ITEM/ARTICULO #234955

MODEL/MODELO #K13015F

Operator’s Manual and Parts List

Manual del Operador y Lista de las Piezas (pag. 15)

Oilless, Single Stage, Direct Drive,

Electric Air Compressor

WARNING: Read and understand all safety precautions in this manual before operating. Failure to comply with

instructions in this manual could result in personal injury, property damage, and/or voiding of your warranty.

The manufacturer WILL NOT be liable for any damage because of failure to follow these instructions.

K13015FOM_Ver.0406Printed in China

TABLE OF CONTENTS

SAFETY GUIDELINES ........................................................................................................................................................................ 3

FEATURES - Product specifications .................................................................................................................................................... 4

ELECTRICAL POWER REQUIREMENTS .......................................................................................................................................... 5

OVERVIEW .......................................................................................................................................................................................... 6

GLOSSARY OF TERMS ...................................................................................................................................................................... 6

ASSEMBLY .......................................................................................................................................................................................... 7

OPERATION ........................................................................................................................................................................................ 9

MAINTENANCE ................................................................................................................................................................................. 11

TROUBLESHOOTING CHART .......................................................................................................................................................... 11

PARTS DIAGRAM .............................................................................................................................................................................. 12

PARTS LIST ....................................................................................................................................................................................... 14

3 YEAR LIMITED WARRANTY

Nu Air Compressors and Tools S.p.A. (the Company) warrants to the original retail consumer that it will repair or replace, free of

charge, any parts found by the Company or its authorized service representatives to be defective in material or workmanship. The

warranty period will be 36 months from the date of purchase for use in consumer applications only.

This warranty covers the cost of replacement parts and labor. Transportation charges for submitting products for warranty

service, or for shipping repaired or replacement products back to the consumer, must be borne by the consumer. The effects of

corrosion, erosion and normal wear and tear are excluded from this warranty coverage. This warranty will be void if the purchaser

fails to install, maintain and operate the product in accordance with the instructions and recommendations of the Company set forth

in the owner’s manual, or if the product is used as rental equipment. The Company will not be liable for any repairs or adjustments

to the product or for any costs or labor performed by the purchaser without the Company’s prior authorization.

THE COMPANY MAKES NO OTHER WARRANTY OF ANY KIND WHATSOEVER, EXPRESS OR IMPLIED. ALL IMPLIED

WARRANTIES, INCLUDING WARRANTIES OF MERCHANTABILITY AND OF FITNESS FOR A PARTICULAR PURPOSE,

ARE HEREBY DISCLAIMED. THE WARRANTY SERVICE DESCRIBED ABOVE IS THE EXCLUSIVE REMEDY UNDER THIS

WARRANTY; LIABILITY FOR INCIDENTAL AND CONSEQUENTIAL DAMAGES IS EXCLUDED TO THE EXTENT PERMITTED

BY LAW.

Some states do not allow a disclaimer of implied warranties, or the exclusion or limitation of incidental and consequential

damages, so the above disclaimers and exclusions may not apply to you. Notwithstanding the above, any claim against the

Company under this warranty will be barred unless legal action is commenced within twelve (12) months after the warranty period

expires.

This warranty gives you specific rights, and you may have other rights that vary from state to state.

All warranty communications should be directed to the Technical Service at 1-866-242-4298.

2

K13015FOM_Ver.0406

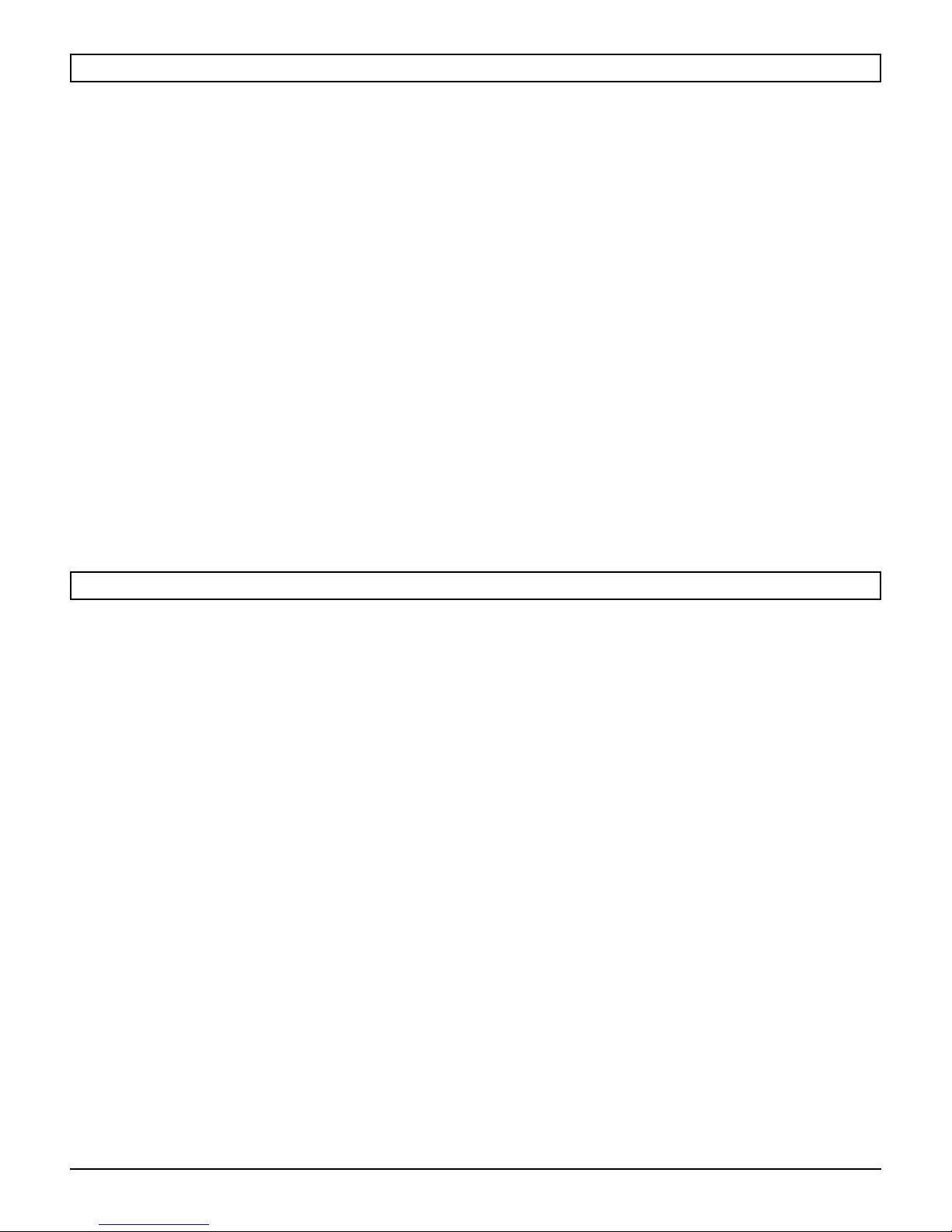

SAFETY GUIDELINES

The following information relates to protecting YOUR SAFETY and PREVENTING EQUIPMENT PROBLEMS.

To help you recognize this information, we use the following symbols. Please read the manual and pay attention to these sections.

- A POTENTIAL HAZARD THAT WILL CAUSE SERIOUS INJURY OR LOSS OF LIFE.

DANGER:

- A POTENTIAL HAZARD THAT COULD CAUSE SERIOUS INJURY OR LOSS OF LIFE.

WARNING:

- A POTENTIAL HAZARD THAT MAY CAUSE MODERATE INJURY OR DAMAGE TO EQUIPMENT.

CAUTION:

WARNING:

1. RISK OF FIRE OR EXPLOSION. Never spray

flammable liquids in a confined area. It is normal for

the motor and pressure switch to produce sparks while

operating. If sparks come into contact with vapors from

gasoline or other solvents, they may ignite, causing

fire or explosion. Always operate the compressor in a

well-ventilated area. Do not smoke while spraying. Do

not spray where sparks or flame are present. Keep

compressor as far from spray area as possible.

2. RISK OF BURSTING. Rust can weaken the tank. Drain

the condensed water from the tank after each use to

reduce rusting. If a leak is detected in the tank, replace

the tank immediately. Do not weld, drill or modify the

air tank of this compressor. Welding or modifications

on the air compressor tank can severely impair tank

strength and cause an extremely hazardous condition.

Welding or modifying the tank in any manner will void

the warranty.

3. RISK OF ELECTRICAL SHOCK. A licensed electrician

in accordance with all local and national codes must

install all wiring. Never use an electric air compressor

outdoors when it is raining or on a wet surface, as it

may cause an electric shock.

4. RISK OF INJURY. This unit starts automatically.

ALWAYS shut off the compressor, remove the plug

from the outlet, and bleed all pressure from the system

before servicing the compressor, and when the

compressor is not in use. Do not operate the unit with

the shroud removed. Serious injury could occur from

contact with moving parts.

6. RISK OF BURNS. High temperatures are generated

by the pump and manifold. To prevent burns or other

injuries, DO NOT touch the pump, manifold or transfer

tube while the pump is running. Allow them to cool

before handling or servicing. Keep children away from

the compressor at all times.

7. RISK TO BREATHING. Do not use this air compressor

to spray chemicals. Your lungs can be damaged by

inhaling toxic fumes. A respirator may be necessary

in dusty environments or when spraying paint. Do not

carry while painting.

8. RISK OF EYE INJURY. Always wear ANSI Z87.1

approved safety goggles when using an air

compressor. Never point any nozzle or sprayer toward

a person or any part of the body. Equipment can cause

serious injury if the spray penetrates the skin.

9. RISK OF BURSTING. Do not tamper with the control

knob or adjust the relief valve for any reason. Doing

so voids all warranties. They have been preset at the

factory for the maximum pressure of this unit.

Personal injury and/or property damage may result if

the control board or the relief valve are tampered with.

10. RISK OF BURSTING. Check hoses for weak or

worn condition before each use, making certain all

connections are secure. Do not use if defect is found.

Purchase a new hose or notify an authorized service

center for examination or repair.

11. RISK TO HEARING. Always wear hearing protection

when using an air compressor. Failure to do so may

result in hearing loss.

5. RISK OF BURSTING. Check the manufacturer’s

maximum pressure rating for air tools and accessories.

Compressor outlet pressure must be regulated so as to

never exceed the maximum pressure rating of the tool.

Relieve all pressure through the hose before attaching

or removing accessories.

CAUTION:

1. Drain the moisture from the tank on a daily basis. A

clean, dry tank will help prevent corrosion.

2. Pull the pressure relief valve ring daily to ensure that

the valve is functioning properly, and to clear the valve

of any possible obstructions.

3. To provide proper ventilation for cooling, the

compressor must be kept a minimum of 12 inches (31

cm) from the nearest wall, in a well-ventilated area.

4. Fasten the compressor down securely if transporting

is necessary. Pressure must be released from the tank

before transporting.

K13015FOM_Ver.0406

12. RISK TO BREATHING. Never directly inhale the

compressed air produced by a compressor. It is not

suitable for breathing purposes.

13. The power cord on this product contains lead, a

chemical known to the State of California to cause

cancer, and birth defects or other reproductive harm.

Wash hands after handling.

5. Protect the air hose and electric cord from damage and

puncture. Inspect them weekly for weak or worn spots,

and replace if necessary.

6. To reduce the risk of electric shock, do not expose to

rain. Store indoors.

7. Never operate the compressor if the power cord or

plug are damaged. Take the equipment to the nearest

Authorized Service Center, and have a Technician

replace it.

