilling.

When using a rotary hammer for upward drilling

operations in concrete, attach the dust receptacle

to collect dust or particles for easy operation.

Insert the dust receptacle from the tip of the bit.

9. Operating the Rotary Hammer

WARNING

• To reduce the risk of explosion, identify any utility

lines, such as electricity, gas, or water supply

lines that are hidden in the work area, BEFORE

completing any work.

NOTE: When working at low temperatures, the

hammering mechanism will operate after the tool

has reached a minimum operating temperature.

Press the tip of the rotary hammer bit briey against

the work surface with the trigger engaged. Repeat

this procedure as necessary until the tool reaches

the minimum operating temperature required to

engage the hammering mechanism.

8

9a

7b

G

B

A

Page 12

12

OPERATING INSTRUCTIONS

Drilling

For drilling in wood, metal, and plastic, and for

screw driving: to work with accessories without

SDS-plus (e.g., a drill bit with a cylindrical shaft),

a corresponding SDS-plus adapter (not included)

should be used.

a. Support the workpiece close to the drilling

location.

b. Clamp the workpiece securely so that the

workpiece will not move during drilling.

c. Unplug the rotary hammer.

d. Install the suitable adapter.

e. Set the tool to drilling mode

, and set the

desired drilling depth.

f. Plug in the rotary hammer.

g. Hold the rotary hammer rmly with both hands.

h. When drilling ferrous metal, pre-drill a smaller

hole and lubricate drill bit with oil.

i. Always wait for the tool to stop completely

before laying it on the work piece or other

surface.

Hammer Drilling

WARNING

• Do not use a bit without SDS-plus for hammer

drilling; the bit and drill chuck will be damaged by

hammer drilling.

When working with an SDS-plus bit, set the mode

selector (C) to hammer-drilling mode

.

Chipping and Chiseling

a. Unplug the rotary hammer.

b. Set the mode selector (C) to chiseling

mode

.

c. Install an appropriate chisel accessory.

d. To adjust the head of the chisel to the desired angle, set the operating mode to non-

working mode

and rotate the chisel by hand to the appropriate orientation. Return the

operating mode to chiseling mode .

e. Adjust the auxiliary handle as required.

f. Plug in the rotary hammer.

g. Hold the tool rmly with both hands.

h. Turn on the tool and start working.

NOTE: Turn the tool on and apply slight pressure on the tool so that the tool will not bounce

uncontrolled. Pressing very hard on the tool will not increase its efciency.

i. Always wait for the tool to stop completely before laying it on the work piece or other

surface.

9b

9c

Page 13

13

CARE AND MAINTENANCE

All maintenance should only be carried out by a qualied service technician.

Cleaning

Before cleaning or performing any maintenance, disconnect the plug from the power

source. For safe and proper operation, always keep the tool and its ventilation slots clean.

Always use only a soft, dry cloth to clean your rotary hammer; never use detergent or alcohol.

TROUBLESHOOTING

WARNING

• Turn the switch to the “OFF” position and disconnect the plug from the power source before

performing troubleshooting procedures.

PROBLEM POSSIBLE CAUSE CORRECTIVE ACTION

Bit doesn’t rotate. Operating mode selector is

not engaged.

Move the operating mode selector

until it engages.

No hammering action

and the tool wobbles

.

1. The tool is too cold. 1. Allow tool to reach the minimum

operating temperature.

2. Mode selector is set to

drilling mode.

2. Set the mode selector to hammerdrilling mode.

WARRANTY

This rotary hammer is warranted to the original purchaser from the original purchase date for

ve (5) years subject to the warranty coverage described herein.

This rotary hammer is warranted for the original user to be free from defects in material and

workmanship.

If you believe the rotary hammer is defective at any time during the specied warranty period,

simply return the rotary hammer along with proof of purchase to the place of purchase for a

free replacement or refund, or call 1-888-3KOBALT (1-888-356-2258) for warranty service.

This warranty is void if: defects in materials or workmanship or damages result from repairs

or alterations which have been made or attempted by others or the unauthorized use of

nonconforming parts; the damage is due to normal wear, damage is due to abuse (including

overloading of the tool beyond capacity), improper maintenance, neglect or accident; or the

damage is due to the use of the tool after partial failure or use with improper accessories or

unauthorized repair or alteration.

This warranty excludes accessories.

This warranty gives you specic legal rights, and you may also have other rights that vary from

state to state.

Printed in China

Page 14

Date d’achatNuméro de série

JOIGNEZ VOTRE REÇU ICI

Des questions, des problèmes, des pièces manquantes? Avant de retourner l’article

au détaillant, appelez notre service à la clientèle au 1 888 3KOBALT (1 888 356-2258),

entre 8 h et 20 h (HNE), du lundi au vendredi.

ARTICLE #0953776

MARTEAU ROTATIF

DE 7 A

MODÈLE #K7RH-03

Page 15

15

TABLE DES MATIÈRES

Caractéristiques du produit ............................................................................ 15

Contenu de l’emballage .................................................................................16

Consignes de sécurité ....................................................................................17

Préparation .....................................................................................................21

Mode d’emploi ................................................................................................ 22

Entretien ......................................................................................................... 27

Dépannage .....................................................................................................28

Garantie .........................................................................................................28

CARACTÉRISTIQUES DU PRODUIT

COMPOSANT CARACTÉRISTIQUES

Puissance d’alimentation nominale 120 V, 60 Hz, 7 A

Vitesse à vide De 0 à 1150/min

Nombre de coups nominal 0 à 4000 coups par minute

Diamètre de perçage maximal Béton : 26 mm (1 1/32 po)

Bois : 30 mm (1 3/16 po)

Acier : 13 mm (1/2 po)

Maçonnerie de briques avec foret creux :

68 mm (2 11/16 po)

Porte-outils SDS-Plus

Page 16

16

CONTENU DE L’EMBALLAGE

PIÈCE DESCRIPTION PIÈCE DESCRIPTION

A

Capuchon de protection contre

la poussière

F Sélecteur de sens de rotation

B Manchon de blocage G Collecteur de poussière

C Sélecteur de mode H Poignée auxiliaire

D Interrupteur à vitesse variable I Logement de la poignée auxiliaire

E Bouton de verrouillage J Jauge de profondeur

AVERTISSEMENT

• Retirez l’outil de l’emballage et examinez-le soigneusement. Ne jetez ni la boîte ni le

matériel d’emballage avant d’avoir examiné toutes les pièces.

• Si une pièce de la scie est manquante ou endommagée, évitez de brancher la che sur le

cordon d’alimentation ou d’utiliser l’outil tant que la pièce n’a pas été réparée ou remplacée.

Le non-respect de cet avertissement pourrait entraîner de graves blessures.