3

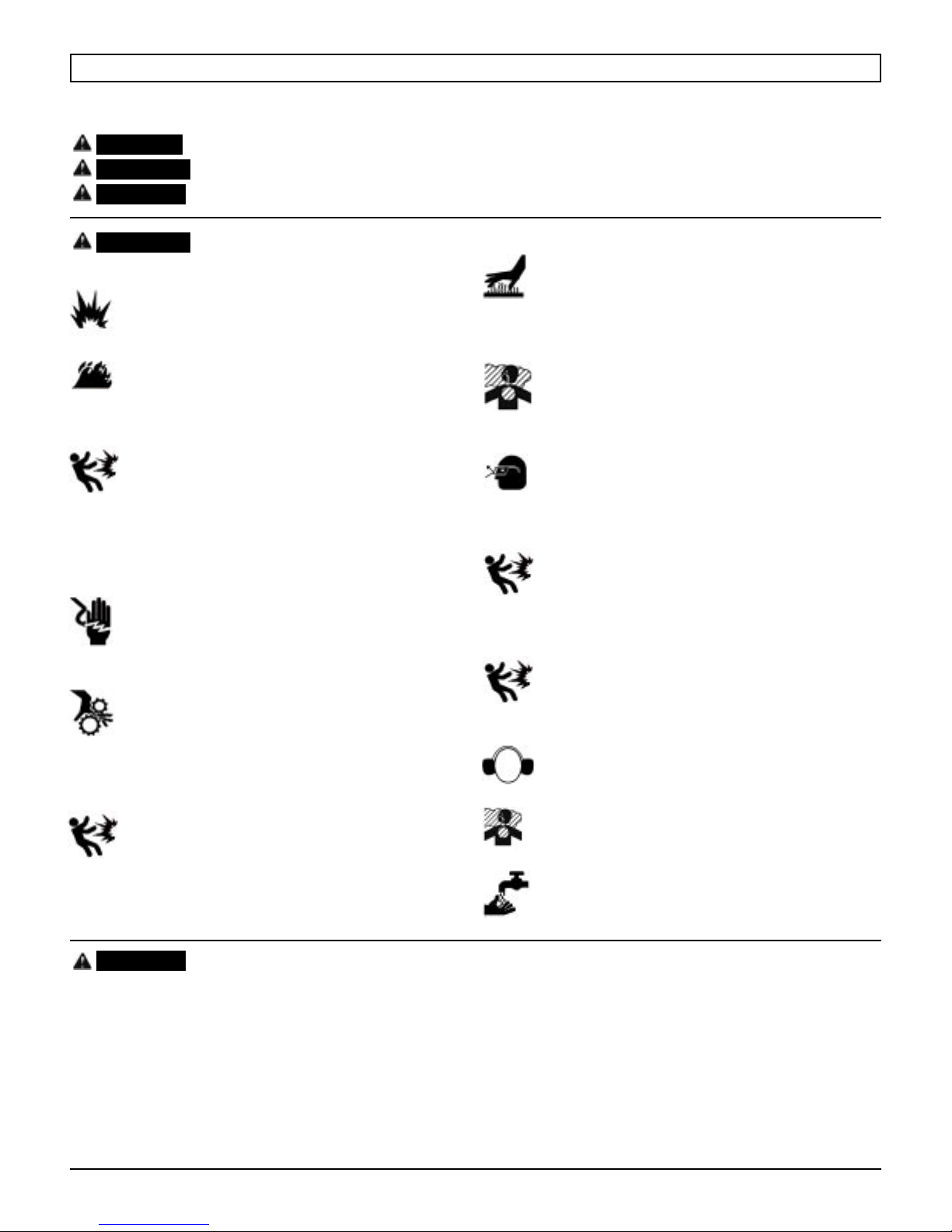

FEATURES

PRODUCT SPECIFICATIONS

Running Horsepower ........................................................1.3 HP

Air Tank Capacity ............................................................ 1.5 gal.

Air Pressure ........................................................... 135 psi max.

Air Delivery ................................................. 2.4 SCFM @ 90 psi

PRESSURE

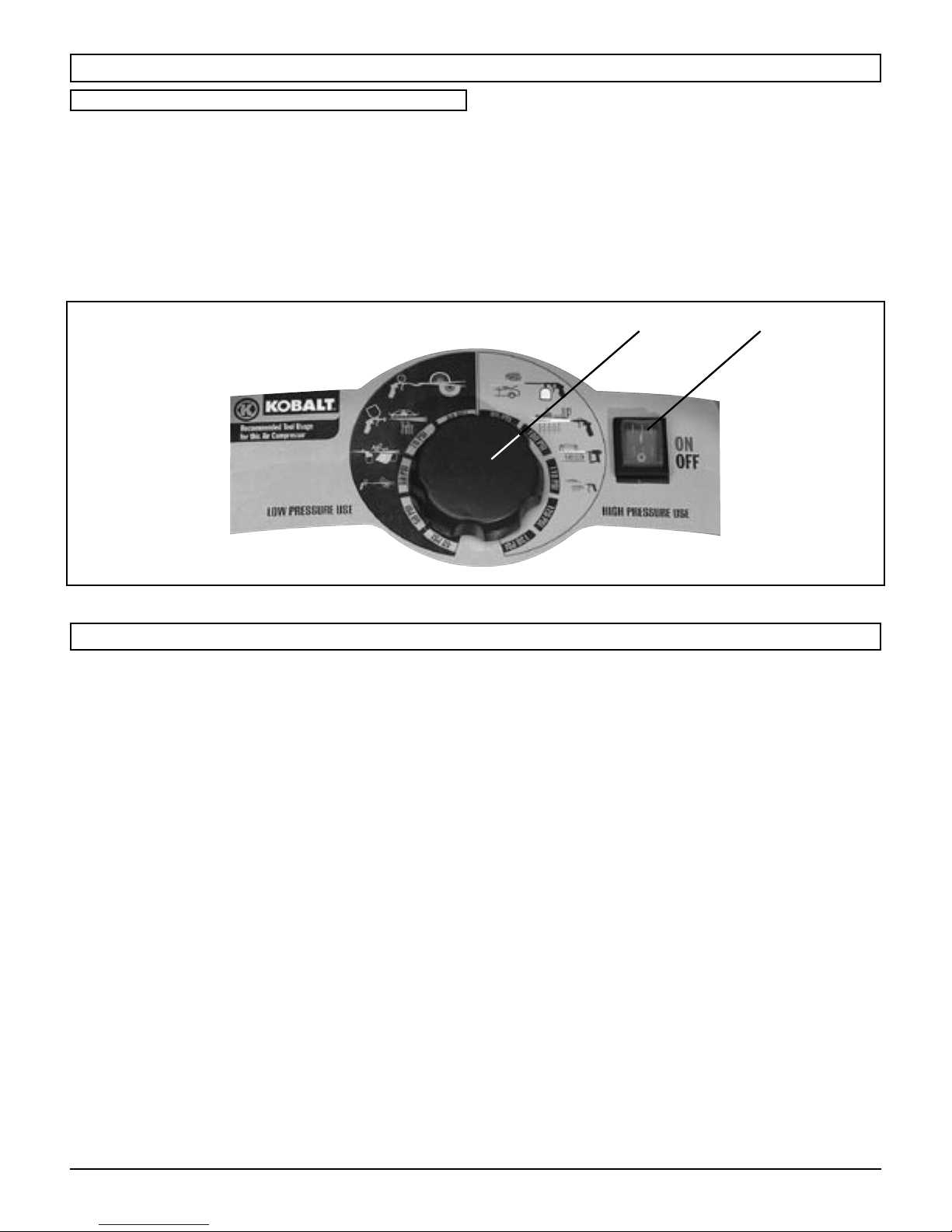

REGULATOR

KNOB

SWIVEL HANDLE

ON / OFF SWITCH

Lubrication ......................................................................Oil-Free

Adjustable Air Outlet ...................................... from 40 to 135 PSI

Gauges ...............................................................1.5 in. diameter

Input ........................................ 120 V, 60 Hz, AC only, 12 Amps

Net Weight ......................................................... 24.2 lbs. / 11 kg

Fig. A

TANK PRESSURE

GAUGE

ELECTRICAL CABLE

SHELL

AIR OUTLET

INFLATION

ADAPTER

DRAIN VALVE

INFLATION NEEDLE

INFLATION

NOZZLES

SAFETY VALVE

WHEELS

AIR CHUCK

1/4 IN. NPT MALE

CONNECTOR FITTING

1/4 IN. NPT FEMALE

CONNECTOR FITTING

QUICK COUPLER

ELECTRICAL

CABLE

SAFETY NOZZLE

BLOWER

ATTACHMENT

TIRE GAUGE

4

COIL HOSE

SEAL THREAD TAPE

K13015FOM_Ver.0406

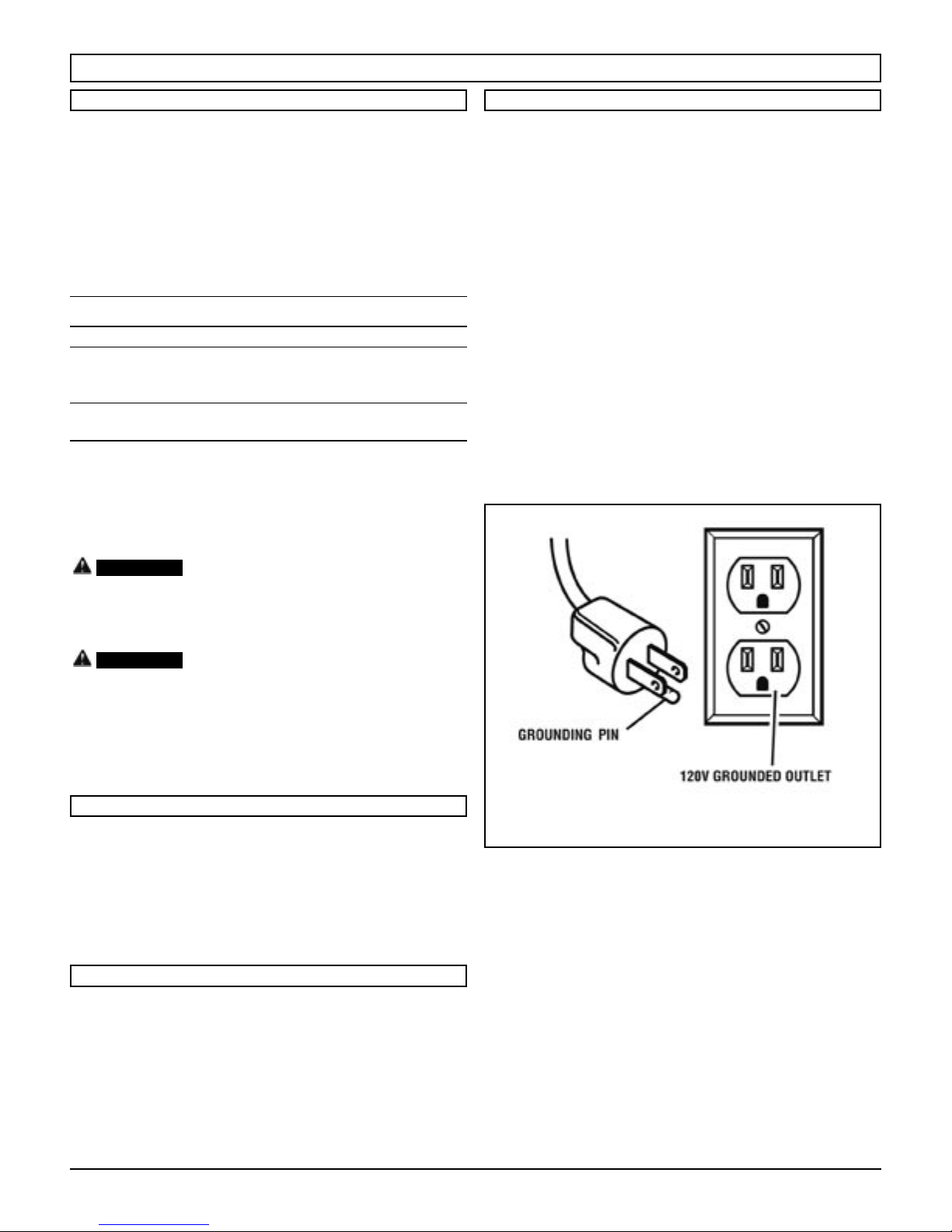

ELECTRICAL POWER REQUIREMENTS

EXTENSION CORDS

Use only 3-wire extension cords that have 3-prong grounding

plugs and 3-pole receptacles that accept the air compressor’s plug.

When using the air compressor at a considerable distance from

the power source, use an extension cord heavy enough to carry

the current that the compressor will draw. An undersized extension

cord will cause a drop in line voltage, resulting in a loss of power

and causing the motor to overheat. Use the chart provided below

to determine the minimum wire size required in an extension cord.

Only round jacketed cords listed by Underwriter’s Laboratories (UL)

should be used.

**Ampere rating (on air compressor data plate)

0-2.0 2.1-3.4 3.5-5.0 5.1-7.0 7.1-12.0 12.1-16.0

Cord Length Wire Size (A.W.G.)

25 ft. 16 16 16 16 14 14

50 ft. 16 16 16 14 14 12

100 ft. 16 16 14 12 10 ----

**Used on 12 gauge - 20 amp circuit.

NOTE: AWG = American Wire Gauge

When working with the air compressor outdoors, use an

extension cord that is designed for outside use. This is indicated by

the letters “W-A” on the cord’s jacket.

Before using an extension cord, inspect it for loose or exposed

wires and cut or worn insulation.

GROUNDING INSTRUCTIONS

In the event of a malfunction or breakdown, grounding provides

a path of least resistance for electric current to reduce the risk of

electric shock. This air compressor is equipped with an electric cord

having an equipment-grounding conductor and a grounding plug.

The plug must be plugged into a matching outlet that is properly

installed and grounded in accordance with all local codes and

ordinances.

Do not modify the plug provided. If it will not fit the outlet,

have the proper outlet installed by a qualified electrician. Improper

connection of the equipment-grounding conductor can result in a

risk of electric shock. The conductor with insulation having an outer

surface that is green with or without yellow stripes is the equipmentgrounding conductor. If repair or replacement of the electric cord

or plug is necessary, do not connect the equipment-grounding

conductor to a live terminal.

Check with a qualified electrician or service personnel if the

grounding instructions are not completely understood, or if in doubt

as to whether the tool is properly grounded.

Repair or replace a damaged or worn cord immediately.

This air compressor is intended for use on a circuit that has an

outlet like the one shown in Figure 1. It also has a grounding pin

like the one shown.

This product must be grounded.

WARNING:

Keep the extension cord clear of the

working area. Position the cord so that it will not get caught on

lumber, tools, or other obstructions while you are working with

a power tool. Failure to do so can result in serious personal

injury.

WARNING:

Check extension cords before each use. If

damaged, replace immediately. Never use air compressor with

a damaged cord since touching the damaged area could cause

electrical shock resulting in serious injury.

NOTE: Use longer air hoses instead of long extension cords.

Your air compressor will run better and last longer.

ELECTRICAL CONNECTION

This air compressor is powered by a precision built electric

motor. It should be connected to a power supply that is 120 volts,

60 Hz, AC only (normal household current). Do not operate this

tool on direct current (DC). A substantial voltage drop will cause

a loss of power and the motor will overheat. If the air compressor

does not operate when plugged into an outlet, double check the

power supply.

SPEED AND WIRING

The no-load speed of this air compressor is approximately

26,000 rpm. This speed is not constant and decreases under a

load or with lower voltage. For voltage, the wiring in a shop is as

important as the motor’s horsepower rating. A line intended only for

lights cannot properly carry a power tool motor. Wire that is heavy

enough for a short distance will be too light for a greater distance. A

line that can support one power tool may not be able to support two

or three tools.

Fig. 1

K13015FOM_Ver.0406

5

OVERVIEW

BASIC AIR COMPRESSOR COMPONENTS

Oilless air compressors are factory lubricated for life and do

not require any oil.

The basic components of the air compressor are the electric

motor, pump, control panel and tank.

The electric motor powers the pump. The electric motor is

equipped with an overload protector and an automatic reset. If the

motor becomes overheated, the overload protector will shut it down

to prevent damage to the motor. When the motor sufficiently cools,

it will automatically restart.

The pump compresses the air and discharges it into the tank.

The tank stores the compressed air.

The control panel of the compressor consists of the ON/OFF

button (A) and of the pressure regulator knob (B)

As compressed air is used and the pressure level in the

tank drops to the cut-in pressure, the control board restarts the

motor automatically, without warning, and the pump resumes

compressing air. The pressure regulator shuts down the motor

when the air pressure in the tank reaches the cut-out pressure.

.

AB

GLOSSARY OF TERMS

Air Filter

Porous element contained within a metal or plastic housing

attached to the compressor cylinder head which removes

impurity from the intake air of the compressor.

Air Tank

Cylindrical component which contains the compressed air.

Check Valve

Device that prevents compressed air from flowing back from the

air tank to the compressor pump.

Cut-In Pressure

The low pressure at which the motor will automatically restart.

Cut-Off Pressure

The high pressure at which the motor will automatically shut off.

Electric Motor

Device which provides the rotational force necessary to operate

the compressor pump.

Manual On/Off Switch

Control which turns the air compressor on or off. The pressure

switch will not automatically start and control the compressor

unless the manual On/Off Switch is in the ON ( l ) position.

NPT (National Pipe Thread)

A seal thread tape must be used to provide a leak-free seal on

pipe threaded connections.

Pressure Regulator

Automatically controls the on/off cycling of the compressor.

It stops the compressor when the cut-off pressure in the tank is

reached and starts the compressor when the air pressure drops

below the cut-in pressure.

PSI (Pounds Per Square Inch)

Measurement of the pressure exerted by the force of the

air. The actual PSI is measured by a pressure gauge on the

compressor.

Pump

Produces the compressed air with a reciprocating piston

contained within the cylinder.

Safety Valve

Prevents air pressure in the air tank from rising over a

predetermined limit.

SCFM (Standard Cubic Feet Per Minute)

A unit of measure of air delivery.

Tank Pressure Gauge

Indicates the pressure in the air tank.

Thermal Overload Switch

Automatically shuts off the compressor if the temperature of the

electric motor exceeds a predetermined limit.

6

K13015FOM_Ver.0406

ASSEMBLY

FEATURES

KNOW YOUR AIR COMPRESSOR (See Fig. A, p. 4)

Before attempting to use this product, familiarize yourself with all

operating features and safety rules.

AIR OUTLET

The air outlet is located on the front of the compressor. Its pressure

is adjustable for each use from 40 to 135 psi. Pressure is adjusted

by simply rotating the knob arrow to the desired pressure setting or

use icon.

OIL-FREE UNIVERSAL MOTOR

Your air compressor features permanently lubricated bearings.

SAFETY VALVE

The safety valve is designed to automatically release air if the air

receiver pressure exceeds the preset maximum.

TANK PRESSURE GAUGE

The tank pressure gauge indicates the pressure of the air in the

tank.

ASSEMBLY

Estimated Time of Assembly: 2 minutes

Tools Required: 9/16 in., 5/8 in. and 11/16 in. wrenches

(not included)

1) UNPACKING

• Carefully remove the tool and any accessories from the

box. Make sure that all items listed in the packing list

are included.

• Inspect the tool carefully to make sure no breakage or

damage occurred during shipping.

• Do not discard the packing material until you have

carefully inspected and satisfactorily operated the tool.

• If any parts are damaged or missing, please call

1-866-242-4298 for assistance, or send a detailed FAX

request to 1-803-328-0375.

WARNING:

cause serious personal injury, always unplug the tool when

assembling parts.

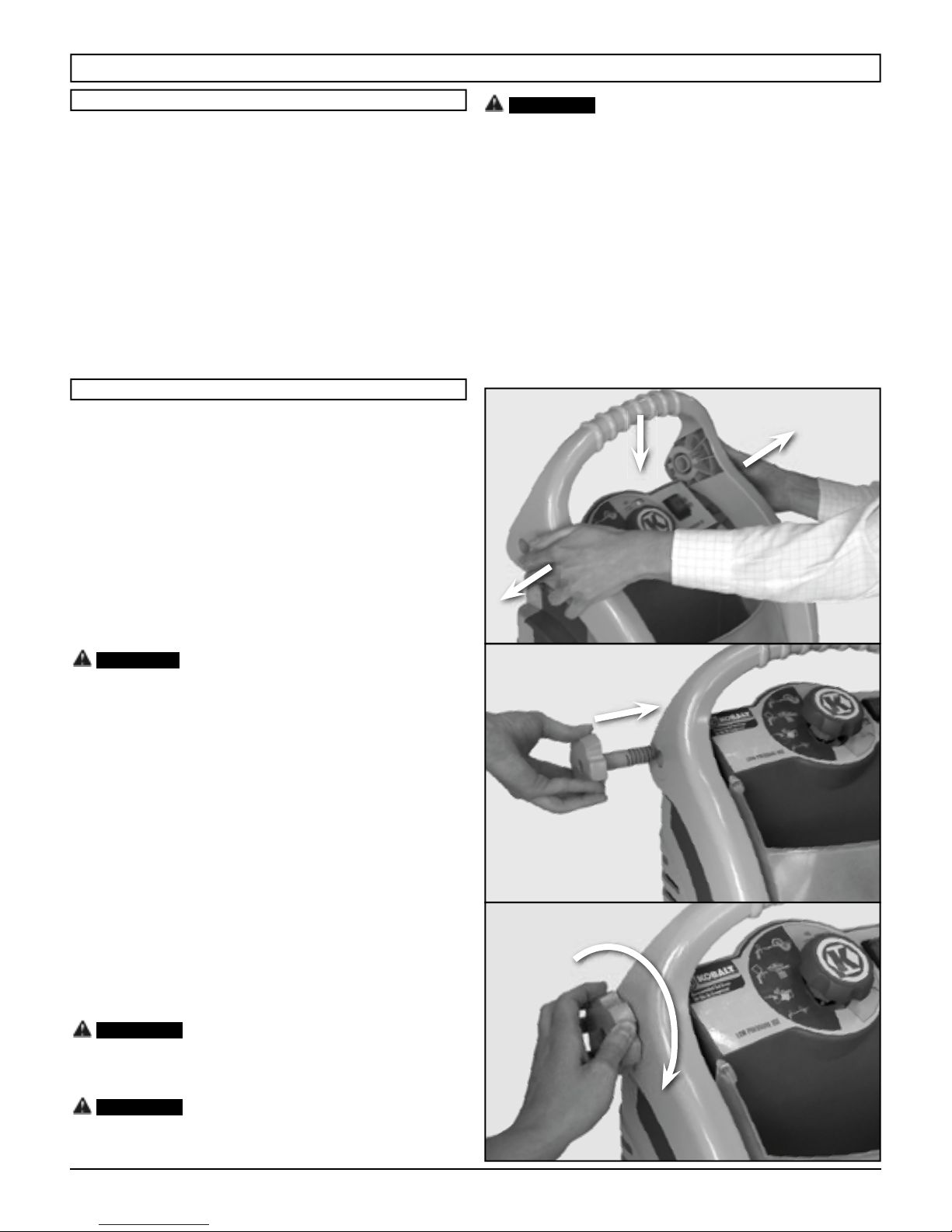

2) ASSEMBLING THE HANDLE

Slightly stretch out the handle and lower it onto the

compressor body, as shown in (Pic. 1). The handle should

line up with the guides on each side of the compressor.

Insert the two handle knobs into the holes on the sides of

the handle (Pic. 2). Tighten firmly in a clockwise direction to

secure the handle in position (Pic. 3).

3) ASSEMBLING THE ELECTRICAL CABLE SHELL

Align the 4 holes of the shell with the 4 hooks located on

the underside of the compressor (Pic. 4).

Press the sides of the shell inwards as shown in (Pic. 5).

Then push the shell forwards. The shell will click into

position when it is correctly located (Pic. 6).

To prevent accidental starting that could

Pic. 1

CAUTION:

base for an operating compressor.

Remove the compressor from the shipping pallet or carton and

place it on the floor or a hard, level surface. The compressor must

be level to ensure proper drainage of the moisture in the tank.

PACKING LIST

Air Compressor

Handle

Handle knobs (2)

Electrical cable shell

Coil Hose

Blower Attachment with Safety Nozzle

Air Chuck

Inflation Nozzles (2)

Inflation Adapter

Inflation Needle

1/4 in. NPT Quick Coupler

1/4 in. NPT Male Connector Fitting (2)

1/4 in. NPT Female Connector Fitting

Tire Gauge

Seal Thread Tape

Operator’s Manual

WARNING:

not operate this tool until the damaged or missing parts are

replaced. Failure to do so could result in possible serious

personal injury.

WARNING:

accessories not recommended for use with this tool. Any such

alteration or modification is misuse and could result in a

hazardous condition leading to possible serious personal injury.

The shipping pallet is not designed as a

If any parts are damaged or missing do

Do not attempt to modify this tool or create

Pic. 2

Pic. 3

K13015FOM_Ver.0406

7

ASSEMBLY

Pic. 4

Pic. 5

click !