A

B

C

F

E

D

G H

J

I

Page 17

17

CONSIGNES DE SÉCURITÉ

Assurez-vous de lire et de comprendre l’intégralité de ce manuel avant de tenter d’assembler

ou d’utiliser le produit. Si vous avez des questions, veuillez communiquer avec notre service à

la clientèle au 1 888 3KOBALT, entre 8 h et 20 h (HNE), du lundi au vendredi.

AVERTISSEMENT

• Les outils électriques peuvent projeter des corps étrangers, présentant ainsi des risques de

blessure aux yeux. Lorsque vous utilisez un outil électrique, portez toujours des lunettes de

sécurité pourvues d’écrans latéraux et d’un écran facial panoramique, au besoin. Il est

• recommandé de porter un masque facial à vision étendue sur vos lunettes ou vos lunettes

de sécurité avec écrans. Portez toujours des lunettes de sécurité conformes à la norme

ANSI Z87.1.

• La poussière créée pendant le ponçage, le sciage, le polissage, le perçage et d’autres

activités liées à la construction peut contenir des produits chimiques reconnus par l’État

de la Californie comme étant la cause de cancer, d’anomalies congénitales et d’autres

problèmes liés aux fonctions reproductrices. Voici des exemples de ces produits chimiques :

– plomb provenant de peintures à base de plomb;

– silice cristalline provenant de la brique, du ciment ou d’autres matériaux de maçonnerie;

– arsenic et chrome provenant du bois d’œuvre traité avec un produit chimique.

• Les risques liés à l’exposition à ces produits varient selon le nombre de fois où vous

pratiquez ces activités. Pour réduire votre exposition à ces produits chimiques :

– Travaillez dans un endroit bien ventilé.

– Munissez-vous de l’équipement de sécurité approuvé tel que des masques

antipoussières conçus spécialement pour ltrer les particules microscopiques.

– Évitez l’exposition prolongée à la poussière causée par le ponçage mécanique, le sciage,

le polissage, le perçage et d’autres activités liées à la construction. Portez des vêtements

de protection et lavez à l’eau et au savon toutes les parties exposées. Les poussières

pénétrant dans votre bouche ou dans vos yeux et les poussières se déposant sur votre

peau peuvent causer l’absorption de produits chimiques dangereux.

Sachez bien comment utiliser l’outil

Veuillez lire attentivement ce manuel et toutes les étiquettes apposées sur l’outil avant de

l’utiliser. Conservez ce manuel pour vous y référer ultérieurement.

Important

L’entretien de cet outil doit être effectué par un technicien qualié uniquement.

Lisez attentivement toutes les instructions.

Page 18

18

CONSIGNES DE SÉCURITÉ

Les symboles suivants peuvent gurer sur l’outil. Familiarisez-vous avec leur signication.

En comprenant ces symboles, vous serez en mesure de faire fonctionner cet outil de façon

adéquate et sécuritaire.

SYMBOLE DÉFINITION SYMBOLE DÉFINITION

V Volts n

0

Vitesse à vide

A Ampères /min Tours ou coups par minute

Hz Hertz IPM Coups par minute

W Watts

Courant continu

Fabrication de classe II Courant alternatif

Un danger, un

avertissement ou une mise

en garde. « Attention! Votre

sécurité est en jeu. »

An de réduire les risques de

blessure, l’utilisateur doit lire le

manuel d’instructions.

Avertissements de sécurité généraux relatifs aux outils électriques

AVERTISSEMENT

• Lisez tous les avertissements et toutes les instructions. Le non-respect des

avertissements et des instructions peut entraîner un choc électrique, un incendie ou des

blessures graves.

Conservez tous les avertissements et toutes les instructions pour les consulter ultérieurement.

L’expression « outil électrique » utilisée dans les avertissements correspond aux outils

électriques alimentés sur secteur (à l) ou alimentés par piles (sans l).

Mesures de sécurité dans l’aire de travail

• L’aire de travail doit être propre et bien éclairée. Une aire de travail encombrée et peu

éclairée augmente le risque d’accident.

• N’utilisez pas d’outils électriques dans un endroit présentant un risque d’explosion,

par exemple où il y a présence de liquides, de vapeurs ou de poussières

inammables. Les outils électriques produisent des étincelles susceptibles d’enammer

ces poussières ou ces vapeurs.

• Gardez les enfants et les autres personnes à l’écart lorsque vous utilisez un outil

électrique. Une distraction peut vous faire perdre la maîtrise de l’outil.

Consignes de sécurité relatives à l’électricité

• Les ches des outils électriques doivent correspondre à la prise. Ne modiez jamais

la che de quelque façon que ce soit. N’utilisez pas d’adaptateur avec les outils

électriques mis à la terre. L’utilisation de ches non modiées dans les prises compatibles

réduit les risques de décharge électrique.

Page 19

19

CONSIGNES DE SÉCURITÉ

• Évitez de toucher à des surfaces mises à la terre, par exemple, un tuyau, un radiateur,

une cuisinière ou un réfrigérateur. Le contact du corps avec une surface mise à la terre

augmente les risques de décharge électrique.

• N’exposez pas les outils électriques à la pluie ni à tout environnement humide. Les

risques de choc électrique sont plus élevés si l’eau s’inltre dans un outil électrique.

• N’utilisez pas le cordon d’alimentation de façon abusive. Ne transportez jamais un

outil électrique en le tenant par son cordon ou ne tirez jamais sur le cordon pour le

débrancher. Tenez le cordon d’alimentation éloigné des sources de chaleur, de l’huile,

des objets coupants et des pièces mobiles. Les risques de choc électrique sont plus

élevés si le cordon d’alimentation est endommagé ou emmêlé.

• Lorsque vous utilisez un outil électrique à l’extérieur, utilisez une rallonge conçue

pour être utilisée à l’extérieur. L’utilisation de ce type de rallonge réduit les risques de

décharge électrique.

• Si vous n’avez d’autres choix que d’utiliser un outil électrique dans un endroit

humide, utilisez une alimentation protégée par un disjoncteur différentiel. L’utilisation

d’un disjoncteur différentiel réduit les risques de décharge électrique.

Sécurité personnelle

• Soyez vigilant, prêtez attention à ce que vous faites et usez de votre jugement

lorsque vous utilisez un outil électrique. N’utilisez pas un outil électrique lorsque

vous êtes fatigué ou sous l’effet de drogues, d’alcool ou de médicaments. Un

moment d’inattention pendant que vous utilisez des outils électriques peut occasionner des

blessures graves.

• Portez de l’équipement de protection individuelle. Portez toujours des lunettes de

sécurité. Le port d’équipement de protection, comme un masque antipoussières, des

chaussures de sécurité antidérapantes, un casque de protection et des protecteurs auditifs,

lorsque les conditions l’exigent, réduit les risques de blessures.