Pic. 6

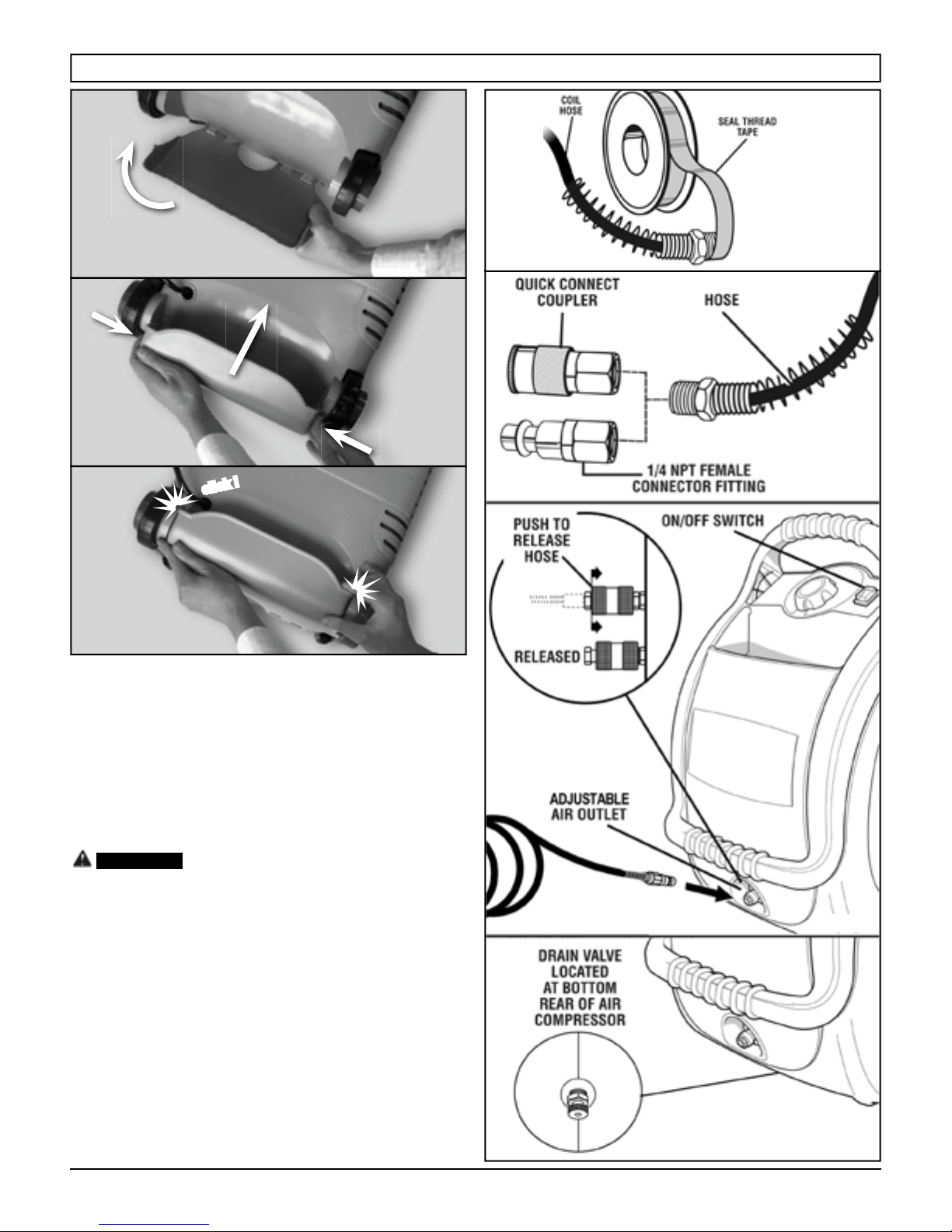

4) ATTACHING HOSE TO COMPRESSOR (See Fig. 7 - 9)

• Make sure the air compressor is off and unplugged.

• Apply seal thread tape to both ends of the coil hose.

• Insert one threaded end of the hose into the open end

of female connector. Hold the end of the hose with a

9/16 in. wrench and use a 5/8 in. wrench on the female

connector to tighten securely.

• Attach quick coupler to other end of the hose. Hold the

end of the hose with a 9/16 in. wrench and use a 11/16 in.

wrench on the quick coupler to tighten securely.

NOTE: Be careful not to allow threads to become

cross-threaded.

Do not attach air chuck or other tool to the

WARNING:

open end of the hose until start-up has been completed.

• Firmly grasp the open end of the hose; hold facing

away from yourself and others.

• Insert the female connector end of the coil hose into the

air outlet on the air compressor. Push the connector

firmly until you hear it click into place.

• To disconnect the hose, push the external ring nut of

the quick coupler backward.

Fig. 7

Fig. 8

Fig. 9

5) BREAKING IN THE PUMP (See Fig. 9 - 10)

• Check and tighten all bolts, fittings, etc.

• Place the switch in the OFF position and plug in the

power cord.

• Open the drain valve completely.

• Turn the air compressor ON ( l ) and run the air

compressor for 10 minutes to break in pump parts.

• Place the switch in the OFF ( O ) position.

• Close the drain valve.

8

Fig. 10

K13015FOM_Ver.0406

OPERATION

WARNING:

Do not allow familiarity with tools to make

you careless. Remember that a careless fraction of a second is

sufficient to inflict serious injury.

WARNING:

Always wear safety goggles or safety

glasses with side shields when operating power tools. Failure

to do so could result in objects being thrown into your eyes

resulting in possible serious injury.

CAUTION:

or otherwise contaminated. Using the air compressor in this

type of environment may cause damage to the unit.

Do not use in an environment that is dusty

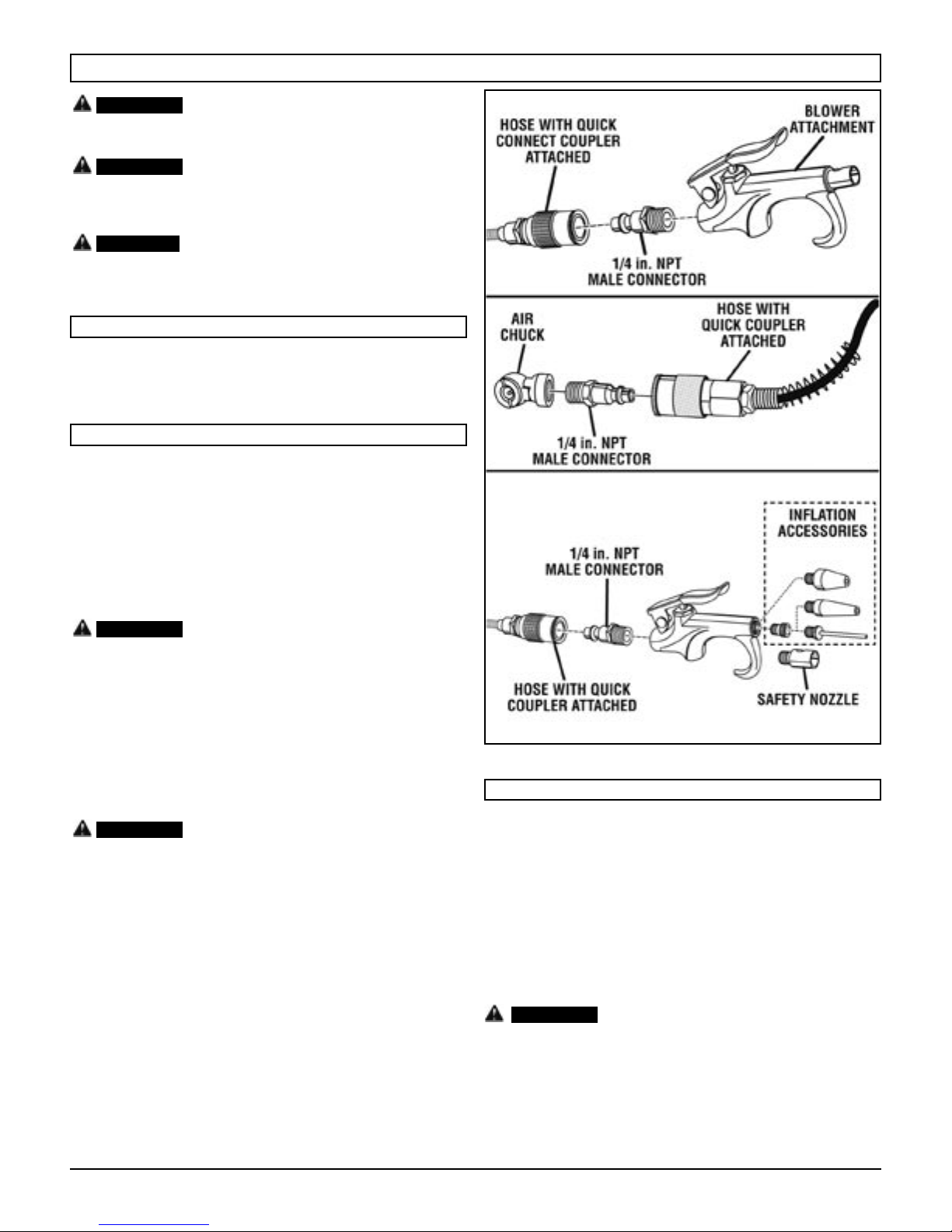

APPLICATIONS

Air compressors are utilized in a variety of air system

applications. Match hoses, connectors, air tools, and accessories to

the capabilities of the air compressor.

USING THE AIR COMPRESSOR

See Figures 9 - 13.

• Ensure power switch is in the OFF ( O ) position and air

compressor is unplugged.

• If not already installed, attach hose to compressor as

previously instructed. The hose has to be inserted into

the quick connect coupler and the regulator knob must

be rotated to select the appropriate use or pressure.

• Insert the blower attachment or connector for the tool

you wish to use into the female connector on the other

end of the spiral hose.

WARNING:

position before changing air tools or disconnecting the hose

from the air outlet. Failure to do so could result in possible

serious personal injury.

Always ensure the switch is in the OFF (O)

Fig. 11

Fig. 12

• Connect the power cord to the power supply.

• Turn the switch ON ( l ).

• Following all safety precautions in this manual and the

manufacturer’s instructions in the air tool manual, you

may now proceed to use your air-powered tool or the

blower attachment.

WARNING:

than this air compressor is capable of providing. Check the

tool manual to avoid damage to the tool or risk of personal

injury.

• When using the blower attachment, the amount of air

pressure can be further controlled by the amount the

lever of the attachment is depressed.

NOTE: Always use the minimum amount of pressure

necessary for your application. Using a higher pressure

than needed will drain air from the tank more rapidly

and cause the unit to cycle on more frequently.

• When finished, always drain the tank and unplug the

unit. Never leave the unit plugged in and/or running

unattended.

Your tool may require more air consumption

Fig. 13

DRAINING THE TANK

See Figure 14.

To help prevent tank corrosion and keep moisture out of the air

used, the tank should be drained daily.

To drain:

• Ensure power switch is in the OFF ( O ) position and air

compressor is unplugged.

• Rotate drain valve counterclockwise (left) to open.

• Drain moisture from tank into a suitable container.

NOTE: Condensate is a polluting material and should

be disposed of in compliance with local regulations.

• If drain valve is clogged, release all air pressure,

remove and clean valve, then reinstall.

WARNING:

all air from the tank before servicing. Failure to depressurize

tank before attempting to remove valve may cause serious

personal injury.

• Rotate drain valve clockwise (right) until tightly closed.

Unplug the air compressor and release

K13015FOM_Ver.0406

9

OPERATION

Fig. 14

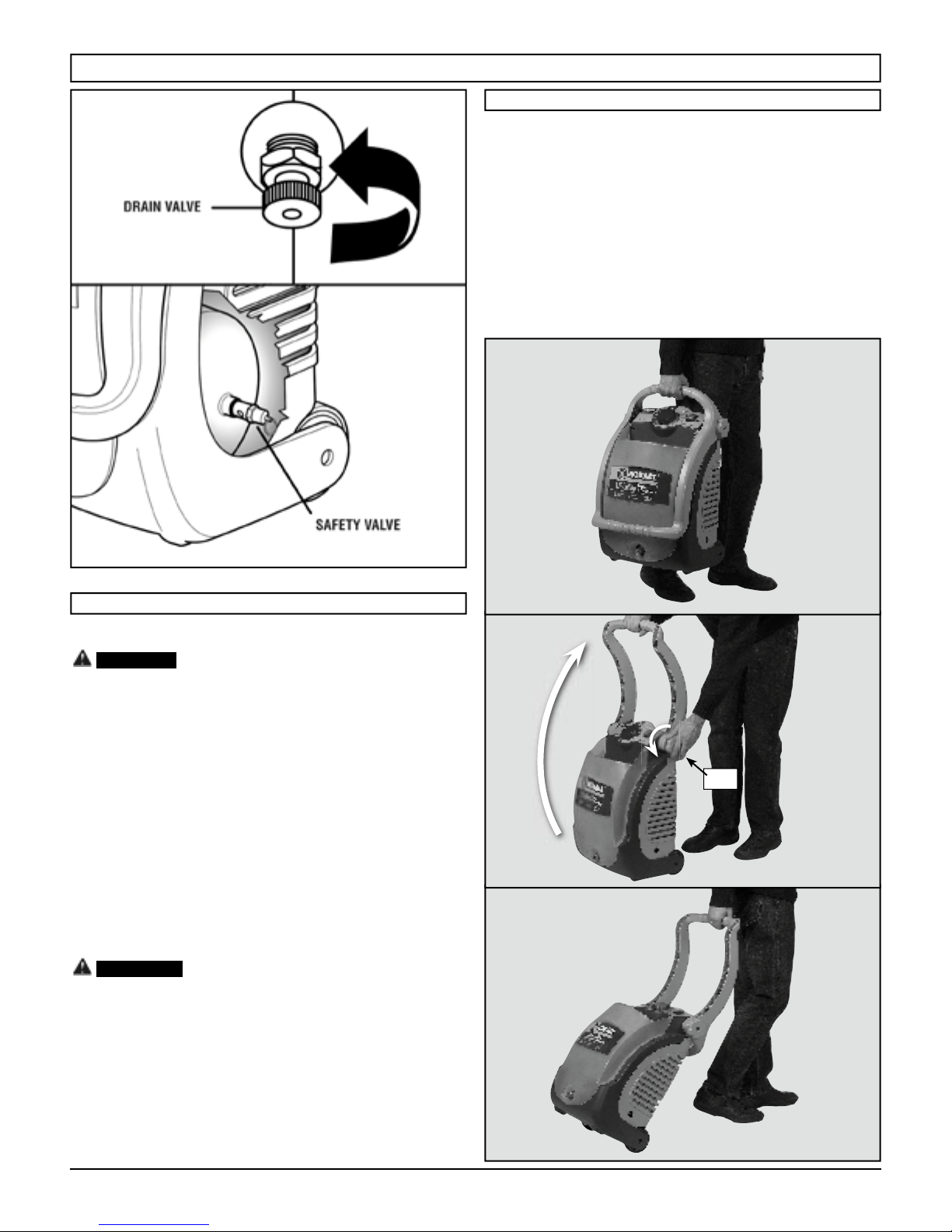

HOW TO USE THE SWIVEL HANDLE

The handle is designed to be used in two different positions.

• To lift up the compressor, use the handle in the ‘closed’

position (Pic. 1). Be sure the 2 handle knobs are well

tightened.

• To move the compressor using the wheels, mount the

handle in the ‘open’ position: loosen the 2 handle knobs

in counterclockwise direction (Pic. 2 - 2.1) and rotate

the handle until it reaches the highest position. At this

point re-tighten the 2 handle knobs.

The compressor can be easily trailed as shown in the

(Pic. 3).

Fig. 15

CHECKING THE SAFETY VALVE

See Figure 15.

Do not attempt to tamper with the safety

DANGER:

valve. Anything loosened from this device could fly up and

hit you. Failure to heed this warning could result in death or

serious personal injury.

The safety valve will automatically release air if the air receiver

pressure exceeds the preset maximum. The valve should be

checked before each day of use by pulling the ring by hand.

• Turn the air compressor on and allow the tank to

fill. The compressor will shut off when the pressure

reaches the preset maximum.

• Turn the air compressor off.

• Pull the ring on the safety valve to release air for three

to five seconds.

• Release the ring. Air must immediately stop escaping

when the ring is released. Any continued loss of air

after releasing the safety valve ring indicates a problem

with the safety valve. Discontinue use and seek service

before continued use of the air compressor.

WARNING:

If air leaks after the ring has been released,

or if the valve is stuck and cannot be actuated by the ring, do

not use the air compressor until the safety valve has been

replaced. Use of the air compressor in this condition could

result in serious personal injury.

Pic. 1

2.1

Pic. 2

10

Pic. 3

K13015FOM_Ver.0406

MAINTENANCE

WARNING:

replacement parts. Use of any other parts may create a hazard

or cause product damage.

WARNING:

glasses with side shields during power tool operation or when

blowing dust. If operation is dusty, also wear a dust mask.

WARNING:

from power supply, and allow unit to cool to the touch before

cleaning or making repairs on the air compressor.

Humidity in the air causes condensate to form in the air tank.

This condensate should be drained daily and/or every hour, using

the instructions found in Draining the Tank. The safety valve

automatically releases air if the air receiver pressure exceeds the

preset maximum. Check the safety valve before each use following

the instructions found in Checking the Safety Valve.

When servicing, use only identical Kobalt

Always wear safety goggles or safety

Always release all pressure, disconnect

Most plastics are susceptible to damage from various types

of commercial solvents. Do not use solvents when cleaning plastic

parts. Use clean cloths to remove dirt, dust, oil, grease, etc.

WARNING:

petroleum-based products, penetrating oils, etc., come in

contact with plastic parts. Chemicals can damage, weaken or

destroy plastic, which may result in serious personal injury.

Consequently, we do not recommended using this tool for

extended work on these types of materials. However, if you do

work with any of these materials, it is extremely important to

clean the tool using compressed air.

LUBRICATION: All of the bearings in this tool are lubricated

with a sufficient amount of high grade lubricant for the life of the unit

under normal operating conditions. Therefore, no further lubrication

of the bearings is required.

Do not at any time let brake fluids, gasoline,

TROUBLESHOOTING CHART

PROBLEM POSSIBLE CAUSE SOLUTION

1) Loss of power or overheating

2) No electrical power

3) Blown shop/house fuse

Compressor will not run

Motor hums but cannot

run or runs slowly

Fuses blow/circuit

breaker trips repeatedly

Thermal overload

protector cuts out

repeatedly

Air receiver pressure

drops when compressor

shuts off

Excessive moisture in

discharge air

Compressor runs

continuously

Compressor vibrates 1) Loose mounting bolts 1) Tighten mounting bolts

Air output lower than

normal

4) Shop/house breaker open

5) Thermal overload open

6) Pressure switch bad

7) Tank is full of air

1) Low voltage

2) Wrong gauge wire or length of extension cord

3) Shorted or open motor winding

4) Defective check valve or unloader

1) Incorrect size fuse, circuit overload

2) Wrong gauge wire or length of extension cord

3) Defective check valve or under loader

1) Low voltage

2) Lack of proper ventilation/room temperature

too high

3) Wrong gauge wire or length of extension cord

1) Loose connections (fittings, tubing, etc.)

2) Loose drain valve

1) Excessive water in air tank

2) High humidity

1) Defective pressure switch

2) Excessive air usage

1) Broken inlet valves 1) Take compressor to service center

1) Check for proper use of extension cord

2) Check to be sure unit is plugged in.

Check fuse/breaker or motor overload

3) Replace shop/house blown fuse

4) Reset shop/house breaker, determining why problem

happened

5) Motor will restart when cool

6) Take compressor to service center

7) Compressor will turn on when tank pressure drops to

cut-in pressure

1) Check with voltmeter

2) Check for proper gauge wire and cord length

3) Take compressor to service center

4) Take compressor to service center

1) Check for proper fuse, use time-delay fuse,

disconnect other electrical appliances from circuit or

operate compressor on its own branch circuit

2) Check for proper gauge wire and cord length

3) Take compressor to service center

1) Check with voltmeter

2) Move compressor to well-ventilated area

3) Check for proper gauge wire and cord length

1) Take compressor to service center

2) Tighten drain valve

Do not disassemble check valve

DANGER:

with air in tank - bleed tank.

1) Drain tank

2) Move to area of less humidity; use air line filter

1) Take compressor to service center

2) Decrease air usage; compressor not large enough

for tool’s requirement

K13015FOM_Ver.0406

11

PARTS DIAGRAM

7 4 19 5 12 11

10

8

27

26

24

31

1496 13

33 21 32 3017

343529

15

23

2

3

34

20

15

12

16

25118281522

K13015FOM_Ver.0406

PARTS DIAGRAM

72

59

58

57

56

51

50

73

54

52

61

60

55

53

64

64

63

70 6766

62

65

71

K13015FOM_Ver.0406

69

68

13

PARTS LIST

COMPRESSOR

ITEM CODE DESCRIPTION QTY

1 9413190040 TANK 1

2 9415089 PUMP OL195S 1

3 9115011 SCREW M6X16 5

4 9038274 FRONT PANEL UL 1

5 9038275 REAR PANEL UL 1

6 9038276 HANDLE 1

7 9038277 HANDLE UPPER GRIP 1

8 9038278 HANDLE LOWER GRIP 1

9 9038279 TRANSPARENT SHELL 1

10 9038280 CORD HOUSING 1

11

9038281 HANDLE KNOB 2

12 9038282 FIXING BLOCK 2

13 9038283 WHEEL 2

14 9038257 FOOT 2

15 9142572 SCREW PARKER 4,2X25 23

16 9415027 CORD 1

17 9415060 SCREW PARKER 2,9X15 2

18 9050392 DRAIN VALVE 1

19 9414765 POWER SWITCH 1

20 9038260 LOCK CABLE 1

21 9063139

22 9047061 QUICK COUPLER 1

23 9270026 RILSAN TUBE (INCHES) 16

24 9412469 ELBOW CONNECTION 1

25 9049105 SAFETY VALVE 1

26 9415024 DELIVERY PIPE 1

27 9048016 CHECK VALVE 1

28 9415023 BRACKET FOR TANK 1

29 9415025

30 9414744 PRESSURE GAUGE 50 1/4 IN. 1

31 9114280 SCREW M8X14 1

32 9053197 CONNECTION 1

33 9038286

34 9053583 ELBOW CONNECTION 2

35 9415139 AIR FILTER 1

PRESSURE SWITCH/

PRESSURE REGULATOR

BRACKET FOR PRESSURE

SWITCH

KNOB FOR PRESSURE

REGULATOR

1

1

1

PUMP

ITEM CODE DESCRIPTION QTY

50 9415090 GROUP MOTOR/CRANKCASE 1

51 A631000 CYLINDER BARREL 1

52 A610101 CONROD/PISTON 1

53 9040019 SEAL RING 1

54 9415053 CONROD COVER 1

55 9011004 SCREW TORX M5X16 1

56 A650300

57 9415091 VALVE PLATE 1

58 9415052

59 9415051 HEAD 1

60 9411131 SCREW M6X35 4

61 9122331 NUT M6 4

62 A661202 CRANKSHAFT 1

63 9170091 BEARING 1

64 9411136 BEARING 2

65 9075047 BELT 1

66 9038193 MOTOR FAN 1

67 9101055 SCREW M5X16 LEFT 1

68 9004015 WASHER SHOULDER 1

69 9411137 SEEGER 1

70 9131010 WASHER 1

71 9038190 SEMIPLASTIC COVER LOW 1

72 9038191 SEMIPLASTIC COVER HIGH 1

73 9142591 SCREW PARKER 3.9X13 4

GASKET CYLINDER-VALVE

PLATE

GASKET VALVE PLATECYLINDER HEAD

1

1

14

K13015FOM_Ver.0406

ARTICULO #234955

MODELO #K13015F

Manual del Operador y Lista de las Piezas

Sin aciete, de una sola etapa, de mando directo,

compresor de aire eléctricos

ADVERTENCIA: Lea y comprenda todas las precauciones de seguridad contenidas en este manual antes de

utilizar esta unidad. Si no cumple con las instrucciones de este manual podría ocasionar lesiones personales, daños a

la propiedad y/o la anulación de su garantía. EI fabricante NO SERÁ responsable de ningún daño por no acatar estas

instrucciones.