• Prenez des mesures an d’éviter que l’outil se mette en marche accidentellement.

Assurez-vous que l’interrupteur est sur la position d’arrêt avant de brancher l’outil sur une

source d’alimentation ou un bloc-piles, de ramasser l’outil ou de le transporter.

• Transporter les outils électriques avec le doigt sur l’interrupteur ou brancher

les outils lorsque l’interrupteur est en position de marche augmente les risques

d’accident. Retirez toutes les clés de réglage de l’outil électrique avant de mettre celui-ci en

marche. Une clé laissée xée à un outil rotatif peut occasionner des blessures graves.

• Ne vous étirez pas pour étendre votre portée. Gardez une posture sécuritaire et un bon

équilibre en tout temps. Cela vous permet de mieux maîtriser l’outil électrique lorsque des

situations inattendues se présentent.

• Habillez-vous convenablement. Ne portez pas de vêtements amples ni de bijoux.

Gardez vos cheveux et vos vêtements loin des pièces mobiles. Les vêtements amples,

les bijoux et les cheveux longs risquent de se prendre dans les pièces en mouvement.

• Si un dispositif permet de raccorder un dépoussiéreur, assurez-vous que celui-ci est

branché et utilisé de manière appropriée. L’emploi d’un dépoussiéreur contribue à réduire

les dangers liés à la poussière.

Utilisation et entretien d’un outil électrique

• Ne forcez pas l’outil électrique. Utilisez l’outil électrique approprié à l’utilisation que

vous envisagez. L’utilisation de l’outil électrique approprié permet d’obtenir de meilleurs

résultats, de façon plus sécuritaire, selon le régime de fonctionnement prévu.

• N’utilisez pas l’outil électrique si l’interrupteur ne fonctionne pas. Tout outil qui ne peut

pas être contrôlé par l’interrupteur est dangereux et doit être réparé.

Page 20

20

CONSIGNES DE SÉCURITÉ

• Débranchez la che de la prise ou retirez, si possible, le bloc-piles de l’outil électrique

avant d’effectuer des réglages, de changer d’accessoire ou de le ranger. De telles

mesures de sécurité préventives réduisent les risques de mise en marche accidentelle de l’outil

électrique.

• Rangez les outils électriques inutilisés hors de la portée des enfants et ne laissez pas

les personnes ne connaissant pas bien l’outil ou ces instructions utiliser l’outil. Les outils

électriques sont dangereux s’ils se retrouvent entre les mains d’utilisateurs inexpérimentés.

• Entretenez vos outils électriques et vos accessoires. Vériez les pièces mobiles pour

vous assurer qu’elles ne sont pas désalignées, enrayées, brisées, ou dans un état qui

pourrait nuire à leur fonctionnement. Si elles sont endommagées, faites-les réparer avant

d’utiliser l’outil électrique. De nombreux accidents sont provoqués par des outils électriques

mal entretenus.

• Gardez vos outils tranchants affûtés et propres. Des outils tranchants bien entretenus et

dont les lames sont affûtées risquent moins de se bloquer et sont plus faciles à maîtriser.

• Utilisez l’outil électrique, les accessoires, les embouts ou autres conformément aux

instructions, en tenant compte des conditions de travail et du travail à effectuer.

L’utilisation de l’outil électrique à des ns autres que celles pour lesquelles il a été conçu pourrait

entraîner une situation dangereuse.

Entretien

Demandez à un technicien qualié qui utilise seulement des pièces de rechange identiques aux

pièces d’origine d’effectuer l’entretien de votre outil électrique. Cela permet de maintenir l’outil

électrique sécuritaire.

Avertissements de sécurité propres au marteau rotatif

• Portez des protecteurs d’oreilles. Une exposition à du bruit peut entraîner une perte

auditive.

• Utilisez une poignée auxiliaire, si elle est fournie avec l’outil. La perte de maîtrise de l’outil

peut causer des blessures.

• Tenez l’outil électrique par sa poignée isolée lorsque l’accessoire tranchant est

susceptible d’entrer en contact avec des ls dissimulés ou avec son propre cordon

d’alimentation. Si un accessoire tranchant entre en contact avec un l sous tension, les

parties métalliques exposées de la perceuse-visseuse peuvent donner un choc électrique à

l’utilisateur.

• Utilisez les détecteurs appropriés pour déterminer si l’aire de travail dissimule

des câbles d’alimentation ou appelez le service à la clientèle de votre fournisseur

d’électricité local pour obtenir de l’aide. Tout contact avec les câbles électriques peut

entraîner un incendie et des risques de choc électrique. Toute conduite de gaz endommagée

peut entraîner une explosion. Toute conduite d’alimentation en eau percée peut entraîner des

dommages matériels ou des risques de choc électrique.

• Lorsque vous travaillez avec l’outil électrique, tenez-le toujours fermement à deux

mains de manière à adopter une position sécuritaire. L’outil électrique se dirige plus

solidement à deux mains.

• Fixez bien la pièce à travailler. Il est préférable d’utiliser des dispositifs de serrage ou un

étau pour tenir la pièce solidement en place plutôt que de la tenir à la main.

• Attendez toujours que l’outil électrique soit complètement arrêté avant de le déposer.

La partie insérée peut bloquer et entraîner une perte de maîtrise de l’outil électrique.

• N’utilisez pas l’outil électrique si le cordon d’alimentation est endommagé. Si vous

endommagez le cordon d’alimentation pendant que vous utilisez l’outil, débranchez la che

de la prise sans toucher au cordon d’alimentation endommagé. Le risque de choc électrique

augmente si le cordon d’alimentation est endommagé.

Page 21

21

PRÉPARATION

Familiarisez-vous avec votre marteau rotatif

Ce marteau rotatif peut être utilisé pour le perçage à percussion du béton, de la brique et

de la pierre, pour les travaux de ciselage légers, pour le perçage du bois, des métaux et du

plastique ainsi que pour le vissage à l’aide des accessoires recommandés.

Avant d’utiliser ce marteau rotatif, familiarisez-vous avec toutes ses caractéristiques et

fonctions ainsi qu’avec les consignes de sécurité.

AVERTISSEMENT

• Maintenez votre vigilance à mesure que vous prenez l’habitude de vous servir de votre

marteau rotatif. Gardez à l’esprit qu’il suft d’être négligent une fraction de seconde pour

causer de graves blessures. Avant d’utiliser un outil, familiarisez-vous avec toutes ses

caractéristiques et fonctions ainsi qu’avec les consignes de sécurité.

• Ne tentez pas de modier cet outil ou de créer des accessoires qui ne sont pas

recommandés pour cet outil. Toute altération ou modication de ce type constitue un

usage inapproprié et peut engendrer une situation dangereuse susceptible de causer des

blessures graves.