K13015FOM_Ver.0406

15

INDICE

PAUTAS DE SEGURIDAD ................................................................................................................................................................. 17

CARACTERÍSTICAS - Especificaciones del producto ........................................................................................................................ 18

REQUERIMIENTOS DE ALIMENTACIÓN ELÉCTRICA ..................................................................................................................... 19

RESUMEN GENERAL ....................................................................................................................................................................... 20

GLOSARIO DE TÉRMINOS ............................................................................................................................................................... 20

MONTAJE .......................................................................................................................................................................................... 21

FUNCIONAMIENTO .......................................................................................................................................................................... 23

MANTENIMIENTO .............................................................................................................................................................................. 25

SOLUCIÓN DE PROBLEMAS ........................................................................................................................................................... 26

ESQUEMA DE LAS PIEZAS ............................................................................................................................................................. 27

LISTA DE LAS PIEZAS ................................................................................................................................................................... 29

GARANTÍA LIMITADA POR 3 AÑOS

Nu Air Compressors and Tools S.p.A. (la empresa) garantiza al comprador minorista original que reparará o reemplazará en

forma gratuita todas las piezas que a juicio de la empresa o de sus representantes de servicio autorizados tengan defectos de

materiales o mano de obra. El período de garantía será de 36 meses a partir de la fecha de compra exclusivamente para el uso en

aplicaciones de consumo.

Esta garantía cubre el costo de las piezas de repuesto y la mano de obra. Los cargos de transporte correspondientes al

envío de productos para servicio de garantía o al envío al consumidor de los productos reparados o de repuesto, deberán ser

cubiertos por el consumidor. Los efectos de corrosìón, erosión, desgaste y uso normal se encuentran específicamente excluidos

de esta garantía. Esta garantía no tendrá validez si el comprador no instala, mantiene y opera el producto de conformidad con

las instrucciones y recomendaciones de la empresa, descritas en el manual de uso, o si el producto es utilizado como equipo de

alquiler. La empresa no será responsable por reparaciones o ajustes al producto, ni por costos o mano de obra, que el comprador

realice sin la autorización previa de la empresa.

LA EMPRESA NO OFRECE NINGUNA OTRA GARANTÍA, YA SEA IMPLÍCITA O EXPLÍCITA. POR LA PRESENTE

SE ANULAN TODAS LAS GARANTÍAS IMPLÍCITAS, INCLUSO TODA GARANTÍA DE COMERCIALIZACIÓN Y APTITUD

PARA UN OBJETIVO EN PARTICULAR. EL SERVICIO DE GARANTÍA PREVIAMENTE DESCRITO ES EL ÙNICO

REMEDIO OFRECIDO POR ESTA GARANTÍA; SE EXCLUYE TODA RESPONSABILIDAD POR DAÑOS INCIDENTES O

CONSECUENTES, EN LA MEDIDA QUE LO PERMITEN LAS LEYES.

En algunos estados no se permite una renuncia a las garantías implícitas o la exclusión o limitación de los daños incidentes y

consecuentes, por lo cual dichas renuncias tal vez no se apliquen en su caso. No obstante lo anterior, se prohíbe toda reclamación

contra la empresa conforme a esta garantía salvo que las acciones legales comiencen en los 12 meses siguientes a la fecha de

vencimiento del período de garantía.

Esta garantía le da las derechas específicas, y usted puede tener otras derechas que varíen de estado al estado.

Todas las comunicaciones referidas a la garantía se deberán dirigir al Servicio de Asistencia Técnica 1-866-242-4298.

16

K13015FOM_Ver.0406

PAUTAS DE SEGURIDAD

La información que sigue se refiere a la protección de SU SEGURIDAD y la PREVENCIÓN DE PROBLEMAS DEL EQUIPO. Como

ayuda para reconocer esta información, usamos los siguientes símbolos. Lea por favor el manual y preste atención a estas secciones.

- UN POSIBLE RIESGO QUE CAUSARÁ LESIONES GRAVES O LA PÉRDIDA DE LA VIDA.

PELIGRO:

- UN RIESGO POTENCIAL QUE PODRÍA PROVOCAR GRAVES LESIONES O MUERTE.

ADVERTENCIA:

- UN RIESGO POTENCIAL QUE PODRIA PROVOCAR LESIONES LEVES O DAÑAR EL EQUIPO.

PRECAUCIÓN:

ADVERTENCIA:

1. RIESGO DE INCENDIO O EXPLOSIÓN. Nunca rocíe

líquidos inflamables en un área confinada. Es normal que el

motory el interruptor de presión produzcan chispas al estar

en funcionamiento. Si las chispas entran en contacto con los

vapores de la gasolina o con otros disolventes, éstos podrían

encenderse, causando un incendio o una explosión. Siempre

opere el compresor en un lugar bien ventilado. No fume al

rociar. No rocíe donde existan chispas o Ilama. Mantenga el

compresor tan lejos del lugar de rociado como sea posible.

2. RIESGO DE EXPLOSIÓN.

tanque. Drene el agua condensada del tanque después de

cada uso para reducir la oxidación. Si detecta una fuga en el

tanque, reem plácelo inmediatamente. No suelde, no perfore

ni modifique el tanque del aire de este compresor.

La soldadura o las modificaciones en el tanque del compre-

sor de aire podrían deteriorar gravemente la resistencia del

tanque y causar una condición extremadamente peligrosa.

Soldar o modificar el tanque de cualquier manera anulará la

garantía.

3. RIESGO DE DESCARGA ELÉCTRICA.

autorizado debe hacer todas las conexiones de acuerdo con

todos los códigos elécricos nacionalesy locales. Nunca utilice

un compresor eléctrico de aire en el exterior cuando esté

Iloviendo ni lo coloque sobre una superficie mojada, ya que

esto podría causar descargas eléctricas.

4. RIESGO DE LESIONES.

automáticamente. SIEMPRE apague el compresor, quite

el enchufe del tomacorrientes, y purgue toda la presión del

sistema antes de realizar el servicio al compresor y cuando

el compresor no esté en uso. No utilice la unidad sin las

cubiertas o sin el protector de la correa ya que podría sufrir

lesiones por el contacto con las piezas móviles.

5. RIESGO DE EXPLOSIÓN. Verifique la presión nominal

máxima sugerida por el fabricante para las herramientas

y los accesorios neumáticos. La presión de salida del

compresor se debe regular de tal manera que nunca se

exceda la presión nominal máxima de la herramienta.

Antes de conectar o retirar accesorios, alivie toda presión

del tubo.

La corrosión puede debilitar el

Un electricista

Esta unidad arranca

6. RIESGO DE QUEMADURAS. La bomba y el múltiple

producen altas temperaturas. Para prevenir quemaduras u

otro tipo de heridas, NO TOQUE la bomba, el múltiple ni el

tubo de transferencia mientras la bomba se está funcionando.

Permita que se enfríe antes de manipularlos o realizar

el servicio necesario. Mantenga a los niños alejados del

compresor en todo momento.

7. RIESGO PARA LA RESPIRACIÓN. No utilice este

compresor de aire para rociar productos químicos. Pueden

resultar afectados los pulmones debido a la inhalación

de emanaciones tóxicas. Puede ser necesario utilizar un

respirador en entornos polvorientos o al rociar pintura. No

acarree la unidad mientras esté pintando.

8. RIESGO DE LESIONES OCULARES. Cuando utilice un

compresor de aire siempre use gafas de seguridad aprobadas

según ANSI Z87.1. Nunca dinja la boquilla ni el rociador hacia

una persona ni hacia alguna parte del cuerpo. EI equipo

puede causar una lesión grave si el rocio penetra en la piel.

9. RIESGO DE EXPLOSIÓN. No toque la perilla de control

ni ajuste la válvula de alivio por ninguna razón. Si lo hace

anulará la garantía. Los dos fueron preajustados de fábrica

para obtener la máxima presión en esta unidad. Alterar el

tablero de control o válvula de alivio puede producir lesiones

personales y/o daños en la propiedad.

10. RIESGO DE EXPLOSIÓN. Antes de usar la unidad revise

las mangueras para ver muestran daños o desgaste,

asegurándose de que estén seguras todas las conexiones.

No utilice la unidad si encuentra algún defecto. Adquiera una

manguera nueva o lleve la unidad a un centro de servicio

autorizado para que la examinen y reparen.

11. RIESGO AL SENTIDO DEL OÍDO. Siempre use protectores

auditivos cuando use un compresor de aire. Si no lo hace

podría sufrir pérdida de la audición.

12. RIESGO PARA LA RESPIRACIÓN. Nunca inhale

directamente el aire comprimido producido por un compresor.

No es adecuado para respirarly.

13. EI cable eléctrico en este producto contiene el plomo, un

producto químico sabido al estado de California para causar

el cáncer, y el nacimiento deserta o el otro daño reproductivo.

Manos de la colada después de dirigir.

PRECAUCIÓN:

1. Elimine la humedad del tanque todos los días. Un tanque

limpio y seco ayudará a evitar la corrosión.

2. Tire del anillo de la válvula de alivio de la presión todos los

días para asegurarse de que la válvula esté funcionando

adecuadamente y para eliminar cualquier obstrucción en la

válvula .

3. A fin de lograr una ventilación adecuada para el enfriamiento,

el compresor debe mantenerse a un minimo de 31 cm

(12 pulgadas) de la pared más cercana, en una zona bien

ventilada.

K13015FOM_Ver.0406

4. Sujete el compresor muy bien si es necesario su transporte.

Debe liberarse la presión del tanque antes de su transporte.

5. Proteja la manguera de aire y el conducto eléctrico contra

daños y pinchaduras. Inspecciónelos todas las semanas para

comprobar que no existen zonas débiles o desgastadas, y

reemplácelos si fuera necesario.

6. Para reducir el riesgo de choque eléctrico, proteja la unidad

de la Iluvia. Almacene en el interior.

7. Nunca opere el compresor si el cable de energia o el conector

están dañados. Lieve el equipo al Centro de Servicio Autorizado más cercano y pídale a un técnico que lo reemplace.

17

CARACTERÍSTICAS

ESPECIFICACIONES DEL PRODUCTO

Potencia de funcionamiento ..............................................1,3 HP

Capacidad del tanque de aire ............................... 5,3 lt (1,5 gal)

Presión de aire ....................................... 931 kPa (135 psi) máx.

Suministro de aire .......68 DCPM (2,4 PCEPM) @ 621 kPa (90 psi)

PERILLA

DEL REGULADOR

DE PRESIÓN

MANIJA

GIRATORIA

BOTÓN DE

ENCENDIDO/APAGADO

Lubricación ............................................Lubricación permanente

Toma de aire ajustable ........................................... 40 a 135 PSI

Manómetros ............................... 38 mm (1,5 pulg.) de diámetro

Corriente de entrada .............. 120 V, 60 Hz, 12 A, sólo corr. alt.

Peso neto .......................................................... 24,2 lbs. / 11 kg

Fig. A

MANÓMETRO

DEL TANQUE

CARCASA DEL

CABLE ELÉCTRICO

TOMA DE AIRE

ADAPTADOR

DE INFLADO

VÁLVULA DE

DRENAJE

AGUJA DE INFLADO

BOQUILLAS

DE INFLADO

VÁLVULA DE

SEGURIDAD

RUEDAS

CONECTOR

DE INFLADO

CONECTOR MACHO DE

6 MM (1/4 PULG.) NPT

CONECTOR HEMBRA DE

6 MM (1/4 PULG.) NPT

ACOPLADOR

RÁPIDO

CABLE

ELÉCTRICO

BOQUILLA DE

SEGURIDAD

ACCESORIO DE

SOPLADO

CALIBRE DE LAS

RUEDAS

18

MANGUERA

ESPIRAL

CINTA PARA

SELLAR ROSCAS

K13015FOM_Ver.0406

REQUERIMIENTOS DE ALIMENTACIÓN ELÉCTRICA

CORDONES DE EXTENSIÓN

Sólo utilice cordones de extensión de tres conductores con

clavijas de tres patillas y receptáculos de tres polos que acepten

la clavija del cordón del compresor. Al utilizar el compresor de

aire a una distancia considerable del suministro de corriente,

asegúrese de utilizar un cordón de extensión del grueso suficiente

para soportar el consumo de corriente del compresor. Un cordón

de extensión de un grueso insuficiente causa una caída en el

voltaje de línea, además de producir una pérdida de potencia y un

recalentamiento del motor. Básese en la tabla suministrada abajo

para determinar el calibre mínimo requerido de los conductores

del cordón de extensión. Solamente deben utilizarse cordones con

forro redondo registrados en Underwriter’s Laboratories (UL).