Page 22

22

MODE D’EMPLOI

1. Interrupteur à vitesse variable

a. Pour mettre le marteau rotatif en marche,

appuyez sur l’interrupteur à vitesse variable (D).

AVERTISSEMENT

• Le foret doit atteindre la pleine vitesse avant

d’entrer en contact avec la pièce.

b. Pour arrêter le marteau rotatif, relâchez

l’interrupteur à vitesse variable.

c. Si vous appuyez plus fortement sur l’interrupteur

à vitesse variable, la vitesse augmente, et si vous

relâchez la pression, la vitesse diminue.

2. Bouton de verrouillage

Ce marteau rotatif est muni d’un bouton de

verrouillage (E) pratique pour les longues

opérations de perçage ou de perçage à percussion

en continu.

a. Pour le perçage ou le perçage à percussion

en continu, appuyez sur l’interrupteur à vitesse

variable (D), maintenez-le enfoncé, puis

appuyez sur le bouton de verrouillage. Relâchez

l’interrupteur.

b. Appuyez sur l’interrupteur pour libérer le bouton de

verrouillage et arrêter le fonctionnement continu.

3. Sélecteur de mode

AVERTISSEMENT

• Débranchez TOUJOURS le marteau rotatif avant

de lui apporter des ajustements. Omettre de

débrancher le marteau rotatif pourrait provoquer

des mises en marche accidentelles, ce qui peut

entraîner des blessures graves.

Le sélecteur de mode (C) permet de régler l’outil

pour diverses utilisations. Pour changer le mode de

fonctionnement, appuyez sur le bouton du sélecteur de

mode, puis faites tourner le sélecteur jusqu’à ce que le

bouton s’enclenche.

Mode de perçage

: pour le perçage du bois, des

métaux, du plastique ou d’autres matériaux, ainsi que

pour le vissage.

Mode de perçage à percussion

: pour le perçage à percussion du béton, de la brique ou d’autres

matériaux durs semblables.

Mode de ciselage

: pour les travaux légers de burinage et de ciselage.

Mode d’inactivité

: à utiliser uniquement pour faire tourner un ciseau plat dans la position désirée.

1

D

2

E

D

3

C

bouton

Page 23

23

MODE D’EMPLOI

REMARQUE : Ne changez jamais de mode pendant que l’outil est en marche. Sinon, l’outil

risque d’être endommagé.

4. Sélecteur de sens de rotation

Le sens de rotation peut être modié à l’aide

d’un sélecteur situé au-dessus du bouton de

verrouillage (E). En tenant le marteau rotatif en

position de fonctionnement habituelle :

a. Placez le sélecteur de sens de rotation (F) sur

la position indiquant la

rotation vers la

droite (serrage/vissage).

b. Placez le sélecteur de sens de rotation sur

la position indiquant la rotation vers la

gauche (desserrage/dévissage).

Le sélecteur de sens de rotation n’est pas

disponible en mode ciselage.

REMARQUE : Pour éviter d’endommager

l’engrenage, attendez toujours l’arrêt complet du marteau rotatif avant de modier le sens de

rotation.

REMARQUE : Le marteau rotatif ne fonctionnera pas tant que le sélecteur de sens de rotation

ne sera pas entièrement enclenché vers la gauche ou la droite.

5. Poignée auxiliaire

AVERTISSEMENT

• Débranchez TOUJOURS le marteau rotatif avant

de lui apporter des ajustements. Omettre de

débrancher le marteau rotatif pourrait provoquer

des mises en marche accidentelles, ce qui peut

entraîner des blessures graves.

Ce marteau rotatif est doté d’une poignée

auxiliaire (H). Par souci de commodité, cette

poignée peut être disposée de façon à être utilisée

avec la main gauche ou avec la main droite. Pour

un fonctionnement optimal, la poignée peut être

positionnée à n’importe quel endroit autour de l’outil.

Pour assembler la poignée auxiliaire :

a. Débranchez la che de la source d’alimentation.

b. Dévissez la poignée auxiliaire en tournant la poignée dans le sens contraire des aiguilles

d’une montre.

c. Insérez le marteau rotatif dans la bague de la poignée auxiliaire. Faites glisser la poignée

auxiliaire sur le manchon de blocage (B) jusqu’à ce qu’elle repose dans le logement de la

poignée auxiliaire (I).

d. Serrez la poignée à la main en la tournant dans le sens des aiguilles d’une montre.

4

F

F

5

I

B

H

Page 24

24

MODE D’EMPLOI

Pour positionner l’ensemble de la poignée auxiliaire :

a. Débranchez la che de la source d’alimentation.

b. Dévissez la poignée auxiliaire (H) en la tournant dans le sens contraire des aiguilles

d’une montre.

c. Une fois la poignée desserrée, tournez-la dans la position désirée.

d. Serrez la poignée à la main en la tournant dans le sens des aiguilles d’une montre.

6. Jauge de profondeur

AVERTISSEMENT

• Débranchez TOUJOURS le marteau rotatif avant

de lui apporter des ajustements. Omettre de

débrancher le marteau rotatif pourrait provoquer

des mises en marche accidentelles, ce qui peut

entraîner des blessures graves.

Le marteau rotatif est doté d’une jauge de

profondeur (J) pour régler la profondeur du perçage

lorsque vous utilisez l’outil.

a. Débranchez la che de la source

d’alimentation.

b. Appuyez sur le bouton de serrage de la

poignée auxiliaire (H), puis insérez la jauge

de profondeur dans le trou hexagonal de la poignée. Placez la jauge de profondeur an

que les nervures soient orientées tel qu’il est illustré. Assurez-vous que le côté avec les

nervures est orienté vers le bas.

c. Réglez la jauge de profondeur à la position désirée, puis relâchez le bouton de serrage. La

jauge de profondeur sera xée en place.

7. Remplacement des accessoires

AVERTISSEMENT

• Débranchez TOUJOURS le marteau rotatif avant de lui apporter des ajustements ou

d’installer des accessoires. Omettre de débrancher le marteau rotatif pourrait provoquer des

mises en marche accidentelles, ce qui peut entraîner des blessures graves.

Sélection des accessoires

Pour le perçage du bois, des métaux et du plastique et pour le vissage, utilisez un adaptateur

SDS-Plus (non inclus) compatible avec un foret normal qui n’est pas de type SDS-Plus.

Pour le perçage à percussion et le ciselage, utilisez des forets de type SDS-Plus.

6

J

H

bouton

Page 25

25

MODE D’EMPLOI

Pour installer l’accessoire

Le capuchon de protection contre la poussière (A)

aide à empêcher la poussière de perçage de pénétrer

dans le porte-outil pendant l’utilisation. Lorsque vous

installez l’adaptateur et le foret, assurez-vous que le

capuchon de protection contre la poussière n’est pas

endommagé. S’il est endommagé, remplacez-le

immédiatement. Veuillez communiquer avec notre

service à la clientèle au 1 888 3KOBALT.

a. Nettoyez et graissez légèrement l’extrémité de la

tige de l’accessoire SDS-Plus.

b. Insérez l’accessoire dans le mandrin en

le tournant jusqu’à ce qu’il s’enclenche.

L’accessoire se xe en place automatiquement.

c. Tirez sur l’accessoire pour vous assurer qu’il

est installé correctement.

Pour retirer l’accessoire.

a. Tirez le manchon de blocage (B) vers l’arrière.

b. Tenez le manchon de blocage et retirez

l’accessoire.

Les accessoires SDS-Plus sont conçus pour

une liberté de mouvement, ce qui cause une

excentricité lorsque l’outil est déchargé; cependant,

l’accessoire se centre automatiquement lorsqu’il

fonctionne, et ce, sans modier la précision du

perçage.

AVERTISSEMENT

• N’utilisez pas de forets et de ciseaux dont la tige

est endommagée.

8. Utilisation avec le collecteur de poussière

AVERTISSEMENT

• Le collecteur de poussière (G) doit être utilisé

exclusivement pour le perçage du béton.

N’utilisez pas cet article pour le perçage du bois

ou des métaux.

• Jetez les particules accumulées tous les deux ou

trois trous lors du perçage.

Lorsque vous utilisez le marteau rotatif pour les

travaux de perçage à la verticale dans le béton, xez

le collecteur de poussière pour recueillir la poussière

ou les particules an de faciliter le fonctionnement.

Insérez le collecteur de poussière à partir de

l’extrémité du foret.

7b

B

A

8

G

7a

B

A

Page 26

26

MODE D’EMPLOI

9. Mode d’emploi du marteau rotatif

AVERTISSEMENT

• An de diminuer les risques d’explosion,

déterminez l’emplacement de tous les circuits

d’alimentation, comme les câbles d’alimentation

en électricité, les conduites de gaz ou d’eau,

dissimulés dans l’aire de travail, et ce, AVANT

d’effectuer tout travail.

REMARQUE : Si vous travaillez à de basses

températures, le mécanisme de percussion devra

atteindre une température de fonctionnement

minimale avant que vous puissiez utiliser l’outil.

En maintenant la gâchette enfoncée, appuyez

brièvement l’embout du marteau rotatif sur la

surface de travail. Répétez ce processus au besoin,

jusqu’à ce que l’outil atteigne la température de

fonctionnement minimale nécessaire pour activer le

mécanisme de percussion.

Perçage

Pour le perçage du bois, des métaux et du

plastique, et pour le vissage; pour les accessoires

qui ne sont pas de type SDS-Plus (par exemple,

un foret avec une tige cylindrique), utilisez un

adaptateur SDS-Plus compatible (non inclus).

a. Supportez la pièce travaillée près de

l’emplacement du perçage.

b. Fixez solidement la pièce travaillée an qu’elle

ne se déplace pas durant le perçage.

c. Débranchez le marteau rotatif.

d. Installez l’adaptateur approprié.

e. Réglez l’outil au mode de perçage

et réglez la profondeur du perçage désirée.

f. Branchez le marteau rotatif.

g. Tenez le marteau rotatif fermement avec vos deux mains.

h. Pour le perçage des métaux ferreux, percez d’abord un avant-trou plus petit et lubriez le

foret avec de l’huile.

i. Attendez toujours que l’outil soit complètement arrêté avant de le déposer sur la pièce

travaillée ou sur toute autre surface.

Perçage à percussion

AVERTISSEMENT

• N’utilisez pas un foret de type autre que SDS-Plus pour le perçage à percussion; le foret et

le mandrin de la perceuse seront endommagés par le perçage à percussion. Lorsque vous

travaillez avec un foret de type SDS-Plus, réglez le sélecteur de mode (C) sur le mode de

perçage à percussion .

9b

9a

Page 27

27

MODE D’EMPLOI

Burinage et ciselage

a. Débranchez le marteau rotatif.

b. Réglez le sélecteur de mode (C) au mode de

ciselage

.

c. Installez un accessoire de ciselage approprié.

d. Pour régler la tête du ciseau à l’angle désiré,

réglez le mode de fonctionnement au mode

d’inactivité et tournez à la main le ciseau dans

le sens approprié. Réglez de nouveau le mode

de fonctionnement au mode de ciselage .

e. Positionnez la poignée auxiliaire au besoin.

f. Branchez le marteau rotatif.

g. Tenez l’outil fermement avec vos deux mains.

h. Mettez l’outil en marche et commencez à

travailler.

REMARQUE : Mettez l’outil en marche et appliquez une légère pression sur celui-ci an

qu’il ne rebondisse pas de façon non maîtrisée. Appliquer une pression très forte sur l’outil

n’augmentera pas son efcacité.

i. Attendez toujours que l’outil soit complètement arrêté avant de le déposer sur la pièce

travaillée ou sur toute autre surface.

ENTRETIEN

L’entretien ne doit être effectué que par un technicien qualié.

Nettoyage

Débranchez la che de la source d’alimentation avant de nettoyer la scie ou d’effectuer

tout entretien. Pour assurer un fonctionnement approprié et sécuritaire, gardez toujours l’outil

et ses fentes de ventilation propres.

Utilisez seulement un linge doux et sec pour nettoyer votre marteau rotatif. N’utilisez jamais de

détergent ni d’alcool.

9c

Page 28

28

Imprimé en Chine

DÉPANNAGE

AVERTISSEMENT

• Mettez l’interrupteur à la position OFF (arrêt) et débranchez la che de la source

d’alimentation avant d’effectuer toute tâche de dépannage.

PROBLÈME CAUSE POSSIBLE MESURE CORRECTIVE

Le foret ne tourne

pas.

Le sélecteur de mode de

fonctionnement n’est pas

engagé.

Tournez le sélecteur de mode de

fonctionnement jusqu’à ce qu’il

s’enclenche.

La fonction à

percussion n’est pas

engagée, mais l’outil

oscille.

1. L’outil est trop froid. 1. Laissez l’outil atteindre la

température de fonctionnement

minimale.

2. Le sélecteur de mode est

réglé au mode de perçage.

2. Réglez le sélecteur de mode au

mode de perçage à percussion.

GARANTIE

Le fabricant offre à l’acheteur initial de ce marteau rotatif une garantie de cinq (5) ans à partir

de la date d’achat, selon les modalités décrites par la présente.

Ce marteau rotatif est garanti contre les défauts de matériaux et de fabrication.

Si vous croyez que le marteau rotatif est défectueux pendant la période de garantie, retournez-

le simplement, accompagné d’une preuve d’achat, là où vous l’avez acheté pour obtenir un

remplacement ou un remboursement. Vous pouvez également appeler au 1 888 3KOBALT

(1 888 356-2258) pour effectuer une réclamation au titre de la garantie.