**Amperaje (aparece en la placa de datos del compresor)

Longitud del cordón

25 ft. 16 16 16 16 14 14

50 ft. 16 16 16 14 14 12

100 ft. 16 16 14 12 10 ----

**Se usa en los circuitos de calibre 12, de 20 A.

NOTA: AWG = Calibre conductores norma americana

0-2.0 2.1-3.4 3.5-5.0 5.1-7.0 7.1-12.0 12.1-16.0

Calibre conductores (A.W.G.)

Al trabajar a la intemperie con el compresor, utilice un cordón

de extensión fabricado para uso en el exterior. Tal característica

está indicada con las letras “W-A” en el forro del cordón.

Antes de utilizar un cordón de extensión, inspecciónelo para

ver si tiene conductores flojos o expuestos y aislamiento cortado o

gastado.

ADVERTENCIA

Mantenga el cordón de extensión

:

fuera del área de trabajo. Al trabajar con una herramienta

eléctrica, coloque el cordón de tal manera que no pueda

enredarse en la madera, herramientas o ninguna obstrucción.

La inobservancia de esta advertencia puede causar lesiones

serias.

del motor. Una línea destinada sólo para luces no puede alimentar

el motor de una herramienta eléctrica. El cable con el calibre

suficiente para una distancia corta será demsiado delgado para

una mayor distancia. Una línea que alimenta una herramienta

eléctrica quizá no sea suficiente para alimentar dos o tres

herramientas.

INSTRUCCIONES DE CONEXIÓN A TIERRA

En caso de un mal funcionamiento o desperfecto, la conexión

a tierra brinda a la corriente eléctrica una trayectoria de mínima

resistencia para disminuir el riesgo de una descarga eléctrica. Este

compresor de aire está equipado de un cordón eléctrico con una

clavija dotada de un conductor de conexión a tierra. La clavija debe

conectarse en una toma de corriente igual que esté instalada y

conectada a tierra correctamente, de conformidad con los códigos

y reglamentos de la localidad.

No modifique la clavija suministrada. Si no entra en la toma

de corriente, llame a un electricista calificado para que instale una

toma de corriente adecuada. Si se conecta de forma incorrecta el

conductor de conexión a tierra del equipo puede presentarse un

riesgo de descarga eléctrica.

El conductor con aislamiento que tiene una superficie exterior

verde con o sin tiras amarillas es el conductor de conexión a tierra

del equipo. Si es necesaria la reparación o reemplazo del cordón

eléctrico o de la clavija, no conecte el conductor de conexión a

tierra a una terminal portadora de corriente.

Consulte a un electricista calificado o técnico de servicio si no

ha comprendido completamente las instrucciones de conexión a

tierra o si no está seguro si la herramienta está conectada a tierra

correctamente.

Repare o reemplace de inmediato todo cordón dañado o

gastado.

Este compresor de aire debe utilizarse conectado a un

circuito con una toma de corriente como la mostrada en la Figura

1. También dispone de una patilla de conexión a tierra como la

mostrada. Este producto debe conectarse a tierra.

ADVERTENCIA

:

Inspeccione los cordones de extensión

cada vez antes de usarlos. Si están dañados, reemplácelos de

inmediato. Nunca utilice el compresor con un cordón dañado,

ya que si toca la parte dañada puede producirse una descarga

eléctrica, y las consecuentes lesiones serias.

NOTA: Utilice mangueras de aire largas en lugar de cordones

de extensión largos. De esta manera el compresor funciona mejor

y dura más.

CONEXIÓN ELÉCTRICA

Este compresor de aire está accionado por un motor eléctrico

fabricado con precisión. Debe conectarse únicamente a una línea

de voltaje de 120 V, 60 Hz, de corriente alterna solamente

(corriente normal para uso doméstico). No utilice esta

herramienta con corriente continua (c.c.). Una caída considerable

de voltaje causa una pérdida de potencia y el recalentamiento del

motor. Si el compresor no funciona al conectarlo en una toma de

corriente, vuelva a revisar el suministro de corriente.

VELOCIDAD Y CABLEADO

La velocidad en vacío de este compresor es 26000 rpm

aproximadamente. Esta velocidad no es constante y disminuye

durante el corte o con un voltaje bajo. En cuanto al voltaje, el

cableado de un taller es tan importante como la potencia nominal

Fig. 1

K13015FOM_Ver.0406

19

RESUMEN GENERAL

COMPONENTES BÁSICOS

DEL COMPRESOR DE AIRE

Los compresores de aire sin aceite se lubrican en fábrica para

toda su vida útil, y no requieren aceite.

Los componentes básicos del compresor de aire son el motor

eléctrico, la bomba, el panel de control

EI motor eléctrico acciona la bomba. EI motor eléctrico

está equipado con un protector contra sobrecargas y un reajuste

automático. Si el motor se sobrecalienta, el protector contra

sobrecargas lo apagará para evitar que sufra daños. Cuando el

y el tanque.

motor se enfríe lo suficiente, volverá a arrancar automáticamente.

La bomba comprime el aire y lo descarga hacia el tanque.

EI tanque almacena el aire comprimido.

El panel de control del compresor consiste en el botón de

encendido/apagado ON/OFF (A) y la perilla del regulador de

presión (B).

AI utilizar el aire comprimido y cuando el nivel de presión del

tanque baja hasta la presión de activación, el tablero de control

reinicia automáticamente el motor, sin advertencia, y la bomba

comienza a comprimir el aire. EI regulador de presión apaga el motor

cuando la presión del aire en el tanque alcanza la presión de corte.

AB

GLOSARIO DE TÉRMINOS

Bomba

Es el dispositivo que produce el aire comprimido mediante un

pistón de vaivén contenido dentro del cilindro.

Filtro de aire

Es un elemento poroso contenido dentro de un alojamiento de

metal o plástico unido al cilindro de la culata del cilindro del

compresor, el cual sirve para eliminar las impurezas del aire de

entrada del compresor.

Interruptor de encendido manual

Es el control empleado para encender y apagar el

compresor. El interruptor de presión no enciende y controla

automáticamente el compresor a menos que el interruptor de

encendido manual esté en la posición de ENCENDIDO ( l ) .

Interruptor de sobrecarga térmica

Sirve para apagar automáticamente el compresor si la

temperatura del motor eléctrico se excede de un límite

predeterminado.

Manómetro del tanque

Sirve para indicar la presión interna del tanque.

Motor eléctrico

Es el dispositivo encargado de suministrar la fuerza rotatoria

necesaria para accionar la bomba del compresor.

PCEPM (Pies cúbicos estándar por minuto)

La unidad de medida de suministro de aire.

Presión de activación

Es la presión baja a la cual arranca automáticamente el motor.

Presión de interrupción

Es la presión alta a la cual se apaga automáticamente el motor.

PSI (Libras por pulgada cuadrada)

Son las unidades de medida de la presión ejercida por la fuerza

del aire. La presión real en PSI es medida por el manómetro del

compresor.

Regulador de presión

Sirve para controlar los ciclos de encendido y apagado del

compresor. Apaga el compresor cuando se alcanza la presión

de interrupción del tanque y arranca el compresor cuando la

presión del aire desciende abajo de la presión de interrupción.

Tanque de aire

Es un componente cilíndrico que contiene el aire comprimido.

Válvula de retención

Es un dispositivo cuya función es impedir que el aire

comprimido se regrese del tanque de aire a la bomba del

compresor.

NPT (Norma Nacional de Roscado de Tubos)

Debe utilizarse una cinta selladora de roscas para tener un sello

a prueba de fugas en las conexiones roscadas de tubos.

20

Válvula de seguridad

Su función es impedir que la presión del aire ascienda más allá

de un límite predeterminado.

K13015FOM_Ver.0406

MONTAJE

CARACTERÍSTICAS

FAMILIARÍCESE CON EL COMPRESOR (Vea la Fig. A, p. 18)

Antes de intentar utilizar este producto, familiarícese con todas

las características de funcionamiento y normas de seguridad de

la unidad.

TOMA DE AIRE

La toma de aire está ubicada en la parte frontal del compresor. Se

puede ajustar la presión de 40 a 135 psi para cada uso. El ajuste

de la presión es posible simplemente rotando la flecha de la perilla

hasta el uso o la presión deseados.

MOTOR UNIVERSAL DE LUBRICACIÓN PERMANENTE

El compresor incorpora cojinetes lubricados permanentemente.

VÁLVULA DE SEGURIDAD

La válvula de seguridad está diseñada para soltar aire automáticamente si la presión del aparato receptor del aire sobrepasa el

límite máximo prefijado.

MANÓMETRO DEL TANQUE

El manómetro indica la presión del aire en el interior del tanque.

MONTAJE

Tiempo Estimado para el Montaje: 2 minutos

Equipos Necesarios: Llaves de 14, 16, 17mm (no incluidas)

1) DESEMPAQUETADO

• Extraiga cuidadosamente de la caja la herramienta y los

accesorios. Asegúrese de que estén presentes todos

los artículos enumerados en la lista de empaquetado.

• Inspeccione cuidadosamente la herramienta para

asegurarse de que no haya sufrido ninguna rotura o

daño durante el transporte.

• No deseche el material de empaquetado hasta que

haya inspeccionado cuidadosamente la herramienta y

la haya utilizado satisfactoriamente.

• Si hay piezas dañadas o faltantes, le suplicamos

llamar al 1-866-242-4298, donde le brindaremos

asistencia, o enviar un FAX al 1-803-328-0375.

la herramienta al montarle piezas a aquélla.

2) MONTAJE DE LA MANIJA

Levante levemente la manija y bájela hasta el cuerpo del

compresor, como se indica en la (Foto 1). La manija debe

quedar alineada con las guías ubicadas a cada lado del

compresor. Inserte las dos perillas de la manija en los

agujeros ubicados a los lados de ésta (Foto 2). Ajuste con

firmeza girando en la dirección de las agujas del reloj para

que la manija quede firme en su posición (Foto 3).

3) MONTAJE DE LA CARCASA DEL CABLE ELÉCTRICO

Alinee los 4 orificios de la carcasa con los 4 ganchos

ubicados en el lado inferior del compresor (Foto 4).

Presione los lados de la carcasa hacia adentro, como se

muestra en la (Foto 5). Luego empuje la carcasa hacia

adelante. Escuchará un clic cuando quede correctamente

calzada (Foto 6).

Foto 1

PRECAUCIÓN

diseñada para servir de base de un compresor en operación.

Separe el compresor de la plataforma de transportación y

colóquelo en el piso, sobre una superficie dura y nivelada. EI

compresor debe quedar nivelado para asegurar un drenaje

adecuado del agua de humedad del tanque.

LISTA DE EMPAQUETADO

- Compresor de aire

- Manija

- Perillas de la manija (2)

- Carcasa del cable eléctrico

- Manguera espiral

- Aditamento de soplado con

boquilla de seguridad

- Conector de inflado

- Boquilla de inflado (2)

- Adaptador de inflado

ADVERTENCIA

utilice esta herramienta sin haber reemplazado las piezas dañadas o faltantes. La inobservancia de esta advertencia puede

causar lesiones serias.

ADVERTENCIA

hacer accesorios no recomendados para la misma. Cualquier

alteración o modificación constituye maltrato el cual puede

causar una condición peligrosa, y como consecuencia posibles

lesiones corporales serias.

ADVERTENCIA

podría causar lesiones corporales serias, siempre desconectar

:

La plataforma de embarque no está

- Aguja de inflado

- Acoplador rápido de 6 mm

(1/4 pulg.) NPT

- Conector macho de 6 mm

(1/4 pulg.) NPT (2)

- Conector hembra de 6 mm

(1/4 pulg.) NPT

- Calibre de las ruedas

- Cinta para sellar roscas

- Manual del operador

:

Si hay piezas dañadas o faltantes, no

:

No intente modificar esta herramienta ni

:

Para evitar un arranque accidental que

Foto 2

Foto 3

K13015FOM_Ver.0406

21

MONTAJE

Foto 4

Foto 5

click !

Foto 6

4) CÓMO CONECTAR UNA MANGUERA AL COMPRESOR

(

Vea las

• Asegúrese de que esté apagado y desconectado el

• Aplique cinta para sellar roscas a ambos extremos de la

• Introduzca un extremo roscado de la manguera en el

• Conecte el acoplador rápido al otro extremo de la man-

NOTA: Tenga cuidado de no estropear las roscas.