Cette garantie sera annulée si : les défauts de matériaux ou de fabrication, ou les dommages,

résultent de réparations ou de modications non autorisées, de l’utilisation de pièces non

conformes, de l’usure normale, d’un usage abusif (notamment une surcharge de l’outil), d’un

entretien inadéquat, d’une négligence, d’un accident, ou de l’utilisation de l’outil après une

panne partielle ou de la réparation ou de la modication non autorisées de l’outil avec des

accessoires inadéquats.

Cette garantie exclut les accessoires.

Cette garantie vous confère des droits précis. Il est possible que vous disposiez également

d’autres droits, qui varient d’un État ou d’une province à l’autre.

Page 29

Número de serie

Fecha de compra

¿Preguntas, problemas, piezas faltantes? Antes de volver a la tienda, llame a nuestro

Departamento de Servicio al Cliente al 1-888-3KOBALT (1-888-356-2258), de lunes a

viernes de 8 a.m. a 8 p.m., hora estándar del Este.

ADJUNTE SU RECIBO AQUÍ

ARTÍCULO #0953776

TALADRO PERCUTOR

DE 7 AMPERIOS

MODELO #K7RH-03

Page 30

30

ÍNDICE

Especicaciones del producto ........................................................................30

Contenido del paquete ................................................................................... 31

Información de seguridad ...............................................................................32

Preparación .................................................................................................... 37

Instrucciones de funcionamiento ....................................................................38

Cuidado y mantenimiento ..............................................................................42

Solución de problemas ...................................................................................43

Garantía ........................................................................................................ 43

ESPECIFICACIONES DEL PRODUCTO

COMPONENTE ESPECIFICACIONES

Entrada de alimentación calicada 120 V~60 Hz, 7 A

Velocidad sin carga 0 a 1.150/min

Clasicación contra impactos 0 a 4000 IPM

Diámetro de perforación máximo Concreto: 2,6 cm (1-1/32 pulg.)

Madera: 3 cm (1-3/16 pulg.)

Acero: 1,3 cm (1/2 pulg.)

Ladrillo con broca hueca: 6,8 cm (2-11/16 pulg.)

Soporte para herramientas SDS-plus

Page 31

31

CONTENIDO DEL PAQUETE

PIEZA DESCRIPCIÓN PIEZA DESCRIPCIÓN

A

Tapa de protección contra el

polvo

F Selector de dirección de rotación

B Manguito de jación G Receptáculo para polvo

C Selector de modo H Mango auxiliar

D

Interruptor de gatillo de

velocidad variable

I Rebaje para el mango auxiliar

E Botón de bloqueo J Medidor de profundidad

ADVERTENCIA

• Retire la herramienta del paquete y examínela con cuidado. No deseche la caja ni ningún

material de embalaje hasta después de examinar todas las piezas.

• Si falta alguna pieza de la herramienta o si alguna pieza está dañada, no conecte el

enchufe a la fuente de alimentación ni use la herramienta hasta reparar o reemplazar la

pieza. El incumplimiento de esta advertencia podría provocar lesiones graves.

A

B

C

F

E

D

G H

J

I

Page 32

32

INFORMACIÓN DE SEGURIDAD

Lea y comprenda completamente este manual antes de intentar ensamblar u operar este

producto. Si tiene preguntas relacionadas con el producto, llame al Departamento de Servicio

al Cliente al 1-888-3KOBALT, de lunes a viernes de 8 a.m. a 8 p.m., hora estándar del Este.

ADVERTENCIA

• Durante el funcionamiento de cualquier herramienta eléctrica, pueden entrar objetos

extraños a los ojos y causar graves daños oculares. Use siempre lentes o gafas de

seguridad con protecciones laterales y, cuando sea necesario, una mascarilla que cubra

todo el rostro antes de comenzar a operar una herramienta eléctrica. Recomendamos

usar una máscara de seguridad de visión amplia sobre los lentes o las gafas de seguridad

estándar con protección. Siempre use lentes de protección que cumplan con la norma

ANSI Z87.1.

• Parte del polvo producido por el lijado, el aserrado, la trituración y el taladrado, así como

también otras actividades de construcción, contiene sustancias químicas reconocidas por

el estado de California como causantes de cáncer, defectos congénitos u otros daños en el

aparato reproductivo. Algunos ejemplos de estos químicos son:

– Plomo de pinturas a base de plomo

– Sílice cristalina de ladrillos, cemento y otros productos de mampostería

– Arsénico y cromo de madera tratada con químicos

• El riesgo que corre debido a la exposición a estos químicos varía según la frecuencia con

que realiza este tipo de trabajo. Para reducir la exposición a estas sustancias químicas:

– Trabaje en un área bien ventilada.

– Trabaje con un equipo de seguridad aprobado, como las mascarillas antipolvo

especialmente diseñadas para ltrar partículas microscópicas.

– Evite estar en contacto prolongado con el polvo producido por el lijado, serruchado,

trituración y taladrado eléctricos, y otras actividades de construcción. Use ropa protectora

y lave todas las áreas expuestas del cuerpo con agua y jabón. Si permite que el polvo

llegue a su boca o a sus ojos, o que caiga sobre la piel, podría fomentar la absorción de

químicos dañinos.

Conozca la herramienta

Para operar esta herramienta, lea cuidadosamente este manual y las etiquetas jadas a la

herramienta antes de usarla. Guarde este manual para referencia futura.

Importante

Solo un técnico calicado puede reparar esta herramienta.

Lea por completo todas las instrucciones

Page 33

33

INFORMACIÓN DE SEGURIDAD

Algunos de los siguientes símbolos pueden aplicarse al uso de esta herramienta. Obsérvelos

y aprenda su signicado. La interpretación correcta de estos símbolos le permitirá utilizar la

herramienta de manera ecaz y segura.

SÍMBOLO DEFINICIÓN SÍMBOLO DEFINICIÓN

V Voltios n

0

Velocidad sin carga

A Amperios /min

Revoluciones o pasadas por

minuto

Hz Hertz IPM Impacto por minuto

W Vatios

Corriente continua

De clase II para construcción Corriente alterna

Peligro, advertencia o

precaución. Signica:

“¡Atención! Su seguridad

está comprometida”.

Para reducir el riesgo de

lesiones, el usuario debe leer el

manual de instrucciones.

Advertencias de seguridad general en el manejo de herramientas eléctricas

ADVERTENCIA

• Lea todas las advertencias de seguridad y todas las instrucciones. El incumplimiento

de las advertencias y las instrucciones podría provocar descargas eléctricas, incendios o

lesiones graves.

Guarde todas las advertencias e instrucciones para referencia futura.

El término “herramienta eléctrica” que aparece en las advertencias se reere a la herramienta

eléctrica que se conecta a la línea principal (con cable) o a la herramienta eléctrica que

funciona a batería (inalámbrica).

Seguridad en el área de trabajo

• Mantenga el área de trabajo limpia y bien iluminada. Las áreas desordenadas u

oscuras aumentan las posibilidades de accidentes.

• No utilice herramientas eléctricas en atmósferas en las que exista riesgo de

explosión, como por ejemplo en presencia de líquidos inamables, gases o polvo.

Las herramientas eléctricas producen chispas que podrían encender el polvo o el humo.

• Mantenga a los niños y transeúntes alejados mientras opera una herramienta

eléctrica. Las distracciones pueden hacerle perder el control.

Page 34

34

INFORMACIÓN DE SEGURIDAD

Seguridad eléctrica

• Los enchufes de las herramientas eléctricas deben encajar en el tomacorriente.

Nunca modique el enchufe de ninguna manera. No utilice ningún enchufe adaptador

con herramientas eléctricas con puesta a tierra. Los enchufes sin modicaciones y que

encajan en los tomacorrientes reducen el riesgo de descarga eléctrica.

• Evite el contacto del cuerpo con supercies con puesta a tierra, como tuberías,

radiadores, estufas o refrigeradores. Existe un riesgo adicional de descarga eléctrica si

su cuerpo tiene puesta a tierra.

• No exponga las herramientas eléctricas a la lluvia o a condiciones de humedad. Si

ingresa agua en una herramienta eléctrica, el riesgo de descarga eléctrica aumentará.

• No maltrate el cable. Nunca use el cable para transportar, jalar ni desenchufar la

herramienta eléctrica. Mantenga el cable alejado del calor, el aceite, los bordes

losos o las piezas en movimiento. Los cables dañados o enredados aumentan el riesgo

de descarga eléctrica.

• Cuando utilice una herramienta eléctrica en exteriores, use una extensión eléctrica

apta para uso en exteriores. El uso de un cable apto para uso en exteriores reduce el

riesgo de descarga eléctrica.

• Si debe utilizar una herramienta eléctrica en un área húmeda, use un suministro

protegido con un interruptor de circuito de falla de puesta a tierra (GFCI, por sus

siglas en inglés). El uso de un GFCI disminuye el riesgo de descarga eléctrica.

Seguridad personal

• Manténgase alerta, preste atención a lo que hace y utilice el sentido común cuando

utilice una herramienta eléctrica. No utilice una herramienta eléctrica si está cansado

o bajo los efectos de drogas, alcohol o medicamentos. Un momento de desatención

mientras opera herramientas eléctricas puede provocar lesiones personales graves.

• Use un equipo de protección personal. Use siempre lentes de protección. Los equipos

de protección, como mascarillas antipolvo, zapatos de seguridad antideslizantes, cascos

protectores o protección auditiva, utilizados para las condiciones adecuadas, disminuyen el

riesgo de lesiones personales.

• Evite los arranques accidentales. Asegúrese de que el interruptor esté en la posición

de apagado antes de conectar la herramienta a la fuente de alimentación o la batería,

o antes de levantarla o transportarla. Transportar herramientas eléctricas con el dedo

en el interruptor o enchufar herramientas eléctricas que tienen el interruptor encendido

aumenta las posibilidades de accidentes.

• Retire todas las llaves de ajuste o llaves inglesas antes de encender la herramienta

eléctrica. Si se deja una llave inglesa o una llave conectada a una pieza giratoria de la

herramienta eléctrica, se podrían producir lesiones personales.

• No se extienda demasiado. Mantenga una postura y un equilibrio adecuados en

todo momento. Esto permite un mejor control de la herramienta eléctrica en situaciones

inesperadas.

• Use ropa adecuada. No use ropa holgada ni joyas. Mantenga el cabello y la ropa

alejados de las piezas en movimiento. La ropa holgada, las joyas o el cabello largo

pueden quedar atrapados en las piezas en movimiento.

• Si se proporcionan dispositivos para la conexión de instalaciones de extracción

y recolección de polvo, asegúrese de que se conecten y se usen debidamente. La

recolección de polvo puede disminuir los peligros relacionados con el polvo.

Page 35

35

INFORMACIÓN DE SEGURIDAD

Uso y cuidado de las herramientas eléctricas

• No fuerce la herramienta eléctrica. Utilice la herramienta eléctrica adecuada para

su tarea. La herramienta eléctrica adecuada realizará un trabajo más seguro y de mejor

calidad al ritmo para el que se diseñó.

• No utilice la herramienta eléctrica si el interruptor no la enciende o apaga. Cualquier

herramienta eléctrica que no pueda controlarse con el interruptor es peligrosa y debe

repararse.

• Desconecte el enchufe de la fuente de alimentación o retire el paquete de baterías

de la herramienta eléctrica (si es posible) antes de realizar cualquier ajuste, cambiar

accesorios o almacenarla. Este tipo de medidas de seguridad preventivas reduce el

riesgo de arranques accidentales de la herramienta eléctrica.

• Almacene las herramientas eléctricas que no estén en uso alejadas del alcance de

los niños y no permita que las personas no familiarizadas con la herramienta o estas

instrucciones la operen. Las herramientas eléctricas son peligrosas en manos de usuarios

sin capacitación.

• Realice mantenimiento a las herramientas eléctricas y a los accesorios. Revise si hay

piezas móviles desalineadas o torcidas, si hay piezas rotas y cualquier otra condición

que pueda afectar el funcionamiento de la herramienta eléctrica. Si se daña la

herramienta eléctrica, hágala reparar antes de usarla. Muchos accidentes son producto

del mantenimiento incorrecto de las herramientas eléctricas.

• Mantenga las herramientas de corte aladas y limpias. Las herramientas de corte que

se mantienen adecuadamente, con sus bordes de corte alados, son menos propensas a

trabarse y son más fáciles de controlar.

• Use la herramienta eléctrica, los accesorios, las brocas, etc., de acuerdo con estas

instrucciones, considerando las condiciones de trabajo y el trabajo que desea

realizar. El uso de la herramienta eléctrica en operaciones distintas para las que fue

diseñada podría crear una situación de peligro.

Reparación

• Permita que solo una persona capacitada repare la herramienta eléctrica, utilizando

solo piezas de repuesto idénticas. Esto mantendrá la seguridad de la herramienta

eléctrica.

Advertencias especícas de seguridad para el taladro percutor

• Utilice protectores para los oídos. La exposición al ruido puede causar la pérdida de la

audición.

• Use los mangos auxiliares, si se suministran con la herramienta. La pérdida de control

puede causar lesiones personales graves.