No conecte el conector de inflado o la

otra herramienta en el extremo abierto de la manguera sin

haber efectuado el procedimiento inicial.

• Sujete firmemente el extremo abierto de la manguera,

• Introduzca el extremo del conector hembra de la

• Para desconectar la manguera, empuje hacia atrás la

Figs. 7 - 9)

compresor de aire.

manguera espiral.

extremo abierto del conector hembra. Lleve un extremo

de la manguera con una llave de 14mm y usar una llave

de 16mm para apretar firmemente el conecor hembra.

guera, sostenga éste con una llave de 14mm y usar una

llave de 17mm para apretar firmemente el acoplador rápido.

ADVERTENCIA

y sosténgalo orientado en una dirección donde no se

encuentre usted ni otras personas.

manguera espiral en la toma de aire del compresor de

aire. Empuje firmemente el conector hasta que lo oiga

hacer un chasquido al entrar en su lugar.

tuerca de anillo externo del acoplador rápido.

:

Fig. 7

Fig. 8

Fig. 9

5) USO INICIAL DE LA BOMBA (

• Revise y apriete todos los pernos, adaptadores, etc.

• Coloque el interruptor en la posición de APAGADO y

conecte el cordón de corriente.

• Abra completamente la válvula de drenaje.

• ENCIENDA el compresor, posición (l), y déjelo funcionar

10 minutos para dar a las piezas de la bomba un uso inicial.

• Ponga el interruptor en la posición de APAGADO (O).

• Cierre la válvula de drenaje.

22

Vea las

Figs. 9 - 10)

Fig. 10

K13015FOM_Ver.0406

FUNCIONAMIENTO

No permita que su familarización con

ADVERTENCIA:

las herramientas lo vuelva descuidado. Tenga presente que

un descuido de un instante es suficiente para causar una

lesión grave.

Cuando utilice herramientas eléctricas,

ADVERTENCIA:

póngase siempre gafas de seguridad o anteojos protectores

con protección lateral. La inobservancia de esta advertencia

puede causar el lanzamiento de objetos a los ojos, y por

consecuencia posibles lesiones serias.

PRECAUCIÓN:

polvoriento o contaminado de cualquier forma. Si se utiliza el

compresor de aire en este tipo de entorno puede dañarse.

Los compresores de aire se utilizan en una variedad de usos

de sistemas de suministro de aire. Las mangueras, conectores,

herramientas de aire y accesorios deben corresponder a la

capacidad del compresor de aire.

USO DEL COMPRESOR DE AIRE

Vea las Figuras 9 a 13.

• Asegúrese de que el interruptor de corriente esté en

la posición de APAGADO (O) y el compresor esté

desconectado.

• Si no está instalada aún la manguera, conéctela al

compresor como se indicó anteriormente. La manguera

debe insertarse en el acoplador de conexión rápida y

la perilla del regulador debe girarse hasta la marca del

uso o la presión apropiado.

• Introduzca el aditamento de soplado o el conector de

la herramienta de aire deseada en el conector hembra

situado en el otro lado de la manguera espiral.

No utilice la unidad en ningún entorno

APLICACIONES

Fig. 11

Fig. 12

ADVERTENCIA:

ruptor esté en la posición de APAGADO (O) antes de cambiar

de herramienta de aire o desconectar la manguera de la

salidad de aire. La inobser-vancia de esta advertencia puede

causar lesiones serias.

• Conecte el cordón al suministro de corriente.

• Ponga el interruptor en la posición de ENCENDIDO (l).

• Ahora puede proceder a utilizar la herramienta

accionada por aire deseada o el aditamento de

soplado, siguiendo las medidas de precaución

indicadas en este manual y las instrucciones del

fabricante de la herramienta de aire señaladas en el

manual de la herramienta correspondiente.

ADVERTENCIA:

necesitar más aire del que este compresor es capaz de

suministrar. Estudie el manual de la herramienta para evitar

dañarla y sufrir un riesgo de lesiones.

• Al utilizar el aditamento de soplado, la cantidad de

presión de aire puede controlarse adicionalmente

mediante el grado de presión aplicado con la mano en

la palanca de dicho aditamento.

NOTA: Siempre use la cantidad de presión mínima

necesaria en cada caso. Si usa una presión mayor

de la necesaria se drena el aire del tanque con mayor

rapidez y la unidad efectúa con mayor frecuencia su

ciclo de funcionamiento.

• Al terminar, siempre drene el tanque y desconecte

la unidad. Nunca deje conectada ni funcionando

desatendida la unidad.

Siempre asegúrese de que el inter-

Una herramienta determinada puede

Fig. 13

DRENADO DEL TANQUE

Vea la Figura 14.

Como ayuda para impedir la corrosión del tanque y mantener

el aire libre de humedad, debe drenarse diariamente el tanque de

aire.

Para drenar el tanque:

• Asegúrese de que el interruptor de corriente esté en

la posición de APAGADO (O) y el compresor esté

desconectado.

• Gire a la izquierda la válvula de drenaje para abrirla.

• Drene la humedad del tanque, recibiéndola en un

recipiente adecuado.

NOTA: La humedad condensada es material

contaminante y debe desecharse de conformidad con

los reglamentos locales.

• Si se tapa la válvula de drenaje, purgue toda la presión

de aire, retire la válvula, límpiela y vuelva a instalarla.

ADVERTENCIA:

suelte todo el aire del tanque antes de prestar servicio a la

unidad. Si no se purga la presión del tanque antes de intentar

retirar la válvula, pueden producirse lesiones serias.

• Gire a la derecha la válvula de drenaje hasta dejarla

firmemente cerrada.

Desconecte el compresor de aire y

K13015FOM_Ver.0406

23

FUNCIONAMIENTO

La manija está diseñada para usarse en dos posiciones

diferentes.

• Para levantar el compresor, coloque la manija en la

posición ‘cerrada’ (Foto 1). Asegúrese de que las 2

perillas de la manija estén bien apretadas.

• Para desplazar el compresor usando las ruedas,

coloque la manija en la posición ‘abierta’: afloje las 2

perillas de la manija girándolas en el sentido contrario

al de las agujas del reloj (Foto 2 - 2.1) y gire la manija

Fig. 14

hasta que llegue a la posición más alta y una vez

logrado esto, vuelva a ajustar las 2 perillas.

El compresor puede arrastrarse fácilmente como se

muestra en la (Foto 3

CÓMO USAR LA MANIJA GIRATORIA

).

Fig. 15

REVISIÓN DE LA VÁLVULA DE SEGURIDAD

Vea la Figura 15.

No intente forzar o alterar la válvula de segu-

PELIGRO:

ridad. Cualquier pieza floja de este dispositivo puede volar y

golpearlo. La inobservancia de esta advertencia podría causar

lesiones serias e incluso la muerte.

La válvula de seguridad está diseñada para soltar aire

automáticamente si la presión del aparato receptor del aire

sobrepasa el límite máximo prefijado. Debe revisarse la válvula

cada día antes de usar la unidad; para ello, tire del aro con la mano.

• Encienda el compresor y permita que se llene el

tanque. El compresor se apaga cuando la presión

alcanza el límite máximo prefijado.

• Apague el compresor.

• Tire del aro de la válvula de seguridad para soltar aire

durante tres o cinco segundos.

• Suelte el aro. Al soltar el aro, el aire debe dejar de

salir de inmediato. Cualquier pérdida de aire que

permanezca después de soltarse el aro de la válvula

de seguridad indica un problema en ésta. Interrumpa

el uso de la unidad y permita que se dé servicio a la

misma antes de volver a usar el compresor.

Foto 1

2.1

Foto 2

ADVERTENCIA:

Si se fuga aire después de soltar el aro,

o si está pegada la válvula y no puede accionarse con el aro,

no utilice el compresor de aire, sino hasta haber reemplazado

la válvula. Utilizar el compresor de aire en estas condiciones

puede producir lesiones serias.

24

Foto 3

K13015FOM_Ver.0406

MANTENIMIENTO

Al dar servicio a la unidad, sólo utilice

ADVERTENCIA

piezas de repuesto Kobalt idénticas. El empleo de piezas

diferentes puede causar un peligro o dañar el producto.

ADVERTENCIA

o anteojos protectores con protección lateral al usar

herramientas eléctricas o al soplar el polvo con aire

comprimido. Si la operación genera mucho polvo, también

póngase una mascarilla contra el polvo.

ADVERTENCIA

desconecte la unidad del suministro de corriente y permita

que se enfríe antes de limpiarla o efectuarle reparaciones.

La humedad del aire causa se condensa en el tanque. Esta

humedad condensada debe drenarse diariamente y/o cada

hora siguiendo las instrucciones encontradas en el apartado

Drenado del tanque. La válvula de seguridad está diseñada para

soltar aire automáticamente si la presión del aparato receptor

del aire sobrepasa el límite máximo prefijado. Revise la válvula

de seguridad cada vez antes de usar la unidad siguiendo las

instrucciones indicadas en el apartado Revisión de la válvula de

seguridad

.

:

Siempre use gafas de seguridad

:

Siempre purgue toda la presión,

:

La mayoría de los plásticos son susceptibles a diferentes tipos

de solventes comerciales. Evite el empleo de solventes al limpiar

piezas de plástico. Utilice paños limpios para eliminar la suciedad,

el polvo, el aceite, la grasa, etc.

ADVERTENCIA

No permita en ningún momento que

:

fluidos para frenos, gasolina, productos a base de petróleo,

aceites penetrantes, etc., lleguen a tocar las piezas de

plástico. Las sustancias químicas pueden dañar, debilitar o

destruir el plástico, lo cual a su vez puede producir lesiones

corporales serias. Por consiguiente, no recomendamos el uso

de esta herramienta durante períodos prolongados de trabajo

en estos tipos de materiales. Sin embargo, si usted trabaja

con cualquiera de estos materiales, es sumamente importante

limpiar la herramienta con aire comprimido.

LUBRICACIÓN: Todos los cojinetes de esta herramienta

están lubricados con suficiente cantidad de aceite de alta calidad

para toda la vida útil de la unidad en condiciones normales de

funcionamiento. Por lo tanto, no se necesita lubricación adicional

de los cojinetes.

K13015FOM_Ver.0406

25

SOLUCIÓN DE PROBLEMAS

PROBLEMA CAUSA SOLUCIÓN

1) Recalentamiento o pérdida de potencia

2) No hay corriente eléctrica

El compresor no

arranca

El motor zumba pero

no funciona o lo hace

con lentitud

Los fusibles

se funden o el

disyuntor del

circuito se dispara

continuamente

El protector

contra sobrecarga

térmica interrumpe

la corriente

continuamente

La presión del

aparato receptor

del aire desciende

cuando se apaga el

compresor

Humedad excesiva

en el aire de descarga

El compresor

funciona

continuamente

El compresor vibra 1) Afloje los pernos de montaje 1) Apriete los pernos de montaje

Producción de aire

más baja de lo normal

3) Fusible fundido en el taller o casa

4) Disyuntor abierto en el taller o casa

5) Protector sobrecarga térmica activado

6) Interruptor de presión defectuoso

7) Tanque lleno de aire

1) Voltaje bajo

2) Cordón de extensión de calibre o

longitud equivocados

3) El devanado del motor tiene corto o

está abierto

4) Válvula de retención o de seguridad

defectuosa

1) Fusible de capacidad incorrecta,

sobrecarga en el circuito

2) Cordón de extensión de calibre o

longitud equivocados

3) Válvula de retención o de seguridad

defectuosa

1) Voltaje bajo

2) Ventilación insuficiente/temperatura

ambiental demasiado elevada

3) Cordón de extensión de calibre o

longitud equivocados

1) Conexiones flojas (adaptadores,

mangueras, etc.)

2) Válvula de drenaje floja

1) Cantidad excesiva de agua en el

tanque de aire

2) Alta humedad

1) Interruptor de presión defectuoso

2) Uso excesivo de aire

1) Válvulas de entrada descompuestas 1) Lleve el compresor a un centro de servicio

1) Verifique que el cordón de extensión esté usándose de forma

correcta.

2) Revise para asegurarse de que esté conectada la unidad.

Revise fusible, disyuntor o protector contra sobrecarga térmica

3) Reemplace el fusible fundido del taller o casa

4) Restablezca el disyuntor del taller o casa, y determine la

causa del problema

5) El motor vuelve a arrancar al enfriarse

6) Lleve el compresor a un centro de servicio