• Sostenga la herramienta eléctrica por las áreas de agarre aisladas al realizar una

operación en la que el accesorio de corte pueda entrar en contacto con cableado

oculto o con su propio cable. Es posible que un accesorio de corte que entre en

contacto con un cable “energizado” también “energice” las piezas de metal expuestas de la

herramienta eléctrica y podría provocar una descarga eléctrica al operador.

• Use detectores adecuados para determinar si hay líneas de servicios básicos ocultas

en el área de trabajo o llame a la compañía de servicios local para solicitar ayuda.

El contacto con las líneas eléctricas puede producir un incendio o una descarga eléctrica.

Dañar una línea de gas puede provocar una explosión. Penetrar una línea de agua causa

daños a la propiedad o puede causar una descarga eléctrica.

Page 36

36

INFORMACIÓN DE SEGURIDAD

• Cuando trabaje con la herramienta eléctrica, siempre sosténgala rmemente con

ambas manos y adopte una posición segura. Es más seguro guiar la herramienta

eléctrica con ambas manos.

• Asegure la pieza de trabajo. Las piezas de trabajo pueden sostenerse de forma más

segura con dispositivos de sujeción que con las manos.

• Siempre espere hasta que la herramienta eléctrica se detenga por completo antes

de colocarla hacia abajo. El accesorio de la herramienta se puede atascar y provocar la

pérdida de control sobre la herramienta eléctrica.

• No use la herramienta eléctrica si el cable está dañado. No toque el cable dañado ni jale

del enchufe para extraerlo del tomacorriente cuando el cable está dañado mientras trabaja.

Los cables dañados aumentan el riesgo de descargas eléctricas.

PREPARACIÓN

Conozca su taladro percutor

Este taladro percutor se puede usar para aplicaciones de perforación con martillo en concreto,

ladrillo y piedra, además de cincelado ligero; y para taladrar en madera, metal y plástico, así

como también para atornillar con accesorios especícos.

Antes de intentar usar el taladro percutor, familiarícese con todas sus características de

operación y requisitos de seguridad.

ADVERTENCIA

• Sea cuidadoso, incluso si está familiarizado con el taladro percutor. Recuerde que un

momento de descuido es suciente para causar lesiones graves. Antes de intentar utilizar

cualquier herramienta, asegúrese de familiarizarse con todas las características de

funcionamiento e instrucciones de seguridad.

• No intente modicar esta herramienta ni crear accesorios que no sean los recomendados

para la misma. Cualquier alteración o modicación es considerada un mal uso y podría

causar una condición peligrosa que podría producir lesiones personales graves.

Page 37

37

INSTRUCCIONES DE FUNCIONAMIENTO

1. Interruptor de gatillo de velocidad variable

a. Presione el interruptor de gatillo de velocidad

variable (D) para encender el taladro percutor.

ADVERTENCIA

• La hoja debe alcanzar la velocidad máxima

antes de entrar en contacto con la pieza de

trabajo.

b. Para APAGAR el taladro percutor, suelte el

interruptor de gatillo de velocidad variable.

c. El interruptor de gatillo de velocidad variable

proporciona mayor velocidad con mayor

presión en el gatillo y menor velocidad con

menor presión en el gatillo.

2. Botón de bloqueo

Este taladro percutor está equipado con un botón

de bloqueo (E), el que es conveniente para una

operación continua de taladrado/perforación con

martillo por un período extendido.

a. Para taladrar o perforar con martillo

continuamente, mantenga presionado el

interruptor de gatillo de velocidad variable (D)

y luego presione el botón de bloqueo. Suelte el

interruptor de gatillo.

b. Para desbloquear el botón de bloqueo y

detener la operación continua, presione

interruptor de gatillo.

3. Selector de modo

ADVERTENCIA

• SIEMPRE desenchufe el taladro percutor antes

de realizar cualquier ajuste. El incumplimiento

de esta advertencia puede provocar un arranque

accidental del taladro percutor, lo que puede

causar lesiones personales graves.

El selector de modo (C) permite congurar la

herramienta para varias aplicaciones. Para cambiar

el modo de operación, presione el botón del selector

de modo, luego gire el selector hasta que el botón

se bloquee.

Modo de taladrado

: para una acción de

taladrado en madera, metales, plásticos u otros

materiales, además de atornillado.

Modo de perforación con martillo

: para taladrar con acción de martillo en concreto, ladrillo o

materiales duros similares.

2

3

1

D

C

E

D

botón

Page 38

38

INSTRUCCIONES DE FUNCIONAMIENTO

Modo de cincelado

: para aplicaciones ligeras de picado y cincelado.

Modo no apto para trabajo

: para usar solo si se necesita girar un accesorio de cincel plano a

la posición deseada.

NOTA: Nunca cambie la conguración de modo mientras la herramienta esté en

funcionamiento. De lo contrario, se podría dañar la máquina.

4. Selector de dirección de rotación

La dirección de rotación de la broca es reversible

y se controla mediante el selector ubicado sobre

el botón de bloqueo (E). Con el taladro percutor

sostenido en la posición de operación normal:

a. Coloque el selector de dirección de rotación

(F) en la posición marcada

para que gire

hacia delante.

b. Coloque el selector de dirección de rotación

a la posición marcada para que gire en

reversa.

El ajuste de dirección de rotación no está

disponible mientras se encuentra en el modo de

cincelado.

NOTA: para evitar el daño en los engranajes, siempre deje que el taladro percutor se detenga

por completo antes de cambiar la dirección de la rotación.

NOTA: el taladro percutor no funciona a menos que el selector de dirección de rotación esté

completamente posicionado a la izquierda o la derecha.

5. Mango auxiliar

ADVERTENCIA

• SIEMPRE desenchufe el taladro percutor antes

de realizar cualquier ajuste. El incumplimiento

de esta advertencia puede provocar un arranque

accidental del taladro percutor, lo que puede

causar lesiones personales graves.

Este taladro percutor está equipado con un mango

auxiliar (H). Para una operación más fácil, usted

puede usar el mango con la mano izquierda o

derecha. Para una operación óptima, el mango se

puede ubicar en cualquier ubicación alrededor de la

herramienta.

Para ensamblar el mango auxiliar:

a. Desconecte el enchufe de la fuente de alimentación.

b. Aoje el mango auxiliar (B) en el taladro girándolo en dirección contraria a las manecillas del

reloj.

c. Inserte el taladro percutor a través del anillo del mango auxiliar. Deslice el mango auxiliar

sobre el manguito de jación (B) hasta que se posicione en el rebajo para el mango auxiliar (I).

d. Apriete a mano el mango girándolo en dirección de las manecillas del reloj.

4

5

I

B

F

F

H

Page 39

39

INSTRUCCIONES DE FUNCIONAMIENTO

Para ajustar el ensamble del mango auxiliar: